AEDR-8300-1Wx Encoders

Reflective Surface Mount Optical Encoder

Data Sheet

Description

Features

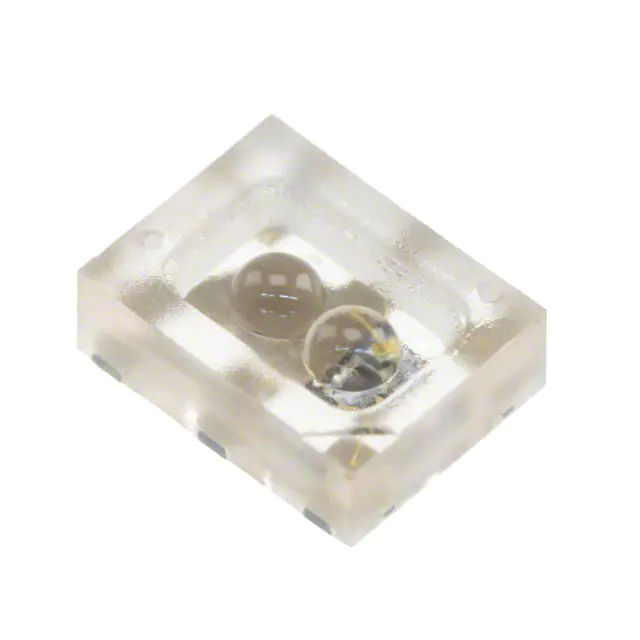

The AEDR-8300-1Wx is the smallest optical encoder

employing reflective technology for motion control

purposes. The encoder houses an LED light source and a

photo-detecting circuitry in a single package.

• Reflective technology

The AEDR-8300-1Wx offers two-channel quadrature

digital outputs. Being TTL compatible, the outputs of

the AEDR-8300-1Wx can be interfaced directly with most

of the signal processing circuitries. Hence the encoder

provides great design-in flexibility and easy integration

into existing systems. The AEDR-8300-1Wx could yields

encoding resolution at 212 lines per inch (LPI) which is

8.35 lines per mm.

The AEDR-8300-1Wx provides motion sensing at a competitive cost, making it ideal for high volume applications.

Its small size and surface mount package make it ideal for

many consumer products, particularly where space and

weigh are primary design constraint.

• Surface mount leadless package

• Two channel quadrature outputs for direction sensing

• TTL compatible output

• Single 3.3 V to 5 V supply

• -20° C to 85° C absolute operating temperature

• Encoding resolution: 212 (lines/inch) or 8.35 (lines/mm)

Applications

Ideal for high volume applications:

• Printers

• Copiers

• Card readers

• Scanners

• Cameras

• Motor Solutions

• Automated Wheel-chair

• Vending Machines

• Low Servo Systems

• ATM Machines

• Textile Machines

• Industrial Sewing Machines

• Consumer Product Applications

�Theory of Operation

Definitions

The AEDR-8300-1Wx combines an emitter and a detector

in a single surface mount leadless package. When used

with a codewheel or linear codestrip, the encoder translates rotary or linear motion into digital outputs. As seen

in the block diagram, the AEDR-8300-1Wx consists of

three major components: a light emitting diode (LED)

light source, a detector IC consisting photodiodes and

lens to focus light beam from the emitter as well as light

falling on the detector.

State Width (S): The number of electrical degrees between

Block Diagram of AEDR-8300-1Wx

VLED

R

GND

State Width Error (∆S): The deviation of state width, in electrical degree, from its ideal value of 90°e.

Phase (φ): The number of electrical degrees between the

center of high state of Channel A and the center of high

state of Channel B. Nominally 90°e.

Phase Error (∆φ): The deviation of phase, in electrical

degree, from its ideal value of 90°e.

CODEWHEEL

or

CODESTRIP

VCC

Pulse Width (P): The duration of high state of the output,

in electrical degree, within one cycle. Nominally 180°e or

half a cycle.

Pulse Width Error (∆P): The deviation of pulse width, in elec-

CH A

CH B

a transition in Channel A and the neighboring transition

in Channel B. There are 4 states per cycle, each nominally

90°e.

SIGNAL

PROCESSING

CIRCUITRY

GND

trical degree, from its ideal value of 180°e.

Count (N): The number of window and bar pair per revolu-

tion (CPR) of codewheel. For linear codestrip, defined as

the number of window and bar pair per unit length (lines

per inch [LPI] or lines per mm [LPmm]).

One Cycle (C): 360 electrical degrees (°e). Equivalent to one

window and bar pair.

