HSME-Cxxx

AlInGaP Green ChipLED

Data Sheet

HSME-C110/C120/C150/C170/C177/C190/

C191/C197/C265

Description

Features

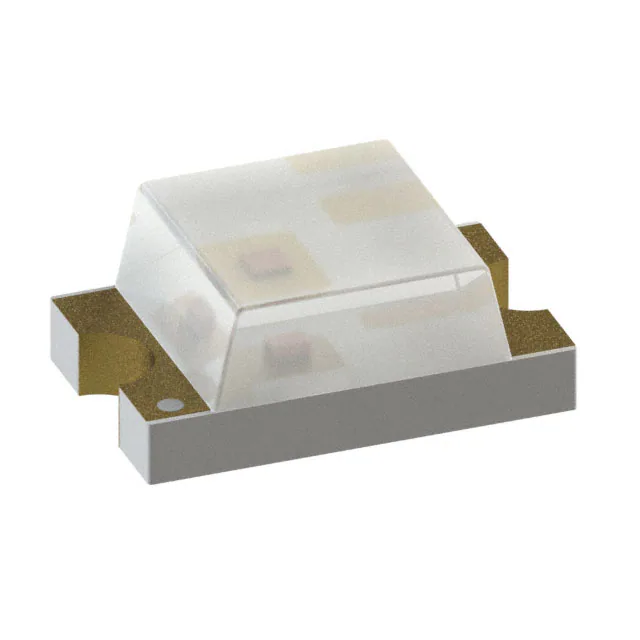

This chip-type LED utilizes Aluminum Indium Gallium

Phosphide (AlInGaP) material technology. The AlInGaP

material has a very high luminous efficiency, capable of

producing high light output.

• Small size

These chipLEDs come in top mounting, top emitting

packages (HSMx-C150/170/177/190/191/197), top mounting, side emitting packages (HSMx-C110/120) or reverse

mounting, top emitting package (HSMx-C265).

All packages are binned by both color and intensity.

In order to facilitate pick and place operation, these

chipLEDs are shipped in Tape & Reel, with 4000 units per

reel for HSMx-C120/170/ 177/190/191/197 and 3000 units

per reel for HSMx-C110/C150/265.

These packages are compatible with reflow soldering

process.

• Industry standard footprint

• Operating temperature range of –40°C to +85°C

• Compatible with IR soldering

• Available in 8 mm tape on 7” diameter reel

• Reel sealed in zip-locked moisture barrier bags

Applications

• Membrane switch indicator

• LCD backlighting

• Pushbutton backlighting

• Front panel indicator

• Symbol backlighting

• Keypad backlighting

CAUTION: HSME-Cxxx LEDs are Class 1A ESD sensitive per JESD22-A114C.01. Please observe appropriate

precautions during handling and processing. Refer to Application Note AN-1142 for additional details.

Avago reserves the right to alter prices, specification, features, capabilities, functions, release dates, and remove availability of the product(s) at anytime.

�Package Dimensions

CATHODE

LINE

LED DIE

CATHODE

MARK

1.0 (0.039)

1.25 (0.049)

2.6 (0.102 )

3.2 (0.126 )

2.00 (0.079 )

POLARITY

CLEAR

EPOXY

1.5 (0.059)

PC BOARD

1.40

(0.055)

DIFFUSED

EPOXY

POLARITY

0.30 (0.012)

PC BOARD

1.6 (0.063 )

0.80 (0.031)

0.30 (0.012)

0.5 (0.020)

CATHODE LINE

3.2 (0.126 )

0.8 (0.031)

CATHODE LINE

0.40 ± 0.15

(0.016 ± 0.006)

0.40 ± 0.15

(0.016 ± 0.006)

1.0 (0.039)

SOLDERING

TERMINAL

SOLDERING

TERMINAL

HSMx-C110

HSMx-C170

CATHODE

MARK

CATHODE

MARK

0.8 (0.031)

0.8 (0.031)

1.6

(0.063 )

1.6

(0.063 )

1.0

(0.039)

1.0

(0.039)

POLARITY

0.3 (0.012)

0.3 (0.012)

DIFFUSED EPOXY

DIFFUSED EPOXY

PC BOARD

POLARITY

PC BOARD

0.8 (0.031)

0.3 (0.012)

CATHODE LINE

CATHODE LINE

0.3 ± 0.15

(0.012 ± 0.006)

0.3 ± 0.15

(0.012 ± 0.006)

0.6 (0.023)

0.3 (0.012)

0.3 ± 0.15

(0.012 ± 0.006)

0.3 ± 0.15

(0.012 ± 0.006)

0.7 (0.028) MIN.

