LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

LM2657 Dual Synchronous Buck Regulator Controller

Check for Samples: LM2657

FEATURES

DESCRIPTION

•

•

The LM2657 is an adjustable 200kHz-500kHz dual

channel

voltage-mode

controlled

high-speed

synchronous buck regulator controller ideally suited

for high current applications. The LM2657 requires

only N-channel FETs for both the upper and lower

positions of each stage. It features line feedforward to

improve the response to input transients. At very light

loads, the user can choose between the highefficiency Pulse-skip mode or the constant frequency

Forced-PWM mode. Lossless current limiting without

the use of external sense resistors is made possible

by sensing the voltage drop across the bottom FET.

A unique adaptive duty cycle clamping technique is

incorporated to significantly reduce peak currents

under abnormal load conditions. The two

independently programmable outputs switch 180° out

of phase (interleaved switching) reducing the input

capacitor and filter requirements. The input voltage

range is 4.5V to 28V while the output voltages are

adjustable down to 0.6V.

1

2

•

•

•

•

•

•

•

•

•

•

•

•

•

Input Voltage Range from 4.5V to 28V

Synchronous Dual-Channel Interleaved

Switching

Forced-PWM or Pulse-Skip Modes

Lossless Bottom-Side FET Current Sensing

Adaptive Duty Cycle Clamp

High Current N-Channel FET Drivers

Low Shutdown Supply Current

Reference Voltage Accurate to within ±1.5%

Output Voltage Adjustable Down to 0.6V

Power Good Flag and Chip Enable

Under-Voltage Lockout

Over-Voltage/Under-Voltage Protection

Soft-Start

Switching Frequency Adjustable 200kHz500kHz

28-Pin TSSOP Package

APPLICATIONS

•

Standard supervisory and control features include

Soft-start, Power Good, output Under-voltage and

Over-voltage protection, Under-voltage Lockout, and

chip Enable.

Low Output Voltage High-Efficiency Buck

Regulators

1

2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2005–2013, Texas Instruments Incorporated

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

Typical Application (Channel 2 in parenthesis)

VIN

5V

D2

(D1)

VIN

Q1

(Q4)

BOOT1 (2)

VRON

LM2657

FPWM

C30

(C28)

C32

(C1)

HDRV1 (2)

L1

(L2)

Vo1

(Vo2)

SW1 (2)

R8 (R7)

ILIM1 (2)

C25

(C22)

R18

FPWM

LDRV1 (2)

Q2

(Q5)

R17

EN

POK

C26

(C23)

PGND1 (2)

SENSE1 (2)

C31

R20

PGOOD

V5

C6 (C5)

R9 (R6)

C17

(C14)

COMP1 (2)

VDD

R1

C7 (C4)

FB1 (2)

FREQ

R21

(R15)

SS1 (2)

SGND

C16

(C15)

C29

R19

R23

(R14)

R22

(R16)

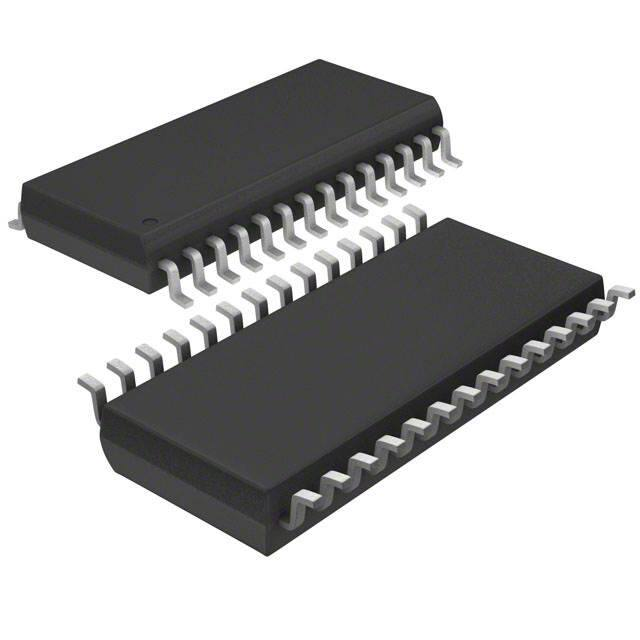

Connection Diagram

SENSE1

1

28

ILIM1

FB1

2

27

SW1

COMP1

3

26

HDRV1

SS1

4

25

BOOT1

VDD

5

24

PGND1

FREQ

6

23

LDRV1

SGND

7

22

VIN

EN

8

21

V5

PGOOD

9

20

LDRV2

FPWM

10

19

PGND2

SS2

11

18

BOOT2

COMP2

12

17

HDRV2

FB2

13

16

SW2

SENSE2

14

15

ILIM2

Figure 1. 28-Pin TSSOP (Top View)

See PW Package

PIN DESCRIPTION

Pin 1, SENSE1: Output voltage sense pin for Channel 1. It is tied directly to the output rail. The SENSE pin voltage is used by the IC,

together with the VIN voltage (Pin 22) to calculate the CCM (continuous conduction mode) duty cycle. This is used by the

IC to set the minimum duty cycle in the SKIP mode to 85% of the CCM value. It is also used to set the adaptive duty

cycle clamp (see Pin 3).

