Product

Folder

Sample &

Buy

Support &

Community

Tools &

Software

Technical

Documents

LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

LM5140-Q1 Wide Input Range Dual Synchronous Buck Controller

1 Features

2 Applications

•

•

•

•

•

•

1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Qualified for Automotive Applications

AEC-Q100 Test Guidance With the Following

– Device Temperature Grade 1: –40ºC to

+125ºC Ambient Operating Temperature

– Device HBM ESD Classification Level 2

– Device CDM ESD Classification Level C4B

Input Operating Range from 3.8 V to 65 V (70 V

Absolute Maximum)

Two Interleaved Buck Controllers With:

– VOUT1 Fixed 3.3 V, 5 V, or Adjustable

from 1.5 V – 15 V, Accuracy ±1%

– VOUT2 Fixed 5 V, 8 V, or Adjustable

from 1.5 V – 15 V, Accuracy ±1%

Fixed 2.2-MHz or 440-kHz Switching Frequency,

Accuracy ±7%

Optional Synchronization to an External Clock

SYNC Output Clock for Additional Converters

Shutdown Mode Current: 9 µA Typical

No Load Standby Current: 35 µA Typical (One

Channel Operating)

Current Limit Threshold Programmable to 50 mV

or 75 mV, Accuracy ±10%

Independent Enable Inputs for VOUT1 and

VOUT2

Hiccup Mode Protection for Sustained Overload

Independent Power Good Outputs

High-Side and Low-Side Gate Drivers With

Adjustable Slew Rate Control

Selectable Diode Emulation or Continuous

Conduction at Light Load

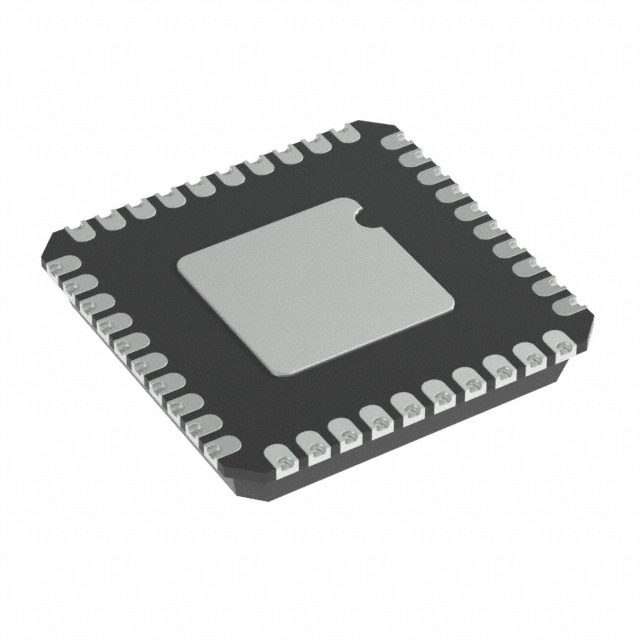

40-Pin VQFN Package With Wettable Flanks

Automotive Electronics

Infotainment Systems

Instrument Clusters

Advanced Driver Assistance (ADAS)

3 Description

The LM5140-Q1 is a dual synchronous buck

controller intended for high voltage wide VIN stepdown converter applications. The control method is

based on current mode control. Current mode control

provides inherent line feedforward, cycle-by-cycle

current limiting, and easier loop compensation.

The LM5140-Q1 features adjustable slew rate control

to simplify compliance with the CISPR and

automotive EMI requirements. The LM5140-Q1

operates at selectable switching frequencies of 2.2

MHz or 440 kHz with the two controller channels

switching 180º out of phase. In light or no-load

conditions, the LM5140-Q1 operates in skip cycle

mode for improved low power efficiency. The

LM5140-Q1 includes a high voltage bias regulator

with automatic switchover to an external bias supply

to improve efficiency and reduce input current.

Additional features include frequency synchronization,

cycle-by-cycle current limit, hiccup mode fault

protection for sustained overloads, independent

power good outputs, and independent enable inputs.

Device Information(1)

PART NUMBER

LM5140-Q1

PACKAGE

VQFN (40)

BODY SIZE (NOM)

6.00 mm × 6.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Simplified Schematic

VIN

VCC

VOUT1

VIN

VCC

HB1

HB2

HO1

HOL1

HO2

HOL2

SW1

SW2

LO1

LOL1

PGND1

PG1

EN1

ILSET

CS1

VOUT1

SYNIN

COMP1

VCC

VIN

LM5140-Q1

VOUT2

LO2

LOL2

PGND2

EN2

VIN

PG2

SYNOUT

CS2

VOUT2

VCCX

COMP2

FB2

FB1

OSC AGND SS1 RES SS2 DEMB VDDA

VCC

VCC

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

6.1

6.2

6.3

6.4

6.5

6.6

6.7

7

1

1

1

2

3

5

Absolute Maximum Ratings ...................................... 5

ESD Ratings.............................................................. 5

Recommended Operating Conditions....................... 6

Thermal Information .................................................. 6

Electrical Characteristics........................................... 7

Switching Characteristics .......................................... 9

Typical Characteristics ............................................ 11

Detailed Description ............................................ 14

7.1 Overview ................................................................. 14

7.2 Functional Block Diagram ....................................... 15

7.3 Feature Description................................................. 16

7.4 Device Functional Modes........................................ 23

8

Application and Implementation ........................ 26

8.1 Application Information............................................ 26

8.2 Typical Application ................................................. 26

9 Power Supply Recommendations...................... 38

10 Layout................................................................... 38

10.1 Layout Guidelines ................................................. 38

10.2 Layout Example .................................................... 39

11 Device and Documentation Support ................. 41

11.1

11.2

11.3

11.4

11.5

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

41

41

41

41

41

12 Mechanical, Packaging, and Orderable

Information ........................................................... 41

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Original (January 2016) to Revision A

