Data Sheet

HDSM-281B/283B

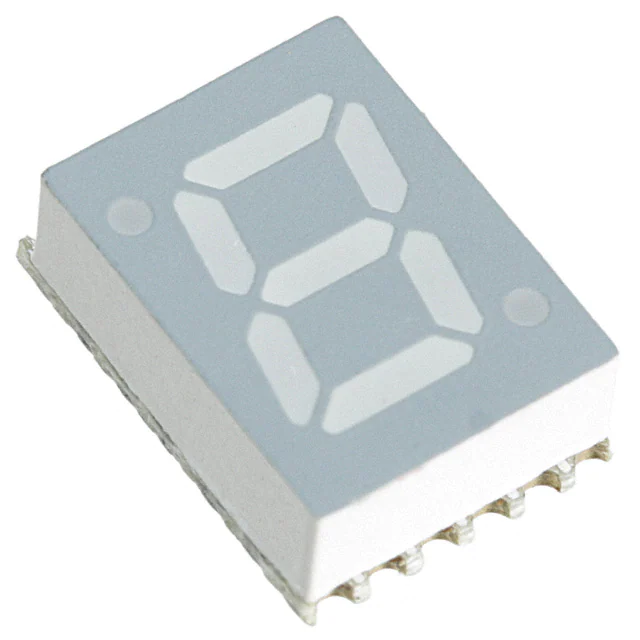

0.28-in. (7.0-mm) Single-Digit Surface-Mount

LED Display

Description

Features

This Broadcom® 0.28-in. (7.0-mm) height single-digit

display uses InGaN blue LED chips. This device comes with

a gray top surface and white segments.

Ordering Information

Blue

Description

HDSM-281B

Common Anode, Upper and Lower Decimal

HDSM-283B

Common Cathode, Upper and Lower Decimal

0.28-in. digit height

Low current operation

Excellent character appearance

Available in CA and CC

1000 pieces per reel

Moisture Sensitivity Level: Level 3

RoHS compliant

CAUTION! LEDs are Class 1A ESD sensitive per JESD22-A114C.01. Observe appropriate precautions during handling

and processing.

Broadcom

AV02-1645EN

March 29, 2021

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

Package Dimensions

NOTE:

1. All dimensions are in millimeters.

2. Tolerance: ± 0.25 mm unless otherwise noted.

Broadcom

AV02-1645EN

2

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

Pin Connection

(Common Anode)

Pin Number

Pin Connection

(Common Cathode)

Connection

Pin Number

Connection

1

CATHODE G

1

ANODE G

2

CATHODE DP1

2

ANODE DP1

3

CATHODE F

3

ANODE F

4

COMMON ANODE

4

COMMON CATHODE

5

CATHODE A

5

ANODE A

6

CATHODE B

6

ANODE B

7

CATHODE DP2

7

ANODE DP2

8

CATHODE C

8

ANODE C

9

COMMON ANODE

9

COMMON CATHODE

10

CATHODE D

10

ANODE D

11

CATHODE E

11

ANODE E

Internal Circuit Diagram

(Common Anode)

Internal Circuit Diagram

(Common Cathode)

4, 9

4, 9

A

B

5

Broadcom

C

6

D

8

10

E

F

11

G

3

DP2

DP1

1

2

A

7

B

5

C

6

D

8

E

10

11

F

G

3

DP2

DP1

1

2

7

AV02-1645EN

3

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

Absolute Maximum Ratings at TA = 25°C

Parameter

Power Dissipation Per Segment

Blue

Units

100

mW

Peak Forward Current Per Segment (1/10 Duty Cycle, 0.1-ms pulse width)

80

mA

Continuous Forward Current Per Segment

Derating Linearly From 25°C Per Segment

25

mA

0.25

mA/°C

Reverse Voltage Per Segment

Not designed for reverse bias operation

Operating Temperature Range

–40°C to +105°C

Storage Temperature Range

–40°C to +105°C

CAUTION! ESD: Static electricity and surge damage the LED. Use a wrist strap or anti-electrostatic glove when handling

the LED. All devices, equipment, and machinery must be properly grounded.

Electrical/Optical Characteristics at TA = 25°C

Blue

Parameter

Symbol

Min.

Typ.

Max.

Units

IV

3.4

6.7

—

mcd

IF = 10 mA

p/d

—

462/467

—

nm

IF = 20 mA

Spectral Line Half-Width

—

20

—

nm

IF = 20 mA

Forward Voltage, Per Segmente

VF

—

2.9

4.0

V

IF = 20 mA

Reverse Current, Per Segmentf

IR

—

—

100

µA

VR = 5V

IV-m

—

—

2:1

—

IF = 10 mA

Average Luminous Intensitya, b, c

Emission Wavelengthd

Luminous Intensity Matching Ratio

Test Condition

a. The luminous intensity, IV, is measured at the mechanical axis of the package.

b. The optical axis is closely aligned with the mechanical axis of the package.

c. Tolerance is ± 15%.

d. The dominant wavelength, d is derived from the CIE Chromaticity Diagram and represents the perceived color of the device.

e. Forward voltage tolerance is ± 0.1V.

f. Indicates product final test condition. Long-term reverse bias is not recommended.

