Technical Reference Note

Embedded Power for

Business-Critical Continuity

SXX06E

Rev. 08.01.06

Page 1 of 2

Rev. 04.25.11

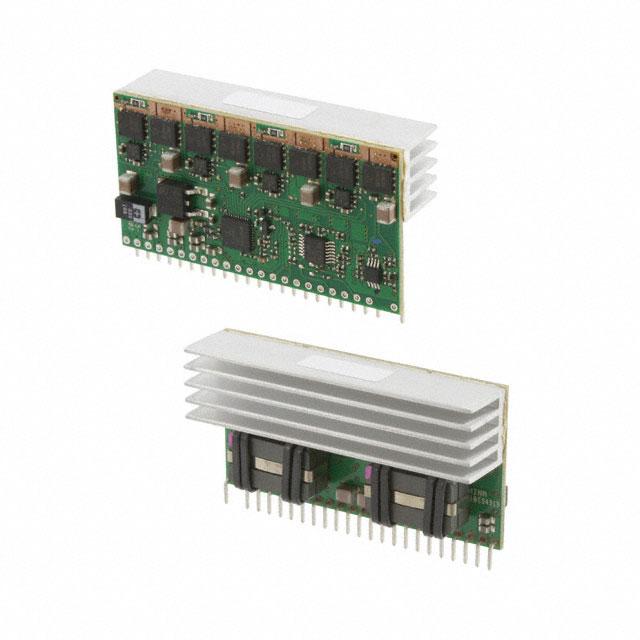

SIL/SMT80C2

1 of 20

SIL/SMT80C2

80 Amp

Total Power: 400 W

Input Voltage: 4.7 - 13.8 VDC

# of Outputs: Single

Special Features

• 80 A current rating

• Input voltage range:

4.7-13.8 V

• Output voltage: 0.8375-5.1 V

• Current sharing

• Industry leading value

• Cost optimized design

• Excellent transient response

• Output voltage adjustability

• Pathway for future upgrades

• Supports silicon voltage

migration

• Reduced design-in and

qualification time

• Over-temperature protection

• RoHS compliant

Safety

Designed to meet:

• UL, cUL 60950-1

• (EN60950)

Product Family:

Function:

Usage:

SIL/SMT80C2 Series

Single In-Line Power

LEDs, ASIC, Memory, FPGAs, Telecom and

Networking Equipment, Servers,

Industrial Equipment, POL Regulation

Definition:

The SIL/SMT80C2 is a new high density open frame non-isolated

converter series for space-sensitive applications. Each model has

a wide input voltage range (4.7 - 13.8 V) and offers a wide 0.8375

- 5.1 V output voltage range with a 80 A load. An external resistor

adjusts the output voltage from its pre-set value of 0.8375 V to

any value up to the maximum allowed value for that model. The

SIL/SMT80C2 offers remote ON/OFF and over-current protection

as standard.

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

2 of 20

General Description

Electrical Description

The SIL/SMT80C2 is implemented using a multi-phase synchronous buck topology. A block diagram of

the converter is shown in Figure 1.

The output is adjustable over a range of

0.8375-5.1 V by using a resistor from the trim pin

to -trim pin, or by driving the TRIM pin with a

voltage.

SIL80C2

Vin

Vout

Phase 1

Upper G/Drive

Tri

m

Ilimit

PWRGD

The converter can be shut down via the enable

pin. This input is run with positive logic that is

compatible with popular logic devices. Positive

logic implies that the converter is enabled if the

input is high (or floating), and disabled if it is low.

L out1

∩∩∩

V out

Lower G/Drive

Remote

ON/OFF

GND

Phase 2

L out2

Upper G/Drive

∩∩∩

Lower G/Drive

Phase 3

L out3

Upper G/Drive

∩∩∩

Lower G/Drive

Phase 4

Output is monitored for overcurrent and shortcircuit conditions. When the PWM controller

detects an overcurrent condition, it forces the

module into hiccup mode.

L out4

Upper G/Drive

∩∩∩

Lower G/Drive

Figure 1 - Electrical Block Diagram

A typical application is shown in Figure 2.

