Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

LM2588 5-A Flyback Regulator With Shutdown

1 Features

3 Description

•

•

•

•

•

The LM2588 series of regulators are monolithic

integrated circuits specifically designed for flyback,

step-up (boost), and forward converter applications.

The device is available in 4 different output voltage

versions: 3.3 V, 5 V, 12 V, and adjustable.

1

•

•

•

•

•

•

•

•

Requires Few External Components

Family of Standard Inductors and Transformers

NPN Output Switches 5 A, Can Stand Off 65 V

Wide Input Voltage Range: 4 V to 40 V

Adjustable Switching Frequency: 100 kHz to 200

kHz

External Shutdown Capability

Draws Less Than 60 μA When Shut Down

Frequency Synchronization

Current-mode Operation for Improved Transient

Response, Line Regulation, and Current Limit

Internal Soft-start Function Reduces In-rush

Current During Start-up

Output Transistor Protected by Current Limit,

Undervoltage Lockout, and Thermal Shutdown

System Output Voltage Tolerance of ±4% Max

Over Line and Load Conditions

Create a Custom Design Using the LM2588With

the WEBENCH® Power Designer

2 Typical Applications

•

•

•

•

Flyback Regulator

Forward Converter

Multiple-output Regulator

Simple Boost Regulator

Requiring a minimum number of external

components, these regulators are cost effective, and

simple to use. Included in this data sheet are typical

circuits of boost and flyback regulators. Also listed

are selector guides for diodes and capacitors and a

family of standard inductors and flyback transformers

designed to work with these switching regulators.

The power switch is a 5-A NPN device that can

stand-off 65 V. Protecting the power switch are

current and thermal limiting circuits, and an

undervoltage lockout circuit. This IC contains an

adjustable frequency oscillator that can be

programmed up to 200 kHz. The oscillator can also

be synchronized with other devices, so that multiple

devices can operate at the same switching frequency.

Other features include soft start mode to reduce inrush current during start up, and current mode control

for improved rejection of input voltage and output

load transients and cycle-by-cycle current limiting.

The device also has a shutdown pin, so that it can be

turned off externally. An output voltage tolerance of

±4%, within specified input voltages and output load

conditions, is ensured for the power supply system.

Device Information(1)

PART NUMBER

LM2588

PACKAGE

BODY SIZE (NOM)

TO-220 (7)

10.1 mm × 8.89 mm

DDPAK /TO-263 (7) 14.986 mm × 10.16 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Flyback Regulator

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Table of Contents

1

2

3

4

5

6

Features ..................................................................

Typical Applications ..............................................

Description .............................................................

Revision History.....................................................

Pin Configurations.................................................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

Absolute Maximum Ratings ...................................... 4

ESD Ratings.............................................................. 4

Recommended Operating Ratings............................ 4

Electrical Characteristics: 3.3 V ................................ 5

Electrical Characteristics: 5 V ................................... 5

Electrical Characteristics: 12 V ................................. 6

Electrical Characteristics: Adjustable ........................ 6

Electrical Characteristics: All Output Voltage Versions

...................................................................................7

6.9 Typical Characteristics .............................................. 9

7

Detailed Description ............................................ 12

7.1 Overview ................................................................. 12

7.2 Functional Block Diagram ....................................... 12

7.3 Feature Description................................................. 12

8

Application and Implementation ........................ 18

8.1 Application Information............................................ 18

8.2 Typical Applications ............................................... 18

8.3 System Examples ................................................... 28

9

Layout ................................................................... 29

9.1 Layout Guidelines ................................................... 29

9.2 Layout Example ...................................................... 29

9.3 Heat Sink/Thermal Considerations ......................... 29

10 Device and Documentation Support ................. 31

10.1

10.2

10.3

10.4

10.5

10.6

Device Support......................................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

31

31

31

31

32

32

11 Mechanical, Packaging, and Orderable

Information ........................................................... 32

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision D (April 2013) to Revision E

Page

•

Editorial changes only; no technical revisions ....................................................................................................................... 1

•

Added links for WEBENCH ................................................................................................................................................... 1

Changes from Revision C (April 2013) to Revision D

•

2

Page

Changed layout of National Semiconductor data sheet to TI format .................................................................................... 1

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

5 Pin Configurations

NDZ Package

7-Pin TO-220

Top View, Bent, Staggered Leads

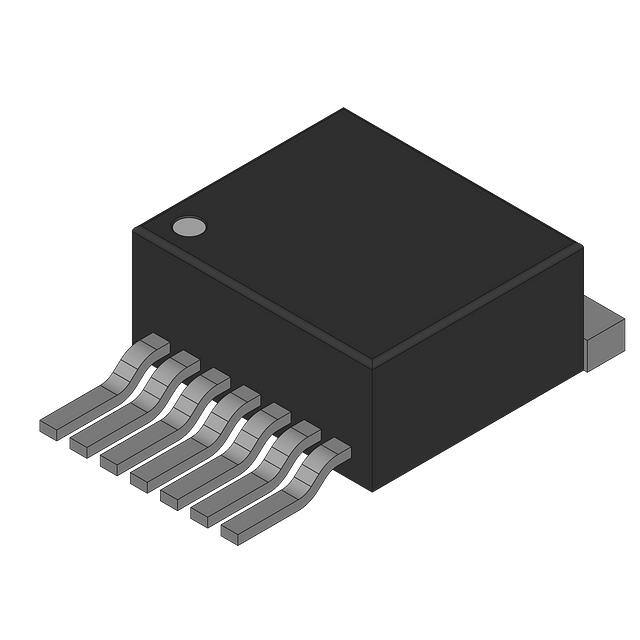

KTW Package

7-Pin DDPAK/TO-263

Top View

NDZ Package

7-Pin TO-220

Side View; Bent, Staggered Leads

KTW Package

7-Pin DDPAK/TO-263

Side View

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

3

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

See

(1) (2)

−0.4V ≤ VIN ≤ 45V

Input Voltage

−0.4V ≤ VSW ≤ 65V

Switch Voltage

Switch Current (3)

Internally Limited

Compensation Pin Voltage

−0.4V ≤ VCOMP ≤ 2.4V

Feedback Pin Voltage

−0.4V ≤ VFB ≤ 2 VOUT

−0.4V ≤ VSH ≤ 6V

ON /OFF Pin Voltage

−0.4V ≤ VSYNC ≤ 2V

Sync Pin Voltage

Power Dissipation (4)

Internally Limited

−65°C to +150°C

Storage Temperature Range

Lead Temperature

(Soldering, 10 sec.)

