Sample &

Buy

Product

Folder

Technical

Documents

Support &

Community

Tools &

Software

LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

LM3410, LM3410-Q1 525-kHz and 1.6-MHz, Constant-Current Boost and SEPIC LED Driver

With Internal Compensation

1 Features

3 Description

•

•

The LM3410 and LM3410-Q1 constant current LED

driver are a monolithic, high frequency, PWM DC-DC

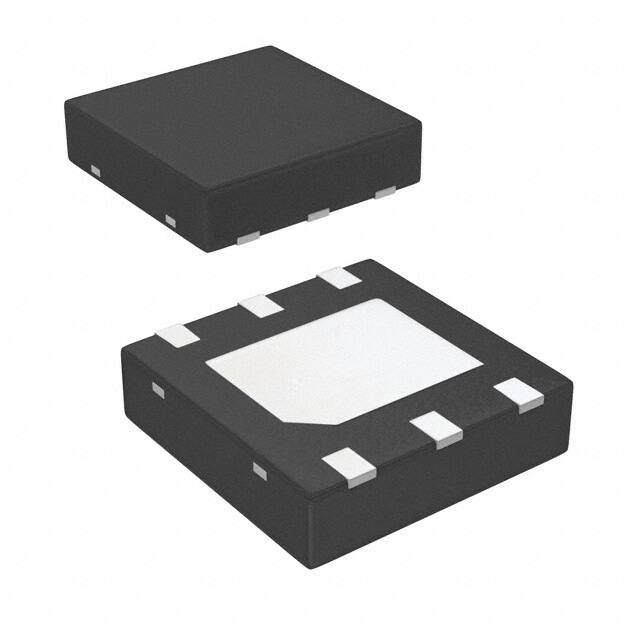

converter, available in 6-pin WSON, 8-pin MSOPPowerPad™, and 5-pin SOT-23 packages. With a

minimum of external components the LM3410 and

LM3410-Q1 are easy to use. It can drive 2.8-A

(typical) peak currents with an internal 170-mΩ

NMOS switch. Switching frequency is internally set to

either 525 kHz or 1.6 MHz, allowing the use of

extremely small surface mount inductors and chip

capacitors. Even though the operating frequency is

high, efficiencies up to 88% are easy to achieve.

External shutdown is included, featuring an ultra-low

standby current of 80 nA. The LM3410 and LM3410Q1 use current-mode control and internal

compensation to provide high-performance over a

wide range of operating conditions. Additional

features include PWM dimming, cycle-by-cycle

current limit, and thermal shutdown.

1

•

•

•

•

•

•

•

•

•

•

Qualified for Automotive Applications

AEC-Q100 Test Guidance With the Following:

– Device Temperature Grade 1: –40°C to 125°C

Ambient Operating Temperature Range

– Device HBM ESD Classification Level 2

– Device CDM ESD Classification Level C6

Space-Saving SOT-23 and WSON Packages

Input Voltage From 2.7 V to 5.5 V

Output Voltage From 3 V to 24 V

2.8-A (Typical) Switch Current Limit

High Switching Frequency

– 525 KHz (LM3410Y)

– 1.6 MHz (LM3410X)

170-mΩ NMOS Switch

190-mV Internal Voltage Reference

Internal Soft Start

Current-Mode, PWM Operation

Thermal Shutdown

PART NUMBER

LM3410,

LM3410Q

2 Applications

•

•

•

•

•

Device Information(1)

LED Backlight Current Sources

LiIon Backlight OLED and HB LED Drivers

Handheld Devices

LED Flash Drivers

Automotive Applications

BODY SIZE (NOM)

3.00 mm × 3.00 mm

MSOP-PowerPAD (8)

2.90 mm × 1.60 mm

SOT-23 (5)

3.00 mm × 3.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Boost Application Circuit

L1

PACKAGE

WSON (6)

Typical Efficiency (LM3410X)

D1

DIMM

4

DIM

5

C1

VIN

L M3410

VIN

3

FB

2

GND

1

LEDs

C2

SW

R1

Copyright © 2016, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

6

Detailed Description .............................................. 8

7.1

7.2

7.3

7.4

8

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Overview ................................................................... 8

Functional Block Diagram ....................................... 10

Feature Description................................................. 10

Device Functional Modes........................................ 10

Application and Implementation ........................ 11

8.1 Application Information............................................ 11

8.2 Typical Applications ................................................ 19

9 Power Supply Recommendations...................... 31

10 Layout................................................................... 32

10.1 Layout Guidelines ................................................. 32

10.2 Layout Examples................................................... 32

10.3 Thermal Considerations ........................................ 33

11 Device and Documentation Support ................. 40

11.1

11.2

11.3

11.4

11.5

11.6

11.7

11.8

Device Support......................................................

Documentation Support ........................................

Related Links ........................................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

40

41

41

41

41

41

41

41

12 Mechanical, Packaging, and Orderable

Information ........................................................... 42

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision G (April 2013) to Revision H

Page

•

Added Device Information table, ESD Ratings table, Thermal Information table, Detailed Description section,

Feature Description section, Device Functional Modes section, Application and Implementation section, Typical

Application section, Power Supply Recommendations section, Layout section, Device and Documentation Support

section, and Mechanical, Packaging, and Orderable Information section.............................................................................. 1

•

Added AEC-Q100 Test Guidance bullets to Features............................................................................................................ 1

•

Changed RθJA value for NGG package from 80°C/W : to 55.3°C/W ...................................................................................... 4

•

Changed RθJA value for DGN package from 80°C/W : to 53.7°C/W ...................................................................................... 4

•

Changed RθJA value for DBV package from 118°C/W : to 164.2°C/W ................................................................................... 4

•

Changed RθJC(top) value for NGG package from 18°C/W : to 65.9°C/W ................................................................................. 4

•

Changed RθJC(top) value for DGN package from 18°C/W : to 61.4°C/W ................................................................................. 4

•

Changed RθJC(top) value for DBV package from 60°C/W : to 115.3°C/W ................................................................................ 4

Changes from Revision F (May 2013) to Revision G

•

2

Page

Changed layout of National Semiconductor Data Sheet to TI format .................................................................................... 1

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

5 Pin Configuration and Functions

NGG Package

6-Pin WSON

Top View

PGND

1

VIN

2

DIM

3

DAP

DGN Package

8-Pin MSOP-PowerPad

Top View

6

SW

5

AGND

4

FB

NC

1

PGND

2

8

NC

7

SW

DAP

VIN

3

6

AGND

DIM

4

5

FB

Not to scale

Not to scale

DBV Package

5-Pin SOT-23

Top View

SW

1

GND

2

FB

3

5

VIN

4

DIM

Not to scale

Pin Functions

PIN

I/O

DESCRIPTION

—

—

Signal ground pin. Place the bottom resistor of the feedback network as close

as possible to this pin and FB.

4

4

I

Dimming and shutdown control input. Logic high enables operation. Duty

Cycle from 0% to 100%. Do not allow this pin to float or be greater than VIN +

0.3 V.

4

5

3

I

Feedback pin. Connect FB to external resistor to set output current.

