PA340

PA340

PA340

High Voltage Power Operational Amplifier

DESCRIPTION

FEATURES

The PA340 is a high voltage monolithic MOSFET operational amplifier achieving performance features previously found only in hybrid designs while increasing reliability. Inputs are protected from excessive common

mode and differential mode voltages. The safe operating area (SOA) has no second breakdown limitations.

External compensation provides the user flexibility in

choosing optimum gain and bandwidth for the application.

♦ RoHS COMPLIANT

♦ MONOLITHIC MOS TECHNOLOGY

♦ LOW COST

♦ HIGH VOLTAGE OPERATION – 350V

♦ LOW QUIESCENT CURRENT TYP. – 2.2mA

♦ NO SECOND BREAKDOWN

♦ HIGH OUTPUT CURRENT – 120 mA PEAK

APPLICATIONS

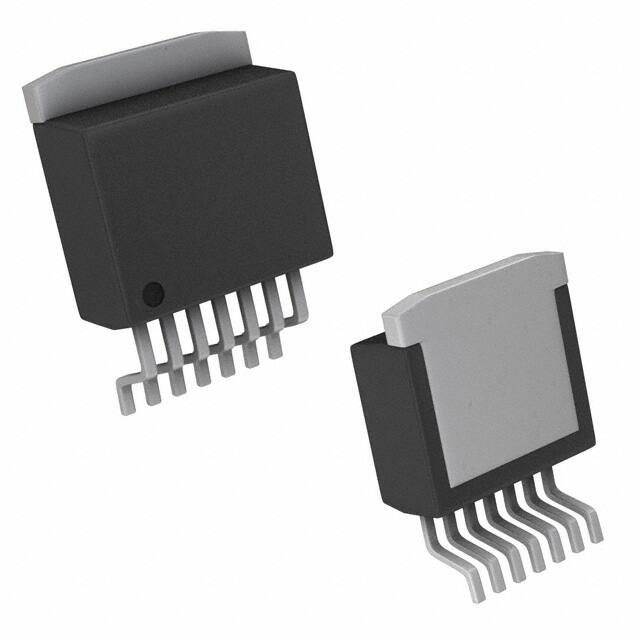

The surface mount package of the PA340CC is an industry standard non-hermetic plastic 7-pin DDPAK.

♦ TELEPHONE RING GENERATOR

♦ PIEZO ELECTRIC POSITIONING

♦ ELECTROSTATIC TRANSDUCER &

DEFLECTION

♦ DEFORMABLE MIRROR FOCUSING

♦ PACKAGING OPTIONS

7-pin DDPAK Surface Mount Package (PA340CC)

FIGURE 1: Equivalent Schematic

3

+VS

D1

Q1

Q2

Q3

Q4

6

COMP

–IN

D2

D3

D4

Q6

D5

COMP Q8

Q12

Q13

2

+IN

5

Q5

1

I OUT

7

Q11

Q10

Q14

–VS

4

SUB

Copyright © Apex Microtechnology, Inc. 2012

www.apexanalog.com

PA340U

(All Rights Reserved)

OCT 2013

PA340U REVC1

�PA340

High voltage considerations should be taken when designing board layouts for the PA340. The PA340 may require a

derate in supply voltage depending on the spacing used for board layout. The 14-mil minimum spacing of the 7-pin

DDPAK is adequate to standoff the 350V rating of the PA340. However, a supply voltage derate to 250V is required

if the spacing of circuit board artwork is less than 11 mils.

The metal tab of the PA340CC package is directly tied to -Vs.

PA340CX

TYPICAL APPLICATION

PA340CC

A

A

1

1

-IN

+IN

+Vs

-Vs

OUT

COMP (Cc)

COMP (Cc)

DDPAK

PKG. STYLE CC

FIGURE 2. External Connections.

-IN

+IN

+Vs

-Vs

OUT

COMP (Cc)

COMP (Cc)

For CC values, see graph on page 4.

Note: CC must be rated for full supply voltage.

Ref: APPLICATION NOTE 20: "Bridge Mode Operation of Power Amplifiers"

Two PA340 amplifiers operated as a bridge driver for a piezo transducer provides a low cost 660 volt total drive

capability. The RN CN network serves to raise the apparent gain of A2 at high frequencies. If RN is set equal to R the

amplifiers can be compensated identically and will have matching bandwidths.

