bq27620-G1

www.ti.com

SLUSAE3 – OCTOBER 2012

System-Side Impedance Track™ Fuel Gauge with Dynamic Voltage Correlation

Check for Samples: bq27620-G1

1 INTRODUCTION

1.1

FEATURES

1.2

• Battery Fuel Gauge for 1-Series Li-Ion

applications based on Patented Impedance

Track™ Technology with Dynamic Voltage

Correlation (IT-DVC)

• Resides on System Main Board

• No Sense Resistor Required

• Powered directly from battery with integrated

LDO

• Supports embedded or removable Battery

Packs

• System Side Fuel-Gauge Provides:

– Accurate Battery Fuel Gauging; models the

Battery Discharge Curve for Accurate Timeto-Empty Predictions

– Automatically Adjusts for Battery Aging,

Battery Self-Discharge, and

Temperature/Rate Inefficiencies

– Internal Temperature Sensor for Battery

Temperature Reporting

– Battery Low Interrupt Warning

– Battery Insertion Indicator

– Configurable Level of State of Charge (SOC)

Interrupts

– State of Health Indicator

– 32 Bytes of Non-Volatile Scratch-Pad FLASH

• 400-kHz I2C™ Interface for Connection to

System Microcontroller Port

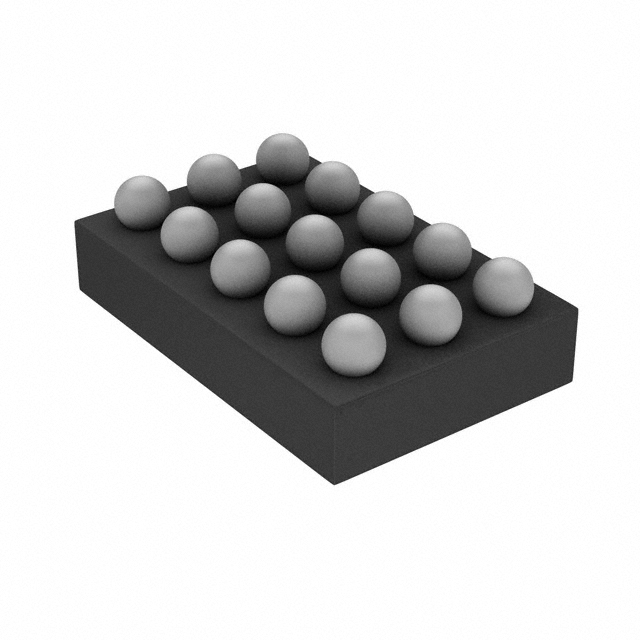

• In a 15-Pin NanoFree™ (CSP) Packaging

•

•

•

•

123

APPLICATIONS

Smartphones

Digital Still and Video Cameras

Handheld Terminals

MP3 or Multimedia Players

1.3

DESCRIPTION

The Texas Instruments bq27620-G1 system-side is

an easy configure microcontroller peripheral that

provides fuel gauging for single-cell Li-Ion battery

packs. The device requires minimal user

configuration and system microcontroller firmware

development.

The bq27620-G1 uses the patented Impedance

Track™ algorithm with Dynamic Voltage Correlation

for fuel gauging. This patented process eliminates the

need for a sense resistor when calculating

remaining battery capacity (mAh), state-of-charge

(%), run-time to empty (min), battery voltage (mV),

temperature (°C) and state of health (%).

Battery fuel gauging with the bq27620-G1 requires

connections only to PACK+ (P+), PACK– (P–), and

Thermistor (T) connections to a removable battery

pack or embedded battery circuit. The CSP option is

a 15-ball package in the nominal dimensions of 2610

× 1956 µm with 0,5 mm lead pitch. It is ideal for

space constrained applications.

TYPICAL APPLICATION

Host System

Single Cell Li-lon

Battery Pack

VCC

LDO

CE

Power

Management

Controller

I2C

PACK+

Battery

Low

Voltage

Sense

DATA

Temp

Sense

PROTECTION

IC

T

bq27620

BAT_GD

PACK-

FETs

CHG

DSG

SOC_INT

1

2

3

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Impedance Track, NanoFree are trademarks of Texas Instruments.

I2C is a trademark of NXP B.V. Corp Netherlands.

PRODUCTION DATA information is current as of publication date. Products conform to

specifications per the terms of the Texas Instruments standard warranty. Production

processing does not necessarily include testing of all parameters.

Copyright © 2012, Texas Instruments Incorporated

�bq27620-G1

SLUSAE3 – OCTOBER 2012

www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

1

2

3

INTRODUCTION

.........................................

..........................................

1.2

APPLICATIONS .....................................

1.3

DESCRIPTION ......................................

DEVICE INFORMATION ................................

2.1

AVAILABLE OPTIONS ..............................

2.2

THERMAL INFORMATION ..........................

1

1.1

1

2.3

PIN ASSIGNMENT AND PACKAGE DIMENSIONS

4

ELECTRICAL SPECIFICATIONS

.....................

..................

RECOMMENDED OPERATING CONDITIONS .....

SUPPLY CURRENT .................................

5

3.1

5

FEATURES

ABSOLUTE MAXIMUM RATINGS

3.2

3.3

3.4

.................................

2.5V LDO REGULATOR .............................

INTERNAL CLOCK OSCILLATORS ................

POWER-ON RESET

3.6

3.7

3.8

ADC (TEMPERATURE AND CELL

MEASUREMENT) CHARACTERISTICS

3.9

3.10

2

5.6

34

CHARGING AND CHARGE-TERMINATION

INDICATION ........................................ 34

5.7

POWER MODES

1

3

3

5

3

6

6

7

............

7

............................. 9

................................ 10

DATA COMMANDS

DATA FLASH INTERFACE

19

4.3

MANUFACTURER INFORMATION BLOCK

20

8

...................................

.........

APPLICATION-SPECIFIC INFORMATION

6.1

6

6

DATA FLASH MEMORY CHARACTERISTICS ..... 8

I2C-COMPATIBLE INTERFACE COMMUNICATION

TIMING CHARACTERISTICS ....................... 8

GENERAL DESCRIPTION

4.1

5

1

DIGITAL INPUT AND OUTPUT DC

CHARACTERISTICS ................................ 6

3.5

4

5

........................

.......

4.4

ACCESS MODES ..................................

4.5

SEALING/UNSEALING DATA FLASH .............

4.6

DATA FLASH SUMMARY ..........................

FUNCTIONAL DESCRIPTION ........................

5.1

FUEL GAUGING ...................................

5.2

IMPEDANCE TRACK™ VARIABLES ..............

5.3

DETAILED PIN DESCRIPTION ....................

5.4

TEMPERATURE MEASUREMENT ................

5.5

OVERTEMPERATURE INDICATION ..............

4.2

21

21

22

26

26

27

29

34

35

36

BATTERY PROFILE STORAGE AND SELECTION

......................................................

...................................

7.1

I2C INTERFACE ....................................

7.2

I2C Time Out .......................................

7.3

I2C Command Waiting Time ........................

7.4

I2C Clock Stretching ................................

REFERENCE SCHEMATICS .........................

8.1

SCHEMATIC ........................................

COMMUNICATIONS

Contents

36

37

37

37

38

38

39

39

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

SLUSAE3 – OCTOBER 2012

2 DEVICE INFORMATION

2.1

AVAILABLE OPTIONS

PART NUMBER

bq27620YZFR-G1

bq27620YZFT-G1

(1)

FIRMWARE

VERSION (1)

PACKAGE (1)

TA

COMMUNICATION FORMAT

1.06

(0x106)

CSP-15

–40°C to 85°C

I2C

3000

250

For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

website at www.ti.com.

2.2

THERMAL INFORMATION

THERMAL METRIC (1)

bq27620-G1

YZF(15 PINS)

θJA

Junction-to-ambient thermal resistance

70

θJCtop

Junction-to-case (top) thermal resistance

17

θJB

Junction-to-board thermal resistance

20

ψJT

Junction-to-top characterization parameter

1

ψJB

Junction-to-board characterization parameter

18

Junction-to-case (bottom) thermal resistance

n/a

θJCbot

(1)

TAPE and REEL

QUANTITY

UNITS

°C/W

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953

DEVICE INFORMATION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

3

�bq27620-G1

SLUSAE3 – OCTOBER 2012

2.3

www.ti.com

PIN ASSIGNMENT AND PACKAGE DIMENSIONS

(TOP VIEW)

(BOTTOM VIEW)

B3

C3

D3

E3

E3

D3

C3

B3

A3

A2

B2

C2

D2

E2

E2

D2

C2

B2

A2

A1

B1

C1

D1

E1

E1

D1

C1

B1

A1

A3

E

xx

xx

Pin A1

Index Area

D

DIM

MIN

TYP

MAX

D

2580

2610

2640

E

1926

1956

1986

UNITS

m

Table 2-1. PIN FUNCTIONS

PIN

NAME

NO.

