Sample &

Buy

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

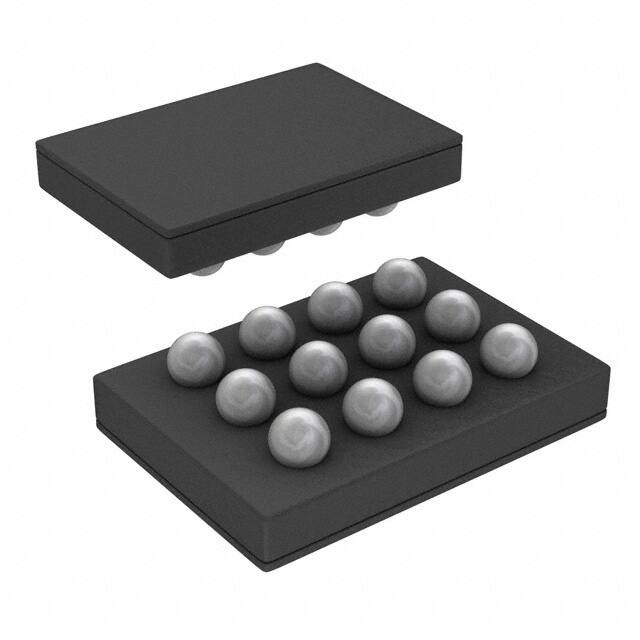

LM2758 Switched Capacitor Flash LED Driver in DSBGA Package

1 Features

3 Description

•

•

•

•

The LM2758 device is an integrated low-noise, highcurrent switched capacitor DC-DC converter with a

regulated current sink. The device is capable of

driving loads up to 700 mA from a single-cell Li-Ion

battery. Maximum efficiency is achieved over the

input voltage range by actively selecting the proper

gain based on the LED forward voltage and current

requirements.

1

•

•

•

•

Up to 700-mA Output Current

90% Peak Efficiency

Indicator, Torch, and Flash Modes

Time-Out Circuitry Limits Flash Duration to 814

Milliseconds (Typical)

Adaptive 1× and 1.5× Gains for Maximum

Efficiency

True Shutdown

Internal Soft-Start Eliminates Inrush Current

Ultra-Small Solution Size

– No Inductor, Only 4 Capacitors and a Resistor

Required

– 2.022 mm × 1.527 mm × 0.6 mm Thin DSBGA

package

One external low-power resistor sets the desired

current for indicator, torch, and flash modes. To

protect the devices and the flash LED, internal timeout circuitry turns off the LM2758 in case of a faulty

prolonged flash mode. Internal soft-start circuitry

limits the amount of inrush current during start-up.

Device Information(1)

PART NUMBER

LM2758

2 Applications

•

•

PACKAGE

DSBGA (12)

BODY SIZE (MAX)

2.022 mm × 1.527 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Camera Flash in Mobile Phones

Flash for Digital Cameras

Typical Application Circuit

C1

C1-

C1+

2.7 V to 5.5 V

+

-

C2

C2+

VIN

C2CPOUT

CIN

COUT

LM2758

EN1

EN2

LEDISET

PGND SGND

RSET

Copyright © 2016, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

6

Absolute Maximum Ratings .....................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description .............................................. 7

7.1

7.2

7.3

7.4

Overview ................................................................... 7

Functional Block Diagram ......................................... 7

Feature Description................................................... 7

Device Functional Modes........................................ 10

8

Application and Implementation ........................ 11

8.1 Application Information............................................ 11

8.2 Typical Application ................................................. 11

9

Power Supply Recommendations...................... 14

9.1 Power Dissipation ................................................... 14

10 Layout................................................................... 15

10.1 Layout Guidelines ................................................. 15

10.2 Layout Example .................................................... 15

10.3 DSBGA Package Assembly and Use ................... 16

11 Device and Documentation Support ................. 17

11.1

11.2

11.3

11.4

11.5

11.6

Device Support......................................................

Documentation Support ........................................

