LM22679, LM22679-Q1

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

LM22679/-Q1 42-V, 5-A SIMPLE SWITCHER® Step-Down Voltage Regulator

With Easy-to-Use Package

(> 90%) are featured. Voltage mode control offers

short minimum on-time, allowing the widest ratio

between input and output voltages. Internal loop

compensation means that the user is free from the

tedious task of calculating the loop compensation

components. Fixed 5-V output and adjustable output

voltage options are available. A switching frequency

of 500 kHz allows for small external components

and good transient response. An adjustable soft-start

feature is provided through the selection of a single

external capacitor. In addition, the switch-current limit

can be programmed with a single external resistor,

allowing solution optimization. The LM22679 device

also has built-in thermal shutdown and current limiting

to protect against accidental overloads.

1 Features

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

New product available: LM61460 3-V to 36-V, 6-A

low EMI synchronous converter

Wide input voltage range: 4.5 V to 42 V

Internally compensated voltage mode control

Stable with low-ESR ceramic capacitors

100-mΩ N-channel MOSFET

Output voltage options:

-ADJ (outputs as low as 1.285 V)

-5.0 (output fixed to 5 V)

±1.5% feedback reference accuracy

Switching frequency of 500 kHz

–40°C to 125°C operating junction temperature

range

Adjustable soft start

Adjustable current limit

Integrated bootstrap diode

Fully WEBENCH® enabled

LM22679-Q1 is AEC-Q100 qualified and

manufactured on an automotive-grade flow

PFM (exposed pad) package

The new product, LM61460, offers higher efficiency,

lower stand-by quiescent current, and improved EMI

performance. See the device comparison table to

compare. Start WEBENCH design with LM61460

The LM22679 device is a member of Texas

Instruments' SIMPLE SWITCHER® family. The

SIMPLE SWITCHER concept provides for an easy

to use complete design using a minimum number of

external components and the TI WEBENCH design

tool. TI's WEBENCH tool includes features such as

external component calculation, electrical simulation,

thermal simulation, and Build-It boards for easy

design-in.

2 Applications

•

•

•

•

Industrial distributed power applications

Test and measurement

Appliances

General-purpose wide VIN applications

3 Description

The LM22679 switching regulator provides all of the

functions necessary to implement an efficient highvoltage step-down (buck) regulator using a minimum

of external components. This easy-to-use regulator

incorporates a 42-V N-channel MOSFET switch that

can provide up to 5 A of load current. Excellent

line and load regulation along with high efficiency

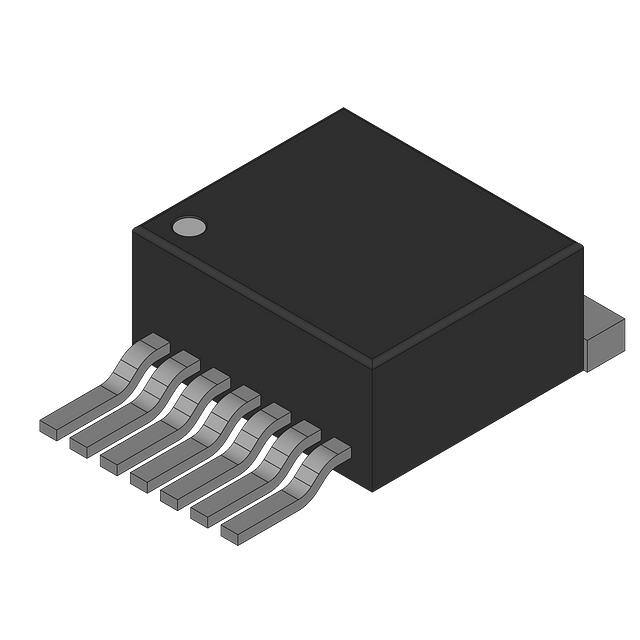

Device Information

PART NUMBER

LM22679

LM22679-Q1

(1)

PACKAGE(1)

TO-263 (7)

BODY SIZE (NOM)

10.16 mm x 9.85 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

VIN

VIN

FB

LM22679-ADJ

BOOT

VOUT

SW

IADJ

SS

GND

Simplified Application Schematic

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

Pin Functions.................................................................... 3