Pin 2, FB1:

2

Feedback pin for Channel 1. This is the inverting input of the channel’s error amplifier. The voltage on this pin under

regulation is nominally at 0.6V. A ‘Power Good window’ on this pin determines if the output voltage is within regulation

limits (±13%). If the voltage (on either channel) falls outside this window for more than 7µs, ‘Power Not Good’ is signaled

on the PGOOD pin (Pin 9). Additionally, if the FB voltage is above the upper limit, an over-voltage fault condition occurs

which turns on the low-side FET. The part will resume normal operation on the next high side cycle in which no fault is

detected. When single channel operation is desired (one channel is used, the other is disabled), the feedback pins of

both channels must be connected together, near the IC. All other pins specific to the unused channel should be left

floating (not connected to each other, either).

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

�LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

PIN DESCRIPTION (continued)

Pin 3, COMP1:

Compensation pin for Channel 1. This is the output of the error amplifier. The voltage level on this pin is compared with

an internally generated ramp signal to set the duty cycle for normal regulation. Since the Feedback pin is the inverting

input of the same error amplifier, the appropriate control loop compensation components are placed between this pin and

the Feedback pin. The COMP pin is internally pulled low during Soft-start to limit the duty cycle. Once Soft-start is

completed, the voltage on this pin can take up the value required to maintain output regulation. Note that an internal

voltage clamp does not allow the pin to go much higher than the steady-state requirement. This forms the ‘adaptive duty

cycle clamp’ circuit, which serves to limit the maximum allowable duty cycle and peak currents under sudden overloads.

Also note that this clamp has been designed with enough ‘headroom’ to permit an adequate response to step loads

within normal operating range.

Pin 4, SS1:

Channel 1 Soft-start pin. A Soft-start capacitor is placed between this pin and ground. A typical capacitance of 0.1µF is

recommended. During startup using chip Enable/power-up, soft-start is reset by connecting an internal 1.8 kΩ resistor

between this pin and ground (RSS_DCHG, see ELECTRICAL CHARACTERISTICS table). It discharges any remaining

charge on the Soft-start capacitors to ensure that the voltage on both Soft-start pins is below 100mV. Reset having thus

been obtained, an 11µA current source at this pin charges up the Soft-start capacitor. The voltage on this pin controls the

maximum duty cycle, and this produces a gradual ramp-up of the output voltage, thereby preventing large inrush currents

into the output capacitors. The voltage on this pin finally clamps close to 5V. During current limit, VDD UVLO, or VIN

UVLO this pin is connected to an internal 115µA current sink whenever a current limit event is in progress. This sink

current quickly discharges the Soft-start capacitor and forces the duty cycle low to protect the power components.

Pin 5, VDD:

5V supply rail for the control and logic sections of both channels. For normal operation to start, the voltage on this pin

must be brought above 4.5V. Subsequently, the voltage on this pin (including any ripple component) should not be

allowed to fall below 4V for a duration longer than 7µs. Since this pin is also the supply rail for the internal control

sections, it should be well-decoupled particularly at high frequencies. A minimum 0.1µF-0.47µF (ceramic) capacitor

should be placed on the component side very close to the IC with no intervening vias between this capacitor and the

VDD/SGND pins. If the voltage on Pin 5 falls below the lower UVLO threshold, the upper and lower FETs are both turned

OFF. ‘Power Not Good’ is also signaled immediately (on Pin 9.) Normal operation will resume once the fault condition

has cleared. Additionally if the voltage on this pin falls below the minimum voltage required for logic operation (about

1.8V typ) the part will shutdown identically to enable (see pin 8) being pulled low.

Pin 6, FREQ:

Frequency adjust pin. The switching frequency (for both channels) is set by a resistor connected between this pin and

ground. A value of 22.1kΩ sets the frequency to 300kHz (nominal). If the resistance is increased, the switching frequency

falls. An approximate relationship is that for every 7.3kΩ increase (or decrease) in the value of the frequency adjust

resistance, the time period (1/f) increases (or decreases) by about 1µs.

Pin 7, SGND:

Signal Ground pin. This is the lower rail for the control and logic sections of both channels. SGND should be connected

on the PCB to the system ground, which in turn is connected to PGND1 and PGND2. The layout is important and the

recommendations in the section LAYOUT GUIDELINES should be followed.

Pin 8, EN:

IC Enable pin. When EN is taken high, both channels are enabled by means of a Soft-start power-up sequence (see Pin

4). When EN is brought low, ‘Power Not Good’ is signaled within 100ns. The Soft-start capacitor is then discharged by an

internal 1.8kΩ resistor (RSS_DCHG, see ELECTRICAL CHARACTERISTICS table) to ground.