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

17

17

17

17

17

17

12 Mechanical, Packaging, and Orderable

Information ........................................................... 17

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision D (May 2013) to Revision E

Page

•

Added Device Information and Pin Configuration and Functions sections, ESD Ratings table, Feature Description,

Device Functional Modes, Application and Implementation, Power Supply Recommendations, Layout, Device and

Documentation Support, and Mechanical, Packaging, and Orderable Information sections ................................................. 1

•

Added Thermal Information table with revised RθJA value (from 56°C/W to 93.6°C/W) and additional thermal values. ....... 4

Changes from Revision C (May 2013) to Revision D

•

2

Page

Changed layout of National Semiconductor Data Sheet to TI format ................................................................................. 16

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

5 Pin Configuration and Functions

YZR Package

12-Pin DSBGA

Top View

LEDEN2

B3

B2

YZR Package

12-Pin DSBGA

Bottom View

PGND LED- EN2

D3

C3

ISET

A3

D3

PGND

A2

SGND

D2

C1

A1

EN1

D1

C2

B1

+

C1

C2

C2

+

C2

C2

C3

B3

+

-

SGND

A2

-

EN1

A1

C1

D2

C2

D1

C1

VIN

C1

VIN

ISET

A3

B2

CPOUT

B1

+

C1

Pin Functions

PIN

TYPE

DESCRIPTION

EN1

Input

The EN2 pins is used to select the modes (torch, indicator, flash), as well as to put the part into

shutdown mode.

A2

SGND

Ground

Analog and control ground for charge pump. Connect this pin directly to a low impedance

ground plane.

A3

ISET

Power

LED current programming resistor pin. A resistor connected between this pin, and GND is used

to set torch, flash and indicator currents.

B1

C1+

Power

Flying capacitor pin — connect a 1-µF ceramic capacitor from C1+ to C1−

B2

CPOUT

Output

Charge pump regulated output. A 2.2-µF ceramic capacitor is required from CPOUT to GND.

Connect flash LED anode to this pin.

B3

EN2

Input

The EN1 pin is used to select the modes (torch, indicator, flash), as well as to put the part into

Shutdown mode.

C1

VIN

Input

Supply voltage connection

NO.

NAME

A1

C2

C2+

Power

Flying capacitor pins — connect a 1-µF ceramic capacitor from C2+ to C2−.

C3

LED−

Output

Regulated current source output. Connect flash LED cathode to this pin.

D1

C2−

Power

Flying capacitor pin — connect a 1-µF ceramic capacitor from C2+ to C2−.

D2

C1−

Power

Flying capacitor pin — connect a 1-µF ceramic capacitor from C1+ to C1−

D3

PGND

Ground

Power ground for the charge pump and the current source. Connected the pin directly to a lowimpedance ground plane.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

3

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1) (2) (3)

MIN

MAX

UNIT

VIN, CPOUT pins: voltage to GND

–0.3

6

V

EN1, EN2 pins: Voltage to GND

–0.3

(VIN + 0.3) w/ 6 V

maximum

V

150

°C

Continuous power dissipation

Junction temperature, TJ-MAX

See (4)

Maximum lead temperature (soldering)

Storage temperature, Tstg

(1)

(2)

(3)

(4)

–65°C

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

If Military/Aerospace specified devices are required, contact the Texas Instruments Sales Office/ Distributors for availability and

specifications.

All voltages are with respect to the potential to the GND pin.

For detailed soldering specifications and information, see AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009).

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22-C101 (2)

±200

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

Input voltage

2.7

5.5

V

Junction temperature, TJ

–40

125

°C

–40

85

°C

Ambient temperature, TA

(1)

(2)

(2)

UNIT

All voltages are with respect to the potential at the GND pin.

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be derated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operation junction temperature (TJ-MAX-OP =

125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to ambient thermal resistance of the

part/package in the application (RθJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (RθJA × PD-MAX).

6.4 Thermal Information

LM2758

THERMAL METRIC (1)

YZR (DSBGA)

UNIT

12 PINS

RθJA

Junction-to-ambient thermal resistance

93.6

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

0.7

°C/W

RθJB

Junction-to-board thermal resistance

16.1

°C/W

ψJT

Junction-to-top characterization parameter

2.9

°C/W

ψJB

Junction-to-board characterization parameter

16.0

°C/W

(1)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

6.5 Electrical Characteristics

Unless otherwise specified, aspecifications apply to the Figure 8 with VIN = 3.6 V, VEN1 = VIN, VEN2 = 0 V,

C1 = C2 = 1 µF, CIN = COUT = 2.2 µF, RSET = 20 kΩ, TJ = 25°C. (1) (2) (3)