260°C

Maximum Junction Temperature (4)

(1)

(2)

(3)

(4)

150°C

Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. These ratings apply when the current is

limited to less than 1.2 mA for pins 1, 2, 3, and 6. Operating ratings indicate conditions for which the device is intended to be functional,

but device parameter specifications may not be ensured under these conditions. For ensured specifications and test conditions, see the

Electrical Characteristics.

If Military/Aerospace specified devices are required, contact the TI Sales Office/ Distributors for availability and specifications.

Note that switch current and output current are not identical in a step-up regulator. Output current cannot be internally limited when the

LM2588 is used as a step-up regulator. To prevent damage to the switch, the output current must be externally limited to 5A. However,

output current is internally limited when the LM2588 is used as a flyback regulator (see the section for more information).

The junction temperature of the device (TJ) is a function of the ambient temperature (TA), the junction-to-ambient thermal resistance

(θJA), and the power dissipation of the device (PD). A thermal shutdown will occur if the temperature exceeds the maximum junction

temperature of the device: PD × θJA + TA(MAX) ≥ TJ(MAX). For a safe thermal design, check that the maximum power dissipated by the

device is less than: PD ≤ [TJ(MAX) − TA(MAX)]/θJA. When calculating the maximum allowable power dissipation, derate the maximum

junction temperature—this ensures a margin of safety in the thermal design.

6.2 ESD Ratings

V(ESD)

(1)

Electrostatic discharge

(minimum)

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

(C = 100 pF, R = 1.5 kΩ)

VALUE

UNIT

2000

V

(1)

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Ratings

4V ≤ VIN ≤ 40V

Supply Voltage

0V ≤ VSW ≤ 60V

Output Switch Voltage

ISW ≤ 5.0A

Output Switch Current

−40°C ≤ TJ ≤ +125°C

Junction Temperature Range

4

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

6.4 Electrical Characteristics: 3.3 V

Specifications with standard type face are for TJ = 25°C, and those in boldtype face apply over full Operating Temperature

Range. Unless otherwise specified, VIN = 5V.

PARAMETER

TEST CONDITIONS

TYP

MIN

MAX

UNIT

3.17/3.14

3.43/3.46

V

SYSTEM PARAMETERS Test Circuit of Figure 54 (1)

VOUT

Output Voltage

VIN = 4V to 12V

ILOAD = 400 mA to 1.75A

3.3

ΔVOUT/

ΔVIN

Line Regulation

VIN = 4V to 12V

ILOAD = 400 mA

20

50/100

mV

ΔVOUT/

ΔILOAD

Load Regulation

VIN = 12V

ILOAD = 400 mA to 1.75A

20

50/100

mV

η

Efficiency

VIN = 12V, ILOAD = 1A

75

Measured at Feedback Pin

VCOMP = 1.0V

3.3

UNIQUE DEVICE PARAMETERS

VREF

Output Reference

Voltage

ΔVREF

Reference Voltage Line VIN = 4V to 40V

Regulation

GM

Error Amp

Transconductance

ICOMP = −30 μA to +30 μA

VCOMP = 1.0V

AVOL

Error Amp Voltage

Gain

VCOMP = 0.5V to 1.6V

RCOMP = 1.0 MΩ (3)

(1)

(2)

(3)

%

(2)

3.242/3.234

3.358/3.366

V

2.0

mV

1.193

0.678

260

151/75

2.259

mmho

V/V

External components such as the diode, inductor, input and output capacitors can affect switching regulator performance. When the

LM2588 is used as shown in Figure 54 and Figure 55, system performance will be as specified by the system parameters.

All room temperature limits are 100% production tested, and all limits at temperature extremes are specified via correlation using

standard Statistical Quality Control (SQC) methods.

A 1.0 MΩ resistor is connected to the compensation pin (which is the error amplifier output) to ensure accuracy in measuring AVOL.

6.5 Electrical Characteristics: 5 V

Specifications with standard type face are for TJ = 25°C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, VIN = 5V.

PARAMETER

TEST CONDITIONS

SYSTEM PARAMETERS Test Circuit of Figure 54

TYP

MIN

MAX

UNIT

4.80/4.75

5.20/5.25

V

(1)

VOUT

Output Voltage

VIN = 4V to 12V

ILOAD = 500 mA to 1.45A

5.0

ΔVOUT/

ΔVIN

Line Regulation

VIN = 4V to 12V

ILOAD = 500 mA

20

50/100

mV

ΔVOUT/

ΔILOAD

Load Regulation

VIN = 12V

ILOAD = 500 mA to 1.45A

20

50/100

mV

η

Efficiency

VIN = 12V, ILOAD = 750 mA

80

Measured at Feedback Pin

VCOMP = 1.0V

5.0

UNIQUE DEVICE PARAMETERS

VREF

Output Reference

Voltage

ΔVREF

Reference Voltage Line VIN = 4V to 40V

Regulation

GM

Error Amp

Transconductance

ICOMP = −30 μA to +30 μA

VCOMP = 1.0V

AVOL

Error Amp Voltage

Gain

VCOMP = 0.5V to 1.6V

RCOMP = 1.0 MΩ (3)

(1)

(2)

(3)

%

(2)

4.913/4.900

5.088/5.100

V

3.3

mV

0.750

0.447

165

99/49

1.491

mmho

V/V

External components such as the diode, inductor, input and output capacitors can affect switching regulator performance. When the

LM2588 is used as shown in Figure 54 and Figure 55, system performance will be as specified by the system parameters.

All room temperature limits are 100% production tested, and all limits at temperature extremes are specified via correlation using

standard Statistical Quality Control (SQC) methods.