6 Specifications.................................................................. 4

6.1 Absolute Maximum Ratings........................................ 4

6.2 Handling Ratings: LM22679........................................4

6.3 Handling Ratings: LM22679-Q1..................................4

6.4 Recommended Operating Conditions.........................4

6.5 Thermal Information....................................................4

6.6 Electrical Characteristics.............................................5

6.7 Typical Characteristics................................................ 6

7 Detailed Description........................................................8

7.1 Overview..................................................................... 8

7.2 Functional Block Diagram........................................... 8

7.3 Feature Description.....................................................9

7.4 Device Functional Modes..........................................10

8 Application and Implementation.................................. 14

8.1 Application Information............................................. 14

8.2 Typical Application.................................................... 15

9 Power Supply Recommendations................................19

10 Layout...........................................................................20

10.1 Layout Guidelines................................................... 20

10.2 Layout Example...................................................... 21

10.3 Thermal Considerations..........................................22

11 Device and Documentation Support..........................23

11.1 Documentation Support.......................................... 23

11.2 Support Resources................................................. 23

11.3 Receiving Notification of Documentation Updates.. 23

11.4 Trademarks............................................................. 23

11.5 Glossary.................................................................. 23

11.6 Electrostatic Discharge Caution.............................. 23

4 Revision History

Changes from Revision L (November 2014) to Revision M (October 2020)

Page

• Added LM61460 bullet to the Features ..............................................................................................................1

• Updated the numbering format for tables, figures and cross-references throughout the document...................1

Changes from Revision K (March 2013) to Revision L (November 2014)

Page

• Added Pin Configuration and Functions section, Handling Rating tables, Feature Description section, Device

Functional Modes, Application and Implementation section, Power Supply Recommendations section, Layout

section, Device and Documentation Support section, and Mechanical, Packaging, and Orderable Information

section ............................................................................................................................................................... 1

• Deleted Inverting Regulator Application .......................................................................................................... 14

2

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

5 Pin Configuration and Functions

7 SS

6 FB

5 IADJ

4 GND

3 BOOT

2 VIN

1 SW

Exposed Pad

Connect to GND

Figure 5-1. 7-Pin NDR Package Top View

Pin Functions

PIN

NAME

NO.

TYPE

DESCRIPTION

APPLICATION INFORMATION

SW

1

O

Switch Output

Switching output of regulator

VIN

2

I

Input Voltage

Supply input to regulator

BOOT

3

I

Bootstrap input

Provides the gate voltage for the high side NFET

Ground input to

regulator; system

common

System ground pin

GND

4

—

IADJ

5

I

Current limit adjust

input pin

A resistor attached between this pin and GND can be used to set the current limit

threshold. Pin can be left floating and internal setting will be default.

FB

6

I

Feedback Input

Feedback input to regulator

SS

7

O

Soft-start pin

Used to increase soft-start time. See Section 7.3.2.

EP

EP

—

Exposed Pad

Connect to ground. Provides thermal connection to PCB. See Section 8.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

3

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

6 Specifications

6.1 Absolute Maximum Ratings

MIN

MAX

VIN to GND

SS, IADJ Pin Voltage

SW to GND(1)

V

–0.5

7

V

–5

VIN

V

VSW + 7

V

7

V

150

°C

Boot Pin Voltage

FB Pin Voltage

–0.5

Power Dissipation

Internally Limited

Junction Temperature(2)

(1)

(2)

UNIT

43

The absolute-maximum specification of the ‘SW to GND’ applies to dc voltage. An extended negative voltage limit of –10 V applies to a

pulse of up to 50 ns.

For soldering specifications, refer to refer to application report Absolute Maximum Ratings for Soldering (SNOA549).

6.2 Handling Ratings: LM22679

Tstg

Storage temperature range

V(ESD)

(1)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

pins(1)

MIN

MAX

UNIT

–65

150

°C

–2

2

kV

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

6.3 Handling Ratings: LM22679-Q1

Tstg

Storage temperature range

V(ESD)

Electrostatic discharge

(1)

Human body model (HBM), per AEC Q100-002(1)

MIN

MAX

UNIT

–65

150

°C

–2

2

kV

AEC Q100-002 indicates HBM stressing is done in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

6.4 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

VIN

MAX

UNIT

Supply Voltage

4.5

42

V

Junction Temperature Range

–40

125

°C

6.5 Thermal Information

LM22679

THERMAL METRIC(1) (2)

NDR

UNIT

7 PINS

RθJA

(1)

(2)

4

Junction-to-ambient thermal resistance

22

°C/W

For more information about traditional and new thermal metrics, see the application report IC Package Thermal Metrics (SPRA953).

The value of RθJA for the PFM (TJ) package of 22°C/W is valid if package is mounted to 1 square inch of copper. The RθJA value can

range from 20 to 30°C/W depending on the amount of PCB copper dedicated to heat transfer. See application note AN-1797 TO-263

THIN Package (SNVA328) for more information.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

6.6 Electrical Characteristics

Typical values represent the most likely parametric norm at TA = TJ = 25°C, and are provided for reference purposes only.

Unless otherwise specified: VIN = 12 V.