PARAMETER

ILED

LED current accuracy

TEST CONDITIONS

ILED = 500 mA, flash mode

ISET pin voltage

ID/ISET

LED current to set current

ratio

ILED-IND

Indicator current level

TYP

MAX

UNIT

550

mA

500

ILED = 500 mA, flash mode

–40°C ≤ TJ ≤ 125°C

VSET

MIN

450

1.3

Flash mode

V

7650

Torch mode

1639

1/32 ×

ILED-

Indicator mode

32-kHZ PWM mode

mA

TORCH

VGDX

VOUT

1× to 1.5× gain transition

voltage threshold on VLED–

Output voltage

IOUT = 500 mA

300

1× mode, IOUT = 0 mA

VIN

1.5× mode, IOUT = 0 mA (4)

4.8

1.5× mode, IOUT = 0 mA

–40°C ≤ TJ ≤ 125°C (4)

1× mode output impedance

1.5× mode output

impedance

FSW

IOUT = 200 mA, VIN = 3.3 V

–40°C ≤ TJ ≤ 125°C

Switching frequency

IOUT = 500 mA, VIN = 3.3 V

0.33

0.53

(5)

1.5

0.8

Quiescent current

1.5

Shutdown current

TOUT

Timeout duration

0.8

IOUT = 0 mA 1.5× mode

4

640

1.2

Pins: EN1, EN2, –40°C ≤ TJ ≤ 125°C

Pins: EN1, EN2, –40°C ≤ TJ ≤ 125°C

(3)

(4)

(5)

(6)

(7)

814

See (7)

Input logic low

µA

1

–40°C ≤ TJ ≤ 125°C, see (7)

Input logic high

(1)

(2)

0.01

Device disabled, –40°C ≤ TJ ≤ 125°C (6)

VIL

mA

5

Device disabled (6)

VIH

MHz

0.7

IOUT = 0 mA 1x mode

IOUT = 0 mA 1.5× mode, –40°C ≤ TJ ≤ 125°C

ISD

Ω

2.0

1.25

–40°C ≤ TJ ≤ 125°C

IOUT = 0 mA 1× mode, –40°C ≤ TJ ≤ 125°C

IQ

V

5.3

IOUT = 200 mA, VIN = 3.3 V (5)

ROUT

mV

msec

1000

V

0.4

V

All voltages are with respect to the potential at the GND pin.

Minimum (MIN) and maximum (MAX) limits are specified by design, test, or statistical analysis. Typical (TYP) numbers are not ensured,

but do represent the most likely norm. Unless otherwise specified, conditions for TTYP specifications are: VIN = 3.6 V and TA = 25°C.

CIN, COUT, C1, C2: Low-ESR surface-mount ceramic capacitors (MLCCs) used in setting electrical characteristics.

Output voltage is internally limited not to exceed maximum specified value.

These table entries are specified by design. These parameters are not ensured by production testing. The temperature limits for test are

(–40°C ≤ TA ≤ +85°C).

The temperature limits for ISD (shutdown current) test are -40°C ≤ TA ≤ +85°C, as in shutdown mode ambient temperature is equal to

junction temperature.

The timeout specifications are calculated values based on the switching frequency spread.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

5

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

6.6 Typical Characteristics

Unless otherwise specified: TA = 25°C, VIN = 3.6 V, CIN = COUT = 2.2 µF, C1 = C2 = 1 µF. Capacitors are low-ESR multi-layer

ceramic capacitors (MLCCs). Luxeon PWF1 Flash LED.

110

1.15

500 mA

1.13

FREQUENCY (MHz)

EFFICIENCY (%)

90

70

50

700 mA

100 mA

30

1.11

1.09

1.07

10

2.7

3.2

3.7

4.2

4.7

1.05

2.7

5.2

3.2

3.7

4.2

VIN (V)

4.7

5.2

VIN (V)

Figure 1. Efficiency vs VIN

Figure 2. Oscillator Frequency vs VIN

5.000

0.04

1.5x

4.000

ISHUTDOWN (µA)

IQUIESCENT (mA)

0.03

3.000

2.000

1x

0.02

EN1 = EN2 = 0V

0.01

1.000

0.000

2.7

3.1

3.5

3.9

4.3

4.7

5.1

0.00

2.7

5.5

3.1

3.5

3.9

4.3

4.7

5.1

5.5

VIN (V)

VIN (V)

