Data Sheet

ASMT-UWB1-Nxxxx

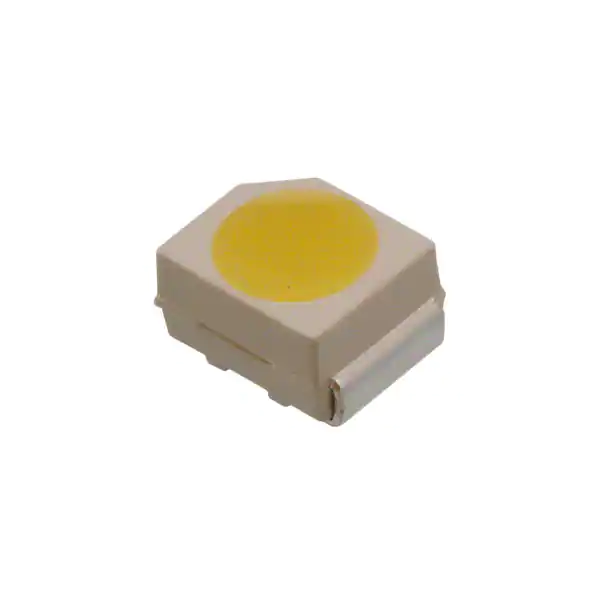

OneWhite Surface-Mount PLCC-2 LED Indicator

Description

Features

This family of SMT LEDs is packaged in the industry

standard PLCC-2 package. These SMT LEDs have high

reliability performance and are designed to work under a

wide range of environmental conditions. This high-reliability

feature makes them ideally suited to be used as signs in

various application conditions.

To facilitate easy pick and place assembly, the LEDs are

packed in EIA-compliant tape and reel. Every reel will be

shipped in single intensity and color bin.

These LEDs are compatible with reflow soldering process.

Applications

The wide viewing angle at 120° makes these LEDs ideally

suited for panel, push button, office equipment, industrial

equipment, and home appliances. The flat top emitting

surface makes it easy for these LEDs to mate with light

pipes. With the built-in reflector pushing up the intensity of

the light output, these LEDs are also suitable to be used as

LED pixels in electronic signs.

High reliability package with silicone encapsulation

Compatible with reflow soldering process

High optical efficiency with 100 lm/W

Available in 8-mm carrier tape with reel diameter

180 mm

JEDEC MSL 3 product

ESD threshold of 1000V (HBM model) per JEDEC

Home appliances

Amusement machine backlighting

Industrial lighting

Light strips

General signage backlighting

Sign and display

CAUTION! LEDs are ESD sensitive. Please observe appropriate precautions during handling and processing.

Broadcom

AV02-2936EN

October 7, 2019

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Package Drawing

2.8 ± 0.2

1.9 ± 0.2

2.2 ± 0.2

0.1 TYP.

3.2 ± 0.2

0.8 ± 0.1

3.5 ± 0.2

0.8 ± 0.3

0.5 ± 0.1

CATHODE MARKING

NOTE:

1. All dimensions in millimeters.

2. Terminal finish = Ag plating.

Device Selection Guide

Luminous Intensity (mcd)a, b

Color

Part Number

CCT (K)

Min.

Typ.

Max.

Test Current

(mA)

Chip

White

ASMT-UWB1-NX302

4500 ~ 8000

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX312

2700 ~ 4000

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3A2

8000

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3B2

6500

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3C2

5700

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3D2

5000

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3E2

4500

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3F2

4000

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3G2

3500

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3H2

3000

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX3J2

2700

1800

2300

3550

20

InGaN

White

ASMT-UWB1-NX7B2

6500

2240

—

4500

20

InGaN

White

ASMT-UWB1-NX7D2

5000

2240

—

4500

20

InGaN

White

ASMT-UWB1-NX7C2

5700

2240

—

4500

20

InGaN

White

ASMT-UWB1-NX7A2

8000

2400

—

4500

20

InGaN

a. The luminous intensity is measured at the mechanical axis of the lamp package. The actual peak of the spatial radiation pattern may not be

aligned with this axis.

