EK57

Evaluation Kit

APPLICABLE PARTS (SOLD SEPARATELY)

•

•

•

MP108FD

MP111FD

MP118FD (See EK57 - Addendum)

INTRODUCTION

This easy-to-use kit provides a platform for the evaluation of linear power amplifiers circuits using the

MP108FD & MP111FD pin out. With ample bread boarding areas it is flexible enough to analyze a multitude

of standard or proprietary circuit configurations. Critical connections for power supply bypassing are prewired. Components not usually readily available in engineering labs are provided. External connection to the

evaluation kit can be made via the terminal block and terminal pads at the edges of the circuit board. The terminal pads are suitable for soldering standard banana jacks or direct soldering of wires. Additionally, banana

jacks and a BNC connector can be inserted into the holes at the edge of the board and wired to the numbered

terminal pads.

Figure 1: Schematic Diagram

PCB AMPLIFIER TERMINALS

PCB WIRING TERMINALS

TERMINAL STRIP TERMINALS

ACCESSORY TERMINALS

C1

1

+

C2

C5

TS1

SPARE

OUT OUT OUT

2

1

2

3

4

5

6

7

8

9

10

11 12

TP BPLT GND +V B CC1 CC2 NC +V B NC NC

3

13 14

15

16

VIEW FROM PCB COMPONENT SIDE

4

+V S

+V S +V S +V S

+V B

-IN +IN GND NC -V B NC +CL -CL NC -V B

34 33 32 31 30 29 28 27 26 25

NC NC

24

-V S -V S -V S

23 22 21 20 19 18

OUT OUT OUT

17

OUT

GND

-V S

RLIM

5

-V B

C6

C3

+

C4

www.apexanalog.com

© Apex Microtechnology Inc.

All rights reserved

Jan 2023

EK57U Rev H

�EK57

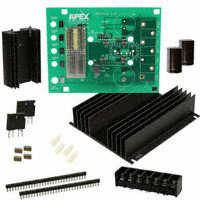

Figure 2: PCB

TOP VIEW

COMPONENT SIDE

MICROTECHNOLOGY

1

+Vs

GND

IC1

SPARE

SPARE

EVAL57 R

BANANA

JACK

C2

DUT

ON BOTTOM

+Vb

Cc

16

+Vs

BANANA

JACK

+

+Vb

1

2

BANANA

JACK

C5

OUT

C1

34

Rlim

C4

4.890

REF.

GND

C6

HS28

BANANA

JACK

3

17

5

-Vs

-Vb

GND

OUT

-Vs

-Vb

4

BNC

INPUT SIG

5

C3

+

TS1

GND

6.250

REF.

BOTTOM VIEW

DUT SIDE

2

EK57U Rev H

�EK57

PARTS LIST

Reference

Manufacturer Part #

Description

C1,4,5,6

TS1

C2,3

RLIM*

RLIM*

HS28

HS31

S703-93-130-47-052100

EVAL57

60SPG00004

1825B105K201N

TS02

KMH200VN681M25MX40T2

PBV-R050-1

PBV-R100-1

Heat Sink

Heat Sink

Strip of 30 cage jacks

PC Board

Spacer Grommets/ Micro Plastics

Cap, 1uF, 200V, 10%-R

Terminal Strip

680uF 200V/ United Chemi-Con

0.050 Ω Resistor

0.100 Ω Resistor

QTY

1

1

2

1

4

4

1

2

1

1

*Chosen per directions.

BEFORE YOU GET STARTED

•

•

•

•

•

•

All Apex Microtechnology amplifiers should be handled using proper ESD precautions.

Do not change connections while the circuit is powered.

Initially set all power supplies to the minimum operating voltage allowed in the device data sheet.

For instructions adapting EK57 for MP118 see EK57 addendum.

Always use the heatsink provided in this kit and proper power supply bypassing.

Please refer to the Application Note, AN01, for general operating considerations.

ASSEMBLY

During assembly refer to Figure 2 and the data sheet for the product being evaluated.

1. Note that each side of the circuit board is identified as either the “component side” or “DUT side”.

2. Cut the MS11 into groups of 16 and 18 cage jacks and insert from the “DUT side” of the board. On the

“component side” of the board, solder all cage jacks having solder pads (7, 9, 10, 23, 24, 26, 29, and 31

have no solder pads). Make sure the cage jacks are fully seated before soldering. Be careful that solder

does not flow into the cage jacks.

3. Pull out the plastic carrier strip from the soldered cage jacks. Without this step, the amplifier will not

properly seat! The unsoldered cage jacks will be removed with the carrier strip.

4. Solder the surface mount capacitors at C1, C4, C5, and C6 on the “component side” of the board.

5. Low ohm value resistors are provided with this evaluation kit: 0.050 ohm and 0.100 ohm. These are used

to implement current limiting in the output circuit. Select the value most appropriate for your application.

Refer to the product data sheet to determine which resistor value you should use.

6. Mount the HS28 heat sink to the PCB and solder the mounting posts of the heat sink.

7. Apply a thin layer of thermal grease on the back of the chosen current limiting sense resistor, insert the

resistor into the PCB and mount the resistor to the HS28 heat sink using #4 screw and nut hardware (not

supplied). Be sure to cut off the excess resistor lead lengths.

