DRV8899-Q1

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

DRV8899-Q1 Automotive Stepper Driver with Integrated Current Sense and 1/256

Micro-Stepping

1 Features

•

•

•

•

•

•

AEC-Q100 Qualified for Automotive

Up to 1/256 microstepping

Integrated current sense functionality

– No sense resistors required

Smart tune decay technology,

Fixed slow, and mixed decay options

4.5 to 45-V Operating supply voltage range

Pin to pin RDS(ON) variants:

- DRV8889/A-Q1: 900 mΩ HS + LS at 25°C

•

•

•

•

•

•

•

•

•

•

- DRV8899-Q1: 1200 mΩ HS + LS at 25°C

High current capacity per bridge

– DRV8889/A-Q1: 2.4-A peak, 1.5-A full-scale

– DRV8899-Q1: 1.7-A peak, 1-A full-scale

TRQ_DAC bits to scale full-scale current

Configurable off-time PWM chopping

Simple STEP/DIR interface

SPI with daisy chain support

Low-current sleep mode (2 μA)

Programmable output slew rate

Spread spectrum clocking to minimize EMI

Protection features

– VM undervoltage lockout

– Overcurrent protection

– Open load detection

– Overtemperature warning and shutdown

– Undertemperature warning

– Fault condition indication pin (nFAULT)

Functional Safety-Capable

– Documentation available to aid functional

safetysystem design

for two external resistors, saving board space and

cost. DRV8899-Q1 provides 8 decay mode options

including: smart tune, slow, and mixed decay options.

Smart tune automatically adjusts for optimal current

regulation performance and compensates for any

motor variation and aging effects. The device also

includes an integrated torque DAC which allows for

the controller to scale the output current through

SPI without needing to scale the VREF voltage

reference. A low-power sleep mode is provided for

very low standby current using an nSLEEP pin. The

device features full duplex, 4-wire synchronous SPI

communication, with daisy chain support for up to

63 devices connected in series, for configurability

and detailed fault reporting. View our full portfolio of

stepper motor drivers on ti.com.

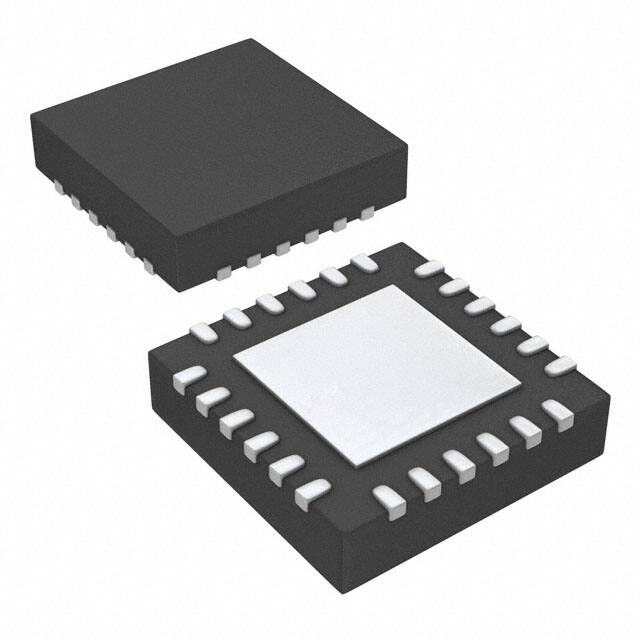

Device Information

PART NUMBER

(1)

DRV8899QWRGERQ1

(1)

PACKAGE

BODY SIZE (NOM)

VQFN (24)

(Wettable Flank)

4.00 mm × 4.00 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

2 Applications

•

•

•

•

•

Automotive bipolar stepper motors

Headlight position adjustment

Head-up display (HUD)

HVAC stepper motors

Electronic fuel injection (EFI)

Simplified Schematic

3 Description

The DRV8899-Q1 is a fully integrated stepper motor

driver, supporting up to 1 A full scale current with

an internal microstepping indexer, smart tune decay

technology, and integrated current sensing. With a

simple step/dir interface to manage the direction

and step rate, DRV8899-Q1 supports up to 1/256

levels of microstepping to enable a smooth motion

profile. Integrated current sensing eliminates the need

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

Pin Functions.................................................................... 3

6 Specifications.................................................................. 5

6.1 Absolute Maximum Ratings........................................ 5

6.2 ESD Ratings............................................................... 5

6.3 Recommended Operating Conditions.........................6

6.4 Thermal Information....................................................6

6.5 Electrical Characteristics.............................................7

6.6 SPI Timing Requirements........................................... 8

6.7 Indexer Timing Requirements................................... 10

6.8 Typical Characteristics.............................................. 11

7 Detailed Description......................................................12

7.1 Overview................................................................... 12

7.2 Functional Block Diagram......................................... 13

7.3 Feature Description...................................................14

7.4 Device Functional Modes..........................................35

7.5 Programming............................................................ 36

7.6 Register Maps...........................................................41

8 Application and Implementation.................................. 49

8.1 Application Information............................................. 49

8.2 Typical Application.................................................... 49

9 Power Supply Recommendations................................59

9.1 Bulk Capacitance...................................................... 59

10 Layout...........................................................................60

10.1 Layout Guidelines................................................... 60

10.2 Layout Example...................................................... 61

11 Device and Documentation Support..........................62

11.1 Documentation Support.......................................... 62

11.2 Receiving Notification of Documentation Updates.. 62

11.3 Support Resources................................................. 62

11.4 Trademarks............................................................. 62

11.5 Electrostatic Discharge Caution.............................. 62

11.6 Glossary.................................................................. 62

12 Mechanical, Packaging, and Orderable

Information.................................................................... 62

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (August 2020) to Revision B (April 2021)

Page

• Added Functional Safety information .................................................................................................................1

• Fixed typo in Absolute Maximum Ratings table..................................................................................................5

• Updated Full Step with 100% Current table......................................................................................................15

• Removed duplicate package drawings............................................................................................................. 62

Changes from Revision * (November 2019) to Revision A (August 2020)

Page

• Changed Device status to Production Data .......................................................................................................1

2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

5 Pin Configuration and Functions

Figure 5-1. WRGE Package 24-Pin VQFN With Exposed Thermal Pad Top View

Pin Functions

PIN

I/O

TYPE

3

O

Output

Winding A output. Connect to stepper motor winding.

4

O

Output

Winding A output. Connect to stepper motor winding.

PGND

2, 7

—

Power

Power ground. Both PGND pins are shorted internally. Connect to system

ground on PCB.

BOUT1

6

O

Output

Winding B output. Connect to stepper motor winding

BOUT2

5

O

Output

Winding B output. Connect to stepper motor winding

CPH

23

CPL

22

—

Power

Charge pump switching node. Connect a X7R, 0.022-µF, VM-rated ceramic

capacitor from CPH to CPL.

DIR

19

I

Input

Direction input. Logic level sets the direction of stepping; internal pulldown

resistor.

DRVOFF

20

I

Input

Logic high to disable device outputs; logic low to enable; internal pullup to

DVDD.

DVDD

10

GND

9

VREF

NAME

NO.

AOUT1

AOUT2

DESCRIPTION

Power

Logic supply voltage. Connect a X7R, 0.47-µF, 6.3-V or 10-V rated ceramic

capacitor to GND.

—

Power

Device ground. Connect to system ground.

12

I

Input

Current set reference input. Maximum value 2.2 V. DVDD can be used to

provide VREF through a resistor divider.

SCLK

17

I

Input

Serial clock input. Serial data is shifted out and captured on the corresponding

rising and falling edge on this pin.

