MUSB Rugged USB

Product Specification S6046C Rev 1.2

About Amphenol

Commercial Products

Amphenol’s commercial

connector products are

used in a variety of end

user applications

including networking,

telecom, server &

computer, storage &

HDD, consumer

electronics and

entertainment,

professional audio &

Industrial &

Military/Aerospace.

MUSB-C111-30

SERIES A, RIGHT

ANGLE, STACKED

MUSB-A511-00

SERIES A, VERTICAL

MUSB-D111-30

SERIES B, RIGHT ANGLE

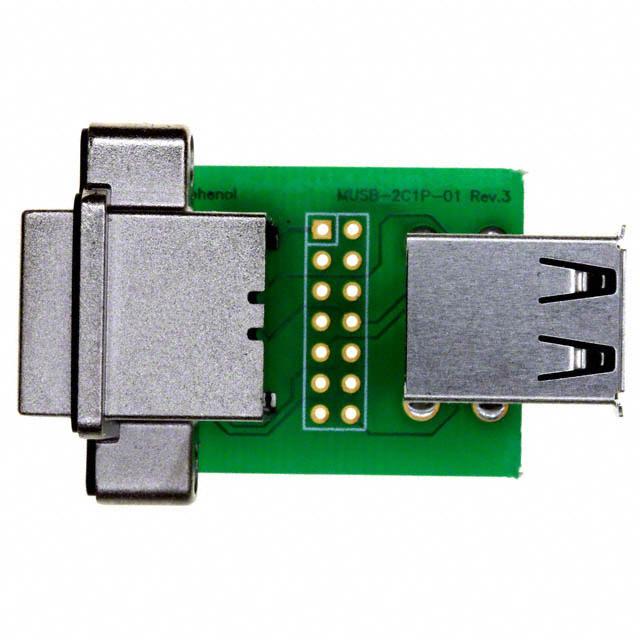

Related Products

With matching USB

MUSB-B151-34

SERIES MINI-B, RIGHT ANGLE

MUSB-E151-04

SERIES MINI-AB, RIGHT ANGLE

MUSB-K152-X0

SERIES MICRO-AB, RIGHT

ANGLE

With Cable Header

Overview

This Product Specification defines the general use and performance parameters for Amphenol’s

MUSB series of connector.

With Terminal Block

Availability: Series A (single & stacked), series B, series Mini-B, series Mini-AB, series Micro-AB

with right angle and vertical PCB tails. Right angle connectors mounted on a PCB with matching

USB, cable headers or terminal blocks are available for all series. Dust covers for enhanced mating

area protection are also available.

Usage

With PCB for wiring

These connectors meet Military shock & vibration levels and IP67 per IEC 60529 in mated and

unmated conditions. The connector system is designed to provide a standard USB interface for

enclosures exposed to harsh environments. Connectors mate with any standard USB 2.0 plug.

Achieves data rates up to 480 Mb/s (USB 2.0).

Applications

Intended for use in applications such as:

Medical equipment

Microwave transmitters

GPS, positioning equipment

Military vehicles, radios, computers

Revision date: July 13, 2015

Test equipment

Mobile entertainment systems

Traffic control & monitoring systems

Page 1 of 3

�S6046C Rev 1.2

About Amphenol

Commercial Products

Amphenol’s commercial

connector products are

used in a variety of end

user applications

including networking,

telecom, server &

computer, storage &

HDD, consumer

electronics and

entertainment,

professional audio &

Industrial &

Military/Aerospace.

Connector Electrical Characteristics

Parameter

Current rating:

Contact resistance:

Insulation resistance:

DWV:

Series A & B

1.5A per contact

30 mΩ max

1000 MΩ min

500V AC @ sea level

Series Mini-B & Mini-AB

1.0A per contact

50 mΩ max

100 MΩ min

100V AC @ sea level

Series Micro-AB

Up to 1.8A per contact (see dwg)

30 mΩ max

100 MΩ min

100V AC @ sea level

Connector Mechanical Characteristics

Thermal Shock: 5 cycles @ -40° to +125° C

Physical Shock: Per EIA364-27 Condition H (11ms 30G)

Humidity: Per EIA364-31 Condition C, method III

Vibration: Per EIA364-28 per Condition V, Letter A

Salt spray: Per EIA364-26, 250 Hrs

Related Products

Process Characteristics

MDB

Recommended soldering process: Hand or wave soldering peaked at 260°C for 8 seconds max.

Recommended Torque for #4-40 or M3 Panel Mount Screws: 0.45 to 0.65 Nm (4 – 5.75 in-lbs).

Recommended Torque for #2-56 or M2.5 Panel Mount Screws: 0.23 to 0.34 Nm (2 - 3 in-lbs).

Solder tails suitable for PCB thickness of 1.52mm (.062”)

Mating Cycles: 1500 (Series A & B)

5000 (Series Mini-B & Mini-AB)

10000 (Series Micro-AB)

9 POSITION CONNECTOR

SHOWN

MRJ

Material Requirements

MUSB connectors are RoHS compliant.

Unless otherwise specified, the materials for each component shall be:

Contacts: Phosphor Bronze with 30µ” (0.76µm) min Gold over 50µ” (1.27µm) min Nickel

Housing: Engineering thermoplastic, UL94V-0 rated, Black. White for series B.