DAP

DAP

—

—

Die attach pad. Signal and Power ground. Connect to PGND and AGND on

top layer. Place 4 to 6 vias from DAP to bottom layer GND plane.

—

—

2

—

Signal and power ground pin. Place the bottom resistor of the feedback

network as close as possible to this pin.

NC

—

1, 8

—

—

No connection

PGND

1

2

—

—

Power ground pin. Place PGND and output capacitor GND close together.

SW

6

7

1

O

Output switch. Connect to the inductor, output diode.

VIN

2

3

5

I

Supply voltage pin for power stage, and input supply voltage.

NAME

WSON

MSOPPowerPAD

SOT-23

AGND

5

6

DIM

3

FB

GND

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

3

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1) (2)

Input voltage

Operating juction temperature

MIN

MAX

VIN

–0.5

7

SW

–0.5

26.5

FB

–0.5

3

DIM

–0.5

7

(3)

, TJ

Storage temperature, Tstg

(1)

(2)

(3)

–65

UNIT

V

150

°C

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

If Military/Aerospace specified devices are required, please contact the Texas Instruments Sales Office/Distributors for availability and

specifications.

Thermal shutdown occurs if the junction temperature exceeds the maximum junction temperature of the device.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

(1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22-C101 (2)

±1000

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

VIN

MAX

2.7

5.5

V

0

VIN

V

3

24

V

–40

125

°C

400

mW

(1)

VDIM

DIM control input

VSW

Switch output

TJ

Operating junction temperature

Power dissipation (Internal)

(1)

MIN

Input voltage

SOT-23

UNIT

Do not allow this pin to float or be greater than VIN + 0.3 V.

6.4 Thermal Information

LM3410, LM3410-Q1

NGG

(WSON)

DGN

(MSOPPowerPAD)

DBV

(SOT-23)

6 PINS

8 PINS

5 PINS

55.3

53.7

164.2

°C/W

RθJC(top) Junction-to-case (top) thermal resistance

65.9

61.4

115.3

°C/W

RθJB

Junction-to-board thermal resistance

29.6

37.3

27

°C/W

ψJT

Junction-to-top characterization parameter

1.1

7.1

12.8

°C/W

ψJB

Junction-to-board characterization parameter

29.7

37

26.5

°C/W

RθJC(bot) Junction-to-case (bottom) thermal resistance

9.3

6.8

—

°C/W

THERMAL METRIC (1)

RθJA

(1)

4

Junction-to-ambient thermal resistance

0 LFPM Air Flow

UNIT

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

6.5 Electrical Characteristics

Typical values apply for TJ = 25°C; Minimum and maximum limits apply for TJ = –40°C to 125°C and VIN = 5 V (unless

otherwise noted). Typical values represent the most likely parametric norm at TJ = 25°C, and are provided for reference

purposes only.

PARAMETER

TEST CONDITIONS

VFB

Feedback voltage

ΔVFB/VIN

Feedback voltage line regulation

IFB

Feedback input bias current

fSW

Switching frequency

DMAX

Maximum duty cycle

DMIN

Minimum duty cycle

RDS(ON)

Switch on resistance

ICL

Switch current limit

SU

Start-up time

VDIM_H

0.06

0.1

1

1200

1600

2000

LM3410Y

360

525

680

LM3410X

88%

92%

LM3410Y

90%

95%

LM3410X

5%

LM3410Y

2%

MSOP and SOT-23

170

330

WSON

190

350

2.8

Undervoltage lockout

11

LM3410Y, VFB = 0.25 V

3.4

7

80

2.3

VIN falling

1.7

0.4

Enable threshold voltage

1.8

Switch leakage

VSW = 24 V

Dimming pin current

Sink and source

Thermal shutdown temperature

(1)

kHz

mΩ

mA

nA

2.65

1.9

Shutdown threshold voltage

µA

µs

7

VIN rising

mV

A

LM3410X, VFB = 0.25 V

All versions, VDIM = 0 V

UNIT

%/V

LM3410X

IDIM

(1)

202

VIN = 2.7 V to 5.5 V

ISW

TSD

MAX

190

20

Quiescent current (shutdown)

UVLO

TYP

178

2.1

Quiescent current (switching)

IQ

MIN

V

V

1

µA

100

nA

165

°C

Thermal shutdown occurs if the junction temperature exceeds the maximum junction temperature of the device.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

5

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

6.6 Typical Characteristics

All curves taken at VIN = 5 V with the 50-mA boost configuration shown in Figure 18. TJ = 25°C, unless otherwise specified.

RSET = 4 Ω

Figure 1. LM3410X Efficiency vs VIN

500-Hz DIM Frequency

6

Figure 2. LM3410X Start-Up Signature

D = 50%

Figure 3. Four 3.3-V LEDs

Figure 4. DIM Frequency and Duty Cycle vs Average ILED

Figure 5. Current Limit vs Temperature

Figure 6. RDS(ON) vs Temperature

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Typical Characteristics (continued)

All curves taken at VIN = 5 V with the 50-mA boost configuration shown in Figure 18. TJ = 25°C, unless otherwise specified.

LM3410X

LM3410Y

Figure 7. Oscillator Frequency vs Temperature

Figure 8. Oscillator Frequency vs Temperature

Figure 9. VFB vs Temperature

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

7

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

7 Detailed Description

7.1 Overview

The LM3410 and LM3410-Q1 are a constant frequency PWM, boost regulator IC. It delivers a minimum of 2.1-A

peak switch current. The device operates very similar to a voltage regulated boost converter except that the

device regulates the output current that passes through LEDs. The current magnitude is set with a series

resistor. The converter regulates to the feedback voltage (190 mV) created by the multiplication of the series

resistor and the LED current. The regulator has a preset switching frequency of either 525 kHz or 1.6 MHz. This

high frequency allows the LM3410 or LM3410-Q1 to operate with small surface mount capacitors and inductors,

resulting in a DC-DC converter that requires a minimum amount of board space. The LM3410 and LM3410-Q1

are internally compensated and requires few external components, making usage simple. The LM3410 and

LM3410-Q1 use current-mode control to regulate the LED current.

The LM3410 and LM3410-Q1 supply a regulated LED current by switching the internal NMOS control switch at

constant frequency and variable duty cycle. A switching cycle begins at the falling edge of the reset pulse

generated by the internal oscillator. When this pulse goes low, the output control logic turns on the internal

NMOS control switch. During this ON time, the SW pin voltage (VSW) decreases to approximately GND, and the

inductor current (IL) increases with a linear slope. IL is measured by the current sense amplifier, which generates

an output proportional to the switch current. The sensed signal is summed with the regulator’s corrective ramp

and compared to the error amplifier’s output, which is proportional to the difference between the feedback

voltage and reference voltage (VREF). When the PWM comparator output goes high, the output switch turns off

until the next switching cycle begins. During the switch OFF time, inductor current discharges through diode D1,

which forces the SW pin to swing to the output voltage plus the forward voltage (VD) of the diode. The regulator

loop adjusts the duty cycle (D) to maintain a regulated LED current.