TYPE (1)

DESCRIPTION

VSS

A1, B1,

C1, C2

P

Device ground

VCC

D1

P

Regulator output and bq27620-G1 processor power. Decouple with 1μF ceramic capacitor to Vss.

REGIN

E1

P

Regulator input. Decouple with 0.1μF ceramic capacitor to Vss.

SOC_INT

A2

O

SOC state interrupts output. Generates a pulse under the conditions specified by Table 5-7. Open drain output. (RA3)

BAT_GD

B2

O

Battery-good indicator. Active-low by default, though polarity can be configured through the [BATG_POL] bit of

Operation Configuration. Push-pull output. (RC1)

CE

D2

I

Chip Enable. Internal LDO is disconnected from REGIN when driven low.

BAT

E2

I

Cell-voltage measurement input. ADC input. Recommend 4.8V maximum for conversion accuracy. (RC3)

SCL

A3

I

Slave I2C serial communications clock input line for communication with system (Master). Use with 10kΩ pull-up

resistor (typical). (RA2)

SDA

B3

I/O

Slave I2C serial communications data line for communication with system (Master). Open-drain I/O. Use with 10kΩ

pull-up resistor (typical). (RA1)

BAT_LOW

C3

O

Battery Low output indicator. Active high by default, though polarity can be configured through the [BATL_POL] bit of

Operation Configuration. Push-pull output. (RC0)

TS

D3

IA

Pack thermistor voltage sense (use 103AT-type thermistor). ADC input. (RC2)

BI/TOUT

E3

I/O

Battery-insertion detection input. Power pin for pack thermistor network. Thermistor-multiplexer control pin. Use with

pull-up resistor >1MΩ (1.8 MΩ typical). (RA0)

(1)

4

I/O = Digital input/output, IA = Analog input, P = Power connection

DEVICE INFORMATION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

SLUSAE3 – OCTOBER 2012

3 ELECTRICAL SPECIFICATIONS

3.1

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted) (1)

PARAMETER

VREGIN

VALUE

Regulator input range

UNIT

–0.3 to 5.5

–0.3 to 6.0

V

(2)

V

VCC

Supply voltage range

–0.3 to 2.75

V

VIOD

Open-drain I/O pins (SDA, SCL, SOC_INT )

–0.3 to 5.5

V

VBAT

BAT input pin

–0.3 to 5.5

V

–0.3 to 6.0

VI

Input voltage range to all other pins ( BI/TOUT , TS , BAT_GD )

ESD

(2)

V

–0.3 to VCC + 0.3

Human-body model (HBM), BAT pin

V

1.5

Human-body model (HBM), all other pins

kV

2

TA

Operating free-air temperature range

–40 to 85

°C

TF

Functional temperature range

–40 to 100

°C

Tstg

Storage temperature range

–65 to 150

°C

(1)

(2)

Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Condition not to exceed 100 hours at 25 °C lifetime.

3.2

RECOMMENDED OPERATING CONDITIONS

TA = -40°C to 85°C, VREGIN = VBAT = 3.6V (unless otherwise noted)

PARAMETER

VREGIN

Supply voltage

CREGIN

External input capacitor for internal

LDO between REGIN and VSS

CLDO25

External output capacitor for internal

LDO between VCC and VSS

tPUCD

Power-up communication delay

3.3

TEST CONDITIONS

No operating restrictions

No FLASH writes

Nominal capacitor values specified.

Recommend a 5% ceramic X5R type

capacitor located close to the device.

MIN

TYP

MAX

2.8

4.5

2.45

2.8

0.47

UNIT

V

0.1

μF

1

μF

250

ms

SUPPLY CURRENT

TA = 25°C and VREGIN = VBAT = 3.6V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

ICC

Normal operating-mode

current (1)

Fuel gauge in NORMAL mode.

ILOAD > Sleep Current

ISLP

Low-power storage-mode

current (1)

Fuel gauge in SLEEP mode.

ILOAD < Sleep Current

IHIB

Hibernate operating-mode

current (1)

Fuel gauge in HIBERNATE mode.

ILOAD < Hibernate Current

(1)

MIN

TYP

MAX

UNIT

118

μA

23

μA

8

μA

Specified by design. Not production tested.

ELECTRICAL SPECIFICATIONS

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

5

�bq27620-G1

SLUSAE3 – OCTOBER 2012

3.4

www.ti.com

DIGITAL INPUT AND OUTPUT DC CHARACTERISTICS

TA = –40°C to 85°C, typical values at TA = 25°C and VREGIN = 3.6 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

VOL

Output voltage, low (SCL, SDA,

SOC_INT , BAT_LOW ,

BAT_GD )

IOL = 3 mA

VOH(PP)

Output voltage, high

(BAT_LOW , BAT_GD )

IOH = –1 mA

VCC –

0.5

VOH(OD)

Output voltage, high (SDA,

SCL, SOC_INT )

External pullup resistor connected to

VCC

VCC –

0.5

Input voltage, low (SDA, SCL

pins)

VIL

Input voltage, low ( BI/TOUT

pin)

Input voltage, high ( BI/TOUT

pin)

VIL(CE)

0.4

Input voltage, high (CE pin)

Ilkg

Input leakage current (I/O pins)

UNIT

V

V

0.6

V

BAT INSERT CHECK MODE active

–0.3

0.6

1.2

BAT INSERT CHECK MODE active

VCC +

0.3

1.2

Input voltage, low (CE pin)

VIH(CE)

(1)

MAX

–0.3

Input voltage, high (SDA, SCL

pins)

VIH

TYP

V

0.8

VREGIN = 2.8 to 4.5V

V

VREGIN –

0.5

0.3

(1)

μA

Specified by design. Not production tested.

3.5

POWER-ON RESET

TA = –40°C to 85°C, typical values at TA = 25°C and VREGIN = 3.6 V (unless otherwise noted)

PARAMETER

VIT+

Positive-going battery voltage

input at VCC

VHYS

Power-on reset hysteresis

3.6

TEST CONDITIONS

MIN

TYP

MAX

UNIT

2.05

2.15

2.20

V

45

115

185

mV

UNIT

2.5V LDO REGULATOR

TA = –40°C to 85°C, CLDO25 = 1μF, VREGIN = 3.6V (unless otherwise noted)

PARAMETER

VREG25

3.7

Regulator output voltage

MIN

NOM

MAX

2.8V ≤ VREGIN ≤ 4.5V, IOUT ≤ 16mA

TEST CONDITION

2.3

2.5

2.6

2.45V ≤ VREGIN < 2.8V (low battery),

IOUT ≤ 3mA

2.3

V

V

INTERNAL CLOCK OSCILLATORS

TA = –40°C to 85°C, 2.4 V < VCC < 2.6 V; typical values at TA = 25°C and VCC = 2.5 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

fOSC

High Frequency Oscillator

2.097

MHz

fLOSC

Low Frequency Oscillator

32.768

kHz

6

ELECTRICAL SPECIFICATIONS

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

3.8

SLUSAE3 – OCTOBER 2012

ADC (TEMPERATURE AND CELL MEASUREMENT) CHARACTERISTICS

TA = –40°C to 85°C, 2.4 V < VCC < 2.6 V; typical values at TA = 25°C and VCC = 2.5 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

VA1

Input voltage range (TS )

VSS –

0.125

2

V

VA2

Input voltage range (BAT)

VSS –

0.125

5

V

VIN(ADC)

Input voltage range

GTEMP

Internal temperature sensor

voltage gain

tADC_CONV

Conversion time

0.05

Resolution

14

VOS(ADC)

Input offset

ZADC1

Effective input resistance

(TS ) (1)

ZADC2

Effective input resistance

(BAT) (1)

Ilkg(ADC)

(1)

Input leakage current

1

–2

V

mV/°C

125

ms

15

bits

1

bq27620-G1 not measuring cell

voltage

bq27620-G1 measuring cell voltage

(1)

mV

8

MΩ

8

MΩ

100

kΩ

0.3

μA

Specified by design. Not tested in production.

