DLPC230-Q1, DLPC231-Q1

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

DLPC23x-Q1 Automotive Digital Micromirror Device Controller

1 Features

3 Description

•

•

The DLPC23x-Q1 digital micromirror display (DMD)

controller for automotive applications is used in

chipsets for interior applications such as HUD and

exterior application such as high resolution headlight.

The DLP5530-Q1 chipset includes a 0.55” DMD

and the DLP4620-Q1 chipset includes a 0.46"

DMD. Both chipsets also include the TPS99000-Q1

System Management and Illumination controller. The

DLPC23x-Q1 integrates an embedded processor with

error code correction (SECDED ECC), enabling host

control and real-time feedback, on-chip diagnostics,

and system monitoring functions. On-chip SRAM is

included to remove the need for external DRAM.

Combined with the TPS99000-Q1, the DLPC23xQ1 supports high dynamic range dimming of over

5000:1 for HUD applications. Sub-LVDS 600-MHz

DMD interface allows high DMD refresh rates to

generate seamless and brilliant digital images, while

simultaneously reducing radiated emissions.

•

•

•

•

•

•

•

•

•

Qualified for automotive applications

AEC-Q100 qualified with the following results:

– Device temperature grade 2: –40°C to 105°C

ambient operating temperature

– Device HBM ESD Classification Level 2

– Device CDM ESD Classification Level C4B

DMD display controller supporting:

– DLP553x-Q1 and DLP462x-Q1 automotive

interior display and exterior lighting chipsets

Video processing

– Scales input image to Match DMD resolution

– Bezel adjustment up ±50% vertical image

position and ±10% horizontal reducing the need

for mechanical alignment (HUD)

– Support for pixel doubling or quadrupling to

allow low resolution video input

– Gamma correction

Embedded processor with error correction (ECC)

– On-chip diagnostic and self-test capability

– System diagnostics including temperature

monitoring, device interface monitoring, and

photodiode monitoring

– Integrated Management of Smooth Dimming

– Configurable GPIO

No external RAM required, internal SRAM for

image processing

600-MHz Sub-LVDS DMD interface for low power

and emission

Spread spectrum clocking for reduced EMI

Video input interface

– Single OpenLDI (FPD-Link I) port up

to 110 MHz

– 24-bit RGB parallel interface up to 110 MHz

Configurable host control interface

– Serial Peripheral Interface (SPI) 10 MHz

– I2C (400 kHz)

– Host IRQ signal to provide real-time feedback

for critical system errors

Interface to TPS99000-Q1 system management

and illumination controller

To aid in the design and manufacture of automotive

qualified projectors based on DLP technology,

there are a number of established optical module

manufacturers and design houses that can be

leveraged to support your design.

Device Information

PART NUMBER

•

•

Wide field of view and augmented reality

head-up display (HUD)

Digital cluster, navigation, and infotainment

windshield displays

High resolution headlight

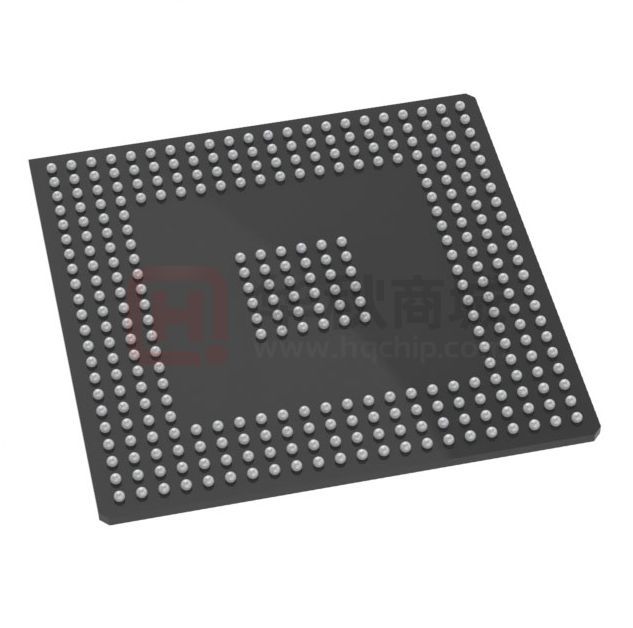

BODY SIZE (NOM)

DLPC230-Q1

ZDQ (BGA, 324)

DLPC231-Q1

ZEK (nfBGA, 324) 15.00 mm × 15.00 mm

(1)

23.00 mm × 23.00 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

Voltage

Monitor and

Enables

Power

Regulation

TPS99000-Q1

1.1V

1.8V

3.3V

6.5V

LED dimming

SPI

DLPC23X-Q1

SPI

Video

ARM®

Cortex®-R4F

2 Applications

•

PACKAGE(1)

Video

memory

VOFFSET

DMD power

management

VRESET

VBIAS

DLPxxxx-Q1

SubLVDS

DMD video

processing &

control

LED

ENABLE

System

diagnos�cs

TMP411

Temperature

Sensor

I2C

SPI

DMD

Flash

DLP5530-Q1 or DLP4620-Q1 DLP® Chipset System

Block Diagram

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. UNLESS OTHERWISE NOTED, this document contains PRODUCTION

DATA.

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications................................................................ 15

6.1 Absolute Maximum Ratings...................................... 15

6.2 ESD Ratings............................................................. 15

6.3 Recommended Operating Conditions.......................16

6.4 Thermal Information..................................................16

6.5 Electrical Characteristics...........................................17

6.6 Electrical Characteristics for Fixed Voltage I/O.........18

6.7 DMD High-Speed Sub-LVDS Electrical

Characteristics.............................................................19

6.8 DMD Low-Speed Sub-LVDS Electrical

Characteristics.............................................................20

6.9 OpenLDI LVDS Electrical Characteristics................. 21

6.10 Power Dissipation Characterisics........................... 21

6.11 System Oscillators Timing Requirements............... 21

6.12 Power Supply and Reset Timing Requirements..... 22

6.13 Parallel Interface General Timing Requirements ... 23

6.14 OpenLDI Interface General Timing Requirements..23

6.15 Parallel/OpenLDI Interface Frame Timing

Requirements.............................................................. 25

6.16 Host/Diagnostic Port SPI Interface Timing

Requirements.............................................................. 26

6.17 Host/Diagnostic Port I2C Interface Timing

Requirements.............................................................. 26

6.18 Flash Interface Timing Requirements .................... 27

6.19 TPS99000-Q1 SPI Interface Timing

Requirements ............................................................. 29

6.20 TPS99000-Q1 AD3 Interface Timing

Requirements ............................................................. 31

6.21 Master I2C Port Interface Timing Requirements .... 32

6.22 Chipset Component Usage Specification............... 32

7 Parameter Measurement Information.......................... 33

7.1 HOST_IRQ Usage Model......................................... 33

7.2 Input Source..............................................................33

8 Detailed Description......................................................35

8.1 Overview................................................................... 35

8.2 Functional Block Diagram......................................... 35

8.3 Feature Description...................................................36

8.4 Device Functional Modes..........................................48

9 Application and Implementation.................................. 49

9.1 Application Information............................................. 49

9.2 Typical Application.................................................... 49

9.3 Power Supply Recommendations.............................52

9.4 Layout....................................................................... 53

10 Device and Documentation Support..........................64

10.1 Device Support....................................................... 64

10.2 Trademarks............................................................. 65

10.3 Electrostatic Discharge Caution..............................65

10.4 Glossary..................................................................65

11 Mechanical, Packaging, and Orderable

Information.................................................................... 66

11.1 DLPC230-Q1 Mechanical Data...............................67

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision F (June 2018) to Revision G (September 2023)

Page

• Updated device name from DLP553x and DLP462x to DLP5530 and DLP4620. Removed Advance

Information note..................................................................................................................................................1

• Changed the DMD Pins assignment: DMD_HS1_WDATA4_P – DMD_HS1_WDATA7_N................................ 3

Changes from Revision E (June 2018) to Revision F (August 2023)

Page

• Updated the data sheet title to DLPC23x - for DLPC230 and DLPC231 controllers.......................................... 1

• Updated the numbering format for tables, figures, and cross-references throughout the document ................ 1

• Added the new nfBGA package for DLPC231....................................................................................................1

• Added the ZEK package diagram for DLPC231................................................................................................. 3

• Updated OpenLDI timing diagram to reflect actual bit assignments.................................................................23

• Changed minimum compatible SPI size to 16Mb............................................................................................. 41

• Added PLL Filter and Crystal Layout for DLPC231.......................................................................................... 53

2

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

5 Pin Configuration and Functions

Note that there is one VCCK power ball located in the thermal ball array.