PARAMETER

TEST CONDITIONS

MIN(1)

TYP(2)

MAX(1)

4.925

5.0

5.075

UNIT

LM22679-5.0

VFB

Feedback Voltage

VIN = 8 V to 42 V

VIN = 8 V to 42 V, –40°C ≤ TJ ≤ 125°C

4.9

5.1

V

LM22679-ADJ

VFB

Feedback Voltage

VIN = 4.7 V to 42 V

1.266

VIN = 4.7 V to 42 V, –40°C ≤ TJ ≤ 125°C

1.259

1.285

1.304

1.311

V

ALL OUTPUT VOLTAGE VERSIONS

IQ

Quiescent Current

VADJ

Current Limit Adjust Voltage

VFB = 5 V

3.4

VFB = 5 V, –40°C ≤ TJ ≤ 125°C

6

mA

0.8

0.65

0.9

V

–40°C ≤ TJ ≤ 125°C

ICL

Current Limit

IL

Output Leakage Current

RDS(ON)

Switch On-Resistance

fO

Oscillator Frequency

TOFFMIN

Minimum Off-time

TONMIN

Minimum On-time

IBIAS

Feedback Bias Current

ISS

Soft-start Current

TSD

Thermal Shutdown Threshold

(1)

(2)

6.0

–40°C ≤ TJ ≤ 125°C

7.1

5.75

VIN = 42 V, SS Pin = 0 V, VSW = 0 V

8.75

32

VSW = –1 V

8.4

60

µA

31

75

µA

0.10

0.14

0.2

500

–40°C ≤ TJ ≤ 125°C

400

600

200

–40°C ≤ TJ ≤ 125°C

100

VFB = 1.3 V (ADJ Version Only)

300

Ω

kHz

ns

100

ns

230

nA

50

–40°C ≤ TJ ≤ 125°C

A

30

70

150

µA

°C

MIN and MAX limits are 100% production tested at 25°C. Limits over the operating temperature range are ensured through correlation

using Statistical Quality Control (SQC) methods. Limits are used to calculate TI's Average Outgoing Quality Level (AOQL).

Typical values represent most likely parametric norms at the conditions specified and are not ensured.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

5

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

6.7 Typical Characteristics

Vin = 12 V, TJ = 25°C (unless otherwise specified)

6

Figure 6-1. Efficiency vs IOUT and VIN (VOUT = 3.3 V)

Figure 6-2. Current Limit vs Temperature

Figure 6-3. Normalized Switching Frequency vs

Temperature

Figure 6-4. Feedback Bias Current vs Temperature

Figure 6-5. Normalized Feedback Voltage vs

Temperature

Figure 6-6. Normalized RDS(ON) vs Temperature

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

Figure 6-7. Normalized Feedback Voltage vs Input

Voltage

Figure 6-8. Soft-Start Current vs Temperature

Figure 6-9. Current Limit vs IADJ Resistor

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

7

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

7 Detailed Description

7.1 Overview

The LM22679 incorporates a voltage mode constant frequency PWM architecture. In addition, input voltage

feedforward is used to stabilize the loop gain against variations in input voltage. This allows the loop

compensation to be optimized for transient performance. The power MOSFET, in conjunction with the diode,

produces a rectangular waveform at the switch pin, that swings from about zero volts to VIN. The inductor and

output capacitor average this waveform to become the regulator output voltage. By adjusting the duty cycle of

this waveform, the output voltage can be controlled. The error amplifier compares the output voltage with the

internal reference and adjusts the duty cycle to regulate the output at the desired value.

The internal loop compensation of the -ADJ option is optimized for outputs of 5 V and below. If an output voltage

of 5 V or greater is required, the -5.0 option can be used with an external voltage divider. The minimum output

voltage is equal to the reference voltage, that is, 1.285 V (typ).

7.2 Functional Block Diagram

VIN

VIN

BOOT

Vcc

INT REG, EN, UVLO

ILimit

IADJ

FB

TYPE III

COMP

+

PWM Cmp.

+

-

LOGIC

Error Amp.

VOUT

SW

OSC

1.285V

&

Soft-start

SS

8

GND

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�www.ti.com

LM22679, LM22679-Q1

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

7.3 Feature Description

7.3.1 UVLO

The LM22679 also incorporates an input undervoltage lock-out (UVLO) feature. This prevents the regulator from

turning on when the input voltage is not great enough to properly bias the internal circuitry. The rising threshold

is 4.3 V (typ) while the falling threshold is 3.9 V (typ).

7.3.2 Soft-Start

The soft-start feature allows the regulator to gradually reach steady-state operation, thus reducing start-up

stresses. The internal soft-start feature brings the output voltage up in about 500 µs. This time can be extended

by using an external capacitor connected to the SS pin. Values in the range of 100 nF to 1 µF are recommended.

The approximate soft-start time can be estimated from Equation 1.

TSS ≈ 26 × 103 × CSS

(1)

Soft-start is reset any time the part is shut down or a thermal overload event occurs.