IL

L1

Q1

VIN

Control

VO

D1

IC

+

VSW

C 1

I LED

Figure 10. Simplified Boost Topology Schematic

8

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Overview (continued)

V OUT + VD

Vsw ( t)

t

VIN

VL(t)

t

VIN - VOUT - VD

IL (t)

iL

t

I DIODE(t)

t

(

iL - - iOUT )

I Capacitor(t)

t

- i OUT

'v

VOUT(t)

DTS

TS

Figure 11. Typical Waveforms

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

9

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

7.2 Functional Block Diagram

DIM

VIN

ThermalSHDN

Control Logic

+

Ramp

Artificial

UVLO=2.3V

Oscillator

+

-

cv

1. 6 MHz

+

S

R

SW

+

NMOS

+

R

Q

-

VFB

+

VREF = 190 mV

Internal

Compensation

ILIMIT

ISENSE

+

GND

Copyright © 2016, Texas Instruments Incorporated

7.3 Feature Description

7.3.1 Current Limit

The LM3410 and LM3410-Q1 use cycle-by-cycle current limiting to protect the internal NMOS switch. This

current limit does not protect the output from excessive current during an output short circuit. The input supply is

connected to the output by the series connection of an inductor and a diode. If a short circuit is placed on the

output, excessive current can damage both the inductor and diode.

7.3.2 DIM Pin and Shutdown Mode

The average LED current can be controlled using a PWM signal on the DIM pin. The duty cycle can be varied

from 0 to 100%, to either increase or decrease LED brightness. PWM frequencies from 1 Hz to 25 kHz can be

used. For controlling LED currents down to the µA levels, it is best to use a PWM signal frequency from 200 to

1 kHz. The maximum LED current would be achieved using a 100% duty cycle, that is the DIM pin always high.

7.4 Device Functional Modes

7.4.1 Thermal Shutdown

Thermal shutdown limits total power dissipation by turning off the output switch when the IC junction temperature

exceeds 165°C. After thermal shutdown occurs, the output switch does not turn on until the junction temperature

drops to approximately 150°C.

10

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

8.1.1 Boost Converter

8.1.1.1 Setting the LED Current

I LED

V FB

R SET

Figure 12. Setting ILED

The LED current is set using the following equation:

VFB

R SET

= ILED

where

•

RSET is connected between the FB pin and GND.

(1)

8.1.1.2 LED-Drive Capability

When using the LM3410 or LM3410-Q1 in the typical application configuration, with LEDs stacked in series

between the VOUT and FB pin, the maximum number of LEDs that can be placed in series is dependent on the

maximum LED forward voltage (VFMAX).

(VFMAX × NLEDs) + 190 mV < 24 V

(2)

When inserting a value for maximum VFMAX the LED forward voltage variation over the operating temperature

range must be considered.

8.1.1.3 Inductor Selection

The inductor value determines the input ripple current. Lower inductor values decrease the physical size of the

inductor, but increase the input ripple current. An increase in the inductor value decreases the input ripple

current.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

11

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Application Information (continued)

'i L

I L (t)

iL

VIN

L

VIN - VOUT

L

DTS

TS

t

Figure 13. Inductor Current

2'iL § VIN ·

=¨

¸

DTS ¨© L ¹

§ VIN ·

¸¸ x DTS

'iL = ¨¨

© 2L ¹

(3)

The Duty Cycle (D) for a Boost converter can be approximated by using the ratio of output voltage (VOUT) to input

voltage (VIN).

§ 1 ·= 1

=¨

1 - D¸ Dc

VOUT

VIN

¹

©

(4)

Therefore:

VOUT - VIN

D=

VOUT

(5)

Power losses due to the diode (D1) forward voltage drop, the voltage drop across the internal NMOS switch, the

voltage drop across the inductor resistance (RDCR) and switching losses must be included to calculate a more

accurate duty cycle (see Calculating Efficiency and Junction Temperature for a detailed explanation). A more

accurate formula for calculating the conversion ratio is:

V OUT

V IN

=

K

'¶

where

•

η equals the efficiency of the device application.

(6)

Or:

K

12

VOUT u ILED

VIN u IIN

Submit Documentation Feedback

(7)

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Application Information (continued)

Therefore:

VOUT KVIN

VOUT

D

(8)

Inductor ripple in a LED driver circuit can be greater than what would normally be allowed in a voltage regulator

Boost and Sepic design. A good design practice is to allow the inductor to produce 20% to 50% ripple of

maximum load. The increased ripple is unlikely to be a problem when illuminating LEDs.

From the previous equations, the inductor value is then obtained.

§ VIN ·

L = ¨¨

¸ x DTS

©2'iL¹

where

•

1 / TS = fSW

(9)

Ensure that the minimum current limit (2.1 A) is not exceeded, so the peak current in the inductor must be

calculated. The peak current (Lpk I) in the inductor is calculated by Equation 10:

ILpk = IIN + ΔIL or ILpk = IOUT /D' + ΔiL

(10)

When selecting an inductor, make sure that it is capable of supporting the peak input current without saturating.

Inductor saturation results in a sudden reduction in inductance and prevent the regulator from operating correctly.

Because of the speed of the internal current limit, the peak current of the inductor only needs to be specified for

the required maximum input current. For example, if the designed maximum input current is 1.5 A and the peak

current is 1.75 A, then the inductor must be specified with a saturation current limit of >1.75 A. There is no need

to specify the saturation or peak current of the inductor at the 2.8-A typical switch current limit.

Because of the operating frequency of the LM3410 and LM3410-Q1, ferrite based inductors are preferred to

minimize core losses. This presents little restriction because the variety of ferrite-based inductors is huge. Lastly,

inductors with lower series resistance (DCR) provides better operating efficiency. For recommended inductor

value examples, see Typical Applications.

8.1.1.4 Input Capacitor

An input capacitor is necessary to ensure that VIN does not drop excessively during switching transients. The

primary specifications of the input capacitor are capacitance, voltage, RMS current rating, and ESL (Equivalent

Series Inductance). TI recommens an input capacitance from 2.2 µF to 22 µF depending on the application. The

capacitor manufacturer specifically states the input voltage rating. Make sure to check any recommended

deratings and also verify if there is any significant change in capacitance at the operating input voltage and the

operating temperature. The ESL of an input capacitor is usually determined by the effective cross sectional area

of the current path. At the operating frequencies of the LM3410 and LM3410-Q1, certain capacitors may have an

ESL so large that the resulting impedance (2πfL) is higher than that required to provide stable operation. As a

result, TI recommends surface mount capacitors. Multilayer ceramic capacitors (MLCC) are good choices for

both input and output capacitors and have very low ESL. For MLCCs TI recommends use of X7R or X5R

dielectrics. Consult the capacitor manufacturer's datasheet for rated capacitance variation over operating

conditions.

8.1.1.5 Output Capacitor

The LM3410 and LM3410-Q1 operate at frequencies allowing the use of ceramic output capacitors without

compromising transient response. Ceramic capacitors allow higher inductor ripple without significantly increasing

output ripple. The output capacitor is selected based upon the desired output ripple and transient response. The

initial current of a load transient is provided mainly by the output capacitor. The output impedance therefore

determines the maximum voltage perturbation. The output ripple of the converter is a function of the capacitor’s

reactance and its equivalent series resistance (ESR) (see Equation 11).