b. Tolerance ±12%

Broadcom

AV02-2936EN

2

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Part Numbering System

ASMT – U X1 B1 – N X2 X3 X4 X5

Packaging Option

Color Bin Selection

Intensity Bin Selection

LED Chip Color

Absolute Maximum Ratings (TA = 25°C)

Parameters

Rating

DC Forward Current

30 mA

a

100 mA

b

Peak Forward Current

Power Dissipation

108 mW

Junction Temperature

110°C

Operating Temperature

–40°C to +100°C

Storage Temperature

–40°C to +100°C

a. Derate linearly as shown in derating curve.

b. Duty factor = 10%, frequency = 1 kHz.

Optical Characteristics (TA = 25°C)

Color

Part Number

Dice

Technology

White

ASMT-UWB1

InGaN

Typ. Chromaticity

Coordinatesa

Viewing Angle

2½b (Degrees)

Luminous

Efficiency e

(lm/W)

Total Flux /

Luminous

Intensity

V (lm) / IV (cd)

CRI

x

y

Typ.

Typ.

Typ.

Min.

0.33

0.34

120

100

2.8

70

a. The chromaticity coordinates are derived from the CIE 1931Chromaticity diagram and represents the perceived color of the device.

b. ½ is the off-axis angle where the luminous intensity is ½ the peak intensity.

Electrical Characteristics (TA = 25°C)

Forward Voltage

VF (Volts) @ IF = 20 mA

Reverse Voltage VRa

@ 10 µA

Color

Part Number

Min.

Max.

Min.

Thermal Resistance

RJ-P (°C/W)

White

ASMT-UWB1

2.4

3.2

5

150

a. Reverse Voltage indicates product final test condition. Long-term reverse bias is not recommended.

Broadcom

AV02-2936EN

3

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Figure 2: Relative Intensity vs. Forward Current

35

1.6

30

1.4

RELATIVE LUMINOUS INTENSITY

(NORMALIZED AT 20 mA)

FORWARD CURRENT (mA)

Figure 1: Forward Current vs. Forward Voltage

25

20

15

10

5

1.2

1

0.8

0.6

0.4

0.2

0

0

1

2

FORWARD VOLTAGE (V)

3

Figure 3: Chromaticity Shift vs. Current

0.003

0

4

0

5

10

15

20

25

DC FORWARD CURRENT (mA)

30

35

Figure 4: Radiation Pattern

1

30mA

0.001

NORMALIZED INTENSITY

0.002

20mA

0

Y

-0.001

-0.002

10mA

-0.003

-0.004

-0.005

0.75

0.5

0.25

5mA

-0.006

-0.0014

-0.001

-0.0006

-0.0002 0 0.0002

0

0.0006

-90

X

Figure 5: Maximum Forward Current vs. Ambient

Temperature. Derated based on Tjmax 110°C, Rthja 600°C/W

-60

-30

0

30

ANGULAR DISPLACEMENT (q)

60

90

Figure 6: Recommended Pb-Free Reflow Soldering Profile

30

10 - 30 SEC.

25

TEMPERATURE

MAXIMUM FORWARD CURRENT (mA)

35

20

15

10

255 - 260° C

3°C/SEC. MAX.

6°C/SEC. MAX.

150° C

3°C/SEC. MAX.

5

0

217° C

200° C

100 SEC. MAX.

60 - 120 SEC.

0

Broadcom

20

40

60

80

AMBIENT TEMPERATURE (°C)

100

120

TIME

(Acc. to J-STD-020C)

AV02-2936EN

4

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Figure 7: Recommended Soldering Pad Pattern

2.60

1.50

4.50

SOLDER RESIST

Figure 8: Tape Leader and Trailer Dimensions

END

THERE SHALL BE A

MINIMUM OF 160 mm

OF EMPTY COMPONENT

POCKETS SEALED WITH

COVER TAPE.

