A-SP1943BR6GHB1C-C01-2T 数据手册

========================================================

客户(Customer):

承认书

Approval Sheet

谨致执事者:兹提供敝公司之有关详细规格及图面数据,敬请给予办理试认定手续.

同时敬请送返一份附有贵公司签认之测试认定后之样品承认书.

We are pleased in sending you herewith on specification and drawings for your approval.

Please return to us one copy “Approval sheet” with your approved signature.

型号 (Model No.)

:

A-SP1943BR6GHB1C-C01-2T

发文日期(Issue Date): 2020/04/29

Checking signature of Amicc

Designer

Checker

Approver

承认日期(Approved Date):

Approval signature of customer

Designer

Checker

Approver

Katryn

江苏欧密格光电科技股份有限公司

Jiangsu Amicc Opto-Electronics Technology Co.,Ltd

地址:江苏省常州市湖塘鸣凰沟南工业区武南中路 98 号

Add: 98.Wu Nan middle road.Gounan Industrial Park Changzhou

TEL:0086-519-89806966

FAX:0086-519-86523668

1

Release Date: 29.Apr.2020. Issue No: V2

Issue No:ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Features

‧Multi-Color Type

‧Compatible with infrared and vapor phase reflow solder process.

‧Wide viewing angle

‧Pb-free

‧RoHS compliant

Description

‧The Amicc 1943 SMD LED is much smaller than lead frame type components,thus enable smaller board size, higher

packing density,reduced storage space and finally smaller equipment to be obtained.

‧Besides,lightweight makes them ideal for miniature applications etc.

Applications

‧LCD Back-light

‧Decorative and Entertainment Lighting

‧Indicators

‧Automotive Telecommunication

‧Switch lights

Device Selection Guide

Type

2

Chip

Materials

Emitted Color

R6

AlGaInp

Brilliant Red

GH

InGaN

Green

B1

InGaN

Blue

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

Resin Color

Water Clear

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Absolute Maximum Ratings (TSoldering=25℃)

Parameter

Symbol

Color

Rating

Unit

Reverse Voltage

VR

5

V

Forward Current

IF

25

mA

Peak Forward Current

(Duty 1/10 @1ms)

Power Dissipation

Electrostatic Discharge(HBM)

IFP

Pd

ESD

R6

60

GH

100

B1

100

R6

60

GH

95

B1

95

R6

2000

GH

150

B1

150

mA

mW

V

Operating Temperature

Topr

-40~+85

℃

Storage Temperature

Tstg

-40~+100

℃

Soldering Temperature

Tsol

3

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

Reflow Soldering : 260 ℃ for 10 sec.

Hand Soldering : 350 ℃ for 3 sec.

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Electro-Optical Characteristics (TSoldering=25℃)

Parameter

Luminous Intensity

Peak Wavelength

Dominant

Wavelength

Forward Voltage

Viewing Angle

Spectrum Radiation

Bandwidth

Reverse Current

Symbol

Color

Min.

Typ.

Max.

R6

36.0

-----

90.0

GH

140.0

-----

360.0

B1

22.5

-----

90.0

R6

-----

632

-----

GH

-----

518

-----

B1

-----

468

-----

R6

-----

622

-----

GH

520.0

-----

535.0

B1

465.0

-----

475.0

R6

1.6

-----

2.1

GH

2.5

-----

3.1

B1

2.5

-----

3.1

2θ1/2

-----

130

Δλ

-----

IR

-----

Iv

λp

λd

VF

Unit

Condition

mcd

IF=5mA

nm

IF=5mA

nm

IF=5mA

V

IF=5mA

-----

deg

IF=5mA

20

-----

nm

IF=5mA

-----

10

μA

VR =5V

Notes:

1. Tolerance of Luminous Intensity ±10%.

2. Tolerance of Dominant Wavelength: ±1nm

3. Tolerance of Forward Voltage : ±0.1V.

4

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Bin Code Description

R6: Bin Range of Luminous Intensity

Bin Code

Min.

Max.

Unit

NA

36.0

57.0

PA

57.0

90.0

Condition

mcd

IF=5mA

GH: Bin Range of Luminous Intensity

Bin Code

Min.

Max.

RA

140.0

225.0

SA

225.0

360.0

Unit

Condition

mcd

IF=5mA

B1: Bin Range of Luminous Intensity

Bin Code

Min.

Max.

