User's Guide

SLUUAH1 – June 2013

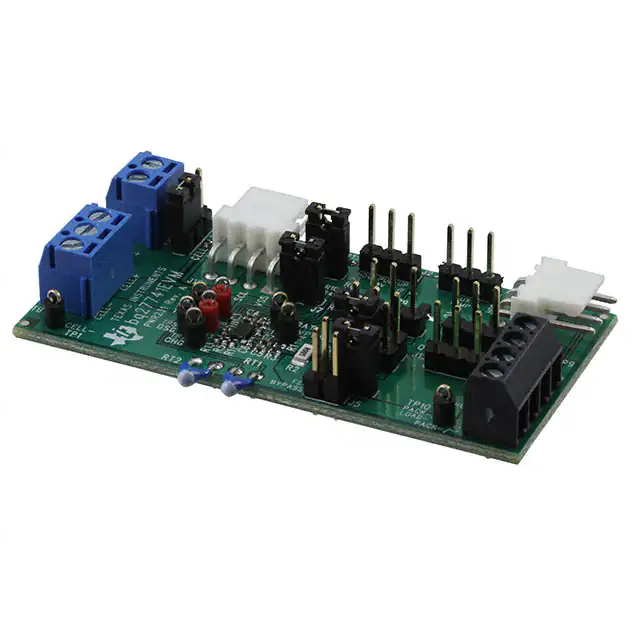

bq27741EVM Single-Cell Impedance Track™ Technology

Evaluation Module

This evaluation module (EVM) is a complete evaluation system for the bq27741-G1. The EVM includes

one bq27741 circuit module, a current sense resistor, two thermistors, and two protection N-FETs. An

EV2400 PC interface board and a PC USB cable are required for gas gauge interface, but must be

ordered separately. The circuit module includes one bq27741 integrated circuit and all other onboard

components necessary to monitor and predict capacity for a pack-side fuel gauge solution and to perform

the protection. The circuit module connects directly across the battery cell. With the EV2400 interface

board and software, the user can read the bq27741 data registers, program the chipset for different pack

configurations, log cycling data for further evaluation, and evaluate the overall functionality of the bq27741

solution under different charge and discharge conditions. The latest Windows™-based PC software can

be downloaded from the product folder on the Texas Instruments Web site.

1

2

3

4

5

6

7

8

9

10

11

12

Contents

Features ...................................................................................................................... 2

bq27741-Based Circuit Module ........................................................................................... 2

Circuit Module Physical Layouts, Bill of Materials, and Schematic ................................................... 3

EVM Hardware and Software Setup ..................................................................................... 8

Troubleshooting Unexpected Dialog Boxes ............................................................................. 8

Hardware Connection ...................................................................................................... 8

Operation ................................................................................................................... 11

Calibrate Screen ........................................................................................................... 14

Firmware Screen .......................................................................................................... 16

Preparing the Mass Production File ..................................................................................... 17

Send HDQ Screen ........................................................................................................ 23

Related Documentation From Texas Instruments ..................................................................... 23

List of Figures

1

bq27741EVM Layout, Silk Screen ........................................................................................ 3

2

Top Assembly ............................................................................................................... 4

3

Top Layer .................................................................................................................... 4

4

Bottom Layer

5

Schematic .................................................................................................................... 7

6

bq27741 Circuit Module Connection to Cell and System Load/Charger

7

GaugeStudio Screen ...................................................................................................... 11

8

DataMemory Screen ...................................................................................................... 12

9

Calibration Screen ......................................................................................................... 14

10

Firmware Screen

11

12

13

14

15

16

................................................................................................................

............................................

..........................................................................................................

bqCONFIG Screen ........................................................................................................

Configuration Parameters Screen .......................................................................................

Calibration Averaging Tool Screen ......................................................................................

Chemistry Screen .........................................................................................................

Learning Cycle Screen....................................................................................................

Create Image Files Screen ...............................................................................................

