AEDR-871x

3-Channel High Resolution Reflective Incremental Encoder

(Digital Outputs)

Data Sheet

Description

Features

The AEDR-871x encoder is the smallest 3-channel optical encoder with digital outputs that employs Reflective

Technology for motion control.

• World's smallest 3-channel reflective technology

encoder

The encoder is designed to operate over the -20 °C to 85

°C temperature range and so is suitable for both commercial and industrial applications.

• Digital Output option - 3 channels TTL compatible; 2

channel quadrature (AB) digital outputs for direction

sensing and a third channel, Index digital output. Builtin interpolator for 4×, 8× and 16× interpolation.

AEDR-871x offers high resolution (318 LPI) with built-in

interpolation, enabling great flexibility and versatility in

resolution range.

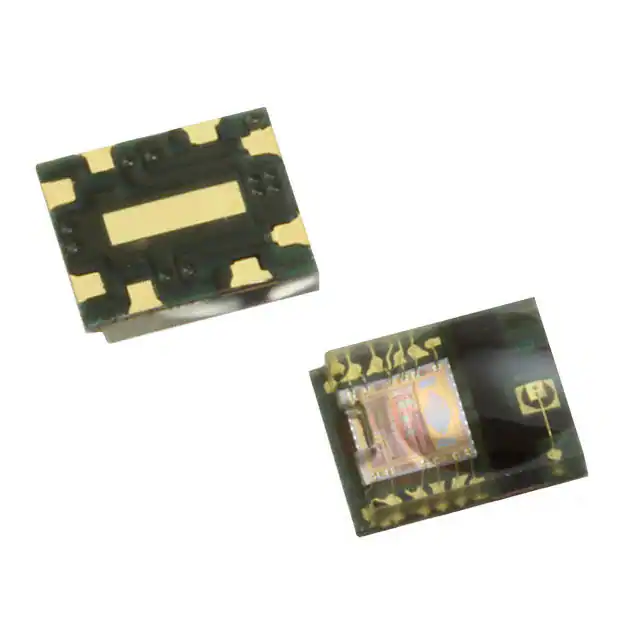

• Surface mount leadless package 3.95 mm (L) × 3.4 mm

(W) × 0.9562 mm (H)

The compact dimensions of 3.95 mm (L) × 3.4 mm (W) ×

0.9562 mm (H) coupled with the low operating 3.3 V option allows it to be used in a wide range of miniature commercial applications and portable devices in which space

and power consumption is a primary concern.

• Built-in LED current regulation, removing need for

external biasing resistor

AEDR-871x encoder offers two-channel (AB) quadrature

digital outputs and a third channel, index digital outputs.

Being TTL compatible, the outputs of the AEDR-871x encoder can be interfaced directly with most of the signal

processing circuitries. Therefore, the encoder provides

great design-in flexibility and easy integration into existing systems.

• Operating voltage of 3.3 V or 5 V supply

• -20 °C to 85 °C absolute operating temperature

• Encoding resolution: 318 (lines/inch, LPI)

Applications

Ideal for high volume applications:

• Miniature motors

• Printers and copiers

• Card readers

• Miniature camera module

• Portable measurement devices

• Healthcare, lab diagnostic equipment and portable

devices

• Optometric equipment

• Consumer and industrial product applications

�Output Waveform

Top View

P

C

360 e Deg

Amplitude

A

S1

B

S2

S3

φ

S4

Anti-clockwise

Po

Index of 90 e Deg option

I

I

I

Po

Encoder

CH A leads

CH B

Index of 180 e Deg option

Po

Codewheel

Index of 360 e Deg option

Codewheel rotation movement (Anti-clockwise)

Note: Drawing not to scale

QUADRATURE SIGNALS A, B and I

Test Parameter Definitions

Parameter

Symbol

Description

Count

N

The number of bar and window pairs, or counts per revolution (CPR), of the codewheel.

One Cycle

C

360 electrical degrees (°e), 1 bar and window pair.

One Shaft Rotation

360 mechanical degrees, N cycles.