A 1.0 MΩ resistor is connected to the compensation pin (which is the error amplifier output) to ensure accuracy in measuring AVOL.

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

5

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

6.6 Electrical Characteristics: 12 V

Specifications with standard type face are for TJ = 25°C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, VIN = 5V.

PARAMETER

TEST CONDITIONS

TYP

MIN

MAX

UNIT

12.0

11.52/11.40

12.48/12.60

V

20

100/200

mV

20

100/200

mV

SYSTEM PARAMETERS Test Circuit of Figure 55 (1)

VOUT

Output Voltage

VIN = 4V to 10V

ILOAD = 300 mA to 1.2A

ΔVOUT/

ΔVIN

Line Regulation

ΔVOUT/

ΔILOAD

Load Regulation

η

Efficiency

ILOAD = 300 mA

VIN = 10V

ILOAD = 300 mA to 1.2A

UNIQUE DEVICE PARAMETERS

VREF

VIN = 4V to 10V

VIN = 10V, ILOAD = 1A

Output Reference

Voltage

Measured at Feedback Pin

Reference Voltage Line VIN = 4V to 40V

Regulation

GM

Error Amp

Transconductance

ICOMP = −30 μA to +30 μA

Error Amp Voltage

Gain

VCOMP = 0.5V to 1.6V

(1)

(2)

(3)

%

12.0

11.79/11.76

12.21/12.24

V

VCOMP = 1.0V

ΔVREF

AVOL

90

(2)

7.8

mV

0.328

0.186

70

41/21

0.621

mmho

VCOMP = 1.0V

V/V

RCOMP = 1.0 MΩ (3)

External components such as the diode, inductor, input and output capacitors can affect switching regulator performance. When the

LM2588 is used as shown in Figure 54 and Figure 55, system performance will be as specified by the system parameters.

All room temperature limits are 100% production tested, and all limits at temperature extremes are specified via correlation using

standard Statistical Quality Control (SQC) methods.

A 1.0 MΩ resistor is connected to the compensation pin (which is the error amplifier output) to ensure accuracy in measuring AVOL.

6.7 Electrical Characteristics: Adjustable

Specifications with standard type face are for TJ = 25°C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, VIN = 5V.

PARAMETER

TEST CONDITIONS

TYP

MIN

MAX

UNIT

12.0

11.52/11.40

12.48/12.60

V

SYSTEM PARAMETERS Test Circuit of Figure 55 (1)

VOUT

Output Voltage

VIN = 4V to 10V

ILOAD = 300 mA to 1.2A

ΔVOUT/

ΔVIN

Line Regulation

VIN = 4V to 10V

ILOAD = 300 mA

20

100/200

mV

ΔVOUT/

ΔILOAD

Load Regulation

VIN = 10V

ILOAD = 300 mA to 1.2A

20

100/200

mV

η

Efficiency

VIN = 10V, ILOAD = 1A

90

UNIQUE DEVICE PARAMETERS

VREF

Output Reference

Voltage

ΔVREF

Reference Voltage Line VIN = 4V to 40V

Regulation

GM

Error Amp

Transconductance

ICOMP = −30 μA to +30 μA

VCOMP = 1.0V

AVOL

Error Amp Voltage

Gain

IB

Error Amp Input Bias

Current

(1)

(2)

(3)

6

%

(2)

Measured at Feedback Pin

VCOMP = 1.0V

1.230

1.208/1.205

1.252/1.255

1.5

V

mV

3.200

1.800

VCOMP = 0.5V to 1.6V

RCOMP = 1.0 MΩ (3)

670

400/200

VCOMP = 1.0V

125

6.000

mmho

V/V

425/600

nA

External components such as the diode, inductor, input and output capacitors can affect switching regulator performance. When the

LM2588 is used as shown in Figure 54 and Figure 55, system performance will be as specified by the system parameters.

All room temperature limits are 100% production tested, and all limits at temperature extremes are specified via correlation using

standard Statistical Quality Control (SQC) methods.

A 1.0 MΩ resistor is connected to the compensation pin (which is the error amplifier output) to ensure accuracy in measuring AVOL.

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

6.8 Electrical Characteristics: All Output Voltage Versions

(1)

Specifications with standard type face are for TJ = 25°C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, VIN = 5V.

PARAMETER

MAX

UNIT

Switch Off (2)

TEST CONDITIONS

TYP

11

MIN

15.5/16.5

mA

ISWITCH = 3.0A

85

140/165

mA

VSH = 3V

16

100/300

μA

3.05

3.75

V

85/75

115/125

kHz

IS

Input Supply Current

IS/D

Shutdown Input

Supply Current

VUV

Input Supply

Undervoltage Lockout

RLOAD = 100Ω

3.30

fO

Oscillator Frequency

Measured at Switch Pin

RLOAD = 100Ω, VCOMP = 1.0V

Freq. Adj. Pin Open (Pin 1)

100

RSET = 22 kΩ

200

kHz

25

kHz

fSC

Short-Circuit Frequency Measured at Switch Pin

RLOAD = 100Ω

VFEEDBACK = 1.15V

VEAO

Error Amplifier Output

Swing

Upper Limit (3)

2.8

Lower Limit (2)

0.25

IEAO

Error Amp Output

Current (Source or

Sink)

See (4)

165

ISS

Soft Start Current

VFEEDBACK = 0.92V

VCOMP = 1.0V

DMAX

Maximum Duty Cycle

IL

2.6/2.4

V

0.40/0.55

V

110/70

260/320

μA

11.0

8.0/7.0

17.0/19.0

μA

RLOAD = 100Ω (3)

98

93/90

Switch Leakage

Current

Switch Off

VSWITCH = 60V

15

VSUS

Switch Sustaining

Voltage

dV/dT = 1.5V/ns

VSAT

Switch Saturation

Voltage

ISWITCH = 5.0A

ICL

NPN Switch Current

Limit

VSTH

Synchronization

Threshold Voltage

ISYNC

%

300/600

65

0.7

μA

V

1.1/1.4

V

6.5

5.0

9.5

A

FSYNC = 200 kHz

VCOMP = 1V, VIN = 5V

0.75

0.625/0.40

0.875/1.00

V

Synchronization

Pin Current

VIN = 5V

VCOMP = 1V, VSYNC = VSTH

100

200

μA

VSHTH

ON /OFF Pin (Pin 1)

Threshold Voltage

VCOMP = 1V (5)

ISH

ON /OFF Pin (Pin 1)

Current

VCOMP = 1V

VSH = VSHTH

(1)

(2)

(3)

(4)

(5)

1.6

1.0/0.8

2.2/2.4

V

40

15/10

65/75

μA

All room temperature limits are 100% production tested, and all limits at temperature extremes are specified via correlation using

standard Statistical Quality Control (SQC) methods.

