EK15

EK15

nnoovvaa t i o n FFr roomm

P EK15

r o d u c t IInnSA08

Evaluation Kit for SA08 Pin-Out

INTRODUCTION

PARTS LIST

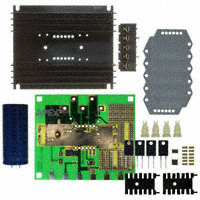

This easy-to-use kit provides a platform for the evaluation of

PWM amplifiers using the SA08 pin-out configuration. It can be

used to analyze a multitude of standard or proprietary circuit

configurations, and is flexible enough to do most standard

amplifier test configurations.

The schematic is shown in Figure 3. Note that all of the

components shown on the schematic will probably not be used

for any single circuit. Some components will simply be omitted, while others require installation of a jumper to complete

the signal path.

Only components unique to the EK15 are provided in this

kit. Hardware similar to that shown in Figure 1 must be obtained locally.

Apex Part #

HS18

MS04

EVAL19

60SPG00001

TW05

ZX7R105KTL

OX7R105KWN

TS01

EC01

HS22

CSR03

CSR04

BEFORE YOU GET STARTED

* All Apex Precision Power amplifiers should be handled using

proper ESD precautions.

* Always use the heatsink included in this kit with TW05

washer.

* Always use adequate power supply bypassing.

* Do not change connections while the circuit is powered.

* Initially set all power supplies to the minimum operating

levels allowed in the device data sheet.

* Check for oscillations.

Description

Quantity

Heatsink

1

PC mount Cage Jacks

1 Bag/12 each

PC Board

1

Spacer Grommets

4

Thermal Washer

1 Box/10 each

1µF Cap ST2225B105K501LLXW

2

Novacap

1µF Cap 1825B105K201N,

1

Novacap

Terminal Strip 66505

1

Beau Interconnect

470 µf Cap

1

United Chemi-Con

82DA471M500MG2D

Heatsink

2

Thermolly 6025B

0.010 ohm resistor

2

Caddock MP916-0.010 - 5%

0.020 ohm resistor

2

Caddock MP930-0.020 - 5%

FIGURE 1.

EK15U

http://www.cirrus.com

Copyright © Cirrus Logic, Inc. 2009

(All Rights Reserved)

MAY 20091

APEX − EK15UREVC

�EK15

M I C R O T E C H N O L O G Y

EVAL19 R-C

COMPONENT SIDE

+

PWR

GND

+

B OUT

+Vs

A OUT

Vcc

12

7

Rb

Ra

R1

IC

CVs1

CVs3

4.686

CVcc

CVs2

R2

Vcc SIG

GND

R3

D1

SHDN

SIG

GND

1

6

C3

J1

C2

IC

C1

RAMP/-PWM

OR

FLAG

SIG

GND

R4

SPARE

+PWM

SPARE

5.500

BOTTOM SIDE

6

2

TB1

CIRCUIT DUT SIDE

EVAL19

During assembly refer to Figure 1 and

Figure 2.

1. From the DUT of the PCB insert and

solder the 12 cage jacks. Also solder

the cage jacks from the circuit side

as well, making sure the cage jack

remains flush with the component side

of the PCB.

2. Solder the 3 surface mount ceramic

capacitors to the component side of

the PCB.

3. From the component side of the PCB

insert the terminal strip. Solder from

the circuit side of the PCB. Be sure that

the GND terminal hole in the PCB is

fully filled with solder.

4. Two values of current limiting power

resistors are supplied. Select one

value (see the amplifier data sheet to

learn how to calculate which resistor

will suit your need). Coat the backside

of the power resistor with heat sink

compound (not supplied). Using 4-40

screws and nuts (not supplied) mount

the resistors to the two small heat sinks

supplied. Solder the resistor/heat sink

assembly to the component side of the

PCB.

5. Insert the electrolytic capacitor into

the PCB from the component side and

solder from the circuit side making sure

to fill the mounting holes with solder.

6. From the circuit side, push spacer

grommets into PCB until fully seated.

Grommets will snug when screws are

inserted for heatsink mounting.

7. Apply TW05 thermal washer to the

bottom of the amplifier.

8. Use #14 sleeving to insulate and align

at least 2 opposite pins of the amplifier.

9. Mount amplifier to heatsink using #6

screws and nuts. Torque the part to

the specified 8 to 10 in-lbs (.9 to 1.13

N*M). Do not over torque.