SDI

16

I

Input

Serial data input. Data is captured on the falling edge of the SCLK pin

SDO

15

O

Push Pull Serial data output. Data is shifted out on the rising edge of the SCLK pin.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

3

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

PIN

I/O

TYPE

18

I

Input

VCP

24

—

Power

Charge pump output. Connect a X7R, 0.22-μF, 16-V ceramic capacitor to VM.

VM

1, 8

—

Power

Power supply. Connect to motor supply voltage and bypass to GND with two

0.01-µF ceramic capacitors (one for each pin) plus a bulk capacitor rated for

VM.

VSDO

14

Power

Supply pin for SDO output. Connect to 5-V or 3.3-V depending on the desired

logic level.

nFAULT

11

O

Open

Drain

Fault indication. Pulled logic low with fault condition; open-drain output

requires an external pullup resistor.

nSCS

13

I

Input

Serial chip select. An active low on this pin enables the serial interface

communications. Internal pullup to DVDD.

nSLEEP

21

I

Input

Sleep mode input. Logic high to enable device; logic low to enter low-power

sleep mode; internal pulldown resistor.

-

-

-

NAME

NO.

STEP

PAD

4

DESCRIPTION

Step input. A rising edge causes the indexer to advance one step; internal

pulldown resistor.

Thermal pad. Connect to system ground.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) 1

MIN

MAX

UNIT

Power supply voltage (VM)

–0.3

50

V

Charge pump voltage (VCP, CPH)

–0.3

VM + 7

V

Charge pump negative switching pin (CPL)

–0.3

VM

V

nSLEEP pin (nSLEEP)

–0.3

VM

V

Internal regulator voltage (DVDD)

–0.3

5.75

V

SDO output reference voltage (VSDO)

–0.3

5.75

V

Control pin voltage (STEP, DIR, DRVOFF, nFAULT, SDI, SDO, SCLK, nSCS)

–0.3

5.75

V

Open drain output current (nFAULT)

0

10

mA

Reference input pin voltage (VREF)

–0.3

5.75

V

Continuous phase node pin voltage (AOUT1, AOUT2, BOUT1, BOUT2)

–1.0

VM + 1.0

V

Transient 100 ns phase node pin voltage (AOUT1, AOUT2, BOUT1, BOUT2)

–3.0

VM + 3.0

Peak drive current (AOUT1, AOUT2, BOUT1, BOUT2)

V

Internally Limited

A

Operating ambient temperature, TA

–40

125

°C

Operating junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–65

150

°C

1. Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the

device. These are stress ratings only, which do not imply functional operation of the device at these or any

other conditions beyond those indicated under Recommended Operating Conditions. Exposure to absolutemaximum-rated conditions for extended periods may affect device reliability.

6.2 ESD Ratings

VALUE

V(ESD)

Electrostatic

discharge

Human body model (HBM), per AEC Q100–002 (1)

±2000

Charged device model (CDM), per AEC Q100–011

±500

UNIT

V

1. AECQ100–002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS–

001specification.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

5

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted) 1

MIN

VVM

Supply voltage range for normal (DC) operation

VI

Logic level input voltage

VSDO

SDO buffer supply voltage

VVREF

VREF voltage

MAX

UNIT

4.5

45

V

0

5.5

V

2.9

5.5

V

0.05

2.2

V

ƒSTEP

Applied STEP signal (STEP)

0

100 (2)

IFS

Motor full-scale current (xOUTx)

0

1 (3)

kHz

A

Irms

Motor RMS current (xOUTx)

0

0.7 (3)

A

TA

Operating ambient temperature

–40

125

°C

TJ

Operating junction temperature

–40

150

°C

6.4 Thermal Information

DRV8899-Q1

THERMAL METRIC 1

RGE (VQFN)

UNIT

24 PINS

RθJA

Junction-to-ambient thermal resistance

40.7

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

31.1

°C/W

RθJB

Junction-to-board thermal resistance

17.9

°C/W

ψJT

Junction-to-top characterization parameter

0.6

°C/W

ψJB

Junction-to-board characterization parameter

17.8

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

4.3

°C/W

1. For more information about traditional and new thermalmetrics, see the Semiconductor and IC Package

Thermal Metrics application report

6

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

6.5 Electrical Characteristics

Over recommended operating conditions unless otherwise noted. Typical limits apply for TJ = 25°C and VVM = 13.5 V

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

5

7

mA

2

4

μA

POWER SUPPLIES (VM, DVDD, VSDO)

IVM

VM operating supply current

DRVOFF = 0, nSLEEP = 1, No output

IVMQ

VM sleep mode supply current

nSLEEP = 0

tSLEEP

Sleep time

nSLEEP = 0 to sleep-mode

75

tRESET

nSLEEP reset pulse

nSLEEP low to only clear fault

registers

18

tWAKE

Wake-up time

nSLEEP = 1 to output transition

tON

Turn-on time

VM > UVLO to output transition

VDVDD

Internal regulator voltage

No external load, 6 V < VVM < 45 V

4.5

μs

35

μs

0.6

0.9

ms

0.6

0.9

ms

5

5.5

V

CHARGE PUMP (VCP, CPH, CPL)

VVCP

VCP operating voltage

f(VCP)

Charge pump switching

frequency

VM + 5

VVM > UVLO; nSLEEP = 1

V

400

kHz

LOGIC-LEVEL INPUTS (STEP, DIR, nSLEEP, nSCS, SCLK, SDI, DRVOFF)

VIL

Input logic-low voltage

VIH

Input logic-high voltage

VHYS

Input logic hysteresis

0

0.6

1.5

5.5

150

IIL1

Input logic-low current

VIN = 0 V (nSCS, DRVOFF)

IIL2

Input logic-low current

VIN = 0 V

IIH1

Input logic-high current

VIN = DVDD (nSCS, DRVOFF)

IIH2

Input logic-high current

VIN = 5 V

V

V

mV

8

12

μA

–1

1

μA

500

nA

50

μA

40

75

Ω

30

60

Ω

1

μA

0.4

V

1

μA

PUSH-PULL OUTPUT (SDO)

RPD,SDO

Internal pull-down resistance

5mA load, with respect to GND

RPU,SDO

Internal pull-up resistance

5mA load, with respect to VSDO

ISDO

SDO Leakage Current

SDO = VSDO and 0V

-1

CONTROL OUTPUTS (nFAULT)

VOL

Output logic-low voltage

IO = 5 mA

IOH

Output logic-high leakage

VVM = 13.5 V

–1

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

7

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Over recommended operating conditions unless otherwise noted. Typical limits apply for TJ = 25°C and VVM = 13.5 V

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

MOTOR DRIVER OUTPUTS (AOUT1, AOUT2, BOUT1, BOUT2)

RDS(ONH)

RDS(ONL)

High-side FET on resistance

Low-side FET on resistance

TJ = 25°C, IO = -1 A

600

730

mΩ

TJ = 125°C, IO = -1 A

900

1100

mΩ

TJ = 150°C, IO = -1 A

1040

1250

mΩ

TJ = 25°C, IO = -1 A

600

730

mΩ

TJ = 125°C, IO = -1 A

900

1100

mΩ

TJ = 150°C, IO = -1 A

1040

1250

mΩ

SR = 00b, VM = 13.5 V, IO = 0.5 A

tSR

Output slew rate

10

SR = 01b, VM = 13.5 V, IO = 0.5 A

35

SR = 10b, VM = 13.5 V, IO = 0.5 A

50

SR = 11b, VM = 13.5 V, IO = 0.5 A

105

V/µs

PWM CURRENT CONTROL (VREF)

KV

Transimpedance gain

tOFF

PWM off-time

2.2

TOFF = 00b

7

TOFF = 01b

16

TOFF = 10b

24

TOFF = 11b

ΔITRIP

Current trip accuracy

IO,CH

AOUT and BOUT current

matching

V/A

μs

32

IO = 1 A, 10% to 30% current setting

–13

10

IO = 1 A, 30% to 100% current setting

–8

8

IO = 1 A

–2.5

2.5

VM falling, UVLO falling

4.15

4.25

4.35

VM rising, UVLO rising

4.25

4.35

4.45

%

%

PROTECTION CIRCUITS

VUVLO

VM UVLO lockout

VUVLO,HYS

Undervoltage hysteresis

Rising to falling threshold

VRST

VM UVLO reset

VM falling, device reset, no SPI

communications

VCPUV

Charge pump undervoltage

VCP falling; CPUV report

IOCP

Overcurrent protection

Current through any FET

tOCP

Overcurrent deglitch time

100

VM + 2

A

VVM ≥ 37 V

0.5

Overcurrent retry time

OCP_MODE = 1b

Open load detection time

EN_OL = 1b

IOL

Open load current threshold

TOTW

Overtemperature warning

μs

4

ms

200

30

Die temperature TJ

V

V

1.7

3

tOL

mV

3.9

VVM < 37 V

tRETRY

V

135

ms

mA

150

165

°C

TUTW

Undertemperature warning

Die temperature TJ

-25

-10

5

°C

TOTSD

Thermal shutdown

Die temperature TJ

150

165

180

°C

THYS_OTSD

Thermal shutdown hysteresis

Die temperature TJ

20

°C

THYS_OTW

Overtemperature warning

hysteresis

Die temperature TJ

20

°C

THYS_UTW

Undertemperature warning

hysteresis

Die temperature TJ

10

°C

6.6 SPI Timing Requirements

MIN

t(READY)

8

SPI ready, VM > VRST

NOM

1

Submit Document Feedback

MAX

UNIT

ms

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

MIN

t(CLK)

SCLK minimum period

NOM

MAX

100

UNIT

ns

t(CLKH)

SCLK minimum high time

50

ns

t(CLKL)

SCLK minimum low time

50

ns

tsu(SDI)

SDI input setup time

20

ns

th(SDI)

SDI input hold time

30

ns

td(SDO)

SDO output delay time, SCLK high to SDO valid, CL = 20 pF

tsu(nSCS)

nSCS input setup time

50

30

th(nSCS)

nSCS input hold time

50

t(HI_nSCS)

nSCS minimum high time before active low

tdis(nSCS)

nSCS disable time, nSCS high to SDO high impedance

ns

ns

ns

2

10

µs

ns

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

9

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

6.7 Indexer Timing Requirements

Over recommended operating conditions unless otherwise noted. Typical limits apply for TJ = 25°C and VVM = 13.5 V

NO.

(1)

10

MIN

1

ƒSTEP

Step frequency

2

tWH(STEP)

Pulse duration, STEP high

970

MAX

UNIT

500(1)

kHz

ns

3

tWL(STEP)

Pulse duration, STEP low

970

ns

4

tSU(DIR, Mx)

Setup time, DIR to STEP rising

200

ns

5

tH(DIR, Mx)

Hold time, DIR to STEP rising

200

ns

STEP input can operate up to 500 kHz, but system bandwidth islimited by the motor load.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

6.8 Typical Characteristics

Over recommended operating conditions (unless otherwise noted)

Figure 6-1. Sleep Current over VM

Figure 6-2. Sleep Current over Temperature

Figure 6-3. Operating Current over VM

Figure 6-4. Operating Current over Temperature

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

11

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7 Detailed Description

7.1 Overview

The DRV8899-Q1 device is an integrated motor-driver solution for bipolar stepper motors. The device integrates

two N-channel power MOSFET H-bridges, integrated current sense and regulation circuitry, and a microstepping

indexer. The DRV8899-Q1 device can be powered with a supply voltage from 4.5 to 45 V and is capable

of providing an output current up to 1.7-A peak, 1-A full-scale, or 0.7-A root mean square (rms). The actual

full-scale and rms current depends on the ambient temperature, supply voltage, and PCB thermal capability.

The device uses an integrated current-sense architecture which eliminates the need for two external power

sense resistors. This architecture removes the power dissipated in the sense resistors by using a current mirror

approach and using the internal power MOSFETs for current sensing. The current regulation set point is adjusted

by the voltage at the VREF pin. These features reduces external component cost, board PCB size, and system

power consumption.

A simple STEP/DIR interface allows for an external controller to manage the direction and step rate of the

stepper motor. The internal indexer can execute high-accuracy microstepping without requiring the external

controller to manage the winding current level. The indexer is capable of full step, half step, and 1/4, 1/8, 1/16,

1/32, 1/64, 1/128 and 1/256 microstepping. In addition to a standard half stepping mode, a noncircular half

stepping mode is available for increased torque output at higher motor RPM.

The current regulation is configurable between several decay modes. The decay mode can be selected as a

slow-mixed, mixed decay, smart tune Ripple Control, or smart tune Dynamic Decay current regulation scheme.

The slow-mixed decay mode uses slow decay on increasing steps and mixed decay on decreasing steps. The

smart tune decay modes automatically adjust for optimal current regulation performance and compensate for

motor variation and aging effects. Smart tune Ripple Control uses a variable off-time, ripple control scheme

to minimize distortion of the motor winding current. Smart tune Dynamic Decay uses a fixed off-time, dynamic

decay percentage scheme to minimize distortion of the motor winding current while also minimizing frequency

content.

The device integrates a spread spectrum clocking feature for both the internal digital oscillator and internal

charge pump. This feature combined with output slew rate control minimizes the radiated emissions from the

device.

A torque DAC feature allows the controller to scale the output current without needing to scale the VREF voltage

reference. The torque DAC is accessed using a digital input pin which allows the controller to save system power

by decreasing the motor current consumption when high output torque is not required.

A low-power sleep mode is included which allows the system to save power when not actively driving the motor.

12

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.2 Functional Block Diagram

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

13

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3 Feature Description

Table 7-1 lists the recommended external components for the DRV8899-Q1 device.

Table 7-1. DRV8899-Q1 External Components

COMPONENT

PIN 1

PIN 2

CVM1

VM

GND

Two X7R, 0.01-µF, VM-rated ceramic capacitors

RECOMMENDED

CVM2

VM

GND

Bulk, VM-rated capacitor

CVCP

VCP

VM

X7R, 0.22-µF, 16-V ceramic capacitor

CSW

CPH

CPL

X7R, 0.022-µF, VM-rated ceramic capacitor

CDVDD

DVDD

GND

X7R, 0.47-µF to 1-µF, 6.3-V ceramic capacitor

RnFAULT

VCC (1)

nFAULT

RREF1

VREF

VCC

RREF2 (Optional)

VREF

GND

(1)

>4.7-kΩ resistor

Resistor to limit chopping current. It is recommended that the value of parallel

combination of RREF1 and RREF2 should be less than 50-kΩ.

VCC is not a pin on the DRV8899-Q1 device, but a VCC supply voltage pullup is required for open-drain output nFAULT; nFAULT may

be pulled up to DVDD

7.3.1 Stepper Motor Driver Current Ratings

Stepper motor drivers can be classified using three different numbers to describe the output current: peak, rms,

and full-scale.

7.3.1.1 Peak Current Rating

The peak current in a stepper driver is limited by the overcurrent protection trip threshold IOCP. The peak current

describes any transient duration current pulse, for example when charging capacitance, when the overall duty

cycle is very low. In general the minimum value of IOCP specifies the peak current rating of the stepper motor

driver.

For the DRV8899-Q1 device, the peak current rating is 1.7 A per bridge.

7.3.1.2 rms Current Rating

The rms (average) current is determined by the thermal considerations of the IC. The rms current is calculated

based on the RDS(ON), rise and fall time, PWM frequency, device quiescent current, and package thermal

performance in a typical system at 25°C. The actual operating rms current may be higher or lower depending on

heatsinking and ambient temperature.

For the DRV8899-Q1 device, the rms current rating is 0.7 A per bridge.

7.3.1.3 Full-Scale Current Rating

The full-scale current describes the top of the sinusoid current waveform while microstepping. Because the

sinusoid amplitude is related to the rms current, the full-scale current is also determined by the thermal

considerations of the device. The full-scale current rating is approximately √2 × IRMS.

For the DRV8899-Q1 device, the full-scale current rating is 1 A per bridge.

Full-scale current

Output Current

RMS current

AOUT

BOUT

Step Input

Figure 7-1. Full-Scale and RMS Current

14

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.2 PWM Motor Drivers

The device has drivers for two full H-bridges to drive the two windings of a bipolar stepper motor. Figure 7-2

shows a block diagram of the circuitry.

VM

xOUT1

Current

Sense

Microstepping and

Current Regulation

Logic

VM

Gate

Drivers

xOUT2

Current

Sense

PGND

Figure 7-2. PWM Motor Driver Block Diagram

7.3.3 Microstepping Indexer

Built-in indexer logic in the device allows a number of different step modes. The MICROSTEP_MODE bits in the

SPI register are used to configure the step mode as shown in Table 7-2.

Table 7-2. Microstepping Settings

MICROSTEP_MODE

STEP MODE

0000b

Full step (2-phase excitation) with 100%

current

0001b

Full step (2-phase excitation) with 71%

current

0010b

Non-circular 1/2 step

0011b

1/2 step

0100b

1/4 step

0101b

1/8 step

0110b

1/16 step

0111b

1/32 step

1000b

1/64 step

1001b

1/128 step

1010b

1/256 step

Table 7-3 shows the relative current and step directions for full-step (71% current), 1/2 step, 1/4 step and 1/8

step operation. Higher microstepping resolutions follow the same pattern. The AOUT current is the sine of the

electrical angle and the BOUT current is the cosine of the electrical angle. Positive current is defined as current

flowing from the xOUT1 pin to the xOUT2 pin while driving.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

15

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

At each rising edge of the STEP input the indexer travels to the next state in the table. The direction is shown

with the DIR pin logic high. If the DIR pin is logic low, the sequence is reversed.

Note

If the step mode is changed on the fly while stepping, the indexer advances to the next valid state for

the new step mode setting at the rising edge of STEP.

Note

While DIR = 0 and the electrical angle is at a full step angle (45, 135, 225, or 315 degrees), two rising

edge pulses on the STEP pin are required in order to advance the indexer after changing from any

microstep mode to the full step mode. The first pulse will induce no change in the electrical angle, the

second pulse will move the indexer to the next full step angle.

The home state is an electrical angle of 45°. This state is entered after power-up, after exiting logic undervoltage

lockout, or after exiting sleep mode.

Table 7-3. Relative Current and Step Directions

1/8 STEP

1/4 STEP

1/2 STEP

1

1

1

FULL

STEP

71%

2

3

2

4

5

3

2

1

6

7

4

8

9

5

3

10

11

6

12

13

7

4

2

14

15

8

16

17

9

5

18

19

10

20

21

11

6

3

22

23

12

24

25

13

7

26

27

14

28

29

16

15

8

4

AOUT CURRENT BOUT CURRENT

(% FULL-SCALE) (% FULL-SCALE)

ELECTRICAL

ANGLE (DEGREES)

0

100

0

20

98

11

38

92

23

56

83

34

71

71

45

83

56

56

92

38

68

98

20

79

100

0

90

98

–20

101

92

–38

113

83

–56

124

71

–71

135

56

–83

146

38

–92

158

20

–98

169

0

–100

180

–20

–98

191

–38

–92

203

–56

–83

214

–71

–71

225

–83

–56

236

–92

–38

248

–98

–20

259

–100

0

270

–98

20

281

–92

38

293

–83

56

304

–71

71

315

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Table 7-3. Relative Current and Step Directions (continued)

1/8 STEP

1/4 STEP

FULL

STEP

71%

1/2 STEP

30

31

16

32

AOUT CURRENT BOUT CURRENT

(% FULL-SCALE) (% FULL-SCALE)

ELECTRICAL

ANGLE (DEGREES)

–56

83

326

–38

92

338

–20

98

349

Table 7-4 shows the full step operation with 100% full-scale current. This stepping mode consumes more power

than full-step mode with 71% current, but provides a higher torque at high motor RPM.

Table 7-4. Full Step with 100% Current

FULL

STEP

100%

AOUT CURRENT

(% FULL-SCALE)

BOUT CURRENT

(% FULL-SCALE)

100

100

1

ELECTRICAL ANGLE

(DEGREES)

45

2

100

-100

135

3

-100

-100

225

4

-100

100

315

Table 7-5 shows the noncircular 1/2–step operation. This stepping mode consumes more power than circular

1/2-step operation, but provides a higher torque at high motor RPM.

Table 7-5. Non-Circular 1/2-Stepping Current

NON-CIRCULAR 1/2-STEP

AOUT CURRENT

(% FULL-SCALE)

BOUT CURRENT

(% FULL-SCALE)

1

0

100

ELECTRICAL ANGLE

(DEGREES)

0

2

100

100

45

3

100

0

90

4

100

–100

135

5

0

–100

180

6

–100

–100

225

7

–100

0

270

8

–100

100

315

7.3.4 Controlling VREF with an MCU DAC

In some cases, the full-scale output current may need to be changed between many different values, depending

on motor speed and loading. The voltage of the VREF pin can be adjusted in the system to change the full-scale

current.

In this mode of operation, as the DAC voltage increases, the full-scale regulation current increases as well. For

proper operation, the output of the DAC should not rise above 2.2 V.

Figure 7-3. Controlling VREF with a DAC Resource

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

17

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

The VREF pin can also be adjusted using a PWM signal and low-pass filter. The R-C time constant for the

low-pass filter should be longer than 10 times the period of the PWM signal.

Figure 7-4. Controlling VREF With a PWM Resource

18

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.5 Current Regulation

The current through the motor windings is regulated by a PWM current-regulation circuit. When an H-bridge is

enabled, current rises through the winding at a rate dependent on the DC voltage, inductance of the winding,

and the magnitude of the back EMF present. When the current hits the current regulation threshold, the bridge

enters a decay mode for a period of time determined by the TOFF register setting and the selected decay mode

to decrease the current. After the off-time expires, the bridge is re-enabled, starting another PWM cycle.

Figure 7-5. Current Chopping Waveform

The PWM regulation current is set by a comparator which monitors the voltage across the current sense

MOSFETs in parallel with the low-side power MOSFETs. The current sense MOSFETs are biased with a

reference current that is the output of a current-mode sine-weighted DAC whose full-scale reference current is

set by the voltage at the VREF pin. In addition, the TRQ_DAC register can further scale the reference current.

Use Equation 1 to calculate the full-scale regulation current.

(1)

The TRQ_DAC is adjusted via the SPI register. Table 7-6 lists the current scalar value for different inputs.