MA

22.5

36.0

NA

36.0

57.0

PA

57.0

90.0

Unit

Condition

mcd

IF=5mA

Note:

Tolerance of Luminous Intensity: ±10%.

GH: Bin Range of Dominant Wavelength

Bin Code

Min.

Max.

A5

520.0

525.0

A6

525.0

530.0

A7

530.0

535.0

Unit

Condition

nm

IF=5mA

B1: Bin Range of Dominant Wavelength

Bin Code

Min.

Max.

A6

465.0

470.0

A7

470.0

475.0

Unit

Condition

nm

IF=5mA

Note:

Tolerance of Dominant Wavelength: ±1nm

5

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Spectrum Distribution

R6: Spectrum Distribution

GH: Spectrum Distribution

B1: Spectrum Distribution

6

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Typical Electro-Optical Characteristics Curve(Chip code: R6)

Fig.1-Forword Voltage Shift vs.

Juntion Temperature

Fig.2-Relative Luminous Intensity

vs. Forword Current

Ts=25°C

1.6

Relative Luminous Intensity

(Normalized at 20mA)

Forword Voltage Shift -V

0.20

0.15

0.10

0.05

0.00

-0.05

-0.10

-0.15

-0.20

-50

-25

0

25

50

75

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

100

0

200

1.4

Forward Current IF (mA)

Relative luminous intensity (%)

Fig.3-Relative Luminous Intensity

vs.Juntion Temperature

1.2

1.0

0.8

0.6

0.4

-25

0

50

25

75

Forward Current IF (mA)

15

20

25

30

100

Fig.4-Forward Current vs.

Forward Voltage Ta=25°C

100

10

1

1.0

1.5

2.0

2.5

3.0

Forward Voltage VF (V)

Tj-Juntion Temperature (°C)

50

10

Forward Current IF (mA)

Tj-Juntion Temperature (°C)

0.2

-50

5

Fig.6-Radiation Diagram Ta=25°C

0°

10° 20°

30°

Fig.5-Max.Driving Forward Current

vs.Soldering Temperture

40

30

25

20

10

0

40°

1.0

0.9

50°

0.8

60°

70°

0.7

0

20

40

60

85

100

80°

90°

0.5

0.3

0.1

0.2

0.4

0.6

Soldering Temperature Ts (°C)

7

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Typical Electro-Optical Characteristics Curve (Chip code: GH/B1)

Fig.1-Forword Voltage Shift vs.

Juntion Temperature

Fig.2-Relative Luminous Intensity

vs. Forword Current

Ts=25°C

1.6

Relative Luminous Intensity

(Normalized at 20mA)

Forword Voltage Shift -V

0.20

0.15

0.10

0.05

0.00

-0.05

-0.10

-0.15

-0.20

-50

-25

0

25

50

75

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

100

0

Tj-Juntion Temperature (°C)

Fig.3-Relative Luminous Intensity

vs.Juntion Temperature

200

Forward Current IF (mA)

Relative luminous intensity (%)

1.4

1.2

1.0

0.8

0.6

0.4

0.2

-50

-25

0

50

25

75

10

1

2.0

100

Forward Current IF (mA)

2.5

3.0

3.5

4.0

Forward Voltage VF (V)

Fig.6-Radiation Diagram Ta=25°C

0° 10° 20°

30°

Fig.5-Max.Driving Forward Current

vs.Soldering Temperture

40

30

25

40°

1.0

20

10

0

0.9

50°

0.8

60°

70°

0.7

0

20

40

60

85

100

Soldering Temperature Ts (°C)

8

Fig.4-Forward Current vs.

Forward Voltage Ta=25°C

100

Tj-Juntion Temperature (°C)

50

5

10 15 20 25 30

Forward Current IF (mA)

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

80°

90°

0.5

0.3

0.1

0.2

0.4

0.6

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

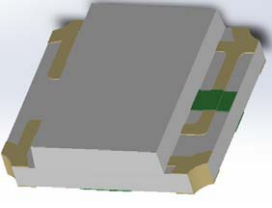

Package Dimension

1.6

Blue

2

Polarity

3

1.5

Red

1

4(Common cathode)

Green

0.2

0.4

1.0

Recommended Solder Pad

0.8

4

2

3

0.8

0.8

0.55

0.4

1

0.6

0.8

0.5

0.4

0.55

0.5

0.6

Note:

Tolerance unless mentioned is ±0.1mm, Unit = mm.

