Product

Folder

Sample &

Buy

Technical

Documents

Support &

Community

Tools &

Software

LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

LM3017 High Efficiency Low-Side Controller With True Shutdown

1 Features

3 Description

•

The LM3017 device is a versatile low-side NFET

controller incorporating true shutdown and input side

current limiting. The LM3017 is designed for simple

implementation

of

boost

conversions

in

Thunderbolt™ Technology. The LM3017 can also be

configured for flyback or SEPIC designs. The input

voltage range of 5 V to 18 V accommodates a two- or

three-cell lithium ion battery or a 12-V rail. The enable

pin accepts a single input to drive three different

modes of operation: boost, pass-through, or

shutdown mode. The LM3017 draws very low current

in shutdown mode, typically 40 nA from the input

supply.

1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Fully Compliant to Thunderbolt™ Technology

Specifications

True Shutdown for Short-Circuit Protection

Input Side Current Limit

Single Enable Pin With Three Modes of

Operation: Boost, Pass-Through, or Shutdown

Built-in Charge Pump for High-Side NFET

Disconnect Switch

1-A Push-Pull Driver for Low-Side NFET

Peak Current Mode Control

Simple Slope Compensation

Protection Features: Thermal Shutdown, Cycleby-Cycle Current Limit, Short-Circuit Protection,

Output Overvoltage Protection, and Latch-Off

Internal Soft Start

Input Voltage Range: 5 V to 18 V

600-kHz Fixed Frequency Operation

±1% Reference Voltage Accuracy Over

Temperature

Low Shutdown Current (< 1 µA), 40 nA Typical

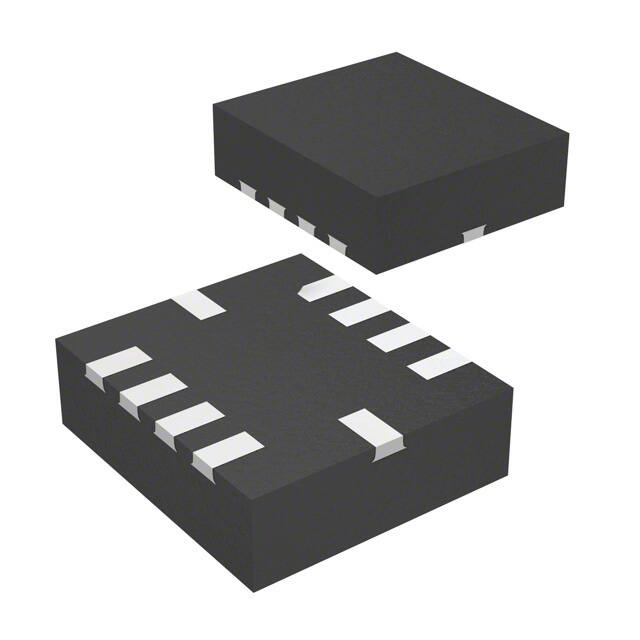

2.4 mm × 2.7 mm × 0.8 mm, 10-Pin WQFN

Package

The LM3017 provides an adjustable output to drive

the Power Load Switch or MUX for the host

Thunderbolt™ port. The ability to drive an external

high-side NMOS provides for true isolation of the load

from the input. Current limiting on the input ensures

that inrush and short-circuit currents are always under

control. The LM3017 incorporates built-in thermal

shutdown, cycle-by-cycle current limit, short-circuit

protection, output overvoltage protection, and soft

start. It is available in a 10-pin WQFN package.

Device Information(1)

PART NUMBER

LM3017

2 Applications

•

•

•

•

•

Thunderbolt™ Technology Host Ports

Notebook and Desktop Computers, Tablets, and

Other Portable Consumer Electronics

Hard Disc Drives, Solid-State Drives

Offline Power Supplies

Set-Top Boxes

PACKAGE

WQFN (10)

BODY SIZE (NOM)

2.40 mm × 2.70 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application Circuit

Copyright © 2016, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

7

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description .............................................. 9

7.1

7.2

7.3

7.4

Overview ................................................................... 9

Functional Block Diagram ......................................... 9

Feature Description................................................. 10

Device Functional Modes........................................ 12

8

Application and Implementation ........................ 14

8.1 Application Information............................................ 14

8.2 Typical Application .................................................. 14

9 Power Supply Recommendations...................... 28

10 Layout................................................................... 28

10.1 Layout Guidelines ................................................. 28

10.2 Layout Examples................................................... 30

10.3 Thermal Considerations ........................................ 30

11 Device and Documentation Support ................. 31

11.1

11.2

11.3

11.4

11.5

11.6

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

31

31

31

31

31

31

12 Mechanical, Packaging, and Orderable

Information ........................................................... 31

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision C (March 2013) to Revision D

Page

•

Added ESD Ratings table, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section .................................................................................................. 1

•

Changed RθJA value in the Thermal Information table From: 36 To: 79.2.............................................................................. 4

Changes from Revision B (November 2012) to Revision C

•

2

Page

Added Updated to Rev C as Rev A and B were SVA Confidentials ...................................................................................... 1

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

5 Pin Configuration and Functions

NKL Package

10-Pin WQFN

Top View

30180903

Pin Functions

PIN

NO.

NAME

TYPE (1)

DESCRIPTION

1

VCC

O

Driver supply voltage pin: output of internal regulator powering low side NMOS driver. A minimum of

0.47 µF must be connected from this pin to PGND for proper operation.

2

DR

O

Low-side NMOS gate driver output: output gate drive to low side NMOS gate.

3

PGND

G

Power ground: ground for power section. External power circuit reference. Must be connected to

AGND at a single point.

4

VG

O

High side NMOS gate driver output: output gate drive to high side NMOS gate.

5

EN/MODE

A

Multi-function input pin: this input provides for chip enable, and mode selection. See Device

Functional Modes for details.

6

FB

A

Feed-back input pin: negative input to error amplifier. Connect to feedback resistor tap to regulate

output.

7

COMP

A

Compensation pin: a resistor and capacitor combination connected to this pin provides frequency

compensation for the regulator control loop.

8

AGND

G

Analog ground: ground for analog control circuitry. Reference point for all stated voltages.

9

ISEN

A

Current sense input: current sense input, with respect to VIN, for all current limit functions.

10

VIN

P

Power supply input pin: input supply to regulator. See Application and Implementation for

recommendations on bypass capacitors on this pin.

(1)

A = Analog, G = Ground, O = Output, P = Power

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

3

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1) (2)

MIN

MAX

UNIT

VIN to PGND, AGND

–0.3

20

V

FB, COMP, VCC,DR to PGND, AGND

–0.2

6

V

EN/MODE

–0.2

5.5

V

VG

–0.3

VIN + 6

V

VIN – 0.3

VIN

V

1

A

ISEN to PGND, AGND

Peak low side driver output current

Power dissipation

Internally limited

Junction temperature, TJ

Storage temperature, Tstg

(1)

(2)

–65

150

°C

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

If Military/Aerospace specified devices are required, please contact the Texas Instruments Sales Office/Distributors for availability and

specifications.