Pin 9, PGOOD:

Power Good output pin. An open-Drain logic output that is pulled high with an external pull-up resistor, indicating that

both output voltages are within a pre-defined ‘Power Good’ window, VIN and VDD are within required operating range, and

enable is high. Outside this window, this pin is internally pulled low (‘Power Not Good’ signaled) provided the output error

lasts for more than 7µs. The pin also goes low within 100ns of the Enable pin being taken low, or VDD going below

UVLO, or VIN going below UVLO irrespective of the output voltage level. Regulation on both channels must be achieved

first before fault monitoring becomes active (i.e. PGOOD must have been high prior to occurrence of the fault condition

for a fault to be asserted). For correct signaling on this pin under single-channel operation, see description of Pin 2.

Pin 10, FPWM:

Logic input for selecting either the Forced PWM (‘FPWM’) Mode or Pulse-skip Mode (‘SKIP’) for both channels (together).

When the pin is driven high, the IC operates in the FPWM mode, and when pulled low or left floating, the SKIP mode is

enabled. In FPWM mode, the lower FET of a given channel is always ON whenever the upper FET is OFF (except for a

narrow shoot-through protection deadband). This leads to continuous conduction mode of operation, which has a fixed

frequency and (almost) fixed duty cycle down to very light loads. But this does reduce efficiency at light loads. The

alternative is the SKIP mode, where the lower FET remains ON only till the voltage on the Switch pin (see Pin 27 or Pin

16) goes above -2.2mV (typical). So for example, for a 21mΩ FET, this translates to a current threshold of 2.2/21 = 0.1A.

Therefore if the (instantaneous) inductor current falls below this value, the lower FET will turn OFF every cycle at this

point (when operated in SKIP mode). This threshold is set by the ‘Zero-cross Comparator’ in the Block Diagram. Note

that if the inductor current waveform is high enough to cause the SW pin to be always below this ‘zero-cross threshold’

(see ELECTRICAL CHARACTERISTICS table), there will be no observable difference between FPWM and SKIP mode

settings (in steady-state). SKIP mode, when it occurs, is clearly a discontinuous mode of operation. However, in

conventional discontinuous mode, the duty cycle keeps falling (towards zero) as the load decreases. But the LM2657

does not ‘allow’ the duty cycle to fall by more than 15% of its original value (at the CCM-DCM boundary). This leads to

pulse-skipping, and so the average frequency decreases as the load decreases. This mode of operation improves

efficiency at light loads, but the frequency is effectively no longer a constant. Note that a minimum preload of 0.1mA

should be maintained on the output of each channel to ensure regulation in SKIP mode. The resistive divider from output

to ground used to set the output voltage could be designed to serve as this preload.

Pin 11, SS2:

Soft-start pin for Channel 2. See Pin 4.

Pin 12, COMP2: Compensation pin for Channel 2. See Pin 3.

Pin 13, FB2:

Feedback pin for Channel 2. See Pin 2.

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

3

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

PIN DESCRIPTION (continued)

Pin 14,

SENSE2:

Output voltage sense pin for Channel 2. See Pin 1.

Pin 15, ILIM2:

Channel 2 Current Limit pin. When the bottom FET is ON, a 62µA (typical) current flows out of this pin into an external

current limit setting resistor connected to the drain of the lower FET. This is a current source so the drop across this

resistor tries to push the voltage on this pin to a more positive value. However, the drain of the lower FET, which is

connected to the other side of the same resistor, is trying to go more negative as the load current increases. Therefore at

some value of current, the voltage on this pin will cross zero and start to go negative. This is the current limiting condition

and it is detected by the ‘Current Limit Comparator’ seen in the BLOCK DIAGRAM. When a current limit condition has

been detected, the next ON-pulse of the upper FET will be omitted. The lower FET will again be monitored to determine if

the current has fallen below the threshold. If it has, the next ON-pulse will be permitted. If not, the upper FET will stay

OFF, and remain so for several cycles if necessary, until the current returns to normal. Eventually, if the overcurrent

condition persists and the upper FET has not been turned ON, the output will start to fall eventually triggering “Power not

Good”.

Pin 16, SW2:

The Switching node of the buck regulator of Channel 2. Also serves as the lower rail of the floating driver of the upper

FET.

Pin 17, HDRV2: Gate drive pin for the upper FET of Channel 2 (High-side drive). The top gate driver is interlocked with the bottom gate

driver to prevent shoot-through/cross-conduction.

Pin 18, BOOT2: Bootstrap pin for Channel 2. This is the upper supply rail for the floating driver of the upper FET. It is bootstrapped by

means of a ceramic capacitor connected to the channel Switching node. This capacitor is charged up by the IC to a value

of about 5V as derived from the V5 pin (Pin 21).

Pin 19, PGND2: Power Ground pin of Channel 2. This is the return path for the bottom FET gate drive. Both the PGND's are to be

connected on the PCB to the system ground and also to the Signal ground (Pin 7) in accordance with the recommended

Layout Guidelines .