ELECTRICAL SPECIFICATIONS

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

7

�bq27620-G1

SLUSAE3 – OCTOBER 2012

3.9

www.ti.com

DATA FLASH MEMORY CHARACTERISTICS

TA = –40°C to 85°C, 2.4 V < VCC < 2.6 V; typical values at TA = 25°C and VCC = 2.5 V (unless otherwise noted)

PARAMETER

tDR

Data retention

TEST CONDITIONS

(1)

Flash-programming write

cycles (1)

tWORDPROG

MIN

TYP

MAX

UNIT

10

Years

20,000

Cycles

Word programming time (1)

(1)

ms

10

mA

ICCPROG

Flash-write supply current

tDFERASE

Data flash master erase time (1)

200

ms

tIFERASE

Instruction flash master erase

time (1)

200

ms

tPGERASE

Flash page erase time (1)

20

ms

(1)

5

2

Specified by design. Not production tested

I2C-COMPATIBLE INTERFACE COMMUNICATION TIMING CHARACTERISTICS

3.10

TA = –40°C to 85°C, 2.4 V < VCC < 2.6 V; typical values at TA = 25°C and VCC = 2.5 V (unless otherwise noted)

MAX

UNIT

tr

SCL/SDA rise time

PARAMETER

300

ns

tf

SCL/SDA fall time

300

ns

tw(H)

SCL pulse duration (high)

600

ns

tw(L)

SCL pulse duration (low)

1.3

μs

tsu(STA)

Setup for repeated start

600

ns

td(STA)

Start to first falling edge of SCL

600

ns

tsu(DAT)

Data setup time

100

ns

th(DAT)

Data hold time

0

ns

tsu(STOP)

Setup time for stop

600

ns

t(BUF)

Bus free time between stop and

start

66

μs

fSCL

Clock frequency

(1)

TEST CONDITIONS

MIN

(1)

TYP

400

kHz

If the clock frequency (fSCL) is > 100 kHz, use 1-byte write commands for proper operation. All other transactions types are supported at

400 kHz. (Refer to Section 7.1 and Section 7.3)

Figure 3-1. I2C-Compatible Interface Timing Diagrams

8

ELECTRICAL SPECIFICATIONS

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

SLUSAE3 – OCTOBER 2012

4 GENERAL DESCRIPTION

The bq27620-G1 accurately predicts the battery capacity and other operational characteristics of a single

Li-based rechargeable cell. It can be interrogated by a system processor to provide cell information, such

as time-to-empty (TTE), time-to-full (TTF) and state-of-charge (SOC) as well as SOC interrupt signal to the

host.

Information is accessed through a series of commands, called Standard Commands. Further capabilities

are provided by the additional Extended Commands set. Both sets of commands, indicated by the general

format Command( ), are used to read and write information contained within the device control and status

registers, as well as its data flash locations. Commands are sent from system to gauge using the

bq27620-G1’s I2C serial communications engine, and can be executed during application development,

system manufacture, or end-equipment operation.

Cell information is stored in the device in non-volatile flash memory. Many of these data flash locations are

accessible during application development. They cannot, generally, be accessed directly during endequipment operation. Access to these locations is achieved by either use of the bq27620-G1’s companion

evaluation software, through individual commands, or through a sequence of data-flash-access

commands. To access a desired data flash location, the correct data flash subclass and offset must be

known.

The bq27620-G1 provides a 32-byte user-programmable data flash Manufacturer Info Block. This data

space is accessed through a data flash interface. For specifics on accessing the data flash,

MANUFACTURER INFORMATION BLOCKS.

The key to the bq27620-G1’s high-accuracy gas gauging prediction is Texas Instrument’s proprietary

Impedance Track™ algorithm with Dynamic Voltage Correlation (IT-DVC). This algorithm uses cell

measurements, characteristics, and properties to create state-of-charge predictions that can achieve less

than 5% error across a wide variety of operating conditions and over the lifetime of the battery.

The device utilizes a comprehensive battery model to estimate the average current in real time,

eliminating the need of a sense resistor. When a cell is attached to the device, cell impedance is

computed, open-circuit voltage (OCV), and cell voltage under loading conditions.

The device external temperature sensing is optimized with the use of a high accuracy negative

temperature coefficient (NTC) thermistor with R25 = 10.0kΩ ±1%. B25/85 = 3435K ± 1% (such as Semitec

NTC 103AT). The bq27620-G1 can also be configured to use its internal temperature sensor. When an

external themistor is used, a 18.2k pull up resistor between BT/TOUT and TS pins is also required. The

bq27620-G1 uses temperature to monitor the battery-pack environment, which is used for fuel gauging

and cell protection functionality.

To minimize power consumption, the device has different power modes: NORMAL, SLEEP, HIBERNATE,

and BAT INSERT CHECK. The bq27620-G1 passes automatically between these modes, depending upon

the occurrence of specific events, though a system processor can initiate some of these modes directly.

More details can be found in POWER MODES.

NOTE

FORMATTING CONVENTIONS IN THIS DOCUMENT:

Commands: italics with parentheses and no breaking spaces, e.g., RemainingCapacity( )

Data flash: italics, bold, and breaking spaces, e.g., Design Capacity

Register bits and flags: brackets and italics, e.g., [TDA]

Data flash bits: brackets, italics and bold, e.g., [LED1]

Modes and states: ALL CAPITALS, e.g., UNSEALED mode.

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

9

�bq27620-G1

SLUSAE3 – OCTOBER 2012

4.1

www.ti.com

DATA COMMANDS

4.1.1

STANDARD DATA COMMANDS

The bq27620-G1 uses a series of 2-byte standard commands to enable system reading and writing of

battery information. Each standard command has an associated command-code pair, as indicated in

Table 4-1. Because each command consists of two bytes of data, two consecutive I2C transmissions must

be executed both to initiate the command function, and to read or write the corresponding two bytes of

data. Additional options for transferring data, such as spooling, are described in Section of

Communication. Read/Write permissions depend on the active access mode, SEALED or UNSEALED

(for details on the SEALED and UNSEALED states, see Section 4.4 , Access Modes.)

Table 4-1. Standard Commands

NAME

Control( )

CNTL

AtRate( )

AtRateTimeToEmpty( )

COMMAND CODE

UNITS

SEALED

ACCESS

0x00 / 0x01

N/A

R/W

0x02 / 0x03

mA

R/W

0x04 / 0x05

Minutes

R

Temperature( )

TEMP

0x06 / 0x07

0.1 K

R/W

Voltage( )

VOLT

0x08 / 0x09

mV

R

FLAGS

Flags( )

0x0a / 0x0b

N/A

R

NominalAvailableCapacity( )

0x0c / 0x0d

mAh

R

FullAvailableCapacity( )

0x0e / 0x0f

mAh

R

RemainingCapacity( )

RM

0x10 / 0x11

mAh

R

FullChargeCapacity( )

FCC

0x12 / 0x13

mAh

R

EffectiveCurrent( )

0x14 / 0x15

mA

R

TimeToEmpty( )

0x16 / 0x17

Minutes

R

TimeToFull( )

0x18 / 0x19

Minutes

R

StandbyCurrent( )

0x1a / 0x1b

mA

R

StandbyTimeToEmpty( )

0x1c / 0x1d

Minutes

R

MaxLoadCurrent( )

0x1e / 0x1f

mA

R

MaxLoadTimeToEmpty( )

0x20 / 0x21

Minutes

R

AvailableEnergy( )

0x22 / 0x23

mWh

R

AveragePower( )

0x24 / 0x25

mW

R

0x26 / 0x27

Minutes

R

0x28 / 0x29

% / num

R

0x2A / 0x2B

num

R

TTEatConstantPower( )

StateOfHealth( )

SOH

CycleCount( )

StateOfCharge( )

0x2c / 0x2d

%

R

InternalTemperature( )

0x36 / 0x37

0.1 K

R

OperationConfiguration( )

0x3A / 0x3B

N/A

R

ApplicationStatus()

0x6A / 0x6B

N/A

R

10

SOC

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

4.1.1.1

SLUSAE3 – OCTOBER 2012

Control( ): 0x00/0x01

Issuing a Control( ) command requires a subsequent 2-byte subcommand. These additional bytes specify

the particular control function desired. The Control( ) command allows the system to control specific

features of the bq27620-G1 during normal operation and additional features when the device is in different

access modes, as described in Table 4-2.

