Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

DLPC4422

DLPS074 – FEBRUARY 2017

DLPC4422 DLP® Display Controller

1 Features

•

1

•

•

•

•

•

•

•

•

•

Provides Two 30-bit Input Pixel Interfaces or One

60-bit Input Pixel Interface:

– YUV, YCrCb, or RGB Data Format

– 8, 9 or 10 Bits per Color

– Pixel Clock Support Up to 175 MHz for 30-bit

and 160 MHz for 60-bit

Supports 24-30 Hz and 47-120 Hz Frame Rates

Full Single DLP Controller Support For DMD™s

Up to 1920 Pixels Wide

Dual DLP Controller Support For Up to 4K Ultra

High Definition (UHD) Resolution Display Using

DLP660TE TRP DMD

High-Speed, Low Voltage Differential Signaling

(LVDS) DMD Interface

150 MHz ARM946™ Microprocessor

Microprocessor Peripherals

– Programmable Pulse-Width Modulation (PWM)

and Capture Timers

– Three I2C Ports, Three UART Ports and Three

SSP Ports

– One USB 1.1 Slave Port

Image Processing

– Multiple Image Processing Algorithms

– Frame Rate Conversion

– Color Coordinate Adjustment

– Programmable Color Space Conversion

– Programmable Degamma and Splash

– Integrated Support for 3-D Display

On-Screen Display (OSD)

Integrated Clock Generation Circuitry

– Operates on a Single 20 MHz Crystal

– Integrated Spread Spectrum Clocking

External Memory Support

– Parallel Flash for Microprocessor and PWM

Sequence

– Optional SRAM

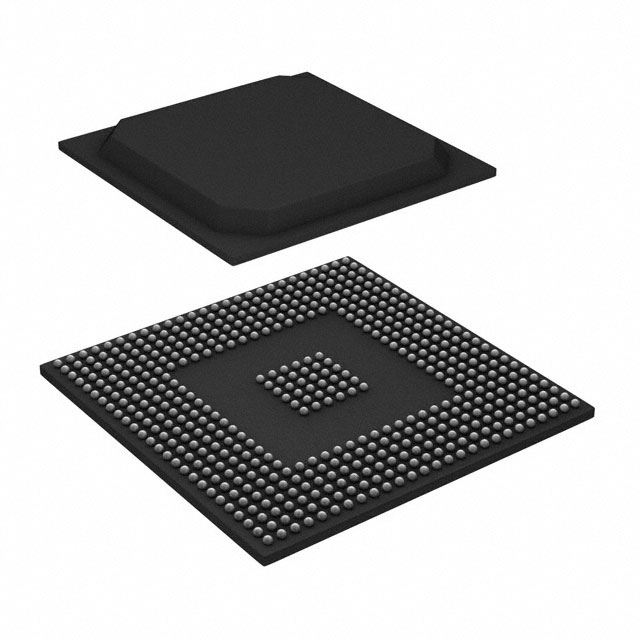

516 Pin Plastic Ball Grid Array Package

Supports Lamp, LED, and Laser Hybrid

Illumination Systems

•

•

•

2 Applications

•

•

•

•

4K Ultra High Definition (UHD) Display

Laser TV

Digital Signage

Projection Mapping

3 Description

DLPC4422 is a digital display controller for the DLP

4K UHD display chipset. The DLPC4422 display

controller, together with the DLP660TE DMD and

DLPA100 power management and motor driver

device, comprise the chipset. This solution is a great

fit for display systems that require high resolution,

high brightness and system simplicity. To ensure

reliable operation, the DLPC4422 display controller

must always be used with the DLP660TE DMD and

the DLPA100 power management and motor driver

device.

Device Information(1)

PART NUMBER

DLPC4422

PACKAGE

ZPC (516)

BODY SIZE (NOM)

27.00 mm × 27.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Simplified Schematic

LENS

12 V

CTRL

Signals

FLASH

Front End Ctrl

ADDR

Optical Path

1.8 V

DATA

16

2.5 V

3.3 V

5V

DLP

DMD

Phosphor Wheel

Motor Control

Data, 60 BIT

DLPC4422

Illumination

Path

Illumination

Source

2xLVDS Data

DAD Ctrl and SCP Ctrl

FLEX

Front End

Board

Connector

23

1.1 V

DLPA100

TPS65145

JTAG

DMD Board

Laser

Driver

LED/Laser Driver Ctrl

Formatter Board

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Table of Contents

1

2

3

4

5

6

6.15 JTAG Interface: I/O Boundary Scan Application

Switching Characteristics ......................................... 23

Features .................................................................. 1

Applications ........................................................... 1

Description ............................................................. 1

Revision History..................................................... 2

Pin Configuration and Functions ......................... 3

Specifications....................................................... 14

7

Detailed Description ............................................ 27

7.1 Overview ................................................................. 27

7.2 Functional Block Diagram ....................................... 27

7.3 Feature Description................................................. 27

8

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

Absolute Maximum Ratings .................................... 14

ESD Ratings............................................................ 14

Recommended Operating Conditions..................... 15

Thermal Information ................................................ 15

Electrical Characteristics......................................... 16

System Oscillators Timing Requirements ............... 18

Test and Reset Timing Requirements .................... 18

JTAG Interface: I/O Boundary Scan Application

Timing Requirements............................................... 19

6.9 Port 1 Input Pixel Timing Requirements ................. 19

6.10 Port 3 Input Pixel Interface (via GPIO) Timing

Requirements........................................................... 20

6.11 DMD LVDS Interface Timing Requirements ......... 21

6.12 Synchronous Serial Port (SSP) Interface Timing

Requirements........................................................... 21

6.13 Programmable Output Clocks Switching

Characteristics ......................................................... 22

6.14 Synchronous Serial Port Interface (SSP) Switching

Characteristics ......................................................... 22

Application and Implementation ........................ 32

8.1 Application Information............................................ 32

8.2 Typical Application .................................................. 32

9

Power Supply Recommendations...................... 35

9.1

9.2

9.3

9.4

System Power Regulations.....................................

System Power-Up Sequence ..................................

Power-On Sense (POSENSE) Support ..................

System Environment and Defaults..........................

35

35

36

36

10 Layout................................................................... 37

10.1 Layout Guidelines ................................................. 37

11 Device and Documentation Support ................. 44

11.1

11.2

11.3

11.4

11.5

11.6

Device Support......................................................

Documentation Support ........................................

Support Resources ...............................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

44

45

46

46

46

46

12 Mechanical, Packaging, and Orderable

Information ........................................................... 46

4 Revision History

2

DATE

REVISION

NOTES

February 2017

*

Initial release.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

5 Pin Configuration and Functions

ZPC Package

516-Pin BGA

Bottom View

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

3

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Pin Configurations and Functions

PIN (1)

NAME

POSENSE

PWRGOOD

EXT_ARTZ

MTR_ARTZ

I/O (2)

DESCRIPTION

NO.

P22

T26

T24

T25

I4

Power-On Sense, High true, signal provided from an external voltage monitor circuit.

This signal should be driven active (high) when all ASIC supply voltages have

reached 90% of their specified minimum voltage. This signal should be driven

inactive (low) after the falling edge of PWRGOOD as specified.

I4

Power Good, High true, signal from external power supply or voltage monitor. A high

value indicates all power is within operating voltage specs and the system is safe to

exit its reset state. A transition from high to low is used to indicate that the controller

or DMD supply voltage will drop below their rated minimum level. This transition must

occur prior to the supply voltage drop as specified. During this interval, POSENSE

must remain active high. This is an early warning of an imminent power loss

condition. This warning is required to enhance long term DMD reliability. A DMD park

followed by a full controller reset is performed by the DLPC4422 controller when

PWRGOOD goes low for the specified minimum, protecting the DMD. This minimum

de-assertion time is used to protect the input from glitches. Following this the

DLPC4422 controller will be held in its reset state as long as PWRGOOD is low.

PWRGOOD must be driven high for normal operation. The DLPC4422 controller will

acknowledge PWRGOOD as active once it’s been driven high for it’s specified

minimum time. Uses hysteresis.

O2

General purpose, LOW true, reset output. This output is asserted low immediately

upon asserting power-up reset (POSENSE) low and remains low while POSENSE

remains low. EXT_ARSTZ continues to be held low after the release of power-up

reset (that is, POSENSE set high) until released by software. EXT_ARSTZ is also

asserted low approximately 5µs after the detection of a PWRGOOD or any internally

generated reset. In all cases it will remain active for a minimum of 2ms. Note that the

ASIC contains a software register that can be used to independently drive this output.

