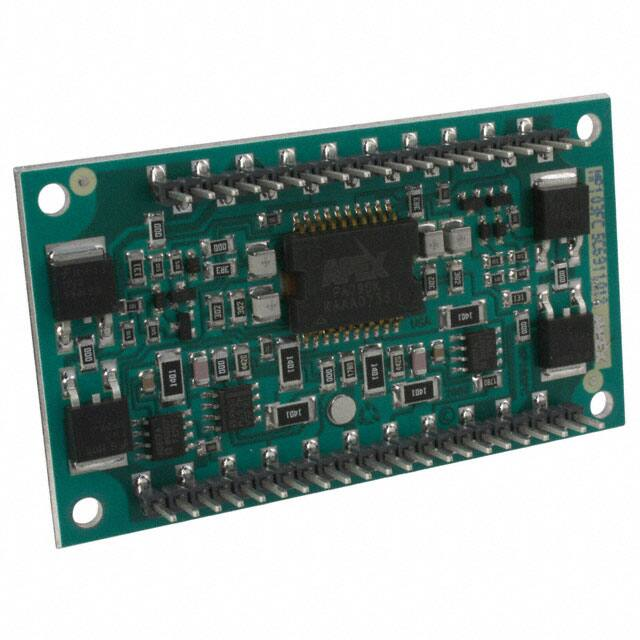

MP103

RoHS

Power Amplifier

COMPLIANT

FEATURES

•

•

•

•

Low Cost Integrated Solution

Output Current > 10A within SOA

Internal Power Dissipation 35W Per Channel

167V/µs Slew Rate

APPLICATIONS

•

Piezoelectric Actuation For Ink Jet Printer Nozzles

DESCRIPTION

The MP103 is a high voltage, high output current dual channel operational amplifier for driving capacitive

loads such as piezo devices use in ink jet printing applications. The MP103 utilizes proprietary IC’s combined

with discrete semiconductor and passive elements on a thermally conductive insulated metal substrate,

delivering very high power from a compact module. The amplifier gain is fixed at 65 V/V when the feedback

pin is connected to the VOUT pin. Internal compensation provides optimum slew rate and ensures stability.

The only external components required are the current limit resistors RLIM, a series isolation resistor RS

(when driving a capacitative load) and the power supply bypass capacitors.

Figure 1: Equivalent Schematic

Feedback A

+VS

+VS

+VS

IL

IL

+VAUX

IL

IN_A

-VS

-VS

-VS

Out A

-5V

Feedback B

+VS

+VS

+VS

IL

IL

IL

IN_B

Out B

-VS

-VS

-VS

www.apexanalog.com

© Apex Microtechnology Inc.

All rights reserved

JAN 2018

MP103U Rev E

�MP103

TYPICAL CONNECTION

Figure 2: Typical Connection

+V S +V AUX

10μF

100nF

100nF

RCL

+V S

+V AUX

IN

V OUT

CL

½ MP103

GND

FDBK

OUT

RFEEDBACK

RL

-V S

-V S

2

100nF

10μF

MP103U Rev E

�MP103

PINOUT AND DESCRIPTION TABLE

Figure 3: External Connections

42

-VS_A

41

-VS_A

40

-VS_A

NC 39

1 +V _A

S

2

+VS_A

3

+VS_A

4 CL_A

5 CL_A

IN_A

37

NC

FBK_A 36

NC 35

6 CL_A

7 NC

8

OUT_A

9 NC

10 NC

11 NC

12 NC

38

MP103

(viewed from

backplate)

+VAUX 34

NC 33

32

GND

NC 31

FBK_B 30

NC 29

13 NC

14 NC

IN_B 28

NC 27

15 OUT_B

16 NC

CL_B 26

CL_B 25

17 NC

18

+VS_B

19 +V _B

S

20 +V _B

S

CL_B

-VS_B

-VS_B

-VS_B

24

23

22

21

Pin Number

Name

Description

1, 2, 3

+Vs_A

The positive supply rail for channel A.

4, 5, 6

CL_A

Connect to the current limit resistor. Output current flows into/out of these pins

through RCL. The output pin and the load are connected to the other side of RCL.

8

OUT_A

The output for channel A. Connect this pin to load and to the feedback resistor.

15

OUT_B

The output for channel B. Connect this pin to load and to the feedback resistor.

18, 19, 20

+Vs_B

The positive supply rail for channel B.

21, 22, 23

-Vs_B

The negative supply rail for channel B. Internally connected to -Vs_A.