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

4

9

16

17

18

19

20

21

22

1

�Features

www.ti.com

List of Tables

1

1

Ordering Information ........................................................................................................ 2

2

Bill of Materials .............................................................................................................. 5

3

Performance Specification Summary..................................................................................... 8

4

Circuit Module to EV2300 Connections – I2C .......................................................................... 10

5

Circuit Module to EV2300 Connections – HDQ ....................................................................... 10

Features

•

•

•

•

•

1.1

Complete evaluation system for the bq27741 gas gauge with Impedance Track™ Technology

Populated circuit module for quick setup

Personal computer (PC) software and interface board for easy evaluation

Software that allows data logging for system analysis

Ability to upgrade to the latest firmware version by flash reprogramming

Kit Contents

•

bq27741 circuit module

This EVM is used for the evaluation of different bq27741-based products. Please ensure that you visit the

product Web folder at http://www.ti.com to download the latest firmware version, evaluation software, and

documentation for the associated product to be evaluated.

1.2

Ordering Information

Table 1. Ordering Information

2

EVM Part Number

Chemistry

Configuration

Capacity

bq27741EVM

Li-Ion

1 cell

Any

bq27741-Based Circuit Module

The bq27741-based circuit module is a complete and compact example solution of a bq27741 circuit for

battery management. The circuit module incorporates a bq27741 battery gas gauge IC, dual N-FETs for

high-side protection, and all other components necessary to protect and accurately predict the capacity of

a 1-series Li-Ion cell.

2.1

Circuit Module Connections

Contacts on the circuit module provide the following connections:

• Direct connection to the battery cell (TB1 or TP1/TP2): CELL+ and CELL–

• Connect a charger power to TB2: PACK+ and PACK–, or short the PACK+ and CELL+ to wake up the

gauge, then remove the connection of PACK+ and CELL+ or the charger

• To the serial communications port: SDA, SCL, and VSS (J10) or HDQ and VSS (J8)

• The system load and charger connect across charger and load (TB2 or TP9/TP10): PACK–/LOAD–

and PACK+/LOAD+.

Impedance Track is a trademark of Texas Instruments.

Windows is a trademark of Microsoft Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

I2C is a trademark of NXP B.V Corporation.

2

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Circuit Module Physical Layouts, Bill of Materials, and Schematic

www.ti.com

2.2

Pin Descriptions

Pin Name

PACK+

PACK–

CELL+

CELL–

TERM

SDA

SCL

HDQ

VSS

3

Description

Pack positive terminal

Pack negative terminal

Cell positive terminal

Cell negative terminal

Thermistor input that leads to IC TS pin

I2C communication data line

I2C communication clock line

Single-wire communication line

Signal return for communication line

Circuit Module Physical Layouts, Bill of Materials, and Schematic

This section contains the printed-circuit board (PCB) layout, bill of materials, assembly drawings, and

schematic for the bq27741 circuit module.

3.1

Board Layout

This section shows the printed-circuit board (PCB) layers (Figure 1 through Figure 4), assembly drawing,

and schematic for the bq27741 module.

RT2

C5 R3

RT1

HDQ

J11

Q3

TB2

HDQ

Q1

THERM

R2 J6

FET

BYPASS

PACK+/

LOAD+

Q4

J13

J12

TP9

TP10

J5

LOAD-

DSG

TP7

CHG

TP3

VPWR

C1

C7

R1 TP4

U1C3

RA0

TP5

Q2

TP11 BAT

C2

R13

R5

R11

C6

TS

C8

TP8

J15

VSS

R14R15

C4

R6

R7 D2

J14

J7

VSS

SCL

SDA

TP6

REG25

D1

Ext.

CELL

+

PWR231 Rev. A

bq27741EVM

VSS Ext.