Table 4-2. Control( ) Subcommands

CNTL

DATA

SEALED

ACCESS

CONTROL_STATUS

0x0000

Yes

Reports the status of DF checksum, hibernate, IT, etc.

DEVICE_TYPE

0x0001

Yes

Reports the device type in hex digits. (type = 0x0620)

FW_VERSION

0x0002

Yes

Reports the firmware version on the device type

HW_VERSION

0x0003

Yes

Reports the hardware version of the device type

PREV_MACWRITE

0x0007

Yes

Returns previous MAC subcommand code

CHEM_ID

0x0008

Yes

Reports the chemical identifier of the Impedance Track™ configuration

OCV_CMD

0x000c

Yes

Request the gauge to take a OCV measurement

BAT_INSERT

0x000d

Yes

Forces the BAT_DET bit set when the [BIE] bit is 0

BAT_REMOVE

0x000e

Yes

Forces the BAT_DET bit clear when the [BIE] bit is 0

SET_HIBERNATE

0x0011

Yes

Forces CONTROL_STATUS [HIBERNATE] to 1

CLEAR_HIBERNATE

0x0012

Yes

Forces CONTROL_STATUS [HIBERNATE] to 0

DF_VERSION

0x001F

Yes

Returns the Data Flash Version code

SEALED

0x0020

No

Places the bq27620-G1 in SEALED access mode

OPTIMIZ

0x0030

No

Sets the OPTIMIZ bit and enables the optimization cycle

RESET

0x0041

No

Forces a full reset of the bq27620-G1

CNTL FUNCTION

DESCRIPTION

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

11

�bq27620-G1

SLUSAE3 – OCTOBER 2012

www.ti.com

4.1.1.1.1 CONTROL_STATUS: 0x0000

Instructs the fuel gauge to return status information to control addresses 0x00/0x01. The status word

includes the following information.

Table 4-3. CONTROL_STATUS Bit Definitions

High byte

Low byte

bit7

INITCOMP

bit6

FAS

HIBERNATE

bit5

SS

RLearn

bit4

RSVD

SLEEP

bit3

LDMD

bit2

RUP_DIS

bit1

OCVCMDCOMP

VOK

bit0

OCVFAIL

OPTMIZ

FAS = Status bit indicating the bq27620-G1 is in FULL ACCESS SEALED state. Active when set.

SS = Status bit indicating the bq27620-G1 is in SEALED state. Active when set.

OCVCMDCOMP = Status bit indicating the bq27620-G1 has executed the OCV command. This bit can only be set with battery’s presence.

True when set.

OCVFAIL = Status bit indicating bq27620-G1 OCV reading is failed due to the current. This bit can only be set with battery’s presence. True

when set.

INITCOMP = Initialization completion bit indicating the initialization completed. This bit can only be set with battery’s presence. True when

set.

HIBERNATE = Status bit indicating a request for entry into HIBERNATE from SLEEP mode. True when set. Default is 0.

RLean = Indicates that resistance has been learned. True when set.

LDMD = Status bit indicating the bq27620-G1 Impedance Track™ algorithm is using constant-power mode. True when set. Default is 0

(constant-current mode).

RUP_DIS = Status bit indicating the bq27620-G1 Ra table updates are disabled. Updates disabled when set.

VOK = Status bit indicating that a relaxed OCV measurement has occurred, always clears at the onset of charge or discharge currents.

True when set.

OPTMIZ = Status bit indicating the bq27620-G1 is in an optimization mode; when set the gauge is in its optimization mode of operation for

determining Qmax. True when set.

4.1.1.1.2 DEVICE_TYPE: 0x0001

Instructs the fuel gauge to return the device type to addresses 0x00/0x01.

4.1.1.1.3 FW_VERSION: 0x0002

Instructs the fuel gauge to return the firmware version to addresses 0x00/0x01. Refer to Available Options

for the expected data value.

4.1.1.1.4 HW_VERSION: 0x0003

Instructs the fuel gauge to return the hardware version to addresses 0x00/0x01.

4.1.1.1.5 PREV_MACWRITE: 0x0007

Instructs the fuel gauge to return the previous subcommand written to addresses 0x00/0x01. Note: This

subcommand is only supported for previous subcommand codes 0x0000 through 0x0014. For

subcommand codes greater than 0x0009, a value of 0x0007 is returned.

4.1.1.1.6 CHEM_ID: 0x0008

Instructs the fuel gauge to return the chemical identifier for the Impedance Track™ configuration to

addresses 0x00/0x01.

4.1.1.1.7 OCV CMD: 0X000C

This command is to request the gauge to take a OCV reading. This command can only be issued after the

[INICOMP] has been set, indicating the initialization has been completed. The OCV measurement take

place at the beginning of the next repeated 1s firmware synchronization clock. During the same time

period, the SOC_INT will pulse. The host should use this signal to reduce the load current below the C/20

in 8ms for a valid OCV reading. The OCV command [OCVFAIL] bit will be set if the OCV_CMD is issued

when [CHG_INH] is set.

12

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

SLUSAE3 – OCTOBER 2012

4.1.1.1.8 BAT_INSERT: 0X000D

This command is to force the BAT_DET bit to be set when the battery insertion detection is disabled.

When the BIE is set to 0, the battery insertion detection is disabled. The gauge relies on the host to inform

the battery insertion with this command to set the BAT_DET bit.

4.1.1.1.9 BAT_REMOVE: 0X000E

This command is to force the BAT_DET bit to be clear when the battery insertion detection is disabled.

When the BIE is set to 0, the battery insertion detection is disabled. The gauge relies on the host to inform

it of the battery removal with this command to clear the BAT_DET bit.

4.1.1.1.10 SET_HIBERNATE: 0x0011

Instructs the fuel gauge to force the CONTROL_STATUS [HIBERNATE] bit to 1. This will allow the gauge

to enter the HIBERNATE power mode after the transition to SLEEP power state is detected. The

[HIBERNATE] bit is automatically cleared upon exiting from HIBERNATE mode.

4.1.1.1.11 CLEAR_HIBERNATE: 0x0012

Instructs the fuel gauge to force the CONTROL_STATUS [HIBERNATE] bit to 0. This prevents the gauge

from entering the HIBERNATE power mode after the transition to the SLEEP power state is detected. It

can also be used to force the gauge out of HIBERNATE mode.

4.1.1.1.12 DF_VERSION: 0x001F

Instructs the fuel gauge to return the 16-bit data flash revision code to addresses 0x00/0x01. The code is

stored inData Flash Version and provides a simple method for the customer to control data flash

revisions. The default DF_VERSION is 0x0000.

4.1.1.1.13 SEALED: 0x0020

Instructs the fuel gauge to transition from the UNSEALED state to the SEALED state. The fuel gauge must

always be set to the SEALED state for use in end equipment.

4.1.1.1.14 OPTIMIZ: 0x0030

This MAC command should be issued at the end of full charge cycle before the full discharge cycle

begins. This command will set bit 0 (OPTMIZ) of the Control/Status register. When the bit is set and the

gauge detects discharge it will stop using estimated current for Q measurement. Instead it will use

DataFlash IT.LearnCurrent and accumulate charge using that current until discharge termination is

detected from the current estimation engine. At that point the current used by the gauge defaults to zero

mA. This command is only available when the fuel gauge is UNSEALED.

4.1.1.1.15 RESET: 0x0041

This command instructs the fuel gauge to perform a full reset. This command is only available when the

fuel gauge is UNSEALED.

4.1.1.2

AtRateTimeToEmpty( ): 0x04/0x05

This read-word function returns an unsigned integer value of the predicted remaining operating time if the

battery is discharged at the AtRate( ) value in minutes with a range of 0 to 65,534. A value of 65,535

indicates AtRate( ) = 0. The fuel gauge updates AtRateTimeToEmpty( ) within 1 s after the system sets the

AtRate( ) value. The fuel gauge automatically updates AtRateTimeToEmpty( ) based on the AtRate( )

value every 1 s. Both the AtRate( ) and AtRateTimeToEmpty( ) commands must only be used in NORMAL

mode.

