Features

Applications

n 3.3 volt supply

n Compensated digital output (I2C)

n Ultra-low pressure sensing (250 Pa)

n Gauge and differential types

n For use in clean, dry air and non-corrosive

gas environments

n RoHS compliant*

Industrial:

n HVAC systems

n Process monitoring

n Packaging automation

**Medical Devices (low/medium risk):

n Diagnostic equipment

n Analysis equipment

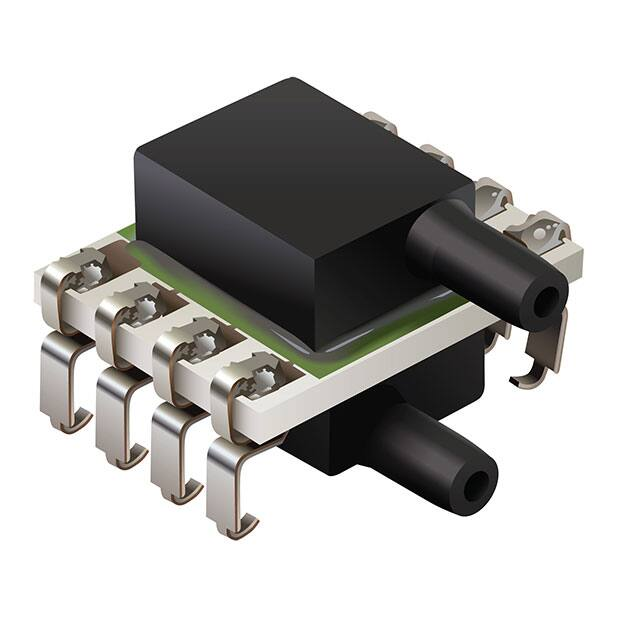

BPS125 Series - 12 mm Digital Low Pressure Sensor

Additional Information

Electrical Characteristics

Supply Voltage (Vs)............................................ 3.0 V minimum, 3.3 V typical, 3.6 V maximum

Supply Current @ 3.3 V................................1.2 mA minimum, 2 mA typical, 3.5 mA maximum

Click these links for more information:

PRODUCT

TECHNICAL INVENTORY

LIBRARY

SAMPLES

CONTACT

Performance Characteristics

Operating Temperature.................................................................................................................................... -40 °C to +85 °C (-40 °F to +185 °F)

Storage Temperature..................................................................................................................................... -55 °C to +100 °C (-67 °C to +212 °F)

Pressure Range.......................................................................................... 250 to 500 Pa, 0.15 to 1.0 PSI (1 ” H2O to 2 ” H2O, 1.03 to 6.89 kPa)

Output...................................................................................................................................................................................................Digital I2C (1)

Effective ADC Resolution................................................................................................................................................................................. 13 bit

Accuracy @ 25 °C.................................................................................................................................................................................. ±0.25 % FS

Total Error Band over 0 °C to 60 °C (+32 °F to +140 °F)......................................................................................................................... ± 1.5 % FS

Long Term Stability.................................................................................................................................................................................. ± 0.5 % FS

Startup Time................................................................................................................................................................................... 15 ms maximum

Digital Update Time.............................................................................................................................................................................8.5 ms typical

Proof Pressure....................................................................................................................................................................... 5X full scale pressure

Burst Pressure................................................................................................................................................................................................. 10 psi

(1) I2C address is set to (0x28). Alternative addresses are available. Consult the factory for custom options.

Product Characteristics

Media Compatibility.......................................................................................................................................................... Non-corrosive dry gasses

Moisture Sensitivity Level........................................................................................................................................................................................2

ESD Classification (HBM)..................................................................................................................................................................................2 kV

Marking................................................................................... Partial model number, media compatibility, pressure type, pressure rating, lot code

Standard Packaging................................................................................................................................................................ 250 pcs./13-inch reel

Weight..................................................................................................................................................................................1.307 grams (0.046 oz)

Transfer Function Formula

(

Pcounts – 0.1 • Max

Ppsi = (Pmax – Pmin) •

Where

0.8 • Max

Ppsi

= Measured Pressure in PSI

Pmin

= Minimum Pressure

Max

= 16384 = 14 Bits

)

Basic Circuit Schematic

1

+ Pmin

Vs

DIGITAL

OUT

Pcounts = Pressure Counts

Pmax

SSC

SCL

8

SDA

7

= Maximum Pressure

Consult factory for custom options such as supply voltage,

temperature calibration range, output range accuracy

specification, and update rate.