6.2 ESD Ratings

V(ESD)

(1)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

VALUE

UNIT

±1500

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

MAX

VIN

Supply voltage

5.4

18

UNIT

V

TJ

Junction temperature

–40

125

°C

6.4 Thermal Information

LM3017

THERMAL METRIC (1)

NKL (WQFN)

UNIT

10 PINS

RθJA

Junction-to-ambient thermal resistance

79.2

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

29.8

°C/W

RθJB

Junction-to-board thermal resistance

21.4

°C/W

ψJT

Junction-to-top characterization parameter

0.6

°C/W

ψJB

Junction-to-board characterization parameter

20.7

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

—

°C/W

(1)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

6.5 Electrical Characteristics

Minimum and maximum limits are specified through test, design, or statistical correlation, and apply over the junction

temperature range at TJ = –40°C to 125°C. Typical values are provided for reference purposes only, and represent the most

likely parametric norm at TJ = 25°C. VIN = 12 V (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN (1)

TYP (2)

MAX (1)

1.256

1.27

1.282

VFB

Feedback voltage

Vcomp = 1.4 V

ΔVLINE

Feedback voltage line regulation

5 V ≤ VIN ≤ 18 V

Input undervoltage lockout voltage

Rising

Input undervoltage lockout hysteresis

Falling, below VUVLO

Nominal switching frequency

EN/MODE = 1.6 V

Low-side NMOS driver resistance,

top driver FET

VIN = 5 V, IDR = 0.2 A

3.4

Low-side NMOS driver resistance,

bottom driver FET

VIN = 5 V, IDR = 0.2 A

1

VUVLO

FSW

RDS(ON)

UNIT

V

0.33%

4.6

4.82

4.9

280

550

600

V

mV

635

kHz

Ω

VIN < 6 V

VIN

VIN ≥ 6 V

5.6

VCC

Driver voltage supply

Dmax

Maximum duty cycle

Tmin(on)

Minimum on-time

IQ-boost

Supply current in boost mode,

no switching

EN/MODE = 1.6 V, FB = 1.4 V

IQ-SD

Supply current in shutdown mode

EN/MODE pin = 0.4 V

IQ-pass

Supply current in pass-through mode

EN/MODE = 2.6 V, FB = 1.4 V

Ven-pass

Pass-through mode threshold (3)

Rising

2.19

Vmode-hyst

Mode change hysteresis, falling (3)

Falling

65

V

86%

125

(3)

ns

5.2

9

mA

0.025

1

µA

1.4

2.3

mA

2.4

2.56

V

107

165

V

V

Ven-shutdown

Shutdown mode threshold

Falling

0.2

0.4

0.59

Ven-boost

Boost mode enable window (3)

Rising

0.65

1.22

1.6

Ien

EN/MODE pin bias current (4)

EN/MODE = 1.6 V

VSENSE

Cycle-by-cycle current limit threshold

during boost mode

EN/MODE = 1.6 V, FB = 50 V

142

170

182

mV

ΔVSC

Short-circuit current limit threshold

during boost mode

EN/MODE = 1.6 V, FB = 0 V

18

30

42

mV

VSL

Internal ramp compensation voltage

VLIM1

Input current limit threshold voltage in

pass-through mode during TLIM1 (3)

EN/MODE = 2.6 V

70

85

95

mV

ΔVLIM2

Input current limit threshold voltage in

pass-through mode during TLIM2 (3)

EN/MODE = 2.6 V

14.5

18

21

mV

±1

90

(3)

TLIM1

Curent limit time at TLIM1

TLIM2

Current limit time at TLIM2 (3)

TSC

Current limit time at TSC (3)

µs

3.6

ms

900

µs

Rising threshold measured at FB pin with

respect to FB pin, VCOMP = 1.45 V

40

Lower-output overvoltage protection

threshold

Falling threshold measured at FB pin with

respect to FB pin, VCOMP = 1.45 V

26

VGS-on

On-state drive voltage at VG pin (5)

VIN = 5 V, ISEN = 5 V, IG = 0 A

VGS-off

Off-state drive voltage at VG pin (6)

Vin = 5 V, ISEN = VIN – 200 mV, IG = 0 A

IG

Maximum drive current at VG pin

VIN = 5 V, ISEN = 5 V, VG = VIN

Gm

Error amplifier transconductance

VCOM = 1.4 V, ICOMP = ±50 µA

(1)

(2)

(3)

(4)

(5)

(6)

mV

900

Upper-output overvoltage protection

threshold

VOVP

V

µA

mV

3.8

4.9

V

5

mV

20

340

522

µA

900

µA/V

All limits are specified at room temperature and at temperature extremes. All room temperatures are 100% production tested. All limits at

temperature extremes are specified through correlation using Statistical Quality Control (SQD) methods. All limits are used to calculate

Average Outgoing Quaity Level (AOQL).

Typical numbers are at 25°C and represent the most likely parametric norm.

See Device Functional Modes and Overvoltage Protection.

The bias current flowing through this pin is compensated and can flow either into or out-of this pin.

This is the gate-to-source voltage drive of Q2, when the controller turns on this FET.

This voltage is measured from the VG pin to AGND, when the controller fully turns off Q2.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

5

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

Electrical Characteristics (continued)

Minimum and maximum limits are specified through test, design, or statistical correlation, and apply over the junction

temperature range at TJ = –40°C to 125°C. Typical values are provided for reference purposes only, and represent the most

likely parametric norm at TJ = 25°C. VIN = 12 V (unless otherwise noted).

PARAMETER

TEST CONDITIONS

TYP (2)

MAX (1)

190

313

450

UNIT

AVOL

Error amplifier open-loop voltage gain

RO

Error amplifier open-loop output

resistance (7)

IEAO

Error amplifier output current swings

VEAO

Error amplifier output voltage limits

Tr

Drive pin rise time

Cload = 3 nF, VDR = 0 V to 3 V

25

ns

Tf

Drive pin fall time

Cload = 3 nF, VDR = 3 V to 0 V

25

ns

TSD

Thermal shutdown threshold

165

°C

TSD-hyst

Thermal shutdown threshold hysteresis

10

°C

(7)

6

VCOM = 1.2 V to 1.8 V, ICOMP = 0 A

MIN (1)

600

kΩ

Sourcing: VCOMP = 1.4 V, VFB = 1.1 V

27

66

115

Sinking: VCOMP = 1.4 V, VFB = 1.4 V

49

68

125

Upper: VFB = 0 V, COMP pin floating

Lower: VFB = 1.4 V

2.3

0.82

V/V

µA

V

This parameter is calculated from the error amplified Gm and AVOL, and is not tested.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

6.6 Typical Characteristics

VIN = 12 V, TJ = 25°C, and see Figure 16 (unless otherwise noted).

650

1.6

8V

12V

SUPPLY CURRENT (mA)

640

FREQUENCY (kHz)

630

620

610

600

590

580

570

-40°C

27°C

90°C

1.4

1.2

1.0

560

550

0.8

-60 -40 -20 0 20 40 60

TEMPERATURE (°C)

80 100

Figure 1. Switching Frequency vs Temperature

3.4

3.2

18

135

130

125

120

115

110

3.0

4

6

8

10 12 14

INPUT VOLTAGE (V)

16

18

-60 -40 -20 0 20 40 60

TEMPERATURE (°C)

TLIM1

TLIM2

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

-60 -40 -20 0 20 40 60

TEMPERATURE (°C)

80 100

Figure 5. Current Limit Timing vs Temperature

80 100

Figure 4. Minimum ON-Time vs Temperature

PASS FET GATE-SOURCE VOLTAGE (V)

Figure 3. Supply Current in Boost Mode (IQ-boost)

CURRENT LIMIT TIMING (ms)

16

140

3.6

4.5

8

10 12 14

INPUT VOLTAGE (v)

145

-40°C

27°C

90°C

3.8

5.0

6

Figure 2. Supply Current in Pass-Through Mode (IG-pass)

MINIMUM ON-TIME (ns)

SUPPLY CURRENT (mA)

4.0

4

6.5

-40°C

27°C

90°C

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

4

5

6

7 8 9 10 11 12 13 14

INPUT VOLTAGE (V)

Figure 6. Pass FET Drive Voltage vs Input Voltage (VGS-on)

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

7

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

Typical Characteristics (continued)

VIN = 12 V, TJ = 25°C, and see Figure 16 (unless otherwise noted).

