Environmental Specifications.............................. 2

Equivalent Circuit ............................................... 2

Performance Characteristics............................... 3

I2C & SPI Electrical Parameters .......................... 4

Pressure Output Transfer Function ..................... 4

Temperature Output Transfer Function .............. 4

Device Options ................................................... 5

Operation Overview ........................................ 6-7

Digital Interface Command & Data Formats ... 7-8

I2C Interface.................................................... 8-9

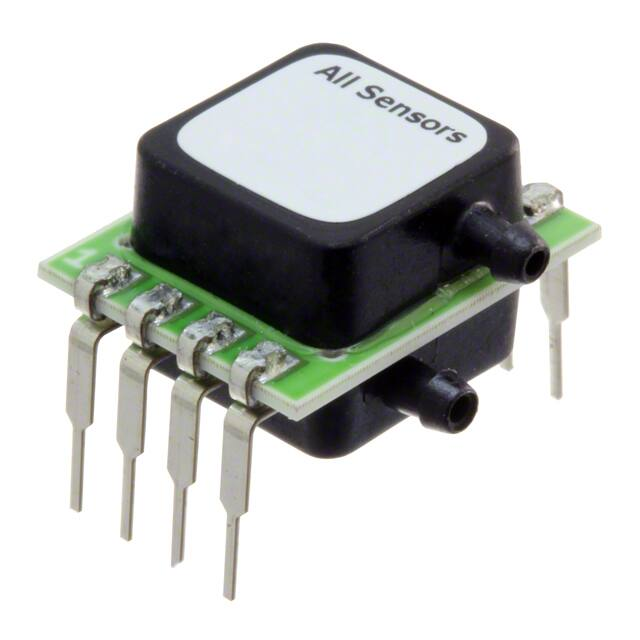

The digital interface eases integration of the sensors into a

wide range of process control and measurement systems,

allowing direct connection to serial communications channels. For battery-powered systems, the sensors can enter very

low-power mode between readings to minimize load on the

power supply.

These calibrated and compensated sensors provide accurate,

stable output over a wide temperature range. This series is

intended for use with non-corrosive, non-ionic working fluids such as air, dry gases and the like. A protective parylene

coating is optionally available for moisture/harsh media

protection.

https://www.allsensors.com/products/dlhr-series

SPI Interface ..................................................9-10

Interface Timing Diagrams ............................... 11

How to Order Guide ........................................ 12

Dimensional Package Drawings

SIP ...............................................................13-14

DIP ..............................................................15-16

SMT .................................................................. 17

Suggested Pad Layout ....................................... 18

Product Labeling ............................................... 18

Soldering Recommendations ............................ 18

All Sensors

f 408 225 2079

Pressure Sensor Maximum Ratings ..................... 2

The DLHR Series Mini Digital Output Sensor is based on

All Sensors’ CoBeam2 TM Technology. This reduces package

stress susceptibility, resulting in improved overall long term

stability and vastly improves the position sensitivity.

p 408 225 4314

Features & Applications ...................................... 2

Standard Pressure Ranges ................................... 2

Introduction

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

Table of Contents

e www.allsensors.com

all sensors

DLHR - Low Voltage Digital Pressure Sensors Series

DS-0350 Rev C

Page 1 of 18

�Applications

• 0.5 to 60 inH2O Pressure Ranges

• 1.68V to 3.6V Supply Voltage Range

• I2C or SPI Interface (Automatically Selected)

• Better than 0.25% Accuracy

• High Resolution 16/17/18 bit Output

• Medical Breathing

• Environmental Controls

• HVAC

• Industrial Controls

• Portable/Hand-Held Equipment

Standard Pressure Ranges

inH2O

Burst Pressure

kPa

inH2O

Nominal Span

kPa

Counts

DLHR-F50D

± 0.5

125

100

25

300

75

±0.4 * 224

DLHR-L01D

±1

250

100

25

300

75

±0.4 * 224

DLHR-L02D

±2

500

100

25

300

75

±0.4 * 224

DLHR-L05D

±5

1,250

200

50

300

75

±0.4 * 224

DLHR-L10D

± 10

2,500

200

50

300

75

±0.4 * 2

DLHR-L20D

± 20

5,000

200

50

500

125

±0.4 * 2

DLHR-L30D

± 30

7,500

200

50

500

125

±0.4 * 2

DLHR-L60D

± 60

15,000

200

50

800

200

±0.4 * 2

24

24

24

24

24

DLHR-L01G

0 to 1

250

100

25

300

75

0.8 * 2

DLHR-L02G

0 to 2

500

100

25

300

75

0.8 * 2

DLHR-L05G

0 to 5

1,250

200

50

300

75

0.8 * 2

DLHR-L10G

0 to 10

2,500

200

50

300

75

0.8 * 2

DLHR-L20G

0 to 20

5,000

200

50

500

125

0.8 * 2

DLHR-L30G

0 to 30

7,500

200

50

500

125

0.8 * 2

DLHR-L60G

0 to 60

15,000

200

50

800

200

0.8 * 2

24

24

24

24

24

24

Note A: Operating range in Pa is expressed as an approximate value.