Pin 20, LDRV2:

Gate drive pin for the Channel 2 bottom FET (Low-side drive). The bottom gate driver is interlocked with the top gate

driver to prevent shoot-through/cross-conduction.

Pin 21, V5:

Upper rail of the lower FET drivers of both channels. Also used to charge up the bootstrap capacitors of the upper FET

drivers. This is connected to an external 5V supply. The 5V rail may be the same as the rail used to provide power to the

VDD pin (Pin 5). If these rails are connected, the VDD pin must be well-decoupled so that it does not interact with the V5

pin. A minimum 0.1µF (ceramic) capacitor should be placed on the component side very close to the IC with no

intervening vias between this capacitor and the V5/PGND pins.

Pin 22, VIN:

The input that powers both the buck regulator channels. It also is used by the internal ramp generator to implement the

line ‘feedforward’ feature. The VIN pin is also used with the SENSE pin voltage to predict the CCM (continuous

conduction mode) duty cycle and to thereby set the minimum allowed DCM duty cycle to 85% of the CCM value (in SKIP

mode, see Pin 10). This is a high input impedance pin, drawing only about 115µA from the input rail. A fault condition will

occur if this voltage drops below its UVLO threshold.

Pin 23, LDRV1:

LDRV pin of Channel 1. See Pin 20.

Pin 24, PGND1: PGND pin for Channel 1.See Pin 19.

Pin 25, BOOT1: Boot pin of Channel 1. See Pin 18.

Pin 26, HDRV1: HDRV pin of Channel 1. See Pin 17.

Pin 27, SW1:

SW pin of Channel 1. See Pin 16.

Pin 28, ILIM1:

Channel 1 Current Limit pin. See Pin 15.

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

4

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

�LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

ABSOLUTE MAXIMUM RATINGS (1) (2)

Voltages from the indicated pins to GND unless otherwise indicated (3):

VIN

-0.3V to 30V

V5

-0.3V to 7V

VDD

-0.3V to 7V

BOOT1, BOOT2

-0.3V to 36V

BOOT1 to SW1, BOOT2 to SW2

-0.3V to 7V

SW1, SW2

-0.3V to 30V

ILIM1, ILIM2

-0.3V to 30V

SENSE1, SENSE2, FB1, FB2

-0.3V to 7V

PGOOD

-0.3V to 7V

EN

-0.3V to 7V

Junction Temperature

+150°C

ESD Rating (4)

2kV

Ambient Storage Temperature Range

Soldering Dwell Time, Temperature

(1)

-65°C to +150°C

Wave

4 sec, 260°C

Infrared

10 sec, 240°C

Vapor Phase

75 sec, 219°C

Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions under which

operation of the device is specified. For specified performance limits and associated test conditions, see the Electrical Characteristics

table.

If Military/Aerospace specified devices are required, please contact the TI Sales Office/ Distributors for availability and specifications.

PGND1, PGND2 and SGND are all electrically connected together on the PCB.

ESD is applied by the human body model, which is a 100pF capacitor discharged through a 1.5 kΩ resistor into each pin.

(2)

(3)

(4)

OPERATING RATINGS (1)

VIN

4.5V to 28V

VDD, V5

4.5V to 5.5V

Junction Temperature

(1)

-40°C to +125°C

Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions under which

operation of the device is specified. For specified performance limits and associated test conditions, see the Electrical Characteristics

table.

ELECTRICAL CHARACTERISTICS

Specifications with standard typeface are for TJ = 25°C, and those with boldface apply over full Operating Junction

Temperature range. VDD = V5 = 5V, VSGND = VPGND = 0V, VIN = 15V, VEN = 3V, RFADJ = 22.1kΩ unless otherwise stated (1).

Datasheet min/max specification limits are specified by design, test, or statistical analysis.

Symbol

Parameter

Conditions

Min

Typical (2)

Max

Units

591

600

609

mV

Reference

VFB

FB Pin Voltage at

Regualtion (either FB Pin)

VDD = 4.5V to 5.5V,

VIN = 4.5V to 28V

VFB_LINE REG

VFB Line Regulation (ΔVFB)

VDD = 4.5V to 5.5V,

VIN = 4.5V to 28V

0.5

IFB

FB Pin Current (sourcing)

VFB at regulation

20

100

nA

IQ_VIN

VIN Quiescent Current

VFB1 = VFB2 = 0.7V

100

200

µA

ISD_VIN

VIN Shutdown Current

VEN = 0V

0

5

µA

IQ_VDD

VDD Quiescent Current

VFB1 = VFB2 = 0.7V

2.5

4

mA

ISD_VDD

VDD Shutdown Current

VEN = 0V

6

15

µA

IQ_V5

V5 Normal Operating

Current

VFB1 = VFB2 = 0.7V

0.3

0.5

mA

VFB1 = VFB2 = 0.5V

1

1.5

Chip Supply

(1)

(2)

RFADJ is the frequency adjust resistor between FREQ pin and SGND pin.

