User's Guide

SLVU701B – March 2012 – Revised July 2019

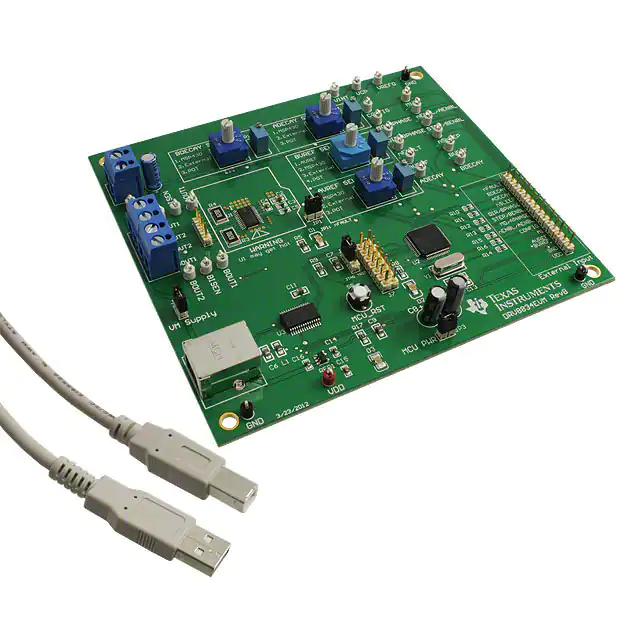

DRV8834 Evaluation Module

This document is provided as a supplement to the DRV8834 datasheet. It details the hardware

implementation of the DRV8834 customer evaluation module (EVM).

1

2

3

4

5

Contents

Introduction ................................................................................................................... 2

Block Diagram ................................................................................................................ 2

2.1

Power Connectors .................................................................................................. 3

2.2

Test Stakes .......................................................................................................... 3

2.3

Jumpers .............................................................................................................. 4

2.4

Switches ............................................................................................................. 4

2.5

Motor Outputs ....................................................................................................... 4

GUI Software Installation .................................................................................................. 4

3.1

System Requirements .............................................................................................. 4

3.2

Installation Procedure .............................................................................................. 4

The Windows Application ................................................................................................. 15

4.1

Dual H Bridge Mode .............................................................................................. 16

4.2

The CONFIG Control Signal ..................................................................................... 18

4.3

Configuring Switches ............................................................................................. 18

4.4

Menu Options ..................................................................................................... 19

4.5

DRV8834 GPIO Control Signals ................................................................................ 20

4.6

Updating DAC Output for Current Control (VREF) ........................................................... 20

4.7

Stepper Control .................................................................................................... 21

4.8

Move Steps Frame ................................................................................................ 22

Schematics and Bill of Materials ......................................................................................... 24

5.1

Schematics ......................................................................................................... 24

5.2

Bill of Materials .................................................................................................... 26

Trademarks

Windows is a registered trademark of Microsoft corporation.

All other trademarks are the property of their respective owners.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

1

�Introduction

1

www.ti.com

Introduction

The DRV8834 customer EVM is a platform revolving around the DRV8834, a low voltage dual H-bridge

driver and highly configurable power stage. This device has been optimized to drive either two brushed

DC motors, a single bipolar stepper with up to 32 degrees of internally generated microstepping, or a

single bipolar stepper with high resolution externally generated microstepping. In this EVM, high resolution

is meant to imply 512 degrees of microstepping, but higher resolution, as given by any given DAC

resource, can be implemented.

The EVM houses an MSP430 microcontroller and an USB interface chip. The USB chip allows for serial

communications from a PC computer where a Windows® application is used to schedule serial

commands. These commands can be used to control each of the device’s signals, or control both devices

at the same time to drive a stepper motor.

The microcontroller firmware operates in one of three modes. Each of the three modes can be selected

through the Windows application by choosing the respective operation TAB. The three modes are:

• Dual H-Bridge with independent current control and PWM control on the ENABLE and PHASE lines.

• Internal indexer microstepping driver capable of supplying up to 32 degrees of microstepping to a

single bipolar stepper motor.

• Dual H-Bridge configured to supply up to 512 degrees of microstepping to a single bipolar stepper

motor.

This user's guide details the operation of the EVM in any of the three modes, as well as the hardware

configurability of the evaluation module.

2

Block Diagram

Motor Outputs

VM Power

USB

Conn

DRV8834

BDECAY

Config

Switch

ADECAY

Config

Switch

BVREF

Config

Switch

Test

Points

AVREF

Config

Switch

USB Chip

MSP430

3.3V LDO

2

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�Block Diagram

www.ti.com

2.1

Power Connectors

The DRV8834EVM offers access to VM (motor voltage) power rail via a terminal block (J1). A set of test

clips in parallel with the terminal block allows for the monitoring of the input power rail.