Wide Operating Temperature Range

The SIL/SMT80C2's ability to accommodate a wide

range of ambient temperatures is the result of its

extremely high power conversion efficiency and

resultant low power dissipation, combined with the

excellent thermal performance of the PCB substrate.

Maximum output power that the module can deliver

depends on a number of parameters, primarily:

Ishare

Enable On/Off

Power Good

4

Vout

15,16,18,

20,22,24

11

+Sense

SIL80C2

6

9

R uvlo

Vin

12-14

3,7,8,17,

19,21,23 1

C in

GND

5

R trim

10

C out

R

L

O

A

D

-Sense GND

•

•

•

•

Input voltage range

Output load current

Figure 2 - Standard Application Drawing

Air velocity (forced or natural convection)

Mounting orientation of target application PCB, i.e., vertical/horizontal mount, or mechanically tied

down (especially important in natural convection conditions).

• Target application PCB design, especially ground planes. These can be effective heatsinks for the converter.

The SIL/SMT80C2 module has an operating temperature range of 0 °C to 85 °C with suitable derating and/

or forced air cooling.

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

3 of 20

Features and Functions

Output Voltage Adjustment

The output voltage on all models is adjustable from 0.8375-5.1 V.

Undervoltage Lockout

The default undervoltage lockout is set at 4.7 V.

Current Limit and Short-Circuit Protection

The SIL/SMT80C2 model has a built-in non-latching current limit function and continuous short-circuit

protection. When an overcurrent condition occurs, the module goes into hiccup mode, where it attempts

to power up periodically to determine if the problem persists.

Note that none of the module specifications are guaranteed when the unit is operated in an overcurrent

condition.

Enable

The enable pin allows external circuitry to put the SIL/SMT80C2 converter into a low dissipation standby

mode. Positive logic enable pin is available as standard.

The unit is turned on if the enable pin is high (or floating). Pulling the pin low will disable the unit. To

guarantee turn-on, the enable voltage must be above 1.25 V. To disable, the enable voltage must be

pulled below 0.7 V.

Figures 3 and 4 show various circuits for driving the Enable feature. The Enable input can be driven

through a discrete device (i.e. a bipolar signal transistor) or directly from a logic gate output. The output

of the logic gate may be an open-collector (or open-drain) device.

SIL80C2

Vin

Vout

Enable

Tri

m

Ground

Figure 3 - Enable Input Drive Circuit for Non-Isolated Biopolar

5 V

SIL80C2

Vin

Vout

Enable

Tri

m

Ground

Figure 4 - Enable Input Drive Circuit for Logic Driver

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

4 of 20

Features and Functions

Power Good

The SIL/SMT80C2 modules have a power good indicator output. This output pin uses positive logic and is

open collector. Also, the power good output is able to sink 1 mA. The power good signal should not be

pulled any higher than 5.1 V.

When the output of the module is within ±10% of the nominal set point, the power good pin can be pulled

high.

Overtemperature Protection (OTP)

The SIL/SMT80C2 is equipped with non-latching overtemperature protection. A temperature sensor

monitors the temperature of the PCB near one the main FETs. If the temperature exceeds a threshold of

150 °C (typical) the converter will shut down, disabling the output. When the substrate temperature has

decreased by 10 °C the converter will automatically restart.

The converter might experience overtemperature conditions during a persistent overload on the output.

Overload conditions can be caused by external faults. OTP might also be entered due to a loss of control

of the environmental conditions (e.g. an increase in the converter’s ambient temperature due to a failing

fan).

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

5 of 20

Application

Output Voltage Adjustment

The output of the module can be adjusted, or trimmed, from 0.8375 V to 5.1 V. This is accomplished by

connecting an external resistor between the Trim pin and -Trim as shown in Figure 5 or with a voltage as

shown in Figure 6. Extremely high accuracy setpoints can be achieved with the use of a potentiometer as

shown in Figure 7.