O2

Color wheel motor controller, LOW true, reset output. This output is asserted low

immediately upon asserting power-up reset (POSENSE) low and remains low while

POSENSE remains low. MTR_ARSTZ will continue to be held low after the release of

power-up reset (i.e. POSENSE set high) until released by software. MTR_ARSTZ is

also optionally asserted low approximately 5 µs after the detection of a PWRGOOD

or any internally generated reset. In all cases it will remain active for a minimum of 2

ms. Note that the ASIC contains a software register that can be used to

independently drive this output. The ASIC also contains a software register that can

be used to disable the assertion of motor reset upon a lamp strike reset..

BOARD LEVEL TEST AND INITIALIZATION (3)

TDI

N25

I4

JTAG serial data in

TCK

N24

I4

JTAG serial data clock

TMS1

P25

I4

JTAG test mode select

TMS2

P26

I4

JTAG test mode select

TDO1

N23

O5

JTAG serial data out

TDO2

N22

O5

JTAG serial data out

TRSTZ

M23

I4

JTAG reset. This signal includes an internal pull-up and utilizes hysteresis. This pin

should be pulled high (or left unconnected) when the JTAG interface is in use for

boundary scan or ARM debug. Connect this pin to ground otherwise. Failure to tie

this pin low during normal operation will cause startup and initialization problems.

RTCK

E4

O2

JTAG Return Clock

ETM_PIPESTAT_2

A4

B2

ETM_PIPESTAT_1

B5

B2

ETM_PIPESTAT_0

C6

B2

ETM_TRACESYNC

A5

B2

ETM Trace Port Synchronization signal, indicating the start of a branch sequence on

the trace packet port. This signal includes an internal pull-down.

ETM_TRACECLK

D7

B2

ETM Trace Port Clock. This signal includes an internal pull-down.

M24

I4

IC Tri-State Enable (active high). Asserting high will Tri-state all outputs except the

JTAG interface. This signal includes an internal pull-down however TI recommends

an external pull-down for added protection. Uses hysteresis.

TSTPT_7

E8

B2

TSTPT_6

B4

B2

TSTPT_5

C4

B2

TSTPT_4

E7

B2

ICTSEN

ETM Trace Port Pipeline Status. Indicates the pipeline status of the ARM core. These

signals include internal pull-downs.

Test pin 7 - This signal provides internal pull-downs.

Normal Use: reserved for test output. Should be left open or unconnected for normal

use.

Test pin 6 - This signal provides internal pull-downs.

Normal Use: reserved for test output. Should be left open or unconnected for normal

use.

Test pin 5 - This signal provides internal pull-downs.

Normal Use: reserved for test output. Should be left open or unconnected for normal

use.

Test pin 4 - This signal provides internal pull-downs.

(1)

(2)

(3)

4

Normal Use: reserved for test output. Should be left open or unconnected for normal

use.

For instructions on handling unused pins, see General Handling Guidelines for Unused CMOS-Type Pins.

I/O Type: I = Input, O = Output, B = Bidirectional, and H = Hysteresis. See Table 1 for subscript explanation.

All JTAG signals are LVTTL compatible.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

Pin Configurations and Functions (continued)

PIN

NAME

(1)

I/O (2)

DESCRIPTION

NO.

Test pin 3 - This signal provides internal pull-downs.

TSTPT_3

D5

B2

TSTPT_2

E6

B2

Test pin 2 - This signal provides internal pull-downs. Additionally, TI recommends

that jumper options be provided for connecting TSTPT(2:0) to external pull-ups.

TSTPT_1

D3

B2

Test pin 1 - This signal provides internal pull-downs. Additionally, TI recommends

that jumper options be provided for connecting TSTPT(2:0) to external pull-ups.

TSTPT_0

C2

B2

Test pin 0 - This signal provides internal pull-downs. Additionally, TI recommends

that jumper options be provided for connecting TSTPT(2:0) to external pull-ups.

M25

I4

Device manufacturing test enable; This signal includes an internal pull-down and

utilizes hysteresis. TI recommends that this signal be tied to an external ground in

normal operation for added protection.

Normal Use: reserved for test output. Should be left open or unconnected for normal

use.

DEVICE TEST

HW_TEST_EN

ANALOG FRONT END

AFE_ARSTZ

AC12

O2

Analog Front End, LOW true, Reset Output. This output is asserted low immediately

upon asserting power-up reset (POSENSE) low and remains low while POSENSE

remains low. AFE_ARSTZ will continue to be held low after the release of power-up

reset (i.e. POSENSE set high) until released by software. AFE_ARSTZ is also

asserted low approximately 5µs after the detection of a PWRGOOD or any internally

generated reset. In all cases it will remain active for a minimum of 2ms after the reset

condition is released by software. Note that the ASIC contains a software register

that can be used to independently drive this output.

AFE_CLK

AD12

O6

Analog Front End External Clock output for video decoder operation. Supports

programmable output drive.

AFE_IRQ

AB13

I4

Analog Front End Interrupt (Active High). This signal includes an internal pull-down

and utilizes hysteresis.

PORT1 and PORT 2 CHANNEL DATA and CONTROL (4) (5) (6) (7)

P_CLK1

AE22

I4

Input Port Data Pixel Write Clock (selectable as rising or falling edge triggered, and

which port it is associated with (A or B or (A and B))). This signal includes an internal

pull-down.

P_CLK2

W25

I4

Input Port Data Pixel Write Clock (selectable as rising or falling edge triggered, and

which port it is associated with (A or B or (A and B))). This signal includes an internal

pull-down.

P_CLK3

AF23

I4

Input Port Data Pixel Write Clock (selectable as rising or falling edge triggered, and

which port it is associated with (A or B or (A and B))). This signal includes an internal

pull-down.

P_DATAEN1

AF22

I4

Active High Data Enable. Selectable as to which port it is associated with (A or B or

(A and B)).This signal includes an internal pull-down.

P_DATAEN2

W24

I4

Active High Data Enable. Selectable as to which port it is associated with (A or B or

(A and B)).This signal includes an internal pull-down.

P1_A_9

AD15

I4

Port 1 A Channel Input Pixel Data (bit weight 128)

P1_A_8

AE15

I4

Port 1 A Channel Input Pixel Data (bit weight 64)

P1_A_7

AE14

I4

Port 1 A Channel Input Pixel Data (bit weight 32)

P1_A_6

AE13

I4

Port 1 A Channel Input Pixel Data (bit weight 16)

P1_A_5

AD13

I4

Port 1 A Channel Input Pixel Data (bit weight 8)

P1_A_4

AC13

I4

Port 1 A Channel Input Pixel Data (bit weight 4)

P1_A_3

AF14

I4

Port 1 A Channel Input Pixel Data (bit weight 2)

P1_A_2

AF13

I4

Port 1 A Channel Input Pixel Data (bit weight 1)

P1_A_1

AF12

I4

Port 1 A Channel Input Pixel Data (bit weight 0.5)

P1_A_0

AE12

I4

Port 1 A Channel Input Pixel Data (bit weight 0.25)

P1_B_9

AF18

I4

Port 1 B Channel Input Pixel Data (bit weight 128)

P1_B_8

AB18

I4

Port 1 B Channel Input Pixel Data (bit weight 64)

P1_B_7

AC15

I4

Port 1 B Channel Input Pixel Data (bit weight 32)

P1_B_6

AC16

I4

Port 1 B Channel Input Pixel Data (bit weight 16)

P1_B_5

AD16

I4

Port 1 B Channel Input Pixel Data (bit weight 8)

(4)

(5)

(6)

(7)

Ports 1 and 2 can each be used to support multiple source options for a given product (e.g., AFE & HDMI). To do so, the data bus from

both source components must be connected to the same port pins (1 or 2) and control given to the DLPC4422 device to tri-state the

"inactive" source. Tying them together like this will cause some signal degradation due to reflections on the tri-stated path. Given the

clock is the most critical signal, three Port clocks (1,2,and 3) are provided to provide an option to improve the signal integrity.

Ports 1 and 2 can be used separately as two 30-bit ports, or can be combined into one 60-bit port (typically for high data rate sources)

for transmission of two pixels per clock.

The A, B, C input data channels of Ports 1 and 2 can be internally re-configured/ re-mapped for optimum board layout.