0.7 (0.028) MIN.

SOLDERING

TERMINAL

HSMx-C190

Notes:

1. All dimensions in millimeters (inches).

2. Tolerance is ± 0.1 mm (± 0.004 In.) unless otherwise specified.

2

SOLDERING

TERMINAL

HSMx-C191

�Package Dimensions, continued

CATHODE

MARK

3.40 (0.134)

CATHODE

MARK (ETCHED)

LED DIE

1.6 (0.063)

1.25 (0.049)

3.2 (0.126 )

DIFFUSED

EPOXY

POLARITY

2.0 (0.079)

0.6 (0.024)

1.1 (0.043)

PC BOARD

0.5 (0.020)

CATHODE LINE

2– 1.10 (0.043)

1.10 (0.043)

PC BOARD

0.30 (0.012)

0.5 ± 0.2

(0.020 ± 0.008)

0.5 ± 0.2

(0.020 ± 0.008)

POLARITY

1.20

(0.047)

UNDIFFUSED

EPOXY

CATHODE LINE

2– 0.50 ± 0.15

(0.020 ± 0.006)

SOLDERING

TERMINAL

HSMx-C150

HSMx-C265

CATHODE MARK

CATHODE MARK

LED DIE

0.6

(0.024)

0.80 (0.031)

1.6

(0.063)

1.60

(0.063)

POLARITY

DIFFUSED

EPOXY

CLEAR

EPOXY

0.3

(0.012)

POLARITY

1.2

(0.047)

0.40 (0.016)

PC BOARD

0.16 (0.006)

0.5 (0.020)

PC BOARD

0.30 ± 0.15

(0.012 ± 0.006)

CATHODE LINE

3 – 0.3 (0.012)

CATHODE LINE

0.70

(0.028) MIN.

SOLDERING

TERMINAL

SOLDERING

TERMINAL

HSMx-C197

HSMx-C120

Notes:

1. All dimensions in millimeters (inches).

2. Tolerance is ± 0.1 mm (± 0.004 In.) unless otherwise specified.

1.0 (0.039)

�Package Dimensions, continued

CATHODE MARK

1.25

(0.049)

2.00

(0.079)

POLARITY

DIFFUSED EPOXY

0.40 (0.016)

PC BOARD

0.16

(0.006)

0.40 ± 0.15

(0.016 ± 0.006)

CATHODE LINE

1.10 (0.043)

SOLDERING

TERMINAL

HSMx-C177

Notes:

1. All dimensions in millimeters (inches).

2. Tolerance is ± 0.1 mm (± 0.004 In.) unless otherwise specified.

�Device Selection Guide

Package Dimension (mm) [1,2]

AlInGaP Green

Package Description

1.6 (L) x 0.8 (W) x 0.6 (H)

HSME-C191

Untinted, Diffused

1.6 (L) x 0.8 (W) x 0.4 (H)

HSME-C197

Untinted, Diffused

1.6 (L) x 0.8 (W) x 0.8 (H)

HSME-C190

Untinted, Diffused

2.0 (L) x 1.25 (W) x 0.8 (H)

HSME-C170

Untinted, Diffused

2.0 (L) x 1.25 (W) x 0.4 (H)

HSME-C177

Untinted, Diffused

1.6 (L) x 1.0 (W) x 0.6 (H)

HSME-C120

Untinted, Non-diffused

3.2 (L) x 1.5 (W) x 1.0 (H)

HSME-C110

Untinted, Non-diffused

3.2 (L) x 1.6 (W) x 1.1 (H)

HSME-C150

Untinted, Diffused

3.4 (L) x 1.25 (W) x 1.1 (H)

HSME-C265

Untinted, Non-diffused

Notes:

1. Dimensions in mm.

2. Tolerance ± 0.1 mm unless otherwise noted.

Absolute Maximum Ratings at TA = 25°C

Parameter

HSME-C110/120/170/177/

190/191/197/150/265

Units

DC Forward Current [1,2]

20

mA

Power Dissipation

52

mW

Reverse Voltage (IR = 100 µA)

5

V

LED Junction Temperature

95

°C

Operating Temperature Range

–40 to +85

°C

Storage Temperature Range

–40 to +85

°C

Soldering Temperature

See reflow soldering profile (Figures 6 & 7)

Notes:

1. Derate linearly as shown in Figure 4.

2. Drive current above 5 mA is recommended for best long term performance.

Electrical Characteristics at TA = 25°C

Forward Voltage

VF (Volts)

@ IF = 20 mA

Reverse Breakdown

VR (Volts)

@ IR = 100 µA

Capacitance C

(pF), VF = 0,

f = 1 MHz

Thermal

Resistance

RθJ–PIN (°C/W)

Part Number

Typ.