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

13

�bq27620-G1

SLUSAE3 – OCTOBER 2012

4.1.1.3

www.ti.com

Temperature( ): 0x06/0x07

This read-/write-word function returns an unsigned integer value of the temperature in units of 0.1 K

measured by the fuel gauge. If [WRTEMP] bit = 1, a write command sets the temperature to be used for

gauging calculations while a read command returns to temperature previously written. If [WRTEMP] bit = 0

and [TEMPS] bit = 0, a read command will return the internal temperature sensor value.

4.1.1.4

Voltage( ): 0x08/0x09

This read-word function returns an unsigned integer value of the measured cell-pack voltage in mV with a

range of 0 to 6000 mV.

4.1.1.5

Flags( ): 0x0a/0x0b

This read-word function returns the contents of the fuel-gauge status register, depicting the current

operating status.

Table 4-4. Flags Bit Definitions

High byte

Low byte

bit7

OTC

–

bit6

OTD

–

bit5

–

OCVGD

bit4

CALEN

NEEDID

bit3

CHG_INH

BATTDET

bit2

XCHG

SOC1

bit1

FC

SYSDOWN

bit0

CHG

DSG

OTC = Overtemperature in charge condition is detected. True when set. SOC_INT will toggle once if set.

OTD = Overtemperature in discharge condition is detected. True when set. SOC_INT will toggle once if set.

CALEN = Status bit indicating the calibration function is enabled. True when set.

CHG_INH = Charge inhibit: unable to begin charging (temperature outside the range [Charge Inhibit Temp Low, Charge Inhibit Temp

High]). True when set.

XCHG = Charge suspend alert (temperature outside the range [Suspend Temperature Low, Suspend Temperature High]). True when

set.

FC = Full-charged condition reached. Set when charge termination condition is met. (RMFCC=1; Set FC_Set % = -1% when RMFCC = 0).

True when set

CHG = (Fast) charging allowed. True when set.

OCVGD = Good OCV measurement taken. True when set.

NEEDID = Waiting to identify inserted battery. True when set.

BATTDET = Battery detected. True when set.

SOC1 = State-of-charge threshold 1 (SOC1 Set) reached. The flag is enabled when BL_INT bit in Operation Configuration B is set. True

when set.

SysDown = SystemDown bit indicating the system shut down. SOC_INT will toggle once if set.

DSG = Discharging detected. True when set.

4.1.1.6

NominalAvailableCapacity( ): 0x0c/0x0d

This read-only command pair returns the uncompensated (less than C/20 load) battery capacity

remaining. Units are mAh.

4.1.1.7

FullAvailableCapacity( ): 0x0e/0x0f

This read-only command pair returns the uncompensated (less than C/20 load) capacity of the battery

when fully charged. Units are mAh. FullAvailableCapacity( ) is updated at regular intervals, as specified by

the IT algorithm.

4.1.1.8

RemainingCapacity( ): 0x10/0x11

This read-only command pair returns the remaining battery capacity which is compensated for the present

conditions of load, temperature and battery age. RemainingCapacity( ) is typically lower than the

uncompensated NominalAvailableCapacity( ). Units are mAh.

4.1.1.9

FullChargeCapacity( ): 0x12/13

This read-only command pair returns the capacity of the battery when fully charged with compensation for

the present conditions of temperature and battery age. FullChargeCapacity( ) is updated at regular

intervals, as specified by the IT algorithm typically lower than the uncompensated

FullAvailableCapacity( )and . Units are mAh.

14

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

4.1.1.10

SLUSAE3 – OCTOBER 2012

EffectiveCurrent( ): 0x14/0x15

This read-only command pair returns a signed integer value that is taken from the Effective current

Calculation being used by DVC algorithm. Units are mA.

4.1.1.11

TimeToEmpty( ): 0x16/0x17

This read-only function returns an unsigned integer value of the predicted remaining battery life at the

present rate of discharge, in minutes. A value of 65,535 indicates battery is not being discharged.

4.1.1.12

TimeToFull( ): 0x18/0x19

This read-only function returns an unsigned integer value of predicted remaining time until the battery

reaches full charge, in minutes, based upon EffectiveCurrent( ). The computation accounts for the taper

current time extension from the linear TTF computation based on a fixed EffectiveCurrent( ) rate of charge

accumulation. A value of 65,535 indicates the battery is not being charged.

4.1.1.13

StandbyCurrent( ): 0x1a/0x1b

This read-only function returns a signed integer value of the measured standby current from the Effective

Current Calculation. The StandbyCurrent( ) is an adaptive measurement. Initially it reports the standby

current programmed in Initial Standby, and after spending several seconds in standby, reports the

measured standby current.

The register value is updated every 1 second when the effective current is above the Deadband and is

less than or equal to 2 × Initial Standby. The first and last values that meet this criteria are not averaged

in, since they may not be stable values. To approximate a 1 minute time constant, each new

StandbyCurrent( ) value is computed by taking approximate 93% weight of the last standby current and

approximate 7% of the effective current calculation.

4.1.1.14

StandbyTimeToEmpty( ): 0x1c/0x1d

This read-only function returns an unsigned integer value of the predicted remaining battery life at the

standby rate of discharge, in minutes. The computation uses Nominal Available Capacity (NAC), the

uncompensated remaining capacity, for this computation. A value of 65,535 indicates battery is not being

discharged.

4.1.1.15

MaxLoadCurrent( ): 0x1e/0x1f

This read-only function returns a signed integer value, in units of mA, of the maximum load conditions.

The MaxLoadCurrent( ) is an adaptive measurement which is initially reported as the maximum load

current programmed in Initial Max Load Current. If the effective current calculation is ever greater than

Initial Max Load Current, then MaxLoadCurrent( ) updates to the new current calculation.

MaxLoadCurrent( ) is reduced to the average of the previous value and Initial Max Load Current whenever

the battery is charged to full after a previous discharge to an SOC less than 50%. This prevents the

reported value from maintaining an unusually high value.

4.1.1.16

MaxLoadTimeToEmpty( ): 0x20/0x21

This read-only function returns an unsigned integer value of the predicted remaining battery life at the

maximum load current discharge rate, in minutes. A value of 65,535 indicates that the battery is not being

discharged.

4.1.1.17

AvailableEnergy( ): 0x22/0x23

This read-only function returns an unsigned integer value of the predicted charge or energy remaining in

the battery. The value is reported in units of mWh.

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

15

�bq27620-G1

SLUSAE3 – OCTOBER 2012

4.1.1.18

www.ti.com

AveragePower( ): 0x24/0x25

This read-only function returns an signed integer value of the average power during battery charging and

discharging. It is negative during discharge and positive during charge. A value of 0 indicates that the

battery is not being discharged. The value is reported in units of mW.

4.1.1.19

TimeToEmptyAtConstantPower( ): 0x26/0x27

This read-only function returns an unsigned integer value of the predicted remaining operating time if the

battery is discharged at the AveragePower( ) value in minutes. A value of 65,535 indicates

AveragePower( ) = 0. The fuel gauge automatically updates TimeToEmptyatContantPower( ) based on the

AveragePower( ) value every 1 s.

4.1.1.20 StateofHealth( ): 0x28/0x29

0x28 SOH percentage: this read-only function returns an unsigned integer value, expressed as a

percentage of the ratio of predicted FCC(25°C, SOH LoadI) over the DesignCapacity(). The FCC(25°C,

SOH LoadI) is the calculated full charge capacity at 25°C and the SOH LoadI which is specified in the

data flash. The range of the returned SOH percentage is 0x00 to 0x64, indicating 0 to 100%

correspondingly.

0x29 SOH Status: this read-only function returns an unsigned integer value, indicating the status of the

SOH percentage. The meanings of the returned value are:

• 0x00: SOH not valid (initialization)

• 0x01: SOH initial value for unidentified pack

• 0x02: SOH final value, pack identified

4.1.1.21

CycleCount( ): 0x2a/0x2b

This read-only function returns an unsigned integer value of the number of cycles that the active cell has

experienced with a range of 0 to 65535. One cycle occurs when accumulated discharge ≥ CC Threshold.

The gauge maintains a separate cycle counter for both cell profiles and will reset to zero if the insertion of

a new pack has been detected.

4.1.1.22

StateOfCharge( ): 0x2c/0x2d

This read-only function returns an unsigned integer value of the predicted remaining battery capacity

expressed as a percentage of FullChargeCapacity( ), with a range of 0 to 100%.