Sources feeding less than the full 10-bits per color component channel should be MSB justified when connected to the DLPC4422

controller and the LSBs tied off to zero. For example an 8-bit per color input should be connected to bits 9:2 of the corresponding A, B,

C input channel.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

5

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Pin Configurations and Functions (continued)

PIN

NAME

(1)

I/O (2)

DESCRIPTION

NO.

P1_B_4

AE16

I4

Port 1 B Channel Input Pixel Data (bit weight 4)

P1_B_3

AF16

I4

Port 1 B Channel Input Pixel Data (bit weight 2)

P1_B_2

AF15

I4

Port 1 B Channel Input Pixel Data (bit weight 1)

P1_B_1

AC14

I4

Port 1 B Channel Input Pixel Data (bit weight 0.5)

P1_B_0

AD14

I4

Port 1 B Channel Input Pixel Data (bit weight 0.25)

P1_C_9

AD20

I4

Port 1 C Channel Input Pixel Data (bit weight 128)

P1_C_8

AE20

I4

Port 1 C Channel Input Pixel Data (bit weight 64)

P1_C_7

AE21

I4

Port 1 C Channel Input Pixel Data (bit weight 32)

P1_C_6

AF21

I4

Port 1 C Channel Input Pixel Data (bit weight 16)

P1_C_5

AD19

I4

Port 1 C Channel Input Pixel Data (bit weight 8)

P1_C_4

AE19

I4

Port 1 C Channel Input Pixel Data (bit weight 4)

P1_C_3

AF19

I4

Port 1 C Channel Input Pixel Data (bit weight 2)

P1_C_2

AF20

I4

Port 1 C Channel Input Pixel Data (bit weight 1)

P1_C_1

AC19

I4

Port 1 C Channel Input Pixel Data (bit weight 0.5)

P1_C_0

AE19

I4

Port 1 C Channel Input Pixel Data (bit weight 0.25)

P1_VSYNC

AC20

B2

Port 1 Vertical Sync. This signal includes an internal pull-down. While intended to be

associated with Port 1, it can be programmed for use with Port 2.

P1_HSYNC

AD21

B2

Port 1 Horizontal Sync. This signal includes an internal pull-down. While intended to

be associated with Port 1, it can be programmed for use with Port 2.

P2_A_9

AD26

I4

Port 2 A Channel Input Pixel Data (bit weight 128)

P2_A_8

AD25

I4

Port 2 A Channel Input Pixel Data (bit weight 64)

P2_A_7

AB21

I4

Port 2 A Channel Input Pixel Data (bit weight 32)

P2_A_6

AC22

I4

Port 2 A Channel Input Pixel Data (bit weight 16)

P2_A_5

AD23

I4

Port 1 A Channel Input Pixel Data (bit weight 8)

P2_A_4

AB20

I4

Port 2 A Channel Input Pixel Data (bit weight 4)

P2_A_3

AC21

I4

Port 2 A Channel Input Pixel Data (bit weight 2)

P2_A_2

AD22

I4

Port 2 A Channel Input Pixel Data (bit weight 1)

P2_A_1

AE23

I4

Port 2 A Channel Input Pixel Data (bit weight 0.5)

P2_A_0

AB19

I4

Port 2 A Channel Input Pixel Data (bit weight 0.25)

P2_B_9

Y22

I4

Port 2 B Channel Input Pixel Data (bit weight 128)

P2_B_8

AB26

I4

Port 2 B Channel Input Pixel Data (bit weight 64)

P2_B_7

AA23

I4

Port 2 B Channel Input Pixel Data (bit weight 32)

P2_B_6

AB25

I4

Port 2 B Channel Input Pixel Data (bit weight 16)

P2_B_5

AA22

I4

Port 2 B Channel Input Pixel Data (bit weight 8)

P2_B_4

AB24

I4

Port 2 B Channel Input Pixel Data (bit weight 4)

P2_B_3

AC26

I4

Port 2 B Channel Input Pixel Data (bit weight 2)

P2_B_2

AB23

I4

Port 2 B Channel Input Pixel Data (bit weight 1)

P2_B_1

AC25

I4

Port 2 B Channel Input Pixel Data (bit weight 0.5)

P2_B_0

AC24

I4

Port 2 B Channel Input Pixel Data (bit weight 0.25)

P2_C_9

W23

I4

Port 2 C Channel Input Pixel Data (bit weight 128)

P2_C_8

V22

I4

Port 2 B Channel Input Pixel Data (bit weight 64)

P2_C_7

Y26

I4

Port 2 C Channel Input Pixel Data (bit weight 32)

P2_C_6

Y25

I4

Port 2 B Channel Input Pixel Data (bit weight 16)

P2_C_5

Y24

I4

Port 2 C Channel Input Pixel Data (bit weight 8)

P2_C_4

Y23

I4

Port 2 B Channel Input Pixel Data (bit weight 4)

P2_C_3

W22

I4

Port 2 C Channel Input Pixel Data (bit weight 2)

P2_C_2

AA26

I4

Port 2 B Channel Input Pixel Data (bit weight 1)

P2_C_1

AA25

I4

Port 2 C Channel Input Pixel Data (bit weight 0.5)

P2_C_0

AA24

I4

Port 2 B Channel Input Pixel Data (bit weight 0.25)

P2_VSYNC

U22

B2

Port 2 Vertical Sync. This signal includes an internal pull-down. While intended to be

associated with Port 2, it can be programmed for use with Port1.

P2_HSYNC

W26

B2

Port 2 Horizontal Sync. This signal includes an internal pull-down. While intended to

be associated with Port 2, it can be programmed for use with Port1.

AF11

I4

Autolock dedicated vertical sync. This signal includes an internal pull-down and uses

hysteresis.

ALF INPUT PORT CONTROL

ALF_VSYNC

6

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

Pin Configurations and Functions (continued)

PIN

(1)

NAME

I/O (2)

DESCRIPTION

NO.

ALF_HSYNC

AD11

I4

Autolock dedicated horizontal sync. This signal includes an internal pull-down and

uses hysteresis.

ALF_CSYNC

AE11

I4

Autolock dedicated composite sync (sync on green). This signal includes an internal

pull-down and uses hysteresis.

DADOEZ

AE7

O5

DAD1000 / DAD2000 Output Enable (active low)

DADADDR_3

AD6

O5

DADADDR_2

AE5

O5

DADADDR_1

AF4

O5

DADADDR_0

AB8

O5

DADMODE_1

AD7

O5

DADMODE_0

AE6

O5

DADSEL_1

AE4

O5

DADSEL_0

AC7

O5

DADSTRB

AF5

O5

DAD1000 / DAD2000 strobe

DAD_INTZ

AC8

I4

DAD1000 / DAD2000 interrupt (active low). This signal typically requires an external

pull-up and uses hysteresis.

DCKA_P

V4

O7

DCKA_N

V3

O7

SCA_P

V2

O7

SCA_N

V1

O7

DDA_P_15

P4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_15

P3

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_14

P2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_14

P1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_13

R4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_13

R3

O7

DDA_P_12

R2

O7

DMD,Bus

LVDS

I/F channel

Input

B Data

bit 9. A, differential serial data

100-Ω

internal

termination.

DMD, LVDS

I/FLVDS

channel

A, differential serial data

DDA_N_12

R1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_11

T4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_11

T3

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_10

T2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_10

T1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_9

U4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_9

U3

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_8

U2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_8

U1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_7

W4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_7

W3

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_6

W2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_6

W1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_5

Y2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_5

Y1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_4

Y4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_4

Y3

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_3

AA2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_3

AA1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_2

AA4

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_2

AA3

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_1

AB2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_1

AB1

O7

DMD, LVDS I/F channel A, differential serial data

DDA_P_0

AC2

O7

DMD, LVDS I/F channel A, differential serial data

DDA_N_0

AC1

O7

DMD, LVDS I/F channel A, differential serial data

DCKB_P

J3

O7

DMD, LVDS I/F channel A, differential clock

DCKB_N

J4

O7

DMD, LVDS I/F channel A, differential clock

DMD RESET and BIAS CONTROL

DAD1000 / DAD2000 address

DAD1000 / DAD2000 modes

DAD1000 / DAD2000 select

DMD LVDS INTERFACE

DMD, LVDS I/F channel A, differential clock

DMD, LVDS I/F channel A, differential serial control

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

7

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Pin Configurations and Functions (continued)

PIN

NAME

(1)

I/O (2)

DESCRIPTION

NO.