Table 7-6. Torque DAC Settings

TRQ_DAC

CURRENT SCALAR (TRQ)

0000b

100%

0001b

93.75%

0010b

87.5%

0011b

81.25%

0100b

75%

0101b

68.75%

0110b

62.5

0111b

56.25%

1000b

50%

1001b

43.75%

1010b

37.5%

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

19

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Table 7-6. Torque DAC Settings (continued)

TRQ_DAC

CURRENT SCALAR (TRQ)

1011b

20

31.25%

1100b

25%

1101b

18.75%

1110b

12.5%

1111b

6.25%

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6 Decay Modes

During PWM current chopping, the H-bridge is enabled to drive through the motor winding until the PWM current

chopping threshold is reached. This is shown in Figure 7-6, Item 1.

Once the chopping current threshold is reached, the H-bridge can operate in two different states, fast decay or

slow decay. In fast decay mode, once the PWM chopping current level has been reached, the H-bridge reverses

state to allow winding current to flow in a reverse direction. The opposite FETs are turned on; as the winding

current approaches zero, the bridge is disabled to prevent any reverse current flow. Fast decay mode is shown

in Figure 7-6, item 2. In slow decay mode, winding current is re-circulated by enabling both of the low-side FETs

in the bridge. This is shown in Figure 7-6, Item 3.

Figure 7-6. Decay Modes

The decay mode is selected by the DECAY register as shown in Table 7-7.

Table 7-7. Decay Mode Settings

DECAY

INCREASING STEPS

DECREASING STEPS

000b

Slow decay

Slow decay

001b

Slow decay

Mixed decay: 30% fast

010b

Slow decay

Mixed decay: 60% fast

011b

Slow decay

Fast decay

100b

Mixed decay: 30% fast

Mixed decay: 30% fast

101b

Mixed decay: 60% fast

Mixed decay: 60% fast

110b

Smart tune Dynamic Decay

Smart tune Dynamic Decay

111b (default)

Smart tune Ripple Control

Smart tune Ripple Control

Figure 7-7 defines increasing and decreasing current. For the slow-mixed decay mode, the decay mode is

set as slow during increasing current steps and mixed decay during decreasing current steps. In full step and

noncircular 1/2-step operation, the decay mode corresponding to decreasing steps is always used.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

21

�DRV8899-Q1

www.ti.com

AOUT Current

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Increasing

Decreasing

Increasing

Decreasing

STEP Input

BOUT Current

AOUT Current

Decreasing

Increasing

Increasing

Decreasing

STEP Input

Figure 7-7. Definition of Increasing and Decreasing Steps

22

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6.1 Slow Decay for Increasing and Decreasing Current

Increasing Phase Current (A)

ITRIP

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

ITRIP

tBLANK

tOFF

tDRIVE

tBLANK

tDRIVE

tOFF

tBLANK

tDRIVE

Figure 7-8. Slow/Slow Decay Mode

During slow decay, both of the low-side FETs of the H-bridge are turned on, allowing the current to be

recirculated.

Slow decay exhibits the least current ripple of the decay modes for a given tOFF. However on decreasing current

steps, slow decay will take a long time to settle to the new ITRIP level because the current decreases very slowly.

If the current at the end of the off time is above the ITRIP level, slow decay will be extended for another off time

duration and so on, till the current at the end of the off time is below ITRIP level.

In cases where current is held for a long time (no input in the STEP pin) or at very low stepping speeds, slow

decay may not properly regulate current because no back-EMF is present across the motor windings. In this

state, motor current can rise very quickly, and may require a large off-time. In some cases this may cause a loss

of current regulation, and a more aggressive decay mode is recommended.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

23

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6.2 Slow Decay for Increasing Current, Mixed Decay for Decreasing Current

Increasing Phase Current (A)

ITRIP

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

tBLANK

tDRIVE

ITRIP

tBLANK

tFAST

tDRIVE

tBLANK

tOFF

tFAST

tDRIVE

tOFF

Figure 7-9. Slow-Mixed Decay Mode

Mixed decay begins as fast decay for a time, followed by slow decay for the remainder of the tOFF time. In this

mode, mixed decay only occurs during decreasing current. Slow decay is used for increasing current.

This mode exhibits the same current ripple as slow decay for increasing current, because for increasing current,

only slow decay is used. For decreasing current, the ripple is larger than slow decay, but smaller than fast decay.

On decreasing current steps, mixed decay settles to the new ITRIP level faster than slow decay.

24

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6.3 Mode 4: Slow Decay for Increasing Current, Fast Decay for Decreasing current

Increasing Phase Current (A)

ITRIP

tBLANK

tOFF

tBLANK

tOFF

tBLANK

tDRIVE

tDRIVE

tDRIVE

Decreasing Phase Current (A)

Please note that these graphs are not the same scale; tOFF is the same

ITRIP

tBLANK

tOFF

tDRIVE

tBLANK

tOFF

tDRIVE

tBLANK

tOFF

tDRIVE

Figure 7-10. Slow/Fast Decay Mode

During fast decay, the polarity of the H-bridge is reversed. The H-bridge will be turned off as current approaches

zero in order to prevent current flow in the reverse direction. In this mode, fast decay only occurs during

decreasing current. Slow decay is used for increasing current.

Fast decay exhibits the highest current ripple of the decay modes for a given tOFF. Transition time on decreasing

current steps is much faster than slow decay since the current is allowed to decrease much faster.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

25

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6.4 Mixed Decay for Increasing and Decreasing Current

Increasing Phase Current (A)

ITRIP

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

tBLANK

tDRIVE

ITRIP

tBLANK

tFAST

tDRIVE

tBLANK

tOFF

tFAST

tDRIVE

tOFF

Figure 7-11. Mixed-Mixed Decay Mode

Mixed decay begins as fast decay for a time, followed by slow decay for the remainder of tOFF. In this mode,

mixed decay occurs for both increasing and decreasing current steps.

This mode exhibits ripple larger than slow decay, but smaller than fast decay. On decreasing current steps,

mixed decay settles to the new ITRIP level faster than slow decay.

In cases where current is held for a long time (no input in the STEP pin) or at very low stepping speeds, slow

decay may not properly regulate current because no back-EMF is present across the motor windings. In this

state, motor current can rise very quickly, and requires an excessively large off-time. Increasing or decreasing

mixed decay mode allows the current level to stay in regulation when no back-EMF is present across the motor

windings.

26

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6.5 Smart tune Dynamic Decay

The smart tune current regulation schemes are advanced current-regulation control methods compared to

traditional fixed off-time current regulation schemes. Smart tune current regulation schemes help the stepper

motor driver adjust the decay scheme based on operating factors such as the ones listed as follows:

•

•

•

•

•

•

•

Motor winding resistance and inductance

Motor aging effects

Motor dynamic speed and load

Motor supply voltage variation

Motor back-EMF difference on rising and falling steps

Step transitions

Low-current versus high-current dI/dt

The device provides two different smart tune current regulation modes, named smart tune Dynamic Decay and

smart tune Ripple Control.

Increasing Phase Current (A)

ITRIP

tBLANK

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

tDRIVE

tDRIVE

Decreasing Phase Current (A)

ITRIP

tBLANK

tOFF

tBLANK

tDRIVE

tDRIVE

tOFF

tFAST

tBLANK

tDRIVE

tFAST

Figure 7-12. Smart tune Dynamic Decay Mode

Smart tune Dynamic Decay greatly simplifies the decay mode selection by automatically configuring the decay

mode between slow, mixed, and fast decay. In mixed decay, smart tune dynamically adjusts the fast decay

percentage of the total mixed decay time. This feature eliminates motor tuning by automatically determining the

best decay setting that results in the lowest ripple for the motor.

The decay mode setting is optimized iteratively each PWM cycle. If the motor current overshoots the target trip

level, then the decay mode becomes more aggressive (add fast decay percentage) on the next cycle to prevent

regulation loss. If a long drive time must occur to reach the target trip level, the decay mode becomes less

aggressive (remove fast decay percentage) on the next cycle to operate with less ripple and more efficiently. On

falling steps, smart tune Dynamic Decay automatically switches to fast decay to reach the next step quickly.