Figure 5-1. DLPC230 ZDQ Package

324-Pin BGA

Top View

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

3

�DLPC230-Q1, DLPC231-Q1

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

www.ti.com

Figure 5-2. DLPC231 ZEK Package

324-Pin BGA

Top View

4

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-1. Pin Functions – Board Level Test, Debug, and Initialization

PIN

NAME

RESETZ

PMIC_PARKZ

HOST_IF_SEL

HOST_SPI_MODE

RTPPUB_ENZ

ZDQ324

ZEK324

F3

E3

R4

F3

E4

N1

I/O(1)

DESCRIPTION

I7

Active low power-on reset for the DLPC23x-Q1. A low-to-high transition

starts self-configuration and initialization of the ASIC.

('0' = Reset, '1' = Normal Operation)

All ASIC power and input clocks must be stable before this reset is

deasserted high.

The signals listed below must be forced low by external pulldown, and

will then be driven low as the power supplies stabilize with RESETZ

asserted.

PMIC_LEDSEL_0, PMIC_LEDSEL_1, PMIC_LEDSEL_2,

PMIC_LEDSEL_3, DMD_DEN_ARSTZ, PMIC_AD3_CLK, and

PMIC_AD3_MOSI

All other bi-directional and output signals will be tristated while reset is

asserted. External pullups or pulldowns must be added where necessary

to protect external devices that can typically be driven by the ASIC to

prevent device malfunction.

This pin includes hysteresis.

Specific timing requirements for this signal are shown in Section 6.12.

I7

DMD Park Control

('0' = Park, '1' = Un-Park)

The TI TPS99000-Q1 device is used to control this signal. As part of this

function, it monitors power to the DLPC23x-Q1 watching for an imminent

power loss condition, upon which it will drive the PMIC_PARKZ signal

accordingly. The specific timing requirements for this signal are shown in

Section 6.12.

B13,14

Selects which input interface port will be used for Host Command and

Control. The port that is not selected as the Host Command and Control

port will be available as a Diagnostic Processor monitoring port.

('0' = Host SPI, '1' = Host I2C)

This pin includes a weak internal pulldown. If a pull-up is used to obtain

a '1' value, the pull-up value must be ≤ 8 kΩ.

Tristated while RESETZ is asserted low, and is sampled as a host

directive approximately 1.5 µs after RESETZ is deasserted. It can be

driven as an output for TI debug use after sampling.

V1

P2

B13,14

Selects the SPI mode (clock phase and polarity) that will be used with

the HOST SPI interface. This value is applicable regardless of whether

the Host SPI interface is used for Host Command and Control, or for the

Diagnostic Processor monitoring port.

('0' = SPI Mode 0 or 3, '1' = SPI Mode 1 or 2)

This pin includes a weak internal pulldown. If a pullup is used to obtain a

'1' value, the pullup value must be ≤ 8 kΩ.

Tristated while RESETZ is asserted low, and is sampled as a host

directive approximately 1.5 µs after RESETZ is deasserted. It can be

driven as an output for TI debug use after sampling.

AA3

U2

B13,14

TI internal use. Must be left unconnected. Includes a weak pulldown.

Selects whether the Host will use 8-bit CRC or checksum on the Host

Command and Control interface. This value is only applicable for the

Host Command and Control interface. The value for the Diagnostic

Processor monitoring port will be specified in Flash.

('0' = 8-bit CRC, '1' = 8-bit checksum)

This pin includes a weak internal pulldown. If a pullup is used to obtain a

'1' value, the pullup value must be ≤ 8 kΩ.

Tristated while RESETZ is asserted low, and is sampled as a host

directive approximately 1.5 µs after RESETZ is deasserted. It can be

driven as an output for TI debug use after sampling.

CRCZ_CHKSUM_S

EL

AB3

V2

B13,14

ETM_TRACECLK

AB6

R10

O13

TI internal use. Must be left unconnected (clock for Trace Debug)

ETM_TRACECTL

AB7

R9

O13

TI internal use. Must be left unconnected (control for Trace Debug)

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

5

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-1. Pin Functions – Board Level Test, Debug, and Initialization (continued)

PIN

NAME

TSTPT_0

TSTPT_1

TSTPT_2

TSTPT_3

TSTPT_4

TSTPT_5

TSTPT_6

TSTPT_7

HWTEST_EN

JTAGTCK

6

ZDQ324

Y4

AA4

Y5

AA5

Y6

AA6

Y7

ZEK324

R3

R4

R5

R7

P4

R8

P6

I/O(1)

DESCRIPTION

B13,14

Test pin 0 / STAY-IN-BOOT:

Selects whether the system must stay in the Boot Application, or

proceed with the normal load of the Main Application.

('0' = Load Main Application, '1' = Stay in Boot Application)

This pin includes a weak internal pulldown. If a pullup is being used to

obtain a '1' value, the pullup value must be ≤ 8 kΩ.

Tristated while RESETZ is asserted low, and is sampled as a host

directive approximately 1.5 µs after RESETZ is deasserted. It can be

driven as an output for debug use after sampling as described in Section

8.3.11.

B13,14

Test pin 1 :

This pin must be externally pulled down, left open or unconnected.

Includes a weak pulldown.

It can be driven as an output for debug use as described in Section

8.3.11.

B13,14

Test pin 2 :

This pin must be externally pulled down, left open or unconnected.

Includes a weak pulldown.

It can be driven as an output for debug use as described in Section

8.3.11.

B13,14

Test pin 3 :

This pin must be externally pulled down, left open or unconnected.

Includes a weak pulldown.

It can be driven as an output for debug use as described in Section

8.3.11.

B13,14

Test pin 4:

This pin must be externally pulled down, left open or unconnected.

Includes a weak pulldown.

It can be driven as an output for debug use as described in Section

8.3.11.

B13,14

Test pin 5 / Spread Spectrum Disable:

Selects whether spread spectrum flash settings are used or whether

spread spectrum clocking will be disabled.

('0' = Spread Spectrum Disabled, '1' = Use flash Spread Spectrum

settings)

This pin includes a weak internal pulldown. If a pull-up is being used to

obtain a '1' value, the pull-up value must be ≤ 8 kΩ.

This signal is tristated while RESETZ is asserted low, and is sampled

as a host directive approximately 1.5 µs after RESETZ is deasserted. It

can be driven as an output for debug use after sampling as described in

Section 8.3.11.

B13,14

Test pin 6:

An external pull-up resistor must be used (≤ 8 kΩ because pin includes

a weak pull-down).

This signal is tristated while RESETZ is asserted low, and is sampled

as a host directive approximately 1.5 µs after RESETZ is deasserted. It

can be driven as an output for debug use after sampling as described in

Section 8.3.11.

Test pin 7:

This pin must be externally pulled down, left open or unconnected.

Includes a weak pull-down.

It can be driven as an output for debug use as described in Section

8.3.11.

AA7

P7

B13,14

H3

J5

I14

Manufacturing test enable signal.

This signal must be connected directly to ground on the PCB.

Includes weak internal pull-down and hysteresis.

G22

H17

I11

JTAG Serial Data Clock

Includes a weak internal pull-up.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-1. Pin Functions – Board Level Test, Debug, and Initialization (continued)

PIN

NAME

JTAGTMS1

ZDQ324

ZEK324

G21

H16

I/O(1)

DESCRIPTION

I11

JTAG Test Mode Select

Includes weak internal pull-up.

JTAGTRSTZ

L20

G16

I11

JTAG Reset

Includes a weak internal pull-up and Hysteresis.

For normal operation, this pin must be pulled to ground through an

external 8 kΩ or less resistor. Failure to pull this pin low during

normal operation will cause start-up and initialization problems.

For JTAG Boundary Scan, this pin must be pulled-up or left

disconnected.

JTAGTDI

K20

G17

I11

JTAG Serial Data In Includes a weak internal pull-up.

JTAGTDO1

J20

G15

B10,11

JTAG Serial Data Out

Includes weak internal pull-up.

JTAGTDO2

H20

F18

B10,11

This pin must be left open or unconnected.

Includes a weak internal pull-up.

JTAGTDO3

G20

F17

B10,11

This pin must be left open or unconnected. Includes a weak internal

pull-up.

JTAGTMS2

N20

H15

I11

This pin must be left open or unconnected. Includes a weak internal

pull-up. See Section 8.3.11 for important debug access considerations.

JTAGTMS3

M20

G18

I11

This pin must be left open or unconnected. Includes a weak internal

pull-up. See Section 8.3.11 for important debug access considerations.

(1)

See Table 5-10 for more information on I/O definitions.