Typical numbers are at 25°C and represent the most likely norm.

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

5

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

Specifications with standard typeface are for TJ = 25°C, and those with boldface apply over full Operating Junction

Temperature range. VDD = V5 = 5V, VSGND = VPGND = 0V, VIN = 15V, VEN = 3V, RFADJ = 22.1kΩ unless otherwise stated(1).

Datasheet min/max specification limits are specified by design, test, or statistical analysis.

Symbol

Conditions

Min

Typical (2)

Max

Units

ISD_V5

V5 Shutdown Current

VEN = 0V

0

5

µA

IQ_BOOT

BOOT Quiescent Current

VFB1 = VFB2 = 0.7V

2

5

µA

VFB1 = VFB2 = 0.5V

300

500

ISD_BOOT

BOOT Shutdown Current

VEN = 0V

VDD_UVLO

VDD UVLO Threshold

VDD rising up to VUVLO

VDD UVLO Hysteresis

VIN UVLO Threshold

VIN UVLO Hysteresis

VIN falling from VUVLO

IEN

EN Input Current

VEN = 0 to 5V

VEN_HI

Minimum EN Input Logic

High

VEN_LO

Maximum EN Input Logic

Low

RFPWM

FPWM Pull-down

VFPWM_HI

Minimum FPWM Input

Logic High

VFPWM_LO

Maximum FPWM Input

Logic Low

VIN_UVLO

Parameter

1

5

µA

3.9

4.2

4.5

V

VDD = V5 falling from VUVLO

0.5

0.7

0.9

V

VIN rising up to VUVLO

3.9

4.2

4.5

V

0.1

0.3

V

Logic

0

µA

2

VFPWM = 2V

100

V

200

0.8

V

1000

kΩ

2

V

0.8

V

Power Good and OVP

VPGOOD_HI

Power Good Upper

Threshold as a Percentage

of Internal Reference

FB voltage rising above VFB

110

113

116

%

VPGOOD_LOW

Power Good Lower

Threshold as a Percentage

of Internal Reference

FB voltage falling below VFB

84

87

90

%

HYSPGOOD

Power Good Hysteresis

ΔtPG_OK

Power Good Delay

ΔtPG_NOK

ΔtSD

7

%

From both output voltages

“good” to PGOOD assertion.

10

20

30

From the first output voltage

“bad” to PGOOD de-assertion

4

7

10

µs

From Enable low to PGOOD low

0.03

0.1

VPGOOD_SAT

PGOOD Saturation Voltage

PGOOD de-asserted (Power

Not Good) and sinking 1.5mA

0.12

0.4

V

IPGOOD_LEAK

PGOOD Leakage Current

PGOOD = 5V and asserted

0

1

µA

ISS_CHG

Soft-start Charging Current

VSS = 1V

11

14

µA

RSS_DCHG

Soft-shutdown Resistance

(SS pin to SGND, either

channel)

VEN = 0V, VSS = 1V

ISS_DCHG

Soft-start Discharge Current In Current Limit

VSS_RESET

Soft-start pin reset

voltage (3)

VOS

SS to COMP Offset Voltage VSS = 0.5V and 1V, VFB1 = VFB2

= 0V

Soft-start

(3)

6

SS charged to 0.5V, EN low to

high

8

Ω

1800

80

115

160

µA

100

mV

600

mV

If the LM2657 starts up with a pre-charged soft start capacitor, it will first discharge the capacitor to VSS_RESET and then begin the

normal Soft-start process.

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

�LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

ELECTRICAL CHARACTERISTICS (continued)

Specifications with standard typeface are for TJ = 25°C, and those with boldface apply over full Operating Junction

Temperature range. VDD = V5 = 5V, VSGND = VPGND = 0V, VIN = 15V, VEN = 3V, RFADJ = 22.1kΩ unless otherwise stated(1).

Datasheet min/max specification limits are specified by design, test, or statistical analysis.

Symbol

Parameter

Conditions

Min

Typical (2)

Max

Units

Error Amplifier

GAIN

DC Gain

VSLEW

Voltage Slew Rate

BW

70

dB

COMP rising

4.45

V/µs

COMP falling

2.25

Unity Gain Bandwidth

6.5

MHz

ICOMP_SOURCE COMP Source Current

VFB = lower COMP = 0.5V

2

5

mA

ICOMP_SINK

VFB = higher than internal

reference

COMP = 5V

7

14

mA

VILIM1 = VILIM2 = 0V

46

62

76

µA

-10

0

10

mV

COMP Sink Current

Current Limit and Zero-Cross

IILIM

ILIM Pin Current (sourcing,

either ILIM pin)

VILIM_TH

ILIM Threshold Voltage

VSW_ZERO

Zero-cross Threshold (SW

Pin)