Pressure Sensor Maximum Ratings

Supply Voltage (Vs)

Absolute Maximum

Recommended

3.63 Vdc

1.75 to 3.60 Vdc

Common Mode Pressure

10 psig

Lead Temperature (soldering 2-4 sec.)

270 °C

Environmental Specifications

Temperature Ranges

Compensated:

Commercial

Industrial

0°C to 70°C

-20°C to 85°C

-25°C to 85 °C

-40°C to 125 °C

Humidity Limits (non condensing)

0 to 95% RH

Operating

Storage

Equivalent Circuit

Vs

SCL

I2C

SDA

- OR -

EOC

Table of Contents

Vs

SCLK

MISO

MOSI

/SS

EOC

Gnd

Gnd

All Sensors

SPI

f 408 225 2079

Pa

DS-0350 Rev C

Page 2 of 18

p 408 225 4314

Proof Pressure

inH2O

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

Operating Range A

Device

e www.allsensors.com

Features

all sensors

DLHR Series Low Voltage Digital Pressure Sensors

�Performance Characteristics for DLHR Series - Commercial and Industrial Temperature Range

All parameters are measured at 3.3V ±5% excitation and 25C unless otherwise specified (Note 9). Pressure measurements are with positive

pressure applied to PORT B.

Parameter

Output Span (FSS)

LxxD, FxxD

LxxG

Offset Output @ Zero Diff. Pressure (Osdig)

LxxD, FxxD

LxxG

Total Error Band

F50D

L01x

L02x

L05x

L10x, L20x, L30x, L60x

Span Temperature Shift

F50x, L01x, L02x

L05x, L10x, L20x, L30x, L60x

Offset Temperature Shift

F50x, L01x, L02x

L05x, L10x, L20x, L30x, L60x

Offset Warm-up Shift

F50x, L01x, L02x

L05x, L10x, L20x, L30x, L60x

Offset Position Sensitivity (±1g)

F50x, L01x, L02x

L05x, L10x, L20x, L30x, L60x

Offset Long Term Drift (One Year)

F50x, L01x, L02x

L05x, L10x, L20x, L30x, L60x

Linearity, Hysteresis Error

FxxD, LxxD

LxxG

Pressure Digital Resolution - No Missing Codes

16-bit Option

17-bit Option

18-bit Option

Temperature Output

Resolution

Overall Accuracy

Supply Current Requirement

During Active State (ICCActive)

During Idle State (ICCIdle)

Power On Delay

Data Update Time (tDU)

Min

Typ

Max

Units

Notes

-

±0.4 * 224

0.8 * 224

-

Dec Counts

Dec Counts

1

1

-

0.5 * 224

0.1 * 224

-

Dec Counts

Dec Counts

-

-

±0.35

±0.25

±0.25

±0.20

±0.15

±1.50

±1.00

±0.75

±0.75

±0.75

%FSS

%FSS

%FSS

%FSS

%FSS

2

2

2

2

2

-

±0.5

±0.2

-

%FSS

%FSS

3

3

-

±0.5

±0.2

-

%FSS

%FSS

3

3

-

±0.25

±0.15

-

%FSS

%FSS

4

4

-

±0.10

±0.05

-

%FSS

%FSS

-

-

±0.25

±0.15

-

%FSS

%FSS

-

-

±0.25

±0.10

-

%FSS

%FSS

6

6

15.7

16.7

17.7

-

-

bit

bit

bit

-

-

16

2

-

bit

°C

-

-

2

100

-

2.6

250

2.5

mA

nA

ms

5, 7, 8

5, 7, 8

5

ms

5, 7

(see table below)

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 3 of 18

�Symbol

Min

Typ

Max

Units

Notes

Input High Level

-

80

-

100

% of Vs

5

Input Low Level

-

0

-

20

% of Vs

5

Output Low Level

-

-

-

10

% of Vs

5

I2C Pull-Up Resistor

-

1,000

-

-

Ω

5

I2C Load Capacitance on SDA, @ 400 kHz

I2C Input Capacitance (each pin)

CSDA

-

-

200

pF

5

CI2C_IN

-

-

10

pF

5

-

-

41

-

decimal

-

I2C Address

Pressure Output Transfer Function

Is the sensor 24‐bit digital output.

�����

Is the specified digital offset

For Gage Operating Range sensors:

For Differential Operating Range sensors:

�������� ��

The sensor Full Scale Span in inches H2O

For Gage Operating Range sensors: Full Scale Pressure

For Differential Operating Range sensors: 2 x Full Scale Pressure.

e www.allsensors.com

�������

������� � �����

� � �������� ��

2��

0.1 * 224

0.5 * 224

f 408 225 2079

Where:

������������� �� � ��2� � �

Temperature Output Transfer Function

������� ∗ 125

� � ��

2��

p 408 225 4314

����������� ��� � �

Where:

�������

The sensor 24‐bit digital temperature output.