Figure 3. Quiescent Current vs VIN

Figure 4. Shutdown Current vs VIN

800

1k

700

900

800

700 mA

700

500

ILED (mA)

ILED (mA)

600

400

500 mA

300

100 mA

Flash

600

500

400

300

Torch

200

200

100

0

0.0

100

0.5

1.0

0

10

1.5

VLED- (V)

20

25

30

35

R SET (k:)

Figure 5. ILED vs VLED–

6

15

Figure 6. LED Current vs RSET

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

7 Detailed Description

7.1 Overview

The LM2758 is an adaptive 1× and 1.5× CMOS charge pump, optimized for driving flash LEDs in camera phones

and other portable applications. It provides a constant current of 500 mA (typical) for flash mode and 107 mA

(typical) for torch mode with RSET = 20 kΩ. These current can change (see Setting LED Currents).

There are four modes of operation for LM2758: the flash mode, torch mode, indicator mode, and shutdown mode

(see Table 1). Torch and flash modes sink a constant DC current while indicator mode operates in pulsating DC

at 1/32 positive duty cycle with same current magnitude as torch mode. The LED is driven from CPOUT and

connected to the current sink. LED drive current mode is programmed by connecting a resistor, RSET, to the

current set pin, ISET. The LM2758 device also controls CPOUT with variable gain (1× or 1.5×) and adjustable

impedance (ROUT) to provide an output voltage that would account for LED forward voltage drop and headroom

for the current sink to drive desired current through LED.

7.2 Functional Block Diagram

LED

COUT = 2.2 µF

LED-

CPOUT

VIN

Gain Control

GND

CIN

= 2.2 µF

Ind.

Current

Control

C1+

Torch

Flash

Flash, Torch

Mode

Control

EN1

EN2

1 µF

C1-

1x, 1.5x

Charge Pump

VREF

C2+

1 µF

OSC

C2-

ISET

RSET

Copyright © 2016, Texas Instruments Incorporated

7.3 Feature Description

7.3.1 Charge Pump and Gain Transitions

The input to the 1×/1.5× charge pump is connected to the VIN pin, and the loosely regulated output of the charge

pump is connected to the CPOUT pin. In 1× mode, as long as the input voltage is less than 4.7 V, the output

voltage is approximately equal to the input voltage. When input voltage is over 4.7 V the output voltage is

regulated to 4.7 V. In 1.5× mode, the output voltage is always less than or equal to 4.7 V over entire input

voltage range.

The gain of the charge pump is selected depending on the headroom voltage across the current sink of LM2758.

When headroom voltage VLED– (at the LED pin) drops below 300 mV (typical) the charge-pump gain transition

happens from 1× to 1.5× to maintain current regulation across the LED. Once the charge pump transition to a

higher gain, it remains at that gain for as long as the device remains enabled. Shutting down and then reenabling the device resets the gain mode to the minimum gain required to maintain the load.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

7

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

Feature Description (continued)

7.3.2 Soft Start

The LM2758 contains internal soft-start circuitry to limit inrush currents when the part is enabled. Soft start is

implemented internally with a controlled turnon of the internal voltage reference.

7.3.3 Current Limit Protection

The LM2758 charge pump contains current limit protection circuitry that protects the device during VOUT fault

conditions where excessive current is drawn. Output current is limited to 1.2 A typically.

7.3.4 Flash Time-out Feature

Flash time-out protection circuitry disables the current sinks when the signal on EN1 and EN2 is held high for

more than 814 msec (typical). This prevents the device from self-heating due to the high power dissipation during

flash conditions. During the time-out condition, voltage is still present on CPOUT but the current sinks are shut off,

resulting in no current through the flash LED. When the device goes into a time-out condition, placing a logic low

signal on EN1 and EN2 resets the timeout; a subsequent logic high signal on EN1 or EN2 returns the device to

normal operation.

7.3.5 Setting LED Currents

The current through the LED can be set by connecting an appropriately sized resistor RSET between the ISET pin

of the LM2758 and GND.

The LED current in torch mode is approximately 1639 times greater than the current of ISET, while the LED

current in flash mode is approximately 7650 times of the same ISET current. The feedback loop of an internal

amplifier sets the voltage of the ISET pin to 1.3 V (typical). The statements above are simplified in Equation 1:

ILED = GAINFLASH/TORCH × (1.3 / RSET)

(1)

The maximum recommended current through LED is 500 mA in torch mode / 700 mA in flash mode.