4.1.1.23 InternalTemperature( ): 0x36/0x37

This read-only function returns an unsigned integer value of the internal temperature sensor in units of 0.1

K measured by the fuel gauge. This function can be useful as an additional system-level temperature

monitor if the main Temperature( ) function is configured for external or host reported temperature.

4.1.1.24 OperationConfiguration( ): 0x3a/0x3b

This read-only function returns the contents of the data flash Operation Configuration register and is

most useful for system level debug to quickly determine device configuration.

4.1.1.25 ApplicationStatus(): 0x6a/0x6b

This read-only function returns the contents of the data flash Host Cfg register.

16

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

4.1.2

SLUSAE3 – OCTOBER 2012

EXTENDED DATA COMMANDS

Extended commands offer additional functionality beyond the standard set of commands. They are used in

the same manner; however, unlike standard commands, extended commands are not limited to 2-byte

words. The number of commands bytes for a given extended command ranges in size from single to

multiple bytes, as specified in Table 4-5.

Table 4-5. Extended Data Commands

COMMAND

CODE

UNITS

SEALED

ACCESS (1) (2)

UNSEALED

ACCESS (1) (2)

Reserved

0x34...0x3b

N/A

R

R

DesignCapacity( )

NAME

0x3c / 0x3d

mAh

R

R

DataFlashClass( ) (2)

0x3e

N/A

N/A

R/W

DataFlashBlock( ) (2)

0x3f

N/A

R/W

R/W

BlockData( )

0x40…0x5f

N/A

R

R/W

BlockDataCheckSum( )

0x60

N/A

R/W

R/W

BlockDataControl( )

0x61

N/A

N/A

R/W

ApplicationStatus( )

0x6a

N/A

R

R

0x6b...0x7f

N/A

R

R

Reserved

(1)

(2)

SEALED and UNSEALED states are entered via commands to Control() 0x00/0x01.

In sealed mode, data flash CANNOT be accessed through commands 0x3e and 0x3f.

4.1.2.1

DesignCapacity( ): 0x3c/0x3d

SEALED and UNSEALED Access: This command returns the value is stored in Design Capacity and is

expressed in mAh. This is intended to be the theoretical or nominal capacity of a new pack, but has no

bearing on the operation of the fuel gauge functionality.

4.1.2.2

DataFlashClass( ): 0x3e

UNSEALED Access: This command sets the data flash class to be accessed. The class to be accessed

must be entered in hexadecimal.

SEALED Access: This command is not available in SEALED mode.

4.1.2.3

DataFlashBlock( ): 0x3f

UNSEALED Access: This command sets the data flash block to be accessed. When 0x00 is written to

BlockDataControl( ), DataFlashBlock( ) holds the block number of the data flash to be read or written.

Example: writing a 0x00 to DataFlashBlock( ) specifies access to the first 32-byte block, a 0x01 specifies

access to the second 32-byte block, and so on.

SEALED Access: This command directs which data flash block is accessed by the BlockData( )

command. Writing a 0x01 or 0x02 instructs the BlockData( ) command to transfer the Manufacturer Info

Block. All other DataFlashBlock( ) values are reserved.

4.1.2.4

BlockData( ): 0x40…0x5f

UNSEALED Access: This data block is the remainder of the 32 byte data block when accessing data

flash.

SEALED Access: This data block is the remainder of the 32 byte data block when accessing

Manufacturer Block Info.

4.1.2.5

BlockDataChecksum( ): 0x60

UNSEALED Access: This byte contains the checksum on the 32 bytes of block data read or written to

data flash. The least-significant byte of the sum of the data bytes written must be complemented

([255 – x], for x the least-significant byte) before being written to 0x60.

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

17

�bq27620-G1

SLUSAE3 – OCTOBER 2012

www.ti.com

SEALED Access: This byte contains the checksum for the 32 bytes of block data written to the

Manufacturer Info Block. The least-significant byte of the sum of the data bytes written must be

complemented ([255 – x], for x the least-significant byte) before being written to 0x60.

4.1.2.6

BlockDataControl( ): 0x61

UNSEALED Access: This command is used to control data flash access mode. Writing 0x00 to this

command enables BlockData( ) to access general data flash. Writing a 0x01 to this command enables

SEALED mode operation of DataFlashBlock( ).

SEALED Access: This command is not available in SEALED mode.

4.1.2.7

ApplicationStatus( ): 0x6a

This byte function allows the system to read the bq27620-G1 Host Cfg data flash location. See Table 6-1

for specific bit definitions.

4.1.2.8

18

Reserved — 0x6b–0x7f

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

4.2

4.2.1

SLUSAE3 – OCTOBER 2012

DATA FLASH INTERFACE

ACCESSING THE DATA FLASH

The bq27620-G1 data flash is a non-volatile memory that contains bq27620-G1 initialization, default, cell

status, calibration, configuration, and user information. The data flash can be accessed in several different

ways, depending on what mode the bq27620-G1 is operating in and what data is being accessed.

Commonly accessed data flash memory locations, frequently read by a system, are conveniently

accessed through specific instructions, already described in Section 4.1, DATA COMMANDS . These

commands are available when the bq27620-G1 is either in UNSEALED or SEALED modes.

Most data flash locations, however, are only accessible in UNSEALED mode by use of the bq27620-G1

evaluation software or by data flash block transfers. These locations should be optimized and/or fixed

during the development and manufacture processes. They become part of a golden image file and can

then be written to multiple battery packs. Once established, the values generally remain unchanged during

end-equipment operation.

To access data flash locations individually, the block containing the desired data flash location(s) must be

transferred to the command register locations, where they can be read to the system or changed directly.

This is accomplished by sending the set-up command BlockDataControl( ) (0x61) with data 0x00. Up to 32

bytes of data can be read directly from the BlockData( ) (0x40…0x5f), externally altered, then rewritten to

the BlockData( ) command space. Alternatively, specific locations can be read, altered, and rewritten if

their corresponding offsets are used to index into the BlockData( ) command space. Finally, the data

residing in the command space is transferred to data flash, once the correct checksum for the whole block

is written to BlockDataChecksum( ) (0x60).

Occasionally, a data flash CLASS will be larger than the 32-byte block size. In this case, the

DataFlashBlock( ) command is used to designate which 32-byte block the desired locations reside in. The

correct command address is then given by 0x40 + offset modulo 32. For example, to access Terminate

Voltage in the Gas Gauging class, DataFlashClass( ) is issued 80 (0x50) to set the class. Because the

offset is 44, it must reside in the second 32-byte block. Hence, DataFlashBlock( ) is issued 0x01 to set the

block offset, and the offset used to index into the BlockData( ) memory area is 0x40 + 44 modulo 32 =

0x40 + 12 = 0x40 + 0x0C = 0x4C.

Reading and writing subclass data are block operations up to 32 bytes in length. If during a write the data

length exceeds the maximum block size, then the data is ignored.

None of the data written to memory are bounded by the bq27620-G1 – the values are not rejected by the

fuel gauge. Writing an incorrect value may result in hardware failure due to firmware program

interpretation of the invalid data. The written data is persistent, so a power-on reset does resolve the fault.

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

19

�bq27620-G1

SLUSAE3 – OCTOBER 2012

4.3

www.ti.com

MANUFACTURER INFORMATION BLOCK

The bq27620-G1 contains 32 bytes of user programmable data flash storage called the Manufacturer

Info Block. The method for accessing these memory locations is slightly different, depending on whether

the device is in UNSEALED or SEALED modes.

When in UNSEALED mode and when and 0x00 has been written to BlockDataControl( ), accessing the

manufacturer information blocks is identical to accessing general data flash locations. First, a

DataFlashClass( ) command is used to set the subclass, then a DataFlashBlock( ) command sets the

offset for the first data flash address within the subclass. The BlockData( ) command codes contain the

referenced data flash data. When writing the data flash, a checksum is expected to be received by

BlockDataChecksum( ). Only when the checksum is received and verified is the data actually written to

data flash.

When in SEALED mode or when 0x01 BlockDataControl( ) does not contain 0x00, data flash is no longer

available in the manner used in UNSEALED mode. Rather than issuing subclass information, a

designated Manufacturer Information Block is selected with the DataFlashBlock( ) command. Issuing a

0x01 or 0x02 with this command causes the corresponding information blockto be transferred to the

command space 0x40…0x5f for editing or reading by the system. Upon successful writing of checksum

information to BlockDataChecksum( ), the modified block is returned to data flash. Note: The

Manufacturer Info Block is read-only when in SEALED mode.