Page

•

Updated data sheet text to the latest TI documentation and translations standards ............................................................. 1

•

Added AEC-Q100 Test Guidance bullets to Features............................................................................................................ 1

•

Added content to the Minimum Output Voltage Adjustment section .................................................................................... 21

•

Changed Equation 11........................................................................................................................................................... 22

•

Changed content and Equation 12 in Slope Compensation section .................................................................................... 23

•

Changed content and Equation 14 and Equation 15 in Inductor Calculation section .......................................................... 27

•

Changed Equation 39........................................................................................................................................................... 30

•

Changed Equation 41........................................................................................................................................................... 31

•

Changed content and Equation 52 through Equation 55 in Control Loop section ............................................................... 34

•

Changed content, Equation 57, and Equation 60 through Equation 63 in Error Amplifier section ..................................... 35

•

Added equations Equation 56, Equation 58 and Equation 61 in Error Amplifier section .................................................... 35

•

Changed Figure 38............................................................................................................................................................... 36

•

Changed Equation 64........................................................................................................................................................... 36

2

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

5 Pin Configuration and Functions

EN2

SYNOUT

SYNIN

OSC

VDDA

AGND

ILSET

DEMB

RES

EN1

RWG Package

40-Pin VQFN

Top View

40

39

38

37

36

35

34

33

32

31

SS2

1

30

SS1

COMP2

2

29

COMP1

FB2

3

28

FB1

CS2

4

27

CS1

VOUT2

5

26

VOUT1

25

VIN

Exposed Pad on Bottom

Connect to Ground

HOL1

HO2

9

22

HO1

SW2

10

21

SW1

12

13

14

PGND2

11

15

16

17

18

19

20

HB1

23

LOL1

8

LO1

HOL2

PGND1

PG1

VCC

24

VCC

7

LO2

PG2

LOL2

6

HB2

VCCX

Connect Exposed Pad on bottom to AGND and PGND on the PCB.

Pin Functions

PIN

NO.

NAME

I/O

DESCRIPTION

1

SS2

I

Channel 2 soft-start programming pin. An external capacitor and an internal 20-μA current

source set the ramp rate of the internal error amplifier reference during soft-start. Pulling SS

pin below 80 mV turns off the channel 2 gate driver outputs, but all the other functions

remain active.

2

COMP2

O

Output of the channel 2 transconductance error amplifier.

3

FB2

I

Feedback input of channel 2. Connect the FB2 pin to VDD for a 5-V output or connect FB2

to ground for a fixed 8-V output. A resistive divider from the VOUT2 to the FB2 pin sets the

output voltage level between 1.5 V and 15 V. The regulation threshold at the FB2 pin is 1.2

V.

4

CS2

I

Channel 2 current sense amplifier input. Make a low current Kelvin connection between this

pin and the inductor side of the external current sense resistor.

5

VOUT2

I

Output and the current sense amplifier input of channel 2 . Connect this pin to the output

side of the channel 2 current sense resistor.

6

VCCX

I

Optional input for an external bias supply. If VCCX > 4.5 V, VCCX is internally connected to

VCC and the internal VCC regulator is disabled. If VCCX is unused, it must be grounded.

7

PG2

O

An open-collector output which goes low if VOUT2 is outside a specified regulation window.

8

HOL2

O

Channel 2 high-side gate driver turnoff output.

9

HO2

O

Channel 2 high-side gate driver turnon output.

10

SW2

I

Switching node of the channel 2 buck regulator. Connect to the bootstrap capacitor, the

source terminal of the high-side MOSFET and the drain terminal of the low-side MOSFET.

11

HB2

O

Channel 2 high-side driver supply for bootstrap gate drive.

12

LOL2

O

Channel 2 low-side gate driver turnoff output.

13

LO2

O

Channel 2 low-side gate driver turnon output.

14

PGND2

G

Power ground connection pin for low-side NMOS gate driver.

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

3

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Pin Functions (continued)

PIN

NO.

NAME

I/O

DESCRIPTION

15

VCC

P

VCC bias supply pin. Pin 15 and pin 16 must to be connected together on the PCB.

16

VCC

P

VCC bias supply pin. Pin 15 and pin 16 must to be connected together on the PCB.

17

PGND1

G

Power ground connection pin for low-side NMOS gate driver.

18

LO1

O

Channel 1 low-side gate driver turnon output.

19

LOL1

O

Channel 1 low-side gate driver turnoff output.

20

HB1

O

Channel 1 high-side driver supply for bootstrap gate drive.

21

SW1

I

Switching node of the channel 1 buck regulator. Connect to the bootstrap capacitor, the

source terminal of the high-side MOSFET and the drain terminal of the low-side MOSFET.

22

HO1

O

Channel 1 high-side gate driver turnon output

23

HOL1

O

Channel 1 high-side gate driver turnoff output.

24

PG1

O

An open-collector output which goes low if VOUT1 is outside a specified regulation window.

25

VIN

P

Supply voltage input source for the VCC regulators.

26

VOUT1

I

VOUT1 and current sense amplifier input of channel 1. Connect to the output side of the

channel 1 current sense resistor.

27

CS1

I

Channel 1 current sense amplifier input. Make a low current Kelvin connection between this

pin and the inductor side of the external current sense resistor.

28

FB1

I

Feedback input of channel 1. Connect the FB1 pin to VDDA for a 3.3-V output or connect

FB1 to ground for a 5-V output. A resistive divider from the VOUT1 to the FB1 pin sets the

output voltage level between 1.5 V and 15 V. The regulation threshold at the FB1 pin is 1.2

V.

29

COMP1

O

Output of the channel 1 transconductance error amplifier.