START

MOUNTED

WITH

COMPONENTS

THERE SHALL BE A

MINIMUM OF 400 mm

OF EMPTY COMPONENT

POCKETS SEALED WITH

COVER TAPE.

USER FEED

DIRECTION

Broadcom

AV02-2936EN

5

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Figure 9: Tape Dimensions (Unit: mm)

2.00 ±0.05

Cathode Marking

4.00 ±0.1

1.55 ±0.05

1.75 ±0.1

3.5 ±0.1

8.00 ±0.1

3.85 ±0.1

4.00 ±0.1

2.15 ±0.1

3.10 ±0.1

Figure 10: Reel Dimensions (Unit: mm)

2 +0.5

–0

Ø 20.5 ± 0.3

62.5

180

+0

–2.5

Ø 13 ± 0.2

+1.50

8.4 –0.00 (MEASURED AT OUTER EDGE)

14.4 (MAX. MEASURED AT HUB)

LABEL AREA (111 mm x 57 mm)

WITH DEPRESSION (0.25 mm)

Broadcom

7.9 (MIN.)

10.9 (MAX.)

AV02-2936EN

6

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Figure 11: Reel Orientation

USER FEED DIRECTION

CATHODE SIDE

PRINTED LABEL

Intensity Bin Select (X2 X3)

Color Bin Selection (X4)

Individual reel will contain parts from one half bin only.

Individual reel will contain parts from one full bin only.

X2

X4

Min IV Bin

X3

Bin

Color Bin ID

A

1A, 1B, 1C, 1D

B

2A, 2B, 2C, 2D

C

3A, 3B, 3C, 3D

0

Full Distribution

D

4A, 4B, 4C, 4D

3

3 half bins starting from X21

E

5A, 5B, 5C, 5D

4

4 half bins starting from X21

F

6A, 6B, 6C, 6D

5

5 half bins starting from X21

G

7A, 7B, 7C, 7D

H

8A, 8B, 8C, 8D

J

9A, 9B, 9C, 9D

K

1A, 1B, 1C, 1D, 2A, 2B, 2C, 2D,

L

2A, 2B, 2C, 2D, 3A, 3B, 3C, 3D

M

3A, 3B, 3C, 3D, 4A, 4B, 4C, 4D

N

4A, 4B, 4C, 4D, 5A, 5B, 5C, 5D

Q

6A, 6B, 6C, 6D, 7A, 7B, 7C, 7D

Max. (mcd)

R

7A, 7B, 7C, 7D, 8A, 8B, 8C, 8D

8A, 8B, 8C, 8D, 9A, 9B, 9C, 9D

7

3 half bins starting from X22

8

4 half bins starting from X22

9

5 half bins starting from X22

Intensity Bin Limits

Bin ID

Min. (mcd)