To measure this parameter, the feedback voltage is set to a high value, depending on the output version of the device, to force the error

amplifier output low and the switch off.

To measure this parameter, the feedback voltage is set to a low value, depending on the output version of the device, to force the error

amplifier output high and the switch on.

To measure the worst-case error amplifier output current, the LM2588 is tested with the feedback voltage set to its low value (specified

in Note 3 under the Electrical Characteristics: All Output Voltage Versions (1) table) and at its high value (specified in Note 2 under the

Electrical Characteristics: All Output Voltage Versions (1) table).

When testing the minimum value, do not sink current from this pin—isolate it with a diode. If current is drawn from this pin, the frequency

adjust circuit will begin operation (see Figure 20).

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

7

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Electrical Characteristics: All Output Voltage Versions

(1)

(continued)

Specifications with standard type face are for TJ = 25°C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, VIN = 5V.

PARAMETER

θJA

θJA

θJC

θJA

θJA

θJA

θJC

Thermal Resistance

TEST CONDITIONS

TYP

NDZ Package, Junction to Ambient (6)

NDZ Package, Junction to Ambient (7)

NDZ Package, Junction to Case

65

45

2

Junction to Ambient (8)

Junction to Ambient (9)

Junction to

56

35

26

2

KTW Package,

KTW Package,

KTW Package,

Ambient (10)

KTW Package,

MIN

MAX

UNIT

°C/W

Junction to Case

(6)

Junction to ambient thermal resistance (no external heat sink) for the 7 lead TO-220 package mounted vertically, with ½ inch leads in a

socket, or on a PC board with minimum copper area.

(7) Junction to ambient thermal resistance (no external heat sink) for the 7 lead TO-220 package mounted vertically, with ½ inch leads

soldered to a PC board containing approximately 4 square inches of (1 oz.) copper area surrounding the leads.

(8) Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board area of 0.136 square inches (the

same size as the TO-263 package) of 1 oz. (0.0014 in. thick) copper.

(9) Junction to ambient thermal resistance01242001 for the 7 lead TO-263 mounted horizontally against a PC board area of 0.4896 square

inches (3.6 times the area of the TO-263 package) of 1 oz. (0.0014 in. thick) copper.

(10) Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board copper area of 1.0064 square

inches (7.4 times the area of the TO-263 package) of 1 oz. (0.0014 in. thick) copper. Additional copper area will reduce thermal

resistance further. See the thermal model in Switchers Made Simple® software.

8

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

6.9 Typical Characteristics

Figure 1. Supply Current vs Temperature

Figure 2. Reference Voltage vs Temperature

Figure 3. ΔReference Voltage vs Supply Voltage

Figure 4. Supply Current vs Switch Current

Figure 5. Current Limit vs Temperature

Figure 6. Feedback Pin Bias Current vs Temperature

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

9

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Typical Characteristics (continued)

10

Figure 7. Switch Saturation Voltage vs Temperature

Figure 8. Switch Transconductance vs Temperature

Figure 9. Oscillator Frequency vs Temperature

Figure 10. Error Amp Transconductance vs Temperature

Figure 11. Error Amp Voltage Gain vs Temperature

Figure 12. Short Circuit Frequency vs Temperature

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Typical Characteristics (continued)

Figure 13. Shutdown Supply Current vs Temperature

Figure 14. ON /Off Pin Current vs Voltage

Figure 15. Oscillator Frequency vs Resistance

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

11

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

7 Detailed Description

7.1 Overview

The LM2588 series of regulators are monolithic integrated circuits specifically designed for flyback, step-up

(boost), and forward converter applications. The device is available in 4 different output voltage versions: 3.3 V,

5 V, 12 V, and adjustable. Requiring a minimum number of external components, these regulators are cost

effective, and simple to use. Included in the datasheet are typical circuits of boost and flyback regulators. Also

listed are selector guides for diodes and capacitors and a family of standard inductors and flyback transformers

designed to work with these switching regulators.

7.2 Functional Block Diagram

For Fixed Versions 3.3V, R1 = 3.4k, R2 = 2k5.0V, R1 = 6.15k, R2 = 2k12V, R1 = 8.73k, R2 = 1kFor Adj. VersionR1 =

Short (0Ω), R2 = Open

7.3 Feature Description

7.3.1 Flyback Regulator Operation

The operation of a flyback regulator is as follows (refer to Figure 16): when the switch is on, current flows

through the primary winding of the transformer, T1, storing energy in the magnetic field of the transformer. Note

that the primary and secondary windings are out of phase, so no current flows through the secondary when

current flows through the primary. When the switch turns off, the magnetic field collapses, reversing the voltage

polarity of the primary and secondary windings. Now rectifier D1 is forward biased and current flows through it,

releasing the energy stored in the transformer. This produces voltage at the output.

The output voltage is controlled by modulating the peak switch current. This is done by feeding back a portion of

the output voltage to the error amp, which amplifies the difference between the feedback voltage and a 1.23-V

reference. The error amp output voltage is compared to a ramp voltage proportional to the switch current (in

other words, inductor current during the switch on-time). The comparator terminates the switch on time when the

two voltages are equal, thereby controlling the peak switch current to maintain a constant output voltage.