LDRV goes low

PWM Frequency

RFADJ = 22.1kΩ

-2.2

mV

Oscillator

FOSC

VRAMP

PWM Ramp Peak-to-peak

Amplitude

VVALLEY

PWM Ramp Valley

ΔFOSC_VIN

ΔFOSC_VDD

255

300

RFADJ = 12.4kΩ

500

RFADJ = 30.9kΩ

200

VIN = 4.5V

0.48

VIN = 15V

1.6

VIN = 28V

3.0

345

kHz

V

0.8

V

Frequency Change with VIN VIN = 4.5V to 28V

±1

%

Frequency Change with

VDD

VDD = 4.5V to 5.5V

±2

%

øCH

Phase Shift Between

Channels

Phase from HDRV1 to HDRV2

VFREQ_VIN

FREQ Pin Voltage vs. VIN

165

180

195

deg

0.107

V/V

System

ton-min

Minimum ON Time

DMAX

Maximum Duty Cycle

VFPWM = 3V

30

ns

VIN = 4.5V

60

70

%

VIN = 15V

40

50

%

VIN = 28V, VDD= 4.5V

24

30

%

Gate Drivers

HDRV Source Impedance

HDRV Pin Current (sourcing)=

1.2A

7

Ω

RHDRV_SINK

HDRV Sink Impedance

HDRV Pin Current (sinking) =

1A

2

Ω

RLDRV_SOURC

LDRV Source Impedance

LDRV Pin Current (sourcing) =

1.2A

7

Ω

RLDRV_SINK

LDRV Sink Impedance

LDRV Pin Current (sinking) =

2A

1

Ω

tDEAD

Cross-conduction Protection HDRV Falling to LDRV Rising

Delay (deadtime)

LDRV Falling to HDRV Rising

40

ns

RHDRV_SOURC

E

E

70

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

7

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

BLOCK DIAGRAM

SENSE1

1

VDD

Controller 1

SKIP

CMP

HS_ON

+

PWM

LOGI

C

RAMP1

VDD

SW1

27

+

-

+

-

EN

CURRENT

LIMIT CMP

PWM

CMP

E.A.

ILIM1

28

CL1

V5

LS_ON

+

-

V5

85%Ton

ZERO

CROSS CMP

SENSE1

+

-

COMP1

3

HDRV1

26

IN

+

-

0.35V

Vref1

BOOT1

25

6

PA

2

21

EN

LDRV1

23

IN

PGND1

24

FB1

2

+

-

PGOOD1

SW2

CONTROL

LOGIC

FB2

16

Controller2

13

+

ILIM2

15

Supervisory 2

SS2

0.87 x Vref1

HDRV2

17

COMP2

12

OVP

1.13 x Vref1

BOOT2

18

SENSE2

14

Supervisory 1

11

+

-

VDD

V5

11 PA

SS1

4

LDRV2

20

PGND2

19

VDD

COMP1

+

4.2V

RAMP1

200k

Vref1

VDD

SGND

7

8

BIAS/

REFERENCES

VDD UV

UVLO

VDD

5

CL1

Vref2

115 PA

PGOOD

9

EN

Submit Documentation Feedback

RAMP/

TIMING

VIN

FPWM

8

CLK1

RAMP2

CLK2

1.8k

10

22

FREQ

6

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

�LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

TYPICAL PERFORMANCE CHARACTERISTICS

The system efficiency plots below were measured using input voltages of 15V, 20V, 24V, 28V. These input voltages

correspond with the uppermost curve to lowermost curve, respectively. The output current (IO) refers to simultaneous loading

of both channels.

System Efficiency for 2.5V/3.3V Outputs

100

95

95

90

90

85

85

EFFICIENCY (%)

EFFICIENCY (%)

System Efficiency for 5V/3.3V Outputs

100

80

75

80

75

70

70

65

65

60

0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75 3

60

0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75 3

IO (A)

IO (A)

Figure 2.

Figure 3.

System Efficiency for 1.8V/1.2V Outputs

System Max VOUT For A Given VIN

TJ = 25°C

100

6

95

90

MAX VOUT

EFFICIENCY (%)

5

85

80

75

70

4

3

65

2

60

4

0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75 3

6

8

10

12

14

VIN (V)

IO (A)

Figure 4.

Figure 5.

Modulator (Plant) Gain

40

5 PH

GAIN (dB)

16

3.3 PH

-8

-32

10 PH

-56

-80

10

100

1k

10k

100k

1M

10M

FREQUENCY (Hz)

Figure 6.

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

9

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

OPERATION DESCRIPTIONS

GENERAL

The LM2657 provides two identical synchronously switched buck regulator channels that operate 180° out of

phase. A voltage-mode control topology was selected to provide fixed-frequency PWM regulation at very low

duty cycles, in preference to current-mode control, because the latter has inherent limitations in being able to

achieve low pulse widths due to blanking time requirements. Because of a minimum pulse width of about 30ns

for the LM2657, very low duty cycles (low output, high input) are possible. The main advantage of current-mode

control is the fact that the slope of its ramp (derived from the switch current), automatically increases with an

increase in input voltage. This leads to improved line rejection and fast response to line variations. In typical

voltage-mode control, the ramp is derived from the clock, not from the switch current. But by using the input

voltage together with the clock signal to generate the ramp as in the LM2657, this advantage of current-mode

control can in fact be completely replicated. The technique is called line feedforward. In addition, the LM2657

features a user-selectable Pulse-skip mode that significantly improves efficiency at light loads by reducing

switching losses and driver consumption, both of which are proportional to switching frequency.