30

SS1

I

Channel 2 soft-start programming pin. An external capacitor and an internal 20-μA current

source set the ramp rate of the internal error amplifier reference during soft-start. Pulling SS

pin below 80 mV turns off the channel 1 gate driver outputs, but the all the other function

remain active.

31

EN1

I

An active high logic input enables channel 1.

32

RES

O

Restart timer pin. An external capacitor configures the hiccup mode current limiting. The

capacitor at the RES pin determines the time the controller remains off before automatically

restarting in hiccup mode. The two regulator channels operate independently. One channel

may operate in normal mode while the other is in hiccup mode overload protection. The

hiccup mode commences when either channel experiences 512 consecutive PWM cycles

with cycle-by-cycle current limiting. Connect the RES pin to VDD during power up to disable

hiccup mode protection.

33

DEMB

I

Diode Emulation pin. If the DEMB pin is grounded, diode emulation is enabled. If it is

connected to VDDA the LM5140-Q1 operates in FPWM mode with continuous conduction at

light loads.

34

ILSET

I

Current Limit Threshold pin. Connecting the ILSET pin to VDDA sets the current limit

threshold to 73 mV for channel 1 and channel 2.

Connecting the ILSET pin to GND sets the current limit thresholds to 48 mV.

35

AGND

G

Analog ground connection. Ground return for the internal voltage reference and analog

circuits.

36

VDDA

P

Internal analog bias regulator output. Connect a capacitor from the VDDA pin the AGND.

37

OSC

I

Frequency selection pin. Connecting the OSC pin to VDDA selects the default oscillator

frequency of 2.2 MHz. Connecting the OSC pin to ground sets frequency to 440 kHz.

38

SYNIN

I

Sync input pin. The internal oscillator can be synchronized to an external clock. If the

synchronization feature is not used, the SYNIN pin must be connected to AGND.

39

SYNOUT

O

Sync output pin. The TTL level output signal is 180º out of phase with the HO1 gate drive of

channel 1.

40

EN2

I

An active high logic input enables channel 2.

4

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

6 Specifications

6.1 Absolute Maximum Ratings

Over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

UNIT

VIN

–0.3

70

V

SW1,SW2 to PGND

–0.3

70

V

SW1, SW2 to PGND (20ns transient)

–5

HB1 to SW1, HB2 to SW2

HB1 to SW1, HB2 to SW2 (20ns transient)

6.5

–5

HO1 to SW1, HOL1 to SW1, HO2 to SW2, HOL2 to SW2

Input voltage

V

–0.3

V

–0.3

HO1 to SW1, HOL1 to SW1, HO2 to SW2, HOL2 to SW2 (20ns transient)

V

HB + 0.3

–5

V

V

LO1, LOL1, LO2, LOL2 to PGND

–0.3

VCC + 0.3

V

LO1, LOL1, LO2, LOL2 to PGND ( 20ns transient)

–1.5

VCC + 0.3

V

OSC, SS1, SS2, COMP1, COMP2, RES, DEMB, ILSET

–0.3

VDDA + 0.3

V

EN1, EN2 to PGND

–0.3

70

V

VCC, VCCX, VDDA, PG1, PG2, FB1, FB2, SYNIN

–0.3

6.5

V

VOUT1, VOUT2, CS1, CS2

–0.3

15.5

V

VOUT1 to CS1, VOUT2 to CS2

–0.3

0.3

V

PGND to AGND

–0.3

0.3

V

Operating junction temperature (2)

–40

150

ºC

Storage temperature, Tstg

–40

150

°C

(1)

(2)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

High junction temperatures degrade operating lifetimes. Operating lifetime is de-rated for junction temperatures greater than 125°C.

6.2 ESD Ratings

VALUE

Human-body model (HBM), per AEC Q100-002

V(ESD)

(1)

(2)

(3)

Electrostatic discharge

Charged-device model (CDM), per AEC

Q100-011 (3)

(1) (2)

UNIT

±2000

All pins except 1, 10, 11, 20, 21,

30, 31, and 40

±500

Pins 1, 10, 11, 20, 21, 30, 31,

and 40

±750

V

AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Level listed above is the passing level per ANSI/ESDA/JEDEC JS-001. JEDEC document JEP155 states that 500 V HBM allows safe

manufacturing with a standard ESD control process.

Level listed above is the passing level per EIA-JEDEC JESD22-C101. JEDEC document JEP157 states that 250 V CDM allows safe

manufacturing with a standard ESD control process.

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

5

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

6.3 Recommended Operating Conditions (1)

over operating free-air temperature range (unless otherwise noted)

MIN

VIN

VIN

Input voltage

Output voltage

3.8

65

V

65

V

HB1 to SW1, HB2 to SW2

–0.3

5.25

V

HO1 to SW1, HOL1 to SW1, HO2

to SW2, HOL2 to SW2

–0.3

HB + 0.3

V

LO1, LOL1, LO2, LOL2 to PGND

–0.3

5.25

V

FB1, FB2, PG1, PG2, SYNIN,

OSC, SS1, SS2, RES, DEMB,

VCCX, ILSET

–0.3

5

V

EN1, EN2 to PGND

–0.3

VCC, VDDA

–0.3

5

1.5

5

SYNOUT

(1)

(2)

Operating junction temperature

UNIT

–0.3

PGND to AGND

TJ

MAX

SW1, SW2 to PGND

VOUT1, VOUT2, CS1, CS2

VO

NOM

(2)

5

5

65

V

5.25

V

15

V

–0.3

5.25

V

–0.3

0.3

V

–40

150

°C

Recommended Operating Conditions are conditions under which the device is intended to be functional. For specifications and test

conditions, see the Electrical Characteristics.

High junction temperatures degrade operating lifetimes. Operating lifetime is de-rated for junction temperatures greater than 125°C.