9

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Moisture Resistant Packing Materials

Label Explanation

‧CPN: Customer’s Product Number

‧P/N: Product Number

‧QTY: Packing Quantity

‧CAT: Luminous Intensity Rank

‧HUE: Dom. Wavelength Rank

‧REF: Forward Voltage Rank

‧LOT No: Lot Number

Reel Dimensions

Note:

Tolerances unless mentioned ±0.1mm, Unit = mm.

10

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Carrier Tape Dimensions: Loaded Quantity 2000pcs Per Reel

2.0±0.05

4.0

0.23±0.05

-

3.5±0.05

1.75

.1

1.65

4.0

1

0.

0±

1,

8.0±0.03

1,

5±

0

1.75

Progressive direction

0.7

+

Polarity

Note:

1.Tolerance unless mentioned is ±0.1mm, Unit = mm.

2.Minimum packing amount is 1000pcs per reel.

Moisture Resistant Packing Process

Label

Label

Desiccant

Aluminum moisture-proof bag

11

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Reliability Test Items and Conditions

The reliability of products shall be satisfied with items listed below.

Confidence level:90%

LTPD:10%

No.

Items

Test Condition

Test Hours/Cycles

Sample Size

Ac/Re

1

Reflow Soldering

Temp. : 260℃/10sec.

6 Min.

22 PCS.

0/1

2

Thermal Shock

300 Cycles

22 PCS.

0/1

3

Temperature Cycle

300 Cycles

22 PCS.

0/1

4

High Temperature/Humidity

Reverse Bias

Ta=85℃,85%RH

1000 Hrs.

22 PCS.

0/1

5

Low Temperature Storage

Ta=-40℃

1000 Hrs.

22 PCS.

0/1

6

High Temperature Storage

Ta=100℃

1000 Hrs.

22 PCS.

0/1

7

DC Operation Life

Ta=25℃,

IF = 5mA

1000 Hrs.

22 PCS.

0/1

12

H : +100℃ 5min

∫ 10 sec

L : -10℃ 5min

H : +100℃ 15min

∫ 5 min

L : -40℃ 15min

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�DATASHEET

Multi-Color Type Top view Full-color

A-SP1943BR6GHB1C-C01-2T

Amicc

Precautions for Use

1. Over-current-proof

Customer must apply resistors for protection; otherwise slight voltage shift will cause big current change (Burn out will

happen).

2. Storage

2.1 Do not open moisture proof bag before the products are ready to use.

2.2 Before opening the package: The LEDs should be kept at 30℃ or less and 90%RH or less.

2.3 After opening the package: The LED's floor life is 1 year under 30℃ or less and 60% RH or less. If unused LEDs

remain, it should be stored in moisture proof packages.

2.4 If the moisture absorbent material (silica gel) has faded away or the LEDs have exceeded the storage time, baking

treatment should be performed using the following conditions.

Baking treatment: 60±5℃ for 24 hours.

3. Soldering Condition

3.1 Pb-free solder temperature profile

.

.x

x

aa

MM

.

c

Ce

0s

60

21

C.

x

5a

5M

2.

ec

v

e

os

b0

A3

.

x

a

M

.

c

e

s

/

C

3

.

x

a

M

.

c

e

s

/

C

6

.

c

7e

1s

20

e5

v

1

o~

b0

A6

g

n

i

t

a

e

h

e

r

P

.

c

Ce

0s

00

22

~1

0~

50

16

3.2 Reflow soldering should not be done more than two times.

3.3 When soldering, do not put stress on the LEDs during heating.

3.4 After soldering, do not warp the circuit board.

4. Soldering Iron

Each terminal is to go to the tip of soldering iron temperature less than 350℃ for 3 seconds within once in less than the

soldering iron capacity 25W. Leave two seconds and more intervals, and do soldering of each terminal. Be careful

because the damage of the product is often started at the time of the hand solder.

5. Repairing

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering

iron should be used (as below figure). It should be confirmed beforehand whether the characteristics of the LEDs will

or will not be damaged by repairing.

13

Release Date: 29.Apr.2020. Issue No: V2

Issue No: ADE-1943-008

www.amicc.com

�

A-SP1943BR6GHB1C-C01-2T 价格&库存

很抱歉,暂时无法提供与“A-SP1943BR6GHB1C-C01-2T”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 1+0.36400

- 30+0.35100

- 100+0.33800

- 500+0.31200

- 1000+0.29900

- 2000+0.29120