12

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Feature Description (continued)

As shown in Figure 16, the LM2588 can be used as a flyback regulator by using a minimum number of external

components. The switching waveforms of this regulator are shown in Figure 18. Typical characteristics observed

during the operation of this circuit are shown in Figure 19.

Figure 16. 12-V Flyback Regulator Design Example

7.3.2 Step-Up (Boost) Regulator Operation

Figure 17 shows the LM2588 used as a step-up (boost) regulator. This is a switching regulator that produces an

output voltage greater than the input supply voltage.

A brief explanation of how the LM2588 boost regulator works is as follows (refer to Figure 17). When the NPN

switch turns on, the inductor current ramps up at the rate of VIN/L, storing energy in the inductor. When the

switch turns off, the lower end of the inductor flies above VIN, discharging its current through diode (D) into the

output capacitor (COUT) at a rate of (VOUT − VIN)/L. Thus, energy stored in the inductor during the switch on-time

is transferred to the output during the switch off time. The output voltage is controlled by adjusting the peak

switch current, as described in the section.

Figure 17. 12-V Boost Regulator

By adding a small number of external components (as shown in Figure 17), the LM2588 can be used to produce

a regulated output voltage that is greater than the applied input voltage. The switching waveforms observed

during the operation of this circuit are shown in . Typical performance of this regulator is shown in .

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

13

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Feature Description (continued)

A: Switch Voltage, 10V/div

B: Switch Current, 5A/div

C: Output Rectifier Current, 5A/div

D: Output Ripple Voltage, 100 mV/div

AC-Coupled

Figure 18. Switching Waveforms

Figure 19. VOUT Response To Load Current Step

7.3.3 Shutdown Control

A feature of the LM2588 is its ability to be shut down using the ON /OFF pin (pin 1). This feature conserves input

power by turning off the device when it is not in use. For proper operation, an isolation diode is required (as

shown in Figure 20).

The device will shut down when 3 V or greater is applied on the ON /OFF pin, sourcing current into pin 1. In shut

down mode, the device draws typically 56 μA of supply current (16 μA to VIN and 40 μA to the ON /OFF pin). To

turn the device back on, leave pin 1 floating, using an (isolation) diode, as shown in Figure 20 (for normal

operation, do not source or sink current to or from this pin—see the next section).

Figure 20. Shutdown Operation

7.3.4 Frequency Adjustment

The switching frequency of the LM2588 can be adjusted with the use of an external resistor. This feature allows

the user to optimize the size of the magnetics and the output capacitor(s) by tailoring the operating frequency. A

resistor connected from pin 1 (the Freq. Adj. pin) to ground will set the switching frequency from 100 kHz to 200

kHz (maximum). As shown in Figure 20, the pin can be used to adjust the frequency while still providing the shut

down function. A curve in the Performance Characteristics Section graphs the resistor value to the corresponding

switching frequency. The table in Table 1 shows resistor values corresponding to commonly used frequencies.

However, changing the LM2588's operating frequency from its nominal value of 100 kHz changes the magnetics

selection and compensation component values.

14

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Feature Description (continued)

Table 1. Frequency Setting Resistor Guide

RSET(kΩ)

FREQUENCY (kHz)

Open

100

200

125

47

150

33

175

22

200

7.3.5 Frequency Synchronization

Another feature of the LM2588 is the ability to synchronize the switching frequency to an external source, using

the sync pin (pin 6). This feature allows the user to parallel multiple devices to deliver more output power.

A negative falling pulse applied to the sync pin will synchronize the LM2588 to an external oscillator (see

Figure 21 and Figure 22).

Use of this feature enables the LM2588 to be synchronized to an external oscillator, such as a system clock. This

operation allows multiple power supplies to operate at the same frequency, thus eliminating frequency-related

noise problems.

Figure 21. Frequency Synchronization

The scope photo in Figure 22 shows a LM2588 12V Boost Regulator synchronized to a 200-kHz signal. There is

a 700 ns delay between the falling edge of the sync signal and the turning on of the switch.

Figure 22. Waveforms Of A Synchronized

12-V Boost Regulator

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

15

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

7.3.6 Programming Output Voltage (Selecting R1 And R2)

Referring to the adjustable regulator in Figure 23, the output voltage is programmed by the resistors R1 and R2

by the following formula:

VOUT = VREF (1 + R1/R2)

where VREF = 1.23V

(1)

Resistors R1 and R2 divide the output voltage down so that it can be compared with the 1.23-V internal

reference. With R2 between 1k and 5k, R1 is:

R1 = R2 (VOUT/VREF − 1)

wher

where

•

e VREF = 1.23 V

(2)

For best temperature coefficient and stability with time, use 1% metal film resistors.

7.3.7 Short-Circuit Condition

Due to the inherent nature of boost regulators, when the output is shorted (see Figure 23 ), current flows directly

from the input, through the inductor and the diode, to the output, bypassing the switch. The current limit of the

switch does not limit the output current for the entire circuit. To protect the load and prevent damage to the

switch, the current must be externally limited, either by the input supply or at the output with an external current

limit circuit. The external limit should be set to the maximum switch current of the device, which is 5 A.

In a flyback regulator application (Figure 24 ), using the standard transformers, the LM2588 survives a short

circuit to the main output. When the output voltage drops to 80% of its nominal value, the frequency will drop to

25 kHz. With a lower frequency, off times are larger. With the longer off times, the transformer can release all of

its stored energy before the switch turns back on. Hence, the switch turns on initially with zero current at its

collector. In this condition, the switch current limit will limit the peak current, saving the device.

Figure 23. Boost Regulator

16

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Figure 24. Flyback Regulator

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

17

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM2586 series of regulators are monolithic integrated circuits specifically designed for flyback, step-up

(boost), and forward converter applications. Requiring a minimum number of external components, these

regulators are cost effective, and simple to use. Included in the datasheet are typical circuits of boost and flyback

regulators. Also listed are selector guides for diodes and capacitors and a family of standard inductors and

flyback transformers designed to work with these switching regulators.