SIL80C2

SIL80C2

Vout

Vout

Vin

Vin

Rtrim2

Tri

m

Tri

m

Enable

Enable

Rtrim

Vt

Rtrim1

-Trim

-Trim

Figure 5 - Output Voltage Trim

Figure 6 - Output Votlage Trim - with Voltage Source

Vout

Vin

Tri

m

Rtrim1

Enable

Rtrim2

Rpot1

-Trim

REQUIRED TRIM RESISTOR (OHM)

1000000

SIL80C2

100000

10000

1000

100

10

1

0

1

2

3

4

DESIRED OUTPUT VOLTAGE SETPOINT (V)

Figure 7 - Output Voltage - with Potentiometer

Figure 8 - Typical Trim Curves

5

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

6 of 20

Application (cont'd)

Output Voltage Adjustment (cont'd)

The trim equation for the basic configuration shown in Figure 5 is:

R

1.675

trim(kΩ) =

Vout - 0.8375

Where Vout is the desired output voltage, Rtrim is the resistance required between Trim and

-Trim.

The trim equation for the external voltage configuration shown Figure 6 is:

R

Rtrim1 (1.2 - 2Vt)

trim2(kΩ) =

Rtrim1 (Vout - 0.8375) - 1.675

Where Vout is the desired output voltage, Rtrim1 and Rtrim2 are the resistors in Figure 6

and Vt is the applied external voltage.

The trim equation for the potentiometer configurations shown in Figure 7 is:

0.8375

Vout =

(Rtrim2 + Rpot)Rtrim1

X (2Rtrim2 + 2Rpot + Rtrim1Rtrim2 + Rtrim1Rpot + 2Rtrim1)

Where Vout is the desired output voltage, Rtrim1 and Rtrim2 are the resistors in Figure 7

and Rpot is the resistance of the potentiometer.

Undervoltage Lockout

The SIL/SMT80C2 has built-in undervoltage lockout to ensure reliable output power. The lockout prevents

the unit from operating when the input voltage is too low. The UVLO for the SIL/SMT80C2 can be adjusted with the following equation:

The trim equation for the undervoltage lockout is:

124.8 + Vturn_on

Ruvlo (kΩ) =

10 Vturn_on - 42.06

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

7 of 20

Application (cont'd)

Remote Sense Compensation

The remote sense compensation feature minimizes the effect of resistance in the distribution system

and facilitates accurate voltage regulation at the load terminals or another selected point. The remote

sense lines will carry very little current and hence do not require a large cross-sectional area. However, if

the sense lines are routed on a PCB, they should be located close to a ground plane in order to minimize

any noise coupled onto the lines that might impair control loop stability. The module will compensate

for a maximum drop of 400 mV. Remember that when using remote sense compensation all the resistance, parasitic inductance and capacitance of the distribution system are incorporated into the feedback

loop of the power module. This can have an effect on the modules compensation capabilities, affecting

its stability and dynamic response.

Parallel Operation

Parallel operation of multiple converters is available since the SIL/SMT80C2 has a current sharing option.

The converter will share to within ±10% of full load. To current share, Pin 6 of each module should be

connected. Also, the remote sense lines should be connected at the same point. Figure 9 shows the

typical current sharing application.

SIL80C2

Vin 12-14

Vout

Tri

m

10 Sense+

-Trim

11 SenseIshare 6

GND

SIL80C2

Vin 12-14

Vout

Tri

m

10 Sense+

-Trim

11 SenseIshare 6

GND

Figure 9 - Parallel Application

R

L

O

A

D

Cload

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

8 of 20

Application (cont'd)

Output Capacitance

The SIL/SMT80C2 has output capacitors inside the converter. No output capacitance is required for

stable operation. When powering loads with large dynamic current requirements, improved voltage

regulation is obtained by inserting low ESR capacitors as close as possible to the load. Low ESR

ceramic capacitors will handle the short duration high frequency components of the dynamic current

requirement. In addition, higher values of electrolytic capacitors should be used to handle the midfrequency components.

It is equally important to use good design practices when configuring the dc distribution system. Low

resistance and low inductance PCB layout traces should be utilized, particularly in the high current output

section. Remember that the capacitance of the distribution system and the associated ESR are within the

feedback loop of the power capabilities, thus affecting the stability and dynamic response of the module.

Note that the maximum rated value of output capacitance varies between models and for each output

voltage setpoint. A stability vs. Load Capacitance calculator, (see your sales representative), details how

an external load capacitance influences the gain and phase margins of the SIL/SMT80C2.