Shell: Die cast Zinc alloy, Nickel plating

Temperature rise: Meets the requirement of 30° C ΔT

Operating temperature -40° to +105° C

Available Documents

MRJ-5480-01 SHOWN

VERTICAL, PCB TAIL,

8 POSITION RJ45

Drawing Numbers:

P-MUSB-A211-XX MUSB rugged Series A, Right Angle, on PCB with R/A cable header. Thread & Dust cover option

P-MUSB-A511-XX MUSB rugged Series A, Vertical PCB mount

P-MUSB-B151-XX MUSB rugged Series Mini-B, right angle PCB tail

P-MUSB-CA11-XX MUSB rugged Series A, stacked, Right angle, on PCB. Thread & Dust cover options

P-MUSB-D411-3X MUSB rugged Series B, Right Angle, on PCB with terminal block

P-MUSB-E151-XX MUSB rugged Series Mini-AB, Right Angle PCB tail, Thread & Dust Cover options

P-MUSB-K152-X0 MUSB rugged Series Micro-AB, Right Angle PCB tail, Thread options

Contact factory, authorized Amphenol representative or website www.amphenolcanada.com for additional configurations

Quality Test Reports

MRJ-5380-01 SHOWN

RIGHT ANGLE, PCB TAIL,

8 POSITION RJ45

Amphenol Canada Corp.

605 Milner Avenue

Toronto, Ontario, Canada, M1B 5X6

+1 416 291 4401

QTR9300377

QTR9300378

QTR9300482

Series Mini-B & Mini-AB

Series A & B

Series Micro-AB

Page 2 of 3

Copyright © Amphenol Corporation 2011 • All rights reserved

www.amphenolcanada.com

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE DISCLOSED TO OTHERS FOR ANY PURPOSE OR USED FOR MANUFACTURING PURPOSES

WITHOUT WRITTEN PERMISSION FROM AMPHENOL CANADA CORP.

�S6046C Rev 1.1

Product Numbering System

MUSB

MUSB - X

X

X

X - X

X

X

Rugged USB Receptacle, Generation 1

Receptacle Type Per USB 2.0

A – Standard A Series

B – Mini B Series

C – Standard A Series Stacked

D – Standard B Series

E – Mini AB Series

K – Micro AB Series1

Termination Style

1 – Right Angle

2 – Right Angle on PCB with Right Angle Cable Header2

3 – Right Angle on PCB with Right Angle Matching USB Type Connector2

4 – Right Angle on PCB with Terminal Blocks2

5 – Vertical2

8 – Right Angle on PCB with Vertical Cable Header3

A – Right Angle on PCB with Holes for Wiring (Style 3 PCB)2, 4

B – Right Angle on PCB with Vertical Single Row Isolated Header5

D – Right Angle on PCB with Vertical Dual Row Isolated Header6

E – Right Angle on PCB with Vertical Matching USB Type Connector7

Number of Contacts

1 - Standard 4 per Port for Types A, C & D

5 - Standard 5 per Port for Types B, E & K

Insulator Housing Colour

1 – Black for Types A, B, C & E, White for Type D

2 – Grey for Type K

Rear Shield and Thread Options8, 9

0 – No Rear Shield, Unified Thread

3 – With Rear Shield, Unified Thread

M – With Rear Shield, Metric Thread

N – No Rear Shield, Metric Thread

Dust Cover Options10

0 – With No Dust Cover11

1 – With Grey Dust Cover

5 – With Black Dust Cover

Unique Special Code12

No Digit – Standard part defined by previous 10 digits

1 to 9 – Unique special feature

Notes

1)

2)

3)

4)

5)

6)

7)

8)

Receptacle type K (Micro AB) is a generation 2 epoxy free design. It is currently available in right angle only.

Consult with Amphenol for the availability of the vertical version.

Termination styles 2, 3, 4, 5 & A are currently available for receptacle types A, B, C, D & E only.

Termination style 8 is currently available for receptacle types A, C & D only.

Termination style A uses the pcb from termination style 3.

Termination style B is currently available for receptacle types A & D only.

Termination style D is currently available for receptacle type C only.

Termination style E is currently available for receptacle types A & C only.

Rear shields are optional for receptacle types B & E (Mini B & Mini AB) with right angle termination style.

Rear shields are required for all other types with right angle terminations. Rear shields are not available for

vertical termination style.

Amphenol Canada Corp.

605 Milner Avenue

Toronto, Ontario, Canada, M1B 5X6

+1 416 291 4401

9)

For receptacle types A, C & D (Standard A & B Series), the unified thread is #4-40UNC and the metric thread

is M3x0.5. For receptacle types B, E & K (Mini B, Mini AB & Micro AB), the unified thread is #2-56UNC

and the metric thread is M2.5x0.45.

10) When dust covers are supplied with the connector, they are not installed. They are supplied in bulk inside each

package of connectors. For receptacle type C (Standard A Series Stacked), two dust covers are supplied per

connector.

11) For receptacle types B & E (Mini B & Mini AB), dust cover code 4 is frequently used. Code 4 connectors are

identical to code 0. For example, part number MUSB-B151-34 is identical to MUSB-B151-30.

12) Consult with Amphenol for additional termination styles, solder cup contacts, mounting styles, conductive

gaskets or other requirements of interest. See catalogue Accessories pages for dust cover options.

Page 3 of 3

Copyright © Amphenol Corporation 2011 • All rights reserved

www.amphenolcanada.com

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE DISCLOSED TO OTHERS FOR ANY PURPOSE OR USED FOR MANUFACTURING PURPOSES

WITHOUT WRITTEN PERMISSION FROM AMPHENOL CANADA CORP.