(Note that only the upper 16 bits are significant)

Specification Notes

note

1: THE SPAN IS THE ALGEBRAIC DIFFERENCE BETWEEN FULL SCALE DECIMAL COUNTS AND THE OFFSET DECIMAL COUNTS. THE FULL SCALE PRESSURE IS THE

note

2: TOTAL ERROR BAND CONSISTS OF OFFSET AND SPAN TEMPERATURE AND CALIBRATION ERRORS, LINEARITY AND PRESSURE HYSTERESIS ERRORS, OFFSET

note

3: SHIFT IS RELATIVE TO 25C.

note

4: SHIFT IS WITHIN THE FIRST HOUR OF EXCITATION APPLIED TO THE DEVICE.

note

5: PARAMETER IS CHARACTERIZED AND NOT 100% TESTED.

note

6: MEASURED AT ONE-HALF FULL SCALE RATED PRESSURE USING BEST STRAIGHT LINE CURVE FIT.

note

7: DATA UPDATE TIME IS EXCLUSIVE OF COMMUNICATIONS, FROM COMMAND RECEIVED TO END OF BUSY STATUS. THIS CAN BE OBSERVED AS EOC PIN

note

8: AVERAGE CURRENT CAN BE ESTIMATED AS : ICCIdle + (tDU / Reading Interval) * ICCActive). REFER TO FIGURE 2 FOR ACTIVE AND IDLE CONDITIONS OF THE

note

9: THE SENSOR IS CALIBRATED WITH A 3.3V SUPPLY HOWEVER, AN INTERNAL REGULATOR ALLOWS A SUPPLY VOLTAGE OF 1.68V TO 3.6V TO BE USED

MAXIMUM POSITIVE CALIBRATED PRESSURE.

WARM-UP SHIFT, OFFSET POSITION SENSITIVITY AND LONG TERM OFFSET DRIFT ERRORS.

LOW- STATE DURATION.

SENSOR (THE ACTIVE STATE IS WHILE EOC PIN IS LOW).

WITHOUT AFFECTING THE OVERALL SPECIFICATIONS. THIS ALLOWS DIRECT OPERATION FROM A BATTERY SUPPLY.

All Sensors

Table of Contents

DS-0350 Rev C

Page 4 of 18

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

Parameter

all sensors

I2C / SPI Electrical Parameters for DLHR Series

�Device Options

Output Resolution

Calibrated output resolution can be ordered to be 16, 17, or 18 bits.

Higher resolution results in slower update times; see the Data Update Time in the Performance Characteristics table.

Coating

Parylene Coating: Parylene coating provides a moisture barrier and protection form some harsh media. Consult factory

for applicability of Parylene for the target application and sensor type. This option is not available for pressure ranges

below 10 inH2O.

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 5 of 18

�Operation Overview

The DLHR is a digital sensor with a signal path that includes a sensing element, a variable- bit analog to digital

converter, a DSP and an IO block that supports either an I2C or SPI interface (see Figure 1 below). The sensor also

includes an internal temperature reference and associated control logic to support the configured operating mode.

Since there is a single ADC, there is also a multiplexer at the front end of the ADC that selects the signal source for the

ADC.

After completion of the measurement, the result may then be read using the Data Read command. The ADC and DSP

remain in Idle state, and the I/O block returns the 7 bytes of status and measurement data. See Figure 2, following. At

any time, the host may request current device status with the Status Read command. (See Table 1 for a summary of all

commands.)

For optimum sensor performance, All Sensors recommends that Measurement commands be issued at a fixed interval

by the host system. Irregular request intervals may increase overall noise on the output.

Furthermore, if reading intervals are much slower than the Device Update Time, using the Averaging commands is

suggested to reduce offset shift. This shift is constant with respect to time interval, and may be removed by the application. For longer fixed reading intervals, this shift may be removed by the factory on special request.

I/O Interface Configuration: The sensor automatically selects SPI or I2C serial interface, based on the following protocol: If the /SS input is set low by the host (as occurs during a SPI command transaction), the I/O interface will remain

configured for SPI communications until power is removed. Otherwise, once a valid device address and command

have been received over the I2C interface, the I/O interface will remain configured for I2C until power is removed.

NOTE: The four-pin (SIP) packages only support the I2C interface.

All Sensors

Table of Contents

DS-0350 Rev C

Page 6 of 18

f 408 225 2079

Sensor Commands: Five Measurement commands are supported, returning values of either a single pressure / temperature reading or an average of 2, 4, 8, or 16 readings. Each of these commands wakes the sensor from Idle state into

Active state, and starts a measurement cycle. For the Start-Average commands, this cycle is repeated the appropriate

numper of times, while the Start-Single command performs a single iteration. When the DSP has completed calculations and the new values have been made available to the I/O block, the sensor returns to Idle state. The sensor

remains in this low-power state until another Measurement command is received.

p 408 225 4314

The DSP receives the converted pressure and temperature information and applies a multi-order transfer function to

compensate the pressure output. This transfer function includes compensation for span, offset, temperature effects on

span, temperature effects on offset and second order temperature effects on both span and offset. There is also linearity

compensation for gage devices and front to back linearity compensation for differential devices.