20

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

4.4

SLUSAE3 – OCTOBER 2012

ACCESS MODES

The bq27620-G1 provides three security modes (FULL ACCESS, UNSEALED, and SEALED) that control

data flash access permissions, according to Table 4-6. Data Flash refers to those data flash locations,

specified in Section 4.6, that are accessible to the user.

Table 4-6. Data Flash Access

Security Mode

Data Flash

Manufacture Info Block

FULL ACCESS

R/W

R/W

UNSEALED

R/W

R/W

SEALED

None

R

Although FULL ACCESS and UNSEALED modes appear identical, only FULL ACCESS allows the

bq27620-G1 to write access-mode transition keys.

4.5

SEALING/UNSEALING DATA FLASH

The bq27620-G1 implements a key-access scheme to transition between SEALED, UNSEALED, and

FULL-ACCESS modes. Each transition requires that a unique set of two keys be sent to the bq27620-G1

via the Control( ) control command. The keys must be sent consecutively, with no other data being written

to the Control( ) register in between. Note that to avoid conflict, the keys must be different from the codes

presented in the CNTL DATA column of Table 4-2 subcommands.

When in SEALED mode, the CONTROL_STATUS [SS] bit is set, but when the UNSEAL keys are

correctly received by the bq27620-G1, the [SS] bit is cleared. When the full-access keys are correctly

received, then the CONTROL_STATUS [FAS] bit is cleared.

Both the sets of keys for each level are 2 bytes each in length and are stored in data flash. The UNSEAL

key (stored at Unseal Key 0 and Unseal Key 1) and the FULL-ACCESS key (stored at Full-Access Key

0 and Full-Access Key 1) can only be updated when in FULL-ACCESS mode. The order of the keys is

Key 1 followed by Key 0. The order of the bytes entered through the Control( ) command is the reverse of

what is read from the part. For example, if the Key 1 and Key 0 of the Unseal Keys returns 0x1234 and

0x5678, then the Control( ) should supply 0x3412 and 0x7856 to unseal the part.

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

21

�bq27620-G1

SLUSAE3 – OCTOBER 2012

4.6

www.ti.com

DATA FLASH SUMMARY

The following table summarizes the data flash locations available to the user, including their default,

minimum, and maximum values.

Table 4-7. Data Flash Summary

Subclass

ID

Subclass

Class

Offset

Name

Data

Type

Min Value

Max Value

Default Value

Units (EVSW

Units)*

0.1°C

Configuration

2

Safety

0

OT Chg

I2

0

1200

550

Configuration

2

Safety

2

OT Chg Time

U1

0

60

2

s

Configuration

2

Safety

3

OT Chg Recovery

I2

0

1200

500

0.1°C

Configuration

2

Safety

5

OT Dsg

I2

0

1200

600

0.1°C

Configuration

2

Safety

7

OT Dsg Time

U1

0

60

2

s

Configuration

2

Safety

8

OT Dsg Recovery

I2

0

1200

550

0.1°C

Configuration

32

Charge Inhibit Cfg

0

Chg Inhibit Temp Low

I2

-400

1200

0

0.1°C

Configuration

32

Charge Inhibit Cfg

2

Chg Inhibit Temp High

I2

-400

1200

450

0.1°C

Configuration

32

Charge Inhibit Cfg

4

Temp Hys

I2

0

100

50

0.1°C

Configuration

34

Charge

0

Charging Voltage

I2

0

4600

4200

mV

Configuration

34

Charge

2

Delta Temp

I2

0

500

50

0.1°C

Configuration

34

Charge

4

Suspend Low Temp

I2

-400

1200

-50

0.1°C

Configuration

34

Charge

6

Suspend High Temp

I2

-400

1200

550

0.1°C

Configuration

36

Charge Termination

0

Taper Current

I2

0

1000

100

mA

Configuration

36

Charge Termination

2

Min Taper Capacity

I2

0

1000

25

mAh

Configuration

36

Charge Termination

4

Taper Voltage

I2

0

1000

100

mV

Configuration

36

Charge Termination

6

Current Taper Window

U1

0

60

40

s

Configuration

36

Charge Termination

9

FC Set %

I1

-1

100

-1

%

Configuration

36

Charge Termination

10

FC Clear %

I1

-1

100

98

%

Configuration

36

Charge Termination

11

DODatEOC Delta T

I2

0

1000

50

0.1°C

Configuration

48

Data

0

Initial Standby

I1

-256

0

-10

mA

Configuration

48

Data

1

Initial MaxLoad

I2

-32767

0

-750

mA

Configuration

48

Data

3

CC Threshold

I2

100

32767

1050

mAh

Configuration

48

Data

6

Design Capacity

I2

0

32767

1140

mA

Configuration

48

Data

10

Design Voltage

I2

0

32767

3600

MilliVolt

Configuration

48

Data

12

SOH LoadI

I2

-32767

0

-400

mA

Configuration

48

Data

14

Default Temp

I2

0

3050

2982

°K

Configuration

48

Data

16

Data Flash Version

H2

0x0000

0xffff

0x0000

Configuration

48

Data

18

Device Name

S8

x

x

bq27620

-

Configuration

49

Discharge

0

SOC1 Set Threshold

U1

0

255

150

mA

Configuration

49

Discharge

1

SOC1 Clear Threshold

U1

0

255

175

mA

Configuration

49

Discharge

5

SysDown Set Volt Threshold

I2

0

4200

3150

mV

Configuration

49

Discharge

7

SysDown Set Volt Time

U1

0

60

2

s

Configuration

49

Discharge

8

SysDown Clear Volt

I2

0000

4200

3400

mV

Configuration

49

Discharge

15

Def Cell 0 DOD at EOC

I2

0

16384

0

Configuration

49

Discharge

17

Def Avg I Last Run

I2

-32768

32767

-50

mA

Configuration

49

Discharge

19

Def Avg P Last Run

I2

-32768

32767

-50

mWatt

Configuration

64

Registers

0

Op Config

H2

0x0000

0xffff

0x0853

Configuration

64

Registers

2

SOC Delta

U1

0

25

1

%

Configuration

64

Registers

3

i2c Timeout

U1

0

7

4

%

Configuration

64

Registers

4

DF Wr Ind Wait

U2

0

65535

0

%

Configuration

64

Registers

6

OpConfig B

H1

0x00

0xff

0x4b

Configuration

64

Registers

7

OpConfig C

H1

0x00

0xff

0x28

Configuration

64

Registers

8

Clk Ctl Reg

H1

0x00

0x0f

0x09

Hex

Configuration

68

Power

0

Flash Update OK Voltage

I2

0

4200

2800

mV

Configuration

68

Power

4

Sleep Current

I2

0

100

10

mA

Configuration

68

Power

6

Sleep Time

U1

0

100

20

s

22

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

�bq27620-G1

www.ti.com

SLUSAE3 – OCTOBER 2012

Table 4-7. Data Flash Summary (continued)

Class

Subclass

ID

Subclass

Offset

Name

Data

Type

Min Value

Max Value

Default Value

Units (EVSW

Units)*

Configuration

68

Power

7

Hibernate I

U2

0

700

8

mA

Configuration

68

Power

9

Hibernate V

U2

2400

3000

2550

mV

System Data

57

Manufacturer Info

0-31

Block [0-31]

H1

0x00

0xff

[Table]