VIN

20R

20R

R

20R

+175

+175

CC

10pF

CC

10pF

A1

PA340

A2

PA340

PIEZO

TRANSDUCER

–175

LOW COST 660V p-p

PIEZO DRIVER

RN

CN

–175

FIGURE 3. Low Cost 660VP-P Piezo Driver

2

PA340U

�PA340

1. CHARACTERISTICS AND SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

Parameter

Symbol

Min

Max

Units

350

V

OUTPUT CURRENT, continuous within SOA

60

mA

OUTPUT CURRENT, peak

(Note 3)

120

mA

POWER DISSIPATION, continuous @ TC = 25°C

14

W

SUPPLY VOLTAGE, +VS to -VS

INPUT VOLTAGE, differential

-16

+16

V

INPUT VOLTAGE, common mode

-VS

+VS

V

220

°C

TEMPERATURE, pin solder - 10 sec

TEMPERATURE, junction

150

°C

TEMPERATURE, storage

(Note 2)

-65

150

°C

TEMPERATURE RANGE, powered (case)

-40

125

°C

SPECIFICATIONS (PER AMPLIFIER)

Parameter

Test Conditions (Note 1)

Min

Typ

Max

Units

OFFSET VOLTAGE, initial

12

40

mV

OFFSET VOLTAGE, vs. temperature

25°C to 85°C

(Note 3)

17

250

µV/°C

OFFSET VOLTAGE, vs. temperature

-25°C to 25°C

(Note 3)

18

500

µV/°C

OFFSET VOLTAGE, vs. supply

4.5

OFFSET VOLTAGE, vs. time

80

BIAS CURRENT, initial

50

BIAS CURRENT, vs. supply

2

INPUT

OFFSET CURRENT, initial

50

INPUT IMPEDANCE, DC

INPUT CAPACITANCE

µV/V

µV/kh

200

pA

pA/V

200

pA

1011

Ω

3

pF

COMMON MODE, voltage range

+VS - 12

V

COMMON MODE, voltage range

-VS + 12

V

COMMON MODE REJECTION, DC

VCM = ±

90VDC

NOISE, broad band

10kHz BW, RS = 1KΩ

84

115

dB

337

µV RMS

GAIN

OPEN LOOP at 15Hz

RL = 5KΩ

103

dB

GAIN BANDWIDTH PRODUCT

@1MHz

10

MHz

POWER BANDWIDTH

280V p-p

35

kHz

PA340U

90

3

�PA340

Parameter

Test Conditions (Note 1)

Min

Typ

Max

Units

OUTPUT

VOLTAGE SWING

CURRENT, peak

IO = 40mA

(Note 3)

CURRENT, continuous

SETTLING TIME to 0.1%

SLEW RATE

±VS

12

±VS

10

V

120

mA

60

mA

10V step, A V = -10

2

µs

CC = 4.7pF

32

V/µS

RESISTANCE, 10mA

(Note 4) RCL = 0Ω

91

Ω

RESISTANCE, 40mA

(Note 4) RCL = 0Ω

65

Ω

POWER SUPPLY

VOLTAGE

±10

CURRENT, quiescent

±150

±175

V

2.2

2.5

mA

THERMAL

RESISTANCE, AC junction to case

F > 60Hz

5.9

6.85

°C/W

RESISTANCE, DC junction to case

F < 60Hz

7.7

8.9

°C/W

RESISTANCE, junction to air

Full temperature range

(Note 5)

TEMPERATURE RANGE, case

Meets full range specifications

27

-25

25

°C/W

+85

°C

NOTES:

1. Unless otherwise noted TC = 25°C, CC = 6.8pF. DC input specifications are ± value given. Power supply voltage is typical rating.

2. Long term operation at the maximum junction temperature will result in reduced product life. Derate

internal power dissipation to achieve high MTTF. For guidance, refer to heatsink data sheet.

3. Guaranteed but not tested.

4. Since the PA340 has no current limit, load impedance must be large enough to limit output current to

120mA.

5. Heat tab attached to 3/32" FR-4 board with 2oz. copper. Topside copper area (heat tab directly attached) = 1000 sq. mm, backside copper area = 2500 sq. mm, board area = 2500 sq. mm.

CAUTION

The PA340 is constructed from MOSFET transistors. ESD handling procedures must be observed.

4

PA340U

�PA340

8

6

4

VDROP-@85°C

15

VDROP-@27°C

10

5

2

0

25

50

75

100

TEMPERATURE, T (°C)

0

125

-80

-90

100

PHASE, Φ (°)

60

2.2pF

40

0.75pF

-110

2.2pF

6.8pF

-140

-150

68pF

15pF

-160

0

-170

-20

10

10

68pF

-130

15pF

20

PHASE RESPONSE

-120

6.8pF

100 1K 10K 100K 1M 10M

FREQUENCY, F (Hz)

-180

10K

100K

1M

FREQUENCY, F (Hz)

HARMONIC DISTORTION

10M

SLEW RATE

0.01

A V = 20

C C = 15pF

R L = 2K

1K

10K

FREQUENCY, F (Hz)

SLEW RATE, (V/µs)

0.1 180V

P-P

0.001

100

COMMON MODE REJECTION, CMR (dB)