Broadcom

AV02-1645EN

4

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

Typical Electrical/Optical Characteristic Curves at TA = 25°C

Blue

Figure 1: Relative Luminous Intensity vs. Wavelength

Figure 2: Forward Current vs. Forward Voltage

B

1.0

30

0.9

FORWARD CURRENT - mA

RELATIVE INTENSITY

0.8

0.7

0.6

0.5

0.4

0.3

0.2

B

25

20

15

10

5

0.1

0.0

0

400

500

600

700

800

0.0

1.0

2.0

3.0

4.0

FORWARD VOLTAGE - V

WAVELENGTH - nm

Figure 3: Allowable DC Current vs. Ambient Temperature

Figure 4: Relative Intensity vs. Forward Current

2.5

30

B

20

10

0

0

Broadcom

10

20

30

40 50

60 70 80

AMBIENT TEMPERATURE (°C)

90

100 110

RELATIVE LUMINOUS INTENSITY - mcd

(NORMALIZED AT `10mA)

FORWARD CURRENT IF (mA)

40

B

2.0

1.5

1.0

0.5

0.0

0

5

10

15

20

25

30

FORWARD CURRENT- mA

AV02-1645EN

5

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

Intensity Bin Limit (mcd)

Blue

Iv Bin Category

Min.

Max.

L

3.401

5.400

M

5.401

8.600

N

8.601

13.700

Tolerance ±15%.

NOTE:

Bin categories are established for the

classification of products. Products may not be

available in all categories. Contact your Broadcom

representative for information on currently

available bins.

SMT Soldering Profile

Pb-Free Reflow Soldering Profile

Recommended Soldering Pattern

(unit: mm)

1.27 x 5 = 6.35

TEMPERATURE

10 - 30 SEC.

217°C

200°C

250°C

3°C/SEC. MAX.

3

7.8

6°C/SEC. MAX.

150°C

3°C/SEC. MAX.

100 SEC. MAX.

60 - 120 SEC.

TIME

0.8

Recommended stencil window opening is 80%

(Acc. to J-STD-020C)

NOTE:

1. The peak temperature refers to the peak

package body temperature.

2. The number of reflow processes is limited to a

maximum of two times only. A cooling process

to normal temperature is required between the

first and second soldering processes.

Broadcom

AV02-1645EN

6

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

1.75 ± 0.1

Tape Specification (unit: mm)

2.00 ± 0.1

4.0

Ø1.5 +0.10

�0.00

4.00 ± 0.1

11.50

Ø1.5 +0.10

�0.00

22.25

24.00 +0.30

�0.10

0.35

12.00 ± 0.1

Broadcom

AV02-1645EN

7

�HDSM-281B/283B Data Sheet

0.28-in. (7.0-mm) Single-Digit Surface-Mount LED Display

Precautionary Notes

Soldering

Do not perform reflow soldering more than twice. Allow

the product to cool to normal room temperature before

the second reflow. Observe the necessary precautions

of handling moisture-sensitive devices as stated in the

following section.

Do not apply any pressure or force on the LED display

during reflow and after reflow when it is still hot.

Use reflow soldering to solder the LED display. Use

hand soldering only for rework if unavoidable, but it

must be strictly controlled to the following conditions:

– Soldering iron tip temperature = 315°C maximum

– Soldering duration = 2 seconds maximum

– Number of cycles = 1 only

– Power of soldering iron = 50W maximum

Do not touch the LED display with the soldering iron

except for the soldering terminals, as it may cause

damage.

Confirm beforehand whether the functionality and

performance of the LED display is affected by soldering

with hand soldering.

Use solder paste with no-clean flux for soldering.

To remove foreign particles on the surface of the

package, use a wet cotton bud with isopropyl alcohol

(IPA). During cleaning, rub the surface gently without

putting too much pressure. Do not wash or soak the

LED display in any solution.

Control after opening the MBB:

– Read the HIC immediately upon opening the MBB.

– Keep the LEDs at

很抱歉,暂时无法提供与“HDSM-281B”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 1000+22.691021000+2.84802

- 2000+21.880112000+2.74624

- 3000+21.465173000+2.69416

- 国内价格 香港价格

- 1+44.798811+5.62283

- 10+33.3447810+4.18521

- 100+26.59840100+3.33845

- 500+23.68069500+2.97224