8. Mount the electrolytic capacitors at C2 and C3 from the “component side” of the PCB. Match the polarity

markings on the capacitor with the polarity markings on the PCB. Be sure the capacitors have snapped

into the PCB and solder from the “DUT side” of the PCB. Be sure to fill the holes with solder.

9. Mount the terminal strip to the “component side” of the PCB. Make sure the terminal strip is fully seated,

and solder the pins from the “DUT side” of the PCB. Be sure to fill the mounting holes with solder.

EK57U Rev H

3

�EK57

10. Mount and wire the banana jacks and BNC connector (neither supplied) to the PCB pads at locations 1-5

as needed or desired.

11. Mount other components to complete your application circuit using the pads and holes provided.

12. From the “DUT side” of the PCB snap the spacer- grommets into the holes at the four corners of the PCB.

Notice that the holes are slightly rectangular. Match the spacer-grommet's long and short sides to the

holes in the PCB.

13. Apply a thin, uniform layer of thermal grease to the amplifier; a straight edge may be useful here. Position

the amplifier over the mounting holes in the heatsink. Firmly push the amplifier onto the heatsink while

slightly rotating the amplifier back and forth, ending with the mounting holes of the amplifier over the

mounting holes in the heatsink.

14. Attach the amplifier to the heatsink with 4-40x½’ male-female hex spacers (not supplied). These spacers

serve as alignment pins and aide in the assembly of the PCB to the heatsink. Alternatively, use 4-40x¼’

machine screws to mount the amplifier to the heatsink. Do not over-tighten the spacers or screws as this

provides no thermal benefit and may break the hardware.

15. Place the PCB assembly on the heatsink/amplifier assembly so that the hex spacers come through the

aligning holes near the corners of the amplifier location in the PCB. Carefully lower the PCB assembly until

the pins of the amplifier engage the cage jacks. Alternatively, sight through the aligning holes in the PCB

and match-up the PCB to the screws used to mount the amplifier. In either case be sure the pins of the

amplifier are engaged with the cage jacks, and then continue pushing the PCB Assembly in the area

between the amplifier’s pins until the four spacer grommets at the four corners of the PCB touch the

heatsink. At this point the PCB should not be bowed.

16. Use #8 X 1" sheet metal screws (not provided) to mount the PCB to the heat sink at the four spacer-grommets.

17. Inspect the assembly from the side and check that the PCB is not bowed toward the heat sink. If the PCB

is bowed use a small tool to carefully pry the PCB away from the heat sink until the PCB is flat.

18. Hook up power and signals as necessary. The amplifier is now ready for testing.

4

EK57U Rev H

�EK57

Figure 3: Assembly

HS28 HEATSINK

SURFACE MOUNT

CAPACITORS

TERMINAL STRIP

CAGE JACKS

SPACER GROMMET

ELECTROLYTIC CAPACITOR

PC BOARD

NO. 4 MOUNTING HARDWARE

ACCESS HOLES

CURRENT LIMITING SENSE RESISTOR

4-40 x 1/4 SCREWS

DEVICE UNDER TEST (DUT)

ALTERNATE MOUNTING

HARDWARE USING

HEX SPACERS

HS31 HEATSINK

NO. 8 or 10 x 1.0 SHEET METAL SCREWS

NEED TECHNICAL HELP? CONTACT APEX SUPPORT!

For all Apex Microtechnology product questions and inquiries, call toll free 800-546-2739 in North America. For

inquiries via email, please contact apex.support@apexanalog.com. International customers can also request

support by contacting their local Apex Microtechnology Sales Representative. To find the one nearest to you,

go to www.apexanalog.com

IMPORTANT NOTICE

Apex Microtechnology, Inc. has made every effort to insure the accuracy of the content contained in this document. However, the information is

subject to change without notice and is provided "AS IS" without warranty of any kind (expressed or implied). Apex Microtechnology reserves the right

to make changes without further notice to any specifications or products mentioned herein to improve reliability. This document is the property of

Apex Microtechnology and by furnishing this information, Apex Microtechnology grants no license, expressed or implied under any patents, mask

work rights, copyrights, trademarks, trade secrets or other intellectual property rights. Apex Microtechnology owns the copyrights associated with the

information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Apex

Microtechnology integrated circuits or other products of Apex Microtechnology. This consent does not extend to other copying such as copying for

general distribution, advertising or promotional purposes, or for creating any work for resale.

APEX MICROTECHNOLOGY PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED TO BE SUITABLE FOR USE IN PRODUCTS USED FOR LIFE

SUPPORT, AUTOMOTIVE SAFETY, SECURITY DEVICES, OR OTHER CRITICAL APPLICATIONS. PRODUCTS IN SUCH APPLICATIONS ARE UNDERSTOOD TO BE

FULLY AT THE CUSTOMER OR THE CUSTOMER’S RISK.

Apex Microtechnology, Apex and Apex Precision Power are trademarks of Apex Microtechnology, Inc. All other corporate names noted herein may be

trademarks of their respective holders.

EK57U Rev H

5