PASS FET GATE DRIVE CURRENT ( A)

35

6.2

VIN = 12V

-40°C

27°C

90°C

6.0

30

5.8

VCC (V)

25

20

5.6

5.4

5.2

15

5.0

10

4.8

-60 -40 -20 0 20 40 60

TEMPERATURE (°C)

80 100

2

Figure 7. Pass FET Drive Current vs Temperature

0.20

96

0.15

94

0.10

ûVOUT(%)

98

EFFICIENCY (%)

0.25

90

8Vin

10Vin

12Vin

0.05

0.00

-0.10

86

-0.15

84

8Vin

10Vin

12Vin

82

80

-0.20

-0.25

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

OUTPUT CURRENT (A)

= 15 V

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

OUTPUT CURRENT (A)

Figure 9. Efficiency

Figure 10. Load Regulation

0.25

0.1A output current

0.5A output current

1A output current

0.20

0.15

VO

5V/Div

0.10

ûVOUT(%)

5 6 7 8 9 10 11 12

INPUT VOLTAGE (V)

-0.05

88

VOUT

4

Figure 8. VCC Voltage vs Input Voltage

100

92

3

EN

500 mV/Div

0.05

0.00

-0.05

-0.10

IO

200 mA/Div

-0.15

-0.20

-0.25

8

9

10

11

INPUT VOLTAGE (V)

12

TIME (5 ms/DIV)

VIN = 8 V

Figure 12. Start-Up Waveforms

Figure 11. Line Regulation

8

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

7 Detailed Description

7.1 Overview

The LM3017 uses a fixed frequency, Pulse Width Modulated (PWM), current mode control architecture. A highside current sense amplifier provides inductor current information by sensing the voltage drop across RSEN. The

voltage across this resistor is fed into the ISEN pin. This voltage is then level shifted and fed into the positive input

of the PWM comparator. As with all architectures of this type, a compensation ramp is required to ensure stability

of the current control loop under all operating conditions. A nominal value of the ramp is provided internally while

additional ramp can be added through the ISEN pin. The output voltage is sensed through an external feedback

resistor divider network and fed into the error amplifier (EA) negative input (feedback pin, FB). The output of the

error amplifier (COMP pin) is added to the slope compensation ramp and fed into the negative input of the PWM

comparator.

At the start of any switching cycle, the oscillator sets a high signal on the DR pin (gate of the external MOSFET)

and the external MOSFET turns on. When the voltage on the positive input of the PWM comparator exceeds the

negative input, the Drive Logic is reset and the external MOSFET turns off.

Under extremely light load or no-load conditions, the energy delivered to the output capacitor when the external

MOSFET is on during the minimum on time is more than what is delivered to the load. An overvoltage

comparator inside the LM3017 prevents the output voltage from rising under these conditions by sensing the

feedback (FB pin) voltage and resetting the RS latch. The latch remains in a reset state until the output decays to

the nominal value. Thus the operating frequency decreases at light loads, resulting in excellent efficiency.

7.2 Functional Block Diagram

VG

ISEN

VIN

Ramp Adjust

-

+

200 mV

+

Pass

Control

Current

Sense

Amp.

-

A

Internal

Reg

Short-circuit

Comparator

+

Limit

References

Charge

Pump

VCC

Limit

-

Level

Shifter

1.27V

Reference

Soft

Start

+

-

Drive

Logic

+

PWM

-

DR

+

E.A.

-

EN/MODE

Logic

Internal Slope

Compensation

OSC

OVP

FB

EN/MODE

COMP

AGND

PGND

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

9

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

7.3 Feature Description

7.3.1 True Shutdown

The LM3017 incorporates circuitry to control a high side NMOS transistor in series with the inductor. This feature

is used to disconnect the load from the input supply and protect the system from shorts on the output. Using an

NMOS, rather than a PMOS transistor, saves the use of a diode from the inductor to ground. When the NMOS is

turned off, the inductor brings the source belowground, keeping it on until the current is safely brought to zero. A

built-in charge pump supplies typically VIN+ 5 V to drive the gate of this NMOS.

7.3.2 Operation of the EN/MODE Pin

The EN/MODE pin is used to control the modes of the regulator by driving the high side gate (VG pin) to enable

or disable the output through the pass MOSFET. Furthermore, it defines the current limit for each operation

mode (see Device Functional Modes). Table 1 shows the modes versus the voltage on the EN/MODE pin.

Table 1. EN/MODE Voltage

EN/MODE PIN VOLTAGE

MODE

≤ 0.4 V

Shutdown

1.6 V to 2.2 V

Boost

≥ 2.6 V

Pass-through

Figure 13 shows the output voltage behavior in the various operation modes.

7.3.3 EN/MODE Control

As stated previously, the EN/MODE pin controls the state of the LM3017. As with any digital input, the voltage on

this pin must not be allowed to slowly cross the various thresholds. Although hysteresis is used on this input,

slowly varying signal may cause unpredictable behavior. Also, the EN/MODE pin must not be allowed to float.

One way to control the LM3017, from digital logic, is to use the circuit shown in Figure 14. The resistor values

are adjusted based on the above table and the logic supply used. The MOSFET can be any small signal device,

such as the 2N7002.

10

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

EN/MODE

> 2.6V

1.6V < EN/MODE 450 µs the pass FET is latched off. In this way, the current is limited to VSC / Rsen until the short is removed

or the time of TSC = 450 µs is completed. Pulling the EN/MODE pin low (< 0.4 V, typical) is required to reset this

short-circuit latch-off mode. The delay of TSC = 450 µs helps to prevent nuisance latch-off during a momentary

short on the output.

7.4 Device Functional Modes

7.4.1 Shutdown Mode

Pulling the EN/MODE pin to less than 0.4 V (typical), during any mode of operation, places the part in full

shutdown mode. The boost regulator and the pass FET is off and the load is disconnected from the input supply.

In this mode, the regulator draws a maximum of 1 µA from the input supply.

7.4.2 Boost Mode

The boost regulator can be turned on by bringing the EN/MODE pin to greater than 1.6 V, but less than 2.2 V.

This is the run mode for the boost regulator. Note that the LM3017 always starts in pass-through and transitions

to boost mode.

7.4.3 Standby Mode

Setting the EN/MODE pin to greater than 2.6 V (typical), places the part in pass-through mode. The boost

regulator is off and the pass MOSFET is on. During this mode, the load is connected to the input supply through

the inductor and power diode, and is fully protected from output short circuits.

7.4.4 Start-Up Boost Mode

During start-up in boost mode, peak inductor current may be higher compared to normal operation. To allow for

this, current limit levels and timing are different during start-up. The current limit is defined by VLIM2 = 100 mV

(typical) in Electrical Characteristics, for the first TLIM2 = 3.6 ms (typical). The current is limited to VLIM2 / RSEN, for

this period. Once the TLIM2 = 3.6 ms (typical) timer has finished, the current limit is increased to VSC = 200 mV

(typical). For the first TLIM2 = 3.6 ms (typical) of the start-up, the latch-off feature is not enabled; however, the

current is always limited to VLIM2 / RSEN. This allows the part to start up normally. If the current limit is still tripped

at the end of TLIM2 = 3.6 ms (typical) , the TSC = 900 µs (typical) timer is started. Once the TSC = 900 µs (typical)

time has expired, the pass FET (Q2) is latched off. This gives a total current-limited time of TSC + TLIM2 = 4.05 ms

(typical), in cases where the LM3017 is started into a short circuit at the output.