CELL+

CELLTEXAS INSTRUMENTS

J10

R9

1

CELLTP1

R8

R10

R4

AUX

TEMP

1

TB1

HDQ PULLUP

INT. 1.8V Pull up

1

CELL+

TP2

J8

J2 J3

R18

J9

1

J4

J1

PACK-/

LOADPACK-/

Figure 1. bq27741EVM Layout, Silk Screen

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

3

�Circuit Module Physical Layouts, Bill of Materials, and Schematic

www.ti.com

Figure 2. Top Assembly

Figure 3. Top Layer

Figure 4. Bottom Layer

4

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Circuit Module Physical Layouts, Bill of Materials, and Schematic

www.ti.com

3.2

Bill of Materials and Schematic

Table 2. Bill of Materials

Count

Reference

Designator

Value

6

C1, C2, C5,

C6, C7, C8

0.1 µF

1

C3

1 µF

1

C4

2

Description

Size

Part Number

MFR

Capacitor, Ceramic, 10 V,

X5R, 10%

0402

GRM155R61A104KA01D

Murata

Capacitor, Ceramic, 6.3 V,

X5R, 10%

0402

GRM155R60J105KE19D

Murata

0.47 µF

Capacitor, Ceramic, 0.47

µF, 6.3 V, X5R, 10%

0402

GRM155R60J474KE19D

Murata

D1, D2

AZ23C5V6-7

Diode, Dual, Zener, 5.6 V,

300 mW

SOT23

AZ23C5V6-7-F

Diodes

1

J1

ED555/2DS

Terminal Block, 2-pin, 6-A,

3.5 mm

0.27 x 0.25

inch

ED555/2DS

OST

9

J2, J3, J4,

J6, J11,

J12, J13,

J14, J15

PEC03SAAN

Header, Male 3-pin, 100mil 0.100 inch x

spacing

3

PEC03SAAN

Sullins

3

J5, J7, J9

PEC02SAAN

Header, Male 2-pin, 100mil 0.100 inch x

spacing

2

PEC02SAAN

Sullins

2

J8, J10

22-05-3041

1

Q1

0

Q2, Q3, Q4

2

1

Header, Friction Lock

Ass'y, 4-pin Right Angle,

0.400 x

0.500

22-05-3041

Molex

UPA2375T1P-E1A

MOSFET, Dual N-Channel

NexFET, 12 V 3.2 A

WSCP

UPA2375T1P-E1-A

Renesas

Electronics

America

DNP

MOSFET, Dual N-Channel

NexFET, 12 V 3.2 A

WSCP

UPA2375T1P-E1-A

Renesas

Electronics

America

R1, R3

200 Ω

Resistor, Chip, 1/16-W, 5%

0402

CRCW0402200RJNED

Vishay Dale

R12

4.7 kΩ

Resistor, Chip, 1/16-W, 5%

0402

CRCW04024K70JNED

Vishay Dale

1

R13

2 kΩ

Resistor, Chip, 1/16-W, 5%

0402

CRCW04022K00JNED

Vishay Dale

2

R14, R15

10 kΩ

Resistor, Chip, 1/16-W, 5%

0402

CRCW040210K0JNED

Vishay Dale

2

R16, R17

10 Ω

Resistor, Chip, 1/16-W, 5%

0402

CRCW040210R0JNED

Vishay Dale

1

R2

5 mΩ

Res, Metal Current sense,

1W, ±1%, 50 ppm

1632

MCS1632R005FER

Ohmite

6

R4, R6, R7,

R8, R9 R10

100 Ω

Resistor, Chip, 1/16-W, 5%

0402

CRCW0402100RJNED

Vishay Dale

2

R5, R11

1 kΩ

Resistor, Chip, 1/16-W, 5%

0402

CRCW04021K00JNED

Vishay Dale

2

RT1, RT2

10 kΩ

Thermistor, 10 kΩ

0.095 x

0.150 inch

103AT-2

Semitec

1

TB1

ED1515

Terminal Block, 3-pin, 6-A,

3.5 mm

0.41 x 0.25

inch

ED555/3DS

OST

1

TB2

ED555/4DS

Terminal Block, 4-pin, 6-A,

3.5 mm

0.55 x 0.25

inch

ED555/4DS

OST

7

TP1, TP4,

TP5, TP7,

TP8, TP10,

TP11

5001

Test Point, Black, Thru

Hole Color Keyed

0.100 x

0.100 inch

5001

Keystone

4

TP2, TP3,

TP6, TP9

5000

Test Point, Red, Thru Hole

Color Keyed

0.100 x

0.100 inch

5000

Keystone

1

U1

bq27741YZFR-G1 IC, Single Cell Li-Ion Pack

Side Fuel Gauge with

Integrated Protection

BGA-15

bq27741YZFR-G1

TI

1

--

PCB

PWR231

Any

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

5

�Circuit Module Physical Layouts, Bill of Materials, and Schematic

www.ti.com

(1) These assemblies are ESD sensitive, ESD precautions should be observed.

(2) These assemblies must be clean and free from flux and all contaminants.

Use of no clean flux is not acceptable.

(3) These assemblies must comply with workmanship standards IPC-A-610 Class 2.