Max.

Min.

Typ.

Typ.

HSME-C110/120

2.1

2.6

5

18

550

HSME-C150/170/177/190/191/197

2.1

2.6

5

15

450

HSME-C265

2.1

2.6

5

16

450

�Optical Characteristics at TA = 25°C

Luminous Intensity

IV (mcd) @ 20 mA[1]

Peak Wavelength

λpeak (nm)

Color, Dominant

Wavelength

λd[2] (nm)

Viewing Angle

2θ1/2 Degrees[3]

Luminous Efficacy

ηV (lm/w)

Part Number

Min.

Typ.

Typ.

Typ.

Typ.

Typ.

HSME-C110

18

52

570

572

130

570

HSME-C120

18

52

570

572

155

570

HSME-150/170/

190/191

18

50

570

572

170

570

HSME-C177/197

18

50

570

572

130

570

HSME-C265

18

50

570

572

150

570

Notes:

1. The luminous intensity, IV, is measured at the peak of the spatial radiation pattern, which may not be aligned with the mechanical axis of the lamp

package.

2. The dominant wavelength, λd, is derived from the CIE Chromatically Diagram and represents the perceived color of the device.

3. θ1/2 is the off-axis angle where the luminous intensity is 1/2 the peak intensity.

Green Color Bin Limits[1]

Light Intensity (IV) Bin Limits[1]

Dom. Wavelength (nm)

Intensity (mcd)

Bin ID

Min.

Max.

Bin ID

Min.

Max.

A

561.5

564.5

A

0.11

0.18

B

564.5

567.5

B

0.18

0.29

C

567.5

570.5

C

0.29

0.45

D

570.5

573.5

D

0.45

0.72

E

573.5

576.5

E

0.72

1.10

F

1.10

1.80

G

1.80

2.80

H

2.80

4.50

J

4.50

7.20

K

7.20

11.20

L

11.20

18.00

M

18.00

28.50

N

28.50

45.00

P

45.00

71.50

Q

71.50

112.50

R

112.50

180.00

S

180.00

285.00

T

285.00

450.00

U

450.00

715.00

Tolerance: ± 1 nm

Tolerance: ± 15%

Notes:

1. Bin categories are established for classification of products. Products may not be available in all categories. Please contact your Avago representative

for information on currently available bins.

2. The Iv binning specification set-up is for lowest allowable Iv binning only. There are no upper Iv bin limits.

�100

80

70

60

50

40

30

20

10

0

400

450

500

550

600

650

1.2

LUMINOUS INTENSITY

(NORMALIZED @ 20 mA)

90

IF – FORWARD CURRENT – mA

RELATIVE INTENSITY – %

100

10

1

0.1

1.5 1.6

700

1.7

1.8

1.9

2.0

Figure 1. Relative intensity vs. wavelength.

0.6

0.4

0.2

0

5

10

15

20

Figure 2. Forward current vs. forward voltage.

HSME-C110 fig 2

HSME-C110 fig 3

90

RELATIVE INTENSITY – %

IF MAX. – MAXIMUM FORWARD CURRENT – mA

100

20

15

10

5

80

70

60

50

40

30

20

10

0

0

-90 -80 -70 -60 -50 -40 -30 -20 -10

0 10 20 30 40 50 60 70 80 90 100

TA – AMBIENT TEMPERATURE – °C

HSME-C110 fig 5a

100

90

RELATIVE INTENSITY – %

10 20 30 40 50 60 70 80 90

Figure 5a. Relative intensity vs. angle for HSMx-C170, HSMx-C190, HSMx-C191, and HSMx-C150.

HSME-C110 fig 4

80

70

60

50

40

30

20

10

0

-90 -80 -70 -60 -50 -40 -30 -20 -10

0

ANGLE

Figure 4. Maximum forward current vs. ambient

temperature.

0

10 20 30 40 50 60 70 80 90

ANGLE

Figure 5b. Relative intensity vs. angle for HSMx-C177 and HSMx-C197.

HSME-C110 fig 5b

30

Figure 3. Luminous intensity vs. forward current.