Table 5-2. Pin Functions – Parallel Port Input Data and Control

PIN (1)

DESCRIPTION

PARALLEL RGB MODE

I/O(2)

NAME

ZDQ324

ZEK324

PCLK

R22

M18

I11

Pixel clock

VSYNC

H21

J18

I11

Vsync(3)

HSYNC

H22

H18

I11

Hsync(3)

DATEN

P21

M17

I11

Data Valid

PDATA_0

PDATA_1

PDATA_2

PDATA_3

PDATA_4

PDATA_5

PDATA_6

PDATA_7

AA21

AA22

Y21

W21

Y22

V21

W22

U21

V17

U17

U18

T17

T18

R17

R18

P17

PDATA_8

PDATA_9

PDATA_10

PDATA_11

PDATA_12

PDATA_13

PDATA_14

PDATA_15

V22

T21

U22

R21

T22

P22

N21

N22

P18

N18

P16

N16

N17

M16

L18

L17

(TYPICAL RGB 888)

I11

Blue (bit weight 1)

Blue (bit weight 2)

Blue (bit weight 4)

Blue (bit weight 8)

Blue (bit weight 16)

Blue (bit weight 32)

Blue (bit weight 64)

Blue (bit weight 128)

(TYPICAL RGB 888)

I11

Green (bit weight 1)

Green (bit weight 2)

Green (bit weight 4)

Green (bit weight 8)

Green (bit weight 16)

Green (bit weight 32)

Green (bit weight 64)

Green (bit weight 128)

(TYPICAL RGB 888)

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

7

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-2. Pin Functions – Parallel Port Input Data and Control (continued)

PIN (1)

NAME

ZDQ324

ZEK324

M22

M21

L22

L21

K22

K21

J22

J21

L16

K18

K17

K16

K15

J17

J16

J15

PDATA_16

PDATA_17

PDATA_18

PDATA_19

PDATA_20

PDATA_21

PDATA_22

PDATA_23

(1)

(2)

(3)

DESCRIPTION

PARALLEL RGB MODE

I/O(2)

I11

Red (bit weight 1)

Red (bit weight 2)

Red (bit weight 4)

Red (bit weight 8)

Red (bit weight 16)

Red (bit weight 32)

Red (bit weight 64)

Red (bit weight 128)

Unused inputs must be grounded or pulled down to ground through an external resistor (≤ 10 kΩ).

See Table 5-10 for more information on I/O definitions.

VSYNC and HSYNC polarity are software programmable.

Table 5-3. Pin Functions – OpenLDI Ports Input Data and Control

PIN (1) (2)

NAME

I/O(3)

DESCRIPTION

ZDQ324

ZEK325

L1_CLK_P

L1_CLK_N

AB11

AA11

V6

U6

I18

OpenLDI (FPD Link I) Port 1 Clock Lane

L1_DATA0_P

L1_DATA0_N

L1_DATA1_P

L1_DATA1_N

L1_DATA2_P

L1_DATA2_N

L1_DATA3_P

L1_DATA3_N

AB9

AA9

AB10

AA10

AB12

AA12

AB13

AA13

V4

U4

V5

U5

V7

U7

V8

U8

I18

OpenLDI (FPD Link I) Port 1 Data Lanes: Intra-port data lane swapping can

be done on a product configuration basis to support board considerations.

L2_CLK_P

L2_CLK_N

AB17

AA17

V12

U12

I18

OpenLDI (FPD Link I) Port 2 Clock Lane

L2_DATA0_P

L2_DATA0_N

L2_DATA1_P

L2_DATA1_N

L2_DATA2_P

L2_DATA2_N

L2_DATA3_P

L2_DATA3_N

AB15

AA15

AB16

AA16

AB18

AA18

AB19

AA19

V10

U10

V11

U11

V13

U13

V14

U14

I18

OpenLDI (FPD Link I) Port 2 Data Lanes: Intra-port data lane swapping can

be done on a product configuration basis to support board considerations.

(1)

(2)

(3)

The system only supports the operational use of one port. As two ports are available, the host can select which port they wish to be

active (to optimize board routing as an example).

The inputs for any un-used ports must be left unconnected, and will be powered down by the system.

See Table 5-10 for more information on I/O definitions.

Table 5-4. Pin Functions – DMD Reset and Bias Control Interfaces

PIN (1) (2)

NAME

ZEK324

I/O(3)

DESCRIPTION

D11

D9

O1

DMD driver enable signal

('1' = Enabled, '0' = Reset)

This signal will be driven low after the DMD is parked and before power

is removed from the DMD. If the 1.8-V power to the DLPC230-Q1 is

independent of the 1.8-V power to the DMD, then an external pulldown

resistor (≤ 2.2 kΩ) must be used to hold the signal low in the event

DLPC230-Q1 power is inactive while DMD power is applied.

DMD_LS0_CLK

C11

C9

O2

TI internal use. Must be left unconnected.

DMD_LS0_WDATA

C10

D8

O2

TI internal use. Must be left unconnected.

DMD_LS0_RDATA

C9

C7

I3

DMD, low-speed single-ended serial read data

DMD_LS1_RDATA

C8

C8

I3

DMD, low-speed single-ended serial read data (Training data response for

second port of DMD)

DMD_DEN_ARSTZ

8

ZDQ324

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-4. Pin Functions – DMD Reset and Bias Control Interfaces (continued)

PIN (1) (2)

NAME

I/O(3)

DESCRIPTION

ZDQ324

ZEK324

DMD_LS0_CLK_P

DMD_LS0_CLK_N

B12

A12

B10

A10

O4

DMD low-speed differential interface clock

DMD_LS0_WDATA_P

DMD_LS0_WDATA_N

B11

A11

B9

A9

O4

DMD low-speed differential interface write data

(1)

(2)

(3)

The low-speed write control interface to the DMD is differential.

All control interface reads will make use of the single-ended low-speed signals. The read data will be clocked by the write clock .

See Table 5-10 for more information on I/O definitions.

Table 5-5. Pin Functions – DMD Sub-LVDS Interfaces

PIN

NAME

I/O(1)

DESCRIPTION

ZDQ324

ZEK324

DMD_HS0_CLK_P

DMD_HS0_CLK_N

B17

A17

B15

A15

O4

DMD high-speed interface, Port 0 Clock Lane.

DMD_HS0_WDATA0_P

DMD_HS0_WDATA0_N

DMD_HS0_WDATA1_P

DMD_HS0_WDATA1_N

DMD_HS0_WDATA2_P

DMD_HS0_WDATA2_N

DMD_HS0_WDATA3_P

DMD_HS0_WDATA3_N

DMD_HS0_WDATA4_P

DMD_HS0_WDATA4_N

DMD_HS0_WDATA5_P

DMD_HS0_WDATA5_N

DMD_HS0_WDATA6_P

DMD_HS0_WDATA6_N

DMD_HS0_WDATA7_P

DMD_HS0_WDATA7_N

B21

A21

B20

A20

B19

A19

B18

A18

B16

A16

B15

A15

B14

A14

B13

A13

D17

D18

C17

C18

B17

A17

B16

A16

B14

A14

B13

A13

B12

A12

B11

A11

O4

DMD high-speed interface, Port 0 Data Lanes: The true numbering

and application of the DMD_HS_DATA pins are software configuration

dependent as discussed in Section 8.3.3.

DMD_HS1_CLK_P

DMD_HS1_CLK_N

B6

A6

B4

A4

O4

DMD high-speed interface, Port 1 Clock Lane.

DMD_HS1_WDATA0_P

DMD_HS1_WDATA0_N

DMD_HS1_WDATA1_P

DMD_HS1_WDATA1_N

DMD_HS1_WDATA2_P

DMD_HS1_WDATA2_N

DMD_HS1_WDATA3_P

DMD_HS1_WDATA3_N

DMD_HS1_WDATA4_P

DMD_HS1_WDATA4_N

DMD_HS1_WDATA5_P

DMD_HS1_WDATA5_N

DMD_HS1_WDATA6_P

DMD_HS1_WDATA6_N

DMD_HS1_WDATA7_P

DMD_HS1_WDATA7_N

B2

A2

B3

A3

B4

A4

B5

A5

B7

A7

B8

A8

B9

A9

B10

A10

D2

D1

C2

C1

B2

A2

B3

A3

B5

A5

B6

A6

B7

A7

B8

A8

O4

DMD high-speed interface, Port 1 Data Lanes: The true numbering

and application of the DMD_HS_DATA pins are software configuration

dependent as discussed in Section 8.3.3.

(1)

See Table 5-10 for more information on I/O definitions.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

9

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-6. Pin Functions – Peripheral Interfaces

PIN

NAME

ZDQ324

ZEK324

I/O(1)

DESCRIPTION

HOST_IRQ(2)

T20

N15

O10

Host interrupt (output active HIGH)

This signal is used to indicate that the DLPC23x-Q1 has detected a serious error for

which the ASIC has initiated an Emergency Shutdown. This is discussed further in

Section 7.1.

The DLPC23x-Q1 tristates this output during reset. An external pulldown (≤ 10 kΩ)

is required to drive this signal to its inactive state.

HOST_IIC_SCL

R20

M15

B12

I2C Port (Slave), Host Command and Control to ASIC, SCL (bidirectional, opendrain): An external pullup is required.