(4) Ref designators marked with an asterisk ('**') cannot be substituted.

All other components can be substituted with equivalent manufacturer's components.

6

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Circuit Module Physical Layouts, Bill of Materials, and Schematic

www.ti.com

Figure 5. Schematic

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

7

�EVM Hardware and Software Setup

3.3

www.ti.com

bq27741 Circuit Module Performance Specification Summary

This section summarizes the performance specifications of the bq27741 circuit module.

Table 3. Performance Specification Summary

Specification

4

Min

Typ

Max

Unit

Input voltage Pack+ to Pack–

2.7

3.6

4.35

V

Charge and discharge current

0

1

2

A

EVM Hardware and Software Setup

This section describes how to install the bq27741EVM PC software, and how to connect the different

components of the EVM.

4.1

System Requirements

The GaugeStudio software requires Windows XP or later. Using later versions of Windows operating

system can have issues with the USB driver support. The EV2300 USB drivers have been tested for

Windows 98SE, but no assurance is made for problem-free operation with specific system configurations.

EV2300 is not officially supported for 64-bit versions of Windows and typically does not work with

Windows 7 or newer. EV2400 is the recommended USB-I2C interface for Windows 7 and other 64-bit

versions.

4.2

Software Installation

Find the latest software version in the bq27741 tool folder on power.ti.com. Make a search by Part

Number for bq27741 to access the tool folder. Currently the most recent firmware version is bq27741-G1.

Use the following steps to install the bq27741 GaugeStudio software:

1. Ensure that the EV2300 or EV2400 is not connected to the personal computer (PC) through the USB

cable before starting this procedure.

2. Open the archive containing the installation package, and copy its contents into a temporary directory.

3. Open the software file that was downloaded from the TI Web site.

4. Follow the instructions on screen until completing the software installation.

5. Before starting the evaluation software, connect the EV2300 or EV2400 to the computer using the USB

cable.

6. If EV2300 is connected, wait until system prompt New Hardware Found appears. Choose Select

Location Manually, and use the Browse button to point to subdirectory TIUSBWin2K-XP-1.

7. Answer Continue to the warning that drivers are not certified with Microsoft®

8. If the EV2300 is connected, after the previous installation finishes, another system prompt New

Hardware Found appears. Repeat steps through , but specify the directory as TIUSBWin2K-XP-2.

9. Answer Continue to the warning that drivers are not certified with Microsoft. Driver installation is now

finished.

10. For the EV2400, the driver should be installed along with software installation.

5

Troubleshooting Unexpected Dialog Boxes

The user who is downloading the files must be logged in as the administrator. The driver is not signed, so

the administrator must allow installation of unsigned drivers in the operating system. If using Windows 7,

install the software with administrator privileges.

6

Hardware Connection

The bq27741EVM-001 comprises three hardware components:

• bq27741 circuit module

• EV2300 PC interface board

8

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Hardware Connection

www.ti.com

•

.