Smart tune Dynamic Decay is optimal for applications that require minimal current ripple but want to maintain a

fixed frequency in the current regulation scheme.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

27

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.6.6 Smart tune Ripple Control

Increasing Phase Current (A)

ITRIP

IVALLEY

tBLANK

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

tBLANK

tOFF

tDRIVE

tDRIVE

ITRIP

IVALLEY

tBLANK

tOFF

tDRIVE

tBLANK

tOFF

tDRIVE

tBLANK

tOFF

tDRIVE

Figure 7-13. Smart tune Ripple Control Decay Mode

Smart tune Ripple Control operates by setting an IVALLEY level alongside the ITRIP level. When the current level

reaches ITRIP, instead of entering slow decay until the t OFF time expires, the driver enters slow decay until I VALLEY

is reached. Slow decay operates similar to mode 1 in which both low-side MOSFETs are turned on allowing the

current to recirculate. In this mode, tOFF varies depending on the current level and operating conditions.

This method allows much tighter regulation of the current level increasing motor efficiency and system

performance. Smart tune Ripple Control can be used in systems that can tolerate a variable off-time regulation

scheme to achieve small current ripple in the current regulation.

28

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.7 Blanking Time

After the current is enabled (start of drive phase) in an H-bridge, the current sense comparator is ignored for a

period of time (tBLANK) before enabling the current-sense circuitry. The blanking time also sets the minimum drive

time of the PWM. When the device goes into a drive phase at the end of a slow-decay phase, the blanking time

is roughly 500 ns. If the device goes into drive phase at the end of a fast-decay phase, the approximate blanking

time is as shown in the following table Table 7-8. Blanking Time

SLEW_RATE

Blanking Time (tBLANK)

00b

5.6 µs

01b

2 µs

10b

1.5 µs

11b

860 ns

7.3.8 Charge Pump

A charge pump is integrated to supply a high-side N-channel MOSFET gate-drive voltage. The charge pump

requires a capacitor between the VM and VCP pins to act as the storage capacitor. Additionally a ceramic

capacitor is required between the CPH and CPL pins to act as the flying capacitor.

VM

VM

0.22 …F

VCP

CPH

0.022 …F

VM

Charge

Pump

Control

CPL

Figure 7-14. Charge Pump Block Diagram

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

29

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.9 Linear Voltage Regulators

A linear voltage regulator is integrated into the device. The DVDD regulator can be used to provide a reference

voltage. DVDD can supply a maximum of 2 mA load. For proper operation, bypass the DVDD pin to GND using

a ceramic capacitor.

The DVDD output is nominally 5-V. When the DVDD LDO current load exceeds 2 mA, the output voltage drops

significantly.

Figure 7-15. Linear Voltage Regulator Block Diagram

If logic level inputs must be tied permanently high, tying the input to the DVDD pin instead of an external

regulator is preferred. This method saves power when the VM pin is not applied or in sleep mode: the DVDD

regulator is disabled and current does not flow through the input pulldown resistors. For reference, logic level

inputs have a typical pulldown of 200 kΩ.

The nSLEEP pin cannot be tied to DVDD, else the device will never exit sleep mode.

7.3.10 Logic Level Pin Diagrams

Figure 7-16 shows the input structure for the logic-level pins STEP, DIR, nSLEEP, SDI, and SCLK.

Figure 7-16. Logic-Level Input Pin Diagram

Figure 7-17 shows the input structure for the logic-level pins DRVOFF, and nSCS.

30

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Figure 7-17. Logic-Level with Internal Pull-up Input Pin Diagram

7.3.10.1 nFAULT Pin

The nFAULT pin has an open-drain output and should be pulled up to a 5-V or 3.3-V supply. When a fault is

detected, the nFAULT pin is logic low. nFAULT pin will be high after power-up. For a 5-V pullup, the nFAULT pin

can be tied to the DVDD pin with a resistor. For a 3.3-V pullup, an external 3.3-V supply must be used.

Output

nFAULT

Figure 7-18. nFAULT Pin

7.3.11 Protection Circuits

The device is fully protected against supply undervoltage, charge pump undervoltage, output overcurrent, device

overtemperature, and open load events.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

31

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

7.3.11.1 VM Undervoltage Lockout (UVLO)

Figure 7-19. Supply Voltage Ramp Profile

Figure 7-20. Supply Voltage Ramp Profile

If at any time the voltage on the VM pin falls below the UVLO falling threshold voltage, all the outputs are

disabled (High-Z) and the charge pump (CP) is disabled. Normal operation resumes (motor driver and charge

pump) when the VM voltage recovers above the UVLO rising threshold voltage.

When the voltage on the VM pin falls below the UVLO falling threshold voltage (4.25 V typical), but is above the

VM UVLO reset voltage (VRST, 3.9 V maximum), SPI communication is available, the digital core of the device is

alive, the FAULT and UVLO bits are made high in the SPI registers and the nFAULT pin is driven low, as shown

in Figure 7-19. From this condition, if the VM voltage recovers above the UVLO rising threshold voltage (4.35 V

32

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

typical), nFAULT pin is released (is pulled-up to the external voltage), and the FAULT bit is reset, but the UVLO

bit remains latched high until cleared through the CLR_FLT bit or an nSLEEP reset pulse.

When the voltage on the VM pin falls below the VM UVLO reset voltage (VRST, 3.9 V maximum), SPI

communication is unavailable, the digital core is shutdown, the FAULT and UVLO bits are low and the nFAULT

pin is high. During the subsequent power-up, when the VM voltage exceeds the VRST voltage, the digital core

comes alive, UVLO bit stays low but the FAULT bit is made high; and the nFAULT pin is pulled low, as shown in

Figure 7-20. When the VM voltage exceeds the VM UVLO rising threshold, FAULT bit is reset, UVLO bit stays

low and the nFAULT pin is pulled high.

7.3.11.2 VCP Undervoltage Lockout (CPUV)

If at any time the voltage on the VCP pin falls below the CPUV voltage, all the outputs are disabled, and the

nFAULT pin is driven low. The charge pump remains active during this condition. The FAULT and CPUV bits are

made high in the SPI registers. Normal operation resumes (motor-driver operation starts, nFAULT released and

FAULT bit is made low) when the VCP undervoltage condition is removed. The CPUV bit remains set until it is

cleared through the CLR_FLT bit or an nSLEEP reset pulse.

7.3.11.3 Overcurrent Protection (OCP)

An analog current-limit circuit on each FET limits the current through the FET by removing the gate drive. If

this current limit persists for longer than the tOCP time, the FETs in that particular H-bridge are disabled and the

nFAULT pin is driven low. The FAULT and OCP bits are latched high in the SPI registers. For xOUTx to VM

short, corresponding OCP_LSx_x bit goes high in the DIAG Status 1 register. Similarly, for xOUTx to ground

short, corresponding OCP_HSx_x bit goes high. For example, for AOUT1 to VM short, OCP_LS1_A bit goes

high; and for BOUT2 to ground short, the OCP_HS2_B bit goes high. The charge pump remains active during

this condition. The overcurrent protection can operate in two different modes: latched shutdown and automatic

retry.

7.3.11.3.1 Latched Shutdown (OCP_MODE = 0b)

In this mode, after an OCP event, the relevant outputs are disabled and the nFAULT pin is driven low. Normal

operation resumes after sending a CLR_FLT command, or an nSLEEP reset pulse or a power cycling. This is

the default mode for an OCP event for the device.