6.4 Thermal Information

LM5140-Q1

THERMAL METRIC

(1)

RWG (VQFN)

UNIT

40 PINS

RθJA

Junction-to-ambient thermal resistance

34.8

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

22.8

°C/W

RθJB

Junction-to-board thermal resistance

9.5

°C/W

ψJT

Junction-to-top characterization parameter

1.3

°C/W

ψJB

Junction-to-board characterization parameter

9.4

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

0.3

°C/W

(1)

6

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

6.5 Electrical Characteristics

TJ = –40°C to 125°C, VIN = 12 V, VCCX = 5 V, VOUT1 = 3.3 V, VOUT2 = 5 V, EN1 = EN2 = 5 V, OSC = VDDA, SYNIN = 0

V, FSW = 2.2 MHz, no-load on the Drive Outputs (HO1, HOL1, LO2, LOL1, HO2, HOL2, LO2, and LOL2 outputs) (unless

otherwise noted). (1) (2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

9

12.5

µA

VIN SUPPLY VOLTAGE

I(SHUTDOWN)

I(STANDBY)

Shutdown mode current

Standby current

VIN 8 V- 18 V, EN1 = 0 V, EN2 = 0 V,

VCCX = 0 V

EN1 = 5 V, EN2 = 0 V, VOUT1, in

regulation, no-load, not switching.

VIN 8 V - 18 V. DEMB = GND

35

µA

Or EN1 = 0 V, EN2 = 5 V, VOUT2 in

regulation, no-load, not switching,

VOUT2 connected to VCCX,

DEMB = GND.

42

µA

VCC REGULATOR

VCC(REG)

VCC regulation voltage

VIN = 6 V - 18 V, 0 - 150 mA,

VCCX = 0 V

4.75

VCC(UVLO)

VCC under voltage threshold

VCC rising, VCCX = 0 V

3.25

VCC(HYST)

VCC hysteresis voltage

VCCX = 0 V

ICC(LIM)

VCC sourcing current limit

VCCX = 0 V

170

VDDA(REG)

Internal bias supply power

VCCX = 0 V

4.75

5

5.25

VDDA(UVLO)

VDDA undervoltage lockout

VCC rising, VCCX = 0 V

3.1

3.2

3.3

VDDA(HYST)

VDDA hysteresis voltage

VCCX = 0 V

180

mV

R(VDDA)

VDDA resistance

VCCX = 0 V

50

Ω

VCCX(ON)

VCC(ON) threshold

VCC rising

R(VCCX)

VCCX resistance

VCCX = 5 V

VCCX(HYST)

VCCX hysteresis voltage

5

5.25

3.4

3.55

V

V

175

mV

250

mA

VDDA

V

V

VCCX

4.1

4.3

4.4

V

Ω

1

200

mV

OSCILLATOR SELECT THRESHOLDS

2.2-MHz Oscillator select threshold (OSC pin)

440-kHz Oscillator select threshold

2.4

V

(OSC pin)

0.4

V

CURRENT LIMIT

V(CS1)

Current limit threshold1

ILSET = VDDA, Measure from

CS to VOUT

66

73

80

mV

V(CS2)

Current limit threshold2

ILSET = GND, Measure from

CS to VOUT

44

48

53

mV

Current sense delay to output

40

Current sense amplifier gain

ICS(BIAS)

11.4

12

Amplifier input bias

75-mV current limit select threshold

(ILSET)

ns

12.6

V/V

10

nA

2.4

V

75-mV current limit select threshold

(ILSET)

0.4

V

RES

I(RES)

RES current source

20

V(RES)

RES threshold

1.2

V

Timer hIccup mode fault

512

cycles

RDS(ON)

(1)

(2)

RES pulldown

µA

5

Ω

All minimum and maximum limits are specified by correlating the electrical characteristics to process and temperature variations and

applying statistical process control.

The junction temperature (TJ in °C) is calculated from the ambient temperature (TA in °C) and power dissipation (PD in Watts) as follows:

TJ = TA + (PD • RθJA) where RθJA (in °C/W) is the package thermal impedance provided in the Thermal Information section.

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

7

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Electrical Characteristics (continued)

TJ = –40°C to 125°C, VIN = 12 V, VCCX = 5 V, VOUT1 = 3.3 V, VOUT2 = 5 V, EN1 = EN2 = 5 V, OSC = VDDA, SYNIN = 0

V, FSW = 2.2 MHz, no-load on the Drive Outputs (HO1, HOL1, LO2, LOL1, HO2, HOL2, LO2, and LOL2 outputs) (unless

otherwise noted). (1)(2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

OUTPUT VOLTAGE REGULATION

3.3 V

VIN = 3.8 V - 42 V

3.273

3.3

3.327

V

5V

VIN = 5.5 V - 42 V

4.95

5

5.05

V

8V

VIN = 8.5 V - 42 V

7.92

8

8.08

V

FEEDBACK

VOUT1 select threshold 3.3-V

Output

VDDA –

0.3

V

VOUT2 select threshold 5 V

VDDA –

0.3

V

Regulated

Feedback

Voltage

1.19

FB(LOWRES)

Resistance to ground on FB for

FB=0 detection

FB(EXTRES)

Thevenin equivalent resistance at

FB < 2 V

FB for external regulation detection

1.2

1.21

V

500

Ω

5

kΩ

TRANSCONDUCTANCE AMPLIFIER

Gm

Gain

FB

Input Bias Current

Feedback to COMP

1010

1200

µS

15

nA

Transconductance Amplifier source

COMP = 1 V, FB = 1.0 V

current

100

µA

Transconductance Amplifier sink

current

100

µA

COMP = 1 V, FB = 1.4 V

POWER GOOD

PG(UV)

PG1 and PG2 Under Voltage trip

levels

Falling with respect to the regulation

voltage

90%

92%

94%

PG(OVP)

PG1 and PG2 Over Voltage trip

levels

Rising with respect to the regulation

voltage

108%

110%

112%

PG(HYST)

Power Good hysteresis voltage

PG(VOL)

PG1 and PG2

Open Collector, Isink = 2 mA

PG(rdly)

OV Filter Time

VOUT rising

25

µs

PG(fdly)

UV Filter Time

VOUT falling

30

µs

V

3.4%

0.4

V

HO GATE DRIVER

VOLH

HO Low-state output voltage

IHO = 100 mA

0.05

VOHH

HO High-state output voltage

IHO = -100 mA, VOHH = VHB - VHO

0.07

V

trHO

HO rise time (10% to 90%)

CLOAD = 2700 pf

4

ns

tfHO

HO fall time (90% to 10%)

CLOAD = 2700 pf

3

ns

IOHH

HO peak source current

VHO = 0 V, SW = 0 V, HB = 5 V,

VCCX = 5 V

3.25

Apk

IOLH

HO peak sink current

VCCX = 5 V

4.25

Apk

UVLO

HO falling

V(BOOT)

I(BOOT)

8

Hysteresis

Quiescent current

Submit Documentation Feedback

2.5

V

110

mV

3

µA

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Electrical Characteristics (continued)

TJ = –40°C to 125°C, VIN = 12 V, VCCX = 5 V, VOUT1 = 3.3 V, VOUT2 = 5 V, EN1 = EN2 = 5 V, OSC = VDDA, SYNIN = 0

V, FSW = 2.2 MHz, no-load on the Drive Outputs (HO1, HOL1, LO2, LOL1, HO2, HOL2, LO2, and LOL2 outputs) (unless

otherwise noted). (1)(2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

LO GATE DRIVER

VOLL

LO Low-state Output Voltage

ILO = 100 mA

0.05

V

VOHL

LO High-state Output voltage

ILO = -100 mA, VOHL = VCC - VLO

0.07

V

trLO

LO rise time (10% to 90%)

CLOAD = 2700 pf

4

ns

tfLO

LO fall time (90% to 10%)

CLOAD = 2700 pf

3

ns

IOHL

LO peak source current

VCCX = 5 V

3.25

Apk

IOLL

LO peak sink current

VCCX = 5 V

4.25

Apk

ADAPTIVE DEAD TIME CONTROL

V(GS-DET)

VGS detection threshold

2.5

V

tdly1

HO off to LO on dead time

VGS falling, no-load

20

ns

tdly2

LO off to HO on dead time

15

ns

DIODE EMULATION

VIL

DEM input low threshold

VIH

FPWM input high threshold

SW

zero cross threshold

0.4

V

2.4

V

–5

mV

ENABLE INPUTS EN1 AND EN2

VIL

Enable input low threshold

VCCX = 0 V

VIH

Enable input high threshold

VCCX = 0 V

Ilkg

Leakage

EN1, EN2 logic inputs only

0.4

V

2.4

V

1

µA

SYN INPUT

VIL

SYNIN input low threshold

VIH

SYNIN input high threshold

2.4

0.4

V

SYNIN input low frequency range

440 kHz

350

550

kHz

SYNIN input low frequency range

2.2 MHz

1800

2600

kHz

V

SYN OUTPUT

VOH

SYN output high output voltage

Source -16 mA, VDDA = 5 V

VOL

SYN Output low level output

voltage

Sink 16 mA

2.4

V

0.4

Phase between HO1 and HO2

180

Duty Cycle

V

degrees

50%

SOFT-START

ISS

Soft-start current

RDS(ON)

Soft-start pulldown resistance

16

22

28

µA

3

Ω

175

ºC

15

ºC

THERMAL

TSD thermal shutdown

Thermal shutdown hysteresis

6.6 Switching Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER

ton

MIN

TYP

MAX

UNIT

Oscillator frequency, 2.2 MHz

OSC = VDDA, VIN = 8 V – 18 V

TEST CONDITIONS

2060

2200

2340

kHz

Oscillator frequency, 440 kHz

OSC = GND, VIN = 8 V – 18 V

410

440

470

kHz

Minimum on-time

45

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

ns

9

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Switching Characteristics (continued)

over operating free-air temperature range (unless otherwise noted)

PARAMETER

toff

10

TEST CONDITIONS

Minimum off-time

Submit Documentation Feedback

MIN

TYP

MAX

UNIT

100

ns

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

100

100

90

90

80

80

70

70

Efficiency (%)

Efficiency (%)

6.7 Typical Characteristics

60

50

40

30

60

50

40

30

VIN 8 V

VIN 12 V

VIN 18 V

20

10

0.0

0.5

1.0

1.5

VIN 8-18 V

2.0

2.5 3.0

IOUT (A)

3.5

EN1 = EN2 = 12 V

4.0

4.5

VIN 8 V

VIN 12 V

VIN 18 V

20

10

0.0

5.0

2.2 MHz

0.5

VIN 8-18 V

Figure 1. Efficiency vs VIN, FPWM

2.0

2.5 3.0

IOUT (A)

3.5

EN1 = EN2 = 12 V

4.0

4.5

5.0

2.2 MHz

45

10

125qC

25qC

-40qC

40

I(STANDBY) (PA)

8

6

4

0

-60

35

30

25

VIN 8 V

VIN 12 V

VIN 18 V

2

20

-30

0

VIN 8-18 V

30

60

Temperature (qC)

90

120

150

8

EN1 = EN2 = 12 V

9

10

VIN 8-18 V

5.20

3.48

5.15

3.46

5.10

3.44

VCC(UVLO)(qC)

3.50

5.05

5.00

4.95

3.34

4.80

3.32

4.75

VIN 6-18V

14

EN1 = EN2 = 12 V

16

16

17

18

2.2 MHz

3.38

3.36

12

VIN (V)