NOTE

If the ISET for torch mode setting at 500 mA, the flash mode would be over 700 mA

(maximum). See Figure 6. Using the device in conditions where the junction temperature

might rise above the rated maximum requires that the operating ranges and/or conditions

be de-rated. The printed circuit board also must be carefully laid out to account for high

thermal dissipation in the part.

8

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

Feature Description (continued)

7.3.6 Analog Brightness Control

C1

1 µF

C2

1 µF

C1-

C1+

VIN

CPOUT

COUT

2.2 µF

CIN

2.2 µF

+

-

C2-

C2+

LM2758

EN1

EN2

LEDISET

PGND SGND

VA

RA

RSET

Copyright © 2016, Texas Instruments Incorporated

Figure 7. Analog Brightness Control

The current through the LED can be varied dynamically by changing the ISET current. Figure 7 shows the circuit.

The current though the LED can be calculated with Equation 2:

ILED = GainTORCH/FLASH

1.3V

RSET

VA

1.3V

RA

(2)

7.3.7 Thermal Protection

Internal thermal protection circuitry disables the LM2758 when the junction temperature exceeds 150°C (typical).

This feature protects the device from being damaged by high die temperatures that might otherwise result from

excessive power dissipation. The device recovers and operates normally when the junction temperature falls

below 140°C (typical). It is important that the board layout provide good thermal conduction to keep the junction

temperature within the specified operating ratings.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

9

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

7.4 Device Functional Modes

7.4.1 Modes

There are four modes of operation for LM2758: the flash mode, torch mode, indicator mode and shutdown mode

(see Table 1). Torch and flash modes sink a constant DC current while indicator mode operates in pulsating DC

at 1/32 positive duty cycle with same current magnitude as torch mode.

7.4.2 Logic Control Pins

The LM2758 has two logic pins, EN1 and EN2. There is a 500-kΩ (typical) pulldown resistor connected from EN1

to GND and from EN2 to GND. The operating modes of the part function according to Table 1:

Table 1. EN1 and EN2 Truth Table

10

EN1

EN2

MODE

0

0

Shutdown

1

0

Indicator

0

1

Torch

1

1

Flash

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM2758 can drive one flash LED at currents up to 700 mA. The multi-gain charge-pump boost regulator

allows for the use of small value discrete external components.

8.2 Typical Application

C1

C1-

C1+

2.7 V to 5.5 V

+

-

C2

C2-

C2+

VIN

CPOUT

CIN

COUT

LM2758

EN1

EN2

LEDISET

PGND SGND

RSET

Copyright © 2016, Texas Instruments Incorporated

Figure 8. LM2758 Typical Application

8.2.1 Design Requirements

For typical switched-capacitor LED-driver applications, use the parameters listed in Table 2.

Table 2. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

Minimum input voltage

2.7 V

Maximum output current

700 mA

8.2.2 Detailed Design Procedure

8.2.2.1 Capacitor Selection

The LM2758 device requires 4 external capacitors for proper operation. Surface-mount multi-layer ceramic

capacitors are recommended. These capacitors are small, inexpensive and have very low equivalent series

resistance (ESR < 20 mΩ typical). Tantalum capacitors, OS-CON capacitors, and aluminum electrolytic

capacitors are not recommended for use with the LM2758 due to their high ESR compared to ceramic

capacitors. For most applications, ceramic capacitors with X7R or X5R temperature characteristic are preferred

for use with the LM2758. Ceramic capacitors have tight capacitance tolerance (as good as ±10%) and hold their

value over temperature (X7R: ±15% over –55°C to +125°C; X5R: ±15% over –55°C to +85°C). Capacitors with

Y5V or Z5U temperature characteristic are generally not recommended for use with the LM2758. Capacitors with

these temperature characteristics typically have wide capacitance tolerance (+80%, –20%) and vary significantly

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

11

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

over temperature (Y5V: 22%, –82% over –30°C to +85°C range; Z5U: 22%, –56% over 10°C to 85°C range).