7.3.3 Bootstrap Supply

The LM22679 device incorporates a floating high-side gate driver to control the power MOSFET. The supply

for this driver is the external boot-strap capacitor connected between the BOOT pin and SW. A good quality

10-nF ceramic capacitor must be connected to these pins with short, wide PCB traces. One reason the regulator

imposes a minimum off-time is to ensure that this capacitor recharges every switching cycle. A minimum load of

about 5 mA is required to fully recharge the bootstrap capacitor in the minimum off-time. Some of this load can

be provided by the output voltage divider, if used.

7.3.4 Internal Compensation

The LM22679 device has internal loop compensation designed to provide a stable regulator over a wide range of

external power stage components. The internal compensation of the -ADJ option is optimized for output voltages

below 5 V. If an output voltage of 5 V or greater is needed, the -5.0 option with an external resistor divider can be

used.

Ensuring stability of a design with a specific power stage (inductor and output capacitor) can be tricky. The

LM22679 stability can be verified using the WEBENCH Designer online circuit simulation tool. A quick start

spreadsheet can also be downloaded from the online product folder.

The complete transfer function for the regulator loop is found by combining the compensation and power

stage transfer functions. The LM22679 has internal type III loop compensation, as detailed in Internal Loop

Compensation section. This is the approximate "straight line" function from the FB pin to the input of the PWM

modulator. The power stage transfer function consists of a dc gain and a second order pole created by the

inductor and output capacitor or capacitors. Due to the input voltage feedforward employed in the LM22679, the

power stage dc gain is fixed at 20 dB. The second order pole is characterized by its resonant frequency and its

quality factor (Q). For a first pass design, the product of inductance and output capacitance should conform to

Equation 2.

(2)

Alternatively, this pole should be placed between 1.5 kHz and 15 kHz and is given by Equation 3.

(3)

The Q factor depends on the parasitic resistance of the power stage components and is not typically in the

control of the designer. Of course, loop compensation is only one consideration when selecting power stage

components (see Section 8 for more details).

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

9

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

COMPENSATOR GAIN (dB)

40

35

-ADJ

-5.0

30

25

20

15

10

5

0

100

1k

10k

100k

1M

FREQUENCY (Hz)

10M

Figure 7-1. Compensator Gain

In general, hand calculations or simulations can only aid in selecting good power stage components. Good

design practice dictates that load and line transient testing should be done to verify the stability of the

application. Also, Bode plot measurements should be made to determine stability margins. The AN-1889 How to

Measure the Loop Transfer Function of Power Supplies application report (SNVA364) shows how to perform a

loop transfer function measurement with only an oscilloscope and function generator.

7.4 Device Functional Modes

7.4.1 Shutdown Mode

The LM22679 device incorporates an input undervoltage lock-out (UVLO) feature. This prevents the regulator

from turning on when the input voltage is not great enough to properly bias the internal circuitry. The rising

threshold is 4.3 V (typ) while the falling threshold is 3.9 V (typ).

7.4.2 Active Mode

The LM22679 is in Active Mode when VIN is above its UVLO level. See Section 7.3.1 for more information on

the UVLO level.

7.4.3 Current Limit

The LM22679 device has current limiting to prevent the switch current from exceeding safe values during an

accidental overload on the output. This peak current limit is found in Section 6.6 under the heading of ICL. The

maximum load current that can be provided, before current limit is reached, is determined from Equation 4.

(4)

where

•

L is the value of the power inductor

When the LM22679 enters current limit, the output voltage will drop and the peak inductor current will be fixed at

ICL at the end of each cycle. The switching frequency will remain constant while the duty cycle drops. The load

current will not remain constant, but will depend on the severity of the overload and the output voltage.

For very severe overloads ("short-circuit"), the regulator changes to a low frequency current foldback mode of

operation. The frequency foldback is about 1/5 of the nominal switching frequency. This will occur when the

current limit trips before the minimum on-time has elapsed. This mode of operation is used to prevent inductor

current "run-away", and is associated with very low output voltages when in overload. Equation 5 can be used to

determine what level of output voltage will cause the part to change to low frequency current foldback.

10

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

(5)

where

•

•

Fsw is the normal switching frequency

Vin is the maximum for the application

If the overload drives the output voltage to less than or equal to Vx, the part will enter current foldback mode.

If a given application can drive the output voltage to ≤ Vx, during an overload, then a second criterion must be

checked. Equation 6 gives the maximum input voltage, when in this mode, before damage occurs.

(6)

where

•

•

Vsc is the value of output voltage during the overload

fsw is the normal switching frequency

Note

If the input voltage should exceed this value, while in foldback mode, the regulator, the diode can be

damaged, or both.