Cycle Error

ΔC

An indication of cycle uniformity. The difference between an observed shaft angle that gives

rise to one electrical cycle, and the nominal angular increment of 1/N of a revolution.

Pulse Width (Duty)

P

The number of electrical degrees that an output is high during 1 cycle. This value is nominally

180°e or 1/2 cycle.

Pulse Width (Duty) Error ΔP

The deviation, in electrical degrees, of the pulse width from its ideal value of 180°e.

State

S

The number of electrical degrees between a transition in the output of channel A and the

neighboring transition in the output of channel B. There are 4 states per cycle, each nominally

90°e.

State Error

ΔS

The deviation, in electrical degrees, of each state width from its ideal value of 90°e.

Phase

φ

The number of electrical degrees between the center of the high state of channel A and the

center of the high state of channel B. This value is nominally 90°e for quadrature output.

Phase Error

Δφ

The deviation of the phase from its ideal value of 90°e.

Optical Radius

ROP

The distance from the codewheel’s center of rotation to the optical center (O.C.) of the encoder module.

Index Pulse Width

PO

The number of electrical degrees that an index is high during one full shaft rotation.

2

�Absolute Maximum Ratings

Parameter

Value

Storage Temperature, TS

-20 °C to 85 °C

Operating Temperature, TA

-20 °C to 85 °C

Supply Voltage, VCC

7V

Notes:

1. Exposure to extreme light intensity (such as from flashbulbs or spotlights) may cause permanent damage to the device.

2. CAUTION: To avoid damage or degradation induced by ESD, take normal static precautions when handling the encoder.

3. Proper operation of the encoder cannot be guaranteed if the maximum ratings are exceeded.

Recommended Operating Conditions

Parameter

Symbol

Min.

Typ.

Max.

Units

Operating Temperature

TA

-20

25

85

°C

Supply Voltage

VCC

3.0

3.3

3.6

V

4.5

5

5.5

Notes

Ripple < 100 mVp-p

Current

ICC

-

27

60

mA

Output Frequency

F

-

-

240

kHz

4× Interpolation

F

-

-

480

kHz

8× Interpolation

F

-

-

960

kHz

16× Interpolation

Radial Misalignment

ER

-

-

± 0.2

mm

Tangential Misalignment

ET

-

-

± 0.2

mm

Codewheel Gap

G

0.5

0.75

1.0

mm

Parameter

Symbol

Min.

Max.

Unit

Notes

Window/Bar Ratio

WW/WB

0.9

1.1

Window/Bar Length

LW

1.80

(0.071)

-

Specular Reflectance

Rf

60

-

Reflective area [1]

-

10

Non-reflective area

Recommended Codewheel Characteristics

Line Density

Notes:

1. Measurements from TMA µScan meter

2. LPmm = CPR/[2π.Rop(mm)]

3

mm

(inches)

LPmm

12.52

lines/mm

LPI

318

lines/inch

�Encoder Pinouts

VDDD

VDDA

VDDA

CH A

AGND

CH A

AGND

DGND

DGND

CH B

SEL 1

CH I

VDDD

SEL 1

CH B

SEL 2

SEL 2

Pin Configurations (Top View)

CH I

Pin Configurations (Bottom View)

Digital Option - Encoder's Built-in Interpolation

Pin (Interpolation)

SEL 1

SEL 2

Example of CPR

Interpolation Factor Max. output frequency @ ROP = 11 mm

H

H

4×

240 kHz

3460

L

L

8×

480 kHz

6920

H

L

16×

960 kHz

13840

H = HIGH Logic Level

L = LOW Logic Level

This interpolation factor may be used in conjunction with the following formula to cater to the need for various rotation

speeds (RPM) and counts.

RPM = (Count Frequency × 60 )/CPR

The CPR (@1× interpolation) is based on the following formula, which is directly dependent on ROP:

CPR = LPI × 2π x ROP (inch) or CPR = LPmm × 2π × ROP (mm)

Note: LPmm (lines per mm) = LPI/25.4

Recommended Setup For the Power Supply Pins

Connect both VDDD, VDDA and their corresponding grounds (AGND and DGND) appropriately as follows. It is recommended that you use 22 µF and 0.1 µF for bypass capacitor on VDDD and VDDA and place them in parallel as close as

possible to the power and the ground pins.