8.2 Typical Applications

8.2.1 Typical Flyback Regulator Applications

Figure 25 through Figure 30 show six typical flyback applications, varying from single output to triple output. Each

drawing contains the part number(s) and manufacturer(s) for every component except the transformer. For the

transformer part numbers and manufacturers' names, see Table 2. For applications with different output

voltages—requiring the LM2588-ADJ—or different output configurations that do not match the standard

configurations, refer to the Switchers Made Simple software.

Figure 25. Single-Output Flyback Regulator

18

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Typical Applications (continued)

Figure 26. Single-Output Flyback Regulator

Figure 27. Single-Output Flyback Regulator

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

19

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Typical Applications (continued)

Figure 28. Dual-Output Flyback Regulator

Figure 29. Dual-Output Flyback Regulator

20

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Typical Applications (continued)

Figure 30. Triple-Output Flyback Regulator

8.2.1.1 Design Requirements

8.2.1.1.1 Transformer Selection (T)

Table 2 lists the standard transformers available for flyback regulator applications. Included in the table are the

turns ratio(s) for each transformer, as well as the output voltages, input voltage ranges, and the maximum load

currents for each circuit.

Table 2. Transformer Selection Table

APPLICATIONS

Transformers

VIN

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

T1

T1

T1

T2

T3

Figure 30

T4

4V–6V

4V–6V

8V–16V

4V–6V

18V–36V

18V–36V

VOUT1

3.3V

5V

12V

12V

12V

5V

IOUT1 (Max)

1.8A

1.4A

1.2A

0.3A

1A

2.5A

1

1

1

2.5

0.8

0.35

VOUT2

−12V

−12V

12V

IOUT2 (Max)

0.3A

1A

0.5A

2.5

0.8

N1

N2

0.8

VOUT3

−12V

IOUT3 (Max)

0.5A

N3

0.8

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

21

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Table 3. Transformer Manufacturer Guide

Transformer

Type

(1)

(2)

(3)

(4)

Manufacturers' Part Numbers

Coilcraft (1)

Coilcraft Surface Mount (1) Pulse Surface Mount (2)

Renco (3)

Schott (4)

T1

Q4434-B

Q4435-B

PE-68411

RL-5530

67141450

T2

Q4337-B

Q4436-B

PE-68412

RL-5531

67140860

T3

Q4343-B

—

PE-68421

RL-5534

67140920

T4

Q4344-B

—

PE-68422

RL-5535

67140930

Coilcraft Inc.,: Phone: (800) 322-26451102 Silver Lake Road, Cary, IL 60013: Fax: (708) 639-1469European Headquarters, 21

Napier Place: Phone: +44 1236 730 595Wardpark North, Cumbernauld, Scotland G68 0LL: Fax: +44 1236 730 627

Pulse Engineering Inc.,: Phone: (619) 674-810012220 World Trade Drive, San Diego, CA 92128: Fax: (619) 674-8262European

Headquarters, Dunmore Road: Phone: +353 93 24 107Tuam, Co. Galway, Ireland: Fax: +353 93 24 459

Renco Electronics Inc.,: Phone: (800) 645-582860 Jeffryn Blvd. East, Deer Park, NY 11729: Fax: (516) 586-5562

Schott Corp.,: Phone: (612) 475-11731000 Parkers Lane Road, Wayzata, MN 55391: Fax: (612) 475-1786

8.2.1.1.2 Transformer Footprints

Figure 31 through Figure 48 show the footprints of each transformer, listed in Table 3.

Figure 31. T1 - Top View

Coilcraft Q4434-B

Figure 32. T2 - Top View

Coilcraft Q4337-B

Figure 33. T3 - Top View

Coilcraft Q4343-B

Figure 34. T4 - Top View

Coilcraft Q4344-B

Figure 35. T1 - Top View

Coilcraft Q4435-B

(Surface Mount)

22

Figure 36. T2 - Top View

Coilcraft Q4436-B

(Surface Mount)

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Figure 37. T1 - Top View

Pulse PE-68411

(Surface Mount)

Figure 38. T2 - Top View

Pulse PE-68412

(Surface Mount)

Figure 39. T3 - Top View

Pulse PE-68421

(Surface Mount)

Figure 40. T4 - Top View

Pulse PE-68422

(Surface Mount)

Figure 41. T1 - Top View

Renco RL-5530

Figure 42. T2 - Top View

Renco RL-5531

Figure 43. T3 - Top View

Renco RL-5534

Figure 44. T4 - Top View

Renco RL-5535

Figure 45. T1 - Top View

Schott 67141450

Figure 46. T2 - Top View

Schott 67140860

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

23

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Figure 48. T4 - Top View

Schott 67140930

Figure 47. T3 - Top View

Schott 67140920

8.2.1.2 Detailed Design Procedure

8.2.1.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the LM2588 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

8.2.1.2.2 Flyback Regulator Input Capacitors

A flyback regulator draws discontinuous pulses of current from the input supply. Therefore, there are two input

capacitors needed in a flyback regulator—one for energy storage and one for filtering (see Figure 24). Both are

required due to the inherent operation of a flyback regulator. To keep a stable or constant voltage supply to the

LM2588, a storage capacitor (≥ 100 μF) is required. If the input source is a rectified DC supply and/or the

application has a wide temperature range, the required rms current rating of the capacitor might be very large.

This means a larger value of capacitance or a higher voltage rating will be needed for the input capacitor. The

storage capacitor will also attenuate noise which may interfere with other circuits connected to the same input

supply voltage.

In addition, a small bypass capacitor is required due to the noise generated by the input current pulses. To

eliminate the noise, insert a 1-μF ceramic capacitor between VIN and ground as close as possible to the device.