User must apply VM according to datasheet recommended parameters.

NOTE: VDD for logic and microcontroller is derived from a provided 3.3-V regulator stepped down

from the VM input voltage.

2.2

Test Stakes

A 0.100 inch pitch header connector (J3) is used to provide access to every device signal in the event a

different microcontroller is to be employed. To disconnect the internal MSP430 microcontroller, simply

remove power to this resource by removing the shunt from the JP3 jumper.

J3

nFAULT

BDECAY

ADECAY

nSLEEP

DIR/BPHASE

STEP/BENBL

M0/APHASE

nENBL /AENBL

CONFIG

M1

AVREF

BVREF

GND

VDD

Figure 1. J3 Connector

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

3

�Block Diagram

2.3

www.ti.com

Jumpers

The DRV8834EVM module contains three 2-pin jumpers which the user can remove in order modify

certain aspects of configuration.

• JP1: Place a shunt to enable the D1 LED signaling of any fault occurrence.

• JP3: Place a shunt to allow 3.3-V supply to the microcontroller. Remove the shunt to disable MSP430

microcontroller and use external microcontroller of choice.

• JP4: Place a shunt to provide VM power to the LDO. Remove to disconnect all VM loading except

DRV8834 device.

2.4

Switches

A series of switches allow the proper selection of analog input to configure the reference voltage and

decay set points.

Table 1. Switches

SWITCH NAME

DESCRIPTION

BDECAY SEL

Selects Decay B source to be MSP430 GPIO (only HI or LO), externally

supplied or derived from the R1 potentiometer.

ADECAY SEL

Selects Decay A source to be MSP430 GPIO (only HI or LO), externally

supplied or derived from the R2 potentiometer.

BVREF SEL

Selects Reference Voltage B source to be same as VREFA (used on internal

indexer mode), MSP430 DAC, externally supplied or derived from the R7

potentiometer.

AVREF SEL

Selects Reference Voltage A source to be MSP430 DAC, externally supplied or

derived from the R6 potentiometer.

Each switch position is properly documented on the board’s top layer overlay silk screen.

2.5

Motor Outputs

There are two ways of connecting the dual brushed DC motor or the single bipolar stepper motor into the

DRV8834 evaluation module: four pin header (J2) or four position terminal block (J4).

3

GUI Software Installation

The following section explains the location of files and the procedure for installing the software correctly.

NOTE: Ensure that no USB connections are made to the EVM until the installation is completed.

The installer will also install LabVIEW RTE 2014 and FTDI Driver, along with the GUI.

3.1

System Requirements

•

•

•

3.2

Supported OS – Windows 7 (32 Bit, 64 Bit). The window text size should be Smaller-100% (Default)

Recommended RAM - 4 GB or higher

Recommended CPU Operating Speed – 3.3 GHz or higher

Installation Procedure

The following procedure helps you install the DRV8834 GUI

1. Double click on the Setup_DRV8834_EVM.exe as shown in Figure 2.

4

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�GUI Software Installation

www.ti.com

Figure 2. Setup_DRV8834_EVM.exe

2. The screen shown in Figure 3 appears, indicating installer initialization. Click the Next button.

Figure 3. Installation Initialization

3. In the newly open installation pop-up window, click Next. The license agreement will be displayed.

Please, read through it carefully and enable the "I Accept the Agreement" radio button and press Next.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

5

�GUI Software Installation

www.ti.com

Figure 4. License Agreement

4. A screen as shown in Figure 5 appears, displaying the license agreement of National Instruments.

Please read through the agreement carefully and enable the “I Accept the License Agreement” radio

button and press the Next button.

Figure 5. NI License Agreement

5. Set the default directory for the GUI Installation and click Next.

6

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�GUI Software Installation

www.ti.com

Figure 6. Installation Directory Screen

NOTE: It is highly recommended to keep the default values as provided in the installer.

6. A screen as shown in Figure 7 appears. This screen is to select the components to install. Select the

Components to Install and Click Next to continue installation. The LabVIEW RTE component checks

out if the LabVIEW RTE 2014 is already installed on the PC.

Figure 7. Component Selection

7. If LabVIEW RTE is selected as a component to install, a screen appears as shown in Figure 8.

Configure the proxy settings as required. This screen is to download the LabVIEW RTE 2014 from

ni.com, Click Next to continue the installation.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

7

�GUI Software Installation

www.ti.com

Figure 8. Configure Proxy

8. A screen as shown in Figure 9appears. Click Next to begin the installation.

Figure 9. Ready to Install

9. If the LabVIEW RTE 2014 is selected as a component to install, LabVIEW RTE downloads and

performs a silent mode installation.