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

13

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Application Information (continued)

§

'V OUT = 'iL x RESR + ¨

©

V OUT x D

·

2 x fSW x ROUT x COUT ¸

¹

(11)

When using MLCCs, the ESR is typically so low that the capacitive ripple may dominate. When this occurs, the

output ripple is approximately sinusoidal and 90° phase shifted from the switching action.

Given the availability and quality of MLCCs and the expected output voltage of designs using the LM3410 or

LM3410-Q1, there no need to review any other capacitor technologies. Another benefit of ceramic capacitors is

their ability to bypass high frequency noise. A certain amount of switching edge noise couples through parasitic

capacitances in the inductor to the output. A ceramic capacitor bypasses this noise while a tantalum does not.

Because the output capacitor is one of the two external components that control the stability of the regulator

control loop, most applications requires a minimum at 0.47 µF of output capacitance. Like the input capacitor, TI

recommends X7R or X5R as multilayer ceramic capacitors. Again, verify actual capacitance at the desired

operating voltage and temperature.

8.1.1.6 Diode

The diode (D1) conducts during the switch off time. TI recommends Schottky diode for its fast switching times

and low forward voltage drop. The diode must be chosen so that its current rating is greater than:

ID1 ≥ IOUT

(12)

The reverse breakdown rating of the diode must be at least the maximum output voltage plus appropriate margin.

8.1.1.7 Output Overvoltage Protection

A simple circuit consisting of an external Zener diode can be implemented to protect the output and the LM3410

or LM3410-Q1 device from an overvoltage fault condition. If an LED fails open, or is connected backwards, an

output open circuit condition occurs. No current is conducted through the LEDs, and the feedback node equals

zero volts. The LM3410 or LM3410-Q1 reacts to this fault by increasing the duty cycle, thinking the LED current

has dropped. A simple circuit that protects the device is shown in Figure 14.

Zener diode D2 and resistor R3 is placed from VOUT in parallel with the string of LEDs. If the output voltage

exceeds the breakdown voltage of the Zener diode, current is drawn through the Zener diode, R3 and sense

resistor R1. Once the voltage across R1 and R3 equals the feedback voltage of 190 mV, the LM3410 and

LM3410-Q1 limits their duty cycle. No damage occurs to the device, the LEDs, or the Zener diode. Once the fault

is corrected, the application will work as intended.

14

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Application Information (continued)

V SW

D1

LEDs

O

V

P

D2

C2

R3

V FB

R1

Figure 14. Overvoltage Protection Circuit

8.1.2 SEPIC Converter

The LM3410 or LM3410-Q1 can easily be converted into a SEPIC converter. A SEPIC converter has the ability

to regulate an output voltage that is either larger or smaller in magnitude than the input voltage. Other converters

have this ability as well (CUK and Buck-Boost), but usually create an output voltage that is opposite in polarity to

the input voltage. This topology is a perfect fit for Lithium Ion battery applications where the input voltage for a

single cell Li-Ion battery varies from 2.7 V to 4.5 V and the output voltage is somewhere in between. Most of the

analysis of the LM3410 Boost Converter is applicable to the LM3410 SEPIC Converter.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

15

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Application Information (continued)

V IN

L1

C1

LM 3410

1

6

2

5

3

4

VO

D1

C3

C2

L2

HB / OLED

R2

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 15. HB or OLED SEPIC Converter Schematic

8.1.2.1 SEPIC Equations

SEPIC Conversion ratio without loss elements:

VOUT

VIN

=

D

'¶

(13)

Therefore:

D=

VOUT

VOUT + VIN

(14)

Small ripple approximation:

In a well-designed SEPIC converter, the output voltage, and input voltage ripple, the inductor ripple IL1 and IL2 is

small in comparison to the DC magnitude. Therefore it is a safe approximation to assume a DC value for these

components. The main objective of the Steady State Analysis is to determine the steady state duty cycle, voltage

and current stresses on all components, and proper values for all components.

In a steady-state converter, the net volt-seconds across an inductor after one cycle equals zero. Also, the charge

into a capacitor equals the charge out of a capacitor in one cycle.

Therefore:

IL2

IL2

16

§ D' ·

¨¨ ¸¸ u IL1

©D¹

and

§D·

¨ ' ¸ u ILED

©D ¹

Submit Documentation Feedback

(15)

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Application Information (continued)

Substituting IL1 into IL2

IL2 = ILED

(16)

The average inductor current of L2 is the average output load.

VL(t )

AREA 1

t (s)

AREA 2

DTS

TS

Figure 16. Inductor Volt-Second Balance Waveform

Applying Charge balance on C1:

VC3 =

D'( VOUT)

D

(17)

Because there are no DC voltages across either inductor, and capacitor C3 is connected to Vin through L1 at

one end, or to ground through L2 on the other end, we can say that

VC3 = VIN

(18)

Therefore:

VIN =

D'( VOUT)

D

(19)

This verifies the original conversion ratio equation.

It is important to remember that the internal switch current is equal to IL1 and IL2 during the D interval. Design the

converter so that the minimum ensured peak switch current limit (2.1 A) is not exceeded.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

17

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Application Information (continued)

8.1.2.2 Steady State Analysis with Loss Elements

- iL1(t)

v ()

C1 t

+

i

i sw

iD1(t)

vD1(t)

L 2 (t)

VIN

iC 2(t)

-

+

RL1

i C1( t )

+

L1(t)

vL2(t )

+

vC2(t)

-

Ron

vO(t)

-

v

+

RL 2

Copyright © 2016, Texas Instruments Incorporated

Figure 17. SEPIC Simplified Schematic

8.1.2.2.1 Details

Using inductor volt-second balance and capacitor charge balance, the following equations are derived:

IL2 = (ILED)

(20)

IL1 = (ILED) × (D/D')

(21)

and

VOUT

VIN

·

§

¸

¨

1

D

§ ·

¸

= ¨¨ ' ¸¸ ¨

¸

2·

·

§

§

© D ¹ ¨§

¨¨1+ VD + R L2 ·¸ + ¨ D ¸ §¨ RON ·¸ + ¨ D ¸ §¨ RL1·¸¸

¨¨© VOUT R ¸¹ ¨ '2 ¸ © R ¹ ¨ ' 2 ¸ © R ¹¸

©D ¹

©D ¹

¸

¨

¹

©

ROUT =

(22)

VOUT

ILED

(23)

Therefore:

·

§

¸

¨

1

¸

¨

K=

¸

¨§

2

·

·

§

§

·

¨ ¨1+ VD + R L2 ¸ + ¨ D ¸ §¨ R ON ·¸ + ¨ D ¸ §¨ R L1 ·¸ ¸

¸

¨

2

2

¨ © VOUT ROUT¹ ¨ D' ¸ ©ROUT ¹ ¨ D' ¸ ©R OUT¹ ¸

¹

¹

©

©

¸

¨

¹

©

(24)

All variables are known except for the duty cycle (D). A quadratic equation is needed to solve for D. A less

accurate method of determining the duty cycle is to assume efficiency, and calculate the duty cycle.