X1

1800

2240

S

X2

2240

2850

0

Y1

2850

3550

1A, 1B, 1C, 1D, 2A, 2B, 2C, 2D, 3A, 3B, 3C, 3D, 4A, 4B,

4C, 4D, 5A, 5B, 5C, 5D

Y2

3550

4500

1

Z1

4500

5600

6A, 6B, 6C, 6D, 7A, 7B, 7C, 7D, 8A, 8B, 8C, 8D, 9A, 9B,

9C, 9D

Z2

5600

7150

AA

2000

2500

Tolerance of each bin limit = ±12%

Broadcom

AV02-2936EN

7

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Color Bin ID Limits

Color

Bin ID

Chromaticity Coordinates Limits

1A

x

0.2950

0.2920

0.2984

0.3009

y

0.2970

0.3060

0.3133

0.3042

x

0.2920

0.2895

0.2962

0.2984

y

0.3060

0.3135

0.3220

0.3133

x

0.2984

0.2962

0.3028

0.3048

y

0.3133

0.3220

0.3304

0.3207

x

0.2984

0.3048

0.3068

0.3009

y

0.3133

0.3207

0.3113

0.3042

x

0.3048

0.3130

0.3144

0.3068

y

0.3207

0.3290

0.3186

0.3113

x

0.3028

0.3115

0.3130

0.3048

y

0.3304

0.3391

0.3290

0.3207

x

0.3115

0.3205

0.3213

0.3130

y

0.3391

0.3481

0.3373

0.3290

x

0.3130

0.3213

0.3221

0.3144

y

0.3290

0.3373

0.3261

0.3186

x

0.3215

0.3290

0.3290

0.3222

y

0.3350

0.3417

0.3300

0.3243

x

0.3207

0.3290

0.3290

0.3215

y

0.3462

0.3538

0.3417

0.3350

x

0.3290

0.3376

0.3371

0.3290

y

0.3538

0.3616

0.3490

0.3417

x

0.3290

0.3371

0.3366

0.3290

y

0.3417

0.3490

0.3369

0.3300

x

0.3371

0.3451

0.3440

0.3366

y

0.3490

0.3554

0.3427

0.3369

x

0.3376

0.3463

0.3451

0.3371

y

0.3616

0.3687

0.3554

0.3490

x

0.3463

0.3551

0.3533

0.3451

y

0.3687

0.3760

0.3620

0.3554

x

0.3451

0.3533

0.3515

0.3440

y

0.3554

0.3620

0.3487

0.3427

5A

x

0.3530

0.3615

0.3590

0.3512

y

0.3597

0.3659

0.3521

0.3465

5B

x

0.3548

0.3641

0.3615

0.3530

y

0.3736

0.3804

0.3659

0.3597

5C

x

0.3641

0.3736

0.3702

0.3615

y

0.3804

0.3874

0.3722

0.3659

5D

x

0.3615

0.3702

0.3670

0.3590

y

0.3659

0.3722

0.3578

0.3521

6A

x

0.3670

0.3702

0.3825

0.3783

y

0.3578

0.3722

0.3798

0.3646

1B

1C

1D

2A

2B

2C

2D

3A

3B

3C

3D

4A

4B

4C

4D

Broadcom

Color

Bin ID

Chromaticity Coordinates Limits

6B

x

0.3702

0.3736

0.3869

0.3825

y

0.3722

0.3874

0.3958

0.3798

x

0.3825

0.3869

0.4006

0.3950

y

0.3798

0.3958

0.4044

0.3875

x

0.3783

0.3825

0.3950

0.3898

y

0.3646

0.3798

0.3875

0.3716

x

0.3889

0.3941

0.4080

0.4017

y

0.3690

0.3848

0.3916

0.3751

x

0.3941

0.3996

0.4146

0.4080

y

0.3848

0.4015

0.4089

0.3916

x

0.4080

0.4146

0.4299

0.4221

y

0.3916

0.4089

0.4165

0.3984

x

0.4017

0.4080

0.4221

0.4147

y

0.3751

0.3916

0.3984

0.3814

x

0.4147

0.4221

0.4342

0.4259

y

0.3814

0.3984

0.4028

0.3853

x

0.4221

0.4299

0.4430

0.4342

y

0.3984

0.4165

0.4212

0.4028

x

0.4342

0.4430

0.4562

0.4465

y

0.4028

0.4212

0.4260

0.4071

x

0.4259

0.4342

0.4465

0.4373

y

0.3853

0.4028

0.4071

0.3893

x

0.4373

0.4465

0.4582

0.4483

y

0.3893

0.4071

0.4099

0.3919

x

0.4465

0.4562

0.4687

0.4582

y

0.4071

0.4260

0.4289

0.4099

x

0.4582

0.4687

0.4813

0.4700

y

0.4099

0.4289

0.4319

0.4126

x

0.4483

0.4582

0.4700

0.4593

y

0.3919

0.4099

0.4126

0.3944

6C

6D

7A

7B

7C

7D

8A

8B

8C

8D

9A

9B

9C

9D

Tolerance of each bin limit = ±0.01

AV02-2936EN

8

�ASMT-UWB1-Nxxxx Data Sheet

OneWhite Surface-Mount PLCC-2 LED Indicator

Figure 12: Color Bins

0.4400

3000K

0.4200