8

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�GUI Software Installation

www.ti.com

Figure 10. Downloading RTE

10. Once the download completes, LabVIEW begins with the self-extraction as shown in Figure 11.

Figure 11. LabVIEW RTE Self Extraction

11. A screen appears as shown in Figure 12. It initializes the LabVIEW RTE Installation.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

9

�GUI Software Installation

www.ti.com

Figure 12. LabVIEW RTE Installation Initialization

12. A display as shown in Figure 13 appears which indicates the progress of LabVIEW RTE installation.

10

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�GUI Software Installation

www.ti.com

Figure 13. Installation of LabVIEW RTE in Progress

13. Once the LabVIEW RTE 2014 is installed, DRV 8834 EVM GUI component installs.

14. After DRV8834 Installation, FTDI Installation begins. A screen as shown in Figure 14 appears, click

Extract to proceed.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

11

�GUI Software Installation

www.ti.com

Figure 14. FTDI Installation Initialization

15. A screen as shown in Figure 15 appears, click Next to proceed.

Figure 15. Driver Installation Wizard

12

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�GUI Software Installation

www.ti.com

16. The License Agreement appears on screen as shown below.

17. Read through the License Agreement carefully and enable the “I Accept this Agreement” radio button

and Click on Next.

Figure 16. License Agreement for FTDI Driver

18. Click Finish to complete the Driver Installation.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

13

�GUI Software Installation

www.ti.com

Figure 17. Driver Installation Completion

19. Figure 18 appears denoting the completion of DRV8834 EVM GUI Installation. Click Finish.

Figure 18. Installation Complete

20. A Readme window as shown in Figure 19 appears displaying the link for LV 2014 RTE.

14

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�The Windows Application

www.ti.com

Figure 19. Readme Window

WARNING

The DRV8834 EVM GUI requires the LabVIEW Run-Time Engine

2014 to be installed before the GUI executes. Please note the

application is not compatible with other versions of LabVIEW

Runtime Engine.

You can download National Instruments LabVIEW Run-Time Engine 2014

from the below link:

LabVIEW Run-Time Engine 2014

NOTE: DRV8834 EVM GGUI executable has been built in LabVIEW 2014 (32-bit) version, and it

expects the LabVIEW Run-Time Engine version to be LabVIEW Run-Time Engine (32-bit

version).

4

The Windows Application

The DRV8834EVM Windows application is the software counterpart for the DRV8834 EVM. It allows the

PC computer to connect to the MSP430F2617 microcontroller though an USB interface chip. Once

connection is established and commands are sent, microcontroller takes care of configuring control

signals and administering certain levels of automation, such as microstepping coordination, stepping rate

acceleration and deceleration, ITrip configuration and PWM generation.

The graphical user interface (GUI) has been designed to allow for all of the DRV8834 device’s

functionality to be tested without having to intervene with the hardware, except for the adjusting of the

reference voltage and decay selector switches.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

15

�The Windows Application

www.ti.com

Figure 20. DRV8834EVM.exe Main Screen

All the control signals needed to control motor enablement (nENABLE or ENABLEx), direction of rotation

(PHASEx or DIR), current control (VREFx) and PWM control for both enablement and direction control

signals are made available throughout one of the three control tabs.

Each one of the three tabs will place the microcontroller and driver chip into one of the three operation

modes. The three tabs are described below.

4.1

Dual H Bridge Mode

See Figure 20.

While in this mode, the microcontroller treats the DRV8834 as a dual H-bridge driver with independent

current regulation, motor enablement and phase control.

In this mode, the Windows application offers control to ENABLE each of the two motors and control the

rotation direction. It also allows control of the speed and/or direction by offering access to a PWM

resource to each of the ENABLEx and PHASEx signals. Both H-bridges can be programmed with a

current regulation parameter by moving the VREFx slider. Other control signals are offered in the form of

check boxes.

16

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�The Windows Application

www.ti.com

4.1.1

Internal Microstepper Control

Figure 21. Internal Microstepper Control

While in this mode, the microcontroller treats the DRV8834 as an internal indexer microstepper with up to

32 degrees of microstepping driver.

In this mode, the Windows application offers control to ENABLE the driver, change motor rotation, select

current regulation decay, select degrees of microstepping resolution and modify maximum current

programming.

The Windows application also offers access to a series of sophisticated algorithms which allow the

stepper motor actuation in both continuous rotation as well as position control mode. The algorithms offer

accurate acceleration and deceleration profiles which help in the obtaining of better motion quality and

performance.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

17

�The Windows Application

4.1.2

www.ti.com

External Microstepper Control

Figure 22. External Microstepper Control

While in this mode, the microcontroller treats the DRV8834 as a dual H-bridge driver with independent

current regulation, motor enablement and phase control. Different than the dual H-bridge control mode in

which two DC motors can be driving, while in this operation style, the microcontroller will recognize

commands to issue high resolution microstepping commutation into a bipolar stepper motor.