The operation of the encoder is based on the principle of

optics where the detector photodiodes sense the absence

and presence of light. In this case, the rotary/linear motion

of an object being monitored is converted to equivalent light pattern via the use of codewheel/codestrip. As

shown in the above diagram, the reflective area (window)

of the codewheel (or codestrip) reflects light back to the

photodetector IC, whereas no light is reflected by the

non-reflective area (bar). An alternating light and dark

patterns corresponding to the window and bar fall on

the photodiodes as the codewheel rotates. The moving

light pattern is exploited by the detector circuitry to

produce digital outputs representing the rotation of the

codewheel. When the codewheel is coupled to a motor,

the encoder outputs are then a direct representation of

the motor rotation. The same concept applies to the use

of a codestrip to detect linear motion.

One Shaft Rotation: 360 mechanical degrees. Also equivalent to N counts (codewheel only).

Line Density: The number of window and bar pair per unit

length, expressed in either lines per inch (LPI) or lines per

mm (LPmm).

Optical radius (Rop): The distance between the codewheel

center and the centerline between the two domes of the

encoder.

Gap (G): The distance from surface of the encoder to the

surface of codewheel or codestrip.

Radial and Tangential Misalignment Error (ER, ET): For rotary

motion, mechanical displacement in the radial and tangential directions relative to the nominal alignment.

Angular Misalignment Error (EA): Angular displacement of

the encoder relative to the tangential line.

Specular Reflectance (Rf ): The amount of incident light

reflected by a surface. Quantified in terms of the percentage of incident light. A spectrometer can be used to

measure specular reflectance of a surface (contact factory

for more information).

2

�Output waveform

C

ALL FOUR STATES (S1 to S4)

ARE MAINTAINED

P

AMPLITUDE

CH. A

S1

S2

S3

S4

φ

CH. B

CODEWHEEL ROTATION OR LINEAR MOVEMENT

RADIAL (E R )

ANGULAR (EA )

TANGENTIAL (E T )

AEDR-8300-1Wx

AEDR-8300-1Wx

SHAFT

SHAFT

CODEWHEEL

CODEWHEEL

Absolute Maximum Ratings

Storage Temperature, TS

-40° C to 85° C

Operating Temperature, TA

-20° C to 85° C

Supply Voltage, VCC

-0.5 V to 7 V

Output Voltage, VO

-0.5 V to VCC

Output Current per Channel, IOUT

-1.0 mA to 8 mA

ESD

Human Body Model JESD22-A114-A Class 2

Machine Model JESD22-A115-A Class B

Notes:

1. Exposure to extreme light intensity (such as from flashbulbs or spotlights) may cause permanent damage

to the device.

2. CAUTION: It is advised that normal static precautions should be taken when handling the encoder in order

to avoid damage and/or degradation induced by ESD.

3. Proper operation of the encoder cannot be guaranteed if the maximum ratings are exceeded.

3

�Recommended Operating Conditions

Parameter

Symbol

Minimum

Typical

Maximum

Units

Temperature

TA

-20

25

85

°C

Supply Voltage

VCC

3.0

3.3 / 5.0

5.5

V

Ripple < 100 mVp-p

LED Current

ILED

13

15

18

mA

See Note 1

Load Capacitance

CL

100

pF

2.7 kW Pull-Up

Count Frequency2

F

60

kHz

See Note 3

Radial Misalignment

ER

±0.38 (±0.015)

mm (in.)

Tangential Misalignment

ET

±0.38 (±0.015)

mm (in.)

Angular Misalignment

EA

0

±1.5

deg.

Codewheel/strip tilt

CT

0

1

deg.

Codewheel/strip Gap

G

2.0 (0.08)

2.5 (0.10)

mm (in.)

0.3

1.0 (0.04)

Notes

Notes:

1. LED Current Limiting Resistor:

For Vcc = 5.0 V, recommended series resistor = 220 Ω (±10 %)

For Vcc = 3.3 V, recommended series resistor = 110 Ω (± 10 %)

2. Count frequency = velocity (rpm) x N / 60.

3. Data collected based on Avago production characterization.

Encoding Characteristics

Encoding characteristics over the recommended operating condition and mounting conditions.

Parameter

Symbol

Typical

Maximum

Unit

Pulse Width Error (Ch.A, Ch.B)

DP

16

75

°e

Phase Error

Df

10

60

°e

Note:

1. Typical values represent the encoder performance at typical mounting alignment, whereas the maximum values represent the encoder

performance across the range of recommended mounting tolerance.

Electrical Characteristics

Characteristics over recommended operating conditions at 25° C.

Parameter

Symbol

Detector Supply Current

ICC

Minimum

Typical

Maximum

Unit

Notes

4.8

6.0

mA

Vcc = 5 V

3.9

4.1

High Level Output Voltage

VOH

Low Level Output Voltage

VOL

Rise Time

tr

500

Fall Time

tf

100

ns

4

2.4

Vcc = 3.3 V

0.4

V

IOH = -0.2 mA

V

IOL = 8.0 mA

ns

CL = 25 pF

RL = 2.7 kW

�Recommended Codewheel and Codestrip Characteristics

Wb

Ww

Lw

Rop

Lw

W w Wb

Parameter

Symbol

Minimum

Maximum

Window/bar Ratio

Ww/Wb

0.9

1.1

Window/bar Length

LW

1.80

(0.071)

2.31

(0.091)

Specular Reflectance

Rf

60

85

Reflective area. See note 1.