8B

4000K

0.4000

4500K

0.3800

5700K

Y 0.3600

0.3200

0.3000

0.2800

0.2800

6500K

3B

8OOOK

2C

2B 2D

1C 2A

1B 1D

1A

0.3000

6B

5C

5B

5D

4B 4C

5A

4D

3C

4A

3D

7A

6D

8C

7C

7B

6C

5000K

0.3400

2700K

3500K

8A

7D

8D

9A

9B

9C

9D

6A

3A

0.3200

0.3400

0.3600

0.3800

0.4000

0.4200

0.4400

0.4600

0.4800

0.5000

X

Packaging Option (X5)

Forward Voltage Bin

Option

Test Current

Package Type Reel Size

Bin ID

Min.

Max

2

20 mA

Top Mount

F03

2.4

2.6

F04

2.6

2.8

F05

2.8

3.0

F06

3.0

3.2

7 Inch

Tolerance of each bin limit = ±0.1V.

Broadcom

AV02-2936EN

9

�ASMT-UWB1-Nxxxx Data Sheet

Precautionary Notes

Handling Precautions

The encapsulation material of the LED is made of silicone

for better product reliability. Compared to epoxy

encapsulant that is hard and brittle, silicone is softer and

flexible. Observe special handling precautions during

assembly of silicone encapsulated LED products. Failure to

comply might lead to damage and premature failure of the

LED. Refer to Application Note AN5288, Silicone

Encapsulation for LED: Advantages and Handling

Precautions, for more information.

Do not poke sharp objects into the silicone encapsulant.

Sharp objects, such as tweezers or syringes, might

apply excessive force or even pierce through the

silicone and induce failures to the LED die or wire bond.

Do not touch the silicone encapsulant. Uncontrolled

force acting on the silicone encapsulant might result in

excessive stress on the wire bond. Hold the LED only

by the body.

Do not stack assembled PCBs together. Use an

appropriate rack to hold the PCBs.

The surface of the silicone material attracts dust and

dirt easier than epoxy due to its surface tackiness. To

remove foreign particles on the surface of silicone, use

a cotton bud with isopropyl alcohol (IPA). During

cleaning, rub the surface gently without putting much

pressure on the silicone. Utrasonic cleaning is not

recommended.

For automated pick and place, Broadcom has tested

the following nozzle size to work well with this LED.

However, due to the possibility of variations in other

parameters, such as pick and place, machine maker/

model and other settings of the machine, verify that the

selected nozzle will not cause damage to the LED.

OneWhite Surface-Mount PLCC-2 LED Indicator

Handling Moisture-Sensitive Devices

This product has a Moisture Sensitive Level 3 rating per

JEDEC J-STD-020. Refer to Broadcom Application Note

AN5305, Handling of Moisture Sensitive Surface Mount

Devices, for additional details and a review of proper

handling procedures.

Before use

– An unopened moisture barrier bag (MBB) can be

stored at < 40°C/90% RH for 12 months. If the actual

shelf life has exceeded 12 months and the humidity

indicator card (HIC) indicates that baking is not

required, it is safe to reflow the LEDs per the original

MSL rating.

– Do not open the MBB prior to assembly (for

example, for IQC).

Control after opening the MBB:

– Read the HIC immediately upon opening the MBB.

– Keep the LEDs at < 30°C / 60% RH at all times and

all high temperature-related processes, including

soldering, curing, or rework, must be completed

within 168 hours.

Control for unfinished reel:

Store unused LEDs in a sealed MBB with desiccant or

desiccator at