SCB_P

J1

O7

DMD, LVDS I/F channel A, differential serial control

SCB_N

J2

O7

DMD, LVDS I/F channel A, differential serial control

DDB_P_15

N1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_15

N2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_14

N3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_14

N4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_13

M2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_13

M1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_12

M3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_12

M4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_11

L1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_11

L2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_10

L3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_10

L4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_9

K1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_9

K2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_8

K3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_8

K4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_7

H1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_7

H2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_6

H3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_6

H4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_5

G1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_5

G2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_4

G3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_4

G4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_3

F1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_3

F2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_2

F3

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_2

F4

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_1

E1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_1

E2

O7

DMD, LVDS I/F channel B, differential serial data

DDB_P_0

D1

O7

DMD, LVDS I/F channel B, differential serial data

DDB_N_0

D2

O7

DMD, LVDS I/F channel B, differential serial data

Input Bus D Data bit 3.

100-Ω internal LVDS termination.

PROGRAM MEMORY (Flash and SRAM) INTERFACE

PM_CSZ_0

D13

O5

PM_CSZ_1

E12

O5

PM_CSZ_2

A13

O5

PM_ADDR_22 (GPIO 36)

A12

B5

PM_ADDR_21 (GPIO 35)

E11

B5

PM_ADDR_20

D12

O5

PM_ADDR_19

C12

O5

PM_ADDR_18

B11

O5

PM_ADDR_17

A11

O5

PM_ADDR_16

D11

O5

PM_ADDR_15

C11

O5

PM_ADDR_14

E10

O5

PM_ADDR_13

D10

O5

PM_ADDR_12

C10

O5

PM_ADDR_11

B9

O5

PM_ADDR_10

A9

O5

8

Input Bus D Data bit 5.

100-Ω internal LVDS termination.

Input Bus D Data bit 10.

100-Ω internal LVDS termination.

Input Bus D Data bit 11.

100-Ω internal LVDS termination.

Input Bus D Data bit 12.

100-Ω internal LVDS termination.

Input Bus D Data bit 13.

100-Ω internal LVDS termination.

Input Bus D Data bit 14.

100-Ω internal LVDS termination.

Input Bus D Data bit 15.

100-Ω internal LVDS termination.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

Pin Configurations and Functions (continued)

PIN

NAME

(1)

I/O (2)

DESCRIPTION

NO.

PM_ADDR_9

E9

O5

PM_ADDR_8

D9

O5

PM_ADDR_7

C9

O5

PM_ADDR_6

B8

O5

PM_ADDR_5

A8

O5

PM_ADDR_4

D8

O5

PM_ADDR_3

C8

O5

PM_ADDR_2

B7

O5

PM_ADDR_1

A7

O5

PM_ADDR_0

C7

O5

PM_WEZ

B12

O5

PM_OEZ

C13

O5

PM_BLSZ_1

B6

O5

PM_BLSZ_0

A6

O5

PM_DATA_15

C17

B5

PM_DATA_14

B16

B5

PM_DATA_13

A16

B5

PM_DATA_12

A15

B5

PM_DATA_11

B15

B5

PM_DATA_10

D16

B5

PM_DATA_9

C16

B5

PM_DATA_8

E14

B5

PM_DATA_7

D15

B5

PM_DATA_6

C15

B5

PM_DATA_5

B14

B5

PM_DATA_4

A14

B5

PM_DATA_3

E13

B5

PM_DATA_2

D14

B5

PM_DATA_1

C14

B5

PM_DATA_0

B13

B5

IIC0_SCL

A10

B8

I2C Bus 0, Clock. This bus support 400 kHz, fast mode operation. This signal

requires an external pull-up to 3.3-V. The minimum acceptable pull-up value is 1 kΩ.

This input is not 5 V tolerant.

IIC0_SDA

B10

B8

2C Bus 0, Data. This bus support 400 kHz, fast mode operation. This signal requires

an external pull-up to 3.3-V. The minimum acceptable pull-up value is 1 kΩ. This

input is not 5 V tolerant.

SSP0_CLK

AD4

B5

Synchronous Serial Port 0, clock

SSP0_RXD

AD5

I4

Synchronous Serial Port 0, receive data in

SSP0_TXD

AB7

O5

Synchronous Serial Port 0, transmit data out

SSP0_CSZ_0

AC5

B5

Synchronous Serial Port 0, chip select 0 (active low)

SSP0_CSZ_1

AB6

B5

Synchronous Serial Port 0, chip select 1 (active low)

SSP0_CSZ_2

AC3

B5

Synchronous Serial Port 0, chip select 2 (active low)

UART0_TXD

AB3

O5

UART0 transmit data output

UART0_RXD

AD1

O5

UART0 receive data input

UART0_RTSZ

AD2

O5

UART0 ready to send hardware flow control output (active low)

UART0_CTSZ

AE2

I4

UART0 clear to send hardware flow control input (active low)

USB_DAT_N

C5

B9

USB D- I/O

USB_DAT_P

D6

B9

USB D+ I/O

PMD_INTZ

AE8

I4

Interrupt from DLPA100 (active low). This signal requires an external pull-up. Uses

hysteresis.

CW_PWM

AD8

O5

Color wheel control PWM output

CW_INDEX

AF7

O5

Color wheel index. Uses hysteresis.

LMPCTRL

AC9

O5

Lamp control output. Lamp enable and synchronization to the ballast.

LMPSTAT

AF8

I4

Lamp status input. Driven high from the ballast once the lamp is lit.

Output Bus A Data bit 0 to DMD.

Output Bus A Data bit 1 to DMD.

Output Bus A Data bit 2 to DMD.

Output Bus A Data bit 3 to DMD.

Output Bus A Data bit 4 to DMD.

Output Bus A Data bit 5 to DMD.

Output Bus A Data bit 6 to DMD.

Output Bus A Data bit 7 to DMD.

Output Bus A Data bit 8 to DMD.

Output Bus A Data bit 9 to DMD.

Output Bus A Data bit 10 to DMD.

Output Bus A Data bit 11 to DMD.

Output Bus A Data bit 12 to DMD.

Output Bus A Data bit 13 to DMD.

Output Bus A Data bit 14 to DMD.

PERIPHERAL INTERFACE

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

9

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Pin Configurations and Functions (continued)

PIN

NAME

(1)

I/O (2)

DESCRIPTION

NO.

GENERAL PURPOSE I/O (GPIO) (8)

Alternate Function 1

Alternate Function 2

GPIO_82

E3

B5

N/A

N/A

GPIO_81

AB10

B2

Reserved

N/A

GPIO_80

AD9

B2

IR_ENABLE (O)

N/A

GPIO_79

AE9

B2

Reserved

N/A

GPIO_78

AF9

B2

FIELD_3D_LR (I)

N/A

GPIO_77

AB11

B2

SAS_INTGTR_EN (O)

SENSE_PWM_OUT (O)

GPIO_76

AC10

B2

SAS_CSZ (O)

N/A

GPIO_75

AD10

B2

SAS_DO (O)

SENSE_FREQ_IN (I)

GPIO_74

AE10

B2

SAS_DI (I)

SENSE_COMP_IN (I)

GPIO_73

AF10

B2

SAS_CLK (O)

N/A

GPIO_72

K24

B2

SSP2_DI (I)

N/A

GPIO_71

K23

B2

SSP2_CLK (B)

N/A

GPIO_70

K22

B2

SSP2_CSZ_1 (B)

N/A

GPIO_69

J26

B2

SSP2_CSZ_0 (B)

N/A

GPIO_68

J25

B2

SSP2_DO (O)

N/A

GPIO_67

J24

B2

SP_Data_7 (O)

SSP2_CSZ_2 (B)

GPIO_66

J23

B2

SP_Data_6 (O)

SSP0_CSZ_5 (B)

GPIO_65

J22

B2

SP_Data_5 (O)

N/A

GPIO_64

H26

B2

SP_Data_4 (O)

CW_PWM_2 (O)

GPIO_63

H25

B2

SP_Data_3 (O)

CW_INDEX_2 (I)

GPIO_62

H24

B2

SP_Data_2 (O)

SP_VC_FDBK (I)

GPIO_61

H23

B2

SP_Data_1 (O)

N/A

GPIO_60

H22

B2

SP_Data_0 (O)

N/A

GPIO_59

G26

B2

SP_WG_CLK (O)

N/A

GPIO_58

G25

B2

LED_SENSE_PULSE (O)

N/A

GPIO_57

F25

B2

Reserved

N/A

GPIO_56

G24

B2

UART2_RXD (O)

N/A

GPIO_55

G23

B2

UART2_TXD (O)

N/A

GPIO_54

F26

B2

PROG_AUX_7 (O)