10. Install components as needed. External connections may be soldered

directly or standard banana jacks may

be soldered to the large pads at the

edge of the PCB.

11. Insert amplifier pins into cage jacks

and fasten PCB to heatsink.

FIGURE 2. PCB

TOP SIDE

1

ASSEMBLY

P r o d u c t I n n o v a t i o nF r o m

EK15U

�EK15

P r o d u c t I n n o v a t i o nF r o m

A block diagram of the SA08 is shown in Figure 2 along with

pcb connections of all the commonly used external components.

Your application circuit will not use all of the components. Add

those components required by your circuit. You may have to

jumper some components to make the desired electrical connections. J1 is an optional way to connect the clock circuit. Power

supply bypassing is particularly important and that is why high

quality ceramic chip capacitors are supplied with the kit. In addition, a large electrolytic capacitor is included. This capacitor

was selected expressly for this evaluation kit and may not be

(and likely won't be) suitable for your end application. You will

need to select an electrolytic capacitor based on your analysis

of the capacitor's ripple current, ripple current tolerance, operating temperature, operating voltage, acceptable service life and

acceptable supply ripple. Note that the signal ground and power

ground are separated and tie together only at the ground pin (5).

A breadboarding area is supplied which can accomodate 1 or

2 IC amplifiers and associated components. The large terminal

pads can be used to solder wire connections or bannana jacks.

The schematic of Figure 3 can be used to verify the functionality of your amplifier and help you gain a familiarity with

proper operation. At either A Out or B Out, with respect to

ground, you should observe a square wave approximately 30

V in amplitude with a fixed frequency and duty cycle that varies

from approximately 0 to 100% at a rate of 1 Hz. The current

limit is set to 2 amps.

FIGURE 3. FUNCTIONAL TEST CIRCUIT

50 OHM 25 WATT

DUMMY LOAD

Vcc

Vcc

A OUT

+ Vs

B OUT

CVcc

1µF

FIGURE 3. PCB SCHEMATIC.

A OUT

30V HIGH

AMP

SUPPLY

15V

200 mA

SUPPLY

CVs1-3

Ra

.1 OHM

B OUT

+ Vs

Rb

.1 OHM

R1

5k

R2

5k

CVcc

CVs1-3

12

R1

R2

12

11

I SENSE A

10

8

9

Vcc

A OUT

10V

1000pf

5V

Vcc

910

H

BRIDGE

DRIVER

.01µF

SA08

Vcc

910

50

50k

50

10V

50k

I SENSE B

B OUT

10V

10V

1000pf

7

+ Vs

5V

I SENSE B

.1V

1k

8

9

Vcc

A OUT

I SENSE A

1k

.1V

10

7

B OUT

+ Vs

11

H BRIDGE DRIVER

Ra

10V

.01µF

5V

SA08

TL

56k

f/2 470pF

5V

56k

5V

TL

CLOCK

10V

f/2

470pF

5V

CLK IN

1

CLOCK

CLK IN

2

+ PWM

3

J1

CLK OUT

2

1

CLK OUT

+ PWM

3

C1

J1

4

GND

5

GND ILim/SHDN

FLAG

5

4

C1

.01µF

FLAG

ILim/SHDN

6

C3

.1µF

5K

6

C2

D1

50

C3

R3

+PWM

R4

+PWM

EK15U

D1

RAMP/-PWM

OR

FLAG

SIG

GND

PWR

GND

ILIM/SHDN

RAMP/-PWM

OR

FLAG

SIG

GND

PWR

GND

ILIM/SHDN

1 Hz SDNE WAVE

+3/+7 V AMPLITUDE

VALLEY TO PEAK

3

�EK15

P r o d u c t I n n o v a t i o nF r o m

Contacting Cirrus Logic Support

For all Apex Precision Power product questions and inquiries, call toll free 800-546-2739 in North America.

For inquiries via email, please contact apex.support@cirrus.com.

International customers can also request support by contacting their local Cirrus Logic Sales Representative.

To find the one nearest to you, go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED TO BE

SUITABLE FOR USE IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER’S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE

CUSTOMER OR CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES,

BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL

LIABILITY, INCLUDING ATTORNEYS’ FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs, Apex Precision Power, Apex and the Apex Precision Power logo designs are trademarks of Cirrus Logic, Inc.

All other brand and product names in this document may be trademarks or service marks of their respective owners.

4

EK15U

