ULP275

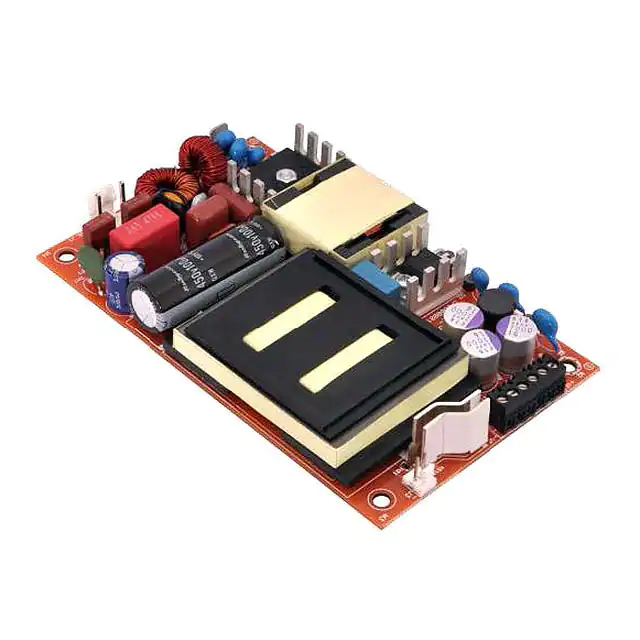

The ABC275 Series of ultra low profile open frame power supplies

feature a wide universal AC input range of 80 – 264 VAC, offering

output power 275 W with 13 CFM forced air cooling, or up to 160 W

with convection cooling. The power supplies are available in a variety

of isolated single output voltages.

The high efficiency and high power density of the ABC family ensures

minimal power loss in end-use equipment, thereby facilitating higher

reliability, easier thermal management and meets regulatory approvals

for environmentally-friendly end products.

These power supplies are ideal for broad range of telecom, datacom,

industrial equipment and other applications.

•

5 x 3 x 0.75 Inch Form Factor

•

275 Watts with Forced Air Cooling

•

Efficiencies up to 92%

•

-40 to 70°C Operating Temperature

•

IEC / EN / UL 62368-1 Compliant

•

12 V / 0.5 A Fan Output

•

Thermal Shut-Down Feature

•

3.37 million Hours, Telcordia -SR332-issue 3 MTBF

•

No Load Power < 0.5 W

•

Instrumentation

•

Renewable Energy

•

Lighting

•

Test and Measurement

•

Industrial Applications

•

Robotics

•

Applied Computing

•

Wireless Communication

�ABC275 Series

2

ABC275-1T12L

Screw Terminal

ABC275-1012L

Header Molex Connector

ABC275-1T15L

Screw Terminal

ABC275-1015L

Header Molex Connector

ABC275-1T24L

Screw Terminal

ABC275-1024L

Header Molex Connector

ABC275-1T30L

Screw Terminal

ABC275-1030L

Header Molex Connector

ABC275-1T48L

Screw Terminal

ABC275-1048L

Header Molex Connector

ABC275-1T58L

Screw Terminal

ABC275-1058L

Header Molex Connector

COVER-275-XBC 2

Metal Cover Kit (accessory)

1

2

12 V

12.5 A

13.33 A

22.92 A

275 W

15 V

10 A

10.66 A

18.33 A

275 W

24 V

6.25 A

6.67 A

11.46 A

275 W

30 V

5A

5.33 A

9.17 A

275 W

48 V

3.12 A

3.33 A

5.73 A

275 W

58 V

2.58 A

2.76 A

4.74 A

275 W

Class II version available. Add suffix “-2” at the end of the Model Number. Class II means without input Earth pin.

When used in Cover Kit, de-rate output power to 70 % under all operating conditions.

Specifications are for nominal input voltage, 25°C unless otherwise stated.

Input Voltage

Universal

(Derate from 100% at 100 VAC to 72% for forced cooling

and 69% for convection cooling at 80 VAC)

Input Frequency

80 – 264 VAC / 390 VDC

47-63 Hz

Input Current

115 VAC:

230 VAC:

2.6 A max.

1.3 A max.

No Load Power

Typical

< 0.5 W

115 VAC:

230 VAC:

264 VAC:

Typical (N/A for Class II Option)

Touch current

PFC

PWM

25 A

45 A

75 A

300 µA

< 100 µA

70 – 130 kHz

50 – 80 kHz

Inrush Current

Leakage Current

Switching Frequency

tech.support@psbel.com

�ABC275 Series

Output Voltage

Output Power 3

Efficiency

Hold-up Time

Power Factor

3

Refer to Model selection table

13 CFM (forced air cooling)

Convection (natural cooling)

48 V, 58 V:

24 V, 30 V:

12 V, 15 V:

At 275 W:

At 160 W:

@ Full Load

From 12 V to 58 V

275 W

up to 160 W

92%

90%

88%

8 ms

16 ms

> 0.95

Line Regulation 4

± 0.5%

Load Regulation 4

± 1%

Minimum Load

Transient Response

Ripple 4, 5

0.0 A

25% step load change, at 0.1 A/ µs slew rate,

50% duty cycle, 50 Hz = 4%

24, 30, 48 & 58 V outputs

12 V & 15 V outputs

Output Voltage Adjustment 6

Rise Time

Typical

recovery time < 5 ms

1.0 % max.

2.0 % max.