8.2.1.2.3 Switch Voltage Limits

In a flyback regulator, the maximum steady-state voltage appearing at the switch, when it is off, is set by the

transformer turns ratio, N, the output voltage, VOUT, and the maximum input voltage, VIN (maximum):

VSW(OFF) = VIN (max) + (VOUT + VF) / N

where

•

24

VF is the forward biased voltage of the output diode, and is typically 0.5 V for Schottky diodes and 0.8V for

ultra-fast recovery diodes

(3)

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

In certain circuits, there exists a voltage spike, VLL, superimposed on top of the steady-state voltage (see

Figure 18, waveform A). Usually, this voltage spike is caused by the transformer leakage inductance and/or the

output rectifier recovery time. To “clamp” the voltage at the switch from exceeding its maximum value, a transient

suppressor in series with a diode is inserted across the transformer primary (as shown in the circuit in Figure 16

and other flyback regulator circuits throughout the datasheet). The schematic in Figure 24 shows another method

of clamping the switch voltage. A single voltage transient suppressor (the SA51A) is inserted at the switch pin.

This method clamps the total voltage across the switch, not just the voltage across the primary.

If poor circuit layout techniques are used (see the section), negative voltage transients may appear on the Switch

pin (pin 5). Applying a negative voltage (with respect to the IC's ground) to any monolithic IC pin causes erratic

and unpredictable operation of that IC. This holds true for the LM2588 IC as well. When used in a flyback

regulator, the voltage at the Switch pin (pin 5) can go negative when the switch turns on. The “ringing” voltage at

the switch pin is caused by the output diode capacitance and the transformer leakage inductance forming a

resonant circuit at the secondary(ies). The resonant circuit generates the “ringing” voltage, which gets reflected

back through the transformer to the switch pin. There are two common methods to avoid this problem. One is to

add an RC snubber around the output rectifier(s), as in Figure 24. The values of the resistor and the capacitor

must be chosen so that the voltage at the Switch pin does not drop below −0.4 V. The resistor may range in

value between 10Ω and 1 kΩ, and the capacitor will vary from 0.001 μF to 0.1 μF. Adding a snubber will (slightly)

reduce the efficiency of the overall circuit.

The other method to reduce or eliminate the “ringing” is to insert a Schottky diode clamp between pins 5 and 4

(ground), also shown in Figure 24. This prevents the voltage at pin 5 from dropping below −0.4 V. The reverse

voltage rating of the diode must be greater than the switch off voltage.

Figure 49. Input Line Filter

8.2.1.2.4 Output Voltage Limitations

The maximum output voltage of a boost regulator is the maximum switch voltage minus a diode drop. In a

flyback regulator, the maximum output voltage is determined by the turns ratio, N, and the duty cycle, D, by the

equation:

VOUT ≈ N × VIN × D / (1 − D)

(4)

The duty cycle of a flyback regulator is determined by the following equation:

(5)

Theoretically, the maximum output voltage can be as large as desired—just keep increasing the turns ratio of the

transformer. However, there exists some physical limitations that prevent the turns ratio, and thus the output

voltage, from increasing to infinity. The physical limitations are capacitances and inductances in the LM2588

switch, the output diode(s), and the transformer—such as reverse recovery time of the output diode (mentioned

above).

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

25

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

8.2.1.2.5 Noisy Input Line Condition

A small, low-pass RC filter should be used at the input pin of the LM2588 if the input voltage has an unusually

large amount of transient noise, such as with an input switch that bounces. The circuit in Figure 49 demonstrates

the layout of the filter, with the capacitor placed from the input pin to ground and the resistor placed between the

input supply and the input pin. Note that the values of RIN and CIN shown in the schematic are good enough for

most applications, but some readjusting might be required for a particular application. If efficiency is a major

concern, replace the resistor with a small inductor (say 10 μH and rated at 200 mA).

8.2.1.2.6 Stability

All current-mode controlled regulators can suffer from an instability, known as subharmonic oscillation, if they

operate with a duty cycle above 50%. To eliminate subharmonic oscillations, a minimum value of inductance is

required to ensure stability for all boost and flyback regulators. The minimum inductance is given by:

where

•

VSAT is the switch saturation voltage and can be found in Typical Characteristics

(6)

8.2.2 Typical Boost Regulator Applications

Figure 50 and Figure 51 through Figure 53 show four typical boost applications—one fixed and three using the

adjustable version of the LM2588. Each drawing contains the part number(s) and manufacturer(s) for every

component. For the fixed 12-V output application, the part numbers and manufacturers' names for the inductor

are listed in a table in Table 4. For applications with different output voltages, refer to the Switchers Made

Simple™software.

Figure 50. 5-V to 12-V Boost Regulator

Figure 51. 12-V to 24-V Boost Regulator

26

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

Figure 52. 24-V to 36-V Boost Regulator

*The LM2588 requires a heat sink in these applications. The size of the heat sink will depend on the maximum

ambient temperature. To calculate the thermal resistance of the IC and the size of the heat sink needed, see the Heat

Sink/Thermal Considerations section in Layout.

Figure 53. 24-V to 48-V Boost Regulator

8.2.2.1 Design Requirements

Table 4 contains a table of standard inductors, by part number and corresponding manufacturer, for the fixed

output regulator of Figure 50.

Table 4. Inductor Selection Table

Coilcraft

(1)

R4793-A

(1)

(2)

(3)

(4)

Pulse

(2)

PE-53900

Renco

(3)

RL-5472-5

Schott

(4)

67146520

Coilcraft Inc.,: Phone: (800) 322-26451102 Silver Lake Road, Cary, IL 60013: Fax: (708) 639-1469European Headquarters, 21

Napier Place: Phone: +44 1236 730 595Wardpark North, Cumbernauld, Scotland G68 0LL: Fax: +44 1236 730 627

Pulse Engineering Inc.,: Phone: (619) 674-810012220 World Trade Drive, San Diego, CA 92128: Fax: (619) 674-8262European

Headquarters, Dunmore Road: Phone: +353 93 24 107Tuam, Co. Galway, Ireland: Fax: +353 93 24 459

Renco Electronics Inc.,: Phone: (800) 645-582860 Jeffryn Blvd. East, Deer Park, NY 11729: Fax: (516) 586-5562

Schott Corp.,: Phone: (612) 475-11731000 Parkers Lane Road, Wayzata, MN 55391: Fax: (612) 475-1786