-

Gas Gauging

80

IT Cfg

0

Load Select

U1

0

255

1

Gas Gauging

80

IT Cfg

1

Load Mode

U1

0

255

0

Gas Gauging

80

IT Cfg

21

Max Res Factor

U1

0

255

15

Gas Gauging

80

IT Cfg

22

Min Res Factor

U1

0

255

5

Gas Gauging

80

IT Cfg

24

Ra Filter

U2

0

1000

800

Gas Gauging

80

IT Cfg

44

Terminate Voltage

I2

-32768

32767

3200

mV

Gas Gauging

80

IT Cfg

46

Term V Delta

I2

0

4200

200

mV

Gas Gauging

80

IT Cfg

49

ResRelax Time

U2

0

65534

500

s

Gas Gauging

80

IT Cfg

53

User Rate-mA

I2

-2000

-100

0

mA

Gas Gauging

80

IT Cfg

55

User Rate-mW

I2

-7200

-350

0

cW

Gas Gauging

80

IT Cfg

57

Reserve Cap-mAh

I2

0

9000

0

mA

Gas Gauging

80

IT Cfg

59

Reserve Cap-mWh

I2

0

14000

0

10mW

Gas Gauging

80

IT Cfg

64

Min Delta Voltage

I2

-32000

32000

0

Gas Gauging

80

IT Cfg

68

Ra Max Delta

U2

0

65535

44

Gas Gauging

80

IT Cfg

70

DeltaV Max dV

U2

0

65535

10

mV

Gas Gauging

80

IT Cfg

72

Max Res Scale

U2

0

32767

5000

Num

Gas Gauging

80

IT Cfg

74

Min Res Scale

U2

0

32767

200

Num

Gas Gauging

80

IT Cfg

76

Fast Scale Start SOC

U1

0

100

10

%

Gas Gauging

80

IT Cfg

83

LC Dection Sensitivity

U1

0

100

80

%

Gas Gauging

81

Current Thresholds

6

Dsg Relax Time

U2

0

8191

60

s

Gas Gauging

81

Current Thresholds

8

Chg Relax Time

U1

0

255

60

s

Gas Gauging

81

Current Thresholds

9

Quit Relax Time

U1

0

63

1

s

Gas Gauging

81

Current Thresholds

10

Transient Factor Charge

U1

0

255

128

Gas Gauging

81

Current Thresholds

11

Transient Factor Discharge

U1

0

255

128

Gas Gauging

81

Current Thresholds

12

Max IR Correct

U2

0

1000

400

Gas Gauging

82

State

0

Host Cfg

H1

0x01

0xff

0x00

Gas Gauging

82

State

1

Qmax Cell 0

I2

0

32767

16384

Gas Gauging

82

State

3

Cycle Count0

U2

0

65535

0

Gas Gauging

82

State

5

Qmax Cell 1

I2

0

32767

16384

Gas Gauging

82

State

7

Cycle Count 1

U2

0

65535

0

Gas Gauging

82

State

9

Chg DoD0 C 0

U2

0

65535

0

Gas Gauging

82

State

11

Chg DoD0 C 1

U2

0

65535

0

Gas Gauging

82

State

15

DoDatEOC

U2

0

65535

0

Gas Gauging

82

State

25

T Rise

U2

0

65535

20

Num

Gas Gauging

82

State

27

T Time Constant

U2

0

65535

1000

Num

OCV Table

83

OCVa Table

0

Chem ID

H2

0x0000

0xffff

0x1124

hex

Default Ra

Tables

85

Def Ra

0

Cell0 R_a flag

H1

0x00

0x00

0x55

-

Default Ra

Tables

85

Def Ra

1

Cell0 R_a 0

I2

1

32767

424

2-10Ω

Default Ra

Tables

85

Def Ra

3

Cell0 R_a 1

I2

1

32767

509

2-10Ω

Default Ra

Tables

85

Def Ra

5

Cell0 R_a 2

I2

1

32767

538

2-10Ω

Default Ra

Tables

85

Def Ra

7

Cell0 R_a 3

I2

1

32767

535

2-10Ω

Default Ra

Tables

85

Def Ra

9

Cell0 R_a 4

I2

1

32767

461

2-10Ω

Default Ra

Tables

85

Def Ra

11

Cell0 R_a 5

I2

1

32767

460

2-10Ω

Default Ra

Tables

85

Def Ra

13

Cell0 R_a 6

I2

1

32767

509

2-10Ω

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: bq27620-G1

mΩ

mV

rate

rate

23

�bq27620-G1

SLUSAE3 – OCTOBER 2012

www.ti.com

Table 4-7. Data Flash Summary (continued)

Class

Subclass

ID

Subclass

Offset

Name

Data

Type

Min Value

Max Value

Default Value

Units (EVSW

Units)*

Default Ra

Tables

85

Def Ra

15

Cell0 R_a 7

I2

1

32767

578

2-10Ω

Default Ra

Tables

85

Def Ra

17

Cell0 R_a 8

I2

1

32767

563

2-10Ω

Default Ra

Tables

85

Def Ra

19

Cell0 R_a 9

I2

1

32767

544

2-10Ω

Default Ra

Tables

85

Def Ra

21

Cell0 R_a 10

I2

1

32767

574

2-10Ω

Default Ra

Tables

85

Def Ra

23

Cell0 R_a 11

I2

1

32767

726

2-10Ω

Default Ra

Tables

85

Def Ra

25

Cell0 R_a 12

I2

1

32767

956

2-10Ω

Default Ra

Tables

85

Def Ra

27

Cell0 R_a 13

I2

1

32767

1222

2-10Ω

Default Ra

Tables

85

Def Ra

29

Cell0 R_a 14

I2

1

32767

8099

2-10Ω

Ra Table

88

R_a0

0

Cell0 R_a flag

H1

0x00

0x255

0x55

-

Ra Table

88

R_a0

1

Cell0 R_a 0

I2

1

32767

424

2-10Ω

Ra Table

88

R_a0

3

Cell0 R_a 1

I2

1

32767

509

2-10Ω

Ra Table

88

R_a0

5

Cell0 R_a 2

I2

1

32767

538

2-10Ω

Ra Table

88

R_a0

7

Cell0 R_a 3

I2

1

32767

535

2-10Ω

Ra Table

88

R_a0

9

Cell0 R_a 4

I2

1

32767

461

2-10Ω

Ra Table

88

R_a0

11

Cell0 R_a 5

I2

1

32767

460

2-10Ω

Ra Table

88

R_a0

13

Cell0 R_a 6

I2

1

32767

509

2-10Ω

Ra Table

88

R_a0

15

Cell0 R_a 7

I2

1

32767

578

2-10Ω

Ra Table

88

R_a0

17

Cell0 R_a 8

I2

1

32767

563

2-10Ω

Ra Table

88

R_a0

19

Cell0 R_a 9

I2

1

32767

544

2-10Ω

Ra Table

88

R_a0

21

Cell0 R_a 10

I2

1

32767

574

2-10Ω

Ra Table

88

R_a0

23

Cell0 R_a 11

I2

1

32767

726

2-10Ω

Ra Table

88

R_a0

25

Cell0 R_a 12

I2

1

32767

956

2-10Ω

Ra Table

88

R_a0

27

Cell0 R_a 13

I2

1

32767

1222

2-10Ω

Ra Table

88

R_a0

29

Cell0 R_a 14

I2

1

32767

8099

2-10Ω

Ra Table

89

R_a1

0

Cell1 R_a flag

H1

0x00

0x255

0x55

-

Ra Table

89

R_a1

1

Cell1 R_a 0

I2

1

32767

424

2-10Ω

Ra Table

89

R_a1

3

Cell1 R_a 1

I2

1

32767

509

2-10Ω

Ra Table

89

R_a1

5

Cell1 R_a 2

I2

1

32767

538

2-10Ω

Ra Table

89

R_a1

7

Cell1 R_a 3

I2

1

32767

535

2-10Ω

Ra Table

89

R_a1

9

Cell1 R_a 4

I2

1

32767

461

2-10Ω

Ra Table

89

R_a1

11

Cell1 R_a 5

I2

1

32767

460

2-10Ω

Ra Table

89

R_a1

13

Cell1 R_a 6

I2

1

32767

509

2-10Ω

Ra Table

89

R_a1

15

Cell1 R_a 7

I2

1

32767

578

2-10Ω

Ra Table

89

R_a1

17

Cell1 R_a 8

I2

1

32767

563

2-10Ω

Ra Table

89

R_a1

19

Cell1 R_a 9

I2

1

32767

544

2-10Ω

Ra Table

89

R_a1

21

Cell1 R_a 10

I2

1

32767

574

2-10Ω

Ra Table

89

R_a1

23

Cell1 R_a 11

I2

1

32767

726

2-10Ω

Ra Table

89

R_a1

25

Cell1 R_a 12

I2

1

32767

956

2-10Ω

Ra Table

89

R_a1

27

Cell1 R_a 13

I2

1

32767

1222

2-10Ω

Ra Table

89

R_a1

29

Cell1 R_a 14

I2

1

32767

8099

2-10Ω

Ra Table

90

R_a0x

0

xCell0 R_a flag

H1

0x00

0x255

0x55

-

Ra Table

90

R_a0x

1

xCell0 R_a 0

I2

1

32767

424

-10

2 Ω

Ra Table

90

R_a0x

3

xCell0 R_a 1

I2

1

32767

509

2-10Ω

24

GENERAL DESCRIPTION

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback