Sample &

Buy

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LM3633

SNVS867 – JUNE 2014

LM3633 Complete Lighting Power Solution for Smartphone Handsets

Check for Samples: LM3633

1 Features

3 Description

•

The LM3633 11-bit LED driver provides highperformance backlight dimming for 1, 2, or 3 parallel

high-voltage LED strings while delivering up to 90%

efficiency. The boost converter with integrated 1-A,

40-V MOSFET automatically adjusts to LED forward

voltage to minimize headroom voltage and effectively

improve LED efficiency.

Drives Three Parallel High-Voltage LED Strings

for Display and Keypad Lighting

High-Voltage Strings Capable of up to 40-V

Output Voltage and up to 90% Efficiency

Up to 30-mA per Current Sink (Both Backlight and

Indicator)

11-Bit High-Voltage LED Dimming

PWM Input for Content Adjustable Brightness

Control (CABC)

Integrated 1-A/40-V MOSFET

Adaptive Boost Output to LED Voltages

Six Low-Voltage Current Sinks for Indicator LEDs

Integrated Charge Pump for Improved Efficiency

and VIN Operating Range

Internal Pattern Generation Engine for Each

Indicator LED

Fully Configurable LED Grouping and Control

Four Programmable Overvoltage Protection

Thresholds (16 V, 24 V, 32 V, and 40 V)

Programmable 500-kHz and 1-MHz Switching

Frequency

Overcurrent Protection

Thermal Shutdown Protection

27 mm2 Total Solution Size

1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Power Source for Smart Phone Illumination

Display, Keypad and Indicator Illumination

RGB Indicator Driver

space

Simplified Schematic

L

VIN

An additional feature is a Pulse Width Modulation

(PWM) control input for content adjustable backlight

control, which can be used to control any highvoltage current sink.

The LM3633 is fully programmable via an I2Ccompatible interface. The device operates over a 2.7V to 5.5-V input voltage range and a −40°C to 85°C

temperature range.

Device Information(1)

PART NUMBER

LM3633

2 Applications

•

•

•

The LM3633 is a complete power source for

backlight, keypad, and indicator LEDs in smartphone

handsets. The high-voltage inductive boost converter

provides the power for three parallel LED strings

(HVLED1, HVLED2 and HVLED3). The integrated

charge pump provides the bias for the six low-voltage

indicator LEDs (LVLED1-LVLED6). All low-voltage

current sinks can have a programmable pattern

modulated onto their output current for a wide variety

of blinking patterns.

D1

2.7V to 5.5V

Dual String Efficiency vs VIN

L=22µH, fSW=1MHz

COUT

92%

SW

LM3633

90%

OVP

88%

C+

CP

C-

SDA

SDA

SCL

SCL

HWEN

HVLED1

HVLED2

HVLED3

HWEN

CPOUT

CPOUT

PWM

PWM

LVLED1

LVLED2

LVLED3

EFFICIENCY (%)

IN

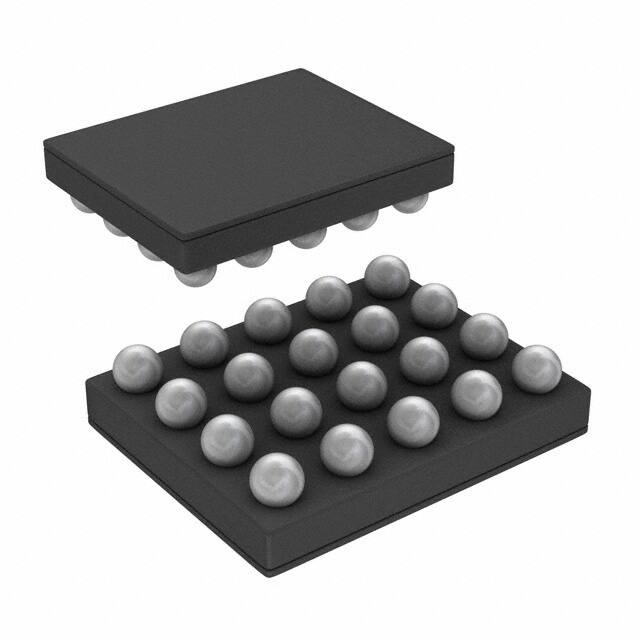

BODY SIZE (MAX)

2.04 mm x 1.78 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

VOUT up to 40V

CIN

PACKAGE

DSBGA (20)

86%

84%

82%

80%

3s3p

78%

76%

4s3p

74%

5s3p

72%

6s3p

70%

LVLED4

LVLED5

LVLED6

2.5

3

3.5

4

4.5

5

5.5

VIN (V)

PGND

C002

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM3633

SNVS867 – JUNE 2014

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

6.7

4

4

4

4

5

7

8

Absolute Maximum Ratings .....................................

Handling Ratings ......................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Timing Requirements ................................................

Typical Characteristics ..............................................

7.4 Device Functional Modes ....................................... 12

7.5 Register Descriptions .............................................. 24

8

Applications and Implementation ...................... 33

8.1 Application Information .......................................... 33

8.2 Typical Application .................................................. 33

8.3 Initialization Set Up ................................................. 45

9 Power Supply Recommendations...................... 48

10 Layout................................................................... 48

10.1 Layout Guidelines (Boost) .................................... 48

10.2 Layout Guidelines (Charge Pump)........................ 51

10.3 Layout Example ................................................... 52

11 Device and Documentation Support ................. 53

11.1

11.2

11.3

11.4

Detailed Description ............................................ 10

7.1 Overview ................................................................ 10

7.2 Functional Block Diagram ...................................... 10

7.3 Feature Description ................................................ 10

Device Support......................................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

53

53

53

53

12 Mechanical, Packaging, and Orderable

Information ........................................................... 53

4 Revision History

2

Date

Revision

Notes

June 2014

*

Initial release

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

5 Pin Configuration and Functions

DSBGA (YFQ)

20 PINS

Bottom View

Top View

A B C D E

4

4

3

3

2

2

1

1

E D C B A

Pin Functions

PIN

DESCRIPTION

NAME

NUMBER

C−

A1

Integrated charge pump flying capacitor negative pin. Connect a 1-µF ceramic capacitor between C+

and C−.

C+

A2

Integrated charge pump flying capacitor positive pin. Connect a 1-µF ceramic capacitor between C+ and

C−.

CPOUT

A3

Integrated charge pump output pin. Bypass CPOUT to GND with a 1-µF ceramic capacitor.

IN

A4

Input voltage connection. Bypass IN to GND with a minimum 2.2-µF ceramic capacitor.

HVLED1

B1

Input pin to high-voltage current sink 1 (40 V max). The boost converter regulates the minimum of

HVLED1, HVLED2 and HVLED3 to VHR.

SDA

B2

Serial data connection for I2C-Compatible Interface.

OVP

B3

Overvoltage sense input. Connect OVP to the positive pin of the inductive boost output capacitor

(COUT).

GND

B4

Ground

HVLED2

C1

Input pin to high-voltage current sink 2 (40 V max). The boost converter regulates the minimum of

HVLED1, HVLED2 and HVLED3 to VHR.

SCL

C2

Serial clock connection for I2C-Compatible Interface.

PWM

C3

PWM brightness control input for CABC operation. PWM is a high-impedance input and cannot be left

floating.

SW

C4

Drain connection for the internal NFET. Connect SW to the junction of the inductor and the Schottky

diode anode.

HVLED3

D1

Input pin to high-voltage current sink 3 (40 V max). The boost converter regulates the minimum of

HVLED1, HVLED2 and HVLED3 to VHR.

HWEN

D2

Hardware enable input. Drive this pin high to enable the device. Drive this pin low to force the device

into a low power shutdown. HWEN is a high-impedance input and cannot be left floating.

LVLED6

D3

Low-voltage current sink 6

LVLED5

D4

Low-voltage current sink 5

LVLED1

E1

Low-voltage current sink 1

LVLED2

E2

Low-voltage current sink 2

LVLED3

E3

Low-voltage current sink 3

LVLED4

E4

Low-voltage current sink 4

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

3

�LM3633

SNVS867 – JUNE 2014

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

VIN to GND

−0.3

6

VSW, VOVP, VHVLED1, VHVLED2, VHVLED3 to GND

−0.3

45

VSCL, VSDA, VPWM to GND

−0.3

6

VHWEN, VCPOUT to GND, VC–, VC+

−0.3

6

VLVLED1- VLVLED6, to GND

−0.3

UNIT

V

6

Continuous power dissipation

Internally

Limited

Junction temperature (TJ-MAX)

150

(1)

°C

Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under recommended

operating conditions. Exposure to absolute–maximum–rated conditions for extended periods may affect device reliability.

6.2 Handling Ratings

MIN

Tstg

(1)

(2)

Electrostatic discharge

UNIT

°C

−65

150

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

pins (1)

−1000

1000

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins (2)

−250

250

Storage temperature range

V(ESD)

MAX

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

VIN to GND

VSW, VOVP, VHVLED1, VVHLED2, VVHLED3 to GND, VPWM, VHWEN, VSDA, VSCL

VLVLED1- VLVLED6 to GND

Junction temperature (TJ)

(1)

(2)

(1) (2)

NOM

MAX

2.7

5.5

0

40

0

6

−40

125

UNIT

V

°C

Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 140°C (typ.) and

disengages at TJ= 125°C (typ.).

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be derated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP =

125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to ambient thermal resistance of the

part/package in the application (θJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (θJA × PD-MAX).

6.4 Thermal Information

THERMAL METRIC (1)

RθJA

(1)

4

Thermal resistance junction-to-ambient

DSBGA

(20 PINS)

55.3

UNIT

°C/W

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

6.5 Electrical Characteristics

Limits apply over the full operating ambient temperature range (−40°C ≤ TA ≤ 85°C) and VIN = 3.6 V, unless otherwise

specified. (1) (2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

1

5.5

UNIT

SUPPLY VOLTAGE (IN PIN)

ISHDN

Shutdown current

2.7 V ≤ VIN ≤ 5.5 V, HWEN = GND

µA

THERMAL SHUTDOWN

Thermal shutdown

TSD

140

Hysteresis

°C

15

BOOST CONVERTER AND HVLED

IHVLED(1/2/3)

IMATCH_HV

Output current regulation

(HVLED1, HVLED2 or

HVLED3)

HVLED1 to HVLED2 or

HVLED3 matching (3)

Full-scale current = 20.2

mA, PWM off, brightness

code = max, exponential

mapping, auto headroom

off, HVLED1 Bank A,

HVLED2/3 Bank B

Full-scale current = 20.2

mA, PWM off, brightness

code = max, exponential

mapping, auto headroom

off, HVLED1 Bank A,

HVLED2/3 Bank B

PWM off, exponential

mapping, auto headroom

off

HVLED1,2,3 = Bank A,

2.7 V ≤ VIN ≤ 5.5 V

18.38

(–9%)

20.2

22.02

(9%)

TA = 25°C

–3.4%

±2.0%

3.2%

TA = 25°C,

3.0 V ≤ VIN ≤ 4.5 V

–3.6%

TA = 25°C

3.4%

±2.0%

2.7 V ≤ VIN ≤ 5.5 V,

ILED = 20.2 mA

–2.5%

2.5%

TA = 25°C,

ILED = 20.2 mA

–2.0%

1.7%

2.7 V ≤ VIN ≤ 5.5 V

ILED = 500 µA

–8.5%

8.5%

ILED_MIN

Minimum LED current

Full-scale current = 20.2 mA, Exponential Mapping

6.0

VREG_CS

Regulated current sink

headroom voltage

Auto headroom off, TA = 25°C

400

VHR_HV

Minimum current sink

headroom voltage for

HVLED current sinks

ILED = 95% of nominal, fullscale current = 20.2 mA,

auto headroom off

RDSON

NMOS switch on

resistance

ISW = 500 mA, TA = 25°C

ICL_BOOST

NMOS switch current limit

VOVP

Output overvoltage

protection

fSW

Switching frequency

DMAX

Maximum duty cycle

mA

2.7 V ≤ VIN ≤ 5.5 V

µA

285

TA = 25°C

mV

190

Ω

0.3

880

TA = 25°C

1120

1000

ON threshold

OVP select bits = 11

2.7 V ≤ VIN ≤ 5.5 V

TA = 25°C

40

Hysteresis

TA = 25°C

1

38.75

Boost frequency select bit = 2.7 V ≤ VIN ≤ 5.5 V

0

TA = 25°C

450

Boost frequency select bit = 2.7 V ≤ VIN ≤ 5.5 V

1

TA = 25°C

900

mA

41.1

V

550

500

1100

kHz

1000

2.7 V ≤ VIN ≤ 5.5 V

94%

CHARGE PUMP AND LVLED

ILVLED(1/2/3/4/5/6)

(1)

(2)

(3)

Full-scale current = 20.2

Output current regulation

mA, brightness code =

(low-voltage current sinks)

0xFF

2.7 V ≤ VIN ≤ 5.5 V

18.38

20.2

22.02

mA

All voltages are with respect to the potential at the GND pin.

Minimum and Maximum limits are verified by design, test, or statistical analysis. Typical (Typ) numbers are not verified, but do represent

the most likely norm. Unless otherwise specified, conditions for typical specifications are: VIN = 3.6 V and TA = 25°C.

LED current sink matching in the high-voltage current sinks (HVLED1 through HVLED3) is given as the maximum matching value

between any two current sinks, where the matching between any two high voltage current sinks (X and Y) is given as (IHVLEDX ( or

IHVLEDY) - IAVE(X-Y))/(IAVE(X-Y)) x 100. In this test all three HVLED current sinks are assigned to Bank A.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

5

�LM3633

SNVS867 – JUNE 2014

www.ti.com

Electrical Characteristics (continued)

Limits apply over the full operating ambient temperature range (−40°C ≤ TA ≤ 85°C) and VIN = 3.6 V, unless otherwise

specified.(1)(2)

PARAMETER

TEST CONDITIONS

IMATCH_LV

LVLED current sink

matching (4)

Full-scale current = 20.2

mA

VHR_LV

Minimum current sink

headroom voltage for

LVLED current sinks

ILED = 95% of nominal, fullscale current = 20.2 mA

VGTH

Threshold for gain

transition

VCPOUT

Charge Pump Output

Voltage

ICL_PUMP

Charge pump current limit

ROUT

2.7 V ≤ VIN ≤ 5.5 V

MIN

TYP

−3.1%

MAX

UNIT

2%

125

TA = 25°C

2.7 V ≤ VIN ≤ 5.5 V

80

65

mV

190

TA = 25°C

125

2X Gain

TA = 25°C

4.42

1X Gain, output referred

3 V ≤ VIN ≤ 5.5 V

2X Gain

TA = 25°C

240

Charge pump output

resistance

1X Gain

TA = 25°C

1.1

VHWEN_L

Logic low

2.7 V ≤ VIN ≤ 5.5 V

0

0.4

VHWEN_H

Logic High

2.7 V ≤ VIN ≤ 5.5 V

1.2

VIN

VPWM_L

Input logic low

2.7 V ≤ VIN ≤ 5.5 V

0

400

VPWM_H

Input logic high

2.7 V ≤ VIN ≤ 5.5 V

1.36

VIN

tPWM

Minimum PWM input

pulse

2.7 V ≤ VIN ≤ 5.5 V, PWM Zero Detect Enabled

180

V

350

mA

Ω

HWEN INPUT

V

PWM INPUT

0.75

mV

µs

I2C-COMPATIBLE VOLTAGE SPECIFICATIONS (SCL, SDA)

VIL

Input logic low

2.7 V ≤ VIN ≤ 5.5 V

0

400

VIH

Input logic high

2.7 V ≤ VIN ≤ 5.5 V

1.35

VIN

V

VOL

Output logic low (SDA)

2.7 V ≤ VIN ≤ 5.5 V, ILOAD = 3 mA

400

mV

(4)

6

mV

LED current sink matching in the low-voltage current sinks (LVLED1 through LVLED3 or LVLED4 through LVLED6) is given as the

maximum matching value between any two current sinks, where the matching between any two low voltage current sinks (X and Y) is

given as (ILVLEDX ( or ILVLEDY) - IAVE(X-Y))/(IAVE(X-Y)) x 100. In this test LVLED1-3 current sinks are assigned to Bank C and LVLED4-6 are

assigned to Bank F.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

6.6 Timing Requirements

Limits apply over the full operating ambient temperature range (−40°C ≤ TA ≤ 85°C) and VIN = 3.6 V, unless otherwise

specified. (1) (2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

I2C-COMPATIBLE TIMING SPECIFICATIONS (SCL, SDA) (3), Figure 1

t1

SCL (Clock Period)

2.7 V ≤ VIN ≤ 5.5 V

2.5

t2

Data In setup time to SCL high

2.7 V ≤ VIN ≤ 5.5 V

100

t3

Data out stable after SCL low

2.7 V ≤ VIN ≤ 5.5 V

0

t4

SDA low setup time to SCL low (Start)

2.7 V ≤ VIN ≤ 5.5 V

100

t5

SDA high hold time after SCL high (Stop)

2.7 V ≤ VIN ≤ 5.5 V

100

µs

ns

INTERNAL POR THRESHOLD AND HWEN TIMING SPECIFICATION

VPOR

POR reset release voltage threshold

tHWEN

First I2C start pulse after HWEN high

VIN ramp time = 100 μs

1.7

2.1

VIN ramp time = 100 μs, TA = 25°C

1.9

POR reset complete, 2.7 V ≤ VIN ≤ 5.5

V

20

POR reset complete, TA = 25°C

(1)

(2)

(3)

V

µs

5

All voltages are with respect to the potential at the GND pin.

Minimum and Maximum limits are verified by design, test, or statistical analysis. Typical (Typ) numbers are not verified, but do represent

the most likely norm. Unless otherwise specified, conditions for typical specifications are: VIN = 3.6 V and TA = 25°C.

SCL and SDA must be glitch-free in order for proper brightness control to be realized.

t1

SCL

t5

t4

SDA_IN

t2

SDA_OUT

t3

2

Figure 1. I C-Compatible Interface Timing

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

7

�LM3633

SNVS867 – JUNE 2014

www.ti.com

6.7 Typical Characteristics

5

0.55

4.5

0.5

Shutdown Current (uA)

4

Rdson (

)

0.45

0.4

0.35

0.3

0.2

-50

-25

0

25

50

75

100

3

2.5

2

1.5

1

VIN=2.7V

VIN=3.6V

VIN=5.5V

0.25

3.5

VIN=2.7V

VIN=3.6V

VIN=5.5V

0.5

0

-50

125

-25

0

Temperature (C)

25

50

75

100

125

Temperature (C)

C001

C001

Figure 2. NMOS RDSON vs Temperature

Figure 3. Shutdown IQ vs Temperature

1040

0.26

1020

0.24

0.22

VHR_HV (V)

OCP (mA)

1000

980

960

940

0.2

0.18

0.16

0.14

VIN=2.7V

VIN=3.6V

VIN=5.5V

920

900

-50

-25

0

25

50

75

100

VIN=2.7V

VIN=3.6V

VIN=5.5V

0.12

0.1

125

-50

-25

0

Temperature (C)

25

50

75

100

125

Temperature (C)

C001

C001

Figure 5. VHR_HV vs Temperature

1000

0.16

900

0.15

800

0.14

VGTH (V)

CP Rout (m

)

Figure 4. Boost OCP vs Temperature

700

600

0.13

0.12

VIN=2.7V

VIN=3.6V

VIN=5.5V

500

400

-50

-25

0

25

50

75

100

0.1

125

-50

Temperature (C)

-25

0

25

50

75

100

125

Temperature (C)

C001

Figure 6. Charge Pump ROUT vs Temperature

8

VIN=2.7V

VIN=3.6V

VIN=5.5V

0.11

C001

Figure 7. Low Voltage LED VGTH vs Temperature

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

4.44

85

4.435

80

4.43

75

VHR_LV (mV)

VCPOUT (V)

Typical Characteristics (continued)

4.425

4.42

4.415

70

65

VIN=2.7V

VIN=3.6V

VIN=5.5V

60

VIN=2.7V

4.41

55

-50

-25

0

25

50

75

100

125

-50

-25

0

Temperature (C)

25

50

75

100

125

Temperature (C)

C001

C001

Figure 8. Charge Pump 2X Mode VCPOUT vs Temperature

Figure 9. VHR_LV vs Temperature

1.4

1.2

1.2

1

PWM Vil (V)

PWM Vih (V)

1

0.8

0.6

0.8

0.6

0.4

0.4

VIN=2.7V

VIN=3.6V

VIN=5.5V

0.2

0

-50

-25

0

25

50

75

100

VIN=2.7V

VIN=3.6V

VIN=5.5V

0.2

0

125

Temperature (C)

-50

-25

0

25

50

75

100

125

Temperature (C)

C001

Figure 10. PWM VIH vs Temperature

C001

Figure 11. PWM VIL vs Temperature

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

9

�LM3633

SNVS867 – JUNE 2014

www.ti.com

7 Detailed Description

7.1 Overview

The LM3633 provides the power for three high-voltage LED strings and six low-voltage LEDs. The three highvoltage LED strings are powered from an integrated boost converter. The six low-voltage LEDs are powered from

an integrated 2X charge pump. The device is programmable over an I2C-compatible interface. Additional features

include a Pulse Width Modulation (PWM) input for content adjustable brightness control and 6 programmable

pattern generators for RGB and indicator blinking functions on the low-voltage LEDs.

7.2 Functional Block Diagram

SW

IN

Programmable

Overvoltage

Protection (16V, 24V,

32V, 40V)

HWEN

Hardware Enable,

Reference and

Thermal Shutdown

1A Current Limit

Boost

Converter

OVP

Programmable

500kHz/1MHz

Switching

Frequency

LED String

Open/Short

Detection

High-Voltage

Current Sinks

HVLED1

HVLED2

Backlight LED Control

1. 5-bit Full-Scale

Current Select

HVLED3

2. 11-bit brightness

adjustment

GND

3. Linear/Exponential

Mapping

C+

4. LED Current

Ramping

PWM

2X

Charge Pump

Internal Low Pass

Filter

Gain Control

(Automatic, 1X,

2X)

6 x Programmable

Pattern

Generators

SDA

I2C Compatible

Interface

SCL

Indicator LED Control

1. 5-bit Full-Scale

Current Select

2. 8-bit Brightness

Adjustment

3. Linear/Exponential

Mapping

C-

CPOUT

Low Voltage

Current Sinks

LVLED1

LVLED2

LVLED3

LVLED4

LVLED5

LVLED6

4, LED Current

Ramping

7.3 Feature Description

7.3.1 Control Bank Mapping

Control of the LM3633’s current sinks is not done directly, but through the programming of Control Banks. The

current sinks are then assigned to the programmed Control Bank. This allows a wide variety of current control

possibilities where LEDs can be grouped and controlled via specific Control Banks (see Figure 12 and

Figure 17).

10

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

Feature Description (continued)

7.3.1.1 High-Voltage Control Banks (A and B)

There are 2 high-voltage control banks (A and B). All three high-voltage current sinks can be assigned to either

Control Bank A or Control Bank B. Assigning all three current sinks to the same control bank allows for better

LED current matching. Assigning a current sink to a different control bank allows for independent current sink

programming. The high-voltage control bank mapping is done via bits [2:0] of the HVLED Current Sink Output

Configuration register (see Table 5).

7.3.1.2 Low-Voltage Control Banks (C, D, E, F, G, and H)

There are 6 low-voltage control banks (C, D, E, F, G, and H). LVLED1 to LVLED3 can be assigned to control

bank C or can be assigned to independent control banks (LVLED2 to Control Bank D and LVLED3 to Control

Bank E). LVLED4 to LVLED6 can be assigned to control bank F or can be assigned to independent control

banks (LVLED5 to Control Bank G and LVLED6 to Control Bank H). Assigning low-voltage current sinks to the

same control bank allows for the best matching between LEDs. Assigning low-voltage current sinks to different

control banks allows for each current sink to be programmed with different current levels. When the pattern

generator is disabled the low-voltage ramp up/down times (Start-up/Shutdown and Run-Time) are controlled by

the LVLED Controls C to E and Controls F to H Ramp Time register (see Table 11).

7.3.2 Pattern Generator

The LM3633 contains 6 independently programmable pattern generators for each low-voltage control bank. Each

pattern generator can have its own separate pattern: delays from turnon, high and low-current settings, and

pattern high and low times. There are two sets of rise and fall time control registers. One set is assigned to

Control Banks C to E and the other set is assigned to Control Banks F to H. All other settings are independent

(see Figure 17).

7.3.3 PWM Input

The PWM input which can be assigned to either of the high-voltage control banks. When assigned to a control

bank, the programmed current in the control bank becomes a function of the duty cycle (DPWM) at the PWM input

and the control bank brightness setting. When PWM is disabled, DPWM is equal to one.

7.3.4 HWEN Input

HWEN is the global hardware enable to the LM3633. HWEN must be pulled high to enable the device. HWEN is

a high-impedance input so it cannot be left floating. When HWEN is pulled low, the LM3633 is placed in

shutdown, and all the registers are reset to their default state.

7.3.5 Thermal Shutdown

The LM3633 contains a thermal shutdown protection. In the event the die temperature reaches 140°C (typ), the

boost, charge pump, and current sinks shut down until the die temperature drops to typically 125°C (typ).

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

11

�LM3633

SNVS867 – JUNE 2014

www.ti.com

7.4 Device Functional Modes

7.4.1 High-Voltage LED Control

Usable

Stimulus

Control

Banks

Outputs

(Assigned to Control banks)

Environmental

Stimulus

HVLED1

HVLED1

HVLED2

HVLED2

HVLED3

HVLED3

BANK A

PWM

PWM

Control

Internal Low Pass

Filter

BANK B

SDA

SCL

I2C

Compatible

Interface

High-Voltage LED Assignment

Control Bank Configuration

Boost Converter Configuration

Startup/Shutdown Ramp Configuration

Run-Time Ramp Configuration

Brightness Control

Figure 12. High-Voltage Functional Control Diagram

7.4.1.1 High-Voltage Boost Converter

The high-voltage boost converter provides power for the three high-voltage current sinks (HVLED1, HVLED2 and

HVLED3). The boost circuit operates using a 4.7-µH to 22-µH inductor and a 1-µF output capacitor. The

selectable 500-kHz or 1-MHz switching frequency allows for use of small external components and provides for

high boost-converter efficiency. HVLED1, HVLED2, and HVLED3 feature an adaptive current regulation scheme

where the feedback point (HVLED1, HVLED2, and HVLED3) regulates the LED headroom voltage to VHR_HV.

When there are different voltage requirements in the high-voltage LED strings (string mismatch), the LM3633

regulates the feedback point of the highest voltage string to VHR_HV and drops the excess voltage of the lowervoltage string across the lower string(s) current sink.

7.4.1.2 High-Voltage Current Sinks (HVLED1, HVLED2 and HVLED3)

HVLED1, HVLED2, and HVLED3 control the current in the high-voltage LED strings as configured by Control

Bank A or Control Bank B. Each Control Bank has 5-bit full-scale current programmability and 11-bit brightness

control. High-voltage current sinks are assigned to a control bank through the HVLED Current Sink Output

Configuration register (see Table 5).

7.4.1.3 High-Voltage Current String Biasing

Each high-voltage current string can be powered from the LM3633 boost output (COUT) or from an external

source. The feedback enable bits (HVLED Current Sink Feedback Enables register bits [2:0]) determine where

the high-voltage current string anodes are connected. When set to '1' (default) the high-voltage current sink

inputs are included in the boost feedback loop. This allows the boost converter to adjust its output voltage to

maintain the LED headroom voltage VHR_HV at the current sink input.

When powered from alternate sources the feedback enable bits should be set to '0'. This removes the particular

current sink from the boost feedback loop. In these configurations the application must ensure that the headroom

voltage across the high-voltage current sink is high enough to prevent the current sink from going into dropout

(see the Figure 63 for data on the high-voltage LED current vs VHR_HV).

Setting the HVLED Current Sink Feedback Enables register bits also determines triggering of the shorted highvoltage LED String Fault flag (see Fault Flags/Protection Features section).

12

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

Device Functional Modes (continued)

7.4.1.4 Boost Switching-Frequency Select

The LM3633 boost converter has two switching frequency settings. The switching frequency setting is controlled

via the Boost Frequency Select bit (bit 0 in the Boost Control register). Operating at the 500-kHz switching

frequency results in better efficiency under lighter load conditions due to the decreased switching losses. In this

mode the inductor must be between 10 µH and 22 µH. Operating at the 1-MHz switching frequency results in

better efficiency under higher load conditions due to in lower conduction losses in the MOSFETs and inductor. In

this mode the inductor can be between 4.7 µH and 22 µH.

7.4.1.5 Automatic Switching Frequency Shift

The LM3633 has an automatic frequency-select mode (bit 3 in the Boost Control register) to optimize the

frequency vs load dependent losses. In Auto-Frequency mode the boost converter switching frequency is

changed based on the high-voltage LED current. The threshold (Control A and Control B brightness code) at

which the frequency switchover occurs is programmable via the Auto-Frequency Threshold register. The AutoFrequency Threshold register contains an 8-bit code which is compared to the 8 MSBs of the brightness code.

When the brightness code is greater than the Auto-Frequency Threshold value the boost converter switching

frequency is 1 MHz. When the brightness code is less than or equal to the Auto-Frequency Threshold register

the boost converter switching frequency is 500 kHz. The default value in the Auto-Frequency Threshold register

is set for the default full-scale current setting (20.2 mA).

Figure 13 shows the LED efficiency improvement (3p5s LED configuration with a 4.7-μH inductor) when the autofrequency feature is enabled. When the LED brightness is less than or equal to 0x6C, the switching frequency is

500 kHz, and it improves the LED efficiency by up to 6%. When the LED brightness is greater than 0x6C, the

switching frequency is 1 MHz, and it improves LED efficiency by up to 2.2%.

Figure 13. Auto-Frequency Boost Efficiency Improvement

Table 1 summarizes the general recommendations for auto-frequency threshold setting vs inductance values and

LED string configurations. These are general recommendations — the optimum auto-frequency threshold setting

should be evaluated for each application

Table 1. Auto-Frequency Threshold Settings

THREE STRING

TWO STRING

INDUCTOR

(µH)

AUTO-FREQUENCY

THRESHOLD

PEAK EFFICIENCY

IMPROVEMENT (%)

PEAK

CONFIGURATION

AUTOFREQUENCY

THRESHOLD

4.7

6C

2.2

3p5s

AC

1.1

2p6s

10

74

1.7

3p4s

B4

1.3

2p5s

22

7C

0.7

3p3s

BC

0.7

2p4s

PEAK EFFICIENCY

IMPROVEMENT(%)

PEAK

CONFIGURATION

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

13

�LM3633

SNVS867 – JUNE 2014

www.ti.com

7.4.1.6 Brightness Register Current Control

The Brightness Register Current Control allows simple user-adjustable current control by writing directly to the

appropriate control bank brightness register. The current for Control Bank A and B is a function of the full-scale

LED current, the 11-bit code in the respective brightness register, and the PWM input duty cycle (if PWM is

enabled). The Control Bank A and B brightness should always be written with LSBs first and MSBs last.

7.4.1.6.1 8-Bit Control (Preferred)

The preferred operating mode is to control the high-voltage LED brightness by setting the Control Bank LSB

register (3 LSBs) to zero, using only the Control Bank MSB register (8 MSBs). In 8-bit control mode the LM3633

controls the 3 LSBs to ramp the high-voltage LED current using all 11 bits.

7.4.1.6.2 11-Bit Control

In this mode of operation, both Control Bank LSB and MSB registers must be written whenever a change in

Brightness is required. The high-voltage LED current does not change until the Control Bank MSB register is

written. If the brightness change affects only the 3 LSBs, the Control Bank MSB register (8 MSBs) must be

rewritten to change the high-voltage LED current.

7.4.1.7 PWM Control

The LM3633 PWM input can be enabled for Control Bank A or B (see Table 21). Once enabled, the LED current

becomes a function of the code in the Control Brightness registers and the PWM input-duty cycle.

The PWM input accepts a logic level voltage and internally filters it to an analog-control voltage. This results in a

linear response of duty cycle to current, where 100% duty cycle corresponds to the programmed brightness code

multiplied by the Full-Scale Current setting.

Analog Domain

PWM Input

LPF

polarity

To Assigned

High Voltage

Current Sinks

Full-Scale

Current

Control

Digital Domain

DAC

Backlight Digital LED Control Block

Full-Scale Current Select

Brightness Setting

Exponential or Linear Mapping

Startup/Shutdown Ramp Generator

Runtime Ramp Generator

Figure 14. PWM Input Architecture

7.4.1.7.1 PWM Input Frequency Range

The usable input frequency range for the PWM input is governed on the low end by the cutoff frequency of the

internal low-pass filter (540 Hz, Q = 0.33) and on the high end by the propagation delays through the internal

logic. For frequencies below 2 kHz the current ripple begins to become a larger portion of the DC LED current.

Additionally, at lower PWM frequencies the boost output voltage ripple increases, causing a non-linear response

from the PWM duty cycle to the average LED current due to the response time of the boost and current-sink

dropout. For the best response of current vs. duty cycle, the PWM input frequency should be kept between 2 kHz

and 100 kHz.

14

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

7.4.1.7.2 PWM Input Polarity

The PWM Input can be set for active low polarity, where the LED current is a function of the negative duty cycle.

This is set via the PWM Configuration register (see Table 21).

7.4.1.7.3 PWM Zero Detection

The LM3633 incorporates a feature to detect when the PWM input is near zero. When this feature is enabled the

minimum PWM input pulse must be greater than tPWM (see Electrical Characteristics). Bit 3 in the PWM

Configuration register is used to enable or disable PWM zero detection.

7.4.1.8 Start-up/Shutdown Ramp

The high-voltage LED start-up and shutdown ramp times are independently programmable in the Control A and

Control B Start-Up/Shutdown Ramp Time register (see Table 7). There are 16 different start-up and 16 different

shutdown times. The start-up times can be programmed independently from the shutdown times, but each

Control bank is not independently programmable.

The start-up ramp time is the period from when the Control Bank is enabled to when the LED current reaches its

initial set point. The shutdown ramp time is the period from when the Control Bank is disabled to when the LED

current reaches 0.

7.4.1.9 Run-Time Ramp

Current ramping from one brightness level to the next is programmed via the Control A and Control B Run-Time

Transition Time register (see Table 9). There are 16 different ramp-up times and 16 different ramp-down times.

The ramp-up time can be programmed independently from the ramp-down time, but each Control Bank cannot

be independently programmed. For example, programming a ramp-up or ramp-down time is a global setting for

all high-voltage LED Control Banks.

7.4.1.10 High-Voltage Control A/B Ramp Select

The LM3633 provides three options for configuring Control A and Control B ramp times. When the run-time ramp

select bits are set to 00 the control bank uses both the start-up/shutdown and run-time ramp times. When the

run-time ramp select bits are set to 01 the control bank uses the start-up/shutdown ramp times for both

startup/shutdown and run-time. When the run-time ramp select bits are set to 1x the control bank uses a zero

µsec run-time ramp.

7.4.1.11 LED Current Mapping Modes

All control banks can be programmed for either exponential or linear mapping modes (see Figure 19). These

modes determine the transfer characteristic of backlight code to LED current. Independent mapping of Control

Bank A and B is not allowed; both banks use the same mapping mode.

7.4.1.12 Exponential Mapping

In Exponential Mapping Mode the current ramp (either up or down) appears to the human eye as a more uniform

transition than the linear ramp. This is due to the logarithmic response of the eye.

7.4.1.12.1 8-Bit Code Calculation

In 8-bit Exponential Mapping Mode the brightness code-to-backlight current transfer function is given by the

equation:

ILED = ILED_FULLSCALE x 0.85

(44 -

Code + 1

5.8181818

)

x DPWM

(1)

Where ILED_FULLSCALE is the full-scale LED current setting (see Table 13), Code is the 8-bit brightness code in the

Control Brightness MSB register and DPWM is the PWM Duty Cycle.

7.4.1.12.2 11-Bit Code Calculation

In 11-bit Exponential Mapping Mode the brightness code-to-backlight current transfer function is given by the

equation:

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

15

�LM3633

SNVS867 – JUNE 2014

www.ti.com

ILED = ILED_FULLSCALE x 0.85

Code

+1

8

(44 - 5.8181818

)

x DPWM

(2)

Where ILED_FULLSCALE is the full-scale LED current setting (see Table 13), Code is the 11-bit brightness code in

the Control Brightness MSB and LSB registers and DPWMis the PWM Duty Cycle.

7.4.1.13 Linear Mapping

In Linear Mapping Mode the brightness code-to-backlight current has a linear relationship.

7.4.1.13.1 8-Bit Code Calculation

In Linear Mapping Mode the brightness code-to-backlight current has a linear relationship and follows the

equation:

ILED = ILED_FULLSCALE x

1 x Code x D

PWM

255

(3)

Where ILED_FULLSCALE is the full-scale LED current setting, Code is the 8-bit brightness code in the Control

Brightness MSB register and DPWMis the PWM Duty Cycle.

7.4.1.13.2 11-Bit Code Calculation

In Linear Mapping Mode the brightness code-to-backlight current has a linear relationship and follows the

equation:

ILED = ILED_FULLSCALE x

1 x Code x D

PWM

2047

(4)

Where ILED_FULLSCALE is the full-scale LED current setting, Code is the 11-bit brightness code in the Control

Brightness MSB and LSB registers and DPWMis the PWM Duty Cycle.

21.00

21

Exponential

Linear

18.00

15

LED CURRENT (mA)

LED CURRENT (mA)

15.00

12.00

9.00

6.00

12

9

6

3.00

3

0.00

0

2048

1792

1536

1280

1024

768

512

BRIGHTNESS CODE

C001

Figure 15. LED Current Mapping Modes (8-bit)

256

0

256

224

192

160

128

96

64

32

0

BRIGHTNESS CODE

16

Exponential

Linear

18

C001

Figure 16. LED Current Mapping Modes (11-bit)

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

7.4.2 Low-Voltage LED Control

Pattern

Generator

Control

Banks

Output Assignment

BANK C

LVLED1

LVLED1

BANK D

LVLED2

LVLED2

BANK E

LVLED3

LVLED3

BANK F

LVLED4

LVLED4

BANK G

LVLED5

LVLED5

BANK H

LVLED6

LVLED6

Pattern C

Run-time Ramp

Up/Down

Control

Pattern D

Pattern E

Pattern F

Run-time Ramp

Up/Down

Control

Pattern G

Pattern H

SDA

SCL

I2CCompatible

Interface

Low-Voltage LED Assignment

Control Bank Configuration

Charge Pump Configuration

Run-Time Ramp

Brightness Control

Pattern Control

Figure 17. Low-Voltage LED Functional Control Diagram

7.4.2.1 Integrated Charge Pump

The LM3633 features an integrated (2X/1X) charge pump capable of supplying LVLED1 to LVLED6 current. The

fixed 1-MHz switching frequency allows for use of tiny 1-µF ceramic flying capacitors (CP) and output capacitor

(CPOUT). The charge pump can supply the power for the low-voltage LEDs connected to LVLED1 to LVLED6

and can operate in 4 different modes: disabled, automatic gain, 1X gain, or 2X gain (see Figure 18).

VIN

IN

CPOUT

CIN

Charge

Pump

Control

Register

CPOUT

1X, 2X

Charge Pump

C+

C-

SDA

SDA

4.4V Typ (2X gain)

CP

SDA

SCL

I2CCompatible

Interface

LVLEDx

GND

Figure 18. Integrated Charge Pump

7.4.2.2 Charge Pump Disabled

With the charge pump disabled, the path from IN to CPOUT is high impedance. Additionally, with the charge

pump disabled, the low-voltage current sinks can still be active, thus allowing the low-voltage LEDs to be biased

from external sources (see Low-Voltage LED Biasing section). Disabling the charge pump also has no influence

on the state of the low-voltage current sinks. For instance, if a low-voltage current string is set to have its anode

connected to CPOUT, and the charge pump is disabled, the current sink continues to try to sink current.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

17

�LM3633

SNVS867 – JUNE 2014

www.ti.com

7.4.2.3 Automatic Gain

In Automatic Gain Mode the charge-pump-gain transition is actively selected to maintain LED current regulation

in the CPOUT-connected, low-voltage current sinks. At higher input voltages the charge pump operates in Pass

Mode (1x gain) allowing the voltage at CPOUT to track the input voltage. As VIN drops, the voltage on the lowvoltage current sink(s) drops also. Once any of the active, CPOUT-connected, low-voltage current sink input

voltages reach VHR_LV (see Electrical Characteristics), the charge pump automatically switches to a gain of 2x

thus preventing dropout (see 2X Gain). Once the charge pump switches over to 2X gain it remains in 2X gain

until the active low-voltage current sinks are turned off (enable bit or brightness code 0), even if the current sink

input voltage goes above the switch over threshold.

7.4.2.4 Automatic Gain (Flying Capacitor Detection)

In Automatic Gain Mode the LM3633 starts up and automatically detects if there is a flying capacitor (CP)

connected between C+ and C−. If there is, Automatic Gain Mode operates normally. If the detection circuitry

does not detect a connected flying capacitor, the LM3633 automatically switches to 1X Gain mode.

7.4.2.5 1X Gain

In 1X Gain Mode the charge pump passes VIN directly through to the output capacitor (CPOUT). There is a

resistive drop between IN and CPOUT in the 1X Gain Mode (typically 1.1 Ω) which should be accounted for

when determining the headroom requirement for the low-voltage current sinks. In forced 1X Gain Mode the

charge pump does not switch; thus, the CP and CPOUT can be omitted from the circuit.

7.4.2.6 2X Gain

In 2X Gain Mode the internal charge pump doubles VIN and post-regulates CPOUT to, typically, 4.4 V. This

allows for biasing LEDs whose forward voltages are greater than the input supply (VIN).

7.4.2.7 Low-Voltage Current Sinks (LVLED1 to LVLED6)

Low-voltage current sinks LVLED1 to LVLED6 each provide the current for a single LED as configured via

Control Banks C to H. Each control bank has 8-bit brightness control and 5-bit full-scale current programmability.

The low-voltage current sinks can be controlled directly through a dedicated brightness register or with different

blinking patterns via the 6 internal pattern generators. Configuration of the low-voltage current sinks is done

through the low-voltage Control Bank C to H (LVLED1, LVLED2, and LVLED3 to Control Bank C to E and

LVLED4, LVLED5, and LVLED6 to Control Bank F to H). (See Table 6.)

7.4.2.8 Low-Voltage LED Biasing

Each low-voltage LED can be powered from the LM3633 charge pump output (CPOUT) or from an external

source. When powered from CPOUT the feedback enable bit (LVLED Current Sink Feedback Enables Register

bits [5:0]) for that particular low-voltage current sink must be set to '1' (default). This allows for the specific lowvoltage current sink to have control over the charge pumps gain control (see Automatic Gain section).

When powered from alternate sources (such as VIN) the feedback enable bit for the particular low-voltage current

sink must be set to '0'. This removes the particular current sink from the charge pump feedback loop. In these

configurations the application must ensure that the headroom voltage across the low-voltage current sink is high

enough to prevent the low-voltage current sinks from going into dropout (see Figure 64 for data on the lowvoltage LED current vs headroom voltage).

The LVLEDX feedback enable bits also determine how the shorted low-voltage LED String fault flag is triggered

(see Fault Flags/Protection Features).

7.4.2.9 Brightness Register Current Control

The LM3633 features brightness register current control for simple user-adjustable current control set by writing

directly to the appropriate Control Bank Brightness Registers. The current for the low-voltage LED Control Bank

C to H is a function of the full-scale LED current and the 8-bit code in the respective brightness register. The

control bank brightness register code represents the percentage of the full-scale LED current. This percentage of

full-scale current is different depending on the selected mapping mode (see Table 12).

18

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

7.4.2.10 LED Current Mapping Modes

All control banks can be programmed for either exponential or linear mapping modes (see Figure 19). These

modes determine the transfer characteristic of brightness code to LED current. All low-voltage control banks use

the same mapping mode.

7.4.2.11 Exponential Mapping

In Exponential Mapping Mode the current ramp (either up or down) appears to the human eye as a more uniform

transition than the linear ramp. This is due to the logarithmic response of the eye.

In Exponential Mapping Mode the brightness code-to-current transfer function is given by the equation:

ILED = ILED_FULLSCALE x 0.85

(44 -

Code + 1

5.8181818

)

(5)

Where ILED_FULLSCALE is the full-scale LED current setting (see Table 13) and Code is the brightness code in the

brightness register.

7.4.2.12 Linear Mapping

In Linear Mapping Mode the brightness code-to-current has a linear relationship and follows the equation:

ILED = ILED_FULLSCALE x

1 x Code

255

(6)

Where ILED_FULLSCALE is the full-scale LED current setting and Code is the brightness code in the brightness

register.

21.00

Exponential

Linear

18.00

LED CURRENT (mA)

15.00

12.00

9.00

6.00

3.00

0.00

256

224

192

160

128

96

64

32

0

BRIGHTNESS CODE

C001

Figure 19. LED Current Mapping Modes

7.4.2.13 Start-up/Shutdown Ramp

The start-up and shutdown ramp times are independently programmable in the Control C to Control H StartUp/Shutdown Ramp-Time registers (see Table 8). There are 8 different start-up and 8 different shutdown times.

The start-up times can be programmed independently from the shutdown times. The start-up ramp time is from

when the Control Bank is enabled to when the LED current reaches its initial set point. The shutdown ramp time

is from when the Control Bank is disabled to when the LED current reaches 0.

7.4.2.14 Run-Time Ramp

Current ramping from one brightness level to the next is programmed via the Control C to E and Control F to H

Ramp-Time registers (see Table 11). There are 8 different ramp-up times and 8 different ramp-down times. The

ramp-up time can be programmed independently from the ramp-down time, but each Control Bank cannot be

independently programmed. There is one ramp time register which is common to Control Bank C to E and one

ramp time register which is common to Control Bank F to H. This register sets the ramp-up and ramp-down times

for both direct brightness control and pattern generator modes of operation.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

19

�LM3633

SNVS867 – JUNE 2014

www.ti.com

7.4.3 Low-Voltage LED Pattern Generator

The LM3633 contains 6 programmable pattern generators (one for each low-voltage control bank). Each pattern

generator has the ability to drive a unique programmable pattern. Each pattern generator has its own set of

registers available for pattern programming. The programmable patterns are : delay time, high period, low period,

high brightness, and low brightness (see Figure 20). The ramp-up and ramp-down times are controlled by the

Control C to E and Control F to H Ramp-Time register. (See Table 11.)

tHIGH

IHIGH

ILOW

tDELAY

tRISE

tFALL

tLOW

Figure 20. Pattern Generator Timing

7.4.3.1 Delay Time

The delay time (tDELAY) is the delay from when the pattern is enabled to when the LED current begins ramping up

in the control bank assigned current source(s). The pattern starts when the respective Control Bank Enable

register is written high if the Pattern Generator is enabled. There is one tDELAY register for each pattern generator

(6 total). The selectable times are programmed with the lower 6 bits of the tDELAY registers. The times are split

into 2 groups where codes 0x00 to 0x3C are short durations from 16.384 ms (code 0x00) up to 999.424 ms

(code 0x3C) or 16.384 ms/bit. The higher codes (0x3D to 0x7F) select tDELAY from 1130.496 ms up to 9781.248

ms, or 131.072 ms/bit (see Table 27).

7.4.3.2 Rise Time

The LED current rise time (tRISE) is the time the LED current takes to move from the low-current brightness level

(ILOW) to the high-current brightness level (IHIGH). The rise time of the LED current (tRISE) is set via the Control C

to E and Control F to H Ramp-Time registers. There are 8 available ramp-up time settings (see Table 11). There

is one ramp-time register which is common to Control Bank C to E and one ramp-time register which is common

to Control Bank F to H.

7.4.3.3 Fall Time

The LED current fall time (tFALL) is the time the LED current takes to move from the high-current brightness level

(IHIGH) to the low-current brightness level (ILOW). The fall time of the LED current (tFALL) is set via the Control C to

E and Control F to H Ramp Time registers. There are 8 available ramp-down settings (see Table 11). There is

one ramp-time register which is common to Control Bank C to E and one ramp-time register which is common to

Control Bank F to H.

7.4.3.4 High Period

The LED current high period (tHIGH) is the duration that the LED pattern spends at the high LED current set point

(tHIGH). The tHIGH times are programmed via the Pattern Generator High-Time registers. The programmable times

are broken into 2 groups. The first set (from code 0x00 to 0x3C) increases the tHIGH time in steps of 16.384 ms.

The second set (from code 0x3D to 0x7F) increases the tHIGH time in steps of 131.072 ms (see Table 29).

7.4.3.5 Low Period

The LED current low period (tLOW) is the duration that the LED current spends at the low LED current set point

(ILOW). The tLOW times are programmed via the Pattern Generator Low-Time registers. There are 256 tLOW

settings that are broken into 3 groups of linearly increasing times. The first set (from code 0x00 to 0x3C)

increases the tLOW time in steps of 16.384 ms. The second set (from code 0x3D to 0x7F) increases the tLOW time

in steps of 131.072 ms. The third set (from code 0x80 to 0xFF) increases the tLOW time in steps of 524.288 ms

(see Table 28).

20

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

7.4.3.6 Low-Level Brightness

The LED current low brightness level (ILOW) is the LED current set point that the pattern rests at during the tLOW

period. This level is set via the Pattern Generator Low-Level Brightness registers (BREGL_C to BREGL_H). The

brightness level has 8 bits of programmability. ILOW is a function of the Control Bank full-scale current setting and

the code in the Pattern Generator Low-Level Brightness registers.

For exponential mapping ILOW is:

(44 -

ILOW = ILED_FULLSCALE x 0.85

BREGL_X + 1

)

5.8181818

(7)

For linear mapping ILOW is:

ILOW = ILED_FULLSCALE x

1 x BREGL_X

255

(8)

BREGL_X is the Pattern Generator Low-Level Brightness Register setting for the specific Control Bank.

7.4.3.7 High-Level Brightness

The LED current high brightness level (IHIGH) is the LED current set point that the pattern rests at during the tHIGH

period. This high-current level is set via the Control Banks Brightness Register (BREGH_C to BREGH_H). The

brightness level has 8 bits of programmability. IHIGH is a function of the Control Bank full-scale current setting and

the code in the Control Banks Brightness Register, prior to the Mapping Mode selected.

For exponential mapping IHIGH is:

IHIGH = ILED_FULLSCALE x 0.85

+1

(44 - BREGH_X

)

5.8181818

(9)

For linear mapping IHIGH is:

IHIGH = ILED_FULLSCALE x

1 x BREGH_X

255

(10)

BREGH_X is the Control Banks Brightness Register setting for the specific Control Bank.

7.4.4 Fault Flags/Protection Features

The LM3633 contains both an LED open-fault and LED short-fault detection. These fault detections are designed

to be used in production-level testing and not during normal operation. For the fault flags to operate they must be

enabled via the LED Fault Enable Register (see Table 35). The Open LED String (HVLED), Shorted LED String

(HVLED), Open LED (LVLED), and Shorted LED (LVLED) sections detail proper procedure for reading back

open and short faults in both the high-voltage LED and low-voltage LED strings.

7.4.4.1 Open LED String (HVLED)

An open LED string is detected when the voltage at the input to any active high-voltage current sink has fallen

below 200 mV, and the boost output voltage has hit the OVP threshold. This test assumes that the HVLED string

being detected for an open is connected to the LM3633 boost output (COUT+) (see Table 31). For an HVLED

string not connected to the LM3633 boost output voltage, but connected to another voltage source, the boost

output does not trigger the OVP flag. In this case an open LED string is not detected.

The procedure for detecting an open fault in the HVLED current sinks (provided they are connected to the boost

output voltage) is:

• Apply power to the LM3633

• Enable Open Fault (Register 0xB4, bit [0] = 1)

• Assign HVLED1, HVLED2 and HVLED3 to Bank A (Register 0x10, Bits [2:0] = (0, 0, 0)

• Set the start-up ramp times to the fastest setting (Register 0x12 = 0x00)

• Set Bank A full-scale current to 20.2 mA (Register 0x20 = 0x13)

• Configure HVLED1, HVLED2, and HVLED3 for LED string anode connected to COUT (Register 0x28, bits[2:0]

= (1,1,1))

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

21

�LM3633

SNVS867 – JUNE 2014

•

•

•

•

•

www.ti.com

Set Bank A brightness to maximum (Register 0x41 = 0xFF)

Enable Bank A (Register 0x2B Bit[0] = 1

Wait 4 ms

Read back bits[2:0] of register 0xB0. Bit [0] = 1 (HVLED1 open). Bit [1] = 1 (HVLED2 open). Bit [2] = 1

(HVLED3 open)

Disable all banks (Register 0x2B = 0x00)

7.4.4.2 Shorted LED String (HVLED)

The LM3633 features an LED short-fault flag indicating one or more of the HVLED strings have experienced a

short. The method for detecting a shorted HVLED strings is if the current sink is enabled and the string voltage

(VOUT - VHVLED1/2/3) falls to below (VIN – 1 V). This test must be performed on one HVLED string at a time.

Performing the test with both current sinks enabled can result in a faulty reading if one of the strings is shorted

and the others are not.

The procedure for detecting a short in an HVLED string is:

• Apply power to the LM3633

• Enable Short Fault (Register 0xB4, bit [1] = 1)

• Enable Feedback on the HVLED Current Sinks (Register 0x28, bits[2:0] = (1,1,1))

• Assign HVLED1 to Bank A (Register 0x10, Bits [2:0] = (1, 1, 0)

• Set the start-up ramp times to the fastest setting (Register 0x12 = 0x00)

• Set Bank A full-scale current to 20.2 mA (Register 0x20 = 0x13)

• Set Bank A brightness to max (Register 0x41 = 0xFF)

• Enable Bank A (Register 0x2B Bit[0] = 1)

• Wait 4 ms

• Read back bits[0] of register 0xB2. 1 = HVLED1 short.

• Disable all banks (Register 0x2B = 0x00)

• Repeat the procedure for the HVLED2 and HVLED3 strings

7.4.4.3 Open LED (LVLED)

The LM3633 features an open-LED-fault flag indicating one or more of the active low-voltage LED strings are

open. An open in a low-voltage LED string is flagged if the voltage at the input to any active low-voltage current

sink goes below VHR_LV (typically 80 mV).

Since the open LED detect is flagged when any active current sink input falls below VHR_LV, certain configurations

can result in falsely triggering an open. These include:

1. LED anode is tied to CPOUT, charge pump is in 1X gain, and VIN drops low enough to bring any active

LVLED current sink below VHR_LV.

2. LED anodeis not tied to CPOUT and VLED_ANODE goes low enough to bring any active LVLED current sink

below VHR_LV.

The following list describes a test procedure that can be used in detecting an open in the LVLED strings:

• Apply power to the LM3633

• Enable Open Fault (Register 0xB4, bit [0] = 1)

• Assign LVLED1, LVLED2, and LVLED3 to Bank C and LVLED4, LVLED5, and LVLED6 to Bank F (Register

0x11 = 0x00)

• Set the start-up ramp times to the fastest setting (Registers 0x14 and 0x17 = 0x00)

• Set Bank C and Bank F full-scale current to 20.2 mA (Registers 0x22 and 0x25 = 0x13)

• Configure all LVLED strings for Anode connected to CPOUT (register 0x29 bits[5:0]=1)

• Force the Charge Pump into 2X gain (Register 0x2A Bits[2:1] = 11). Ensure that CPOUT and CP are in the

circuit and that (VCPOUT is > VFLVLED + VHR_LV)

• Set Bank C and Bank F brightness to max (Registers 0x42 and 0x45 = 0xFF)

• Enable Bank C and Bank F (Register 0x2B Bits[5,2] = 1)

• Wait 4 ms

• Read back bits[5:0] of register 0xB1 (1 indicates an open, and a 0 indicates normal operation (see Table 32))

22

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

•

SNVS867 – JUNE 2014

Disable all banks (Register 0x2B = 0x00)

7.4.4.4 Shorted LED (LVLED)

The LM3633 features an LED short-fault flag indicating when any active low-voltage LED is shorted (Anode to

Cathode). A short in a low-voltage LED is determined when the LED voltage (VCPOUT - VHR_LV) falls below 1 V.

A

•

•

•

•

•

•

•

•

•

•

•

•

procedure for determining a short in an LVLED string is detailed below:

Apply Power

Enable Short Fault (Register 0xB4, bit [1] = 1)

Assign LVLED1, LVLED2, and LVLED3 to Bank C and LVLED4, LVLED5, and LVLED6 to Bank F (Register

0x11 = 0x00)

Set the start-up ramp times to the fastest setting (Registers 0x14 and 0x17 = 0x00)

Set Bank C and Bank F full-scale current to 20.2 mA (Registers 0x22 and 0x25 = 0x13)

Enable Feedback on the LVLED Current Sinks (Register 0x29 = 0x3F)

Set Charge Pump to 1X gain (Register 0x2A = 0x40)

Set Bank C and Bank F brightness to max (Register 0x42 and 0x45 = 0xFF)

Enable Bank C and Bank F(Register 0x2B Bits[5,2] = 1)

Wait 4 ms

Read bits[5:0] from register 0xB3. A 1 indicates short, and a 0 indicates normal operation (see Table 34).

Disable all banks (Register 0x2B = 0x00)

7.4.4.5 Overvoltage Protection (Inductive Boost)

The overvoltage protection threshold (OVP) on the LM3633 has 4 different programmable options: 16 V, 24 V, 32

V, and 40 V. The OVP protects the device and associated circuitry from high voltages in the event a high-voltage

LED string becomes open. During normal operation, the LM3633 inductive boost converter boosts the output up

so as to maintain VHR at the active, high-voltage (COUT connected) current sink inputs. When a high-voltage

LED string becomes open, the feedback mechanism is broken, and the boost converter over-boosts the output.

When the output voltage reaches the OVP threshold the boost converter stops switching, thus allowing the

output node to discharge. When the output discharges to VOVP minus 1 V, the boost converter begins switching

again. The OVP sense is at the OVP pin, so this pin must be connected directly to the inductive boost output

capacitor positive pin.

For high-voltage current sinks that have the HVLED Current Sink Feedback Enables setting such that the highvoltage current sinks anodes are not connected to COUT (feedback is disabled), the overvoltage sense

mechanism is not in place to protect the input to the high-voltage current sink. In this situation the application

must ensure that the voltage at HVLED1, HVLED2, or HVLED3 does not exceed 40 V.

The default setting for OVP is set at 16 V. For applications that require higher than 16 V at the boost output, the

OVP threshold must be programmed to a higher level after power up.

7.4.4.6 Current Limit (Inductive Boost)

The NMOS switch current limit for the LM3633 inductive boost is set at 1 A (typ). When the current through the

LM3633 NFET switch hits this overcurrent protection threshold (OCP), the device turns the NFET off, and the

inductor’s energy is discharged into the output capacitor. Switching is then resumed at the next cycle. The

current limit protection circuitry can operate continuously each switching cycle. The result is that during highoutput power conditions the device can run continuously in current limit. Under these conditions the LM3633

inductive boost converter stops regulating the headroom voltage across the high-voltage current sinks. This

results in a drop in the LED current.

7.4.4.7 Current Limit (Charge Pump)

The LM3633 charge pump output current limit is set high enough so that the device supports 29.8 mA (maximum

full-scale current) in all LVLED current sinks. (This is typically 29.5 mA x 6 = 179 mA.) For 1X gain the output

current limit is typically 350 mA (VIN = 3.6 V). For 2X gain the current limit is typically 240 mA (output referred),

with a typical limit on the input current of 480 mA. Figure 67 and Figure 68 detail the charge pump current limit vs

VIN at both 1X and 2X gain settings.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

23

�LM3633

SNVS867 – JUNE 2014

www.ti.com

7.4.5 I2C-Compatible Interface

7.4.5.1 Start and Stop Conditions

The LM3633 is controlled via an I2C-compatible interface. START and STOP conditions classify the beginning

and the end of the I2C session. A START condition is defined as SDA transitioning from HIGH to LOW while SCL

is HIGH. A STOP condition is defined as SDA transitioning from LOW to HIGH while SCL is HIGH. The I2C

master always generates START and STOP conditions. The I2C bus is considered busy after a START condition

and free after a STOP condition. During data transmission the I2C master can generate repeated START

conditions. A START and a repeated START condition are equivalent function-wise. The data on SDA must be

stable during the HIGH period of the clock signal (SCL). In other words, the state of SDA can only be changed

when SCL is LOW.

SDA

SCL

S

P

Start Condition

Stop Condition

Figure 21. Start and Stop Sequences

7.4.5.2 I2C-Compatible Address

The chip address for the LM3633 is 0110110 (36h). After the START condition, the I2C master sends the 7-bit

chip address followed by an eighth read or write bit (R/W). R/W = 0 indicates a WRITE, and R/W = 1 indicates a

READ. The second byte following the chip address selects the register address to which the data is written. The

third byte contains the data for the selected register.

7.4.5.3 Transferring Data

Every byte on the SDA line must be eight bits long, with the most significant bit (MSB) transferred first. Each byte

of data must be followed by an acknowledge bit (ACK). The acknowledge related clock pulse (9th clock pulse) is

generated by the master. The master releases SDA (HIGH) during the 9th clock pulse. The LM3633 pulls down

SDA during the 9th clock pulse signifying an acknowledge. An acknowledge is generated after each byte has

been received.

7.5 Register Descriptions

Table 2 lists the available registers within the LM3633.

Table 2. LM3633 Register Descriptions

Address

Power On Reset

Operation

Revision

Name

0x00

0x00

Dynamic

Software Reset

0x01

0x00

Dynamic

HVLED Current Sink Output Configuration

0x10

0x06

Static

LVLED Current Sink Output Configuration

0x11

0x36

Static

Control A Start-Up/Shutdown Ramp Time

0x12

0x00

Static

Control B Start-Up/Shutdown Ramp Time

0x13

0x00

Static

Control C Start-Up/Shutdown Ramp Time

0x14

0x00

Static

Control D Start-Up/Shutdown Ramp Time

0x15

0x00

Static

Control E Start-Up/Shutdown Ramp Time

0x16

0x00

Static

Control F Start-Up/Shutdown Ramp Time

0x17

0x00

Static

Control G Start-Up/Shutdown Ramp Time

0x18

0x00

Static

Control H Start-Up/Shutdown Ramp Time

0x19

0x00

Static

Control A and Control B Runtime Ramp Time

0x1A

0x00

Static

24

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: LM3633

�LM3633

www.ti.com

SNVS867 – JUNE 2014

Register Descriptions (continued)

Table 2. LM3633 Register Descriptions (continued)

Name

Address

Power On Reset

Operation

Control A and Control B Runtime Ramp Configuration

0x1B

0x00

Static

Control C to E Runtime Ramp Time

0x1C

0x00

Static

Control F to H Runtime Ramp Time

0x1D

0x00

Static

Reserved

0x1E

0x33

Static

Brightness Configuration

0x1F

0x00

Static (1)

Control A Full-Scale Current Setting

0x20

0x13

Static

Control B Full-Scale Current Setting

0x21

0x13

Static

Control C Full-Scale Current Setting

0x22

0x13

Static

Control D Full-Scale Current Setting

0x23

0x13

Static

Control E Full-Scale Current Setting

0x24

0x13

Static

Control F Full-Scale Current Setting

0x25

0x13

Static

Control G Full-Scale Current Setting

0x26

0x13

Static

Control H Full-Scale Current Setting

0x27

0x13

Static

HVLED Current Sink Feedback Enable

0x28

0x07

Static

LVLED Current Sink Feedback Enable

0x29

0x3F

Static

Charge Pump Control

0x2A

0x00

Dynamic (2)

Control Bank Enables

0x2B

0x00

Dynamic (3)

Pattern Generator Enable

0x2C

0x00

Dynamic

Boost Control

0x2D

0x00

Static

Auto-Frequency Threshold

0x2E

0xCF

Static

PWM Configuration

0x2F

0x04

Dynamic (4)

Reserved

0x30

0x0B

Static

Reserved

0x31

0x00

Static

Control A Brightness LSB

0x40

0x00

Dynamic (5)

Control A Brightness MSB

0x41

0x00

Dynamic

Control B Brightness LSB

0x42

0x00

Dynamic (5)

Control B Brightness MSB

0x43

0x00

Dynamic

Control C Brightness

0x44

0x00

Dynamic

Control D Brightness

0x45

0x00

Dynamic

Control E Brightness

0x46

0x00

Dynamic

Control F Brightness

0x47

0x00

Dynamic

Control G Brightness

0x48

0x00

Dynamic

Control H Brightness

0x49

0x00

Dynamic

Control C Pattern Generator Delay Time

0x50

0x00

Static

Control C Pattern Generator Low Time

0x51

0x00

Static

Control C Pattern Generator High Time

0x52

0x00

Static

Control C Pattern Generator Low-Level Brightness

0x53

0x00

Dynamic

Control D Pattern Generator Delay Time

0x60

0x00

Static

Control D Pattern Generator Low Time

0x61

0x00

Static

Control D Pattern Generator High Time

0x62

0x00

Static

Control D Pattern Generator Low-Level Brightness

0x63

0x00

Dynamic

(1)

(2)

(3)

(4)

(5)

This register requires special handling due to the control of both high-voltage and low-voltage LEDs.

Only the charge pump enable bit is dynamic; the charge pump gain select bits should only be changed when the charge pump is

disabled.