24, 25, 26

CL_B

Connect to the current limit resistor. Output current flows into/out of these pins

through RCL. The output pin and the load are connected to the other side of RCL.

28

IN_B

The input for channel B.

30

FBK_B

The feedback pin for channel B. This pin must be connected to OUT_B to close the

feedback loop. When connected directly to OUT_B the closed loop voltage gain of

channel B is 65 V/V. The gain can be increased by inserting a 1/4 W resistor between

FBK_B and OUT_B.

32

GND

Ground.

34

Vaux

+24 V power supply pin. A 24 V supply is required for operation of front end small

signal circuitry.

36

FBK_A

The feedback pin for channel A. This pin must be connected to OUT_A to close the

feedback loop. When connected directly to OUT_A the closed loop voltage gain of

channel A is 65 V/V. The gain can be increased by inserting a 1/4 W resistor between

FBK_A and OUT_A.

38

IN_A

The input for channel A.

40, 41, 42

-Vs_A

The negative supply rail for channel A. Internally connected to -Vs_B.

All Others

NC

No connection.

MP103U Rev E

3

�MP103

ELECTRICAL SPECIFICATIONS

Notes: a) All Min/Max characteristics and specifications are guaranteed over the Specified Operating Conditions. Typical performance characteristics and specifications are derived from measurements

taken at typical supply voltages and TC = 25°C.

b) +VS and −VS denote the positive and negative supply voltages to the output stages. +VAUX

denotes the positive supply voltage to the input stages.

ABSOLUTE MAXIMUM RATINGS

Parameter

Symbol

Supply Voltage, +VS to −VS

Min

+VS to −VS

−VS

Supply Voltage, −VS

Max

Unit

200

V

-30

V

Supply Voltage, +VAUX

+VAUX

30

V

Output Current, pk, per Channel (Within SOA)

IO(PK)

15

A

Power Dissipation, internal, Each Channel

PD

35

W

Input Voltage

VIN

VAUX

V

225

°C

150

°C

105

°C

-5

Temperature, pin solder, 10s

Temperature, junction1

TJ

Temperature Range, storage

−40

1. Long term operation at the maximum junction temperature will result in reduced product life. Derate power dissipation

to achieve high MTTF.

INPUT

Parameter

Test Conditions

Offset Voltage

Offset Voltage vs. Temperature

Min

Typ

Max

Unit

-6.7

±2

6.7

mV

Full temp range

Bias Current, initial1

±2

µV/°C

-6.6

±3.3

6.6

µA

Test Conditions

Min

Typ

Max

Unit

Fixed Gain

Feedback connected to VOUT

63.5

65

66.5

V/V

Gain Bandwidth, -3db

CL = 47nF

230

kHz

Power Bandwidth, 130 Vp-p

+VS = 145V, -VS = -15V

230

kHz

1. Doubles for every 10°C of case temperature increase.

GAIN

Parameter

4

MP103U Rev E

�MP103

OUTPUT

Parameter

Test Conditions

Min

Typ

Max

Unit

Voltage Swing

IO = 10A

+VS - 15

+VS - 9

V

Voltage Swing

IO = 10A

-VS + 15

-VS + 14

V

12

A

Current, Peak, Source

Rs = 1 Ω, CL = 47nF,

Vin ≥ 8Vp-p

Slew Rate

V/µs

167

POWER SUPPLY

Parameter

Test Conditions

Voltage, -VS

Min

Typ

Max

Unit

-7

-15

-20

V

24

25

V

145

-VS + 200

V

19

26

mA

13.5

15

mA

1

5

mA

Typ

Max

Unit

1.5

1.75

°C/W

Voltage, +VAUX

Voltage, +VS

-VS + 20

Current, quiescent, -VS

Current, quiescent, +VAUX

Current, quiescent, +VS

THERMAL

Parameter

Test Conditions

Min

Resistance, AC, junction to case1

Full temp range, f ≥ 60 Hz

Resistance, DC, junction to case

Full temp range, f < 60 Hz

3.1

3.6

°C/W

Resistance, junction to air

Full temp range

12.5

14

°C/W

70

°C

Temperature Range, case

0

1. Rating applies if the output current alternates between both output transistors at a rate faster than 60 Hz.

MP103U Rev E

5

�MP103

TYPICAL PERFORMANCE GRAPHS

Figure 4: Power Derating

Figure 5: Output Voltage Swing

40

16

Each Channel

14

/ŶƚĞƌŶĂů�WŽǁĞƌ��ŝƐƐŝƉĂƟŽŶ

Per Channel, PD (W)