N/A

GPIO_53

E26

B2

PROG_AUX_6 (O)

N/A

GPIO_52

AB12

B2

CSP_Data (O)

ALF_CLAMP (O)

GPIO_51

AC11

B2

CSP_CLK (O)

ALF_COAST (O)

GPIO_50

V23

B2

Reserved

HBT_CLKOUT (O)

GPIO_49

V24

B2

Reserved

HBT_DO (O)

GPIO_48

V25

B2

Reserved

HBT_CLKIN_2 (I)

GPIO_47

V26

B2

Reserved

HBT_DI_2 (I)

GPIO_46

T22

B2

Reserved

HBT_CLKIN_1 (I)

GPIO_45

U23

B2

Reserved

HBT_DI_1 (I)

GPIO_44

U24

B2

Reserved

HBT_CLKIN_0 (I)

GPIO_43

U25

B2

Reserved

HBT_DI_0 (I)

GPIO_42

U26

B2

Reserved

SSP0_CSZ4 (B)

GPIO_41

R22

B2

Reserved

DASYNC (I)

GPIO_40

T23

B2

Reserved

FSD12 (O)

GPIO_39

F24

B2

SW reserved (Boot Hold)

SW reserved (Boot Hold)

GPIO_38

E25

B2

SW reserved (USB Enumeration Enable)

SW reserved (USB Enumeration

Enable)

GPIO_37

G22

B2

N/A

N/A

GPIO_36

A12

B2

PM_ADDR_22 (O)

I2C_2 SDA (B)

GPIO_35

E11

B2

PM_ADDR_21 (O)

I2C_2 SCL (B)

GPIO_34

F23

B2

SSP1_CSZ_1 (B)

N/A

(8)

10

GPIO signals must be configured by software for input, output, bidirectional, or open-drain. Some GPIOs have one or more alternate use

modes, which are also software configurable. The reset default for all optional GPIOs is as an input signal. However, any alternate

function connected to these GPIO pins with the exception of general-purpose clocks and PWM generation, are reset. An external pullup

to the 3.3-V supply is required for each signal configured as open-drain. External pullup or pulldown resistors may be required to ensure

stable operation before software is able to configure these ports.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

Pin Configurations and Functions (continued)

PIN

(1)

I/O (2)

NAME

DESCRIPTION

NO.

GPIO_33

D26

B2

SSP1_CSZ_0 (B)

N/A

GPIO_32

E24

B2

SSP1_DO (O)

N/A

GPIO_31

F22

B2

SSP1_DI (I)

N/A

GPIO_30

D25

B2

SSP1_CLK (B)

N/A

GPIO_29

E23

B2

IR1 (I)

SSP2 BC CSZ (B)

GPIO_28

C26

B2

IR0 (I)

SSP2 BC CSZ (B)

GPIO_27

AB4

B2

SSP0_CSZ3 (B)

N/A

GPIO_26

D24

B2

Blue LED enable (O)

UART2 TXD (O)

GPIO_25

C25

B2

Green LED enable (O)

LAMPSYNC (O)

GPIO_24

B26

B2

Red LED enable (O)

N/A

GPIO_23

E21

B2

LED Dual Current Control (O)

N/A

GPIO_22

D22

B2

LED Dual Current Control (O)

N/A

GPIO_21

E20

B2

LED Dual Current Control (O)

N/A

GPIO_20

C23

B2

N/A

N/A

GPIO_19

D21

B2

N/A

N/A

GPIO_18

B24

B2

N/A

N/A

GPIO_17

C22

B2

General Purpose Clock 2 (O)

N/A

GPIO_16

B23

B2

General Purpose Clock 1 (O)

N/A

GPIO_15

E19

B2

I2C_1 SDA (B)

N/A

GPIO_14

D20

B2

I2C_1 SCL (B)

N/A

GPIO_13

C21

B2

PWM IN_1 (I)

I2C_2 SDA (B)

GPIO_12

B22

B2

PWM IN_0 (I)

I2C_2 SCL (B)

GPIO_11

A23

B2

PWM STD_7 (O)

N/A

GPIO_10

A22

B2

PWM STD_6 (O)

N/A

GPIO_9

B21

B2

PWM STD_5 (O)

N/A

GPIO_8

A21

B2

PWM STD_4 (O)

N/A

GPIO_7

A20

B2

PWM STD_3 (O)

N/A

GPIO_6

C20

B2

PWM STD_2 (O)

N/A

GPIO_5

B20

B2

PWM STD_1 (O)

N/A

GPIO_4

B19

B2

PWM STD_0 (O)

N/A

GPIO_3

A19

B2

UART1_RTSZ (O)

N/A

GPIO_2

E18

B2

UART1_CTSZ (I)

N/A

GPIO_1

D19

B2

UART1_RXD (I)

N/A

GPIO_0

C19

B2

UART1_TXD (O)

N/A

MOSC

M26

I10

System clock oscillator input (3.3-V LVTTL). Note that MOSC must be stable a

maximum of 25ms after POSENSE transitions from low to high.

MOSCN

N26

O10

MOSC crystal return

OCLKA

AF6

O5

General purpose output clock A. Targeted for driving the CW motor controller. The

frequency is software programmable. Power-up default 787Khz. Note that the output

frequency is not affected by non-power-up reset operations (it will hold the last value

programmed).

AB9

B3

Sequence Sync. This signal is used in multi controller configurations only, in which

case the SEQSYNC signal from each controller should be connected together with

an external pull-up. This signal should either be pulled high or pulled low and not

allowed to float for single controller configurations.

VDD33

F20, F17, F11, F8, L21, R21,

Y21, AA19, AA16, AA10, AA7

POWER

3.3-V I/O Power

VDD18

C1, F5, G6, K6, M5, P5, T5,

W6, AA5, AE1, H5, N6, T6,

AA13, U21, P21, H21, F14

POWER

1.8-V Internal DRAM & LVDS I/O Power

VDD11

F19, F16, F13, F10, F7, H6,

L6, P6, U6, Y6, AA8, AA11,

AA14, AA17, AA20, W21, T21,

N21, K21, G21, L11, T11, T16,

L16

POWER

1.1-V Core Power

CLOCK and PLL SUPPORT

DUAL CONTROLLER SUPPORT

SEQ_SYNC

POWER and GROUND

VDD_PLLD

L22

POWER

1.1-V DMD clock generator PLL digital power

VSS_PLLD

L23

GROUND

1.1-V DMD clock generator PLL digital ground

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

11

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Pin Configurations and Functions (continued)

PIN

NAME

(1)

I/O (2)

DESCRIPTION

NO.

VAD_PLLD

K25

POWER

1.8-V DMD clock generator PLL analog power

VAS_PLLD

K26

GROUND

1.8-V DMD clock generator PLL analog ground

VDD_PLLM1

L26

POWER

1.1-V Master-LS clock generator PLL digital power

VSS_PLLM1

M22

GROUND

1.1-V Master-LS clock generator PLL digital ground

VAD_PLLM1

L24

POWER

1.8-V Master-LS clock generator PLL analog power

VAS_PLLM1

L25

GROUND

1.8-V Master-LS clock generator PLL analog ground

VDD_PLLM2

P23

POWER

1.1-V Master-HS clock generator PLL digital power

VSS_PLLM2

P24

GROUND

1.1-V Master-HS clock generator PLL digital ground

VAD_PLLM2

R25

POWER

1.8-V Master-HS clock generator PLL analog power

VAS_PLLM2

R26

GROUND

1.8-V Master-HS clock generator PLL analog ground

VAD_PLLS

R23

POWER

1.1-V video-2X clock generator PLL analog power

VAS_PLLS

R24

GROUND

1.1-V video-2X clock generator PLL analog ground

B18, D18, B17, E17, A18, C18,

A17, D17, AE17, AC17, AF17,

AC18, AB16, AD17, AB17,

AD18

RESERVED

These should be tied directly to ground for normal operation.

AE26

RESERVED

This should be tied directly to 3.3 I/O power (VDD33) for normal operation.

AB14, AB15, E15, E16

RESERVED

These should be tied directly to ground for normal operation.

V5, K5

POWER

These should be tied directly to ground for normal operation.

AC6

POWER

This should be tied directly to ground for normal operation.