6.1

PC

Connecting the bq27741 Circuit Module to a Battery Cell

SMB I2C HDQ

Figure 6 shows how to connect the bq27741 circuit module to the cell and system load/charger.

USB

EV2300

C2

RT2

R1 TP4

VPWR

C1

C7

R13

R5

R11

C6

TP3

DSG

TP7

CHG

C5 R3

RT1

Q4

J13

J12

HDQ

Q3

TB2

Load

J11

Charger

HDQ

Q1

THERM

R2 J6

FET

BYPASS

PACK+/

LOAD+

Q2

TP11 BAT

TP9

TP10

J5

LOAD-

TP5

J15

VSS

R14R15

RA0

U1C3

TS

C8

TP8

C4

R6

R7 D2

J14

J7

VSS

SCL

SDA

TP6

REG25

D1

Ext.

CELL

+

PWR231 Rev. A

bq27741EVM

VSS Ext.

CELL+

CELLTEXAS INSTRUMENTS

CELLTP1

J10

R9

1

TB1

R8

R10

R4

AUX

TEMP

1

Power

Supply

3.6V

HDQ PULLUP

INT. 1.8V Pull up

1

CELL+

TP2

J9

J8

J2 J3

R18

1

J4

J1

PACK-/

LOADPACK-/

bq27741 EVM

Figure 6. bq27741 Circuit Module Connection to Cell and System Load/Charger

6.2

PC Interface Connection

The bq27741 can be configured as an HDQ communication device or left in default as an I2C™ device.

Once the bq27741 is configured for HDQ communication, it cannot be reverted to I2C mode. See

Section 11 for information on configuring the bq27741 to HDQ mode.

The following steps configure the hardware for interfacing to the PC:

1. Connect the bq27741-based EVM to the EV2300 using wire leads as shown in Table 4 and Table 5.

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

9

�Hardware Connection

www.ti.com

2

Table 4. Circuit Module to EV2300 Connections – I C

bq27741-Based Battery (I2C Mode)

EV2300 (I2C Port)

SDA

SDA

SCL

SCL

VSS

GND

Table 5. Circuit Module to EV2300 Connections – HDQ

bq27741-Based Battery (HDQ Mode)

EV2300 (HDQ Port)

HDQ

HDQ

VSS

GND

2. Connect a charger to wake-up the gauge, can use a power supply between PACK+ and PACK– or

short CELL+ and PACK+. After wake-up, the charger can be removed.

3. Connect the PC USB cable to the EV2300 and the PC USB port.

The bq27741EVM is now set up for operation.

10

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Operation

www.ti.com

7

Operation

This section details the operation of the GaugeStudio software.

7.1

Starting the Program

Run GaugeStudio from the Start → Programs → Texas Instruments → GaugeStudio menu sequence. The

main GaugeStudio window (see Figure 7) appears. The window consists of a tools panel at the top, and

other child windows that can be hidden, docked in various positions or allowed to float as separate

windows.

When GaugeStudio first starts up the Gauge Dashboard window, the Registers window, and DataMemory

window should be seen in the main window. Registers, DataMemory, Commands, and other windows can

be added to the main window by clicking on the corresponding icon in the tools panel at the top of the

main window.

Data should appear initially in the Gauge Dashboard, Registers, and DataMemory sections. The Refresh

(single-time scan) or the Scan (continuous scan) buttons can be clicked to update the data in the

Registers and DataMemory windows. The continuous scan is enabled when the Scan checkbox is

highlighted green and disabled when the Scan checkbox is not highlighted.

The continuous scanning interval can be set with the stopwatch icon next to the Scan button. When the

stopwatch icon is clicked, a drop-down menu appears and the desired scanning interval can be selected.

The scan interval value shows up next to the stopwatch icon.