30VP-P

60VP-P

100

80

60

40

20

0

10

100

1K

10K

FREQUENCY, F (Hz)

100K

10

RISE

5 15 25 35 45 55 65 75 85

COMPENSATION CAPACITANCE, CC (pF)

10

25°C

55°C

1

1000

1

GAIN

10

POWER RESPONSE

2.2pF

6.8pF

15pF

100

33pF

68pF

10

10K

100K

FREQUENCY, F (Hz)

1M

QUIESCENT CURRENT

102

100

5°C

12

C

25°

98

°C

-40

96

20 60 100 140 180 220 260 300 340

TOTAL SUPPLY VOLTAGE, (V)

POWER SUPPLY REJECTION

COMMON MODE REJECTION

120

FALL

20

0

100K

POWER SUPPLY REJECTION, PSR (dB)

DISTORTION, (%)

30

1

125°C

85°C

0.1

0.1

20

40

60

80 100 120

OUTPUT CURRENT, IO (mA)

-100

0.75pF

80

VDROP+@27°C

0

SMALL SIGNAL RESPONSE

OPEN LOOP GAIN, A (dB)

20

COMPENSATION, pF

10

GAIN AND COMPENSATION

VDROP+@85°C

25

12

100

OUTPUT VOLTAGE, (VOUT) (p-p)

14

0

OUTPUT VOLTAGE SWING

30

NORMALIZED QUIESCENT CURRENT, IQ (%)

POWER DERATING

16

VDROP FROM VS, (V)

INTERNAL POWER DISSIPATION, P(W)

2. TYPICAL PERFORMANCE GRAPHS

100

POSITIVE

90

80

70

NEGATIVE

60

50

40

10

100

1K

10K

FREQUENCY, F (Hz)

PA340U

100K

5

�PA340

3.

APPLICATION INFORMATION

3.1

PHASE COMPENSATION

3.2

OTHER STABILITY CONCERNS

Please read Application Note 1 "General Operating Considerations" which covers stability, power supplies, heat

sinking, mounting, current limit, SOA interpretation, and specification interpretation. Visit www.apexanalog.com

for design tools that help automate tasks such as calculations for stability, internal power dissipation, current limit,

heat sink selection, Apex Microtechnology's complete Application Notes library, Technical Seminar Workbook and

Evaluation Kits.

Open loop gain and phase shift both increase with increasing temperature. The PHASE COMPENSATION typical

graph shows closed loop gain and phase compensation capacitor value relationships for four case temperatures.

The curves are based on achieving a phase margin of 50°. Calculate the highest case temperature for the application (maximum ambient temperature and highest internal power dissipation) before choosing the compensation.

Keep in mind that when working with small values of compensation, parasitics may play a large role in performance

of the finished circuit. The compensation capacitor must be rated for at least the total voltage applied to the amplifier

and should be a temperature stable type such as NPO or COG.

There are two important concepts about closed loop gain when choosing compensation. They stem from the fact

that while "gain" is the most commonly used term, β (the feedback factor) is really what counts when designing for

stability.

1. Gain must be calculated as a non-inverting circuit (equal input and feedback resistors can provide a signal gain

of -1, but for calculating offset errors, noise, and stability, this is a gain of 2).

2. Including a feedback capacitor changes the feedback factor or gain of the circuit. Consider RIN = 4.7k, Rf = 47k

for a gain of 11. Compensation of 4.7 to 6.8pF would be reasonable. Adding 33pF parallel to the 47K rolls off the

circuit at 103kHz, and at 2MHz has reduced gain from 11 to roughly 1.5 and the circuit is likely to oscillate.

As a general rule the DC summing junction impedance (parallel combination of the feedback resistor and all input

resistors) should be limited to 5K ohms or less. The amplifier input capacitance of about 6pF, plus capacitance of

connecting traces or wires and (if used) a socket will cause undesirable circuit performance and even oscillation if

these resistances are too high. In circuits requiring high resistances, measure or estimate the total sum point capacitance, multiply by RIN /Rf, and parallel Rf with this value. Capacitors included for this purpose are usually in the

single digit pF range. This technique results in equal feedback factor calculations for AC and DC cases. It does not

produce a roll off, but merely keeps β constant over a wide frequency range. Paragraph 6 of Application Note 19

details suitable stability tests for the finished circuit.