In this mode, the Windows application offers control to change motor rotation and select degrees of

microstepping resolution. The decay is programmed into the microcontroller high resolution microstepping

algorithm to follow sine wave shape generation (slow decay while on quadrants 1 and 3, and mixed decay

while on quadrants 2 and 4). Current is set to 1.5-A sine wave peak. To change the maximum current, the

firmware’s internal look up table must be modified.

The Windows application also offers access to the same series of sophisticated algorithms which allow the

stepper motor actuation in both continuous rotation as well as position control mode. The algorithms offer

accurate acceleration and deceleration profiles which help in the obtaining of better motion quality and

performance.

4.2

The CONFIG Control Signal

In this Windows application, the CONFIG control signal is not made available to the user. The application

will modify the control signal according to which TAB is selected. When the communications are made and

any tab gains focus, a serial command is sent to the microcontroller to set the CONFIG control signal

accordingly. If the COM Port is not open, the serial command pertaining to this configuration is not sent.

4.3

Configuring Switches

Although the proper setting of the CONFIG control signal is made automatically, the EVM switches must

still be properly configured if correct operation is to be observed. Failure to properly set these switches will

result in problems with the current regulation and stepper motor functioning.

18

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�The Windows Application

www.ti.com

The following table shows the recommended switch positions as a different tab is selected. "Required"

implies that the wrong operation will be observed if not followed. Optional implies that any other source

(like the pot or an external signal) can be used, although control through the Windows application will be

lost.

Table 2. Recommended Switch Positions

4.4

DUAL H-BRIDGE

INTERNAL INDEXER

EXTERNAL INDEXER

BDECAY

MSP430 (optional)

MSP430 (optional)

MSP430 (required)

ADECAY

MSP430 (optional)

MSP430 (optional)

MSP430 (required)

BVREF

MSP430 (optional)

AVREF (required)

MSP430 (required)

AVREF

MSP430 (optional)

MSP430 (optional)

MSP430 (required)

Menu Options

•

.

Figure 23. File Menu

•

Debug - The Debug option can be used for the following operations.

Figure 24. Debug Menu

•

•

– Demo - By selecting the Demo in the submenu, the GUI runs in simulation mode, and by

unselecting it, the GUI runs in connected mode.

– Log to File - The log to file submenu is used to log the GUI activities to a log file that is specified.

– Debug log - The Debug log option enables to log all the activities of the user. If that is not selected,

only the high-level operations log.

Help

– Clicking the About in the Help Menu

Figure 25. Help Menu

– The About Page provides the details like the Name of the GUI, GUI version, Supported OS and

Copyright Information.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

19

�The Windows Application

www.ti.com

Figure 26. About Page

4.5

DRV8834 GPIO Control Signals

Once the application is communicating with the interface board, the control signals can be actuated by

checking or un-checking boxes on any of the respective control signals frames.

Functionality of control signals is as follows. A checked box translates to a HI level on the respective

control signal. Un-checked boxes translate to a LO level on the respective control signals.

4.6

Updating DAC Output for Current Control (VREF)

During evaluation, the user may want to study the operation of the ITRIP regulation scheme. Both

MSP430F2617 MCU DAC channels can be controlled through the provided sliders. Moving these sliders

will result on the regulated current to be directly proportional to the slider position per Equation 1.

xVREF , with R

ITRIP = ¾

SENSE = 0.2 W

5 · RSENSE

(1)

It must be noted, however, that during stepper actuation with the external indexer method, the DAC

channels are controlled by the microcontroller’s microstepping application.

Figure 27. Current Control (VREF)

The 12-bit DAC channels 0/1 are connected to the DRV8834 VREF analog inputs VREF. Changing the

DAC digital value from 0 to 4095, changes the analog voltage at the respective VREF pin from 0 V to 2.5

V respectively. See Equation 2.

20

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�The Windows Application

www.ti.com

2.5 V

VREF = DAC_VALUE · ¾

4095

(2)

Where VREF is the MCU DAC output voltage into the DRV8834 device and DAC_VALUE is a number

from 0 to 4095 as, in this case, specified by the slider position.

4.7

Stepper Control

Figure 28. Motion Control

The Windows application has an area which offers access to a series of very useful stepper control

algorithms. The user can control motor enablement, rotation rate, direction of rotation, current decay mode

during microstepping, microstepping resolution (from full step to 32 degrees of microstepping in internal

indexer mode or half step to 512 degrees of microstepping on external indexer mode) and number of

steps the motor will move.