–

10

Non reflective area

8.35

(212)

Line Density

LPmm

(LPI)

8.35

(212)

Optical radius

Rop

11

Unit

Notes

mm

(inches)

lines/mm

(lines/inch)

mm

Recommended value

Notes:

1. Measurements from TMA µScan meter. Contact factory for more information.

2. Contact factory for more information on compatibility of codewheel/strip.

LED Current Limiting Resistor

Moisture Sensitive Level

A resistor to limit current to the LED is required. The

recommended value is 220 Ω (± 10%) and the resistor

should be placed in series between the 5 V supply and pin

3 of the device (VLED). This will result in an LED current of

approximately 15 mA. If 3.3 V voltage supply is used, the

corresponded resistance would be 110 Ω (± 10%).

The AEDR-8300-1Wx is specified to moisture sensitive

level (MSL) 3.

5

�Outline Drawing

Chamfer

PIN 1

PIN 6

Detector

PIN 2

PIN 6

PIN 1

PIN 5

PIN 2

PIN 4

PIN 3

PIN 5

Emitter

PIN 3

PIN 4

Top View

Bottom View

Side View

Notes:

1. All dimensions in millimeter.

2. Tolerance X.XX ± 0.15mm.

3. For ease of reference, a chamfer is incorporated on the detector side (pin 6), as shown in the above diagram.

Encoder Pin Configuration

Encoder option

Pin 1

Pin2

Pin3

Pin4

Pin5

Pin6

AEDR-8300-1Wx

Ch B

Gnd

VLED

Gnd

Ch A

Vcc

Encoder Orientation

The AEDR-8300-1Wx is designed such that both the LED and detector IC should be placed parallel to the window/bar

orientation, as shown. As such, the encoder is tolerant against radial play of ± 0.38 mm. The emitter side (pins 3 and 4)

should be placed closer to the rotating shaft.

6

�Mounting Consideration

Codewheel/codestrip

Gap

Rop

11.00 mm (0.433 IN) < Rop < ∝

Direction of Codewheel Rotation

With the emitter side (pins 3 and 4) of the encoder placed closer to the codewheel centre, Channel A leads Channel B

when the codewheel rotates anti-clockwise and vice versa.

ANTI-CLOCKWISE

CLOCKWISE

EMITTER

EMITTER

CH. A LEADS

CH. B LEADS

CH. B

CH. A

Viewed from Top

Recommended Land Pattern for AEDR-8300-1Wx

0.72

0.94

1.96

1.08

7

Mounting Center

Note: The shaded areas are the

leads for soldering.

Note: The shaded areas are

not encoder pin-outs. They

are electrically grounded and

physically exposed. PCB layout

with tracks running across these

areas should be avoided.

�Recommended Lead-free Reflow Soldering Temperature Profile

10 - 20 SEC.

300

255 C

250 C

250

TEMPERATURE (C)

217 C

200

120 SEC. MAX.

60 - 150 SEC.

150

125 C

100

50

0

40 C

1

22

45

66

87

108

129

150

171

192

213

235

256

278

299

320

341

363

384

TIME (SEC.)

HEAT UP

SOLDER PASTE DRY

SOLDER REFLOW

COOL DOWN

Preheat Temperature 40° C to 125° C = 120 sec max

Temperature maintain above 217° C = 60 – 150 sec

Peak Temperature = 255 ± 5° C

Time above 250° C = 10 – 20 sec

Note: Due to treatment of high temperature, AEDR-8300-1Wx compound may turn to yellow after IR reflow.

Resolution Indicator

Ordering Information

Since the encoder is too small to imprint resolution

marking on its package, color-coding the package is

employed to differentiate resolutions.

AEDR-8300 Option 1W

Resolution (LPI)

212

Color

Light Amber

Shipping Units

0 – 1000 pcs

1 – 500 pcs

2 – 100 pcs

Note: Encoders are packed in tape of quantity 1000 pcs, 500 pcs or 100 pcs.

For product information and a complete list of distributors, please go to our web site:

www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2013 Avago Technologies. All rights reserved. Obsoletes AV01-0178EN

AV02-3572EN - September 9, 2013

�

很抱歉,暂时无法提供与“AEDR-8300-1W2”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 100+71.63528100+8.56194

- 200+67.01448200+8.00966

- 300+64.43880300+7.70181

- 500+61.32177500+7.32926

- 700+59.34318700+7.09278

- 1000+58.748631000+7.02171

- 国内价格 香港价格

- 1+110.987021+13.26531

- 5+95.272085+11.38704

- 10+89.2206010+10.66376

- 25+81.7824925+9.77475

- 50+76.5499950+9.14936