7.4.5 Pass-Through Mode

In pass-through mode the power path is protected from shorts and overloads by the current limit defined as

VLIM1 = 85 mV (typical) in Electrical Characteristics. When this current limit is tripped, the current is limited to

VLIM1 / RSEN by controlling the pass FET. If the short persists for TLIM1 > 900 µs (typical) the pass FET (Q2) is

latched off. In this way, the current is limited to VLIM1 / RSEN until the short is removed or the time of

TLIM1 = 900 µs (typical) is completed. Pulling the EN/MODE pin low (0.4 V, typical) is required to reset this latchoff mode.

12

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

Device Functional Modes (continued)

7.4.6 Start-Up Pass-Through Mode

During start-up in pass mode, the current limit is defined by VLIM2 = 100 mV (typical) in Electrical Characteristics,

for the first TLIM2 = 3.6 ms (typical). The current is limited to VLIM2 / RSEN, for this period. Once the TLIM2 = 3.6 ms

(typical) timer has finished, the current limit is reduced to VLIM1 = 85 mV (typical). For the first TLIM2 = 3.6 ms

(typical) of the start-up, the latch-off feature is not enabled; however, the current is always limited to VLIM2 / RSEN.

This higher limit allows the part to start up normally. If the current limit is still tripped at the end of TLIM2 = 3.6 ms

(typical), the TLIM1 = 900 µs (typical) timer is started. Once the TLIM1= 900 µs time has expired, the pass FET(Q2)

is latched off. This gives a total current-limited time of TLIM1+ TLIM2 = 4.5 ms (typical), in cases where the LM3017

is started into a short circuit at the output.

Figure 15. Current Limit and Short-Circuit Protection

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

13

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM3017 may be operated in either continuous or discontinuous conduction mode. The following descriptions

assume continuous conduction operation (CCM). This mode of operation has higher efficiency and lower EMI

characteristics than the discontinuous mode.

8.2 Typical Application

VIN = 8V to 12V

L1

RSEN

D1

Q2

VOUT = 15V@1A

RS

EN/MODE

U1

ISEN

RFBT

VG

EN/MODE

CIN1

VIN

CO1

Q1

DR

CO2

CO3

VCC LM3017

COMP

CBYP

CVCC

CCOMP2

RCOMP

PGND

FB

AGND

RFBB

CCOMP

GND

GND

Copyright © 2016, Texas Instruments Incorporated

Figure 16. 1-A High Efficiency Step-Up (Boost) Converter

8.2.1 Design Requirements

To properly size the components for the application, the designer requires the following parameters: Input

voltage range, output voltage, output current, and switching frequency. These four main parameters affect the

choices of component available to achieve a proper system behavior.

Table 2 lists the design parameters for this application example.

Table 2. Design Parameters

PARAMETER

VALUE

Input voltage, VIN

8 V to 12 V

Output voltage, VOUT

15 V

Output current, IOUT

1A

Switching frequency, fS

600 kHz

8.2.2 Detailed Design Procedure

The most common topology for the LM3017 is the boost or step-up topology. The boost converter converts a low

input voltage into a higher output voltage. The basic configuration for a boost regulator is shown in Figure 17. In

continuous conduction mode (when the inductor current never reaches zero at steady state), the boost regulator

operates in two cycles. In the first cycle of operation, MOSFET Q is turned on and energy is stored in the

inductor. During this cycle, diode D1 is reverse biased and load current is supplied by the output capacitor,

COUT.

14

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

In the second cycle, MOSFET Q is off and the diode is forward biased. The energy stored in the inductor is

transferred to the load and output capacitor. The ratio of these two cycles determines the output voltage. The

output voltage is defined with Equation 1.

V

V

VOUT = IN ; D = 1 - IN

1- D

VOUT

(1)

Including the voltage drop of the diode in Equation 2.

V

- VIN + VD1

V

VOUT +VD1 = IN ; D = OUT

1- D

VOUT + VD1

where

•

•

D is the duty cycle of the switch

VD1 is the forward voltage drop of the diode

(2)

The following sections describe selection of components for a boost converter.

L

VIN

D1

+

+

Q

PWM

(a)

L

VOUT

COUT

VOUT

+

+

COUT

-

VIN

+

RLOAD

-

(b)

L

+

-

VIN

D1

VOUT

+

COUT

+

RLOAD

-

Figure 17. 4 Simplified Boost Converter Diagram

(a) First Cycle of Operation, (b) Second Cycle of Operation

8.2.2.1 Programming the Output Voltage

The output voltage can be programmed using a resistor divider between the output and the feedback pins, as

shown in Figure 20. The resistors are selected such that the voltage at the feedback pin is equal to VFB (see

Electrical Characteristics). RFBT and RFBB can be selected using Equation 3.

æ R

VOUT = VFB ´ ç 1 + FBT

ç R

FBB

è

ö

÷

÷

ø

(3)

25

MAXIMUM OUTPUT VOLTAGE (V)

MAXIMUM OUTPUT VOLTAGE (V)

140

120

100

80

60

40

20

20

15

10

5

5 6

7

8

9 10 11 12 13 14 15 16 17 18

5 6

INPUT VOLTAGE (V)

7

8

9 10 11 12 13 14 15 16 17 18

INPUT VOLTAGE (V)

Figure 18. Maximum Output Voltage

Figure 19. Minimum Output Voltage

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

15

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

Figure 18 shows maximum regulated output voltage based on maximum duty cycle value of 85% and by

assuming a voltage drop on the output diode of 0.5 V and 90% efficiency. Figure 19 shows the minimum

regulated output voltage, the calculation is based on minimum on time of 126 ns (typical) that generates a

minimum duty cycle equal to Equation 4.

DMIN = tON(min) × fS = 0.076

where

•

fS is the switching frequency and it's equal to 600 kHz and by assuming 90% efficiency

(4)

8.2.2.2 Power Inductor Selection

The inductor is one of the two energy storage elements in a boost converter.

Choose the minimum IOUT to determine the minimum inductance L. A common choice is to set (2 x ΔiL) from 30%

to 50% of IL. Choosing an appropriate core size for the inductor involves calculating the average and peak

currents expected through the inductor. In a boost converter the inductor current IL, the peak of the inductor

current and the inductor current ripple ΔiL are equal to Equation 5.

I

IL = OUT

1- D

ILpeak = IL (max) + DiL (max)

D ´ VIN

DiL =

2 ´ L ´ fS

(5)

The inductance used is a tradeoff between size and cost. Larger inductance means lower input ripple current;

however, because the inductor is connected to the output during the off-time only, there is a limit to the reduction

in output voltage ripple. Lower inductance results in smaller, less expensive magnetics.

All the analysis in this data sheet assumes operation in continuous conduction mode. To operate in continuous

conduction mode, the conditions in Equation 6 must be met.

IL = DiL

IOUT

D ´ VIN

=

1 - D 2 ´ fS ´ L

L³

(1 - D )´ D ´ VIN

2 ´ fS ´ IOUT

(6)

A core size with ratings higher than these values must be chosen. If the core is not properly rated, saturation

dramatically reduces overall efficiency or damage the power stage. Choose an inductor with a saturation current

value higher than ILpeak. The LM3017 senses the peak current through the switch. The peak current through the

switch is the same as the peak current calculated in the previous equation.