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

The ADC performs conversions on the raw sensor signal (P), the temperature reference (T) and a zero reference (Z)

during the ADC measurement cycle.

e www.allsensors.com

all sensors

Figure 1 - DLHR Essential Model

�Operation Overview cont’d

Figure 2 - DLHR Communication Model

Start-Single Command

Command

Start-Single

Internal State

Idle

Interal Operation

Idle

Data Read

Active

Start-Single

Active

Idle

ADC (Temp, Zero, Pressure)

Idle

DSP

ADC (Temp, Zero, Pressure)

Idle

Idle

DSP

New Data Available

EOC

Start-Average2 / 4 / 8 / 16 Commands (Auto Averaging)

Command

Data Read

Start-Average2/4/8/16

Internal State

Idle

Interal Operation

Idle

Active

ADC (Temp, Zero, Pressure)1

ADC (Temp, Zero, Pressure)n

DSP

Start-Average2/4/8/16

Idle

Active

Idle

ADC (T, Z, P)…

New Data Available

EOC

Digital Interface Command Formats

When requesting the start of a measurement, the command length for I2C is 1 byte, for SPI it is 3 bytes.

When requesting sensor status over I2C, the host simply performs a 1-byte read transfer.

When requesting sensor status over SPI, the host must send the Status Read command byte while reading 1 byte.

When reading sensor data over I2C, the host simply performs a 7-byte read transfer.

When reading sensor data over SPI, the host must send the 7-byte Data Read command while reading the data.

SENDING UNDOCUMENTED COMMANDS TO SENSOR WILL CORRUPT CALIBRATION AND IS NOT COVERED

BY WARRANTY.

See Table 1 below for Measurement Commands, Sensor Data read and Sensor Status read details.

Table 1 - DLHR Sensor Command Set

Measurement Commands

Description

SPI ( 3 bytes )

I2C ( 1 byte)

Start-Single

0xAA

0x00

0x00

0xAA

Start-Average2

0xAC

0x00

0x00

0xAC

Start-Average4

0xAD

0x00

0x00

0xAD

Start-Average8

0xAE

0x00

0x00

0xAE

Start-Average16

0xAF

0x00

0x00

0xAF

Read Sensor Data

I2C Read of 7 bytes from device

Read of 7 bytes from device

SPI Host must send [0xF0], then 6 bytes of [0x00] on MOSI

Sensor Returns 7 bytes on MISO

Read Sensor Status

Read

of

1

byte

from device.

I2C

Read of 1 byte from device

SPI Host must send [0xF0] on MOSI

Sensor Returns 1 byte on MISO

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 7 of 18

�Digital Interface Data Format

For either type of digital interface, the format of data returned from the sensor is the same. The first byte consists of

the Status Byte followed by a 24-bit unsigned pressure value and a 24-bit unsigned temperature value. Unused bits

beyond the calibrated bit width are undefined, and may have any value. See the Pressure Output Transfer Function

and Temperature Output Transfer Function definitions on page 3 for converting to pressure and temperature.

Refer to Table 2 for the overall data format of the sensor. Table 3 shows the Status Byte definition.

Note that a completed reading without error will return status 0x40.

P[7:0]

Pressure

Byte 0

T[23:16]

Temperature

Byte 3

T[15:8]

Temperature

Byte 1

T[7:0]

Temperature

Byte 0

Table 3- Status Byte Definition

Description

[Always = 0]

Power : [1 = Power On]

Busy: [ 1 = Processing Command, 0 = Ready]

Mode: [00 = Normal Operation ]

Memory Error [ 1 = EEPROM Checksum Fail]

Sensor Configuration [ always = 0]

ALU Error [1 = Error]

e www.allsensors.com

Bit

Bit 7 [MSB]

6

5

4:3

2

1

Bit 0 [LSB]

I2C Interface

I2C Command Sequence

The part enters Idle state after power-up, and waits for a command from the bus master. Any of the five Measurement

commands may be sent, as shown in Table 1. Following receipt of one of these command bytes, the EOC pin is set

to Low level, and the sensor Busy bit is set in the Status Byte. After completion of measurement and calculation in the

Active state, compensated data is written to the output registers, the EOC pin is set high, and the processing core goes

back to Idle state. The host processor can then perform the Data Read operation, which for I2C is simply a 7-byte

Device Read.

If the EOC pin is not monitored, the host can poll the Status Byte by repeating the Status Read command, which for

I2C is a one-byte Device Read. When the Busy bit in the Status byte is zero, this indicate that valid data is ready, and

a full Data Read of all 7 bytes may be performed.

DO NOT SEND COMMANDS TO SENSOR OTHER THAN THOSE DEFINED IN TABLE 1.

I2C Bus Communications Overview

The I2C interface uses a set of signal sequences for communication. The following is a description of the supported

sequences and their associated mnemonics. Refer to Figure 3 for the associated usage of the following signal sequences.