A26, A25, A24, B25, C24, D23,

E22, F21, F18, F15, F12, F9,

F6, E5, D4, C3, B3, A3, B2,

A2, B1, A1 G5, J5, J6, L5, M6,

N5, R5, R6, U5, V6, W5, Y5,

AA6, AB5, AC4, AD3, AE3,

AF3, AF2, AF1, AA9, AA12,

AA15, AA18, AA21, AB22,

AC23, AD24, AE24, AF24,

AE25, AF25, AF26, V21, M21,

J21, L15, L14, L13, L12, M16,

M15, M14, M13, M12, M11,

N16, N15, N14, N13, N12,

N11, P16, P15, P14, P13, P12,

P11, R16, R15, R14, R13,

R12, R11, T15, T14, T13, T12

GROUND

L-VDQPAD_[7:0], RVDQPAD_[7:0]

CFO_VDD33

VTEST1, VTEST2, VTEST3,

VTEST4

LVDS_AVS1, LVDS_AVS2

VPGM

GROUND

12

Common ground

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

Table 1. I/O Type Subscript Definition

SUBSCRIPT

DESCRIPTION

ESD STRUCTURE

2

3.3 LVTTL I/O Buffer with 8 mA drive

ESD diode to VDD33 and GROUND

3

3.3 LVTTL I/O Buffer, with 12 mA drive

ESD diode to VDD33 and GROUND

4

3.3 LVTTL Receiver

ESD diode to VDD33 and GROUND

5

3.3 LVTTL I/O Buffer with 8 mA drive, with Slew Rate Control

ESD diode to VDD33 and GROUND

6

3.3 LVTTL I/O Buffer, with programmable 4 mA, 8 mA, or 12

mA drive

ESD diode to VDD33 and GROUND

7

1.8 LVDS (DMD I/F)

ESD diode to VDD33 and GROUND

8

3.3 V I2C with 3 mA sink

ESD diode to VDD33 and GROUND

9

USB Compatible (3.3 V)

ESD diode to VDD33 and GROUND

10

OSC 3.3 V I/O Compatible LVTTL

ESD diode to VDD33 and GROUND

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

13

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

UNIT

VDD11 (Core)

–0.30

1.60

VDD18 (LVDS I/O and Internal

DRAM)

–0.30

2.50

VDD33 (I/O)

–0.30

3.90

VDD_PLLD (1.1V DMD clock

generator - Digital)

-0.30

1.60

VDD_PLLM1 (1.1V Master - LS

clock generator - Digital)

-0.30

1.60

VDD_PLLM2 (1.1V Master - HS

clock generator - Digital)

-0.30

1.60

VDD_PLLD (1.8V DMD clock

generator - Analog)

-0.30

2.50

VDD_PLLM1 (1.8V Master - LS

clock generator - Analog)

-0.30

2.50

VDD_PLLM2 (1.8V Master - HS

clock generator - Analog)

-0.30

2.50

VDD_PLLS (1.1V Video 2X Analog)

-0.50

1.40

USB

-1.0

5.25

OSC

-0.3

VDD33 + 0.3

3.3 LVTTL

-0.3

3.6

3.3 I2C

-0.5

3.8

USB

-1.0

5.25

OSC

-0.3

2.2

3.3 LVTTL

-0.3

3.6

3.3 I2C

-0.5

3.8

0

111

°C

–40

125

°C

ELECTRICAL

Supply Voltage (2)

VI Input Voltage (3)

VO Output Voltage

V

V

V

ENVIRONMENTAL

TJ Operating Junction temperature

Tstg Storage temperature range

(1)

(2)

(3)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltage values are with respect to GROUND.

Applies to external input and bidirectional buffers.

6.2 ESD Ratings

VALUE

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

pins (1)

V(ESD)

(1)

(2)

14

Electrostatic discharge

UNIT

± 2000

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins (2)

+500/-300

Machine Model (MM)

+200/-200

V

Level listed above is the passing level per ANSI, ESDA, and JEDEC JS-001. JEDEC document JEP155 states that 500V HBM allows

safe manufacturing with a standard ESD control process.

Level listed above is the passing level per EIA-JEDEC JESD22-C101. JEDEC document JEP157 states that 250-V CDM allows safe

manufacturing with a standard ESD control process.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

I/O (1)

MIN

NOM

MAX

UNIT

3.135

3.3

3.465

V

1.71

1.8

1.89

V

1.045

1.1

1.155

V

ELECTRICAL

VDD33

3.3V Supply voltage, I/O

VDD18

1.8V Supply voltage, LVDS & DRAM

VDD11

1.1V Supply voltage, Core logic

VDD_PLLD

1.8V Supply voltage, PLL Analog

1.71

1.8

1.89

V

VDD_PLLM1

1.8V Supply voltage, PLL Analog

1.71

1.8

1.89

V

VDD_PLLM2

1.8V Supply voltage, PLL Analog

1.71

1.8

1.89

V

VDD_PLLS

1.8V Supply voltage, PLL Analog

1.050

1.10

1.150

V

VDD_PLLD

1.8V Supply voltage, PLL Analog

1.045

1.1

1.155

V

VDD_PLLM1

1.8V Supply voltage, PLL Analog

1.045

1.1

1.155

V

VDD_PLLM2

1.8V Supply voltage, PLL Analog

1.045

1.1

1.155

V

VI

Input Voltage

vo

Output Voltage

USB (9)

0

VDD33

OSC (10)

0

VDD33

3.3 V LVTTL

(1,2,3,4)

0

VDD33

3.3 V I2C (8)

0

VDD33

USB (8)

0

VDD33

3.3 V LVTTL

(1,2,3,4)

0

VDD33

3.3 V I C (8)

0

VDD33

1.8 V LVDS (7)

0

VDD33

2

TA

Operating ambient temperature range

See

(2) (3)

TC

Operating top center case temperature

See

(3) (4)

TJ

Operating junction temperature

(1)

(2)

(3)

(4)

V

V

0

55

°C

0

109.16

°C

0

111

°C

The number inside each parenthesis for the I/O refers to the type defined in the I/O type subscript definition section.

Assumes minimum 1 m/s airflow along with the JEDEC thermal resistance and associated conditions listed at www.ti.com/packaging.

Thus this is an approximate value that varies with environment and PCB design.

Maximum thermal values assume max power of 4.6 watts.

Assume PsiJTequals 0.4 C/W.

6.4 Thermal Information

DLPC4422

THERMAL METRIC

(1)

ZPC (BGA)

UNIT

516 PINS

RθJA

Junction-to-ambient thermal resistance

RθJC

Junction-to-case thermal resistance

(1)

(2)

(2)

14.4

°C/W

4.4

°C/W

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics Application

Report, SPRA953.

In still air.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

15

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

6.5 Electrical Characteristics (1)

over recommended operating conditions

PARAMETER

TEST CONDITIONS

USB (9)

2.0

OSC (10)

2.0

High-level input voltage 3.3-V LVTTL (1,2,3,4)

VIH

Low-level input voltage

0.8

OSC (10)

0.8

3.3-V LVTTL (1,2,3,4)

0.8

-0.5

VDIS

USB(9)

200

VICM

Differential Cross Point

Voltage

USB(9)

0.8

USB(9)

200

VHYS

Hysteresis (VT+-VT-)

VOH

3.3-V LVTTL (1,2,3,4)

300

USB (9)

2.8

1.8-V LVDS (7)

USB (9)

VOD

Low-level output

voltage

Output Differential

Voltage

0.0

IOL = 3 mA sink

0.4

0.065

3.3-V LVTTL (1-4) without Internal Pull

Down

VIH = VDD33

VIH = VDD33

-10.0

10

-10.0

10

10.0

200.