HOST_IIC_SDA

P20

L15

B12

I2C Port (Slave), Host Command and Control to ASIC, SDA. (bidirectional, opendrain): An external pullup is required.

HOST_SPI_CLK

Y20

U16

I11

SPI Port (Slave), Host Command and Control to ASIC, clock

HOST_SPI_CSZ

W20

T16

I11

SPI Port (Slave), Host Command and Control to ASIC, chip select (active low input)

An external pullup resistor (≤ 2.2 kΩ) is required to avoid a floating chip select input

to the ASIC

HOST_SPI_DIN

V20

R16

I11

SPI Port (Slave), Host Command and Control to ASIC, receive data in

HOST_SPI_DOU

T

U20

P15

O10

SPI Port (Slave), Host Command and Control to ASIC, transmit data out

FLSH_SPI_CSZ

Y1

T1

O8

SPI Port (Master), Control Interface to Flash device, chip select (active low output)

An external pullup resistor (≤ 10 kΩ) is required to avoid a floating chip select input

to the Flash

FLSH_SPI_CLK

W1

U1

O8

SPI Port (Master), Control Interface to Flash device, clock

FLSH_SPI_DIO_

0

V2

P1

B8,9

SPI Port (Master), Control Interface to Flash device, transmit and receive data

An external pullup resistor (≤ 10 kΩ) is required

FLSH_SPI_DIO_

1

W2

R2

B8,9

SPI Port (Master), Control Interface to Flash device, transmit and receive data

An external pullup resistor (≤ 10 kΩ) is required

FLSH_SPI_DIO_

2

Y2

R1

B8,9

SPI Port (Master), Control Interface to Flash device, transmit and receive data

An external pullup resistor (≤ 3.3 kΩ) is required

FLSH_SPI_DIO_

3

W3

T2

B8,9

SPI Port (Master), Control Interface to Flash device, transmit and receive data

An external pullup resistor (≤ 3.3 kΩ) is required

PMIC_INTZ(2)

G3

E2

I7

TPS99000-Q1 interrupt (input with hysteresis)

The ASIC provides a weak internal pullup,

PMIC_SPI_CLK

E1

F5

O6

SPI Port (Master), General Control Interface to TPS99000-Q1, clock

PMIC_SPI_CSZ0

E2

G4

O6

SPI Port (Master), General Control Interface to TPS99000-Q1, chip select 0 (active

low output)

An external pullup resistor (≤ 10 kΩ) must be used to avoid floating chip select

inputs to the external SPI device during ASIC reset assertion.

PMIC_SPI_DIN

F1

E3

I7

SPI Port (Master), General Control Interface to TPS99000-Q1, receive data in

PMIC_SPI_DOUT

D1

E5

O6

SPI Port (Master), General Control Interface to TPS99000-Q1, transmit data out

PMIC_AD3_CLK

H2

G1

O20

Sequencer Clock / TPS99000-Q1 primary system clock

An external pulldown resistor (≤ 10 kΩ) must be used to avoid uncontrolled behavior

during ASIC reset assertion.

PMIC_AD3_MISO

J2

G2

I14

Measurement control interface to TPS99000-Q1, receive data in

PMIC_AD3_MOSI

J1

G3

O20

Measurement control interface to TPS99000-Q1, transmit data out

An external pulldown resistor (≤ 10 kΩ) must be used to avoid uncontrolled behavior

during ASIC reset assertion.

PMIC_LEDSEL_0

F2

F4

O6

LED Control Interface to TPS99000-Q1

An external pulldown resistor (≤ 10 kΩ) must be used to avoid uncontrolled

illumination during ASIC reset assertion.

PMIC_LEDSEL_1

G1

E1

O6

LED Control Interface to TPS99000-Q1

An external pulldown resistor (≤ 10 kΩ) must be used to avoid uncontrolled

illumination during ASIC reset assertion.

10

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-6. Pin Functions – Peripheral Interfaces (continued)

PIN

NAME

I/O(1)

DESCRIPTION

ZDQ324

ZEK324

PMIC_LEDSEL_2

G2

F2

O6

LED Control Interface to TPS99000-Q1

An external pulldown resistor (≤ 10 kΩ) must be used to avoid uncontrolled

illumination during ASIC reset assertion.

PMIC_LEDSEL_3

H1

F1

O6

LED Control Interface to TPS99000-Q1

An external pulldown resistor (≤ 10 kΩ) must be used to avoid uncontrolled

illumination during ASIC reset assertion.

B15

I2C Port (Master), SDA. (bidirectional, open-drain)

An external pullup is required. Typical use of the Master I2C port is communication

with temperature sensing devices and an optional EEPROM. The Master I2C I/Os

are powered by VCC3IO (3.3 V only).

B15

I2C Port (Master), SCL. (bidirectional, open-drain)

An external pullup is required. Typical use of the Master I2C port is communication

with temperature sensing devices and an optional EEPROM. The Master I2C I/Os

are powered by VCC3IO (3.3 V only).

MSTR_SDA

AB5

MSTR_SCL

(1)

(2)

T7

AB4

R6

See Table 5-10 for more information on I/O definitions.

For more information about usage, see Section 7.1.

Table 5-7. Pin Functions – GPIO Peripheral Interface

PIN (1) (3)

NAME

I/O(2)

DESCRIPTION

ZDQ324

ZEK324

GPIO_31

D22

E15

B20,14

General purpose I/O 31

GPIO_30

E21

E16

B20,14

General purpose I/O 30

GPIO_29

E22

E17

B20,14

General purpose I/O 29

GPIO_28

F20

E18

B20,14

General purpose I/O 28

GPIO_27

F21

F15

B20,14

General purpose I/O 27

GPIO_26

F22

F16

B20,14

General purpose I/O 26

GPIO_25

V3

P3

B20,14

General purpose I/O 25

GPIO_24

U3

M5

B20,14

General purpose I/O 24

GPIO_23

U2

N4

B20,14

General purpose I/O 23

GPIO_22

U1

N3

B20,14

General purpose I/O 22

GPIO_21

T3

N2

B20,14

General purpose I/O 21

GPIO_20

T2

M4

B20,14

General purpose I/O 20

GPIO_19

T1

M3

B20,14

General purpose I/O 19

GPIO_18

R3

M2

B20,14

General purpose I/O 18

GPIO_17

R2

M1

B20,14

General purpose I/O 17

GPIO_16

R1

L4

B20,14

General purpose I/O 16

GPIO_15

P3

L3

B20,14

General purpose I/O 15

GPIO_14

P2

L2

B20,14

General purpose I/O 14

GPIO_13

P1

L1

B20,14

General purpose I/O 13

GPIO_12

N3

K5

B20,14

General purpose I/O 12

GPIO_11

N2

K4

B20,14

General purpose I/O 11

GPIO_10

N1

K3

B20,14

General purpose I/O 10

GPIO_09

M3

K2

B20,14

General purpose I/O 09

GPIO_08

M2

K1

B20,14

General purpose I/O 08

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

11

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-7. Pin Functions – GPIO Peripheral Interface (continued)

PIN (1) (3)

NAME

I/O(2)

DESCRIPTION

ZDQ324

ZEK324

GPIO_07

M1

J4

B20,14

General purpose I/O 07

GPIO_06

L3

J3

B20,14

General purpose I/O 06

GPIO_05

L2

H2

B20,14

General purpose I/O 05

GPIO_04

L1

H3

B20,14

General purpose I/O 04

GPIO_03

K3

J2

B20,14

General purpose I/O 03

GPIO_02

K2

H1

B20,14

General purpose I/O 02

GPIO_01

K1

J1

B20,14

General purpose I/O 01

GPIO_00

J3

H4

B20,14

General purpose I/O 00

(1)

(2)

(3)

Some GPIO signals are reserved for specific purposes. These signals vary per product configuration. These product allocations are

discussed further in Section 8.3.7. All GPIO that are available for Host use must be configured as an input, a standard output, or an

open-drain output. This is set in the flash configuration or by command using the Host command interface. The reset default for all

GPIO is as an input signal. An external pullup (≤ 10 kΩ) is required for each signal configured as open-drain.

See Table 5-10 for more information on I/O definitions.

All GPIO include hysteresis.

Table 5-8. Pin Functions – Clock and PLL Support

PIN

NAME

I/O(1)

DESCRIPTION

ZDQ324

ZEK324

PLL_REFCLK_I

D15

D12

I17

Reference clock crystal input. If an external oscillator is used in place of a crystal,

this pin must be left unconnected (floating with no added capacitive load).

PLL_REFCLK_O

D14

D13

B16,17

Reference clock crystal return. If an external oscillator is used in place of a crystal,

this pin must be used for the oscillator input.

I19

Selects whether an external crystal or external oscillator will be used to drive the

internal PLL.