15

3.40

4.85

10

13

14

VIN (V)

3.42

4.90

8

12

Figure 4. I(STANDBY) vs VIN

5.25

6

11

EN1 = 12 V, EN2 = 0 V

Figure 3. I(SHUTDOWN) vs Temperature

VCC(REG) (V)

1.5

Figure 2. Efficiency vs VIN, DEMB

12

I(SHUTDOWN)(PA)

1.0

18

3.30

-60

-30

VCC Rising

Figure 5. VCC(REG) vs VIN

0

30

60

Temperature(qC)

90

120

150

EN1 = EN2 = 12 V

Figure 6. VCC(UVLO) vs Temperature

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

11

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

5.25

3.30

5.20

3.28

5.15

3.26

5.10

3.24

VDDA(UVLO)(V)

VDD(REG) (V)

Typical Characteristics (continued)

5.05

5.00

4.95

3.22

3.20

3.18

4.90

3.16

4.85

3.14

4.80

3.12

4.75

-60

3.10

-60

-20

VCC Rising

20

60

Temperature (qC)

100

140

EN1 = EN2 = 12 V

120

150

84

82

80

V(CS) (mV)

VCCX(ON) (V)

90

Figure 8. VDDA(UVLO) vs Temperature

78

76

74

72

70

68

-30

0

30

60

Temperature (qC)

90

120

66

-60

150

VCC Rising

-30

0

VIN = 12 V

Figure 9. VCCX(ON) vs Temperature

30

60

Temperature (qC)

90

120

150

ILSET = VCC

Figure 10. V(CS1) 73-mV Current Limit Threshold vs

Temperature

53

13.0

52

12.8

51

12.6

12.4

Gain (V/V)

50

V(CS) (mV)

30

60

Temperature(qC)

86

VIN = 12 V

49

48

47

12.2

12.0

11.8

11.6

46

11.4

45

11.2

44

-60

11.0

-60

-30

VIN = 12 V

0

30

60

Temperature (qC)

90

120

150

ILSET = GND

-30

0

30

60

Temperature (qC)

90

120

150

VCC Rising

Figure 11. V(CS2) 48-mV Current Limit Threshold vs

Temperature

12

0

VCC Rising

Figure 7. VDDA(REG) vs Temperature

4.36

4.34

4.32

4.30

4.28

4.26

4.24

4.22

4.20

4.18

4.16

4.14

4.12

4.10

-60

-30

Figure 12. Current Sense Amplifier Gain vs Temperature

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Typical Characteristics (continued)

3.332

5.05

125qC

25qC

-40qC

3.326

5.03

3.314

Output Voltage (V)

Output Voltage (V)

3.320

125qC

25qC

-40qC

5.04

3.308

3.302

3.296

3.290

5.02

5.01

5.00

4.99

4.98

3.284

4.97

3.278

4.96

3.272

4.95

0

1

2

VIN 12 V

3

4

Output Current (A)

5

EN1 = 12 V

6

0

EN2 = GND

1

2

3

Output Current (A)

VIN 5.5 V - 42 V

Figure 13. 3.3-V Output Voltage Regulation

4

EN1 = GND

5

EN2 = 12 V

Figure 14. 5-V Output Voltage Regulation

470

2360

465

460

2310

Frequency (kHz)

Frequency (kHz)

455

2260

2210

2160

450

445

440

435

430

425

420

2110

415

2060

-60

-30

0

VIN 12 V

30

60

Temperature (qC)

90

120

410

-60

150

OSC = VCC

-30

0

30

60

Temperature (qC)

VIN 12 V

Figure 15. 2.2-MHz Oscillator Frequency vs Temperature

90

120

150

OSC = GND

Figure 16. 440-kHz Oscillator Frequency vs Temperature

90

80

85

70

80

75

toff(ns)

ton (ns)

60

50

70

65

60

40

55

50

30

45

20

-60

-30

0

30

60

Temperature (qC)

90

120

VIN 18 V

150

40

-40

-20

0

20

40

60

80

Temperature (qC)

100

120

140

VIN 3.8 V

Figure 17. ton Minimum vs Temperature

Figure 18. toff Minimum vs Temperature

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

13

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

7 Detailed Description

7.1 Overview

The LM5140-Q1 is a dual-channel switching controller which features all of the functions necessary to implement

a high efficiency buck power supply that can operate over a wide input voltage range. The LM5140-Q1 is

configured to provide two independent outputs. VOUT1 can be a fixed 3.3 V, 5 V, or adjustable between 1.5 V to

15 V. VOUT2 can be a fixed 5 V, 8 V, or adjustable between 1.5 V to 15 V. This easy to use controller integrates

high-side and low-side MOSFET drivers capable of sourcing 3.25 A and sinking 4.25-A peak . The control

method is current mode control which provides inherent line feedforward, cycle-by-cycle current limiting, and

ease-of-loop compensation. With the OSC pin connected to VDD the default oscillator frequency is 2.2 MHz.

With the OSC pin grounded the oscillator frequency is 440 kHz. A synchronization pin allows the LM5140-Q1 to

be synchronized to an external clock. Fault protection features include current limiting, thermal shutdown, and

remote shutdown capability. The LM5140-Q1 incorporates features that simplify compliance with the CISPR and

Automotive EMI requirements. The LM5140-Q1 gate drivers provide adaptive slew rate control and interleaved

operation (180 degree output of phase) of the two controller channels. The 4-pin VQFN package with Wettable

Flanks features an exposed pad to aid in thermal dissipation.