0

VIH = VDD33

-10.0

10.0

OSC (10)

-10.0

10.0

3.3-V LVTTL (1-4) without Internal Pull

Down

VOH = VDD33

-10.0

10.0

3.3-V LVTTL (1-4) with Internal Pull

Down

VOH = VDD33

-10.0

-200

VOH = VDD33

µA

µA

-10.0

USB(9)

16

V

10.0

USB(9)

3.3-V I C (8)

(1)

0.44

0

V

200

2

High-level output

current

0.3

3.3-V I2C (8)

3.3-V I C (8)

IOH

V

0.4

2

Low-level input current

mV

IOL = Max Rated

1.8-V LVDS (7)

V

600

3.3-V LVTTL (1,2,3)

3.3-V LVTTL (1-4) with Internal Pull

Down

IIL

550

0.88

0

1.8-V LVDS (7)

OSC (10)

High-level input current

2.5

2.7

USB(9)

IIH

mV

1.520

IOH = Max Rated

V

1.0

400

3.3-V I2C (8)

3.3-V LVTTL (1,2,3)

VOL

V

USB (9)

Differential Input

Voltage

UNIT

VDD

33+0

.5

2.4

3.3-V I2C (8)

High-level output

voltage

TYP MAX

2.0

3.3-V I2C (8)

VIL

MIN

-19.1

1.8-V LVDS (7) (VOD = 300mV)

VO = 1.4 V

6.5

3.3-V LVTTL (1)

VO = 2.4 V

-4.0

3.3-V LVTTL (2)

VO = 2.4 V

-8.0

3.3-V LVTTL (3)

VO = 2.4 V

-12.0

mA

The number inside each parenthesis or the I/O refers to the type defined in Table 1.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

Electrical Characteristics(1) (continued)

over recommended operating conditions

PARAMETER

TEST CONDITIONS

USB(9)

IOL

IOZ

Low-level output

current

High-Impedance

leakage current

Input capacitance

TYP MAX

UNIT

19.1

1.8-V LVDS (7) (VOD = 300mV)

VO = 1.0 V

6.5

3.3-V LVTTL (1)

VO = 0.4 V

4.0

3.3-V LVTTL (2)

VO = 0.4 V

8.0

3.3-V LVTTL (3)

VO = 0.4 V

12.0

3.3-V I2C (8)

3.0

USB (9)

-10

LVDS (7)

-10

3.3-V LVTTL (1,2,3)

-10

3.3-V I2C (8)

-10

mA

pF

11.84

17.0

7

3.3-V LVTTL (1)

3.75

5.52

3.3-V LVTTL (2)

3.75

5.52

3.3-V LVTTL (4)

3.75

5.52

3.3-V I2C (8)

5.26

USB (9)

CI

MIN

pF

6.54

ICC11

Supply voltage, 1.1-V core power

Normal Mode

1474

mA

ICC18

Supply voltage, 1.8-V power (LVDS I/O & Internal DRAM)

Normal Mode

1005

mA

ICC33

Supply voltage, 3.3-V I/O power

Normal Mode

33

mA

ICC11_PLLD

Supply voltage, DMD PLL Digital Power (1.1 V)

Normal Mode

4.4

6.2

mA

ICC11_PLLM1

Supply voltage, Master-LS Clock Generator PLL Digital power

(1.1 V)

Normal Mode

4.4

6.2

mA

ICC11_PLLM2

Supply voltage, Master-HS Clock Generator PLL Digital power

(1.1 V)

Normal Mode

4.4

6.2

mA

ICC18_PLLD

Supply voltage, DMD PLL Analog Power (1.8 V)

Normal Mode

8.0

10.2

mA

ICC18_PLLM1

Supply voltage, Master-LS Clock Generator PLL Analog power

(1.8 V)

Normal Mode

8.0

10.2

mA

ICC18_PLLM2

Supply voltage, Master-HS Clock Generator PLL Analog power

(1.8 V)

Normal Mode

8.0

10.2

mA

ICC11_PLLS

Supply voltage, Video-2X PLL Analog Power (1.1 V)

Normal Mode

2.9

mA

Total Power

Normal Mode

3.73

W

ICC11

Supply voltage, 1.1-V core power

Low Power Mode

21

mA

ICC18

Supply voltage, 1.8-V power (LVDS I/O & Internal DRAM)

Low Power Mode

0

mA

ICC33

Supply voltage, 3.3-V I/O power

Low Power Mode

18

mA

ICC11_PLLD

Supply voltage, DMD PLL Digital Power (1.1 V)

Low Power Mode

2.03

mA

ICC11_PLLM1

Supply voltage, Master-LS Clock Generator PLL Digital power

(1.1 V)

Low Power Mode

2.03

mA

ICC11_PLLM2

Supply voltage, Master-HS Clock Generator PLL Digital power

(1.1 V)

Low Power Mode

2.03

mA

ICC18_PLLD

Supply voltage, DMD PLL Analog Power (1.8 V)

Low Power Mode

5.42

mA

ICC18_PLLM1

Supply voltage, Master-LS Clock Generator PLL Analog power

(1.8 V)

Low Power Mode

5.42

mA

ICC18_PLLM2

Supply voltage, Master-HS Clock Generator PLL Analog power

(1.8 V)

Low Power Mode

5.42

mA

ICC11_PLLS

Supply voltage, Video-2X PLL Analog Power (1.1 V)

Low Power Mode

.03

mA

Total Power

Low Power Mode

106

mW

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

17

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

6.6 System Oscillators Timing Requirements

over operating free-air temperature range(unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

MAX

UNIT

SYSTEM OSCILLATORS

fclock

Clock frequency, MOSC (1)

19.998

20.002

MHz

tc

Cycle time, MOSC (1)

49.995

50.005

MHz

tw(H)

Pulse duration (2), MOSC, high

50% to 50% reference points

(signal)

20

ns

tw(L)

Pulse duration (2), MOSC, low

50% to 50% reference points

(signal)

20

ns

tt

Transition time (2), MOSC, tt = tf /tr

20% to 80% reference points

(signal)

tjp

Period Jitter (2), MOSC (This is the deviation

in period from the ideal period due solely to

high frequency jitter).

(1)

(2)

12

ns

18

ps

The frequency range for MOSC is 20 MHz with +/-100 PPM accuracy (This shall include impact to accuracy due to aging, temperature

and trim sensitivity). The MOSC input can not support spread spectrum clock spreading.

Applies only when driven via an external digital oscillator.

6.7 Test and Reset Timing Requirements

MIN

MAX

UNIT

t W1(L)

Pulse duration, inactive low, PWRGOOD

50% to 50% reference points

(signal)

µs

t W1(L)

Pulse duration, inactive low, PWRGOOD

50% to 50% reference points

(signal)

1000 (1)

ms

tt1

Transition time, PWRGOOD, tt1= tf/tr

20% to 80% reference points

(signal)

625

µs

t W2(L)

Pulse duration, inactive low, POSENSE

50% to 50% reference points

(signal)

t W2(L)

Pulse duration, inactive low, POSENSE

50% to 50% reference points

(signal)

1000 (1)

ms

tt2

Transition time, POSENSE, tt1= tf/tr

20% to 80% reference points

(signal)

25 (2)

µs

tPH

Power Hold time, POSENSE remains active after

PWRGOOD is de-asserted

20% to 80% reference points

(signal)

tEW

Early Warning time, PWRGOOD goes inactive low prior

to any power supply voltage going below its specification

tW1(L)+tW2(

The sum of PWRGOOD and POSENSE inactive time

4.0

500

µs

500

µs

500

µs

1050 (1)

ms

L)

(1)

(2)

18

With 1.8 V power applied. If the 1.8 V power is disabled by the controller command (For example – if system is placed in Low Power

mode where the controller disables 1.8 V power), these signals can be placed and remain in their inactive state indefinitely.

As long as noise on this signal is below the hysteresis threshold.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

6.8 JTAG Interface: I/O Boundary Scan Application Timing Requirements

MIN

fclock

Clock frequency, TCK

tC

Cycle time, TCK

MAX

UNIT

10

MHZ

100

ns

40

ns

40

ns

tW(H)

Pulse duration, high

50% to 50% reference points

(signal)

t W(L)

Pulse duration, low

50% to 50% reference points

(signal)

tt

Transition time, tt= tf/tr

20% to 80% reference points

(signal)

tSU

Setup time, TDI valid before TCK↑

8

ns

th

Hold time, TDI valid after TCK↑

2

ns

tSU

Setup time, TMS1 valid before TCK↑

8

ns

th

Hold time, TMS1 valid before TCK↑

2

ns

5

ns

6.9 Port 1 Input Pixel Timing Requirements

TEST CONDITIONS

fclock

Clock frequency, P_CLK1, P_CLK2, P_CLK3 (30-bit bus)

fclock

Clock frequency, P_CLK1, P_CLK2, P_CLK3 (60-bit bus)

tC

Cycle Time, P_CLK1, P_CLK2, P_CLK3

tW(H)

Pulse Duration, high

50% to 50% reference points

(signal)

tW(L)

Pulse Duration, low

50% to 50% reference points

(signal)

MIN

MAX

UNIT

12

175

MHz

12

160

MHz

5.714

83.33

2.3

2.3

ns

ns

ns

See

(1)

ps

tjp

Clock period jitter, P_CLK1, P_CLK2, P_CLK3

Max ƒclock

tt

Transition time, tt=tf/tr, P_CLK1, P_CLK2, P_CLK3

20% to 80% reference points

(signal)