Losses due to DCR of the inductance can be easily calculated with Equation 7.

2

éæ I

Di2 ù

ö

PL = DCR ´ êç OUT ÷ + L ú

12 ú

êè 1 - D ø

ë

û

(7)

No core losses are considered.

16

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

8.2.2.3 Setting the Output Current

The maximum amount of current that can be delivered at the output can be controlled by the sense resistor,

RSEN. Current limit occurs when the voltage that is generated across the sense resistor equals the current sense

threshold voltage, VSENSE. Limits for VSENSE are specified in Electrical Characteristics. This is expressed with

Equation 8.

Isw(peak) × RSEN = VSENSE

(8)

The peak current through the switch is equal to the peak inductor current in Equation 9.

Isw(peak) = IL(max) + ΔiL

(9)

Therefore for a boost converter in Equation 10.

I

D ´ VIN

= OUT +

ISW

peak

1 - D 2 ´ fS ´ L

(10)

Combining the two equations yields an expression for RSEN and includes a 20% margin on the peak of the

switching current with Equation 11.

VSENSE

RSEN =

æI

D ´ VIN ö

1.2 ´ ç OUT +

÷

è 1 - D 2 ´ fS ´ L ø

(11)

Evaluate RSEN at the maximum and minimum VIN values and choose the smallest RSEN calculated.

VIN

RSEN

L1

Q2

D1

VOUT

+

ISEN

VG

DR

Q1

COUT

RFBT

LM3017

FB

RFBB

Copyright © 2016, Texas Instruments Incorporated

Figure 20. Adjusting the Output Voltage

8.2.2.4 Additional Slope Compensation

It is good design practice to only add as much slope compensation as required to avoid instability. Additional

slope compensation (see Figure 24) minimizes the influence of the sensed current in the control loop. With very

large slope compensation the control loop characteristics are similar to a voltage mode regulator which compares

the error voltage to a saw tooth waveform rather than the inductor current. It is possible to calculate the minimum

value of RS to meet Equation 12.

MC > M2/2

(12)

Hence Equation 13,

RS ³

ù

1 é RSEN ´ (VOUT - VIN (min) )

´ê

- VSL ú

K ëê

2 ´ L ´ fS

ûú

where

•

K = 40 µA

(13)

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

17

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

If the result of the previous equation is negative, it means that no additional slope compensation is required. TI

recommends a 100-Ω resistor.

8.2.2.5 Current Limit With Additional Slope Compensation

If an external slope compensation resistor is used, then the internal control signal is modified and this has an

effect on the current limit.

If RS is used, then this adds to the existing slope compensation. The command voltage, VCS, is then given by

Equation 14.

VCS = VSL + ΔVSL

where

•

•

•

VSENSE is a defined parameter in Electrical Characteristics

VSL is the amplitude of the internal compensation ramp

ΔVSL = RS x K is the additional slope compensation generated

(14)

This changes the equation for RSEN to Equation 15.

V

- D ´ VCS

RSEN = SENSE

æ IOUT

D ´ VIN ö

+

ç

÷

è 1 - D 2 ´ fS ´ L ø

(15)

Because ΔVSL = RS × K as defined earlier, RS can be used to provide an additional method for setting the current

limit. In some designs RS can also be used to help filter noise to keep the ISEN pin quiet. Dissipation due to RSEN

resistor is equal to Equation 16.

2

2 ù

éæ I

DiLpp

ö

ú

PSEN = RSEN ´ êç OUT ÷ +

12 ú

êè 1 - D ø

ë

û

(16)

8.2.2.6 Power Diode Selection

Observation of the boost converter circuit shows that the average current through the diode is the average output

current, and the peak current through the diode is the peak current through the inductor. The peak diode current

can be calculated using Equation 17.

ID(Peak) = [IOUT / (1 − D)] + ΔiL

(17)

The peak reverse voltage for a boost converter is equal to the regulator output voltage. The diode must be

capable of handling this peak reverse voltage as well as the output rms current. To improve efficiency, TI

recommends a low forward drop Schottky diode due to low forward drop and near-zero reverse recovery time.

The overall efficiency becomes more dependent on the selection of D at low duty cycles, where the boost diode

carries the load current for an increasing percentage of the time. This power dissipation can be calculated by

checking the typical diode forward voltage VD, from the I-V curve on the diode's datasheet and the multiplying it

by IO. Diode data sheets also provides a typical junction-to-ambient thermal resistance, RθJA, which can be used

to estimate the operating die temperature of the Schottky. Multiplying the power dissipation (PD = IO × VD) by

RθJA gives the temperature rise. The diode case size can then be selected to maintain the Schottky diode

temperature below the operational maximum.

8.2.2.7 Low-Side MOSFET Selection (Switching MOSFET)

The drive pin, DR, of the LM3017 must be connected to the gate of an external MOSFET. In a boost topology,

the drain of the external N-Channel MOSFET is connected to the inductor and the source is connected to the

ground. The drive pin voltage, VDR, depends on the input voltage (see Typical Characteristics).

The selected MOSFET directly affects the efficiency. The critical parameters for selection of a MOSFET are:

1. Minimum threshold voltage, VTH(MIN)

2. On-resistance, RDS(ON)

3. Total gate charge, Qg

4. Reverse transfer capacitance, CRSS

5. Maximum drain to source voltage, VDS(MAX)

18

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

The off-state voltage of the MOSFET is approximately equal to the output voltage. VDS(MAX) of the MOSFET must

be greater than the output voltage plus the voltage drop across the output diode (20% margin recommended).

The power losses in the MOSFET can be categorized into conduction losses, gate charging losses and switching

losses. RDS(ON) is required to estimate the conduction losses. The conduction loss, PCOND, is the I2R loss across

the MOSFET. The maximum conduction loss is given by Equation 18 and Equation 19.

2

æ I

ö

PCOND = ç OUT ÷ ´ DMAX ´ RDS(on)

è 1 - DMAX ø

where

•

DMAX is the maximum duty cycle

DMAX = 1 -

(18)

VIN (min)

VOUT

(19)

To consider the increase in MOSFET on resistance due to heating, a factor of 1.3 is introduced, hence

Equation 20.

PCOND_real = PCOND(max) × 1.3

(20)

Gate charging loss, PG, results from the current required to charge and discharge the gate capacitance of the

power MOSFET and is approximated with Equation 21.

PG = VCC × QG fS

(21)

QG is the total gate charge of the MOSFET. Gate charge loss differs from conduction and switching losses

because the actual dissipation occurs in the LM3017 and not in the MOSFET itself. This loss, PVCC, is estimated

with Equation 22.

PVCC = (VIN – VCC) × QG × fS

(22)

The switching losses are very difficult to calculate due to changing parasitics of a given MOSFET in operation.

Often, the individual MOSFET datasheet does not give enough information to yield a useful result. The following

formulas give a rough idea how the switching losses are calculated with Equation 23.

I ´ VOUT

´ fS ´ (tLH + tHL )

PSW = L

2

where

•

tLH and tHL are rise and fall times of the MOSFET

(23)

8.2.2.8 Pass MOSFET Selection (High-Side MOSFET)

The VG pin drives the gate of the high side MOSFET (Pass FET Q2). This requires special considerations. When

the output is shorted, this FET must sustain the full input voltage and the short-circuit current simultaneously.

This is due to the fact that the controller regulates the short-circuit current in a quasi-linear manner, through Q2.