SAFE OPERATING AREA

The MOSFET output stage of the PA340 is not limited by second

breakdown considerations as in bipolar output stages. However

there are still three distinct limitations:

1. Voltage withstand capability of the transistors.

2. Current handling capability of the die metallization.

3. Temperature of the output MOSFETS.

SOA

1.0

OUTPUT CURRENT FROM +VS OR –VS, (A)

3.3

0.5

0.3

0.2

200mS

300mS

0.1

0.05

0.03

0.02

DC, TC = 25°C

These limitations can be seen in the SOA (see Safe Operating Area

DC, TC = 85°C

graphs). Note that each pulse capability line shows a constant power

0.01

level (unlike second breakdown limitations where power varies with

0.005

voltage stress). These lines are shown for a case temperature of

0.003

25°C. Pulse stress levels for other case temperatures can be calcu0.002

lated in the same manner as DC power levels at different tempera0.001

tures. The output stage is protected against transient flyback by the

10

20 30 50

100 200 300 500

1K

parasitic diodes of the output stage MOSFET structure. However,

SUPPLY TO OUTPUT DIFFERENTIAL, VS - VO, (V)

for protection against sustained high energy flyback external fastFIGURE 4. Safe Operating Area

recovery diodes must be used.

6

PA340U

�PA340

3.4 HEATSINKING

The PA340CC 7-pin DDPAK surface mountable package has a large exposed integrated copper heatslug to which

the monolithic amplifier is directly attached. The PA340CC requires surface mount techniques of heatsinking. A solder connection to a copper foil area as defined in Note 5 of Page 3 is recommended for circuit board layouts. This

may be adequate heatsinking but the large number of variables suggests temperature measurements to be made

on the top of the package. Do not allow the temperature to exceed 85°C.

3.5

OVERVOLTAGE PROTECTION

Although the PA340 can withstand differential input voltages up to 16V, in

some applications additional external protection may be needed. Differential inputs exceeding 16V will be clipped by the protection circuitry. However, if more than a few milliamps of current is available from the overload

source, the protection circuitry could be destroyed. For differential sources

above 16V, adding series resistance limiting input current to 1mA will prevent damage. Alternatively, 1N4148 signal diodes connected anti-parallel

across the input pins is usually sufficient. In more demanding applications

where bias current is important, diode connected JFETs such as 2N4416

will be required. See Q1 and Q2 in Figure 5. In either case the differential

input voltage will be clamped to 0.7V. This is sufficient overdrive to produce

the maximum power bandwidth.

+Vs

+Vs

-IN

Q1

+IN

Z1

OUT

Q2

-Vs

-Vs

Z2

In the case of inverting circuits where the +IN pin is grounded, the diodes

FIGURE 5. Overvoltage Protection

mentioned above will also afford protection from excessive common mode

voltage. In the case of non-inverting circuits, clamp diodes from each input to each supply will provide protection.

Note that these diodes will have substantial reverse bias voltage under normal operation and diode leakage will

produce errors.

Some applications will also need over-voltage protection devices connected to the power supply rails. Unidirectional

zener diode transient suppressors are recommended. The zeners clamp transients to voltages within the power

supply rating and also clamp power supply reversals to ground. Whether the zeners are used or not the system

power supply should be evaluated for transient performance including power-on overshoot and power-off polarity

reversals as well as line regulation. See Z1 and Z2 in Figure 5.

NEED TECHNICAL HELP? CONTACT APEX SUPPORT!

For all Apex Microtechnology product questions and inquiries, call toll free 800-546-2739 in North America.

For inquiries via email, please contact apex.support@apexanalog.com.

International customers can also request support by contacting their local Apex Microtechnology Sales Representative.

To find the one nearest to you, go to www.apexanalog.com

IMPORTANT NOTICE

Apex Microtechnology, Inc. has made every effort to insure the accuracy of the content contained in this document. However, the information is subject to change

without notice and is provided "AS IS" without warranty of any kind (expressed or implied). Apex Microtechnology reserves the right to make changes without further

notice to any specifications or products mentioned herein to improve reliability. This document is the property of Apex Microtechnology and by furnishing this information, Apex Microtechnology grants no license, expressed or implied under any patents, mask work rights, copyrights, trademarks, trade secrets or other intellectual

property rights. Apex Microtechnology owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Apex Microtechnology integrated circuits or other products of Apex Microtechnology. This consent does not

extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

APEX MICROTECHNOLOGY PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED TO BE SUITABLE FOR USE IN PRODUCTS USED FOR

LIFE SUPPORT, AUTOMOTIVE SAFETY, SECURITY DEVICES, OR OTHER CRITICAL APPLICATIONS. PRODUCTS IN SUCH APPLICATIONS ARE UNDERSTOOD TO BE FULLY AT THE CUSTOMER OR THE CUSTOMER’S RISK.

Apex Microtechnology, Apex and Apex Precision Power are trademarks of Apex Microtechnolgy, Inc. All other corporate names noted herein may be trademarks

of their respective holders.

Copyright © Apex Microtechnology, Inc. 2012

www.apexanalog.com

PA340U

(All Rights Reserved)

OCT 2013

7

PA340U REVC