GND

4

Note: Power supply decoupling included.

WARNING Cancer and Reproductive Harm - www.P65Warnings.ca.gov

* RoHS3 Directive 2015/863 Amendments of Annex II on March 31, 2015

** Bourns® products have not been designed for and are not intended for use in “lifesaving,” “life-critical” or “life-sustaining” applications nor any other applications

where failure or malfunction of the Bourns® product may result in personal injury or death. See Legal Disclaimer Notice on the last page of this document, and at

www.bourns.com/docs/legal/disclaimer.pdf.

Specifications are subject to change without notice.

Users should verify actual device performance in their specific applications.

The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

�

BPS125

- 12 mm

Digital Low

Pressure Sensor

3312

- 2Series

mm SMD

Trimming

Potentiometer

I2C Parameters

SCL Clock Frequency fSCL...............................................................................................................................................................100 to 400 kHz

Start Condition Hold Time Relative to SCL Edge tHDSTA................................................................................................................................0.1 µs

Minimum SCL Clock Low Width1 tLOW...........................................................................................................................................................0.6 µs

Minimum SCL Clock High Width1 tHIGH..........................................................................................................................................................0.6 µs

Start Condition Setup Time Relative to SCL Edge tSUSTA..............................................................................................................................0.1 µs

Data Hold Time on SDA Relative to SCL Edge tHDDAT...................................................................................................................................0.0 µs

Data Setup Time on SDA Relative to SCL Edge tSUDAT.................................................................................................................................0.1 µs

Stop Condition Setup Time on SCL tSUSTO....................................................................................................................................................0.1 µs

Bus Free Time Between Stop Condition and Start Condition tBUS.................................................................................................................... 2 µs

1 Combined low and high widths must equal or exceed minimum SCLK period.

I2C Parameters

I2C Communication

Communication to the Model BPS125 is read only. To read the pressure counts, the master performs a read request by asserting a start

condition, sending the 7-bit address of the part (0x28), and sets the read/write bit. The master then waits for an acknowledgement. The

acknowledgement is sent by the pressure sensor along with 2 bits of status and bits 13:8 of the pressure counts, the master acknowledges the

first 8 bits, and the pressure sensor sends the remaining 8 bits of data. The master then does not acknowledge and sends a stop condition,

signaling the end of the transaction.

Specifications are subject to change without notice.

Users should verify actual device performance in their specific applications.

The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

�

BPS125

- 12 mm

Digital Low

Pressure Sensor

3312

- 2Series

mm SMD

Trimming

Potentiometer

Cross Section

Terminal Assignment

DEVICE PINOUT

MEMS Sensing Element

(Differential Pressure)

P1

Cover/Mechanical Protection

Soft Die Attach Material

Integrated Signal

Conditioning

(ASIC)

Media Inlet Ports

Filter Capacitor

Vs

P2

N/C

P3

N/C

P4

VSS - Ground

P5

N/C

P6

N/C

P7

SDA - I2C Data

P8

SCL - I2C Clock

Electrical Connections

Recommended

PCB Layout

2.5

Product Dimensions

8

7

6

8

7

5

6

(0.098)

2.5

2.5

(0.098)

(0.098)

2.5

(0.098)

3.6

(0.142)

3.6

(0.142)

2.2

5

8

(0.087)

2.2

DIA.

(0.087)

DIA.