This power pulse only lasts for TLIM2 or TSC, depending on the operational mode. Therefore, the designer must

carefully examine the SOA curve for the desired FET before committing to the design. Equation 24 and

Equation 25 give the maximum energy pulses that Q2 is required to survive.

æV

ö

E1 ³ (Vin + 2 )´ ç LIM2 ÷ ´ TLIM2

è Rsen ø

(24)

æV ö

E2 ³ (Vin + 2 )´ ç SC ÷ ´ TSC

è Rsen ø

(25)

These two energy points must fall within the SOA of the selected FET. In addition, Q2 must have a low threshold

voltage and low RDS(on) for high efficiency. Power dissipation during boost mode is given by Equation 26.

2

2 ù

éæ I

DiLpp

ö

ú

PQ2 = RDS(on) ´ êç OUT ÷ +

12 ú

êè 1 - D ø

ë

û

(26)

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

19

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

8.2.2.9 Input Capacitor Selection

Due to the presence of an inductor at the input of a boost converter, the input current waveform is continuous

and triangular. The inductor ensures that the input capacitor sees fairly low ripple currents. However, as the input

capacitor gets smaller, the input ripple goes up. The rms current in the input capacitor is given by Equation 27.

ICIN (rms) =

DiL

3

=

(VOUT - VIN )´ VIN

12 ´ VOUT ´ fS

(27)

The input capacitor must be capable of handling this rms current. Although the input capacitor is not as critical in

a boost application, low values can cause impedance interactions. Therefore, a good quality capacitor must be

chosen in the range of 10 µF to 20 µF. Furthermore, TI recommends a low-ESR, 0.1-µF ceramic bypass

capacitor to avoid transients and ringing due to parasitics. Bypass capacitors must be placed as close as

possible to the VIN pin and grounded close to the GND pin on the IC to minimize additional ESR and ESL.

Equation 28 can be used to define the input voltage ripple.

æ

ö

1

DVipp = DiLPP ´ ESR2 + ç

÷

´

´

8

f

C

S

i ø

è

2

where

•

•

ΔiLpp = 2 × ΔiL is the peak-to-peak inductor current ripple

ΔVipp is the peak-to-peak input voltage ripple

(28)

Many times it is necessary to use an electrolytic capacitor on the input in parallel with the ceramics. The ESR of

this capacitor can help to damp any ringing on the input supply caused by long power leads.

8.2.2.10 Output Capacitor Selection

The output capacitor in a boost converter provides all the output current when the inductor is charging and it

determines the steady state output voltage ripple ΔVOpp. As a result it sees very large ripple currents. The output

capacitor must be selected based on its capacitance CO, its equivalent series resistance ESR and its RMS

current rating. The rms current in the output capacitor is calculated with Equation 29.

é

DiL2 úù

D

2

IC OUT (rms) = (1 - D) ´ êIOUT

´

+

ê

(1 - D )2 3 úû

ë

where

•

•

ΔiL is the inductor ripple current

D is the duty cycle

(29)

The magnitude of the output voltage ripple during the on-time is equal to the ripple voltage during the off-time

and it is composed of two parts. For simplicity, the analysis is performed for off-time only.

The first part of the ripple voltage is the surge created as the output diode D turns on. At this point inductor or

diode current is at the peak value, and the ripple voltage increase can be calculated with Equation 30.

ΔVO1 = IPK × ESR

where

•

IPK = IOUT / (1 − D)

(30)

The second portion of the ripple voltage is the increase due to the charging of CO through the output diode. This

portion can be approximated with Equation 31.

ΔVO2 = (IO / CO) × (D / fS)

(31)

Equation 32 can be used to define the output voltage ripple.

´D

æI

ö I

DVOpp = ESR ´ ç OUT + DiL ÷ + OUT

1

D

C

´

è

ø

o fS

20

(32)

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

The ESR of the output capacitor(s) has a strong influence on the slope and direction of the output voltage ripple.

Capacitors with high ESR such as tantalum and aluminum electrolytic create an output voltage ripple that is

dominated by ΔVO1 with a shape shown in Figure 21. Ceramic capacitors, in contrast, have a very low ESR and

lower capacitance, and the shape of the output voltage ripple is dominated by ΔVO2 with a shape shown in

Figure 22.

PsOpp

VOUT

VOUT

PsOpp

ID

ID

Figure 21. ΔVOpp Using High ESR Capacitors

Figure 22. ΔVOpp Using Low ESR Capacitors

Ceramic capacitors are recommended with a typical value from 10 µF to 100 µF. The minimum quality dielectric

that is suitable for switching power supply output capacitors is X5R, while X7R (or better) is preferred. Careful

attention must be paid to the DC voltage rating and case size, as ceramic capacitors can lose 60% or more of

their rated capacitance at the maximum DC voltage. This is the reason that ceramic capacitors often derate to

50% of their capacitance at their working voltage.

8.2.2.11 VCC Decoupling Capacitor

The internal bias of the LM3017 comes from either the internal bias voltage generator as shown in the block

diagram or directly from the voltage at the VIN pin. At input voltages lower than 6 V, the internal IC bias is the

input voltage and at voltages above 6 V the internal bias voltage generator of the LM3017 provides the bias. A

good quality ceramic bypass capacitor must be connected from the VCC pin to the PGND pin for proper

operation. This capacitor supplies the transient current required by the internal MOSFET driver, as well as

filtering the internal supply voltage for the controller. TI recommends a value of between 0.47 µF and 4.7 µF.

8.2.2.12 Slope Compensation Ramp

The LM3017 uses a current mode control scheme. The main advantages of current mode control are inherent

cycle-by-cycle current limit for the switch, simpler control loop characteristics and excellent line and load transient

response. However, there is a natural instability due to subharmornic oscillations that occurs for duty cycles, D,

greater than 50% if slope compensation is not addressed in Equation 33.

MC > M2 / 2

(33)

For best input noise immunity, use Equation 34.

MC = M2

(34)

For best sub-harmonic suppression, use Equation 35.

MC = M2 / 2

where

•

•

•

•

•

•

•

MC is the slope of the compensation ramp

M1 is the slope of the inductor current during the ON time

M2 is the slope of the inductor current during the OFF time

RSEN is the sensing resistor value

VOUT represents the output voltage

VIN represents the input voltage

A is equal to 0.86 and it is the internal sensing amplification of the LM3017

(35)

In the case of the boost topology, use Equation 36 and Equation 37.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

21

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

M1 = [VIN / L] × RSEN × A

M2 = [(VOUT – VIN) / L] × RSEN × A

(36)

(37)

The compensation ramp is added internally in the LM3017. The slope of this compensation ramp is selected to

satisfy most applications, and its value depends on the switching frequency. This slope can be calculated using

Equation 38.

MC = VSL × fS

(38)

In the above equation, VSL is the amplitude of the internal compensation ramp and fS is the controller's switching

frequency. Limits for VSL are specified in Electrical Characteristics.

To provide the user additional flexibility, a patented scheme is implemented inside the IC to increase the slope of

the compensation ramp externally, if the requirement arises. Adding a single external resistor, RS (as shown in

Figure 24) increases the amplitude of the compensation ramp as shown in Figure 23 where Equation 39.

Control Signal

Compensation Ramp

with RSL

Control Signal

Compensation Ramp

without RSL

'VSL

-MC

VSL

Figure 23. Additional Slope Compensation Added Using External Resistor RS

ΔVSL = K × Rs

where

•

K = 40 µA typically and changes slightly as the switching frequency changes

(39)

A more general equation for the slope compensation ramp, MC, is shown in Equation 40 to include ΔVSL caused

by the resistor, Rs.