Motor motion can only happen by using an acceleration profile which will be detailed later on. A detailed

explanation of each stepper control section follows.

4.7.1

Motion Control Frame

This frame allows the configuration and running of the stepper with the direction as specified by the DIR

checkbox, with the current decay mode as specified under the Decay checkbox and the microstepping

resolution as specified under the Microstepping Resolution drop down box.

The Motion Control frame gathers user information regarding stepping rate, or motor speed. An

acceleration profile is employed to start at a programmable speed and increase stepping rate until

reaching the programmable desired speed.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

21

�The Windows Application

www.ti.com

An internal 8-MHz timer is used to measure time and generate the steps on a timely manner. The

Windows application will transform the entered number of PPS and transform it into the respective clock

cycles needed for the timer to generate accurate STEP pulse timing.

The acceleration profile is coded inside of the microcontroller to accept both the starting speed PPS and

target speed PPS as a clock cycle number. When the start steps command is issued (Starts Steps button

is pressed), an interrupt service routine (ISR) generates steps at a rate specified by the start speed PPS

parameter.

The very same start steps command computes how frequent automatic speed updates are issued and a

second timer is used to change the speed according to the programmed acceleration rate profile.

Once the target speed PPS is reached, the acceleration profile ends and the motor stays running until the

stop stepper command is issued (Stop Steps button). When the stepper is commanded to stop, the

controller does exactly as it did while accelerating, but in reverse as to achieve deceleration until the stop

speed PPS is reached, in which case the motor fully stops.

A second motor actuation is provided by the move steps command in which a programmed number of

steps are issued and then the motor stopped. The acceleration and deceleration profiles work similarly as

before, except when the deceleration starts to happen and when the motor actually stops are a function of

the steps to stop and deceleration rate parameters.

Figure 29 shows the acceleration profile and the role each parameter plays during speed computation.

Target Speed

Steps To Stop

Acceleration Rate

Starting Speed

Stopping Speed

Number Of Steps

Figure 29. Acceleration Profile

The following controls are available within the motor control frame:

Start Speed PPS: Number of pulses per second (or full steps per second) at which the motor will rotate at

the beginning of operation. The SW will only allow a number as small as 200 PPS and can be taken to a

number as large as 65535 PPS.

Target Speed PPS: Number of pulses per second (or full steps per second) at which we want the motor

to operate. The acceleration profile will start from the start speed PPS and increase stepping rate until

reaching the desired speed PPS. The SW will only allow a number as small as 200 PPS and can be taken

to a number as large as 65535 PPS.

Acceleration Rate (0-5000): A number from 0 to 5000 which acts as a stepping rate modifier to increase

the start speed PPS up to target speed PPS.

Stop Speed PPS: Number of pulses per second (or full steps per second) at which the motor will stop

rotating after the stop stepper command is invoked and the deceleration profile is issued. The deceleration

profile modifies the stepper speed from the target speed and into the stop speed.

4.8

Move Steps Frame

If the user desires to move the stepper a certain number of steps, this can be easily accomplished by

using the move steps function. Parameters from the other frames are reused and its utilization is as

explained previously. Two new parameters have been added to properly control the limited number of

steps actuation.

Number of Steps: Amount of steps the controller will issue.

Steps to Stop: The controller is continuously monitoring the step being issued and when the current step

is equal to the steps to stop parameter, a deceleration profile is issued. If steps to stop is larger than the

number of steps, then the motor stops abruptly and without undergoing a deceleration profile.

22

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�The Windows Application

www.ti.com

When a deceleration profile is issued, the controller decreases the speed until reaching the stop speed

value. If the number of steps parameter is met before the deceleration profile is complete, then the motor

stops at the current speed. If the stop speed is met before all the number of steps are issued, then the

motor rotates at the stop speed value until all the steps are executed.

Ideally, the system must be tuned to resemble as much the case in which the controller executes all the

commanded steps at a speed as close as possible to the stop speed. In the event this is not possible, due

to the particular parameters being chosen, stopping the motor at a speed very close to the stop speed is

often good enough to ensure good motion quality and application performance.

Target Speed PPS

Steps to Stop

Start Speed PPS

Stop Speed PPS

Total Number Of Steps

Motor Reaches Stop Speed at the Stop Speed

Target Speed PPS

Steps to Stop

Start Speed PPS

Stop Speed PPS

Total Number Of Steps

Motor Reaches Stop Speed before the Stop Speed is reached

Target Speed PPS

Steps to Stop

Start Speed PPS

Total Number Of Steps

Motor runs out of Steps before reaching Stop Speed

Figure 30. Move Steps

4.8.1

Microstepping Resolution

Segmenting a full step into microsteps can be achieved by how many times we can divide the current

regulation magnitude. The DRV8834 device offers the flexibility of using either internal indexing with up to

32 degrees of microstepping for the simplest implementation, or infinite degrees of microstepping when

using the an external reference voltage source.