Bus not Busy (I): During idle periods both data line (SDA) and clock line (SCL) remain HIGH.

START condition (ST): A HIGH to LOW transition of SDA line while the clock (SCL) is HIGH is interpreted as

START condition. START conditions are always set by the master. Each initial request for a pressure value has to

begin with a START condition.

START condition (ST): A HIGH to LOW transition of SDA line while the clock (SCL) is HIGH is interpreted as

START condition. START conditions are always set by the master. Each initial request for a pressure value has to

begin with a START condition.

Slave address (An): The I²C-bus requires a unique address for each device. The DLH sensor has a preconfigured

slave address (see specification table on Page 3). After setting a START condition the master sends the address byte

containing the 7 bit sensor address followed by a data direction bit (R/W). A “0” indicates a transmission from master

to slave (WRITE), a “1” indicates a device-to master request (READ).

All Sensors

Table of Contents

DS-0350 Rev C

Page 8 of 18

f 408 225 2079

P[15:8]

Pressure

Byte 1

p 408 225 4314

P[23:16]

Pressure

Byte 3

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

S[7:0]

Status

Byte

all sensors

Table 2 - Output Data Format

�I2C Interface (Cont’d)

Acknowledge (A or N): Data is transferred in units of 8 bits (1 byte) at a time, MSB first. Each data-receiving

device, whether master or slave, is required to pull the data line LOW to acknowledge receipt of the data. The

Master must generate an extra clock pulse for this purpose. If the receiver does not pull the data line down, a

NACK condition exists, and the slave transmitter becomes inactive. The master determines whether to send

the last command again or to set the STOP condition, ending the transfer.

DATA valid (Dn): State of data line represents valid data when, after a START condition, data line is stable for

duration of HIGH period of clock signal. Data on line must be changed during LOW period of clock signal.

There is one clock pulse per data bit.

STOP condition (P): LOW to HIGH transition of the SDA line while clock (SCL) is HIGH indicates a STOP condition.

STOP conditions are always generated by the master.

Figure 3 - I2C Communication Diagram

1. Measurement Commands: Start-Single ( to start reading of single sample):

Start-Single

C7…C0: 0xAA

Start-Average2

C7…C0: 0xAC

Start-Average4

C7…C0: 0xAD

Start-Average8

C7…C0: 0xAE

Start-Average16

C7…C0: 0xAF

Set by bus master:

Set by sensor:

I

ST A6 A5 A4 A3 A2 A1 A0 W

I

ST A6 A5 A4 A3 A2 A1 A0 R

I

ST A6 A5 A4 A3 A2 A1 A0 R

A

C7 …

C0

N

SP

I

SP

I

2. Status Read:

Set by bus master:

Set by sensor:

A S7 … S0

N

3. Data Read:

Set by bus master:

Set by sensor:

Bus states:

Idle:

Start:

Stop:

Ack:

Nack:

“Read” bit (1):

“Write” bit (0):

I

ST

SP

A

N

R

W

Sensor Address:

A6 … A0

A S7 … S0

A

A

P23 … P16

A

P15 … P8

A

P7 … P0

A

T23 … T16

A

T15 … T8

N SP

I

T7 … T0

Data bits:

Status:

Pressure data:

Temperature data:

S7 … S0

P23 … P0

T23 … T0

Command Bits:

C7 … C0

SPI Interface

SPI Command Sequence

As with the I2C interface configuration, the part enters Idle state after power-up, and waits for a command from the

SPI master. To start a measurement cycle, one of the 3- byte Measurement Commands (see Table 1) must be issued

by the master.

The data returned by the sensor during this command request consists of the Status Byte followed by two undefined

data bytes.

On successful decode of the command, the EOC pin is set Low as the core goes into Active state for measurement

and calculation. When complete, updated sensor data is written to the output registers, and the core goes back to the

Idle state. The EOC pin is set to a High level at this point, and the Busy status bit is set to 0. At any point during the

Active or Idle periods, the SPI master can request the Status Byte by sending a Status Read command (a single byte

with value 0xF0).

As with the I2C configuration, a Busy bit of value 0 in the Status Byte or a high level on the EOC pin indicates that a

valid data set may be read from the sensor. The Data Read command must be sent from the SPI master (The first byte

of value 0xF0 followed by 6 bytes of 0x00).

NOTE: Sending commands that are not defined in Table 1 will corrupt sensor operation.

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 9 of 18

�SPI Interface (Cont’d)

SPI Bus Communications Overview

The sequence of bits and bus signals are shown in the following illustration (Figure 4). Refer to Figure 5 in the Interface Timing Diagram section for detailed timing data.