Figure 7. GaugeStudio Screen

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

11

�Operation

www.ti.com

GaugeStudio provides a logging function which logs selected Data Registers and Data Memory values last

received from the bq27741. To enable this function, click the DataLog icon in the Tools panel. The

DataLog window will appear below the Registers and DataMemory windows. Registers and DataMemory

parameters can be added to the log by clicking on the Add Register and Add DataMemory Parameter

drop-down menus in the DataLog window and then selected the desired Registers or DataMemory

parameters to be added to the log. After all the desired Registers and DataMemory parameters have been

added to the log, click the Play button in order to begin logging. A Stop button will replace the Play button

once logging starts, the Stop button can be clicked to stop logging. The log can be saved by clicking on

the Save icon and specifying a file name.

The logging intervals are specified by the value next to the stopwatch icon in the DataLog window. In

order to change the logging intervals, click the stopwatch icon and choose one of the intervals provided in

the menu selections that appear. Logging interval values will show up next to the stopwatch icon.

Figure 7 shows the main GaugeStudio window. Additional Flag and Status data can be viewed at the

bottom of the Registers window.

Each window can be resized and docked in various positions within the main GaugeStudio window. Each

window can also be pulled out from the main window and allowed its own floating window. Also, the

Gauge Dashboard window and all windows that are enabled in the Tools panel in the Communication and

Debug sections can be set to autohide.

7.2

Setting Programmable bq27741 Options

The bq27741 data flash comes configured per the default settings detailed in the bq27741 data sheet

(SLUSBF2). Ensure that the settings are correctly changed to match the pack and application for the

bq27741 solution being evaluated.

IMPORTANT: The correct setting of these options is essential to get the best performance. The settings

can be configured using the DataMemory window seen in the main GaugeStudio window (see Figure 8).

Figure 8. DataMemory Screen

To read all the data flash from the bq27741, click on the Refresh button in the DataMemory window.

12

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Operation

www.ti.com

To write to a data flash location, click on the desired location, enter the data in dialog box and click “OK”

or hit the Enter key. The data flash must be read before any writes are performed to avoid any incorrect

data being written to the device. Reading the data after any writes is also recommended.

The data-flash configuration can be saved to a file by clicking the Export button and entering a file name.

A data-flash file also can be retrieved in this way by clicking the Import button. The exported file has a .gg

extension and can be opened and edited with a text editor. It does not contain all of the data flash. It only

contains the public volatile parameters and should not be used for production programming. The .senc,

.dfi, .dffs, .bqfs, or .dmi file should be used for production as these contain the entire data flash image,

including hidden static parameters such as the battery profile.

The module calibration data is also stored in the bq27741 data flash.

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

13

�Calibrate Screen

8

www.ti.com

Calibrate Screen

To ensure proper calibration, perform the following steps. These steps may or may not be required,

depending on the type of calibration being performed. Only one calibration item can be selected and

calibrated at a time.

8.1

To Calibrate the bq27741

Calibrate each item one at a time in the order presented in this document. Select the types of calibration

to be performed by clicking the corresponding button (see Figure 9).

Enter the measured values for the types selected, if necessary.

Then press the “Calibrate” button. After all calibration is complete, close the Calibrate screen.

Figure 9. Calibration Screen

8.2

Temperature Calibration

•

•

•

•

8.3

Pack Voltage Calibration

•

•

•

14

Select if the temperature sensor to calibrate is the internal or the external.

Measure the temperature for PACK.

Type the temperature value into Enter measured value.

Press the Calibrate button.

Measure the voltage across Pack+ and Pack– with a calibrated meter.

Type the voltage value in mV into Enter measured value.

Press the Calibrate button.

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Calibrate Screen

www.ti.com

8.4

Coulomb Counter Offset Calibration

This performs the internal calibration of the coulomb counter input offset. Press the Calibrate Part as

indicated below button.

8.5

Board Offset Calibration

This performs the offset calibration for the current offset of the board. It takes approximately 35 seconds to

complete.

It is expected that no current is flowing through the sense resistor while performing this calibration step.