Voltage Drop From Supply (V)

35

30

25

20

15

10

5

SINK

12

10

8

6

4

2

0

0

0

25

50

75

100

0

2.5

5

7.5

10

Output Current, IO�Έ�Ή

Case Temperature, TC (°C)

Figure 6: Frequency Response

Figure 7: Quiescent Current

30

50

SOURCE

1.1

0

30

-30

20

-60

10

-90

Phase

0

1.08

-150

CLOAD = 50nF

-20

1k

10k

100k

Frequency, F (Hz)

6

+VS

1.06

-120

-10

Normalized Quiescent Current, IQ (X)

40

Phase, P�Έ°Ή

Gain, A V�Έ��Ή

Gain

-180

1M

1.04

1.02

VAUX

1

-VS

0.98

0.96

-25

0

25

50

75

Case Temperature, TC (°C)

MP103U Rev E

�MP103

Figure 8: Offset Voltage vs.

Temperature

Figure 9: Max. DC Output

Voltage

150

DC Output Voltage, VO (Vdc)

Normalized Bias Current, IB (X)

1.2

1.1

1.0

0.9

0.8

0.7

0.6

-40

140

130

120

110

100

-20

0

20

40

60

80

0

Case Temperature, TC (°C)

1.6

TC = 25°C

1.5

Normalized Bias Current, IB (X)

Maximum Duty Cycle (%)

75

Figure 11: Input Bias Current vs.

Temperature

100

TC = 70°C

120

140

160

Output Voltage, VO (V)

MP103U Rev E

50

Case Temperature, TC (°C)

Figure 10: Max. Output Pulse

Duty Cycle

10

100

25

180

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

-40

-20

0

20

40

60

80

Case Temperature, TC (°C)

7

�MP103

Figure 12: Offset Voltage vs. Vs

Supply

Figure 13: Offset Voltage vs.

VAux Supply

1.035

EŽƌŵĂůŝnjĞĚ�KīƐĞƚ�sŽůƚĂŐĞ͕�sOS (X)

EŽƌŵĂůŝnjĞĚ�KīƐĞƚ�sŽůƚĂŐĞ͕�sCS (X)

1.2

1.030

1.025

1.020

1.015

1.010

1.005

1.000

0.995

1.0

0.8

0.6

0.4

0.2

0

5

30

55

80

105 130 155 180 205

5

Total Supply Voltage, VSS (V)

20

25

Figure 15: Input Bias Current vs.

VSS Supply

1.2

Normalized Bias Current, IB (X)

1.4

Normalized Bias Current, IB (X)

15

Total Supply Voltage, VAUX (V)

Figure 14: Input Bias Current vs.

VAux Supply

1.2

1.0

0.8

0.6

0.4

0.2

1.0

0.8

0.6

0.4

0.2

0

0

5

10

15

20

Total Supply Voltage, VAUX (V)

8

10

25

5

30

55

80 105 130 155 180 205

Total Supply Voltage, VSS (V)

MP103U Rev E

�MP103

Figure 16: Amplifier Gain vs.

RFDBK

Figure 17: Slew Rate vs.

Temperature

105

450

400

95

Slew Rate, SR (V/μs)

�ŵƉůŝĮĞƌ�'ĂŝŶ͕��V�;sͬsͿ

100

90

85

80

75

350

300

-SLR

250

200

70

65

+SLR

0

500

1000

External Feedback Resistor, RFDBK�;ёͿ

MP103U Rev E

1500

150

-40

-20

0

20

40

60

80

Case Temperature, TC (°C)

9

�MP103

SAFE OPERATING AREA (SOA)

The MOSFET output stage of the MP103 is not limited by second breakdown considerations as in bipolar

output stages. Only thermal considerations and current handling capabilities limit the SOA (see Safe Operating Area graph). The output stage is protected against transient flyback by the parasitic body diodes of the

output stage MOSFET structure. However, for protection against sustained high energy flyback, external fastrecovery diodes must be used.

KƵƚƉƵƚ��ƵƌƌĞŶƚ�&ƌŽŵ��нsS�KZ�ͲsS�;�Ϳ

Figure 18: SOA

1mS

10

10 mS

SOURCE DC

SINK DC

1

1

10

100

^ƵƉƉůLJ�dŽ�KƵƚƉƵƚ��ŝīĞƌĞŶƟĂů͕�sS�Ͳ�sO�;sͿ

10

MP103U Rev E

�MP103

GENERAL

Please read Application Note 1 “General Operating Considerations” which covers stability, supplies, heat

sinking, mounting, current limit, SOA interpretation, and specification interpretation. Visit www.apexanalog.com for Apex Microtechnology’s complete Application Notes library, Technical Seminar Workbook, and

Evaluation Kits.