('0' = Crystal, '1' = Oscillator)

This pin includes a weak internal pulldown. If a pullup is used to obtain a '1' value,

the pullup value must be ≤ 8 kΩ.

OSC_BYPASS

(1)

D16

C13

See Table 5-10 for more information on I/O definitions.

Table 5-9. Pin Functions – Power and Ground

PIN

NAME

I/O(1)

DESCRIPTION

ZDQ324

ZEK324

VCC18A_LVDS

B1, B22, C1, C22, D2,

D3, D4, D5, D7, D18,

D19, D20, D21, E20

B1, B18, C4, C6, C15,

D3, D5, D14, D16, E13,

F7, F8, F10, F12

PWR

1.8-V Power for the differential High-Speed and

Low-Speed DMD Interfaces

GND18A_LVDS

A1, A22, C2, C3, C4, C5,

C6, C7, C16, C17, C18,

C19, C20, C21, D8

A1, A18, C3, C5, C14,

C16, D6, E8, E10, E12,

E14, F6

RTN

1.8-V GND for the differential High-Speed and LowSpeed DMD Interfaces

VCC18IO

D10

E9

PWR

1.8-V Power for 1.8-V IO

VCC3IO_MVGP

H4

G5, H5

PWR

3.3-V Power for TPS99000-Q1 Interfaces

VCC3IO_FLSH

V4

N5, P5

PWR

3.3-V Power for the Serial Flash Interface

VCC3IO_INTF

K19, L19, M19, R19, T19

H14, L14, J14, M14

PWR

3.3-V Power for the Parallel Data, JTAG, and Host

Command Interfaces

VCC3IO_COSC

C15

E11

PWR

3.3-V I/O Power for the Crystal Oscillator

GNDIOLA_COSC

C14

C12

RTN

3.3-V I/O GND for the Crystal Oscillator

12

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-9. Pin Functions – Power and Ground (continued)

PIN

NAME

VCC3IO

ZDQ324

ZEK324

J4, K4, M4, N4, P4, W4,

W5, G19

F14, G14, K6, L5, M6,

N7, P8

I/O(1)

DESCRIPTION

PWR

3.3-V I/O Power for all "other" I/O (such as GPIO,

TSTPT, PMIC_AD3)

PWR

3.3-V I/O Power for the OpenLDI Interface

VCC33A_LVDS

T3, T4, T8, T10, R11,

W9, W13, W15, W19, Y9,

Y13, Y15, Y19

T12, R13, T14, R15, V16

GND33A_LVDS

W14, Y14, AA8, AA14,

AA20, AB8, AB14, AB20,

AB21

R12, R14, T5, T6, T9,

T11, T13, T15, U3, U9,

U15, V3, V9, V15

RTN

3.3-V I/O GND for the OpenLDI Interface

VCC11AD_PLLM

D13

D11

PWR

1.1-V Analog/Digital Power for MCG (Master Clock

Generator) PLL

GND11AD_PLLM

C13

C11

RTN

1.1-V Analog/Digital GND for MCG (Master Clock

Generator) PLL

VCC11AD_PLLD

D12

C10

PWR

1.1-V Analog/Digital Power for DCG (DMD Clock

Generator) PLL

GND11AD_PLLD

C12

D10

RTN

1.1-V Analog/Digital GND for DCG (DMD Clock

Generator) PLL

VCC11A_DDI_0

E19, F19

F13, G13

PWR

1.1-V Filtered Core Power - External Filter Group A

(HS DMD Interface 0)

VCC11A_DDI_1

E4, F4

E6, E7

PWR

1.1-V Filtered Core Power - External Filter Group B

(HS DMD Interface 1)

VCC11A_LVDS

W11, W12, W17, W18

N10, P11, P12, P13, P14

PWR

1.1-V Filtered Core Power - External Filter Group C

(OpenLDI Interface)

VCCK

G4, H19, (J11), J19, L4,

N19, P19, T4, U4, U19,

V19, W6, W8, W10, W16

F9, F11, G6, H13, K13,

L6, J6, M13, N6, N8, N9,

N11

PWR

1.1-V Core Power (Ball numbers in parenthesis are

also used as thermal ball and are located within the

package center region)

GND

(G7, G8, G9, G10, G11,

(J9, J10, J12, J13, J14,

G12, H7, H8, H9, H10,

K9, K10, K11, K12, K13,

K14, L9, L10, L11, L12, H11, H12, J7, J8, J9, J10,

L13, L14, M9, M10, M11,

J11, J12, K7, K8, K9,

M12, M13, M14, N9, N10,

K10, K11, K12, L7, L8,

N11, N12, N13, N14, P9,

L9, L10, L11, L12, M7,

P10, P11, P12, P13,P14),

Y3, AA1, AA2, AB1, AB2, M8, M9, M10, M11, M12),

AB22, Y10, Y11, Y12,

H6, J13, K14, L13, N12,

Y16, Y17, Y18

N13, N14, V1, V18

RTN

1.1-V Core GND (Ball numbers in parenthesis are

also used as thermal ball and are located within the

package center region)

EFUSE_VDDQ

W7

P9

Manufacturing use only. Must be tied to ground.

EFUSE_POR33

Y8

P10

Manufacturing use only. Must be tied to ground.

D17

D15

RPI_0

RPI_1

RPI_LS

(1)

D6

D4

D9

D7

I5

Bandgap Reference for sub-LVDS drivers (Supports

DMD_HS0_xxxx). Requires a resistor (1%

Tolerance) to GND18A_LVDS - Value specified in

Table 9-4.

I5

Bandgap Reference for sub-LVDS drivers (Supports

DMD_HS1_xxxx). Requires a resistor (1%

Tolerance) to GND18A_LVDS - Value specified in

Table 9-4.

I5

Bandgap References for sub-LVDS drivers

(Supports DMD_LS0_xxxx differential bus signals).

Requires a resistor (1% Tolerance) to

GND18A_LVDS - Value specified in Table 9-4.

See Table 5-10 for more information on I/O definitions.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

13

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 5-10. I/O Type Subscript Definition

I/O

SUBSCRIPT

SUPPLY REFERENCE ESD STRUCTURE

DESCRIPTION

1

1.8-V LVCMOS Input

VCC18IO

ESD diode to GND and supply rail

2

1.8-V LVCMOS Output

VCC18IO

ESD diode to GND and supply rail

3

1.8-V LVCMOS Input

4

1.8-V sub-LVDS Output

5

6

VCC18IO

ESD diode to GND and supply rail

VCC18A_LVDS

ESD diode to GND and supply rail

1.8-V sub-LVDS Input

VCC18A_LVDS

ESD diode to GND and supply rail

3.3-V LVCMOS Output

VCC3IO_MVGP

ESD diode to GND and supply rail

7

3.3-V LVCMOS Input

VCC3IO_MVGP

ESD diode to GND and supply rail

8

3.3-V LVCMOS Output

VCC3IO_FLSH

ESD diode to GND and supply rail

9

3.3-V LVCMOS Input

VCC3IO_FLSH

ESD diode to GND and supply rail

10

3.3-V LVCMOS Output

VCC3IO_INTF

ESD diode to GND and supply rail

11

3.3-V LVCMOS Input

VCC3IO_INTF

ESD diode to GND and supply rail

12

3.3-V I2C I/O

VCC3IO_INTF

ESD diode to GND and supply rail

13

3.3-V LVCMOS Output

VCC3IO

ESD diode to GND and supply rail

14

3.3-V LVCMOS Input

VCC3IO

ESD diode to GND and supply rail

I2C

15

3.3-V

16

3.3-V LVCMOS Output

I/O with 3-mA drive

VCC3IO

ESD diode to GND and supply rail

VCC3IO_OSC

ESD diode to GND and supply rail

17

18

3.3-V LVCMOS Input

VCC3IO_OSC

ESD diode to GND and supply rail

3.3-V LVDS Input

VCC33A_LVDS

ESD diode to GND and supply rail

19

3.3-V LVCMOS Input

VCC3IO_OSC

ESD diode to GND and supply rail

20

3.3-V LVCMOS Output

VCC3IO

ESD diode to GND and supply rail

TYPE

I

Input

O

Output

B

Bidirectional

PWR

Power

RTN

Ground return

N/A

Table 5-11. Internal Pullup and Pulldown Characteristics

INTERNAL PULLUP AND PULLDOWN

RESISTOR CHARACTERISTICS (1) (2)

VCCIO

MIN

MAX

UNIT

Weak pullup resistance

3.3 V

40

190

kΩ

Weak pulldown resistance

3.3 V

30

190

kΩ

(1)

(2)

14

The resistance is dependent on the supply voltage level applied to the I/O.