Remove load and short PACK– to LOAD–.

Press the “Calibrate” button.

Remember to calibrate board offset after coulomb counter calibration.

8.6

Current Calibration

•

•

•

•

Connect a load to LOAD– and LOAD+ that draws approximately 1 A, or connect a current source to

PACK+ and Cell+. Ensure that the Measured Current reported is negative, or else reverse the

connections.

Measure the current with a calibrated meter, and type the value into Enter measured Current using (–)

for current in discharge direction.

Press the “Calibrate” button.

Disconnect or stop the load current after calibration.

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

15

�Firmware Screen

9

www.ti.com

Firmware Screen

Firmware screen is used to save or program a complete flash image from or to the gauge. This is done

using a .senc file, which contains the instruction flash image (firmware) and the data flash image. (Figure

10) The bq27741EVM may or may not be shipped with the latest firmware version (currently bq27741-G1

v1.05).

Figure 10. Firmware Screen

16

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Preparing the Mass Production File

www.ti.com

10

Preparing the Mass Production File

BqCONFIG is a tool which allows user to configure the gauge. It is based on Q&A and can help user to

generate mass production files step by step.

Download the bqCONFIG from the bq27741 tool folder and install. Run GaugeStudio from the Start →

Programs → Texas Instruments → bqCONFIG menu sequence. The main GaugeStudio window

(Figure 11) appears.

All sections of preparing the mass production files are shown as a tools panel at the top.

Figure 11. bqCONFIG Screen

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

17

�Preparing the Mass Production File

www.ti.com

10.1 Initial Update and Configuration Parameters

Initial Update section can initialize BQ27741 with an existing configuration. It is recommended to update a

new version default firmware for a new project. Download the .senc file from the bq27741 tool folder and

use “Tools→ Update Device Firmware” menu to program a .senc file into the EVM.

Configuration Parameters section allows user to set appropriate parameters for the gauge. All the settings

must be programmed based on the cell characteristics, the end-system and charger requirements.

Remember the bqCONFIG has two screens in this section (Figure 12), user must check both System

Characteristics and Gauging Characteristics before clicking the “Save to Gauge” button.

Figure 12. Configuration Parameters Screen

18

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Preparing the Mass Production File

www.ti.com

10.2 Calibration

Ensure calibration is finished before chemistry test and learning cycle. Calibration section can be finished

in the GaugeStudio. However, the bqCONFIG has a Calibration Averaging Tool (Figure 13).

This tool can generate an average calibration value to be used in mass production instead of individually

calibrating each board. User may calibrate 20 boards or more to have a sufficient sample size and include

the average result of the calibration into the mass production file. This tool can be accessed through the

Tools menu. It keeps track of the calibration values for each board and determines the average value to

be included in the mass production file.

Figure 13. Calibration Averaging Tool Screen

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

19

�Preparing the Mass Production File

www.ti.com

10.3 Chemistry

This section allows user to select and program the chemistry to match specific cell. TI provides a lot of

chemID which contains cell profile to match different cells.

1. Start GaugeStudio or use other equipment to log time, voltage, current, and temperature. Voltage must

be measured with better than 1-mV error.

2. Charge cell to the manufacturer specified voltage, until taper current reaches C/100.

3. Wait 2 hrs

4. Discharge at C/10 rate to manufacturer specified termination voltage (use 3 V if unknown)

5. Wait 5 hrs

6. Use chemselect_cont.mcd worksheet to find chemical ID

7. Select the correct chemical ID in bqCONFIG and clicking Update Chemistry button.

Figure 14. Chemistry Screen

20

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Preparing the Mass Production File

www.ti.com

10.4 Learning Cycle

Learning Cycle section (Figure 15) shows the information about how to do a learning cycle. After learning

cycle, the gauge will update the capacity and the impedance. The learning cycle need a fully charge and

discharge cycle to finish. For detailed instructions on how to perform a learning cycle and troubleshoot

common issues, please refer to SLUA587.