Figure 4 - SPI Communications Diagram

SCLK

all sensors

Measurement Command

--First Command Byte (0xAA / 0xAC / 0xAD / 0xAE / 0xAF)

MOSI XXXX

C23

C22

C21

MISO HI-Z

S7

S6

S5

Lower Command Bytes (0x00 0x00)

C20

C19

C18

C17

C16

C 15

S4

S3

S2

S1

S0

XX

-----

S7 … S0 (Status)

C1

C0

XXXX

XX

XX

HI-Z

(Undefined Data)

SS

e www.allsensors.com

---

Read Status Command

SCLK

Command (0xF0)

MOSI Don't Care

1

1

1

MISO

S7

S6

S5

Hi-Z

1

0

0

0

0

S4

S3

S2

S1

S0

Don't care

Hi-Z

f 408 225 2079

S7 … S0 (Status)

SS

Data Read Command

---

---

p 408 225 4314

SCLK

Don't Care

1

1

1

1

0

0

0

0

MISO

Hi-Z

S7

S6

S5

S4

S3

S2

S1

S0

S7 … S0 (Status)

SS

All Sensors

Table of Contents

0

0

P23 P22

---

0

0

---

P1

P0

0

0

T23 T22

---

0

0

Don't Care

---

T1

T0

Hi-Z

P23…P0 (Pressure)

T23…T0 (Temperature)

---

---

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

Command (0xF0 then 6 bytes of 0x00)

MOSI

DS-0350 Rev C

Page 10 of 18

�Interface Timing Diagrams

Figure 5 - SPI Timing Diagram

tSSCLK

tLOW

tCLKD

tHIGH

SCLK

MISO

MOSI

(HI•Z)

(HI•Z)

don't care

(don't

care)

tSSSO

tDSU

tDH

SS

tSSZ

tCLKSS

PARAMETER

SCLK frequency (1)

SS low to first clock edge

SS low to serial out

Clock to data out

SCLK low width

SCLK high width

Data setup to clock

Data hold after clock

Last clock to rising SS

SS high to output hi-Z

Bus idle time

(1) Maximum by design, tested to 1.0 MHz.

SYMBOL

fSCLK

tSSCLK

tSSSO

tCLKD

tLOW

tHIGH

tDSU

tDH

tCLKSS

tSSZ

tIDLE

MIN

0.05

120

-8

100

100

50

50

0

-250

TYP

-

tIDLE

MAX

5

20

32

20

-

UNITS

MHz

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Figure 6 - I2C Timing Diagram

tH STA

tHIGH

tLOW

SCL

SDA

tSUS TA

PARAMETER

SCL frequency

SCL low width

SCL high width

Start condition setup

Start condition hold

Data setup to clock

Data hold to clock

Stop condition setup

Bus idle time

tSUDAT

SYMBOL

fSCL

tLOW

tHIGH

tSUSTA

tHSTA

tSUDAT

tHDAT

tSUSTP

tIDLE

tH DAT

MIN

100

1.3

0.6

0.6

0.6

0.1

0

0.6

2.0

tSUS TP

TYP

-

tIDLE

MAX

400

-

UNITS

KHz

us

us

us

us

us

us

us

us

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 11 of 18

�How to Order

Refer to Table 4 for configuring a standard base part number which includes the pressure range, package and temperature range. Table 5 shows the available configuring options. The option identifier is required to complete the

device part number. Refer to Table 6 for the available device packages.

Example P/N with options: DLHR-L02D-E1NS-C-NAV6

Table 4 - How to configure a base part number

Example DLHR - L02D

-

ID

1

2

E

ID

N

B

1

PACKAGE

Lid Style

Description

Non-Barbed

Barbed

ID

S

D

J

N

TEMPERATURE RANGE

Lead Type

Description

SIP (see note 10)

DIP

J-Lead SMT (see note 11)

S

ID

C

I

-

Description

Commercial

Industrial

C

Example

COATING

ID Description

N No Coating

P Parylene Coating (see note 11)

N

ID

A

2

3

4

5

6

7

INTERFACE

Description

Auto I2C, address 0x29/SPI

Auto I2C, address 0x28/SPI

Auto I2C, address 0x38/SPI

Auto I2C, address 0x48/SPI

Auto I2C, address 0x58/SPI

Auto I2C, address 0x68/SPI

Auto I2C, address 0x78/SPI

A

SUPPLY VOLTAGE

ID Description

V 1.68V to 3.6V

V

ID

6

7

8

RESOLUTION

Description

16 Bit

17 bit

18 bit

f 408 225 2079

ORDERING INFORMATION

Table 5 - How to configure an option identifier

6

Table 6 - Available E-Series Package Configurations

Port

Orientation

Non‐Barbed Lid

Lead Style

(1)

SIP

DIP

J Lead SMT

Dual Port

Same Side

Barbed Lid

Lead Style

Low Profile DIP

SIP

(1)

DIP

N/A

E1NS

E1ND

E1NJ

Dual Port

Opposite Side

E1BS

E2ND

E2NJ

E2BS

Specification Notes (Cont.)

note

10: SPI INTERFACE IS ONLY AVAILABLE IN 8-LEAD DIP PACKAGES.

Single Port

N/A

N/A

N/A

N/A

N/A

Note(Gage)

11: PARYLENE COATING NOT OFFERED IN J-LEAD SMT CONFIGURATION.