VCC

0.1 µF

22 µF

9

DGND

4

6

1

VDDA

CH A

AGND

CH B

SEL1X

CH I

5

SEL2X

4

SEL2X

CH B

7

8

VDDD

CH I

CH A

22 µF

Notes:

1. DGND (Pin 9) is the center pad of the package.

2. For SEL1X and SEL2X configuration, see the Digital Option - Encoder's

Built-in Interpolation table.

2

3

0.1 µF

SEL1X

�Encoding Characteristics (Code wheel of ROP @ 11 mm)

Dynamic Performance

Parameter

Symbol

Interpolation Factor

Typical

Unit

4×

8×

16×

Cycle Error

ΔC

±17

±28

±35

°e

Pulse Width (Duty) Error

ΔP

±14

±18

±22

°e

Phase Error

Δ∅

±5

±8

±9

°e

State Error

ΔS

±8

±10

±13

°e

Index Pulse Width (Gated 90°)

Po

90

90

90

°e

Index Pulse Width (Gated 180°)

Po

180

180

180

°e

Index Pulse Width (Gated 360°)

Po

360

360

360

°e

Notes:

1. Typical values represent the average values of encoder performance in our factory-based setup conditions.

2. The optimal performance of encoder depends on the motor/system setup condition of the individual customer.

Electrical Characteristics

Characteristics over recommended operating conditions at 25 °C.

Parameter

Symbol

Min.

Typ.

Max.

Unit

Notes

High Level Output Voltage

VOH

2.4

-

-

V

IOH = -4mA

Low Level Output Voltage

VOL

-

-

0.4

V

IOH = +4mA

Output current per channel, lout

lo

-

-

4

mA

Rise Time

tr

-

< 100

-

ns

Fall Time

tf

-

< 100

-

ns

5

CL ≤ 50 pF

�Codewheel Design Guideline

The index bar (I-) track is opaque and the width is 3 × WB°. The Index (I) track is reflective and the width is 3 × WW°. The

dimension LW should be at least 1.8 mm. (Note: If LW shorter than 1.8 mm is required, please consult factory) There are 6

pairs of incremental track (1 pair= 1 WB° and 1 WW°) between opaque and reflective index tracks.

Note: Encoder is placed on top on this codewheel in this view

WW°

WB°

Opaque

Surface

6×(WW°+WB°)

Reflective

Surface

3×WB°

(Index Bar Track)

LW

3×WW°

(Index Track)

Codewheel design example

The following demonstrates a codewheel design for Rop of 11 mm @ 865 CPR for a 2-channel and a 3-channel encoder.

Reflective

Surface

0.4162°

0.2081°

Opaque

Surface

Pitch= 360/CPR=360/865=0.4162°

WW° and WB° = 360/(2×CPR) = 360/(2×865)=0.2081°

865CPR

Codewheel pattern for a 2-channel encoder

6

�1.8

0.4162°

0.2081°

0.2081°

0.6243°

Opaque

Surface

WW° and WB° = 360/(2×CPR) = 360/(2×865)=0.2081°

Index Width = 3×WW° = 0.6243°

Index Bar Width = 3×WB° = 0.6243°

2.4971°

Reflective

Surface

0.6243°

Codewheel pattern for a 3-channel encoder

Note: The overall physical track count is reduced but not the counts per revolution (CPR). The CPR remains the same because the count during this index transition is generated by an intelligent signal processing circuit.

Package Outline Drawing

0.9562

Note: Unless otherwise specified,

1. All dimensions in mm

2. Tolerance x.xx ± 0.15mm

TOP VIEW

3.40±0.20

0.50

Center of Lens

8×0.350

3.95±0.20

2×0.90

2.15

2×0.90

2.62

8×0.450

2×0.95

FRONT VIEW

7

2×0.95

BACK VIEW

�Recommended Land Pattern

3.40

0.5

2×3.00

Package

outline

2×1.8

2.15

8 ×0.35

3.95

8 ×0.80

2×1.9

All dimensions in mm

Tolerance x.xx ± 0.05mm

2×2.45

Encoder Placement Orientation and Positioning

The AEDR-871x is designed such that both the emitter and the detector ICs are placed parallel to the window/bar orientation, with the encoder mounted on top of the codewheel (see below right). When properly oriented, the detector side

will be closer to the center of codewheel than the emitter. More importantly, the center of the lens of the encoder unit

must be aligned with the codewheel (ROP), or more specifically tangential to the center point of LW (1/2 of the length of

window).