VOUT

VIN

18

=

§ D ·xK

¨1 - D¸

©

¹

Submit Documentation Feedback

(25)

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Application Information (continued)

VOUT

·

§

D=¨

(VIN x K) + VOUT ¸¹

©

(26)

Table 1. Efficiencies for Typical SEPIC Applications

EXAMPLE 1

EXAMPLE 2

EXAMPLE 3

VIN

2.7 V

VIN

3.3 V

VIN

5V

VOUT

3.1 V

VOUT

3.1 V

VOUT

3.1 V

IIN

770 mA

IIN

600 mA

IIN

375 mA

ILED

500 mA

ILED

500 mA

ILED

500 mA

η

75%

η

80%

η

83%

8.2 Typical Applications

8.2.1 Low Input Voltage, 1.6-MHz, 3 to 5 White LED Output at 50-mA Boost Converter

L1

D1

DIMM

4

DIM

L M3410

VIN

5

VIN

C1

3

FB

2

GND

1

LEDs

C2

SW

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 18. Boost Schematic

8.2.1.1 Design Requirements

For this design example, use the parameters listed in Table 2 as the input parameters.

Table 2. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

50 mA

VOUT

14.6 V (four 3.6-V LEDs in series plus 190 mV)

RD

8 Ω (dynamic resistance of 4 LEDs in series)

ΔILp–p

100 mA (maximum)

ΔVOUTp–p

250 mV (maximum)

8.2.1.2 Detailed Design Procedure

This design procedure uses the worst-case minimum input voltage and a nominal 4 LED series load for

calculations.

8.2.1.2.1 Set the LED Current (R1)

Rearranging the LED current equation the current sense resistor R1 can be found using Equation 27.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

19

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

R1 =

www.ti.com

VFB

190mV

=

ILED

50mA

(27)

3.8 Ω is not a standard value so a standard value of R1 = 3.83 Ω is chosen.

8.2.1.2.2 Calculate Maximum Duty Cycle (DMAX)

The maximum duty cycle is required for calculating the inductor value and the minimum output capacitance.

Assuming an approximate conversion efficiency (η) of 90% DMAX is calculated using Equation 28.

DMAX =

VOUT - × VIN(min) 14.6V - 0.9 × 2.7V

=

= 0.834

VOUT

14.6V

(28)

8.2.1.2.3 Calculate the Inductor Value (L1)

Using the maximum duty cycle, the minimum input voltage, and the maximum inductor ripple current (ΔiLp–p) the

minimum inductor value to achieve the maximum ripple current is calculated using Equation 29.

VIN(min) × DMAX × TS

2.7V × 0.834 × 625ns

L1 = F

p

G = l

2 × 100mA

2 × ¨iL-PP

H

(29)

To ensure the maximum inductor ripple current requirement is met with a 20% inductor tolerance an inductor

value of L1 = 10 µH is selected.

8.2.1.2.4 Calculate the Output Capacitor (C2)

To maintain a maximum of 250-mV output voltage ripple the dynamic resistance of the LED stack (RD) must be

used. Assuming a ceramic capacitor is used so the ESR can be neglected this minimum amount of capacitance

can be found using Equation 30.

C2 •

VOUT × DMAX

14.6V × 0.834

=

=

2 × fSW × RD × VOUT 2 × 1.6MHz ×

× 14.6V

F

(30)

1.9 µF is not a standard value so a value of C2 = 2.2 µF is selected.

8.2.1.2.5 Input Capacitor (C1) and Schottky Diode (D1)

TI recommends an input capacitor from 2.2 µF to 22 µF. This is a relatively low power design optimized for a

small footprint. For a good balance of input filtering and small size a 6.3-V capacitor with a value of C1 = 10 µF is

selected. The output voltage with a 5 LED load is over 18 V and the reverse voltage of the schottky diode must

be greater than this voltage. To give some headroom to avoid reverse breakdown and to maintain small size and

reliability the diode selected is D1 = 30 V, 500 mA.

20

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8.2.1.3 Application Curves

Figure 20. PWM Dimming

Figure 19. Efficiency versus Input Voltage

8.2.2 LM3410X SOT-23: 5 × 1206 Series LED String Application

D1

L1

LEDs

VIN

LM3410

DIMM

C1

4

3

2

R2

5

C2

1

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 21. LM3410X (1.6 MHz) 5 × 3.3-V LED String Application Diagram

8.2.2.1 Design Requirements

For this design example, use the parameters listed in Table 3 as the input parameters.

Table 3. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊50 mA

VOUT

≊16.5 V (five 3.3-V LEDs in series)

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

21

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Table 4. Part Values

PART

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

2.2 µF, 25 V, X5R

D1, Catch diode

0.4-Vf Schottky 500 mA, 30 VR

L1

10 µH, 1.2 A

R1

4.02 Ω, 1%

R2

100 kΩ, 1%

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V

8.2.3 LM3410Y SOT-23: 5 × 1206 Series LED String Application

D1

L1

LEDs

VIN

LM3410

DIMM

C1

4

3

2

R2

5

C2

1

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 22. LM3410Y (525 kHz) 5 × 3.3-V LED String Application Diagram

8.2.3.1 Design Requirements

For this design example, use the parameters listed in Table 5 as the input parameters.

Table 5. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊50 mA

VOUT

≊16.5 V (five 3.3-V LEDs in series)

Table 6. Part Values

PART

22

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

2.2 µF, 25 V, X5R

D1, Catch diode

0.4-Vf Schottky 500 mA, 30 VR

L1

15 µH, 1.2 A

R1

4.02 Ω, 1%

R2

100 kΩ, 1%

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8.2.4 LM3410X WSON: 7 × 5 LED Strings Backlighting Application

L1

LEDs

D1

VIN

LM3410

C1

R2

DIMM

1

6

2

5

3

4

ILED

C2

ISET

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 23. LM3410X (1.6 MHz) 7 × 5 × 3.3-V LEDs Backlighting Application Diagram

8.2.4.1 Design Requirements

For this design example, use the parameters listed in Table 7 as the input parameters.

Table 7. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊25 mA

VOUT

≊16.7 V (seven strings of five 3.3-V LEDs in series)

Table 8. Part Values

PART

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

4.7 µF, 25 V, X5R

D1, Catch Diode

0.4-Vf Schottky 500 mA, 30 VR

L1

8.2 µH, 2 A

R1

1.15 Ω, 1%

R2

100 kΩ, 1%

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

23

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

8.2.5 LM3410X WSON: 3 × HB LED String Application

L1

D1

VIN

LM3410

C1

R2

DIMM

1

6

2

5

3

4

HB - LEDs

C2

R3

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 24. LM3410X (1.6 MHz) 3 × 3.4-V LED String Application Diagram

8.2.5.1 Design Requirements

For this design example, use the parameters listed in Table 9 as the input parameters.