2.5

(0.098)

2.5

(0.098)

7

8

12.7

(0.500) 12.7

(0.500)

6

7

5

6

5

11.4

(0.449)

11.4

(0.449)

11.3

(0.445)

11.3

(0.445)

1

2

3

1

2

4

3

1

4

3

2

4

3

1.3

2.5

1.3

2.5

(0.051)

(0.098)

(0.051)

(0.098)

SMT LANDING PAD LAYOUT

SMT LANDING PAD LAYOUT

10.2

(0.402) 10.2

(0.402)

DIMENSIONS:

8.4

(0.331) 8.4

(0.331)

2.5

2.5

(0.098)

(0.098)

2.5

2.5

(0.098)(0.098)

2

1

4

1.9

1.9

(0.075)

(0.075)

MM

(INCHES)

0.3

TOLERANCES:

(0.012)

2.5

2.5

(0.098)

(0.098)

Specifications are subject to change without notice.

Users should verify actual device performance in their specific applications.

The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

�BPS125

- 12 mm

Digital Low

Pressure Sensor

3312

- 2Series

mm SMD

Trimming

Potentiometer

How To Order

BPS125 - A D 0P07 - 2 D G

Model Series

Digital

Media Compatibility

A = Air/Gas

Pressure Type

G = Gauge

D = Differential

Pressure

0P04 = 250 Pa

0P07 = 500 Pa

0P15 = 0.15 PSI

0P30 = 0.30 PSI

01P0 = 1.0 PSI

Terminal Pins

2 = Surface Mount Terminals

Port Style

D = Dual Port, Horizontal

Packaging Designator

G = 250 pcs. per 13-inch Reel

Solder Profile

TEMPERATURE (°C)

300

250 °C Max.

(5 Seconds Max.)

200

150 ±5 °C

100

Time

80-100 Seconds

60 Seconds Max.

Notes:

1. No clean solder paste is recommended.

2. Aqueous wash is not recommended.

3. Use of water soluble soldering flux

should be avoided due to possible

corrosion.

4. Multiple passes through the soldering

process is not recommended.

5. Other SMD processes and profiles

should be verified by the customer.

Processing Method: Reflow soldering with infrared heat or forced air convection (only once).

Specifications are subject to change without notice.

Users should verify actual device performance in their specific applications.

The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

�

BPS125

- 12 mm

Digital Low

Pressure Sensor

3312

- 2Series

mm SMD

Trimming

Potentiometer

Packaging Specification

250 pieces per 13-inch reel.

Meets specifications of EIA-481-1 or EIA-481-2.

12.7

DIA.

(0.5)

3.81

(0.15)

EQUAL SPACED

3 PLCS.

29.21

(1.15)

20.32

DIA.

(0.8)

2.0

(0.079)

4.0

(0.157)

101.6

(4.0)

330.2

DIA.

(13.0)

32.0

(1.260)

16.0

(0.630)

25.4

(1.0)

DIMENSIONS:

MM

(INCHES)

0.25

TOLERANCES:

(0.010)

Asia-Pacific: Tel: +886-2 2562-4117 • Email: asiacus@bourns.com

EMEA: Tel: +36 88 885 877 • Email: eurocus@bourns.com

The Americas: Tel: +1-951 781-5500 • Email: americus@bourns.com

www.bourns.com

REV. 08/21

Specifications are subject to change without notice.

Users should verify actual device performance in their specific applications.

The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

�

Legal Disclaimer Notice

This legal disclaimer applies to purchasers and users of Bourns® products manufactured by or on behalf of Bourns, Inc. and its

affiliates (collectively, “Bourns”).

Unless otherwise expressly indicated in writing, Bourns® products and data sheets relating thereto are subject to change

without notice. Users should check for and obtain the latest relevant information and verify that such information is current and

complete before placing orders for Bourns® products.

The characteristics and parameters of a Bourns® product set forth in its data sheet are based on laboratory conditions, and

statements regarding the suitability of products for certain types of applications are based on Bourns’ knowledge of typical

requirements in generic applications. The characteristics and parameters of a Bourns® product in a user application may vary

from the data sheet characteristics and parameters due to (i) the combination of the Bourns® product with other components

in the user’s application, or (ii) the environment of the user application itself. The characteristics and parameters of a Bourns®

product also can and do vary in different applications and actual performance may vary over time. Users should always verify

the actual performance of the Bourns® product in their specific devices and applications, and make their own independent

judgments regarding the amount of additional test margin to design into their device or application to compensate for

differences between laboratory and real world conditions.