It is important to note that the voltages in these equations are measured at the inductor. Normal trace and wiring

resistance will cause the voltage at the inductor to be higher than that at a remote load. Therefore, even if the

load is shorted with zero volts across its terminals, the inductor will still see a finite voltage. It is this value that

should be used for Vx and Vsc in the calculations. In order to return from foldback mode, the load must be

reduced to a value much lower than that required to initiate foldback. This load "hysteresis" is a normal aspect of

any type of current limit foldback associated with voltage regulators.

The safe operating area, when in short circuit mode, is shown in Figure 7-2. Operating points below and to the

right of the curve represent safe operation.

45

INPUT VOLTAGE (v)

40

35

30

25

SAFE OPERATING AREA

20

15

10

5

0.0

0.2

0.4

0.6

0.8

1.0

SHORT CIRCUIT VOLTAGE (v)

1.2

Figure 7-2. SOA

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

11

�LM22679, LM22679-Q1

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

www.ti.com

7.4.4 Current Limit Adjustment

A key feature of the LM22679 device is the ability to adjust the peak switch current limit. This can be useful when

the full current capability of the regulator is not required for a given application. A smaller current limit may allow

the use of power components with lower current ratings, thus saving space and reducing cost. A single resistor

between the IADJ pin and ground controls the current limit in accordance with Figure 7-3. The current limit mode

is set during start-up of the regulator. When VIN is applied, a weak pullup is connected to the IADJ pin and, after

approximately 100 µs, the voltage on the pin is checked against a threshold of about 0.8 V. With the IADJ pin

open, the voltage floats above this threshold, and the current limit is set to the default value of 7.1 A (typ). With

a resistor present, an internal reference holds the pin voltage at 0.8 V; thus, the resulting current sets the current

limit. The accuracy of the adjusted current limit will be slightly worse than that of the default value; +35% / –25%

is to be expected. Resistor values should not exceed the limits shown in Figure 7-3.

Figure 7-3. Current Limit vs IADJ Resistor

7.4.5 Thermal Protection

Internal thermal shutdown circuitry protects the LM22679 device, should the maximum junction temperature be

exceeded. This protection is activated at about 150°C, with the result that the regulator will shut down until the

temperature drops below about 135°C.

7.4.6 Duty-Cycle Limits

Ideally the regulator would control the duty cycle over the full range of zero to one. However due to inherent

delays in the circuitry, there are limits on both the maximum and minimum duty cycles that can be reliably

controlled. This in turn places limits on the maximum and minimum input and output voltages that can be

converted by the LM22679. A minimum on-time is imposed by the regulator in order to correctly measure the

switch current during a current limit event. A minimum off-time is imposed in order the re-charge the bootstrap

capacitor. Equation 7 can be used to determine the approximate maximum input voltage for a given output

voltage.

(7)

where

•

•

Fsw is the switching frequency

TON is the minimum on-time

Both parameters are found in Section 6.6.

Nominal values should be used. The worst case is lowest output voltage. If this input voltage is exceeded,

the regulator will skip cycles, effectively lowering the switching frequency. The consequences of this are higher

output voltage ripple and a degradation of the output voltage accuracy.

12

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

The second limitation is the maximum duty cycle before the output voltage will "dropout" of regulation. Equation

8 can be used to approximate the minimum input voltage before dropout occurs:

where

(8)

•

The values of TOFF and RDS(ON) are found in Section 6.6.

The worst case here is largest load. In this equation, RL is the dc inductor resistance. Of course, the lowest input

voltage to the regulator must not be less than 4.5 V (typ).

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

13

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

8 Application and Implementation

Note

Information in the following applications sections is not part of the TI component specification, and

TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining

suitability of components for their purposes. Customers should validate and test their design

implementation to confirm system functionality.

8.1 Application Information

The LM22679 device is a step down dc-to-dc regulator. It is typically used to convert a higher dc voltage to a

lower dc voltage with a maximum output current of 5 A. The following design procedure can be used to select

components for the LM22679. Alternately, the WEBENCH software may be used to generate complete designs.

When generating a design, the WEBENCH software utilizes iterative design procedure and accesses

comprehensive databases of components. Go to WEBENCH Designer for more details. This section presents a

simplified discussion of the design process.

8.1.1 Output Voltage Divider Selection

For output voltages between about 1.285 V and 5 V, the -ADJ option should be used, with an appropriate voltage

divider as shown in Figure 8-1. Equation 9 can be used to calculate the resistor values of this divider.

(9)

A good value for RFBB is 1 kΩ. This will help to provide some of the minimum load current requirement and

reduce susceptibility to noise pick-up. The top of RFBT should be connected directly to the output capacitor or

to the load for remote sensing. If the divider is connected to the load, a local high-frequency bypass should be

provided at that location.

For output voltages of 5 V, the -5.0 option should be used. In this case no external divider is needed and the

FB pin is connected to the output. The approximate values of the internal voltage divider are as follows: 7.38 kΩ

from the FB pin to the input of the error amplifier and 2.55 kΩ from there to ground.