AMPLIFIER GAIN

When the feedback pin for each channel is connected to the corresponding OUT pin, the gain of the

amplifier is internally set to 65 V/V. The amplifier gain can be increased by connecting a resistor between the

feedback and Out pin. The amplifier gain will be increased approximately 1 V/V for each additional 49.9 Ω

added between the feedback and OUT pin.

POWER SUPPLY BYPASSING

Bypass capacitors to power supply terminals +VS and -VS must be connected physically close to the pins

to prevent local parasitic oscillation in the output stage of the MP103. Use electrolytic capacitors at least

10μF per output amp required. Bypass the electrolytic capacitors with high quality ceramic capacitors (X7R)

0.1μF or greater. Duplicate the supply bypass for the supply terminals of each amplifier channel. A bypass

capacitor of 0.1μF or greater is recommended for the +VAUX terminal.

CURRENT LIMIT

For proper operation, the current limit resistor (RLIM) must be connected as shown in the external connection diagram. For optimum reliability the resistor value should be set as high as possible. The value is calculated as follows; with the maximum practical value of 30 Ω. The current limit function can be disabled by

shorting the IL pin to the OUT pin.

0.7V

R LIM = ----------I LIM

POWER SUPPLY PROTECTION

Unidirectional zener diode transient suppressors are recommended as protection on the supply pins. The

zeners clamp transients to voltages within the power supply rating and also clamp power supply reversals to

ground. Whether the zeners are used or not, the system power supply should be evaluated for transient performance including power-on overshoot and power-off polarity reversal as well as line regulation. Conditions

which can cause open circuits or polarity reversals on either power supply rail should be avoided or protected

against. Reversals or opens on the negative supply rail is known to induce input stage failure. Unidirectional

transzorbs prevent this, and it is desirable that they be both electrically and physically as close to the amplifier as possible.

SERIES ISOLATION RESISTOR, RS

To insure stability with all capacitive loads a series isolation resistor should be included between the output and the load as shown in the external connections drawing. A 1 Ω resistor works well for capacitive loads

between 135pF and 44nF. The resistor will affect the rise and fall time of the output pulse at the capacitive

load. This can be compensated for on the input signal.

MP103U Rev E

11

�MP103

BACKPLATE GROUNDING

The substrate of the MP103 is an insulated metal substrate. It is required that it be connected to signal

ground. This is accomplished when the ground pin (Pin 32) is properly connected to signal ground.

12

MP103U Rev E

�MP103

PACKAGE OPTIONS

PACKAGE STYLE FC

NEED TECHNICAL HELP? CONTACT APEX SUPPORT!

For all Apex Microtechnology product questions and inquiries, call toll free 800-546-2739 in North America. For

inquiries via email, please contact apex.support@apexanalog.com. International customers can also request

support by contacting their local Apex Microtechnology Sales Representative. To find the one nearest to you,

go to www.apexanalog.com

IMPORTANT NOTICE

Apex Microtechnology, Inc. has made every effort to insure the accuracy of the content contained in this document. However, the information is

subject to change without notice and is provided "AS IS" without warranty of any kind (expressed or implied). Apex Microtechnology reserves the right

to make changes without further notice to any specifications or products mentioned herein to improve reliability. This document is the property of

Apex Microtechnology and by furnishing this information, Apex Microtechnology grants no license, expressed or implied under any patents, mask

work rights, copyrights, trademarks, trade secrets or other intellectual property rights. Apex Microtechnology owns the copyrights associated with the

information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Apex

Microtechnology integrated circuits or other products of Apex Microtechnology. This consent does not extend to other copying such as copying for

general distribution, advertising or promotional purposes, or for creating any work for resale.

APEX MICROTECHNOLOGY PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED TO BE SUITABLE FOR USE IN PRODUCTS USED FOR LIFE

SUPPORT, AUTOMOTIVE SAFETY, SECURITY DEVICES, OR OTHER CRITICAL APPLICATIONS. PRODUCTS IN SUCH APPLICATIONS ARE UNDERSTOOD TO BE

FULLY AT THE CUSTOMER OR THE CUSTOMER’S RISK.

Apex Microtechnology, Apex and Apex Precision Power are trademarks of Apex Microtechnology, Inc. All other corporate names noted herein may be

trademarks of their respective holders.

MP103U Rev E

13