Under some conditions, a nominal 1 μF Y5V or Z5U capacitor could have a capacitance of only 0.1 μF. Such

detrimental deviation is likely to cause Y5V and Z5U capacitors to fail to meet the minimum capacitance

requirements of the LM2758. The voltage rating of the output capacitor must be 6.3 V or more. For example, a

6.3-V, 0603, 2.2-μF output capacitor (TDK C1608X5R0J225) is acceptable for use with the LM2758, as long as

the capacitance on the output does not fall below a minimum of 1 μF in the intended application. All other

capacitors must have a voltage rating at or above the maximum input voltage of the application and a minimum

capacitance of 1 μF.

Table 3. Suggested Capacitors And Suppliers

MANUFACTURER

PART NUMBER

TYPE

MANUFACTURER

VOLTAGE RATING

CASE SIZE

INCH (mm)

2.2 µF for CIN and COUT

C1608X5R0J225

Ceramic X5R

TDK

6.3 V

0603 (1608)

JMK107BJ225

Ceramic X5R

Taiyo-Yuden

6.3 V

0603 (1608)

1 µF for C1 and C2

C1608X5R0J105

Ceramic X5R

TDK

6.3 V

0603 (1608)

JMK107BJ105M

Ceramic X5R

Taiyo-Yuden

6.3 V

0603 (1608)

8.2.2.2 Power Efficiency

Efficiency of LED drivers is commonly taken to be the ratio of power consumed by the LEDs (PLED) to the power

drawn at the input of the part (PIN). With a 1×/1.5× charge pump, the input current is equal to the charge pump

gain times the output current (total LED current). The efficiency of the LM2758 can be predicted as follows:

PLED = VLED × ILED

PIN = VIN × IIN

PIN = VIN × (Gain × ILED + IQ)

E = (PLED ÷ PIN)

(3)

(4)

(5)

(6)

For a simple approximation, the current consumed by internal circuitry (IQ) can be neglected, and the resulting

efficiency will become:

E = VLED ÷ (VIN × Gain)

(7)

Neglecting IQ results in a slightly higher efficiency prediction, but this impact will be negligible due to the value of

IQ being very low compared to the typical torch and flash current levels (100 mA to 500 mA). It is also worth

noting that efficiency as defined here is in part dependent on LED voltage. Variation in LED voltage does not

affect power consumed by the circuit and typically does not relate to the brightness of the LED. For an advanced

analysis, it is recommended that power consumed by the circuit (VIN × IIN) be evaluated rather than power

efficiency.

12

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

8.2.3 Application Curves

110

500 mA

2V/DIV

90

EFFICIENCY (%)

GAIN = 1.5x

VOUT

70

50

2V/DIV

200 mA/DIV

700 mA

EN1,

EN2

100 mA

200 mA/DIV

30

10

2.7

3.2

3.7

4.2

4.7

IIN

ILED

5.2

400 µs/DIV

VIN (V)

VIN = 3.6 V

ILED = 500 mA

Figure 10. Shutdown to Flash Mode

Figure 9. Efficiency vs VIN

2V/DIV

VOUT

GAIN = 1.5x

2V/DIV

VOUT

2V/DIV

EN1

2V/DIV

EN2

100 mA/DIV

IIN

100 mA/DIV

ILED

100 mA/DIV

IIN

100 mA/DIV

1 ms/DIV

ILED

100 µs/DIV

VIN = 3.6 V

EN1 = 0 V

ILED = 108 mA

Gain = 1×

VIN = 3.6 V

EN2 = 0 V

Figure 11. Shutdown to Torch Mode

ILED (torch) = 108 mA

Figure 12. Shutdown to Indicator Mode

2V/DIV

2V/DIV

EN1

2V/DIV

VOUT

VOUT

200 mA/DIV

100 mA/DIV

ILED

IIN

200 mA/DIV

ILED

20 mA/DIV

IIN

200 ms/DIV

10 µS/DIV

EN1 = VIN = 3.6 V

EN2 = 0 V

ILED (torch) = 108 mA

Gain = 1×

EN2 = VIN = 3.6 V

Figure 13. Indicator Mode

ILED (flash) = 500 mA

Gain = 1.5×

Figure 14. Torch to Flash Mode Transition

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

13

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

2V/DIV

EN2

2V/DIV

VOUT

200 mA/DIV

IIN

200 mA/DIV

ILED

200 ms/DIV

EN1 = VIN = 3.6 V

ILED (flash) = 500 mA

Gain = 1.5×

Figure 15. Indicator to Flash Mode Transition

9 Power Supply Recommendations

The LM2758 is designed to operate from an input voltage supply range from 2.7 V to 5.5 V. This input supply

must be well regulated and capable to supply the required input current. If the input supply is located far from the

device, additional bulk capacitance may be required in addition to the ceramic bypass capacitors.