Figure 15. Learning Cycle Screen

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

21

�Preparing the Mass Production File

www.ti.com

10.5 Create Image Files

This section (Figure 16) allows user to export the image files for mass production. Please check every

section before create image files has not problems. After creating image files, the details of how to update

image files at production, please see SLUA541, Updating bq275xx Firmware at Production.

Figure 16. Create Image Files Screen

22

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

SLUUAH1 – June 2013

Submit Documentation Feedback

�Send HDQ Screen

www.ti.com

11

Send HDQ Screen

To configure a bq27741 into HDQ mode, navigate to the Send HDQ screen. It is possible that all the

screen options on the left are not visible depending on screen resolution. If needed scroll within the left

menu to access the Send HDQ link. Click on the "Change comm to HDQ8" button while having the

bq27741 connected to the EV2300 via I2C. Clicking on the button causes a message to appear indicating

that the process is not reversible and to confirm if the actions are desired. Also, it explains what to do

once the HDQ mode has been activated.

Once converting the bq27741 into HDQ mode, it is required that you connect the HDQ terminal of the

EV2300 with the HDQ connector (J4) of the bq27741 EVM, then restart the EVSW, and select the

"bq27741HDQR1" with the proper firmware version from the list of supported devices within the EVSW.

12

Related Documentation From Texas Instruments

To obtain a copy of any of the following TI documents, call the Texas Instruments Literature Response

Center at (800) 477-8924 or the Product Information Center (PIC) at (972) 644-5580. When ordering,

identify this document by its title and literature number. Updated documents also can be obtained through

the TI Web site at www.ti.com.

1. bq27741-G1, Single Cell Li-Ion Battery Fuel Gauge with Integrated Protection Data Sheet (SLUSBF2)

2. bq27741-G1, Pack-Side Impedance Track™ Battery Fuel Gauge With Integrated Protector and LDO

User's Guide (SLUUAA3)

SLUUAH1 – June 2013

Submit Documentation Feedback

bq27741EVM Single-Cell Impedance Track™ Technology Evaluation Module

Copyright © 2013, Texas Instruments Incorporated

23

�EVALUATION BOARD/KIT IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the product(s) must have

electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental

measures typically found in end products that incorporate such semiconductor components or circuit boards. This evaluation board/kit does

not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling

(WEEE), FCC, CE or UL, and therefore may not meet the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or

services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI’s environmental and/or

safety programs, please contact the TI application engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and can radiate radio

frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15 of FCC rules, which are

designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case the user at his own expense will be required to take whatever measures may

be required to correct this interference.

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of 6 V to 25 V and the output voltage range of 0 V to 16.4 V.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are questions

concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the EVM.

Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 60°C. The EVM is designed to operate

properly with certain components above 60°C as long as the input and output ranges are maintained. These components include but are

not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of devices can be identified

using the EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

�IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products

Applications

Audio

www.ti.com/audio

Automotive and Transportation

www.ti.com/automotive

Amplifiers

amplifier.ti.com

Communications and Telecom

www.ti.com/communications

Data Converters

dataconverter.ti.com

Computers and Peripherals

www.ti.com/computers

DLP® Products

www.dlp.com

Consumer Electronics

www.ti.com/consumer-apps

DSP

dsp.ti.com

Energy and Lighting

www.ti.com/energy

Clocks and Timers

www.ti.com/clocks

Industrial

www.ti.com/industrial

Interface

interface.ti.com

Medical

www.ti.com/medical

Logic

logic.ti.com

Security

www.ti.com/security

Power Mgmt

power.ti.com

Space, Avionics and Defense

www.ti.com/space-avionics-defense

Microcontrollers

microcontroller.ti.com

Video and Imaging

www.ti.com/video

RFID

www.ti-rfid.com

OMAP Applications Processors

www.ti.com/omap

TI E2E Community

e2e.ti.com

Wireless Connectivity

www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