INPUT VOLTAGE FEEDFORWARD

The feedforward circuit of the LM2657 adjusts the slope of the internal PWM ramp in proportion to the regulator

input voltage. See Figure 7 for an illustration of how the duty cycle changes as a result of the change in the slope

of the ramp, even though the error amplifier output has not had time to react to the line disturbance. The almost

instantaneous duty cycle correction provided by the feedforward circuit significantly improves line transient

rejection.

RAMP

Error Amp O/P

VIN = Low

PWM

RAMP

Error Amp O/P

PWM

VIN = High

Figure 7. Voltage Feedforward

FORCED-PWM MODE AND PULSE-SKIP MODE

Forced-PWM mode (FPWM) leads to Continuous Conduction Mode (CCM) even at very light loads. It is one of

two user-selectable modes of operation provided by the LM2657. When FPWM is chosen (FPWM pin high), the

bottom FET will always be turned ON whenever the top FET is OFF. See Figure 8 for a typical FPWM plot.

10

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

�LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

CH1: HDRV, CH2: LDRV, CH3: SW, CH4: IL (0.2A/div)

Output 1V @ 0.04A, VIN = 10V, FPWM, L = 10µH, f = 300kHz

Figure 8. Normal FPWM Mode Operation at Light Loads

In a conventional converter, as the load is decreased to about 10-30% of maximum load current, DCM

(Discontinuous Conduction Mode) occurs. In this condition the inductor current falls to zero during the OFF-time,

and stays there until the start of the next switching cycle. In this mode, if the load is decreased further, the duty

cycle decreases (pinches off), and ultimately may decrease to the point where the required pulse width becomes

less than the minimum ON-time achievable by the converter (controller + FETs). Then a sort of random skipping

behavior occurs as the error amplifier struggles to maintain regulation. There are two ways to prevent random

pulse skipping from occuring.

One way is to keep the lower FET ON until the start of the next cycle (as in the LM2657 operated in FPWM

mode). This allows the inductor current to drop to zero and then actually reverse direction (negative direction

through inductor, passing from drain to source of lower FET, see Channel 4 in Figure 8). Now the current can

continue to flow continuously until the end of the switching cycle. This maintains CCM and the duty cycle does

not start to pinch off as in typical DCM. Nor does it lead to the undesirable random skipping described above.

Note that the pulse width (duty cycle) for CCM is virtually constant for any load and therefore does not usually

run into the minimum ON-time restriction. But it can happen, especially when the application consists of a very

high input voltage, a low output voltage rail, and the switching frequency is set high. Let us check the LM2657 to

rule out this remote possibility. For example, with an input of 24V, an output of 1V, the duty cycle is 1/24 = 4.2%.

This leads to a required ON-time of 0.042* 3.3µs = 0.14 µs at a switching frequency of 300kHz (T=3.3 µs). Since

140ns exceeds the minimum ON-time of 30ns of the LM2657, normal constant frequency CCM mode of

operation is assured in FPWM mode at virtually any load.

The second way to prevent random pulse skipping in discontinuous mode is the Pulse-skip (SKIP) Mode. In SKIP

Mode, a zero-cross detector at the SW pin turns off the bottom FET when the inductor current decays to zero

(actually at VSW_ZERO, see ELECTRICAL CHARACTERISTICS table). This, however, would still amount to

conventional DCM, with its attendant idiosyncrasies at extremely light loads as described earlier. The LM2657

avoids the random skipping behavior and replaces it with a more consistent SKIP mode. In conventional DCM, a

converter would try to reduce its duty cycle from the CCM value as the load decreases, as explained previously.

So it would start with the CCM duty cycle value (at the CCM-DCM boundary), but as the load decreases, the

duty cycle would try to shrink to zero. However, in the LM2657, the DCM duty cycle is not allowed to fall below

85% of the CCM value. So when the theoretically required DCM duty cycle value falls below what the LM2657 is

allowed to deliver (in this mode), pulse-skipping starts. It will be seen that several of these excess pulses may be

delivered until the output capacitors charge up enough to notify the error amplifier and cause its output to

reverse. Thereafter, several pulses could be skipped entirely until the output of the error amplifier again reverses.

The SKIP mode therefore leads to a reduction in the average switching frequency. Switching losses and FET

driver losses, both of which are proportional to frequency, are significantly reduced at very light loads and

efficiency is boosted. SKIP mode also reduces the circulating currents and energy associated with the FPWM

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

11

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

mode. See Figure 9 for a typical plot of SKIP mode at very light loads. Note the bunching of several fixed-width

pulses followed by skipped pulses. The average frequency can actually fall very low at very light loads. When

this happens the inductor core is seeing only very mild flux excursions, and no significant audible noise is

created. But if EMI is a particularly sensitive issue for the particular application, the user can simply opt for the

slightly less efficient, constant frequency FPWM mode.