Both the -ADJ and -5.0 options can be used for output voltages greater than 5 V, by using the correct output

divider. As mentioned in Section 7.3.4, the -5.0 option is optimized for output voltages of 5V. However, for

output voltages greater than 5 V, this option may provide better loop bandwidth than the -ADJ option, in some

applications. If the -5.0 option is to be used at output voltages greater than 5 V, Equation 10 should be used to

determine the resistor values in the output divider:

(10)

A value of RFBB of about 1 kΩ is a good first choice.

Vout

RFBT

FB

RFBB

Figure 8-1. Resistive Feedback Divider

14

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

A maximum value of 10 kΩ is recommended for the sum of RFBB and RFBT to maintain good output voltage

accuracy for the -ADJ option. A maximum of 2 kΩ is recommended for the -5.0 option. For the -5.0 option, the

total internal divider resistance is typically 9.93 kΩ.

In all cases, the output voltage divider should be placed as close as possible to the FB pin of the LM22679,

because this is a high impedance input and is susceptible to noise pick-up.

8.1.2 Power Diode

A Schottky-type power diode is required for all LM22679 applications. Ultra-fast diodes are not recommended

and may result in damage to the IC due to reverse recovery current transients. The near ideal reverse recovery

characteristics and low forward voltage drop of Schottky diodes are particularly important for high input voltage

and low output voltage applications common to the LM22679 device. The reverse breakdown rating of the diode

should be selected for the maximum VIN, plus some safety margin. A good rule of thumb is to select a diode with

a reverse voltage rating of 1.3 times the maximum input voltage.

Select a diode with an average current rating at least equal to the maximum load current that will be seen in the

application.

8.2 Typical Application

8.2.1 Typical Buck Regulator Application

Figure 8-2 shows an example of converting an input voltage range of 5.5 V to 42 V, to an output of 3.3 V at 5 A.

RFBB

976:

VIN 4.5V to 42V

C2

22 PF

+

C1

6.8 PF

C7

6.8 PF

C6

1 PF

FB

VIN

C3

LM22679-ADJ

10 nF

SS

BOOT

IADJ

R3

GND

RFBT

1.54 k:

L1

4.7 PH

SW

VOUT 3.3V

D1

60V, 5A

C4

180 PF

GND

+

GND

Figure 8-2. Typical Buck Regulator Application

8.2.1.1 Design Requirements

DESIGN PARAMETERS

EXAMPLE VALUE

Driver Supply Voltage (VIN)

5.5 to 42 V

Output Voltage (VOUT)

3.3 V

RFBT

Calculated based on RFBB and VREF of 1.285 V.

RFBB

1 kΩ to 10 kΩ

IOUT

5A

8.2.1.2 Detailed Design Procedure

8.2.1.2.1 External Components

The following guidelines should be used when designing a step-down (buck) converter with the LM22679.

8.2.1.2.2 Inductor

The inductor value is determined based on the load current, ripple current, and the minimum and maximum input

voltages. To keep the application in continuous conduction mode (CCM), the maximum ripple current, IRIPPLE,

should be less than twice the minimum load current.

The general rule of keeping the inductor current peak-to-peak ripple around 30% of the nominal output current is

a good compromise between excessive output voltage ripple and excessive component size and cost. Using this

value of ripple current, the value of inductor, L, is calculated using Equation 11.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

15

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

(11)

where

•

•

Fsw is the switching frequency

Vin should be taken at its maximum value, for the given application

The formula in Equation 11 provides a guide to select the value of the inductor L; the nearest standard value will

then be used in the circuit.

Once the inductor is selected, the actual ripple current can be found from Equation 12.

(12)

Increasing the inductance will generally slow down the transient response but reduce the output voltage ripple.

Reducing the inductance will generally improve the transient response but increase the output voltage ripple.

The inductor must be rated for the peak current, IPK, in a given application, to prevent saturation. During normal

loading conditions, the peak current is equal to the load current plus 1/2 of the inductor ripple current.

During an overload condition, as well as during certain load transients, the controller may trip current limit. In

this case the peak inductor current is given by ICL, found in Section 6.6. Good design practice requires that the

inductor rating be adequate for this overload condition.

Note

If the inductor is not rated for the maximum expected current, it can saturate resulting in damage to

the LM22679, the power diode, or both. This consideration highlights the value of the current limit

adjust feature of the LM22679.

8.2.1.2.3 Input Capacitor

The input capacitor selection is based on both input voltage ripple and RMS current. Good quality input

capacitors are necessary to limit the ripple voltage at the VIN pin while supplying most of the regulator

current during switch on-time. Low-ESR ceramic capacitors are preferred. Larger values of input capacitance

are desirable to reduce voltage ripple and noise on the input supply. This noise may find its way into other

circuitry, sharing the same input supply, unless adequate bypassing is provided. A very approximate formula for

determining the input voltage ripple is shown in Equation 13.