HSME-C110 fig 1

25

25

IF – FORWARD CURRENT – mA

VF – FORWARD VOLTAGE – V

WAVELENGTH - nm

0.8

0

2.2

2.1

1.0

�RELATIVE INTENSITY – %

100

80

60

40

20

0

-100

-80

-60

-40

-20

0

20

40

60

80

100

40

60

80

100

ANGLE

RELATIVE INTENSITY – %

100

HSME-C110 fig 5c-1

80

60

40

20

0

-100

-80

-60

-40

-20

0

20

ANGLE

Figure 5c. Relative intensity vs. angle for HSMx-C110.

HSME-C110 fig 5c-2

100

RELATIVE INTENSITY – %

90

80

70

60

50

40

30

20

10

0

-90 -80 -70 -60 -50 -40 -30 -20 -10

0

10 20 30 40 50 60 70 80 90

ANGLE

100

RELATIVE INTENSITY

90

80

HSME-C110 fig 5d-1

70

60

50

40

30

20

10

0

-90 -80 -70 -60 -50 -40 -30 -20 -10 0

10 20 30 40 50 60 70 80 90

ANGLE

Figure 5d. Relative intensity vs. angle for HSMx-C120.

HSME-C110 fig 5d-2

�100

80

70

60

10 SEC. MAX.

50

TEMPERATURE

RELATIVE INTENSITY – %

90

40

30

20

10

0

-90 -80 -70 -60 -50 -40 -30 -20 -10

0

230°C MAX.

4°C/SEC. MAX.

140-160°C

–3°C/SEC.

4°C/SEC.

MAX.

10 20 30 40 50 60 70 80 90

OVER 2 MIN.

TIME

ANGLE

Figure 5e. Relative intensity vs. angle for HSMx-C265.

Figure 6. Recommended reflow soldering profile.

HSME-C110 fig 5e

TEMPERATURE

10 - 30 SEC.

255 - 260 °C

3 °C/SEC. MAX.

217 °C

200 °C

2.2 (0.087) DIA. PCB HOLE

6 °C/SEC. MAX.

150 °C

3 °C/SEC. MAX.

100 SEC. MAX.

60 - 120 SEC.

1.25 (0.049)

1.4

(0.055)

TIME

2.3

(0.091)

1.4

(0.055)

(Acc. to J-STD-020C)

Figure 7. Recommended Pb-free reflow soldering profile.

Figure 8. Recommended soldering pattern for HSMx-C265.

HSME-C110 fig 7

5.0 (0.200)

0.4 (0.016)

0.9 (0.035)

0.4 (0.016)

0.9 (0.035)

0.7 (0.028)

0.15 (0.006)

0.8

(0.031)

1.2

(0.047)

CENTERING

BOARD

0.8

(0.031)

1.0 (0.039)

0.2 (0.008)

1.5

(0.059)

Figure 9. Recommended soldering pattern for HSMx-C120.

2.0

(0.079)

CENTERING

BOARD

1.5

(0.059)

Figure 10. Recommended soldering pattern for HSMx-C110.

HSME-C110 fig 8

0.8 (0.031)

HSME-C110 fig 9

1.5 (0.059)

1.2 (0.047)

1.2

(0.047)

1.2

(0.047)

0.9

(0.035)

Figure 11. Recommended soldering pattern for

HSMx-C170 and HSMx-C177.

Note:

HSME-C110

fig in

10millimeters (inches).

1. All

dimensions

0.8

(0.031)

0.7

(0.028)

0.8

(0.031)

Figure 12. Recommended soldering pattern for

HSMx-C190, HSMx-C191 and HSMx-C197.

HSME-C110 fig 11

1.5

(0.059)

2.0

(0.079)

1.5

(0.059)

Figure 13. Recommended soldering pattern for

HSMx-C150.

HSME-C110 fig 12

�USER FEED DIRECTION

CATHODE SIDE

xxx

xxxxx

xx xx

xxxxxx

xxxxx

xx

PRINTED LABEL

Figure 14. Reeling orientation.

8.0 ± 1.0 (0.315 ± 0.039)

10.50 ± 1.0 (0.413 ± 0.039)

Ø 13.1 ± 0.5

(Ø 0.516 ± 0.020)

Ø 20.20 MIN.

(Ø 0.795 MIN.)

3.0 ± 0.5

(0.118 ± 0.020)

59.60 ± 1.00

(2.346 ± 0.039)

178.40 ± 1.00

(7.024 ± 0.039)

4.0 ± 0.5

(0.157 ± 0.020)

Figure 15. Reel dimensions.