SMT Reflow Guidelines

For a SnPb process: Pads should be above 183C (liquidus) for 90 seconds max (60-75 seconds typical)

with a peak temperature of 225C. For a leadfree SAC305 process: pads should be above 217C (liquidus)

for 90 seconds max (60-75 seconds typical) with a peak temperature of 250C.

Water Washing

Not recommended.

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

9 of 20

Parameter

Test Conditions

Min

Typ

Max

Units

Absolute Maximums

Input Voltage

0

13.8

V

Enable Voltage

0

5

V

Operating Ambient Temperature

0

85

˚C

-40

125

˚C

4.7

13.8

Vdc

Non-Operating Ambient Temperature

Input Specifications

Input Voltage

Input Current (No Load)

Vin(min) - Vin(max), enabled

500

mA

Converter disabled

10

mA

Input Capacitance (Internal)

Internal to converter

176

uF

Input Capacitance (External)

Recommend customer added capacitance

47

uF

Input Current (quiescent)

Output Specifications

0.8375

5.0

V

Output Setpoint Accuracy

-1.0

+1.0

%

Output Regulation (Line)

-0.2

+0.2

%

Output Regulation (Load)

-0.5

+0.5

%

0

80

A

130

140

A

Ouput Voltage

Output Current (continuous)

Output Current (short circuit)

0.9, 2.5, 5.1 Vout

Output Capacitance (Internal)

Output Capacitance (External)

500

uF

12 Vin, 0.9 Vout (Startup capacitance)

0

63,000

uF

12 Vin, 2.5 Vout (Startup capacitance)

0

30,000

uF

12 Vin, 5 Vout (Startup capacitance)

0

11,000

uF

20

mV

12 Vin, 2.5 Vout, 0 uF Cout

20

mV

12 Vin, 5 Vout, 0 uF Cout

20

mV

5.1 Vin, 0.9 Vout, 80 Aout

82.2

%

12 Vin, 2.5 Vout, 80 Aout

89.1

%

12 Vin, 5 Vout, 80 Aout

93.3

%

Dynamic Load Response (Peak Deviation)

12 Vin, 0.9 Vout, 50-75% load at 10 A/us

95

mV

Dynamic Load Response (Setting Time)

12 Vin, 0.9 Vout, 50-75% load at 10 A/us

30

us

Dynamic Load Response (Peak Deviation)

12 Vin, 2.5 Vout, 50-75% load at 10 A/us

150

mV

Dynamic Load Response (Setting Time)

12 Vin, 2.5 Vout, 50-75% load at 10 A/us

30

us

Dynamic Load Response (Peak Deviation)

12 Vin, 5 Vout, 50-75% load at 10 A/us

150

mV

Dynamic Load Response (Setting Time)

12 Vin, 5 Vout, 50-75% load at 10 A/us

30

us

Output Ripple/Noise (Peak/Peak)

Efficiency

5 Vin, 0.9 Vout, 0 uF Cout

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

10 of 20

Parameter

Test Conditions

Min

Typ

Max

Units

2.7

3

ms

3

12

ms

1.8

2

ms

0.7

V

Turn On Specifications

Turn On Delay (with Vin)

Turn On Delay (with Enable)

Output Rise TIme

10% - 90%

Enable Specifications

Signal Low (Unit Off)

0

Signal Low Current

12 Vin

Signal High (Unit On)

12 Vin

1.2

mA

3.4

V

1.0

µA

108

A

Input Under Voltage (Rising)

4.7

V

Input Under Voltage (Falling)

4.0

V

3.7

MHrs

45.36

g

500

kHz

Signal High Current

0

Protection Specifications

Over Current Protection

Hiccup Mode

General Specifications

MTBF

Telcorida SR-332

Weight

Switching Frequency

Per Phase

Coplanarity

TBD

Material Ratings

Flammability

UL94V-0

Material Type

FR4 PCB

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

11 of 20

0.9 V Setpoint

80

80

70

70

60

60

200 LFM

300 LFM

400 LFM

500 LFM

50

Load Current (A)