7.3.11.3.2 Automatic Retry (OCP_MODE = 1b)

In this mode, after an OCP event, the relevant outputs are disabled and the nFAULT pin is driven low. Normal

operation resumes automatically (motor-driver operation starts, nFAULT released and FAULT bit goes low) after

the tRETRY time has elapsed and the fault condition is removed.

7.3.11.4 Open-Load Detection (OL)

If the winding current in any coil drops below the open load current threshold (IOL) and the ITRIP level set by the

indexer, and if this condition persists for more than the open load detection time (tOL), an open-load condition

is detected. The EN_OL bit must be '1' to enable open load detection. When an open load fault is detected,

the OL and FAULT bits are latched high in the SPI register and the nFAULT pin is driven low. If the OL_A bit

is high, it indicates an open load fault in winding A, between AOUT1 and AOUT2. Similarly, an open load fault

between BOUT1 and BOUT2 causes the OL_B bit to go high. Normal operation resumes and the nFAULT line is

released when the open load condition is removed and a clear faults command has been issued either through

the CLR_FLT bit or an nSLEEP reset pulse. The fault also clears when the device is power cycled or comes out

of sleep mode.

If the motor is held at a position corresponding to 0°, 90°, 180° or 270° electrical angles, for more than the open

load detection time, open load fault will be flagged, as one of the coil current is zero. This situation does not arise

in full-step mode, because the coil currents are never zero.

7.3.11.5 Thermal Shutdown (OTSD)

If the die temperature exceeds the thermal shutdown limit (TOTSD) all MOSFETs in the H-bridge are disabled,

and the nFAULT pin is driven low. The charge pump is disabled in this condition. In addition, the FAULT, TF

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

33

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

and OTS bits are latched high. This protection feature cannot be disabled. The overtemperature protection can

operate in two different modes: latched shutdown and automatic recovery.

7.3.11.5.1 Latched Shutdown (OTSD_MODE = 0b)

In this mode, after a OTSD event all the outputs are disabled and the nFAULT pin is driven low. The FAULT,

TF and OTS bits are latched high in the SPI register. Normal operation resumes after sending a CLR_FLT

command, or an nSLEEP reset pulse or a power cycling. This mode is the default mode for a OTSD event.

7.3.11.5.2 Automatic Recovery (OTSD_MODE = 1b)

In this mode, after a OTSD event all the outputs are disabled and the nFAULT pin is driven low. The FAULT,

TF and OTS bits are latched high in the SPI register. Normal operation resumes (motor-driver operation starts,

nFAULT line released and FAULT bit goes low) when the junction temperature falls below the overtemperature

threshold limit minus the hysteresis (TOTSD – THYS_OTSD). The TF and OTS bits remains latched high indicating

that a thermal event occurred until a clear faults command is issued either through the CLR_FLT bit or an

nSLEEP reset pulse.

7.3.11.6 Overtemperature Warning (OTW)

If the die temperature exceeds the trip point of the overtemperature warning (TOTW), the OTW and TF bits

are set in the SPI register. The device performs no additional action and continues to function. When the die

temperature falls below the hysteresis point (THYS_OTW) of the overtemperature warning, the OTW and TF bits

clear automatically. The OTW bit can also be configured to report on the nFAULT pin, and set the FAULT bit in

the device, by setting the TW_REP bit to 1b through the SPI registers. The charge pump remains active during

this condition.

7.3.11.7 Undertemperature Warning (UTW)

If the die temperature falls below the trip point of the undertemperature warning (TUTW), the UTW and TF bits

are set in the SPI register. The device performs no additional action and continues to function. When the die

temperature exceeds the hysteresis point (THYS_UTW) of the undertemperature warning, the UTW and TF bits

clear automatically. The UTW bit can also be configured to report on the nFAULT pin, and set the FAULT bit in

the device, by setting the TW_REP bit to 1b through the SPI registers. The charge pump remains active during

this condition.

Table 7-9. Fault Condition Summary

FAULT

CONDITION

CONFIGU

RATION

ERROR

REPORT

H-BRIDGE CHARGE

PUMP

INDEXER

LOGIC

RECOVERY

VM undervoltage

(UVLO)

VM < VUVLO

(max 4.35 V)

—

nFAULT /

SPI

Disabled

Disabled

Disabled

Reset

(VVM < 3.9

V)

Automatic: VM >

VUVLO

(max 4.45 V)

VCP undervoltage

(CPUV)

VCP < VCPUV

(typ VM + 2.25 V)

—

nFAULT /

SPI

Disabled

Operating

Operating

Operating

VCP > VCPUV

(typ VM + 2.7 V)

OCP_MOD

E = 0b

nFAULT /

SPI

Disabled

Operating

Operating

Operating

Overcurrent (OCP)

IOUT > IOCP

(min 1.7 A)

Latched:

CLR_FLT / nSLEEP

OCP_MOD

E = 1b

nFAULT /

SPI

Disabled

Operating

Operating

Operating

Automatic retry:

tRETRY

EN_OL =

1b

nFAULT /

SPI

Operating

Operating

Operating

Operating

Report only

TW_REP =

1b

nFAULT /

SPI

Operating

Operating

Operating

Operating

TW_REP =

0b

SPI

Operating

Operating

Operating

Operating

TW_REP =

1b

nFAULT /

SPI

Operating

Operating

Operating

Operating

TW_REP =

0b

SPI

Operating

Operating

Operating

Operating

Open Load (OL)

Overtemperature

Warning (OTW)

Undertemperature

Warning (UTW)

34

No load detected

TJ > TOTW

TJ < TUTW

Submit Document Feedback

Automatic: TJ <

TOTW - THYS_OTW

Automatic: TJ >

TUTW + THYS_UTW

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Table 7-9. Fault Condition Summary (continued)

FAULT

CONDITION

Thermal Shutdown

(OTSD)

CONFIGU

RATION

TJ > TOTSD

ERROR

REPORT

H-BRIDGE CHARGE

PUMP

INDEXER

LOGIC

RECOVERY

OTSD_MO

DE = 0b

nFAULT /

SPI

Disabled

Disabled

Operating

Operating

Latched:

CLR_FLT / nSLEEP

OTSD_MO

DE = 1b

SPI

Disabled

Disabled

Operating

Operating

Automatic: TJ <

TOTSD - THYS_OTSD

7.4 Device Functional Modes

7.4.1 Sleep Mode (nSLEEP = 0)

The device state is managed by the nSLEEP pin. When the nSLEEP pin is low, the device enters a low-power

sleep mode. In sleep mode, all the internal MOSFETs are disabled, the DVDD regulator is disabled, the charge

pump is disabled, and the SPI is disabled. The tSLEEP time must elapse after a falling edge on the nSLEEP

pin before the device enters sleep mode. The device is brought out of sleep automatically if the nSLEEP pin is

brought high. The tWAKE time must elapse before the device is ready for inputs.

7.4.2 Disable Mode (nSLEEP = 1, DRVOFF = 1)

The DRVOFF pin is used to enable or disable the half bridges in the device. When the DRVOFF pin is high, the

output drivers are disabled in the Hi-Z state.

The DIS_OUT bit can also be used to disable the output drivers. When the DIS_OUT bit is '1', the output drivers

are disabled in the Hi-Z state. DIS_OUT is OR'ed with DRVOFF pin.

Table 7-10. Conditions to Enable or Disable Output Drivers

nSLEEP

DRVOFF

DIS_OUT

H-BRIDGE

0

Don't Care

Don't Care

Disabled

1

0

0

Operating

1

0

1

Disabled

1

1

0

Disabled

1

1

1

Disabled

7.4.3 Operating Mode (nSLEEP = 1, DRVOFF = 0)

When the nSLEEP pin is high, the DRVOFF pin is low, and VM > UVLO, the device enters the active mode. The

tWAKE time must elapse before the device is ready for inputs.