An external 8-kΩ or less pullup or pulldown (if needed) will work for any voltage condition to correctly override any associated internal

pullups or pulldowns.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature (unless otherwise noted)(1)

MIN

MAX

UNIT

V(VCCK) (Core)

–0.5

1.5

V

V(VCC11A_DDIx) (Core)

–0.5

1.5

V

V(VCC11A_LVDS) (Core)

–0.5

1.5

V

V(VCC11AD_PLLM) (Core)

–0.5

1.5

V

V(VCC11AD_PLLD) (Core)

–0.5

1.5

V

V(VCC18A_LVDS)

–0.5

2.5

V

V(VCC18IO)

–0.5

2.5

V

V(VCC3IO_MVGP)

–0.5

4.6

V

V(VCC3IO_INF)

–0.5

4.6

V

V(VCC3IO_FLSH)

–0.5

4.6

V

V(VCC3IO_OSC)

–0.5

4.6

V

V(VCC3IO)

–0.5

4.6

V

V(VCC33A_LVDS)

–0.5

4.6

V

–40

125

°C

°C

SUPPLY VOLTAGE(2)

GENERAL

TJ

Operating junction temperature

TC

Operating case temperature

–40

124(3)

Ilat

Latch-up

–100

100

mA

Tstg

Storage temperature range

–40

150

°C

(1)

(2)

(3)

Stresses beyond those listed under Section 6.1 may cause permanent damage to the device. These are stress ratings only, which do

not imply functional operation of the device at these or any other conditions beyond those indicated under Section 6.3. Exposure to

absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltage values are with respect to GND.

Value calculated using package parameters defined in Section 6.4.

6.2 ESD Ratings

Human-body model (HBM), per AEC Q100-002(1)

V(ESD)

(1)

Electrostatic

discharge

All pins (except corner pins)

Charged-device model (CDM), per

AEC Q100-011

Corner pins only (ZDQ: A1, A22,

AB0, and AB22)

(ZEK: A1, A18, V1, V18)

VALUE

ZDQ

VALUE

ZEK

Package

Package

±2000

TBD

±500

TBD

UNIT

V

±750

TBD

AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

15

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

1.045

1.1

1.155

V

V(VCCK)

Core power 1.1 V (main 1.1 V)

±5% tolerance

V(VCC11A_DDI_0)

Core power 1.1 V (External Filter Group A - HS

DMD Interface 0)

±8.18% tolerance(1)

1.01

1.1

1.19

V

V(VCC11A_DDI_1)

Core power 1.1 V (External Filter Group B - HS

DMD Interface 1)

±8.18% tolerance(1)

1.01

1.1

1.19

V

V(VCC11A_LVDS)

Core power 1.1 V (External Filter Group C OpenLDI Interface)

±8.18% tolerance(1)

1.01

1.1

1.19

V

V(VCC11AD_PLLM)

MCG PLL 1.1-V power (Analog/Digital)

±8.18% tolerance(1)

1.01

1.1

1.19

V

V(VCC11AD_PLLD)

DCG PLL 1.1-V power (Analog/Digital)

±8.18% tolerance(1)

1.01

1.1

1.19

V

V(VCC18IO)

1.8-V I/O power (Supports DMD Single-Ended

LS interface I/O)

±8.3% tolerance

1.65

1.8

1.95

V

V(VCC18A_LVDS)

1.8-V I/O power (Supports High-Speed and Low±8.3% tolerance

Speed differential DMD interfaces)

1.65

1.8

1.95

V

V(VCC3IO_MVGP)

3/3-V I/O power (Supports TPS99000-Q1: SPI,

±8.5% tolerance

interrupt, park, RESETZ, and LEDSEL interfaces

3.02

3.3

3.58

V

V(VCC3IO_FLSH)

3/3-V I/O power (Supports serial flash interface)

±8.5% tolerance

3.02

3.3

3.58

V

V(VCC3IO_INTF)

3.3-V I/O power (Supports: host command (SPI

and I2C), parallel data interface, HOST_IRQ, and ±8.5% tolerance

JTAG

3.02

3.3

3.58

V

V(VCC3IO_OSC)

3.3-V I/O power (Supports Oscillator)

±8.5% tolerance

3.02

3.3

3.58

V

V(VCC33A_LVDS)

3.3-V I/O power (Supports OpenLDI interface)

±8.5% tolerance

3.02

3.3

3.58

V

V(VCC3IO)

3.3-V I/O power (Supports all remaining

I/O including: GPIO, PMIC_AD3, TSTPT,

ETM_TRACE, et cetera)

±8.5% tolerance

3.02

3.3

3.58

V

TJ

Operating junction temperature

–40

125

°C

TC

Operating case temperature

–40

124

°C

TA

Operating ambient temperature(2)

–40

105

°C

(1)

(2)

These I/O supply ranges are wider to facilitate additional external filtering.

Operating ambient temperature is dependent on system thermal design. Operating case temperature may not exceed its specified

range across ambient temperature conditions.

6.4 Thermal Information

THERMAL

METRIC(1)

ψJT (2)

Temperature variance from junction to package top center

temperature, per unit power dissipation

ψJT (2)

Temperature variance from junction to package top

center temperature, per unit power dissipation “Advance

Information (not Production Data)”

(1)

(2)

16

DLPC230-Q1

DLPC231-Q1

ZDQ (BGA)

ZEK (nfBGA)

324 PINS

324 PINS

0.77

-

°C/W

-

0.2

°C/W

UNIT

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

(1.22 W) × (0.77°C/W) ≈ 1.00°C temperature difference.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6.5 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP(1)

MAX(2)

201

743.9

mA

UNIT

TOTAL

I(VCC11)

1.1-V total current

I(VCC18)

1.8-V total current

71

122.9

mA

I(VCC33)

3.3-V total current

28.1

30.1

mA

131.5

667.5

mA

ESTIMATED CURRENT PER

SUPPLY(3)

I(VCCK)

1.1-V Core current

I(VCC11A_DDI_0)

1.1-V Core current (Filtered)

At 600-MHz data rate

15.8

17.4

mA

I(VCC11A_DDI_1)

1.1-V Core current (Filtered)

At 600-MHz data rate

15.8

17.4

mA

I(VCC11A_LVDS)

1.1-V Core current (Filtered)

OpenLDI Interface, single port, 5

lanes active

22.5

24.8

mA

I(VCC11AD_PLLM)

1.1-V Core current (MCG PLL)

7.7

8.4

mA

I(VCC11AD_PLLD)

1.1-V Core current (DCG PLL)

7.7

8.4

mA

I(VCC18A_LVDS)

1.8-V I/O current (Both 8-bit ports DMD HS differential Interface)

At 600-MHz data rate

63.3

106.6

mA

I(VCC18A_LVDS)

1.8-V I/O current (DMD LS differential

Interface)

At 120-MHz data rate

5.2

8.7

mA

I(VCC18IO)

1.8-V I/O current (DMD LS singleended interfaces, DMD reset)

2.5

7.6

mA

I(VCC3IO_MVGP)

3.3-V I/O current (TPS99000-Q1 SPI,

TPS99000-Q1 Reset, PMIC_PARKZ,

RESETZ)

1.7

1.8

mA

I(VCC3IO_INTF)

3.3-V I/O current (Host SPI, Host I2C,

Host IRQ, JTAG, Parallel Port)

1.7

1.8

mA

I(VCC3IO_FLSH)

3.3-V I/O current (Serial Flash SPI

interface)

5.5

5.9

mA

I(VCC3IO_OSC)

3.3-V I/O current (Crystal/Oscillator)

0.975

1.3

mA

I(VCC3IO)

3.3-V I/O current (GPIO, PMIC_AD3,

Mstr I2C, TSTPT, ETM, and so forth)

12.6

13.5

mA

I(VCC33A_LVDS)

3.3-V I/O current (OpenLDI Interface each port - 5 lanes active)

6.3

6.8

mA

(1)

(2)

(3)

With 3-kΩ external series resistor

(RS)

Typical-case power measured with PVT condition = nominal process, typical voltage, typical temperature (25°C junction). Input source

1152 × 576 24-bit 60-Hz OpenLDI with RGBW ramp image.

Worst-case power PVT condition = corner process, high voltage, high temperature (125°C junction). Input source 1152 × 1152 24-bit.

60 Hz OpenLDI with pseudo-random noise image.

Estimated current per supply was not directly measured. These values are based on an approximate expected current consumption

percentage of the total measured current drawn by each voltage rail.