Unless Bourns has explicitly designated an individual Bourns® product as meeting the requirements of a particular industry

standard (e.g., ISO/TS 16949) or a particular qualification (e.g., UL listed or recognized), Bourns is not responsible for any

failure of an individual Bourns® product to meet the requirements of such industry standard or particular qualification. Users of

Bourns® products are responsible for ensuring compliance with safety-related requirements and standards applicable to their

devices or applications.

Bourns® products are not recommended, authorized or intended for use in nuclear, lifesaving, life-critical or life-sustaining applications, nor in any other applications where failure or malfunction may result in personal injury, death, or severe property or

environmental damage. Unless expressly and specifically approved in writing by two authorized Bourns representatives on a

case-by-case basis, use of any Bourns® products in such unauthorized applications might not be safe and thus is at the user’s

sole risk. Life-critical applications include devices identified by the U.S. Food and Drug Administration as Class III devices and

generally equivalent classifications outside of the United States.

Bourns expressly identifies those Bourns® standard products that are suitable for use in automotive applications on such

products’ data sheets in the section entitled “Applications.” Unless expressly and specifically approved in writing by two

authorized Bourns representatives on a case-by-case basis, use of any other Bourns® standard products in an automotive

application might not be safe and thus is not recommended, authorized or intended and is at the user’s sole risk. If Bourns

expressly identifies a sub-category of automotive application in the data sheet for its standard products (such as infotainment

or lighting), such identification means that Bourns has reviewed its standard product and has determined that if such Bourns®

standard product is considered for potential use in automotive applications, it should only be used in such sub-category of

automotive applications. Any reference to Bourns® standard product in the data sheet as compliant with the AEC-Q standard

or “automotive grade” does not by itself mean that Bourns has approved such product for use in an automotive application.

Bourns® standard products are not tested to comply with United States Federal Aviation Administration standards generally

or any other generally equivalent governmental organization standard applicable to products designed or manufactured for

use in aircraft or space applications. Bourns expressly identifies Bourns® standard products that are suitable for use in aircraft

or space applications on such products’ data sheets in the section entitled “Applications.” Unless expressly and specifically

approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any other Bourns® standard

product in an aircraft or space application might not be safe and thus is not recommended, authorized or intended and is at the

user’s sole risk.

The use and level of testing applicable to Bourns® custom products shall be negotiated on a case-by-case basis by Bourns and

the user for which such Bourns® custom products are specially designed. Absent a written agreement between Bourns and the

user regarding the use and level of such testing, the above provisions applicable to Bourns® standard products shall also apply

to such Bourns® custom products.

Users shall not sell, transfer, export or re-export any Bourns® products or technology for use in activities which involve the

design, development, production, use or stockpiling of nuclear, chemical or biological weapons or missiles, nor shall they use

Bourns® products or technology in any facility which engages in activities relating to such devices. The foregoing restrictions

apply to all uses and applications that violate national or international prohibitions, including embargos or international

regulations. Further, Bourns® products and Bourns technology and technical data may not under any circumstance be

exported or re-exported to countries subject to international sanctions or embargoes. Bourns® products may not, without prior

authorization from Bourns and/or the U.S. Government, be resold, transferred, or re-exported to any party not eligible

to receive U.S. commodities, software, and technical data.

To the maximum extent permitted by applicable law, Bourns disclaims (i) any and all liability for special, punitive, consequential,

incidental or indirect damages or lost revenues or lost profits, and (ii) any and all implied warranties, including implied warranties

of fitness for particular purpose, non-infringement and merchantability.

For your convenience, copies of this Legal Disclaimer Notice with German, Spanish, Japanese, Traditional Chinese and Simplified Chinese

bilingual versions are available at:

Web Page: http://www.bourns.com/legal/disclaimers-terms-and-policies

PDF: http://www.bourns.com/docs/Legal/disclaimer.pdf

C1753 05/17/18R