The Microstepping Resolution drop down box gives the user the option to change the full step divider

factor so that microsteps from half step to 512 degrees of microstepping are obtained, depending on the

chosen operating mode.

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

23

�Schematics and Bill of Materials

www.ti.com

5

Schematics and Bill of Materials

5.1

Schematics

The following pages contain the schematics for the DRV8834EVM.

The DRV8834EVM schematics are also available in the form of a PDF file (SCH.pdf) inside the

EVM_Related folder on the downloadable EVM software package.

GND

GND

GND

GND

VM

1

TP27

GND

1

TP26

GND

1

TP25

GND

1

1

1

1

1

TP24

GND

1

1

1

TP23

VDD

A

TP21

M0/APHASE

M0/APHASE

TP22

VM

TP20

M1

M1

C3

.1uF

TP19

CONFIG

CONFIG

C2

10uF

VM

100uF

TP18

nFAULT

nFAULT

C1

PWR

6

VCP

1

2

TP17

VCP

VINT

J1

1

2

TP16

VINT

1

1

TP15

AVREF

AVREF

BVREF

VREFO

DIR/BPHASE

STEP/BENBL

nENBL/AENBL

BISEN

BOUT1

BOUT2

AISEN

AOUT2

AOUT1

ADECAY

BDECAY

nSLEEP

VM

TP14

BVREF

1

TP10

TP11

TP12

TP13

nENBL/AENBL STEP/BENBL DIR/BPHASE VREFO

1

TP9

BISEN

5

1

TP8

BOUT1

1

TP7

BOUT2

1

TP6

AISEN

1

TP5

AOUT2

1

4

1

3

1

1

1

TP2

TP3

TP4

BDECAY ADECAY AOUT1

1

TP1

nSLEEP

1

A

2

1

1

nSLEEP

1

BDECAY

2

ADECAY

3

AOUT1

4

5

AISEN

AOUT2

6

BOUT2

7

BISEN

8

BOUT1

9

nENBL/AENBL 10

STEP/BENBL 11

DIR/BPHASE 12

J4

AOUT1

AOUT2

BOUT2

BOUT1

4

3

2

1

R4

0.2

R3

OUT

0.2

J2

AOUT1

AOUT2

BOUT2

BOUT1

24

23

22

21

20

19

18

17

16

15

14

13

VREFO

BVREF

AVREF

GND

VINT

VM

VM

VCP

nFAULT

CONFIG

M1

M0/APHASE

VREFO

BVREF

AVREF

VINT

C4 2.2uF

VCP

nFAULT

CONFIG

M1

M0/APHASE

C5 .1uF

DRV8834PWP

0

1

2

3

4

J3

nSLEEP

BDECAY

ADECAY

AOUT1

AISEN

AOUT2

BOUT2

BISEN

BOUT1

nENBL/AENBL

STEP/BENBL

DIR/BPHASE

PWR_PAD

U1

B

VDD

GND

EXT_BVREF

EXT_AVREF

M1

CONFIG

nENBL/AENBL

M0/APHASE

STEP/BENBL

DIR/BPHASE

nSLEEP

EXT_ADECAY

EXT_BDECAY

nFAULT

nFAULT

B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

VDD

Input

Header4

GND

GND

S3

S4

C

C

AVREF

1

C 2

3

1

MSP_AVREF

2

EXT_AVREF

3

AVREF SEL

BVREF

C

1

2

C

3

VREFO

R6

50K

D1

nFAULT

4

1

AVREF

2

MSP_BVREF

3

EXT_BVREF

S2

ADECAY

C

1

C 2

3

4

BVREF SEL

VREFO

1

MSP_ADECAY

2

EXT_ADECAY

VDD

R5

C

274

3

ADECAY SEL

R7

50K

R2

250K

GND

GND

S1

GND

BDECAY C

1

C 2

3

1

MSP_BDECAY

2

EXT_BDECAY

Texas Instruments

3

BDECAY SEL

R1

250K

DRV8834DC and SteppingMotor Drive EVM

GND

D

D

Size

B

FCSMNo.

24

2

3

4

DRV8834 Evaluation Module

Rev

B

Scale

1

DWGNo.