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

17

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6.6 Electrical Characteristics for Fixed Voltage I/O

over operating free-air temperature range (unless otherwise noted)(1)

PARAMETER

VIH

High-level

input

threshold

voltage

TEST CONDITIONS

MIN

1.8-V LVCMOS (I/O type 3)

0.7 × VCC18IO

3.3-V LVCMOS (I/O type 7)

2.0

3.3-V LVCMOS (I/O type 9)

2.0

3.3-V LVCMOS (I/O type 11)

2.0

3.3-V

I2C

buffer (I/O type 12)

0.7 × VCC_INTF

3.3-V LVCMOS (I/O type 14)

2.0

3.3-V LVCMOS (I/O type 16,17)

3.3-V

VIL

Low-level

input

threshold

voltage

buffer (I/O type 15)

0.7 × VCC3IO

0.3 × VCC18IO

3.3-V LVCMOS (I/O type 7)

0.8

3.3-V LVCMOS (I/O type 9)

0.8

3.3-V LVCMOS (I/O type 11)

0.8

3.3-V

buffer (I/O type 12)

0.3 × VCC_INTF

3.3-V LVCMOS (I/O type 14)

0.8

3.3-V

VOL

IOH

Low-level

output

voltage

High-level

output

current

0.8

buffer (I/O type 15)

0.3 × VCC3IO

1.8-V LVCMOS (I/O type 1,2)

IOH = Max rated

0.75 × VCC18IO

3.3-V LVCMOS (I/O type 6)

IOH = Max rated

2.4

3.3-V LVCMOS (I/O type 8)

IOH = Max rated

2.4

3.3-V LVCMOS (I/O type 10)

IOH = Max rated

2.4

3.3-V I2C buffer (I/O type 12)

IOH = Max rated

N/A

3.3-V LVCMOS (I/O type 13)

IOH = Max rated

2.4

3.3-V I2C buffer (I/O type 15)

IOH = Max rated

N/A

3.3-V LVCMOS (I/O type 20)

IOH = Max rated

2.4

1.8-V LVCMOS (I/O type 1,2)

IOL = Max rated

0.4

3.3-V LVCMOS (I/O type 6)

IOL = Max rated

0.4

3.3-V LVCMOS (I/O type 8)

IOL = Max rated

0.4

3.3-V LVCMOS (I/O type 10)

IOL = Max rated

0.4

3.3-V I2C buffer (I/O type 12)

IOL = Max rated

0.4

3.3-V LVCMOS (I/O type 13)

IOL = Max rated

0.4

3.3-V I2C buffer (I/O type 15)

IOL = Max rated

0.4

3.3-V LVCMOS (I/O type 20)

IOL = Max rated

6

1.8-V LVCMOS (I/O type 2)

7.2

3.3-V LVCMOS (I/O type 6)

6

3.3-V LVCMOS (I/O type 8)

6

3.3-V LVCMOS (I/O type 10)

6

3.3-V

I2C

buffer (I/O type 12)

N/A

3.3-V LVCMOS (I/O type 13)

8

I2C

buffer (I/O type 15)

N/A

3.3-V LVCMOS (I/O type 20)

6

Submit Document Feedback

V

V

0.4

1.8-V LVCMOS (I/O type 1)

3.3-V

18

I2C

V

0.3 × VCC3IO

3.3-V LVCMOS (I/O type 19)

VOH

V

1.8-V LVCMOS (I/O type 3)

I2C

UNIT

2.0

3.3-V LVCMOS (I/O type 16,17)

High-level

output

voltage

MAX

0.7 × VCC3IO

3.3-V LVCMOS (I/O type 19)

I2C

TYP

mA

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6.6 Electrical Characteristics for Fixed Voltage I/O (continued)

over operating free-air temperature range (unless otherwise noted)(1)

PARAMETER

Low-level

output

current

IOL

IOZ

MIN

6

1.8-V LVCMOS (I/O type 2)

7.2

3.3-V LVCMOS (I/O type 6)

6

3.3-V LVCMOS (I/O type 8)

6

3.3-V LVCMOS (I/O type 10)

6

3.3-V

I2C

buffer (I/O type 12)

3

3.3-V LVCMOS (I/O type 13)

8

3.3-V

Highimpedance

leakage

current

TEST CONDITIONS

1.8-V LVCMOS (I/O type 1)

I2C

buffer (I/O type 15)

3

3.3-V LVCMOS (I/O type 20)

6

TYP

MAX

mA

1.8-V LVCMOS (I/O type 1,2)

±1.0

±10

3.3-V LVCMOS (I/O type 6)

±1.0

±10

3.3-V LVCMOS (I/O type 8)

±1.0

±10

3.3-V LVCMOS (I/O type 10)

±1.0

±10

3.3-V

I2C

buffer (I/O type 12)

±10

3.3-V LVCMOS (I/O type 13)

±1.0

3.3-V LVCMOS (I/O type 16)

±1.0

µA

±10

3.3-V I2C buffer (I/O type 15)

±10

3.3-V LVCMOS (I/O type 20)

(1)

UNIT

±1.0

±10

The number inside each parenthesis for the I/O refers to the type defined in Table 5-10.

6.7 DMD High-Speed Sub-LVDS Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER

MIN

NOM

MAX

0.8

0.9

1.0

UNIT

V

75

mV

10

mV

250

mV

10

mV

VCM

Steady-state common mode voltage

1.8-V sub-LVDS (I/O type 4,5)

VCM (Δpp)(1)

VCM change peak-to-peak (during

switching)

1.8-V sub-LVDS (I/O type 4,5)

VCM (Δss)(1)

VCM change steady state

1.8-V sub-LVDS (I/O type 4,5)

–10

|VOD|(2)

Differential output voltage magnitude. RBGR

1.8-V sub-LVDS (I/O type 4,5)

= 75kΩ.

155

VOD (Δ)(3)

VOD change (between logic states)

1.8-V sub-LVDS (I/O type 4,5)

–10

VOH

Single-ended output voltage high

1.8-V sub-LVDS (I/O type 4,5)

0.88

1.00

1.125

V

VOL

Single-ended output voltage low

1.8-V sub-LVDS (I/O type 4,5)

0.675

0.80

0.925

V

ps

tR

(2)

200

Differential output rise time

1.8-V sub-LVDS (I/O type 4,5)

250

tF (2)

Differential output fall time

1.8-V sub-LVDS (I/O type 4,5)

250

ps

fMAX

Max switching rate

1.8-V sub-LVDS (I/O type 4,5)

1200

Mbps

DCout

Output duty cycle

1.8-V sub-LVDS (I/O type 4,5)

45%

50%

55%

Txterm (1)

Internal differential termination

1.8-V sub-LVDS (I/O type 4,5)

80

100

120

(1)

Ω

Definition of VCM changes:

VCM

VCM (4ss)

VCM (4pp)

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

19

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

(2)

Note that VOD is the differential voltage swing measured across a 100-Ω termination resistance connected directly between the

transmitter differential pins. |VOD| is the magnitude of the peak to peak voltage swing across the P and N output pins. Because VCM

cancels out when measured differentially, VOD voltage swings relative to 0. Rise and fall times are defined for the differential VOD signal

as follows:

tF

tR

+ Vod

80%

|Vod|

VOD

0V

|Vod|

20%

- Vod

Differential Output Signal

(Note: VCM is removed when signals are viewed differentially)

An invisible line to help with spacing in spec

(3)

When TX data input = '1', differential output voltage VOD1 is defined. When TX data input = '0', differential output voltage VOD0 is

defined. As such, the steady state magnitude of the difference is: |VOD| (Δ) = ||VOD1| – |VOD0||.

6.8 DMD Low-Speed Sub-LVDS Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER

MIN

NOM

MAX

0.8

0.9

1.0

UNIT

V

75

mV

10

mV

250

mV

10

mV

VCM

Steady-state common mode voltage

1.8-V sub-LVDS (I/O type 4,5)

VCM (Δpp)(1)

VCM change peak-to-peak (during

switching)

1.8-V sub-LVDS (I/O type 4,5)

VCM (Δss)(1)

VCM change steady state

1.8-V sub-LVDS (I/O type 4,5)

–10

|VOD|(2)

Differential output voltage magnitude.

RBGR = 75kΩ.

1.8-V sub-LVDS (I/O type 4,5)

155

VOD (Δ)(3)

VOD change (between logic states)

1.8-V sub-LVDS (I/O type 4,5)

–10

VOH

Single-ended output voltage high

1.8-V sub-LVDS (I/O type 4,5)

0.88

1.00

1.125

V

VOL

Single-ended output voltage low

1.8-V sub-LVDS (I/O type 4,5)

0.675

0.80

0.925

V

tR

(2)

200

Differential output rise time

1.8-V sub-LVDS (I/O type 4,5)

250

ps

tF (2)

Differential output fall time

1.8-V sub-LVDS (I/O type 4,5)

250

ps

tMAX

Max switching rate

1.8-V sub-LVDS (I/O type 4,5)

240

Mbps

DCout

Output duty cycle

1.8-V sub-LVDS (I/O type 4,5)

45%

50%

55%

Txterm

Internal differential termination

1.8-V sub-LVDS (I/O type 4,5)

80

100

120

(1)

Ω

Definition of VCM changes:

VCM

VCM (4ss)

VCM (4pp)

(2)

20

Note that VOD is the differential voltage swing measured across a 100-Ω termination resistance connected directly between the

transmitter differential pins. |VOD| is the magnitude of the peak to peak voltage swing across the P and N output pins. Because VCM

cancels out when measured differentially, VOD voltage swings relative to 0. Rise and fall times are defined for the differential VOD signal

as follows:

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

tF

tR

+ Vod

80%

|Vod|

VOD

0V

|Vod|

20%

- Vod

Differential Output Signal

(Note: VCM is removed when signals are viewed differentially)

An invisible line to help with spacing in spec

(3)

When TX data input = '1', differential output voltage VOD1 is defined. When TX data input = '0', differential output voltage VOD0 is

defined. As such, the steady state magnitude of the difference is: |VOD| (Δ) = ||VOD1| - |VOD0||.