Note:

1. All dimensions in millimeters (inches).

6

PS

5.0 ± 0.5

(0.197 ± 0.020)

�4.00 (0.157)

DIM. C

(SEE TABLE 1)

CATHODE

1.50 (0.059)

0.20 ± 0.05

(0.008 ± 0.002)

1.75 (0.069)

3.50 ± 0.05

(0.138 ± 0.002)

DIM. A

(SEE TABLE 1)

8.00 ± 0.30

(0.315 ± 0.012)

DIM. B

(SEE TABLE 1)

CARRIER TAPE

USER FEED

DIRECTION

2.00 ± 0.05

(0.079 ± 0.002)

4.00 (0.157)

DIM. A

DIM. B

DIM. C

± 0.10 (± 0.004) ± 0.10 (± 0.004) ± 0.10 (± 0.004)

PART NUMBER

HSMx-C110/C120

POSITION IN

CARRIER TAPE

DIM. A

(SEE TABLE 1)

DIM. B

(SEE TABLE 1)

COVER TAPE

TABLE 1

DIMENSIONS IN MILLIMETERS (INCHES)

HSMx-C191 SERIES

HSMx-C190 SERIES

1.86 (0.073)

1.75 (0.069)

0.89 (0.035)

0.90 (0.035)

0.87 (0.034)

0.90 (0.035)

HSMx-C170 SERIES

HSMx-C110 SERIES

HSMx-C150 SERIES

HSMx-C120 SERIES

HSMx-C197 SERIES

HSMx-C177 SERIES

2.30 (0.091)

3.40 (0.134)

3.50 (0.138)

1.90 (0.075)

1.75 (0.069)

2.30 (0.091)

1.45 (0.057)

1.70 (0.067)

1.88 (0.074)

1.15 (0.045)

0.95 (0.037)

1.40 (0.055)

0.95 (0.037)

1.20 (0.047)

1.27 (0.050)

0.80 (0.031)

0.60 (0.024)

0.60 (0.024)

HSMx-C110

HSMx-C120

R 1.0 ± 0.05

R 0.5 ± 0.05

(0.039 ± 0.002) (0.020 ± 0.002)

4.00 (0.157)

CATHODE

1.50 (0.059)

DIM. C

(SEE TABLE 1)

0.20 ± 0.05

(0.008 ± 0.002)

1.75 (0.069)

3.50 ± 0.05

(0.138 ± 0.002)

DIM. A

(SEE TABLE 1)

DIM. B

(SEE TABLE 1)

2.00 ± 0.05

(0.079 ± 0.002)

8.00 ± 0.30

(0.315 ± 0.012)

CARRIER TAPE

USER FEED

DIRECTION

4.00 (0.157)

COVER TAPE

TABLE 1

DIMENSIONS IN MILLIMETERS (INCHES)

PART NUMBER

HSMx-C265 SERIES

Figure 16. Tape dimensions.

Notes:

1. All dimensions in millimeters (inches).

2. Tolerance is ± 0.1 mm (± 0.004 In.) unless otherwise specified.

DIM. A

DIM. B

DIM. C

± 0.10 (0.004) ± 0.10 (0.004) ± 0.10 (0.004)

3.70 (0.146)

1.45 (0.057)

1.30 (0.051)

�END

Convective IR Reflow Soldering

START

For more information on soldering,

refer to Application Note 1060,

Surface Mounting SMT LED Indicator

Components.

THERE SHALL BE A

MINIMUM OF 160 mm

(6.3 INCH) OF EMPTY

COMPONENT POCKETS

SEALED WITH COVER

TAPE.

MOUNTED WITH

COMPONENTS

THERE SHALL BE A

MINIMUM OF 160 mm

(6.3 INCH) OF EMPTY

COMPONENT POCKETS

SEALED WITH COVER

TAPE.

MINIMUM OF

230 mm

(9.05 INCH)

MAY CONSIST

OF CARRIER

AND/OR

COVER TAPE.

Figure 17. Tape leader and trailer dimensions.

Storage Condition: 5 to 30°C @ 60%

RH max.

Baking is

condition:

required

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2010 Avago Technologies. All rights reserved.

AV02-0976EN - May 10, 2010

the

a) Humidity Indicator Card is >10%

when read at 23 ± 5°C

b) Device exposed to factory conditions

很抱歉,暂时无法提供与“HSME-C170”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 1+6.935641+0.82916

- 10+4.1427010+0.49527

- 100+2.73989100+0.32756

- 500+2.19102500+0.26194

- 1000+2.022551000+0.24180

- 2000+1.884592000+0.22531

- 国内价格 香港价格

- 4000+1.466854000+0.17537