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

27

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

8.2.2.2 Detailed Design Procedure

See Detailed Design Procedure

8.3 System Examples

8.3.1 Test Circuits

CIN1—100 μF, 25V Aluminum ElectrolyticCIN2—0.1 μF CeramicT—22 μH, 1:1 Schott

#67141450D—1N5820COUT—680 μF, 16V Aluminum ElectrolyticCC—0.47 μF CeramicRC—2k

Figure 54. 3.3-V and 5-V LM2588

CIN1—100 μF, 25V Aluminum ElectrolyticCIN2—0.1 μF CeramicL—15 μH, Renco #RL-5472-5D—1N5820COUT—680

μF, 16V Aluminum ElectrolyticCC—0.47 μF CeramicRC—2kFor 12V Devices: R1 = Short (0Ω) andR2 = OpenFor ADJ

Devices: R1 = 48.75k, ±0.1% andR2 = 5.62k, ±0.1%

Figure 55. 12-V and Adjustable LM2588

28

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

9 Layout

9.1 Layout Guidelines

As in any switching regulator, layout is very important. Rapidly switching currents associated with wiring

inductance generate voltage transients which can cause problems. For minimal inductance and ground loops,

keep the length of the leads and traces as short as possible. Use single point grounding or ground plane

construction for best results. Separate the signal grounds from the power grounds (as indicated in Figure 56).

When using the Adjustable version, physically locate the programming resistors as near the regulator IC as

possible, to keep the sensitive feedback wiring short.

9.2 Layout Example

Figure 56. Circuit Board Layout

9.3 Heat Sink/Thermal Considerations

In many cases, a heat sink is not required to keep the LM2588 junction temperature within the allowed operating

temperature range. For each application, to determine whether or not a heat sink will be required, the following

must be identified:

1) Maximum ambient temperature (in the application).

2) Maximum regulator power dissipation (in the application).

3) Maximum allowed junction temperature (125°C for the LM2588). For a safe, conservative design, a

temperature approximately 15°C cooler than the maximum junction temperature should be selected (110°C).

4) LM2588 package thermal resistances θJA and θJC (given in the Electrical Characteristics).

Total power dissipated (PD) by the LM2588 can be estimated as follows:

Boost:

(7)

VIN is the minimum input voltage, VOUT is the output voltage, N is the transformer turns ratio, D is the duty cycle,

and ILOAD is the maximum load current (and ∑ILOAD is the sum of the maximum load currents for multiple-output

flyback regulators). The duty cycle is given by:

Boost:

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

29

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

Heat Sink/Thermal Considerations (continued)

where

•

•

VF is the forward biased voltage of the diode and is typically 0.5V for Schottky diodes and 0.8V for fast

recovery diodes

VSAT is the switch saturation voltage and can be found in the Characteristic Curves.

(8)

When no heat sink is used, the junction temperature rise is:

ΔTJ = PD • θJA.

(9)

Adding the junction temperature rise to the maximum ambient temperature gives the actual operating junction

temperature:

TJ = ΔTJ + TA.

(10)

If the operating junction temperature exceeds the maximum junction temperatue in item 3 above, then a heat

sink is required. When using a heat sink, the junction temperature rise can be determined by the following:

ΔTJ = PD • (θJC + θInterface + θHeat Sink)

(11)

Again, the operating junction temperature will be:

TJ = ΔTJ + TA

(12)

As before, if the maximum junction temperature is exceeded, a larger heat sink is required (one that has a lower

thermal resistance).

Included in the Switchers Made Simple™ design software is a more precise (non-linear) thermal model that can

be used to determine junction temperature with different input-output parameters or different component values.

It can also calculate the heat sink thermal resistance required to maintain the regulator junction temperature

below the maximum operating temperature.

30

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�LM2588

www.ti.com

SNVS117E – APRIL 1998 – REVISED JUNE 2019

10 Device and Documentation Support

10.1 Device Support

10.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

10.1.2 Development Support

10.1.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the LM2586 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

10.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

10.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

10.4 Trademarks

Switchers Made Simple, E2E are trademarks of Texas Instruments.

WEBENCH is a registered trademark of Texas Instruments.

Switchers Made Simple is a registered trademark of dcl_owner.

All other trademarks are the property of their respective owners.

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

31

�LM2588

SNVS117E – APRIL 1998 – REVISED JUNE 2019

www.ti.com

10.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

10.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

11 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

32

Submit Documentation Feedback

Copyright © 1998–2019, Texas Instruments Incorporated

Product Folder Links: LM2588

�PACKAGE OPTION ADDENDUM

www.ti.com

30-Sep-2021

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

LM2588S-12/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

45

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-12 P+

LM2588S-3.3/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

45

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-3.3 P+

LM2588S-5.0/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

45

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-5.0 P+

LM2588S-ADJ

NRND

DDPAK/

TO-263

KTW

7

45

Non-RoHS

& Green

Call TI

Level-3-235C-168 HR

-40 to 125

LM2588S

-ADJ P+

LM2588S-ADJ/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

45

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-ADJ P+

LM2588SX-12/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

500

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-12 P+

LM2588SX-3.3/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

500

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-3.3 P+

LM2588SX-5.0/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

500

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-5.0 P+

LM2588SX-ADJ/NOPB

ACTIVE

DDPAK/

TO-263

KTW

7

500

RoHS-Exempt

& Green

SN

Level-3-245C-168 HR

-40 to 125

LM2588S

-ADJ P+

LM2588T-3.3/NOPB

ACTIVE

TO-220

NDZ

7

45

RoHS-Exempt

& Green

SN

Level-1-NA-UNLIM

-40 to 125

LM2588T

-3.3 P+

LM2588T-5.0/NOPB

ACTIVE

TO-220

NDZ

7

45

RoHS-Exempt

& Green

SN

Level-1-NA-UNLIM

-40 to 125

LM2588T

-5.0 P+

LM2588T-ADJ/NOPB

ACTIVE

TO-220

NDZ

7

45

RoHS-Exempt

& Green

SN

Level-1-NA-UNLIM

-40 to 125

LM2588T

-ADJ P+

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

Addendum-Page 1

Samples

�PACKAGE OPTION ADDENDUM

www.ti.com

30-Sep-2021

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of