200 LFM

300 LFM

400 LFM

500 LFM

600 LFM

40

40

30

30

20

20

10

10

0

0

30

40

50

60

70

80

30

Ambient (C)

40

50

60

70

80

Ambient (C)

Figure 10: Thermal Derating Curve 5.5 Vin

Figure 11: Thermal Derating Curve 12 Vin

Thermal derating - 600LFM minimum airflow

90

80

70

60

Load (A)

Load Current (A)

600 LFM

50

50

4.7Vin,

0.84Vout

13.8Vin,

5.1Vout

13.8Vin,

5.0Vout

40

30

20

10

0

25

30

35

40

45

50

55

60

65

70

75

80

85

Ambient temp (ºC)

Figure 11A: Thermal derating curve 4.7Vin and 13.8Vin

Figure 13: Control On/Off

(Channel 1: Output Voltage, Channel 3: Enable)

Figure 12: Effiiciency 0.9 V

Figure 14: Typical Ripple Output

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

12 of 20

0.9 V Setpoint

Figure 15: Transient Response 75% - 100%

(Channel 3: Current Step at 10 A/div,

Channel 4: Output Voltage Deviation)

Figure 16: Short Circuit Characteristic

(Channel 1: Output Current at 50 A/div,

Channel 4: Output Voltage)

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

13 of 20

2.5 V Setpoint

80

80

70

70

60

60

50

200 LFM

300 LFM

400 LFM

500 LFM

600 LFM

40

Load Current (A)

Load Current (A)

50

30

30

20

20

10

10

0

200 LFM

300 LFM

400 LFM

500 LFM

600 LFM

40

0

30

40

50

60

70

Ambient (C)

80

30

40

50

60

70

80

Ambient (C)

Figure 17: Thermal Derating Curve 5.1 Vin

Figure18: Thermal Derating Curve 12 Vin

Figure 19: Efficiency 2.5 V

Figure 20: Control On/Off

(Channel 1: Output Voltage, Channel 3: Enable)

Figure 21: Typical Ripple Output

Figure 22: Transient Response 75% - 100%

(Channel 3: Current Step at 10 A/div,

Channel 4: Output Voltage Deviation)

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

14 of 20

2.5 V Setpoint

Figure 23: Short Circuit Characteristic

(Channel 1: Output Current at 50 A/div,

Channel 4: Output Voltage)

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Rev. 04.25.11

SIL/SMT80C2

15 of 20

5.0 V Setpoint

80

70

60

Load Current (A)

50

200 LFM

300 LFM

400 LFM

500 LFM

600 LFM

40

30

20

10

0

30

40

50

60

70

80

Ambient (C)

Figure 24: Thermal Derating Curve 12 Vin

Figure 26: Control On/Off

(Channel 1: Output Voltage, Channel 3: Enable)

Figure 28: Transient Response 75% - 100%

(Channel 3: Current Step at 10 A/div,

Channel 4: Output Voltage Deviation)

Figure 25: Efficiency 5.0 V

Figure 27: Typical Output Ripple - ADD TEST CONDITIONS

Figure 29: Short Circuit Characteristic

(Channel 1: Output Current at 50 A/div,

Channel 4: Output Voltage)

�7

8

6

4

5

Technical Reference Note

3

Embedded Power for

Business-Critical Continuity

PART NUMBER

REV

7091259-0000

A

D

Rev. 04.25.11

SIL/SMT80C2

16 of 20

APPLY LIQUI-BOND BETWEEN HEATSINK

AND PCB. ADJUST APPLICATION STENCIL TO

KEEP EXCESS LIQUI-BOND TO A MINIMUM

Mechanical Drawings

SIL80C-00SADJ-VJ

C

.690 17.53 MAX

2.400 60.96

.040 1.02

REF .110 2.79

2.320 58.93

REF .062 1.57

1.250 31.75

B

1.160 29.46

Pin 1

.140 3.56 TYP

REF .025±.002 0.64±0.05

SQ PINS

.100 2.54 TYP

21 PLACES

.050 1.27

.050 1.27 TYP

(23X)

2.300 58.42

.050 1.27 TYP

MATERIAL

A

-

UNLESS OTHERWISE

DIMENSIONS ARE IN

TOLERANCES:

2 PLACE

3 PLACE

.015

.03

HOLE TOLERANCE:

APPROVALS

FINISH

Footprint

NOTE:

1. 9300161-0000 PACKAGING AND MATERIAL HANDLING PROCEDURE.