Table 9. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊340 mA

VOUT

≊11 V (three 3.4-V LEDs in series)

Table 10. Part Values

PART

24

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

2.2 µF, 25 V, X5R

D1, Catch diode

0.4-Vf Schottky 500 mA, 30 VR

L1

10 µH, 1.2 A

R1

1 Ω, 1%

R2

100 kΩ, 1%

R3

1.5 Ω, 1%

HB – LEDs

340 mA, Vf ≊ 3.6 V

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8.2.6 LM3410Y SOT-23: 5 × 1206 Series LED String Application With OVP

L1

LEDs

D1

VIN

DIMM

LM3410

C1

OVP

4

R2

3

C2

2

5

D2

1

R3

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 25. LM3410Y (525 kHz) 5 × 3.3-V LED String Application With OVP Diagram

8.2.6.1 Design Requirements

For this design example, use the parameters listed in Table 11 as the input parameters.

Table 11. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊50 mA

VOUT

≊16.5 V (five 3.3-V LEDs in series)

Table 12. Part Values

PART

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

2.2 µF, 25 V, X5R

D1, Catch diode

0.4-Vf Schottky 500 mA, 30 VR

D2

18 V Zener diode

L1

15 µH, 0.7 A

R1

4.02 Ω, 1%

R2

100 kΩ, 1%

R3

100 Ω, 1%

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

25

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

8.2.7 LM3410X SEPIC WSON: HB or OLED Illumination Application

V IN

L1

C1

LM 3410

1

6

2

5

3

4

VO

D1

C3

C2

L2

HB / OLED

R2

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 26. LM3410X (1.6 MHz) HB or OLED Illumination Application Diagram

8.2.7.1 Design Requirements

For this design example, use the parameters listed in Table 13 as the input parameters.

Table 13. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊300 mA

VOUT

≊3.8 V

Table 14. Part Values

PART

26

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

10 µF, 6.3 V, X5R

C3

2.2 µF, 25 V, X5R

D1, Catch diode

0.4-Vf Schottky 1 A, 20 VR

L1 and L2

4.7 µH, 3 A

R1

665 mΩ, 1%

R2

100 kΩ, 1%

HB – LEDs

350 mA, Vf ≊ 3.6 V

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8.2.8 LM3410X WSON: Boost Flash Application

VIN

L1

C1

D1

VO

LM3410

1

6

2

5

3

4

C2

LEDs

FLASH CTRL

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 27. LM3410X (1.6 MHz) Boost Flash Application Diagram

8.2.8.1 Design Requirements

For this design example, use the parameters listed in Table 15 as the input parameters.

Table 15. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊1 A (pulse)

VOUT

≊8 V

Table 16. Part Values

PART

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

10 µF, 16 V, X5R

D1, Catch diode

0.4-Vf Schottky 500 mA, 30 VR

L1

4.7 µH, 3 A

R1

200 mΩ, 1%

LEDs

500 mA, Vf ≊ 3.6 V, IPULSE = 1 A

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

27

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

8.2.9 LM3410X SOT-23: 5 × 1206 Series LED String Application With VIN > 5.5 V

D1

L1

LEDs

V PWR

LM3410

DIMM

C1

R3

4

2

R2

5

D2

3

C2

1

C3

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 28. LM3410X (1.6 MHz) 5 × 1206 Series LED String Application With VIN > 5.5 V Diagram

8.2.9.1 Design Requirements

For this design example, use the parameters listed in Table 17 as the input parameters.

Table 17. Design Parameters

PARAMETER

EXAMPLE VALUE

VPWR

9 V to 14 V

ILED

≊50 mA

VOUT

≊16.5 V (five 3.3-V LEDs in series)

Table 18. Part Values

PART

28

VALUE

U1

2.8-A ISW LED Driver

C1, Input VPWRcapacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

2.2 µF, 25 V, X5R

C3, Input VIN capacitor

0.1 µF, 6.3 V, X5R

D1, Catch diode

0.43-Vf Schottky 500 mA, 30 VR

D2

3.3 V Zener, SOT-23

L1

10 µH, 1.2 A

R1

4.02 Ω, 1%

R2

100 kΩ, 1%

R3

576 Ω, 1%

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8.2.10 LM3410X WSON: Camera Flash or Strobe Circuit Application

VIN

L1

C1

VO

D1

C3

LM3410

1

6

2

5

3

4

L2

R2

C2

LED( s)

Q2

R3

R1

R4

Q1

FLASH CTRL

Copyright © 2016, Texas Instruments Incorporated

Figure 29. LM3410X (1.6 MHz) Camera Flash or Strobe Circuit Application Diagram

8.2.10.1 Design Requirements

For this design example, use the parameters listed in Table 19 as the input parameters.

Table 19. Design Parameters

PARAMETER

EXAMPLE VALUE

VIN

2.7 V to 5.5 V

ILED

≊1.5 A (flash)

VOUT

≊7.5 V

Table 20. Part Values

PART

VALUE

U1

2.8-A ISW LED Driver

C1, Input capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

220 µF, 10 V, tantalum

C3 capacitor

10 µF, 16 V, X5R

D1, Catch diode

0.43-Vf Schottky 1 A, 20 VR

L1

3.3 µH, 2.7 A

R1

1 Ω, 1%

R2

37.4 kΩ, 1%

R3

100 kΩ, 1%

R4

0.15 Ω, 1%

Q1 and Q2

30 V, ID = 3.9 A

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V, IPULSE = 1.5 A

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

29

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

8.2.11 LM3410X SOT-23: 5 × 1206 Series LED String Application With VIN and VPWR Rail > 5.5 V

L1

D1

LEDs

VPWR

LM3410

DIMM

C1

4

2

R2

VIN

3

5

C2

1

C3

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 30. LM3410X (1.6 MHz) 5 × 1206 Series LED String Application With VIN and VPWR Rail > 5.5 V

Diagram

8.2.11.1 Design Requirements

For this design example, use the parameters listed in Table 21 as the input parameters.

Table 21. Design Parameters

PARAMETER

EXAMPLE VALUE

VPWR

9 V to 14 V

VIN

2.7 V to 5.5 V

ILED

≊50 mA

VOUT

≊16.5 V (five 3.3-V LEDs in series)

Table 22. Part Values

PART

30

VALUE

U1

2.8-A ISW LED Driver

C1, Input VPWRcapacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

2.2 µF, 25 V, X5R

C3, Input VIN capacitor

0.1 µF, 6.3 V, X5R

D1, Catch diode

0.43-Vf Schottky 500 mA, 30 VR

L1

10 µH, 1.2 A

R1

4.02 Ω, 1%

R2

100 kΩ, 1%

LEDs

SMD-1206, 50 mA, Vf ≊ 3.6 V

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

8.2.12 LM3410X WSON: Boot-Strap Circuit to Extend Battery Life

V IN

C4

L1

D2

C1

C3

VO

D1

LM3410

1

6

2

5

3

4

L2

C2

R3

D3

R1

Copyright © 2016, Texas Instruments Incorporated

Figure 31. LM3410X (1.6 MHz) Boot-Strap Circuit to Extend Battery Life

8.2.12.1 Design Requirements

For this design example, use the parameters listed in Table 3 as the input parameters.