J Lead SMT

Low Profile DIP

N/A

N/A

N/A

N/A

N/A

N/A

E1BD

N/A

E2NS

E2BD

N/A

(1) SPI is not available in SIP packages

(1) SPI is not available in SIP packages

All Sensors

Table of Contents

all sensors

Description

±0.5 inH2O

±1 inH2O

±2 inH2O

±5 inH2O

±10 inH2O

±20 inH2O

±30 inH2O

±60 inH2O

0 to 1 inH2O

0 to 2 inH2O

0 to 5 inH2O

0 to 10 inH2O

0 to 20 inH2O

0 to 30 inH2O

0 to 60 inH2O

Port Orientation

Description

Dual Port Same Side

Dual Port Opposite Side

e www.allsensors.com

ID

F50D

L01D

L02D

L05D

L10D

L20D

L30D

L60D

L01G

L02G

L05G

L10G

L20G

L30G

L60G

ORDERING INFORMATION

ID

DLHR

Base

ID

E

DS-0350 Rev C

Page 12 of 18

p 408 225 4314

PRESSURE RANGE

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

SERIES

�Package Drawings

E1NS Package

Pinout

1) Gnd

2) Vs

3) SDA

4) SCL

7.17

0.282

12.70

0.500

4.88

0.192

0.64

0.025

10.79

0.425

2.10

0.082

2.04

0.080

10.79

0.425

Port A

2.73

0.107

[9.65]

0.380 (nom)

6.45

0.254

9.80

0.386

15.75

0.620

Port B

0.25

0.010

0.51

0.020

2.54

0.100

Pin 1 2 3 4

NOTES

1)Dimensions are in inches [mm]

2)For suggested pad layout, see drawing: PAD-01

E1BS Package

Pinout

1) Gnd

2) Vs

3) SDA

4) SCL

1.68

0.066

10.80

0.425

Port B

0.25

0.010

Port A

2.73

0.107

[9.65]

0.380 (nom)

6.45

0.254

9.80

0.386

1.14

0.045

10.80

0.425

15.75

0.620

0.64

0.025

2.11

0.083

12.70

0.500

4.88

0.192

0.51

0.020

2.24

0.088

9.15

0.360

2.54

0.100

Pin 1 2 3 4

NOTES

1)Dimensions are in inches [mm]

2)For suggested pad layout, see drawing: PAD-01

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 13 of 18

�Package Drawings (Cont’d)

E2NS Package

Pinout

12.70

0.500

2.10

0.082

2.04

0.080

e www.allsensors.com

0.25

0.010

2.54

0.100

0.51

0.020

Pin 1 2 3 4

NOTES

1)Dimensions are in inches [mm]

2)For suggested pad layout, see drawing: PAD-01

E2BS Package

Pinout

1) Gnd

2) Vs

3) SDA

4) SCL

2.12

0.084

1.68

0.066

10.80

0.425

Port B

2.73

0.107

15.75

0.620

[9.65]

0.380 (nom)

9.80

0.386

1.14

0.045

10.80

0.425

Port A

0.25

0.010

2.11

0.083

12.70

0.500

2.24

0.088

9.15

0.360

0.64

0.025

0.51

0.020

2.54

0.100

Pin 1 2 3 4

NOTES

1)Dimensions are in inches [mm]

2)For suggested pad layout, see drawing: PAD-01

All Sensors

Table of Contents

DS-0350 Rev C

Page 14 of 18

f 408 225 2079

10.79

0.425

2.73

0.107

[9.65]

0.380 (nom)

9.80

0.386

15.75

0.620

Port B

p 408 225 4314

10.79

0.425

Port A

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

7.17

0.282

0.64

0.025

2.12

0.084

all sensors

1) Gnd

2) Vs

3) SDA

4) SCL

�Package Drawings (Cont’d)

E1ND Package

Pinout

0.46

0.018

1) Gnd

2) Vs

3) SDA/MOSI

4) SCL/SCLK

5) EOC

6) MISO

7) Not Connected

8) /SS

5.72

0.225

Pin 8 7 6 5

7.17

0.282

0.64

0.025

12.70

0.500

4.88

0.192

10.79

0.425

2.10

0.082

NOTES

1) Dimensions are in inches [mm]

2) For suggested pad layout, see drawing: PAD-03

2.04

0.080

10.79

0.425

15.75

0.620

6.45

0.254

Port A

2.73

0.107

0.25

0.010

1.48

0.058

9.80

0.386

16

0.630

Port B

2.54

0.100

8.89

0.350

(min)

Pin 1 2 3 4

E1BD Package

Pinout

0.46

0.018

1) Gnd

2) Vs

3) SDA/MOSI

4) SCL/SCLK

5) EOC

6) MISO

7) Not Connected

8) /SS

5.72

0.225

Pin 8 7 6 5

9.15

0.360

0.64

0.025

12.70

0.500

4.88

0.192

2.11

0.083

1.14

0.045

10.80

0.425

NOTES

1) Dimensions are in inches [mm]