CH1: HDRV, CH2: LDRV, CH3: SW, CH4: IL (0.2A/div)

Output 1V @ 0.04A, VIN = 10V, SKIP, L = 10µH, f = 300kHz

Figure 9. Normal SKIP Mode Operation at Light Loads

The SKIP mode is enabled when the FPWM pin is held low (or left floating). At higher loads, and under steady

state conditions (above CCM-DCM boundary), there will be absolutely no difference in the behavior of the

LM2657 or the associated converter waveforms based on the voltage applied on the FPWM pin. The differences

show up only at light loads.

Also, under startup, since the currents are high until the output capacitors have charged up, there will be no

observable difference in the shape of the ramp-up of the output rails in either SKIP mode or FPWM mode. The

design has thus forced the startup waveforms to be identical irrespective of whether the FPWM mode or the

SKIP mode has been selected.

The designer must realize that even at zero load condition, there is circulating current when operating in FPWM

mode. This is illustrated in Figure 10. Since duty cycle is the same as for conventional CCM, from V = L* ΔI / Δt it

can be seen that ΔI (or Ipp in Figure 10) must remain constant for any load, including zero. At zero load, the

average current through the inductor is zero, so the geometric center of the sawtooth waveform (the center being

always equal to load current) is along the x-axis. At critical conduction (boundary between conventional CCM and

what should have been DCM were it not in FPWM mode), the load current is equal to Ipp/2. Note that

excessively low values of inductance will produce much higher current ripple and this will lead to higher

circulating currents and dissipation.

12

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

�LM2657

www.ti.com

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

CRITICAL CONDUCTION

Io = Ipp/2

Ipp/2 > Io > 0

NO LOAD

Io = 0

LDRV

HDRV

Figure 10. Inductor Current in FPWM Mode

START-UP AND STATE-TRANSITIONS AT LIGHT LOADS

During startup the LM2657 is allowed to operate in SKIP mode regardless of the voltage on the FPWM pin.

Starting in SKIP mode prevents the low-side FET from having to sink excessive amounts of negative current

during start-up. This would occur if the output was pre-biased and the converter operated in FPWM mode. The

FB pin would sense that the output was high and force a very low duty cycle, which would keep the low-side FET

on longer than it should be in steady state. Without a load on the output the inductor current will reverse and

become negative. This negative inductor current can be quite large depending on the voltage on the output and

the size of the output capacitor.

A similar situation can occur if the converter transitions from SKIP mode to FPWM mode under a light load

condition (converter is operating below the DCM boundary). This can occur after startup if FPWM mode is

selected for use in a light load condition or if the FPWM pin is toggled high during normal operation at light load.

The problem occurs because in SKIP mode the converter is operating at a set duty cycle and a lower average

frequency. When the converter is forced into FPWM mode, this represents a change to the system. The pulse

widths and frequency need to readjust suddenly and in the process momentary imbalances can be created. Like

the case of a pre-biased load, there can be negative surge current passing from drain to source of the lower

FET. It must be kept in mind that though the LM2657 has current limiting for current passing in the ‘positive’

direction (positive with regards to the inductor, i.e. passing from source to drain of the lower FET), there is no

limit for reverse currents. The amount of reverse current when the FPWM pin is toggled ‘on the fly’ can be very

high. This current is determined by several factors. One key factor is the output capacitance. Large output

capacitances will lead to higher peak reverse currents. The reverse swing will be higher for lighter loads because

of the bigger difference between the duty cycles/average frequency in the two modes. See Figure 11 for a plot of

what happened in going from SKIP to FPWM mode at 0A load (worst case). The peak reverse current was as

high as 3A, lasting about 0.1ms. The inductor could also saturate severely at this point if designed for light loads.

In general, if the designer wants to toggle the FPWM pin while the converter is operating or if FPWM mode is

required for a light load application, the low side FET and inductor should be closely evaluated under this specific

condition.

Submit Documentation Feedback

Copyright © 2005–2013, Texas Instruments Incorporated

Product Folder Links: LM2657

13

�LM2657

SNVS342B – JANUARY 2005 – REVISED MARCH 2013

www.ti.com

CH1: PGOOD, CH2: Vo, CH3: LDRV, CH4: IL (1A/div)

Output 1V @ 0A, VIN = 10V, L = 10µH, f = 300kHz

Figure 11. SKIP to FPWM 'On The Fly'

If the part is operated in FPWM mode with a light load the user will experience lower efficiency and negative

current during the transition (as discussed). The user may also experience a momentary drop on Vout when the

transition is made from SKIP to FPWM mode. This only occurs for no load or very light load conditions (above

the DCM boundary there is no difference between SKIP FPWM modes).

In some cases, such as low Vout (