(13)

where

•

Vri is the peak-to-peak ripple voltage at the switching frequency

Another concern is the RMS current passing through this capacitor. Equation 14 determines an approximation to

this current.

(14)

The capacitor must be rated for at least this level of RMS current at the switching frequency.

16

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�www.ti.com

LM22679, LM22679-Q1

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

All ceramic capacitors have large voltage coefficients, in addition to normal tolerances and temperature

coefficients. To help mitigate these effects, multiple capacitors can be used in parallel to bring the minimum

capacitance up to the desired value. This may also help with RMS current constraints by sharing the current

among several capacitors. Many times it is desirable to use an electrolytic capacitor on the input, in parallel with

the ceramics. The moderate ESR of this capacitor can help to damp any ringing on the input supply caused

by long power leads. This method can also help to reduce voltage spikes that can exceed the maximum input

voltage rating of the LM22679.

It is good practice to include a high frequency bypass capacitor as close as possible to the LM22679. This small

case size, low ESR, ceramic capacitor should be connected directly to the VIN and GND pins with the shortest

possible PCB traces. Values in the range of 0.47 µF to 1 µF are appropriate. This capacitor helps to provide a

low impedance supply to sensitive internal circuitry. It also helps to suppress any fast noise spikes on the input

supply that can lead to increased EMI.

8.2.1.2.4 Output Capacitor

The output capacitor is responsible for filtering the output voltage and supplying load current during transients.

Capacitor selection depends on application conditions as well as ripple and transient requirements. Best

performance is achieved with a parallel combination of ceramic capacitors and a low ESR SP™ or POSCAP™

types. Very low ESR capacitors such as ceramics reduce the output ripple and noise spikes, while higher value

electrolytics or polymers provide large bulk capacitance to supply transients. Assuming very low ESR, Equation

15 gives an approximation to the output voltage ripple:

(15)

Typically, a total value of 100 µF or greater is recommended for output capacitance.

In applications with Vout less than 3.3 V, it is critical that low ESR output capacitors are selected. This will limit

potential output voltage overshoots as the input voltage falls below the device normal operating range.

8.2.1.2.5 Bootstrap Capacitor

The bootstrap capacitor between the BOOT pin and the SW pin supplies the gate current to turn on the

N-channel MOSFET. The recommended value of this capacitor is 10 nF and should be a good quality, low-ESR

ceramic capacitor. In some cases, it can be desirable to slow down the turn-on of the internal power MOSFET

to reduce EMI. This can be done by placing a small resistor in series with the Cboot capacitor. Resistors in the

range of 10 Ω to 50 Ω can be used. This technique should only be used when absolutely necessary, because it

will increase switching losses and thereby reduce efficiency.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

17

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

8.2.1.3 Application Curve

Figure 8-3. Efficiency vs IOUT and VIN (VOUT = 3.3 V)

18

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

9 Power Supply Recommendations

The LM22679 device is designed to operate from an input voltage supply range between 4.5 V and 42 V.

This input supply should be well regulated and able to withstand maximum input current and maintain a stable

voltage. The resistance of the input supply rail should be low enough that an input current transient does not

cause a high enough drop at the LM22679 supply voltage that can cause a false UVLO fault triggering and

system reset. If the input supply is located more than a few inches from the LM22679 additional bulk capacitance

may be required in addition to the ceramic bypass capacitors. The amount of bulk capacitance is not critical, but

a 47-µF or 100-µF electrolytic capacitor is a typical choice.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

19

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

10 Layout

10.1 Layout Guidelines

Board layout is critical for the proper operation of switching power supplies. First, the ground plane area

must be sufficient for thermal dissipation purposes. Second, appropriate guidelines must be followed to reduce

the effects of switching noise. Switch mode converters are very fast switching devices. In such cases, the

rapid increase of input current combined with the parasitic trace inductance generates unwanted L di/dt noise

spikes. The magnitude of this noise tends to increase as the output current increases. This noise may turn into

electromagnetic interference (EMI) and can also cause problems in device performance. Therefore, care must

be taken in layout to minimize the effect of this switching noise.

The most important layout rule is to keep the ac current loops as small as possible. Figure 10-1 shows the

current flow in a buck converter. The top schematic shows a dotted line which represents the current flow during

the FET switch on-state. The middle schematic shows the current flow during the FET switch off-state.