14

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

7.2 Functional Block Diagram

VIN

VCCX

VREF 1.2 V

BIAS

SYNIN

CLK1

COMMON

OSC

OSCILLATOR

CLK2

VCC

SYNOUT

VDDA

CONTROL

VDDA

DEMB1

20 µA

HICCUP FAULT

TIMER 512

CYCLES

RESTART

LOGIC

RES

DEMB

DEMB

DEMB2

CL

AGND

OUT1 OUT2

ILSET

75 mV or

50 mV

ILSET

ILSET

EN1

OUT1

CL

CURRENT

LIMIT

Gain = 12

ILSET

CS1

+

VOUT1

-

+

SLOPE

COMPENSATION

RAMP

+ -

3.3 V

5.0 V

300 mV

HB1

HB1 UVLO

8.0 V

VOUT

DECODER/

MUX

DEMB1

+

HO1

HOL1

OUT1

FB1

+

R

-

SScomplete

STBY

1200 µS

FBi

20 µA

CLK1

VREF

SW1

VCC

Q

300 mV

_

SS1

S

LEVEL

SHIFT

PWM ADAPTIVE

Q

DEAD TIME

LO1

LOL1

+

+

SS1

PGND1

SS1

COMP1

STBY

1.356 V

PGOV

+

PG1

Pgdly

25 µs

_

STAND-BY

PGUV

+

VSTBY

+ -

1.056 V

+

EN2

OUT2

CL

CURRENT

LIMIT

Gain = 12

ILSET

CS2

+

VOUT2

-

+

SLOPE

COMPENSATION

RAMP

+ -

3.3 V

5.0 V

300 mV

HB2

HB2 UVLO

8.0 V

VOUT

DECODER/

MUX

DEMB2

+

HO2

HOL2

OUT2

FB2

PWM

+

Q

S

Q

-

SScomplete

STBY

R

1200 µS

FBi

20 µA

_

VREF

SS2

CLK2

300 mV

LEVEL

SHIFT

ADAPTIVE

DEAD TIME

SW2

VCC

LO2

LOL2

+

+

SS2

PGND2

SS2

COMP2

STBY

1.356 V

PGOV

+

PG2

Pgdly

25 µs

_

STAND-BY

PGUV

+

VSTBY

+ -

1.056 V

Submit Documentation Feedback

+

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

15

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

7.3 Feature Description

7.3.1 High Voltage Start-up Regulator

The LM5140-Q1 contains an internal high voltage VCC bias regulator that provides the bias supply for the PWM

controller and the gate drivers for the external MOSFETs. The input pin (VIN) can be connected directly to an

input voltage source up to 65 V. The output of the VCC regulator is set to 5 V. When the input voltage is below

the VCC set-point level, the VCC output tracks VIN with a small voltage drop.

In high voltage applications, take extra care to ensure the VIN pin does not exceed the absolute maximum

voltage rating of 70-V curing line or load transients. Voltage ringing on the VIN pin that exceeds the Absolute

Maximum Ratings can damage the IC. Use care during PCB board layout and high quality bypass capacitors to

minimize ringing.

7.3.2 VCC Regulator

The VCC regulator output current limit is 150 mA (minimum). At power up, the regulator sources current into the

capacitors connected to the VCC pin. When the voltage on the VCC pin exceeds 3.4 V both output channels are

enabled (if EN1 and EN2 are connected to a voltage source > 2.4 V) and the soft-start sequence begins. Both

channels remain active unless the voltage on the VCC pin falls below the VCCUVLO threshold, of 3.2 V (typical) or

the enable pins are switched to a low state. The LM5140-Q1 has two VCC pins; these pin must be connected

together on the PCB. TI recommends that the VCC capacitor be split between the two VCC pins and connected

to the respective PGND pins. The recommended range for the VCC capacitor is from 2.2 µF to 5 µF total.

An internal 5-V linear regulator generates the VDDA bias supply. Bypass VDDA with a 100-nF or greater ceramic

capacitor to ensure a low noise internal bias rail. Normally VDDA is 5 V, but there are two operating conditions

where it regulates at 3.3 V. The first is in skip cycle mode with VOUT1 set to 3.3 V, and VOUT2 is disabled. The

second is in a cold crank start-up where VIN is 3.8 V and VOUT1 is 3.3 V.

Internal power dissipation in the VCC Regulator can be minimized by connecting the VCCX pin to a 5-V output at

VOUT1 or VOUT2 or to an external 5-V supply. If VCCX > 4.5 V, VCCX is internally connected to VCC and the

internal VCC regulator is disabled. If VCCX is unused, it must be grounded. Never connect the VCCX pin to a

voltage greater than 6.5 V.

7.3.3 Oscillator

The LM5140-Q1 has independent oscillators that generate the clock for each channel and can be programmed to

2.2 MHz or 440 kHz with the OSC pin. With the OSC pin connected to VDDA, both oscillators will be set to 2.2

MHz. With OSC grounded, they will both be set to 440 kHz. The state of the OSC pin is read and latched during

VCC power up and thus cannot be changed until VCC drops below the VCCUVLO threshold. CLK1 is the clock for

channel 1; CLK2 is for channel 2. CLK1 and CLK2 are 180º out of phase. The rising edge of SYNOUT always

corresponds to the rising edge of CLK2 which is 180º out of phase with CLK1.

Under low VIN conditions when either of the high-side buck switch on time exceeds the programmed oscillator

period, the LM5140-Q1 will extend the oscillator period of that channel until the PWM latch is reset by the current

sense ramp exceeding the controller compensation voltage. In such an event, the oscillators (CLK1 and CLK2)

operate independently and asynchronously until both channels can maintain output regulation at the programmed

frequency.

The approximate input voltage level where this occurs is in Equation 1:

tp

VINmin = VOUT ´

ton(max)

where

•

•

tp = is the oscillator period, 454 ns (for 2.2 MHz operation)

ton(max) = 354 ns

(1)

For example, if VOUT1 = 3.3 V and VOUT2 = 5 V and VIN drops to 6.41 V (see Equation 2).