6.9 OpenLDI LVDS Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER

MIN

NOM

1.2

VCM

Steady-state common mode voltage

3.3-V LVDS (I/O type 18)

0.35

|VID|

Differential Input Voltage

3.3-V LVDS (I/O type 18)

100

Rxterm

Internal differential termination

3.3-V LVDS (I/O type 18)

90

111

MAX

UNIT

1.6

V

700

mV

132

Ω

6.10 Power Dissipation Characterisics

PARAMETER

PMAX

Package - Maximum Power

VALUE

UNIT

1.22

W

6.11 System Oscillators Timing Requirements

fclock

Clock frequency, MOSC(1)

(1)

MIN

NOM

MAX

UNIT

15.997

16.000

16.003

MHz

62.488

62.500

62.512

ns

2

ns

100

ps

tc

Cycle time, MOSC

tw(H)

Pulse duration(2), MOSC, high

50% to 50% reference points (signal)

40% of tc

tw(L)

Pulse duration(2), MOSC, low

50% to 50% reference points (signal)

40% of tc

tt

Transition time(2), MOSC, tt = tƒ / tr

20% to 80% reference points (signal)

0.2

tjp

(1)

(2)

jitter(2),

Long term periodic

MOSC

(that is the deviation in period from ideal period due solely to high frequency jitter)

The MOSC input cannot support spread spectrum clock spreading.

Applies only when driven through an external digital oscillator. This is a 1 sigma RMS value.

tw(H)

MOSC

50%

tt

tt

tc

tw(L)

50%

80%

80%

20%

20%

50%

Figure 6-1. System Oscillators

Table 6-1. Crystal / Oscillator Electrical Characteristics

PARAMETER

NOMINAL

PLL_REFCLK_I TO GND capacitance

UNIT

3.5

pF

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

21

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

Table 6-1. Crystal / Oscillator Electrical Characteristics (continued)

PARAMETER

NOMINAL

PLL_REFCLK_O TO GND capacitance

UNIT

3.45

pF

6.12 Power Supply and Reset Timing Requirements

MIN

MAX

UNIT

0.5

10

ms

10

µs

TPS99000-Q1 REQUIREMENTS(1)

tramp

Power supply ramp time(2)

Power supply ramp to minimum

recommended operating voltage

tps_aln

1.1-V Power Supply Alignment(3)

Leading edge for application or removal

of power. Each 1.1-V power supply

to the DLPC23x-Q1 must be applied

simultaneously within this time.

trst

RESETZ low to Power Supply disable(4)

Leading edge for removal of power

1.0

µs

tw(L1)

Pulse duration, active low, RESETZ(4)

95% power to 50% RESETZ reference point

At initial application of power

5.0

ms

tw(L2)

Pulse duration, active low, RESETZ

50% to 50% reference points (RESETZ)

Subsequent resets after initial application of

power

1.0

µs

tt

Transition time, RESETZ, tt = tƒ and tr

20% to 80% reference points (signal)

(1)

(2)

(3)

µs

The TPS99000-Q1 controls power supply timing for the DLPC23x-Q1. Refer to the TPS99000-Q1 data sheet for additional system

power timing requirements.

Power supplies do not need to ramp simultaneously, but each supply must reach its minimum voltage within the maximum ramp time

specified.

The DLPC23x-Q1 does not require specific sequencing or alignment of 1.8-V and 3.3-V supplies. However, the TPS99000-Q1

enforces sequencing of the 1.1-V, 1.8-V, and 3.3-V voltage rails. The following describes DLPC23x-Q1 behavior when the voltage rails

are not brought up simultaneously:

•

•

(4)

6

VCCK (1.1-V core) Power = On, I/O Power = Off, RESETZ = '0': While this condition exists, additional leakage current can be

drawn, and all outputs are unknown (likely to be a weak "low").

VCCK (1.1-V core) Power = Off, I/O Power = On, RESETZ = '0': While this condition exists all outputs are tri-stated.

Neither of these two conditions will impact normal DLPC23x-Q1 reliability.

RESETZ must be held low if any supply (Core or I/O) is less than its minimum specified on value. For more information on RESETZ,

see Section 5.

tramp

All 1.1V Power

(Core Power)

95% of specified

nominal value

All 1.8V & 3.3V Power

(I/O Power)

TPS99000

Control

tt

95% of specified

nominal value

RESETZ

50%

trst

80%

20%

tw(L1)

tw(L2)

PARKZ

DLPC230

Control

DMD Control

Signals

Control / Display

Park

Figure 6-2. Power Supply and RESETZ Timing

22

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6.13 Parallel Interface General Timing Requirements

MIN

MAX

UNIT

ƒclock

Clock frequency, PCLK

12.0

110.0

MHz

tp_clkper

Clock period, PCLK

50% reference points

9.091

83.33

ns

tp_wh

Pulse duration low, PCLK

50% reference points

2.286

ns

tp_wl

Pulse duration high, PCLK

50% reference points

2.286

ns

tp_su

Setup time – HSYNC, DATEN,

PDATA(23:0) valid before the active

edge of PCLK

50% reference points

0.8

ns

tp_h

Hold time – HSYNC, DATEN,

PDATA(23:0) valid after the active edge

of PCLK

50% reference points

0.8

ns

tt_clk

Transition time – PCLK

20% to 80% reference points

6

ns

tt

Transition time – all other signals on this

20% to 80% reference points

port

6

ns

ƒspread

Supported Spread Spectrum range

ƒmod

Supported Spread Spectrum Modulation Frequency(1) (2)

tp_clkjit

Clock jitter, PCLK

(1)

(2)

(3)

Percent of ƒclock rate

–1%

+1%(1)

25

65(3)

tp_clkper – 5.414

kHz

ps

This value is limited by the maximum clock frequency for ƒclock (that is, if ƒclock = max clock freq, then ƒspread max = 0%).

Modulation Waveforms supported: Sine and Triangle.

Spread spectrum modulation tested at a maximum of 35 kHz. Simulated up to 65 kHz.

tp_clkper

tp_wh

tp_wl

PCLK

tp_su

tp_h

Figure 6-3. Parallel Interface General Timing

6.14 OpenLDI Interface General Timing Requirements

The DLPC23x-Q1 ASIC input interface supports a subset of the industry standard OpenLDI (FPD-Link I) interface (Open

LVDS Display Interface Specification v0.95 - May 13, 1999). Specifically, from the standard, the ASIC supports the 24-bit,

Single Pixel Format, using the Unbalanced Operating Mode and Pixel Mapping.

MIN

ƒclock

Clock frequency, L1_CLK_P/N, L2_CLK_P/N

NOM

MAX

UNIT

20.0

110

MHz

9.091

50

ns

400(5)

ps

tp

Clock period, PCLK

50% reference

points

tskew

Skew Margin (between clock and

data )

ƒclock = 85 MHz

tskew_ports

Clock to clock skew margin between ports on same

ASIC, and between ports on different ASICs

tip0

Input data position 1

(tp / 7) – tskew

(tp / 7)

(tp / 7) + tskew

ps

tip6

Input data position 2

2 * (tp / 7) – tskew

2 * (tp / 7)

2 * (tp / 7) + tskew

ps

tip5

Input data position 3

3 * (tp / 7) – tskew

3 * (tp / 7)

3 * (tp / 7) + tskew

ps

tip4

Input data position 4

4 * (tp / 7) – tskew

4 * (tp / 7)

4 * (tp / 7) + tskew

ps

tip3

Input data position 5

5 * (tp / 7) – tskew

5 * (tp / 7)

5 * (tp / 7) + tskew

ps

tip2

Input data position 6

6 * (tp / 7) – tskew

6 * (tp / 7)

6 * (tp / 7) + tskew

ps

–400 (5)

0

1

clocks

Submit Document Feedback

Copyright © 2023 Texas Instruments Incorporated

Product Folder Links: DLPC230-Q1 DLPC231-Q1

23

�DLPC230-Q1, DLPC231-Q1

www.ti.com

DLPS054G – DECEMBER 2015 – REVISED SEPTEMBER 2023

6.14 OpenLDI Interface General Timing Requirements (continued)