The bottom schematic shows the currents referred to as ac currents. These ac currents are the most critical

because they are changing in a very short time period. The dotted lines of the bottom schematic are the traces to

keep as short and wide as possible. This will also yield a small loop area reducing the loop inductance. To avoid

functional problems due to layout, review the PCB layout example. Best results are achieved if the placement

of the LM22679, the bypass capacitor, the Schottky diode, RFBB, RFBT, and the inductor are placed as shown in

Figure 10-2. In the layout shown, R1 = RFBB and R2 = RFBT. It is also recommended to use 2 oz copper boards

or heavier to help thermal dissipation and to reduce the parasitic inductances of board traces. See AN-1229

SIMPLE SWITCHER ® PCB Layout Guidelines (SNVA054) for more information.

Figure 10-1. Current Flow in a Buck Application

20

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�www.ti.com

LM22679, LM22679-Q1

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

10.2 Layout Example

Figure 10-2. LM22679 Layout Example

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

21

�LM22679, LM22679-Q1

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

www.ti.com

10.3 Thermal Considerations

The components with the highest power dissipation are the power diode and the power MOSFET internal to the

LM22679 regulator. The easiest method to determine the power dissipation within the LM22679 is to measure

the total conversion losses then subtract the power losses in the diode and inductor. The total conversion loss

is the difference between the input power and the output power. An approximation for the power diode loss is

shown in Equation 16.

(16)

where

•

VD is the diode voltage drop

An approximation for the inductor power is shown in Equation 17.

(17)

where

•

•

RL is the dc resistance of the inductor

The 1.1 factor is an approximation for the ac losses

The regulator has an exposed thermal pad to aid power dissipation. Adding multiple vias under the device to the

ground plane will greatly reduce the regulator junction temperature. Selecting a diode with an exposed pad will

also aid the power dissipation of the diode. The most significant variables that affect the power dissipation of the

regulator are output current, input voltage and operating frequency. The power dissipated while operating near

the maximum output current and maximum input voltage can be appreciable. The junction-to-ambient thermal

resistance of the LM22679 will vary with the application. The most significant variables are the area of copper

in the PC board, the number of vias under the IC exposed pad and the amount of forced air cooling provided.

A large continuos ground plane on the top or bottom PCB layer will provide the most effective heat dissipation.

The integrity of the solder connection from the IC exposed pad to the PC board is critical. Excessive voids will

greatly diminish the thermal dissipation capacity. The junction-to-ambient thermal resistance of the LM22679

PFM package is specified in Section 6.6. See AN-2020 Thermal Design By Insight, Not Hindsight (SNVA419) for

more information.

22

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

�LM22679, LM22679-Q1

www.ti.com

SNVS581M – FEBRUARY 2013 – REVISED OCTOBER 2020

11 Device and Documentation Support

11.1 Documentation Support

11.1.1 Related Documentation

•

•

•

•

AN-2020 Thermal Design By Insight, Not Hindsight (SNVA419)

AN-1229 SIMPLE SWITCHER ® PCB Layout Guidelines (SNVA054)

AN-1891 LM22679 Evaluation Board (SNVA365)

AN-1889 How to Measure the Loop Transfer Function of Power Supplies (SNVA364)

11.2 Support Resources

TI E2E™ support forums are an engineer's go-to source for fast, verified answers and design help — straight

from the experts. Search existing answers or ask your own question to get the quick design help you need.

Linked content is provided "AS IS" by the respective contributors. They do not constitute TI specifications and do

not necessarily reflect TI's views; see TI's Terms of Use.

11.3 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. Click on

Subscribe to updates to register and receive a weekly digest of any product information that has changed. For

change details, review the revision history included in any revised document.

11.4 Trademarks

TI E2E™ is a trademark of Texas Instruments.

WEBENCH® and SIMPLE SWITCHER® are registered trademarks of Texas Instruments.

All trademarks are the property of their respective owners.

11.5 Glossary

TI Glossary

This glossary lists and explains terms, acronyms, and definitions.

11.6 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

Product Folder Links: LM22679 LM22679-Q1

23

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

LM22679QTJ-5.0/NOPB

ACTIVE

TO-263

NDR

7

1000

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

QTJ-5.0

LM22679QTJ-ADJ/NOPB

ACTIVE

TO-263

NDR

7

1000

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

QTJ-ADJ

LM22679QTJE-5.0/NOPB

ACTIVE

TO-263

NDR

7

250

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

QTJ-5.0

LM22679QTJE-ADJ/NOPB

ACTIVE

TO-263

NDR

7

250

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

QTJ-ADJ

LM22679TJ-5.0/NOPB

ACTIVE

TO-263

NDR

7

1000

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

TJ-5.0

LM22679TJ-ADJ/NOPB

ACTIVE

TO-263

NDR

7

1000

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

TJ-ADJ

LM22679TJE-5.0/NOPB

ACTIVE

TO-263

NDR

7

250

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

TJ-5.0

LM22679TJE-ADJ/NOPB

ACTIVE

TO-263

NDR

7

250

RoHS & Green

SN

Level-1-260C-UNLIM

-40 to 125

LM22679

TJ-ADJ

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of