Sheet

5

1 of 2

6

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�Schematics and Bill of Materials

www.ti.com

1

2

3

4

5

6

5VCC

USBDM

USBDP

VDD

RST

R8

330

0.1uF

1

3

5

7

9

11

13

3.3K

GND

S5

D2

MCU-RST

Status

VDD

GND

PVDD

DEVSEL

C6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TX

DTR

RTS

RX

RI

DSR

DCD

CTS

CBUS4

CBUS2

CBUS3

TXD

DTR

RTS

VCCIO

RXD

RI

GND

NC

DSR

DCD

CTS

CBUS4

CBUS2

CBUS3

OSCO

OSCI

TEST

AGND

NC

CBUS0

CBUS1

GND

VCC

RST

GND

3V3O

USBDM

USBDP

U2

OSCO

OSCI

28

27

26

25

24

23

22

21

20

19

18

17

16

15

C10

CBUS0

CBUS1

GND

10uF

P6M5

MSP_AVREF

MSP_BVREF

USBDM

USBDP

Y1

C11

FTD232R

C9

0.1uF

2

C12

0.1uF

1

16 MHZ

33pF

M1

CONFIG

C13

33pF

R14

R16

3.3k

3.3k

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DVCC

P6.3/A3

P6.4/A4

P6.5/A5

P6.6/A6/DAC0

P6.7/A7/DAC1/SVSIN

VREF+

XIN

XOUT

VeREF+

VREF-/VeREFP1.0/TACLK

P1.1/TA0

P1.2/TA1

P1.3/TA2

P1.4/SMCLK

GND

GND

B

P5.4/MCLK

P5.3/UCLK1

P5.2/SOMI1

P5.1/SIMO1

P5.0/STE1

P4.7/TBCLK

P4.6/TB6

P4.5/TB5

P4.4/TB4

P4.3/TB3

P4.2/TB2

P4.1/TB1

P4.0/TB0

P3.7/URXD1

P3.6/UTXD1

P3.5/URXD0

MSP430F2617

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

MSP_BDECAY

MSP_ADECAY

R10

R11

R12

R13

R15

3.3k nSLEEP

3.3k DIR/BPHASE

3.3k STEP/BENBL

3.3k M0/APHASE

3.3k nENBL/AENBL

TX

C

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

C

PWR Select

0.1uF

GND

P1.5/TA0

P1.6/TA1

P1.7/TA2

P2.0/ACLK

P2.1/TAINCLK

P2.2/CAOUT/TA0

P2.3/CA0/TA1

P2.4/CA1/TA2

P2.5/ROSC

P2.6/ADC12CLK/DMAE0

P2.7/TA0

P3.0/STE0

P3.1/SIMO0/SDA

P3.2/SOMI0

P3.3/UCLK0/SCL

P3.4/UTXD0

B

1-2JTG_PWR

2-3TRG_PWR

C7

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

10uF

GND

1

2

3

GND

AVCC

DVSS

AVSS

P6.2/A2

P6.1/A1

P6.0/A0

RST/NMI

TCK

TMS

TDI/TCLK

TDO/TDI

XT2IN

XT2OUT

P5.7/TBOUTH/VSOUT

P5.6/ACLK

P5.5/SMCLK

GND

5VCC

U3

2

4

6

8

10

12

14

JTAG

MCU PWR

C8

VDD

A

JP2

J7

R9

RST

SHLD

SHLD

L1 10mH

1 USB5V

2

3

4

5

6

A

VCC

DM

DP

GND

P6M5

USB B Conn

J6

RX

VM

JP4

VM

REG1

1

2

3

GND

VIN

VOUT

5

VDD

C14

GND

ON BYPASS

Volt_RegLP2985

C15

.01uF

Texas Instruments

R17

330

2.2uF

4

DRV8834DC and SteppingMotor Drive EVM

D3

3.3V

C16

1uF

D

D

GND

GND

GND

Size

B

FCSMNo.

2

3

4

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Rev

B

Scale

1

DWGNo.

Sheet

5

2 of 2

6

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

25

�Schematics and Bill of Materials

5.2

www.ti.com

Bill of Materials

DESIGNATOR

DESCRIPTION

MANUFACTURER

MFG PART NUMBER

VALUE

QUANTITY

C1

Polarized Capacitor (Radial)

Nichicon

RNE1C101MDS1PX

100 uF

1

C2

Capacitor

TDK Corporation

C2012X5R1C106M

10 uF

1

C3, C5

Capacitor

TDK Corporation

C1608X7R1E104K

.1 uF

2

C4

CAP CER 2.2 UF 10V Y5V

0603

TDK Corporation

C1608Y5V1A225Z

2.2 uF

1

C6, C7, C9, C11

CAP .10 UF 50 V CERAMIC

X7R 0805

Kemet

C0805C104K5RACTU

0.1 uF

4

C8, C10

10 uF, 25 V Electrolytic Cap

(Radial)