± 3%

55 ms

Set Point Tolerance 4

± 1%

Over Current Protection

> 110%

Over Voltage Protection

Short Circuit Protection

Cooling

3

4

5

6

7

8

110 to 140%

Hiccup mode

With 13 CFM forced air cooling (100 to 264 VAC) 7

With natural convection cooling (100 to 264 VAC) 8

275 W

Up to 160 W

Combined output power of main output, fan supply shall not exceed max. power rating.

Fan supply output voltage tolerance including set point accuracy, line and load regulation is ± 10% and ripple and noise

is less than 10%.

Ripple is peak to peak with 20 MHz bandwidth and 10 µF (Electrolytic capacitor) in parallel with a 0.1 µF capacitor at rated line

voltage and load ranges.

Adjustment potentiometer is located on the SMT side of the PCB

Refer to Mechanical Drawing

Refer to Derating Curve

Conducted Emissions

Input Current Harmonics

EN 55032-B, CISPR22-B, FCC PART15-B

EN 55032 A

with external core (King core K5B RC 25x12x15-M in input cable)

EN 61000-3-2

Pass

Pass

Level B

Class D

Voltage Fluctuation and Flicker

EN 61000-3-3

Pass

ESD Immunity

EN 61000-4-2

Level 3, Criterion A

Radiated Field Immunity

EN 61000-4-3

Level 3, Criterion A

Electrical Fast Transient Immunity

EN 61000-4-4

Level 3, Criterion A

Surge Immunity

EN 61000-4-5

Level 3, Criterion A

Conducted Immunity

EN 61000-4-6

Level 3, Criterion A

Magnetic Field Immunity

EN 61000-4-8

Level 3, Criterion A

Voltage Dips, Interruptions

EN 61000-4-11

Criterion A & B

Radiated Emissions

Asia-Pacific

+86 755 298 85888

Europe, Middle East

+353 61 49 8941

North America

+1 866 513 2839

© 2022 Bel Power Solutions & Protection

BCD.00881_AE

�ABC275 Series

4

Isolation Voltage

Input to Output: (for ITE applications)

Input to GND: (N/A for Class II Option)

Safety Standard(s)

EN / IEC / UL 62368-1(Ed .3)

Agency Approvals

Nemko, UL, C-UL

CE mark

Complies with LVD Directive

Operating Temperature 9

-40 to 0°C startup guaranteed, with spec deviation

Storage Temperature

Relative Humidity

Altitude

MTBF

9

4000 VDC

2500 VDC

-40 to +70°C

-40 to +85°C

Non-condensing

Operating:

Non-operating:

Telcordia -SR332-issue 3

5% to 95%

16,000 ft.

40,000 ft.

3.37 million hours

Output ripple can be more than 10% of the output voltage.

Convection load: 160 W up to 40 °C

De-rate between 40-50 °C @ 0.625% per °C

De-rate above 50 °C @ 2.33% per °C

Forced air cooled load: 275 W up to 50°C

De-rate above 50 °C @ 2.5% per °C

Figure1. Derating Curves

tech.support@psbel.com

�ABC275 Series

5

AC Input Connector

J1

Pin 1

Pin 2

Pin 3

AC Line

Not Fitted

AC Neutral

DC Output Connector

J2

Pin 1, 2, 3

Pin 4. 5. 6

V1 +VE

V1 -VE

Aux (Fan) Output

J3

Pin 1

Pin 2

FAN +VE

FAN -VE

Molex: 26-60-4030

Mating: 09-50-3031; Pins: 08-50-0106

Option 1 (Screw Terminal): Molex: 39357 Series or equivalent

Option 2 (Molex Connector): Molex: 26-60-4060

Mating: 09-50-3061; Pins: 08-50-0106

AMP: 640456-2

Mating: 640440-2

Weight

approx. 200 g

Dimensions

127 x 76.2 x 19.05 mm (5 x 3 x 0.75 inches)

Figure 2. Mechanical Drawing – Option 1 (Output Connector – Screw Terminal)

NOTES: In case the PCB is mounted in a metal enclosure, using metal hardware ensure the following:

1

Stand off, used to mount PCB has OD of 5.4 mm max.

2

Screws, used to fix PCB on stand off, have head dia of 6.0 mm max.

3

Washer, if used, to have dia of 6.5 mm max.

Asia-Pacific

+86 755 298 85888

Europe, Middle East

+353 61 49 8941

North America

+1 866 513 2839

© 2022 Bel Power Solutions & Protection

BCD.00881_AE

�6

ABC275 Series

Figure 3. Mechanical Drawing – Option 2 (Output Connector – Header Molex)

NOTES: In case the PCB is mounted in a metal enclosure, using metal hardware ensure the following:

4

Stand off, used to mount PCB has OD of 5.4 mm max.

5

Screws, used to fix PCB on stand off, have head dia of 6.0 mm max.

6

Washer, if used, to have dia of 6.5 mm max.

tech.support@psbel.com

�ABC275 Series

7

Figure 4. Mechanical Drawing – Cover Kit Option

NUCLEAR AND MEDICAL APPLICATIONS - Products are not designed or intended for use as critical components in life support systems,

equipment used in hazardous environments, or nuclear control systems.

TECHNICAL REVISIONS - The appearance of products, including safety agency certifications pictured on labels, may change depending on the

date manufactured. Specifications are subject to change without notice.

Asia-Pacific

+86 755 298 85888

Europe, Middle East

+353 61 49 8941

North America

+1 866 513 2839

© 2022 Bel Power Solutions & Protection

BCD.00881_AE