Table 23. Design Parameters

PARAMETER

EXAMPLE VALUE

1.9 V to 5.5 V

VIN

>2.3 V (typical) for start-up

≊300 mA

ILED

Table 24. Part Values

PART

VALUE

U1

2.8-A ISW LED Driver

C1, Input VPWR capacitor

10 µF, 6.3 V, X5R

C2, Output capacitor

10 µF, 6.3 V, X5R

C3, Input VIN capacitor

0.1 µF, 6.3 V, X5R

D1, Catch diode

0.43-Vf Schottky 1 A, 20 VR

D2 and D3

Dual small signal Schottky

L1 and L2

3.3 µH, 3 A

R1

665 mΩ, 1%

R3

100 kΩ, 1%

HB – LEDs

350 mA, Vf ≊ 3.4 V

9 Power Supply Recommendations

Any DC output power supply may be used provided it has a high enough voltage and current range for the

particular application required.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

31

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

10 Layout

10.1 Layout Guidelines

When planning layout there are a few things to consider when trying to achieve a clean, regulated output. The

most important consideration when completing a boost converter layout is the close coupling of the GND

connections of the COUT capacitor and the PGND pin. The GND ends must be close to one another and be

connected to the GND plane with at least two vias. There must be a continuous ground plane on the bottom

layer of a two-layer board except under the switching node island. The FB pin is a high impedance node and the

FB trace must be kept short to avoid noise pickup and inaccurate regulation. The RSET feedback resistor must be

placed as close as possible to the IC, with the AGND of RSET (R1) placed as close as possible to the AGND of

the IC. Radiated noise can be decreased by choosing a shielded inductor. The remaining components must also

be placed as close as possible to the IC. See AN-1229 SIMPLE SWITCHER® PCB Layout Guidelins (SNVA054)

for further considerations and the LM3410 demo board as an example of a four-layer layout.

For certain high power applications, the PCB land may be modified to a dog bone shape (see Figure 33).

Increasing the size of ground plane and adding thermal vias can reduce the RθJA for the application.

10.2 Layout Examples

LEDs

COPPER

PCB

R1

PGND

DIM

FB

4

PGND 1

6

SW

VIN

2

5

AGND

DIM

3

4

FB

3

AGND

5

C2

VIN

VSW

VO

2

6

1

PGND

D1

C1

SW

L1

COPPER

Figure 32. Boost PCB Layout Guidelines

Figure 33. PCB Dog Bone Layout

LED1

VO

PGND

C2

R1

L2

D1

FB

DIM

4

3

AGND

5

2

VIN

C1

C3

6

1

PGND

SW

L1

VIN

The layout guidelines described for the LM3410 boost-converter are applicable to the SEPIC OLED Converter. This is

a proper PCB layout for a SEPIC Converter.

Figure 34. HB or OLED SEPIC PCB Layout

32

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

10.3 Thermal Considerations

10.3.1 Design

When designing for thermal performance, many variables must be considered, such as ambient temperature,

airflow, external components, and PCB design.

The surrounding maximum air temperature is fairly explanatory. As the temperature increases, the junction

temperature increases. This may not be linear though. As the surrounding air temperature increases, resistances

of semiconductors, wires and traces increase. This decreases the efficiency of the application, and more power

is converted into heat, and increases the silicon junction temperatures further.

Forced air can drastically reduce the device junction temperature. Air flow reduces the hot spots within a design.

Warm airflow is often much better than a lower ambient temperature with no airflow.

Choose components that are efficient, and the mutual heating between devices can be reduced.

The PCB design is a very important step in the thermal design procedure. The LM3410 and LM3410-Q1 are

available in three package options (6-pin WSON, 8-pin MSOP, and 5-pin SOT-23). The options are electrically

the same, but there are differences between the package sizes and thermal performances. The WSON and

MSOP have thermal die attach pads (DAP) attached to the bottom of the packages, and are therefore capable of

dissipating more heat than the SOT-23 package. It is important that the customer choose the correct package for

the application. A detailed thermal design procedure has been included in this data sheet. This procedure helps

determine which package is correct, and common applications are analyzed.

There is one significant thermal PCB layout design consideration that contradicts a proper electrical PCB layout

design consideration. This contradiction is the placement of external components that dissipate heat. The

greatest external heat contributor is the external Schottky diode. Increasing the distance between the LM3410 or

LM3410-Q1 and the Schottky diode may reduce the mutual heating effect. This, however, creates electrical

performance issues. It is important to keep the device, the output capacitor, and Schottky diode physically close

to each other (see Layout Guidelines). The electrical design considerations outweigh the thermal considerations.

Other factors that influence thermal performance are thermal vias, copper weight, and number of board layers.

Heat energy is transferred from regions of high temperature to regions of low temperature via three basic

mechanisms: radiation, conduction and convection. Conduction and convection are the dominant heat transfer

mechanism in most applications.

The data sheet values for each packages thermal impedances are given to allow comparison of the thermal

performance of one package against another. To achieve a comparison between packages, all other variables

must be held constant in the comparison (PCB size, copper weight, thermal vias, power dissipation, VIN, VOUT,

load current, and others). This provides indication of package performance, but it would be a mistake to use

these values to calculate the actual junction temperature in an application.

10.3.2 LM3410 and LM3410-Q1 Thermal Models

Heat is dissipated from the LM3410, LM3410-Q1, and other devices. The external loss elements include the

Schottky diode, inductor, and loads. All loss elements mutually increase the heat on the PCB, and therefore

increase each other’s temperatures.

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

33

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Thermal Considerations (continued)

L1

D1

IL(t)

VOUT(t)

VIN

Q1

C1

Figure 35. Thermal Schematic

RTCASE-AMB

TCASE

CTCASE-AMB

RTJ-CASE

CTJ-CASE

INTERNAL

PDISS

SMALL

LARGE

PDISS-TOP

TAMBIENT

PDISS-PCB

TJUNCTION

RTJ-PCB

CTJ-PCB

DEVICE

EXTERNAL

PDISS

RTPCB-AMB

TPCB

CTPCB-AMB

PCB

Figure 36. Associated Thermal Model

34

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Thermal Considerations (continued)

10.3.3 Calculating Efficiency and Junction Temperature

Use Equation 31 to calculate RθJA.

R TJA =

T J - TA

PDissipation

(31)

A common error when calculating RθJA is to assume that the package is the only variable to consider.

Other variables are:

• Input voltage, output voltage, output current, RDS(ON)

• Ambient temperature and air flow

• Internal and external components' power dissipation

• Package thermal limitations

• PCB variables (copper weight, thermal vias, and component placement)

Another common error when calculating junction temperature is to assume that the top case temperature is the

proper temperature when calculating RθJC. RθJC represents the thermal impedance of all six sides of a package,

not just the top side. This document refers to a thermal impedance called RΨJC. RΨJC represents a thermal

impedance associated with just the top case temperature. This allows for the calculation of the junction

temperature with a thermal sensor connected to the top case.

The complete LM3410 and LM3410-Q1 boost converter efficiency can be calculated using Equation 32.

K

POUT

PIN

or

POUT

POUT PLOSS

K

where

•

PLOSS is the sum of two types of losses in the converter, switching and conduction

(32)

Conduction losses usually dominate at higher output loads, where as switching losses remain relatively fixed and

dominate at lower output loads.