MC = (VSL + ΔVSL) × fs

(40)

VIN

L1

Q2

RSEN

CS

RS

ISEN

VG

DR

LM3017

Copyright © 2016, Texas Instruments Incorporated

Figure 24. Increasing the Slope of the Compensation Ramp

An additional capacitor, CS, could be added if the sensing signal generated by RSEN is very noisy (parasitic circuit

capacitance, inductance, and gate drive current create a spike in the current sense voltage at the point where Q1

turns on). The time constant RSEN x CS must be long enough to reduce the parasitics spike without significantly

affecting the shape of the actual current sense voltage (a typical range is from 100 pF to 2.2 nF).

22

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

8.2.2.13 Control Loop Compensation

The LM3017 uses peak current-mode PWM control to correct changes in output voltage due to line and load

transients. Peak current-mode provides inherent cycle-by-cycle current limiting, improved line transient response,

and easier control loop compensation. The control loop is comprised of two parts. The first is the power stage,

which consists of the pulse width modulator, output filter, and the load. The second part is the error amplifier.

Figure 25 shows the regulator control loop components.

L

RSEN

+

D

VIN

CO

RO

+

ESR

RFBT

-

+

A

+

-

Current

Sense

Amp.

+

CCOMP

CCOMP2

RFBB

+ V

REF

-

RCOMP

Figure 25. Power Stage and Error Amp

The power stage in a CCM peak current mode boost converter consists of the DC gain, GVC0, a single low

frequency pole, fP, the ESR zero, fZ, a right-half plane zero, fR, and a double pole resulting from the sampling of

the peak current. The power stage transfer function (also called the Control-to-Output transfer function) can be

written with Equation 41.

æ

s öæ

s ö

ç1 ÷ ç1 +

÷

w

w

R øè

Z ø

GVC (s) = GVC0 ´ è

æ

s öæ

s

s2

+ 2

ç1 +

÷ çç 1 +

wP ø è

wn wn

è

ö

÷

÷

ø

(41)

The DC gain is defined with Equation 42.

RO (1 - D)

GVC0 =

2 ´ A ´ RSEN

where

•

RO = VOUT / IOUT

(42)

In the equation for GVC0, DC gain is highest when input voltage and output current are at the maximum. The

system ESR zero is defined with Equation 43.

wZ

1

=

fZ =

2p 2p ´ CO ´ ESR

(43)

The low frequency pole is Equation 44.

w

2

fP = P =

2p 2p ´ CO ´ (ESR + RO )

(44)

The right-half plane zero is Equation 45.

2

RO ´ (1 - D )

w

fR = R =

2p

2p ´ L

(45)

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

23

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

The sampling double pole quality factor is Equation 46.

1

Qn =

é

ù

æ M ö

p ´ ê(1 - D )´ ç 1 + C ÷ - 0.5 ú

M1 ø

è

ëê

ûú

(46)

The sampling double corner frequency is Equation 47.

ωn = π × fS

(47)

The natural inductor current slope is Equation 48.

M1 = RSEN × VIN / L

(48)

The external ramp slope is Equation 49.

MC = (VSL + ΔVSL) × fS

(49)

A step-up converter produces an undesirable right-half plane zero in the regulation feedback loop. This requires

compensating the regulator such that the crossover frequency occurs well below the frequency of the right-half

plane zero

8.2.2.13.1 Compensation Network Components Calculations

As shown in Figure 25, the LM3017 uses a compensation network base on a transconductance amplifier. The

closed-loop transfer function is defined with Equation 50 through Equation 54.

T(s) = GVA(s) × GVC(s)

where

•

GVA(s) is the transfer function implemented by the compensation network

(50)

æ

s ö

wP1 ç 1 +

÷

wZ1 ø

è

GVA (s) =

æ

s ö

s ç1 +

÷

wP2 ø

è

(51)

1

=

CCOMP ´ RCOMP

(52)

RFBB

Gm ´

RFBB + RFBT

=

CCOMP + CCOMP2

(53)

CCOMP + CCOMP2

=

CCOMP ´ CCOMP2 ´ RCOMP

(54)

wZ1

wP1

wP2

To stabilize the regulator, ensure that the regulator crossover frequency is less than or equal to one-fifth of the

right-half plane zero with Equation 55.

f

fC £ R

5

(55)

To determine the crossover frequency it is important to note that, at that frequency, the compensation impedance

(ZCOMP) is dominated by a resistor, and the output impedance (ZOUT) is dominated by the impedance of an output

capacitor. Therefore, when solving for the crossover frequency, the equation (by definition of the crossover

frequency) of the loop gain is simplified to Equation 56.

V

V

1

1

| T |= FB ´ IN ´ Gm ´

´ RCOMP ´

=1

VOUT VOUT

2p ´ fC ´ CO

A ´ RSEN

where

•

•

•

•

24

|T| is the loop gain magnitude

VFB is feedback voltage, 1.275 V

VOUT is the output voltage

VIN is the input voltage

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

•

•

•

•

•

Gm is the error amplifier transconductance

ZCOMP is the impedance of the compensation network from the COMP pin to ground

RSEN is the current sensing resistor

A is equal to 0.86 and it is the internal sensing amplification of the LM3017

CO is the output capacitor value

(56)

Solve for RCOMP with Equation 57.

RCOMP =

2

2p ´ fC ´ CO ´ VOUT

´ A ´ RSEN

VFB ´ VIN ´ Gm

(57)

Once the compensation resistor is known, set the zero formed by the compensation capacitor and resistor to

one-fourth of the crossover frequency in Equation 58.

2

CCOMP =

p ´ fC ´ RCOMP

where

•

CCOMP is the compensation capacitor

(58)

The high-frequency capacitor CCOMP2, is chosen to cancel the zero introduced by output capacitance ESR with

Equation 59.

ESR ´ CO

CCOMP2 =

RCOMP

(59)

For optimal transient performance, RCOMP and CCOMP might require adjustment by observing the load transient

response.

For detailed explanation on how to select the right compensation components for a boost topology, see AN-1286

Compensation for the LM3478 Boost Controller (SNVA067), and AN-1994 Modeling and Design of Current Mode

Control Boost Converters (SNVA408).

8.2.2.13.2 Compensation Design Example

Table 3 lists the design parameters for this application example to calculate the compensation network.

Table 3. Design Parameters

PARAMETER

VALUE

Input voltage, VIN

8 V to 12 V

Output voltage, VOUT

15 V

Output current, IOUT

1A

Switching frequency, fS

600 kHz

Duty cycle, D

(considering losses)

0.223 with VIN = 12 V

Right-half plane zero, fR

0.482 with VIN = 8 V

136.187 kHz when VIN = 8 V

206.421 kHz when VIN = 12 V

Inductor, L

4.7 µH

Output capacitance, CO

(considering derating due to

applied voltage)

33 µF

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

25

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

space

VIN = 8 V, VOUT = 15 V, IOUT = 1 A

Figure 26. Control-to-Output Transfer Function

GVC(s) Bode Plot

Choose the crossover frequency with Equation 60.

fC = 20 kHz = fS / 20 fR / 5

(60)

Table 4. Calculated Compensation Network Components

PARAMETER

CALCULATED VALUE

ACTUAL VALUE

RCOMP

3.42 kΩ

3.4 kΩ

CCOMP

9.306 nF

10 nF

CCOMP2

96.48 pF

100 pF

space

VIN = 8 V, VOUT = 15 V, IOUT = 1 A

VIN = 8 V, VOUT = 15 V, IOUT = 1 A

Figure 27. GVC(s) and Compensation Network

GVA(s) Bode Plots

Figure 28. Closed-Loop Bode Plot T(s)