9.1 Power Dissipation

The power dissipation (PDISSIPATION) and junction temperature (TJ) can be approximated with the equations

below. PIN is the power generated by the 1×/1.5× charge pump, PLED is the power consumed by the LEDs, TA is

the ambient temperature, and RθJA is the junction-to-ambient thermal resistance for the 12-pin DSBGA package.

VIN is the input voltage to the LM2758, VLED is the nominal LED forward voltage, and ILED is the programmed

LED current.

PDISSIPATION = PIN – PLED

= (Gain × VIN × ILED) − (VLED × ILED)

TJ = TA + (PDISSIPATION × RJθA)

(8)

(9)

(10)

The junction temperature rating takes precedence over the ambient temperature rating. The LM2758 may be

operated outside the ambient temperature rating, so long as the junction temperature of the device does not

exceed the maximum operating rating of 125°C. The maximum ambient temperature rating must be derated in

applications where high power dissipation and/or poor thermal resistance causes the junction temperature to

exceed 125°C.

14

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

10 Layout

10.1 Layout Guidelines

PC board layout is an important part of DC-DC converter design. Poor board layout can disrupt the performance

of a DC-DC converter and surrounding circuitry by contributing to EMI, ground bounce, and resistive voltage loss

in the traces. These can send erroneous signals to the DC-DC converter device, resulting in poor regulation or

instability. Poor layout can also result in re-flow problems leading to poor solder joints between the DSBGA

package and board pads. Poor solder joints can result in erratic or degraded performance.

10.2 Layout Example

GND

EN1

SGND

ISET

C1+

CPOUT

EN2

VIN

C2+

CPOUT

LED-

C2-

C1-

VIN

PGND

GND

GND

Figure 16. LM2758 Layout Example

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

15

�LM2758

SNVS551E – APRIL 2008 – REVISED MAY 2016

www.ti.com

10.3 DSBGA Package Assembly and Use

Use of the DSBGA package requires specialized board layout, precision mounting and careful re-flow techniques

as detailed in AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009). Refer to the section Surface

Mount Assembly Considerations" For best results in assembly, use alignment ordinals on the PC board to

facilitate placement of the device. The pad style used with the DSBGA package must be the NSMD (non-solder

mask defined) typical. This means that the solder-mask opening is larger than the pad size. This prevents a lip

that otherwise forms if the solder mask and pad overlap, from holding the device off the surface of the board and

interfering with mounting. See SNVA009 for specific instructions how to do this. The 12-pin package used for

LM2758 has 300 micron solder balls and requires 10.82 mils pads for mounting on the circuit board. The trace to

each pad should enter the pad with a 90° entry angle to prevent debris from being caught in deep corners.

Initially, the trace to each pad should be 7 mil. wide, for a section approximately 7 mil. long or longer, as a

thermal relief. Then each trace should neck up or down to its optimal width. The important criteria is symmetry.

This ensures the solder bumps on the LM2758 re-flow evenly and that the device solders level to the board. In

particular, special attention must be paid to the pads for bumps C1 and D3, because VIN and GND are typically

connected to large copper planes, thus inadequate thermal relief can result in late or inadequate re-flow of these

bumps.

The DSBGA package is optimized for the smallest possible size in applications with red or infrared opaque

cases. Because the DSBGA package lacks the plastic encapsulation characteristic of larger devices, it is

vulnerable to light. Backside metallization and/or epoxy coating, along with front side shading by the printed

circuit board, reduce this sensitivity. However, the package has exposed die edges. In particular, DSBGA

devices are sensitive to light, in the red and infrared range, shining on the exposed die edges of the package.

16

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

�LM2758

www.ti.com

SNVS551E – APRIL 2008 – REVISED MAY 2016

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.2 Documentation Support

11.2.1 Related Documentation

For additional information, see the following:

AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009)

11.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

11.4 Trademarks

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

11.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

11.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM2758

17

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

LM2758TL/NOPB

ACTIVE

DSBGA

YZR

12

250

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 85

2758

LM2758TLX/NOPB

ACTIVE

DSBGA

YZR

12

3000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 85

2758

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of