Nichicon

UVR1E100MDD

10 uF

2

C12, C13

CAP CERAMIC 33PF 50V

NP0 0805

Yageo

CC0805JRNP09BN330

33 pF

2

C14

Capacitor

TDK Corporation

C1608X5R0J225K

2.2 uF

1

C15

Capacitor

Murata Electronics North

America

GRM188R71E103KA01D

.01 uF

1

C16

Capacitor

TDK Corporation

C1608Y5V1C105Z

1 uF

1

D1, D2, D3

LED RED CLEAR 1206 SMD

Stanley Electric & Co

HBR1105W-TR

LED RED

3

J1

TERM BLOCK 5.08 MM

VERT 2POS PCB

On Shore Technologies

OSTTA024163

1

J2, J5

Sullins Connector Solutions

PBC02SAAN

2

J3

CONN HEADER .100 SINGL

STR 14POS

Sullins Connector Solutions

PBC14SABN

1

J4

TERM BLOCK 5.08 MM

VERT 4POS PCB

On Shore Technology Inc

OSTTA044163

1

J6

CONN USB RT ANG RECPT

TYPE B BLK

Molex

67068-8000

USB B

1

J7

CONN HEADER .100 DUAL

STR 14POS

Sullins

PBC07DAAN

14 Pos Header

1

JP1, JP3

Two Pin Jumper

Sullins Connector Solutions

PBC02SAAN

0.230" (5.84 mm)

2

JP2

CONN HEADER .100 SINGL

STR 3POS

Sullins

PBC03SAAN

3 Pos Header

1

JP4

Two Pin Jumper

Phoenix Contact

1945096

NA

1

L1

Ferrite Bead 1.5A 40 ohm

0805 SMD

Laird-Signal Integrity

Products

MI0805K400R-10

10 mH

1

R1, R2

TRIMMER 10K OHM 0.25W

TH

Murata Electronics North

America

PV37Y254C01B00

250 K

2

R3, R4

RES .2OHM 2W 1% 2512

SMD

Stackpole

CSRN2512FKR200

0.2

2

R5

Resistor

Panasonic - ECG

ERJ-6ENF2740V

274

1

R6, R7

TRIMMER 10K OHM 0.25W

TH

Murata Electronics North

America

PV37Y503C01B00

50K

2

R8, R17

RES 330 OHM 1/8W 5%

0805 SMD

Yageo

RC0805JR-07330RL

330

2

R9

RES 3.3K OHM 1/8W 5%

0805 SMD

Yageo

RC0805JR-073K3L

3.3K

1

R10, R11, R12, R13,

R14, R15, R16

Resistor

Panasonic - ECG

ERJ-3GEYJ332V

3.3k

7

REG1

VoltageRegulator

Texas Instruments

LP2985-50DBVR

1

S1, S2, S4

Copal Electronics

SS-10-23NP-LE

3

S3

Copal Electronics

S-2150

1

S5

SWITCH LIGHT TOUCH 4.3

MM 100GF

Panasonic

EVQ-11A04M

Push Button

1

TP1, TP2, TP3, TP4,

TP5, TP6, TP7, TP8,

TP9, TP10, TP11,

TP12, TP13, TP14,

TP15, TP16, TP17,

TP18, TP19, TP20,

TP21

Glass Beaded Test Point

Kobiconn

151-101-RC

WHITE

21

TP22

Glass Beaded Test Point

Kobiconn

151-107-RC

WHITE

1

TP23

Glass Beaded Test Point

Kobiconn

151-107-RC

RED

1

26

DRV8834 Evaluation Module

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

Copyright © 2012–2019, Texas Instruments Incorporated

�Schematics and Bill of Materials

www.ti.com

DESIGNATOR

DESCRIPTION

MANUFACTURER

MFG PART NUMBER

VALUE

QUANTITY

TP24, TP25, TP26,

TP27

Glass Beaded Test Point

Kobiconn

151-103-RC

BLACK

4

U1

Stepping and DC motor Driver Texas Instruments

U2

IC MCU 16BIT 55K FLASH

64-LQFP

Texas Instruments

MSP430F2617TPMR

MSP430 MCU

1

U3

USB Chip

FTDI

FT232RL R

USB Driver

1

Y1

CRYSTAL 8.00 MHZ 20PF

49US

ECS Inc.

ECS-160-20-4X

Crystal

1

1

SLVU701B – March 2012 – Revised July 2019

Submit Documentation Feedback

DRV8834 Evaluation Module

Copyright © 2012–2019, Texas Instruments Incorporated

27

�IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, regulatory or other requirements.

These resources are subject to change without notice. TI grants you permission to use these resources only for development of an

application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license

is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you

will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these

resources.

TI’s products are provided subject to TI’s Terms of Sale or other applicable terms available either on ti.com or provided in conjunction with

such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2022, Texas Instruments Incorporated