2. COSMETIC AND WORKMANSHIP PER 9300152-0000.

3. LABELS SHOWN FOR PLACEMENT REFERENCE ONLY.

4

5

FOOTPRINT

8

6

7

-

THIRD

ANGLE

PROJECTION

DETACHED LIST

3

.730 18.54

Ø 0.45 ±.003

THROUGH HOLE

[1.14

±0.08]

.040"

DIA

(23X)

23x

.242 6.15

.192 4.88

.130 3.30

PCB OUTLINE

2.370 60.20

2.420 61.47

2.440 61.98

2.170 55.12

2.070 52.58

1.970 50.04

1.870 47.50

1.770 44.96

1.670 42.42

1.570 39.88

1.470 37.34

1.370 34.80

1.270 32.26

1.170 29.72

1.070 27.18

.970 24.64

.870 22.10

.770 19.56

.670 17.02

.570 14.48

.370 9.40

.470 11.94

.270 6.86

0 0

.020 0.51

.070 1.78

.170 4.32

ENGINEER

M. HENNIES

7001259-J000

KEEP OUT AREA

0 0

DRAWN

M. HENNIES

�D

Technical Reference Note

C

Embedded Power for

APPLY LIQUI-BOND BETWEEN

HEATSINK

Business-Critical

Continuity

AND PCB. ADJUST APPLICATION STENCIL TO

KEEP EXCESS LIQUI-BOND TO A MINIMUM

Rev. 04.25.11

SIL/SMT80C2

17 of 20

Mechanical Drawings

SIL/SMT80C2-00SADJ-HJ/H3J

.710 MAX 18.03 MAX

2.400 60.96

.040 1.02

B

REF .062 1.57

2.320 58.93

REF .110 2.79

1.250 31.75

2X 1.160 29.46

.050 1.27 TYP

(23X)

REF

3.05

L - .120

See Table

.050 1.27

Pin 1

.100 2.54 TYP

21 PLACES

.125 3.18 TYP

2.300 58.42

A

Model

L Dimension

SIL80C2-00SADJ

REF .120 [3.05]

SIL80C2-00SADJ-H3J

8

7

Footprint8

4

5

6

3

FOOTPRINT

D

-

REF .138 [3.50]

2

NOTE:

1. 9300161-0000 PACKAGING AND MATERIAL HANDLING PROCEDURE.

2. COSMETIC AND WORKMANSHIP PER 9300152-0000.

3. LABELS SHOWN FOR PLACEMENT REFERENCE ONLY.

4

5

6

7

MATERIAL

FINISH

1

7001259-J100

DETACHED LIST

3

KEEP OUT AREA

D

1.290 32.77

1.270 32.26

1.230 31.24

Ø 0.45 ±.003

THROUGH HOLE

[1.14

±0.08]

.040"

DIA

(25X)

25X

C

C

PCB OUTLINE

B

57.66

60.20

61.47

61.98

2.270

2.370

2.420

2.440

2.170 55.12

2.070 52.58

1.970 50.04

1.870 47.50

1.770 44.96

1.670 42.42

1.570 39.88

1.470 37.34

1.370 34.80

1.270 32.26

1.170 29.72

.970 24.64

.870 22.10

.770 19.56

.670 17.02

.570 14.48

.370 9.40

.470 11.94

1.070 27.18

A

.270 6.86

.070 1.78

.020 0.51

0 0

0 0

.020 0.51

.070 1.78

B

A

DWG. NO.

TITLE:

7091259-0100

REV.