Table 5. Bill of Materials (BOM) for LM3017

DESIGNATION

DESCRIPTION

SIZE

MANUFACTURER PART #

VENDOR

CIN1

Cap 22 µF, 25 V X5R

1206

GRM31CR61E226KE15L

Murata

CO1,CO2, CO3

Cap 22 µF, 25 V X5R

1206

GRM31CR61E226KE15L

Murata

CCOMP

Cap 0.022 µF

0603

C0603C103J1RACTU

Kemet

CCOMP2

Cap 1000 pF

0603

C1608C0G1H101J

TDK

CBYP

Cap 0.1 µF, 25 V X7R

0603

06033C104KAT2A

AVX

CVCC

Cap 0.47 µF, 16 V X7R

0805

C2012X7R1C474K

TDK

RCOMP

RES, 3.4 kΩ, 1%, 0.1W

0603

CRCW06033K40FKEA

Vishay

26

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

Table 5. Bill of Materials (BOM) for LM3017 (continued)

DESIGNATION

DESCRIPTION

SIZE

MANUFACTURER PART #

VENDOR

RFBT

RES, 21.5 kΩ, 1%, 0.1W

0603

CRCW060321K5FKEA

Vishay

RFBB

RES, 2 kΩ, 1%, 0.1W

0603

CRCW06032K00FKEA

Vishay

RS

RES, 100 Ω, 1%, 0.1W

0603

CRCW0603100RFKEA

Vishay

RSEN

RES, 0.03 Ω, 1%, 1W

1206

WSLP1206R0300FEA

Vishay

Q1

NexFET™ N-CH, 25 V, 60 A, RDS(on)= 4.4 mΩ

8-SON

CSD16323Q3

TI

Q2

NexFET™ N-CH, 25 V, 60 A, RDS(on)= 4.3 mΩ

8-SON

CSD16340Q3

TI

D1

Diode Schottky, 30 V, 2 A

SMB

20BQ030TRPBF

Vishay

L1

Shielded Inductor, 4.7 µH, 2.3 A

4 mm L × 4 mm W × 1.85 mm H

MPI4040R3-4R7-R

Cooper

U1

LM3017

—

—

TI

8.2.3 Application Curve

Figure 29. Switch Node and Output Voltage Ripple

With 5.5 VIN and 15 V at 1-A Output

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

27

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

9 Power Supply Recommendations

The LM3017 is designed to operate from an input voltage supply range from 5 V to 18 V. This input supply must

be able to withstand the maximum input current and maintain a voltage above 5 V. In cases where input supply

is placed farther away (more than a few inches) from LM3017, additional bulk capacitance may be required in

addition to the ceramic bypass capacitors.

10 Layout

10.1 Layout Guidelines

Good board layout is critical for switching controllers such as the LM3017. First the ground plane area must be

sufficient for thermal dissipation purposes and second, appropriate guidelines must be followed to reduce the

effects of switching noise. Switch mode converters are very fast switching devices. In such devices, the rapid

increase of input current combined with the parasitic trace inductance generates unwanted voltage noise spikes.

The magnitude of this noise tends to increase as the output current increases. This parasitic spike noise may

create electromagnetic interference (EMI), and can also cause problems in device performance. Therefore, take

care in layout to minimize the effect of this switching noise.

10.1.1 Filter Capacitors

Ceramic filter capacitors are most effective when the inductance of the current loops that they filter is minimized.

Place CBYP as close as possible to the VIN and GND pins of the LM3017. Place CVCC next to the VCC and GND

pins of the LM3017 (see Figure 16 for designators).

10.1.2 Sense Lines

The current sensing circuit in current mode devices can be easily effected by switching noise. This noise can

cause duty cycle jitter which leads to increased spectral noise. RSEN must be connected to the ISEN pin with a

separate trace made as short as possible, TI also recommends to route the trace that connects the VIN pin to

the input voltage as close as possible to RSEN. Route this trace away from the inductor and the switch node

(where D1, Q1, and L1 connect). For the voltage loop, keep RFBB/T close to the LM3017 and run a trace as close

as possible to the positive side of CO. As with the ISEN line, the FB line must be routed away from the inductor

and the switch node. These measures minimize the length of high impedance lines and reduce noise pickup.

10.1.3 Compact Layout

The most important layout rule is to keep the AC current loops as small as possible. Figure 30 shows the current

flow of a boost converter. The top schematic shows a dotted line which represents the current flow during onstate and the middle schematic shows the current flow during off-state. The bottom schematic shows the currents

referred to as AC currents. They are the most critical ones because current is changing in very short time

periods. The dotted line traces of the bottom schematic are the ones to make as short as possible. In a boost

regulator the primary switching loop consists of the output capacitor, diode and MOSFET. Minimizing the area of

this loop reduces the stray inductances and minimizes noise and possible erratic operation (see Layout

Examples). The output capacitor(s) must be placed as close as possible to the diode cathode and MOSFET

GND.

28

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

Layout Guidelines (continued)

Figure 30. Current Flow in a Boost Application

10.1.4 Ground Plane and Vias

A ground plane in the printed-circuit board is recommended as a means to connect the quiet end (input voltage

ground side) of the input filter capacitor to the output filter capacitors and the PGND pin of the controller. Connect

all the low power ground connections directly to the regulator AGND. Connect the AGND and PGND pins

together through a copper area covering the entire underside of the device. Place several vias in this underside

copper area to ground plane. If a via is required to connect the sensing resistor to the ISEN pin, then place that

via in the inner side of the sensing resistor such that no current flow occurs. Place several vias from the ground

side of the output capacitor(s) to ground place, that minimizes the path for AC current. The PGND and AGND

pins have to be connected to the same ground very close to the IC. To avoid ground loop currents attach all the

grounds of the system only at one point.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

29

�LM3017

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

www.ti.com

10.2 Layout Examples

Figure 31. Layout Example (a) Top Layer, (b) Bottom Layer

10.3 Thermal Considerations

The majority of power dissipation and heat generation comes from FETs and diode. Selecting MOSFETs with

exposed pads aids the power dissipation of these devices. Careful attention to RDS(on) at high temperature

must be observed. Diode data sheets provide a typical junction-to-ambient thermal resistance RθJA, which can be

used to estimate the operating die temperature of the Schottky. Multiplying the power dissipation by RθJA gives

the temperature rise. The diode case size can then be selected to maintain the Schottky diode temperature

below the operational maximum. Larger case sizes generally have lower RθJA and lower forward voltage drop.

30

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

�LM3017

www.ti.com

SNOSC66D – MARCH 2012 – REVISED SEPTEMBER 2016

11 Device and Documentation Support

11.1 Documentation Support

11.1.1 Related Documentation

For related documentation see the following:

• AN-1286 Compensation for the LM3478 Boost Controller (SNVA067)

• AN-1994 Modeling and Design of Current Mode Control Boost Converters (SNVA408)

11.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

11.4 Trademarks

E2E is a trademark of Texas Instruments.

Thunderbolt is a trademark of Intel Corporation.

All other trademarks are the property of their respective owners.

11.5 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LM3017

31

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

LM3017LE/NOPB

ACTIVE

WQFN

NKL

10

1000

RoHS & Green

SN

Level-3-260C-168 HR

-40 to 125

SK6B

LM3017LEX/NOPB

ACTIVE

WQFN

NKL

10

4500

RoHS & Green

SN

Level-3-260C-168 HR

-40 to 125

SK6B

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.