2) For suggested pad layout, see drawing: PAD-03

8.89

0.350

(min)

2.24

0.088

1.68

0.066

10.80

0.425

15.75

0.620

16

0.630

6.45

0.254

Port A

2.73

0.107

0.25

0.010

1.48

0.058

9.80

0.386

Port B

2.54

0.100

Pin 1 2 3 4

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 15 of 18

�Package Drawings (Cont’d)

E2ND Package

0.46

0.018

1) Gnd

2) Vs

3) SDA/MOSI

4) SCL/SCLK

5) EOC

6) MISO

7) Not Connected

8) /SS

5.72

0.225

7.17

0.282

Pin 8 7 6 5

0.64

0.025

12.70

0.500

2.12

0.084

10.79

0.425

Port A

2.10

0.082

all sensors

Pinout

E2BD Package

Pinout

0.46

0.018

1) Gnd

2) Vs

3) SDA/MOSI

4) SCL/SCLK

5) EOC

6) MISO

7) Not Connected

8) /SS

5.72

0.225

Pin 8 7 6 5

9.15

0.360

12.70

0.500

0.64

0.025

NOTES

1) Dimensions are in inches [mm]

2) For suggested pad layout, see drawing: PAD-03

All Sensors

Table of Contents

1.68

0.066

10.80

0.425

15.75

0.620

Port B

2.73

0.107

0.25

0.010

1.48

0.058

9.80

0.386

16

0.630

Port A

8.89

0.350

(min)

1.14

0.045

10.80

0.425

2.24

0.088

2.12

0.084

2.11

0.083

2.54

0.100

Pin 1 2 3 4

DS-0350 Rev C

Page 16 of 18

e www.allsensors.com

Pin 1 2 3 4

f 408 225 2079

NOTES

1) Dimensions are in inches [mm]

2) For suggested pad layout, see drawing: PAD-03

p 408 225 4314

2.54

0.100

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

2.04

0.080

10.79

0.425

2.73

0.107

8.89

0.350

(min)

1.48

0.058

15.75

0.620

0.25

0.010

9.80

0.386

16

0.630

Port B

�Package Drawings (Cont’d)

E1NJ Package

Pinout

1) Gnd

2) Vs

3) SDA/MOSI

4) SCL/SCLK

5) EOC

6) MISO

7) Not Connected

8) /SS

Pin 8 7 6 5

7.17

0.282

0.64

0.025

12.70

0.500

4.88

0.192

2.10

0.082

10.79

0.425

15.75

0.620

2.04

0.080

Port A

2.73

0.107

DETAIL A

SCALE 4 : 1

6.45

0.254

9.80

0.386

1.51

0.059

3.94

0.155

0.81

R0.032

10.79

0.425

Port B

0.25

0.010

A

1.27

0.050

2.54

0.100

Pin 1 2 3 4

NOTES

1)Dimensions are in inches [mm]

2)For suggested pad layout, see drawing: PAD-10

E2NJ Package

Pinout

1) Gnd

2) Vs

3) SDA/MOSI

4) SCL/SCLK

5) EOC

6) MISO

7) Not Connected

8) /SS

2.12

0.084

Pin 8 7 6 5

7.17

0.282

2.10

0.082

12.70

0.500

10.79

0.425

Port A

0.64

0.025

2.04

0.080

10.79

0.425

16

0.630

A

2.73

0.107

DETAIL A

SCALE 4 : 1

9.80

0.386

1.51

0.059

3.94

0.155

0.81

R0.032

15.75

0.620

Port B

0.25

0.010

1.27

0.050

2.54

0.100

Pin 1 2 3 4

NOTES

1)Dimensions are in inches [mm]

2)For suggested pad layout, see drawing: PAD-10

DLHR Series Low Voltage Digital Pressure Sensors

Table of Contents

Page 17 of 18

�2.29

0.090

16

0.630

14.99

0.590

PAD-10

e www.allsensors.com

PAD-03

Product Labeling

Company

Part Number

f 408 225 2079

All Sensors

DLHR-L02D

E1NS-C

NAV6

R16J21-14

Lot Number

Example Device Label

Soldering Recommendations

a 16035 Vineyard Blvd. Morgan Hill, CA 95037

If these devices are to be subjected to solder reflow assembly or other high temperature processing, they must be

baked for 30 minutes at 125°C within 24 hours prior to exposure. Failure to comply may result in cracking and/or

delamination of critical interfaces within the package, and is not covered by warranty.

p 408 225 4314

PAD-01

all sensors

2.54

0.100

(typ.)

1.27

0.050

2.54

0.100

(typ.)

0.035~0.039 inch

(Finish Size)

0.035~0.039 inch

(Finished Size)

2.54

0.100

(typ.)

Suggested Pad Layout

All Sensors reserves the right to make changes to any products herein. All Sensors does not assume any liability arising out of the application or use of any product or circuit

described herein, neither does it convey any license under its patent rights nor the rights of others.

All Sensors

Table of Contents

DS-0350 Rev C

Page 18 of 18