A

�7

8

6

4

5

1

2

3

REVISION RECORD

Technical Reference Note

Embedded Power for

7091259-0300

A

RELEASE TO PRODUCTION

Business-Critical Continuity

PART NUMBER

REV

DESCRIPTION

DRAFT

DATE

M. HENNIES

03/06/07

D

Rev. 04.25.11

SIL/SMT80C2

18 of 20

APPLY LIQUI-BOND BETWEEN HEATSINK

AND PCB. ADJUST APPLICATION STENCIL TO

KEEP EXCESS LIQUI-BOND TO A MINIMUM

Mechanical Drawings

SMT80C-00SADJ-VJ

C

REF .062 1.57

2.400 60.96

DETAIL A

.677 17.20

.040 1.02

REF .110 2.79

.040 1.02 TYP

(2X)

B

1.315 33.40

.065 1.65

.280 7.11

.050 1.27 TYP

(23X)

.100 2.54 TYP

21 PLACES

.050 1.27

NOTE: OUTSIDE SUPPORT IS HIDDEN

TO SHOW PIN DIMENSIONS.

A

Pin 1

2.300 58.42

.610 15.49 REF

2.480 62.99

A

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES:

2 PLACE

3 PLACE

ANGLES

1

.015

.03

MATERIAL

-

HOLE TOLERANCE:

.005

DATE

APPROVALS

FINISH

22JUN06

ENGINEER

M. HENNIES

7001259-J300

8

D

8

7 7

4

55

66

3

SIZE

22JUN06

2

3

A

UPPERCUT 80

SCALE: 3 = 2

2

REV.

7091259-0300

PROJECT USED ON:

B

THIRD

ANGLE

PROJECTION

DETACHED LIST

4

TLA DRAWING

DWG. NO.

DRAWN

M. HENNIES

-

ARTESYN TECHNOLOGIES

EDEN PRAIRIE, MN 55433

PH. 952-941-1100

TITLE:

SHEET 1 OF 2

CAD FILE:

1

1

FOOTPRINT

Footprint

D

VERT SMT STAND OUTLINE

SMT PAD

.300X.040" (23X)

KEEP OUT AREA

.752 19.10

C

C

.670 17.02

.445 11.30

.440 11.18

PCB OUTLINE

5.51

3.94

3.56

3.43

1.02

B

2.620 66.55

61.47

61.98

63.75

65.02

2.420

2.440

2.510

2.560

2.240 56.90

2.140 54.36

2.040 51.82

1.940 49.28

1.840 46.74

1.740 44.20

1.640 41.66

1.540 39.12

1.440 36.58

1.340 34.04

1.240 31.50

1.140 28.96

1.040 26.42

.940 23.88

.840 21.34

.740 18.80

.640 16.26

.540 13.72

.440 11.18

.060

.110

.140

.200

.240

.340

1.52

2.79

3.56

5.08

6.10

8.64

0 0

0 0

B

.217

.155

.140

.135

.040

A

A

DWG. NO.

SIZE

B

TITLE:

7091259-0300

FOOTPRINT

REV.

A

�D

Technical Reference Note

Embedded Power for

Business-Critical

APPLY LIQUI-BOND BETWEEN

HEATSINK Continuity

AND PCB. ADJUST APPLICATION STENCIL TO

KEEP EXCESS LIQUI-BOND TO A MINIMUM

Rev. 04.25.11

SIL/SMT80C2

19 of 20

Mechanical Drawings (cont'd)

C

SMT80C2-00SADJ-J

2.400 60.96

.040 1.02

B

REF .062 1.57

2.320 58.93

REF .110 2.79

1.250 31.75

.040 1.02 TYP

(2X)

2X 1.160 29.46

.050 1.27 TYP

(23X)

.050 1.27

.125 3.18

Pin 1

.100 2.54 TYP

21 PLACES

NOTE:

1. 93

2. CO

3. LA

.710[18.03] MAX

2.300 58.42

A

MATERIAL

-

FINISH

8

7

Footprint

4

5

6

3

2

1

7001259-J200

DETACHED LIST

8

FOOTPRINT

D

4

5

6

7

3

D

KEEP OUT AREA

1.290 32.77

1.270 32.26

1.195 30.35

PCB OUTLINE

C

C

SMT PAD

.045X.070" (25X)

B

B

2.348 59.63

2.420 61.47

2.440 61.98

2.248 57.09

2.148 54.55

2.048 52.01

1.948 49.47

1.848 46.93

1.748 44.39

1.648 41.85

1.548 39.31

1.448 36.77

1.348 34.23

1.248 31.69

1.148 29.15

.948 24.07

1.048 26.61

.848 21.53

.748 18.99

.648 16.45

.548 13.91

.448 11.37

.348 8.83

.248 6.29

A

0 0

.020 0.51

.048 1.21

.040 1.02

.020 0.51

0 0

A

DWG. NO.