To calculate losses in the LM3410 or LM3410-Q1 device, use Equation 33.

PLOSS = PCOND + PSW + PQ

where

•

PQ = quiescent operating power loss

(33)

Conversion ratio of the boost converter with conduction loss elements inserted is calculated with Equation 34.

VOUT

VIN

§

·

¨

¸

1

1 §¨1- Dc x VD·¸ ¨

¸

= ¨

¨

¸

R DCR + (D x R DSON)¸

VIN ¹ ¨

Dc ©

¸

2R

¨ 1+

¸

c

D

OUT

©

¹

where

•

RDCR is the Inductor series resistance

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

(34)

Submit Documentation Feedback

35

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

Thermal Considerations (continued)

VOUT

ROUT =

ILED

(35)

If the loss elements are reduced to zero, the conversion ratio simplifies to Equation 36.

VOUT

VIN

V OUT

V IN

=

=

1

'¶

(36)

K

'¶

(37)

Therefore:

K = Dc

VOUT

VIN

D c x VD

§

·

1¸

¨

VIN

¨

¸

=¨

R

+ (D x R DSON) ¸

¸

¨ 1 + DCR

¸

¨

2

D c R OUT

¹

©

(38)

Only calculations for determining the most significant power losses are discussed. Other losses totaling less than

2% are not discussed.

A simple efficiency calculation that takes into account the conduction losses is Equation 39.

§

Dc x VD

·

1¨

¸

VIN

¨

¸

K|¨

R

+ (D x R DSON ) ¸

¸

¨ 1 + DCR

¸

¨

2R

c

D

©

OUT

¹

(39)

The diode, NMOS switch, and inductor (DCR) losses are included in this calculation. Setting any loss element to

zero simplifies the equation.

VD is the forward voltage drop across the Schottky diode. It can be obtained from Electrical Characteristics.

Conduction losses in the diode are calculated with Equation 40.

PDIODE = VD × ILED

(40)

Depending on the duty cycle, this can be the single most significant power loss in the circuit. Choose a diode that

has a low forward voltage drop. Another concern with diode selection is reverse leakage current. Depending on

the ambient temperature and the reverse voltage across the diode, the current being drawn from the output to

the NMOS switch during time (D) could be significant, this may increase losses internal to the LM3410 or

LM3410-Q1 and reduce the overall efficiency of the application. See the Schottky diode manufacturer’s data

sheets for reverse leakage specifications.

Another significant external power loss is the conduction loss in the input inductor. The power loss within the

inductor can be simplified to Equation 41,

PIND = IIN2RDCR

(41)

Or Equation 42.

36

Submit Documentation Feedback

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Thermal Considerations (continued)

·

§I 2 R

PIND = ¨ O DCR ¸¸

¨ D'

¹

©

(42)

The LM3410 and LM3410-Q1 conduction loss is mainly associated with the internal power switch.

PCOND-NFET = I2SW-rms × RDS(ON) × D

(43)

'i

IIN

ISW(t)

t

Figure 37. LM3410 and LM3410-Q1 Switch Current

2

Isw rms

IIND

1 § 'i ·

Du 1

¨

¸ | IIND D

3 © IIND ¹

(44)

(small ripple approximation)

PCOND-NFET = IIN2 × RDS(ON) × D

(45)

Or

2

PCOND - NFET

§I LED·

= ¨ ' ¸ x R DSON x D

©D ¹

(46)

The value for RDS(ON) must be equal to the resistance at the desired junction temperature for analyzation. As an

example, at 125°C and RDS(ON) = 250 mΩ (See Typical Characteristics for value).

Switching losses are also associated with the internal power switch. They occur during the switch ON and OFF

transition periods, where voltages and currents overlap resulting in power loss.

The simplest means to determine this loss is empirically measuring the rise and fall times (10% to 90%) of the

switch at the switch node.

PSWR = 1/2 (VOUT × IIN × fSW × tRISE)

PSWF = 1/2 (VOUT × IIN × fSW × tFALL)

PSW = PSWR + PSWF

(47)

(48)

(49)

Table 25. Typical Switch-Node Rise and Fall Times

VIN (V)

VOUT (V)

tRISE (ns)

tFALL (ns)

3

5

6

4

5

12

6

5

3

12

8

7

5

18

10

8

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

Submit Documentation Feedback

37

�LM3410, LM3410-Q1

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

www.ti.com

10.3.3.1 Quiescent Power Losses

IQ is the quiescent operating current, and is typically around 1.5 mA.

PQ = IQ × VIN

(50)

10.3.3.2 RSET Power Losses

RSET power loss is calculated with Equation 51.

2

VFB

PRSET =

R SET

(51)

10.3.4 Example Efficiency Calculation

Operating Conditions:5 × 3.3-V LEDs + 190 mVREF ≊ 16.7 V

Table 26. Operating Conditions

PARAMETER

VALUE

VIN

3.3 V

VOUT

16.7 V

ILED

50 mA

VD

0.45 V

fSW

1.6 MHz

IQ

3 mA

tRISE

10 ns

tFALL

10 ns

RDS(ON)

225 mΩ

LDCR

75 mΩ

D

0.82

IIN

0.31 A

ΣPCOND + PSW + PDIODE + PIND + PQ = PLOSS

(52)

Quiescent Power Loss:

PQ = IQ × VIN = 10 mW

(53)

Switching Power Loss:

PSWR = 1/2(VOUT × IIN × fSW × tRISE) ≊ 40 mW

PSWF = 1/2(VOUT × IIN × fSW × tFALL) ≊ 40 mW

PSW = PSWR + PSWF = 80 mW

(54)

(55)

(56)

Internal NFET Power Loss:

RDS(ON) = 225 mΩ

PCONDUCTION = IIN2 × D × RDS(ON) = 17 mW

IIN = 310 mA

(57)

(58)

(59)

Diode Loss:

VD = 0.45 V

PDIODE = VD × ILED = 23 mW

(60)

(61)

Inductor Power Loss:

RDCR = 75 mΩ

PIND = IIN2 × RDCR = 7 mW

38

Submit Documentation Feedback

(62)

(63)

Copyright © 2007–2016, Texas Instruments Incorporated

Product Folder Links: LM3410 LM3410-Q1

�LM3410, LM3410-Q1

www.ti.com

SNVS541H – OCTOBER 2007 – REVISED AUGUST 2016

Table 27. Total Power Losses

PARAMETER

VALUE

LOSS PARAMETER

LOSS VALUE

—

—

VIN

3.3 V

VOUT

16.7 V

ILED

50 mA

POUT

VD

0.45 V

PDIODE

fSW

1.6 MHz

IQ

10 ns

PSWR

40 mW

tRISE

10 ns

PSWF

40 mW

IQ

3 mA

PQ

10 mW

RDS(ON)

225 mΩ

PCOND

17 mW

LDCR

75 mΩ

PIND

D

0.82

η

85%

—

—

825 W

23 mW

—

—

7 mW

—

PLOSS

—

137 mW

PINTERNAL = PCOND + PSW = 107 mW

(64)

10.3.5 Calculating RθJA and RΨJC

R TJA =

TJ - TA

PDissipatio n

: R