0.6

2.0

ns

tt

Transition time, tt=tf/tr, P1_A(9-0), P1_B(9-0), P1_C(9-0),

P1_HSYNC, P1_VSYNC, P1_DATAEN

20% to 80% reference points

(signal)

0.6

3.0

ns

tt

Transition time, tt=tf/tr, ALF_HSYNC, ALF_VSYNC,

ALF_CSYNC (2)

20% to 80% reference points

(signal)

0.6

3.0

ns

SETUP AND HOLD TIMES

tsu

Setup time, P1_A(9-0), valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P1_A(9-0), valid before P_CLK1↑↓, P_CLK2↑↓,

or P_CLK3↑↓

0.8

ns

tsu

Setup time, P1_B(9-0), valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P1_B(9-0), valid before P_CLK1↑↓, P_CLK2↑↓,

or P_CLK3↑↓

0.8

ns

tsu

Setup time, P1_C(9-0), valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P1_C(9-0), valid before P_CLK1↑↓, P_CLK2↑↓,

or P_CLK3↑↓

0.8

ns

tsu

Setup time, P1_VSYNC, valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P1_VSYNC valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

tsu

Setup time, P1_HSYNC, valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P1_HSYNC valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

tsu

Setup time, P2_A(9-0), valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

(1)

(2)

For frequencies (fclock) less than 175 MHZ, use following formula to obtain the jitter: Max Clock Jitter = +/- [ (1/ƒclock) – 5414 ps]

ALF_CSYNC, ALF_VSYNC and ALF_HSYNC are Asynchronous signals.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

19

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

Port 1 Input Pixel Timing Requirements (continued)

TEST CONDITIONS

MIN

MAX

UNIT

th

Hold time, P2_A(9-0), valid before P_CLK1↑↓, P_CLK2↑↓,

or P_CLK3↑↓

0.8

ns

tsu

Setup time, P2_B(9-0), valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P2_B(9-0), valid before P_CLK1↑↓, P_CLK2↑↓,

or P_CLK3↑↓

0.8

ns

tsu

Setup time, P2_C(9-0), valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P2_C(9-0), valid before P_CLK1↑↓, P_CLK2↑↓,

or P_CLK3↑↓

0.8

ns

tsu

Setup time, P2_VSYNC, valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P2_VSYNC valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

tsu

Setup time, P2_HSYNC, valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P2_HSYNC valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

tsu

Setup time, P_DATAEN1, valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P_DATAEN1 valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

tsu

Setup time, P_DATAEN2, valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

th

Hold time, P_DATAEN2 valid before P_CLK1↑↓,

P_CLK2↑↓, or P_CLK3↑↓

0.8

ns

tw(A)

VSYNC Active Pulse Width

1

Video Line

tw(A)

HSYNC Active Pulse Width

16

Pixel

Clocks

6.10 Port 3 Input Pixel Interface (via GPIO) Timing Requirements

PARAMETER

fclock

Clock Frequency, P3_CLK

tc

Cycle time, P3_CLK

TEST CONDITIONS

MIN

MAX

UNIT

27

54

MHz

18.5

37.1

ns

tW(H)

Pulse Duration, high

50% to 50% reference points

(signal)

tW(L)

Pulse Duration, low

50% to 50% reference points

(signal)

tjp

Clock period jitter, P3_CLK

Max ƒclock

tt

Transition time, tt= tf/tr, P3_CLK

20% to 80% reference points

(signal)

tt

Transition time, tt= tf/tr, P3_DATA(9-0)

20% to 80% reference points

(signal)

tsu

Setup time, P3_DATA(9-0) valid before P3_CLK↑↓

2.0

ns

th

Hold time, P3_DATA(9-0) valid after P3_CLK↑↓

2.0

ns

(1)

20

7.4

ns

7.4

ns

(1)

ps

1.0

5.0

ns

1.0

5.0

ns

See

(1)

See

For frequencies less than 54 MHZ, use following formula to obtain the jitter: Jitter = [ (1/F) – 5414 ps].

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

�DLPC4422

www.ti.com

DLPS074 – FEBRUARY 2017

6.11 DMD LVDS Interface Timing Requirements

MIN

MAX

UNIT

fclock

Clock frequency, DCK_A

N/A

FROM (INPUT)

DCK_A

100

400

MHz

tC

Cycle time, DCK_A (1)

N/A

DCK_A

2475.3

ps

tW(H)

Pulse duration, high

N/A

DCK_A

1093

ps

tW(L)

Pulse duration, low

N/A

DCK_A

1093

tt

Transition time, tt= tf/tr

N/A

DCK_A

100

tosu

Output Setup time at max clock rate (2)

DCK_A↑↓

SCA, DDA(15:0)

438

(2)

TO (OUTPUT)

ps

400

ps

ps

toh

Output hold time at max clock rate

DCK_A↑↓

SCA, DDA(15:0)

438

fclock

Clock frequency, DCK_B

N/A

DCK_B

100

tC

Cycle time, DCK_B (1)

N/A

DCK_B

2475.3

ps

tW(H)

Pulse duration, high

N/A

DCK_B

1093

ps

tW(L)

Pulse duration, low

N/A

DCK_B

1093

tt

Transition time, tt= tf/tr

N/A

DCK_B

100

tosu

Output Setup time at max clock rate (2)

DCK_B↑↓

SCA, DDB(15:0)

438

DCK_B↑↓

SCA, DDB(15:0)

438

DCK_A↑

DCK_B↑

(2)

toh

Output hold time at max clock rate

tsk

Output Skew, Channel A to Channel B

(1)

(2)

ps

400

MHz

ps

400

ps

ps

ps

250

ps

The minimum cycle time (tc) for DCK_A and DCL_B includes 1.0% spread spectrum modulation. User must verify that DMD can support

this rate.

Output Setup & Hold times for DMD clock frequencies below the maximum can be calculated as follows: tosu(fclock) = tosu(fmax) +

250000*(1/fclock – 1/400) & toh(fclock) = toh(fmax) + 250000*(1/fclock – 1/400) where fclock is in MHz.

6.12 Synchronous Serial Port (SSP) Interface Timing Requirements

PARAMETER

TEST CONDITIONS

MIN

MAX

UNIT

SSP MASTER

tsu

Setup time, SSPx_DI valid before SSPx_CLK

15

ns

tsu

Setup time, SSPx_DI valid before SSPx_CLK

15

ns

th

Hold time, SSPx_DI valid after SSPx_CLK

0

ns

th

Hold time, SSPx_DI valid after SSPx_CLK

0

ns

tt

Transition time, SSPx_DI, tt= tf/tr

20% to 80% reference points

(signal)

1.5

ns

SSP SLAVE

tsu

Setup time, SSPx_DI valid before SSPx_CLK

12

ns

tsu

Setup time, SSPx_DI valid before SSPx_CLK

12

ns

th

Hold time, SSPx_DI valid after SSPx_CLK

12

ns

th

Hold time, SSPx_DI valid after SSPx_CLK

12

ns

tt

Transition time, SSPx_DI, tt= tf/tr

20% to 80% reference points

(signal)

1.5

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: DLPC4422

ns

21

�DLPC4422

DLPS074 – FEBRUARY 2017

www.ti.com

6.13 Programmable Output Clocks Switching Characteristics

over operating free air temperature range, CL(min timing) = 5 pF, CL(max timing) = 50 pF (unless otherwise noted)

PARAMETER

fclock

Clock frequency, OCLKA

tC

Cycle Time, OCLKA

TEST CONDITIONS

(1)

(2)

tW(H)

Pulse Duration, high

tW(L)

Pulse Duration, low (2)

TO (OUTPUT)

Clock frequency, OCLKB

tC

Cycle Time, OCLKB

tW(H)

Pulse Duration, high

tW(L)

Pulse Duration, low (2)

50

20

1270.6

50% to 50% reference points

OCLKA

(signal)

(tC/2_-2)

ns

50% to 50% reference points

OCLKA

(signal)

(tC/2_-2)

ns

Clock frequency, OCLKC

tC

Cycle Time, OCLKC (2)

ns

350

ps

MHz

OCLKB

0.787

50

OCLKB

20

1270.6

50% to 50% reference points

OCLKB

(signal)

(tC/2_-2)

ns

50% to 50% reference points

OCLKB

(signal)

(tC/2_-2)

ns

Jitter

fclock

MHz

0.787

(1)

(2)

UNIT

OCLKA

OCLKA

fclock

MAX

OCLKA

Jitter

OCLKB

(1)