7.4.4 nSLEEP Reset Pulse

In addition to the CLR_FLT bit in the SPI register, a latched fault can be cleared through a quick nSLEEP pulse.

This pulse width must be greater than 18 µs and shorter than 35 µs. If nSLEEP is low for longer than 35 µs but

less than 75 µs, the faults are cleared and the device may or may not shutdown, as shown in the timing diagram

(see Figure 7-21). This reset pulse resets any SPI faults and does not affect the status of the charge pump or

other functional blocks.

Figure 7-21. nSLEEP Reset Pulse

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

35

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Table 7-11 lists a summary of the functional modes.

Table 7-11. Functional Modes Summary

CONDITION

CONFIGURATION

H-BRIDGE

DVDD

Regulator

CHARGE PUMP

INDEXER

LOGIC

Sleep mode

4.5 V < VM <

45 V

nSLEEP pin = 0

Disabled

Disbaled

Disabled

Disabled

Disabled

Operating

4.5 V < VM <

45 V

nSLEEP pin = 1

DRVOFF pin = 0

Operating

Operating

Operating

Operating

Operating

Disabled

4.5 V < VM <

45 V

nSLEEP pin = 1

DRVOFF pin = 1

Disabled

Operating

Operating

Operating

Operating

7.5 Programming

7.5.1 Serial Peripheral Interface (SPI) Communication

The device SPI has full duplex, 4-wire synchronous communication. This section describes the SPI protocol,

the command structure, and the control and status registers. The device can be connected with the MCU in the

following configurations:

• One slave device

• Multiple slave devices in parallel connection

• Multiple slave devices in series (daisy chain) connection

7.5.1.1 SPI Format

The SDI input data word is 16 bits long and consists of the following format:

• 1 read or write bit, W (bit 14)

• 5 address bits, A (bits 13 through 9)

• 8 data bits, D (bits 7 through 0)

The SDO output-data word is 16 bits long and the first 8 bits make up the Status Register (S1). The Report word

(R1) is the content of the register being accessed.

For a write command (W0 = 0), the response word on the SDO pin is the data currently in the register being

written to.

For a read command (W0 = 1), the response word is the data currently in the register being read.

Table 7-12. SDI Input Data Word Format

R/W

DON'T

CARE

ADDRESS

DATA

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

0

W0

A4

A3

A2

A1

A0

X

D7

D6

D5

D4

D3

D2

D1

D0

Table 7-13. SDO Output Data Word Format

STATUS

REPORT

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

1

1

UVLO

CPUV

OCP

RSVD

TF

OL

D7

D6

D5

D4

D3

D2

D1

D0

7.5.1.2 SPI for a Single Slave Device

The SPI is used to set device configurations, operating parameters, and read out diagnostic information. The SPI

operates in slave mode. The SPI input-data (SDI) word consists of a 16-bit word, with 8 bits command and 8 bits

of data. The SPI output data (SDO) word consists of 8 bits of status register with fault status indication and 8 bits

of register data. Figure 7-22 shows the data sequence between the MCU and the SPI slave driver.

36

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

nSCS

A1

D1

S1

R1

SDI

SDO

Figure 7-22. SPI Transaction Between MCU and the device

A valid frame must meet the following conditions:

• The SCLK pin must be low when the nSCS pin goes low and when the nSCS pin goes high.

• The nSCS pin should be taken high for at least 500 ns between frames.

• When the nSCS pin is asserted high, any signals at the SCLK and SDI pins are ignored, and the SDO pin is

in the high-impedance state (Hi-Z).

• Full 16 SCLK cycles must occur.

• Data is captured on the falling edge of the clock and data is driven on the rising edge of the clock.

• The most-significant bit (MSB) is shifted in and out first.

• If the data word sent to SDI pin is less than 16 bits or more than 16 bits, a frame error occurs and the data

word is ignored.

• For a write command, the existing data in the register being written to is shifted out on the SDO pin following

the 8-bit command data.

7.5.1.3 SPI for Multiple Slave Devices in Parallel Configuration

Figure 7-23. Three DRV8899-Q1 Devices Connected in Parallel Configuration

7.5.1.4 SPI for Multiple Slave Devices in Daisy Chain Configuration

The DRV8899-Q1 device can be connected in a daisy chain configuration to keep GPIO ports available when

multiple devices are communicating to the same MCU. Figure 7-24 shows the topology when three devices are

connected in series.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

37

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

Figure 7-24. Three DRV8899-Q1 Devices Connected in Daisy Chain

The first device in the chain receives data from the MCU in the following format for 3-device configuration: 2

bytes of header (HDRx) followed by 3 bytes of address (Ax) followed by 3 bytes of data (Dx).

nSCS

HDR1

HDR2

A3

A2

A1

D3

D2

D1

S1

HDR1

HDR2

A3

A2

R1

D3

D2

S2

S1

HDR1

HDR2

A3

R2

R1

D3

S3

S2

S1

HDR1

HDR2

R3

R2

R1

SDI1

SDO1 / SDI2

SDO2 / SDI3

SDO3

All Address bytes

reach destination

Status response here

All Data bytes

reach destination

Reads executed here

Writes executed here

Figure 7-25. SPI Frame With Three Devices

After the data has been transmitted through the chain, the MCU receives the data string in the following format

for 3-device configuration: 3 bytes of status (Sx) followed by 2 bytes of header followed by 3 bytes of report (Rx).

nSCS

HDR1

HDR2

A3

A2

A1

D3

D2

D1

S3

S2

S1

HDR1

HDR2

R3

R2

R1

SDI

SDO

Figure 7-26. SPI Data Sequence for Three Devices

The header bytes contain information of the number of devices connected in the chain, and a global clear fault

command that will clear the fault registers of all the devices on the rising edge of the chip select (nSCS) signal.

Header values N5 through N0 are 6 bits dedicated to show the number of devices in the chain. Up to 63 devices

can be connected in series for each daisy chain connection.

The 5 LSBs of the HDR2 register are don’t care bits that can be used by the MCU to determine integrity of the

daisy chain connection. Header bytes must start with 1 and 0 for the two MSBs.

38

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8899-Q1

�DRV8899-Q1

www.ti.com

SLVSEE8B – NOVEMBER 2019 – REVISED MAY 2021

HDR 1

1

0

N5

N4

N3

HDR 2

N2

N1

No. of devices in the chain

(up to 26 ± 1= 63)

N0

1

0

CLR

x

1 = global FAULT clear

0 = GRQ¶W FDUH

x

x

x

x

'RQ¶W FDUH

Figure 7-27. Header Bytes

The status byte provides information about the fault status register for each device in the daisy chain so that

the MCU does not have to initiate a read command to read the fault status from any particular device. This

keeps additional read commands for the MCU and makes the system more efficient to determine fault conditions

flagged in a device. Status bytes must start with 1 and 1 for the two MSBs.

Figure 7-28. Contents of Header, Status, Address, and Data Bytes for DRV8899-Q1

When data passes through a device, it determines the position of itself in the chain by counting the number of

status bytes it receives followed by the first header byte. For example, in this 3-device configuration, device 2 in

the chain receives two status bytes before receiving the HDR1 byte which is then followed by the HDR2 byte.

From the two status bytes, the data can determine that its position is second in the chain. From the HDR2

byte, the data can determine how many devices are connected in the chain. In this way, the data only loads

the relevant address and data byte in its buffer and bypasses the other bits. This protocol allows for faster

communication without adding latency to the system for up to 63 devices in the chain.