SIZE

B

TITLE:

7091259-0200

REV.

A

FOOTPRINT

SHEET 2 OF 2

�Technical Reference Note

Embedded Power for

Business-Critical Continuity

Americas

Pin Chart

Pin Assignments

Pin Assignments

Single Output

1

Trim

2

No Pin

3

Ground

4

Power Good

5

(-) Trim

6

Ishare

7

Ground

8

Ground

9

Enable

10

Rem Sense (-)

11

Rem Sense (+)

12

Vin

13

Vin

Single Output

14

Vin

15

Vout

16

Vout

17

Ground

18

Vout

19

Ground

20

Vout

21

Ground

22

Vout

23

Ground

24

Vout

25

*Mech Support

26

*Mech Support

5810 Van Allen Way

Carlsbad, CA 92008

USA

Telephone: +1 760 930 4600

Facsimile: +1 760 930 0698

Rev. 04.25.11

SIL/SMT80C2

20 of 20

Europe (UK)

Waterfront Business Park

Merry Hill, Dudley

West Midlands, DY5 1LX

United Kingdom

Telephone: +44 (0) 1384 842 211

Facsimile: +44 (0) 1384 843 355

Asia (HK)

14/F, Lu Plaza

2 Wing Yip Street

Kwun Tong, Kowloon

Hong Kong

Telephone: +852 2176 3333

Facsimile: +852 2176 3888

*Horizontal version only

For global contact, visit:

www.PowerConversion.com

techsupport.embeddedpower

@emerson.com

Ordering Information

Product Family

SIL

Product Family

SIL = Single In Line

Product Family

SMT

Product Family

SMT = Surface

Mount

Rated Output

Current

80

Rated

Output

Current

80 = 80 A

Rated Output

Current

80

Rated

Output

Current

80 = 80 A

Performance

Generation

C

Performance

C = Cost

Optimized

Performance

2

-

Generation

2 = Increased

Current

Density

Generation

C

Performance

C = Cost

Optimized

Input Voltage

2

Generation

2 = Increased

Current

Density

00

SADJ

Input Voltage

00 = 4.7-13.8 V

Output Voltage

Single

Adjustable

Output

Input Voltage

-

Output Voltage

Mounting

Option

-

Output Voltage

00

SADJ

Input Voltage

00 = 4.7-13.8 V

Output Voltage

Single

Adjustable

Output

RoHs Compliance(9)

X

X

Mounting

Option

Blank = Horizontal

V = Vertical

Custom

Options

Blank = 3.05 mm pin

3 = 3.50 mm pin

RoHS Compliance

J = Pb-free

(RoHS 6/6 compliant)

Custom

Options

RoHs Compliance(9)

Mounting

Option

-

Custom

Options

J

X

X

J

Mounting

Option

Blank = Horizontal

V = Vertical

Custom

Options

Blank = 3.05 mm pin

3 = 3.50 mm pin

RoHS Compliance

J = Pb-free

(RoHS 6/6 compliant)

While every precaution has been taken to ensure

accuracy and completeness in this literature, Emerson

Network Power assumes no responsibility, and disclaims

all liability for damages resulting from use of this

information or for any errors or omissions.

Emerson Network Power.

The global leader in enabling

business-critical continuity.

AC Power

Connectivity

DC Power

Embedded Computing

Embedded Power

Monitoring

Outside Plant

Power Switching & Controls

Precision Cooling

Racks & Integrated Cabinets

Services

Surge Protection

This is a preliminary datasheet. Emerson

Network Power reserves the right to make

changes to the information contained herein

without notice and assumes no liability as a

result of its use or application.

EmersonNetworkPower.com

Emerson Network Power and the Emerson

Network Power logo are trademarks and service marks of Emerson Electric Co. ©2011

Emerson Electric Co.