Codewheel

Codewheel

Codewheel

Emitter

(LED)

Placement orientation of the encoder’s

emitter and detector on the codewheel

2.62

Detector

Center of Codewheel

Center of the lens should be aligned with the ROP of the codewheel

8

�Direction of Movement

With the detector side of the encoder placed closer to the codewheel (see picture on the previous page), Channel A

leads Channel B when the codewheel rotates anti-clockwise and vice versa (with the encoder mounted on top of the codewheel). The optimal gap setting recommended is between 0.5 to 1.0 mm (see the side view below).

Encoder height = 0.9562 mm

Gap = 0.5 to 1.0 mm

Codewheel

Side View

Codewheel

CH A leads

CH B

Codewheel

CH B leads

CH A

Top

View

Emitter

Anti-clockwise

Emitter

Clockwise

Note: Drawing not to scale

Moisture Sensitivity Level

The AEDR-871x is specified to Moisture Sensitive Level (MSL) 3. Precaution is required to handle this moisture-sensitiveproduct to ensure the reliability of the product.

Storage before use

• An unopened Moisture Barrier Bag (MBB) can be stored at < 40 °C/90% RH for 12 months.

• It is not recommended that the MBB is opened before assembly.

Control after the MBB is opened

• Encoder that will be subjected to reflow solder must be mounted within 168 hours of factory condition 10% when read at 23 ± 5 °C

• The encoder floor life exceeded 168 hours.

• Recommended baking condition: 60 ± 5 °C for 20 hours (tape and reel), 125 ± 5 °C for 5 hours (loose unit)

9

�Recommended Lead-free Reflow Soldering Temperature Profile

250

Max. 235 °C

Liquidus point 217 °C

200

150

60 sec Max.

100

Preheat Zone

50

0

0

25

50

60

75

100

125

150

175

200

Average ramp up rate

= 3 °C/sec

Average ramp down rate

= 6 °C/sec

Preheat temperature

= 150 °C to 200 °C

Preheat time

= 60 to 100 sec

Time maintain above 217 °C

= 40 to 60 sec

Peak Temperature

= 235 °C

Time within 5 °C of peak temperature

= 20 to 30 sec

225

Notes:

1. Reflow with peak temperature > 235 °C may damage the component.

2. Due to treatment of high temperature, this clear compound may turn yellow

after IR reflow.

3. Profile shown here is the actual readings from the thermocouple (attached

to AEDR-871x as shown to the right) on the reflow board PCB.

Tape and Reel Information

10

250

275

300

324

354

Thermocouple

Mold

Compound

IC

Reflow PCB

LED

�Order Information

AEDR – 87xx – x 0 x

Output Signal

Index Gating

Packaging

Resolution LPI

Shipping Units

1 – Digital

2 – Analog

0 – Gated 90ºe

1 – Gated 180ºe

2 – Gated 360ºe

3* – Tag 360ºe

1 – Tape and Reel

0 – 318

0 – 1000 pcs

2 – 100 pcs

Notes:

Digital 3.3 V and 5 V operating mode

Analog: 5 V operating mode only

Index Gating: 3* applicable only for analog output

DISCLAIMER: Avago’s products and software are not specifically designed, manufactured or authorized for

sale as parts, components or assemblies for the planning, construction, maintenenace or direct operation of a

nuclear facility or for use in medical devices or applications. Customer is solely responsible, and waives all rights to

make claims against Avago or its suppliers, for all loss, damage, expense or liability in connection with such use.

For product information and a complete list of distributors, please go to our web site:

www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2014 Avago Technologies. All rights reserved.

AV02-4517EN - June 6, 2014