454 ns

VIN = 5.0 V ´

= 6.41 V

354 ns

16

Submit Documentation Feedback

(2)

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Feature Description (continued)

In the above example, CLK2 frequency is required to drop to maintain regulation of VOUT2 while CLK1 can

remain at the programmed frequency (refer to Figure 19). If VIN continues to drop, both CLK1 and CLK2

frequencies are reduced Figure 20.

HO1 (Red)

HO2 (Blk)

SYNOUT (Blue)

Figure 19. HO1, HO2, and SYNOUT VIN 6.41 V

HO1 (Red)

HO2 (Blk)

SYNOUT (Blue)

Figure 20. HO1, HO2, SYNOUT VIN 4.2 V

Under high input voltage conditions (VIN > 20 V) when the buck switch on-time of either controller reaches the

minimum on-time of 45 ns typical, the LM5140-Q1 reduces the oscillator frequency by skipping clock cycles for

the appropriate channel.

Using the same output voltages as in the example above with VIN = 36 V, CLK1 drops to 1.1 MHz and CLK2 is

2.2 MHz, (refer to Figure 21), and SYNOUT is 2.2 MHz.

HO1 (Red)

HO2 (Blk)

SYNOUT (Blue)

Figure 21. HO1, HO2, and SYNOUT VIN 36 V

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

17

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Feature Description (continued)

7.3.4 SYNIN and SYNOUT

The SYNIN pin can be used to synchronize the LM5140-Q1 to an external clock. The synchronization range

when the internal oscillator is set to 440 kHz is 374 kHz minimum to 506 kHz maximum. When the internal

oscillator is set to 2.2 MHz, the synchronization range is 1.87 MHz to 2.53 MHz. If the synchronization feature is

not being used, the SYNIN pin must be grounded.

CLK1 starts on the rising edge of the external synchronization clock (SYNIN). The HO1 pulse will follow

approximately 110 ns after CLK1 due to internal delays (refer to Figure 22). Similarly, CLK2 generates the HO2

pulse after a short delay, and CLK2 is 180º out of phase with CLK1. SYNOUT always corresponds to the rising

edge of CLK2.

Figure 22. SYNIN and HO1 Timing (2.2 MHz)

Under low VIN conditions when the frequency must be reduced to maintain output voltage regulation, the SYNIN

input function adapts as necessary. If VOUT1 can maintain regulation at the SYNIN frequency and VOUT2

cannot, then CLK1 remains synchronized to SYNIN and the CLK2 frequency is reduced (refer to Figure 23). If

VOUT1 cannot maintain regulation at the SYNIN frequency, then the SYNIN signal is ignored and channel 1

frequency is reduced to maintain regulation. Channel 2 runs at the frequency determined by OSC pin or lower if

required to maintain regulation on VOUT2 (refer to Figure 24).

SYNIN

SYNOUT

HO1 (Red)

HO2 (Blk)

Figure 23. SYNIN (2.2 MHz) VIN 6.41 V

18

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Feature Description (continued)

SYNIN

SYNOUT

HO1 (Red)

HO2 (Blk)

Figure 24. SYNIN (2.2 MHz) VIN 4.2 V

At high VIN when pulse skipping is necessary, HO1 drops to 1.1 MHz and HO2 remains at 2.2 MHz (refer to

Figure 25), and SYNOUT is 2.2 MHz.

SYNIN

SYNOUT

HO1 (Red)

HO2 (Blk)

Figure 25. SYNIN (2.2 MHz) VIN 36 V

7.3.5 Enable

The LM5140-Q1 contains two enable inputs, EN1 and EN2. The enable pins allow independent start-up and

shutdown control of VOUT1 (EN1) and VOUT2 (EN2). The enable pins can be connected to a voltage as high as

70 V. If the enable input is greater than 2.4 V, the respective controller output is enabled. If the enable pins is

pulled below 0.4 V, the respective output will be in shutdown. If both outputs are disabled the LM5140-Q1 is in a

low IQ shutdown mode, with 9-µA typical current drawn from the VIN pin. TI does not recommend leaving either

of the EN pins floating.

7.3.6 Power Good

The LM5140-Q1 includes output voltage monitoring signals for VOUT1 and VOUT2 to simplify sequencing and

supervision. The power good function can be used to enable circuits that are supplied by the corresponding

voltage rail or to turn-on sequenced supplies. Each power good output (PG1 and PG2) switches to a high

impedance open-drain state when the corresponding output voltage is in regulation. Each output switches low

when the corresponding output voltage drops below the lower power good threshold (92% typical) or rises above

the upper power good threshold (110% typical). A 25-µs deglitch filter prevents any false tripping of the power

good signals due to transients. TI recommends pullup resistors of 10 kΩ (typical) from PG1 and PG2 to the

relevant logic rail. PG1 and PG2 are asserted low during soft-start and when the corresponding buck converter is

disabled by EN1 or EN2.

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

19

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Feature Description (continued)

7.3.7 Output Voltage

The LM5140-Q1 outputs can be independently configured for one of two fixed output voltages with no external

feedback resistors or adjusted to the desired voltage using external resistor dividers. VOUT1 can be configured

as a 3.3-V output by connecting the FB1 pin to VDDA, or a 5-V output by connecting the FB1 pin to ground with

a maximum resistance of 500 Ω. VOUT2 can be configured as either a 5-V output or 8-V output. For a 5-V output

at VOUT2, connect the FB2 pin to VDDA. For a fixed 8-V output at VOUT2 connect FB2 to ground with a

maximum resistance of 500 Ω. The FB1 and FB2 connections (either VDDA or GND) are detected during power

up. The configuration setting is latched and can not be changed until the LM5140-Q1 is powered down with VCC

falling below VCC(UVLO) (3.4 V typical) and then powered up again.

Alternative output voltages can be set external resistive dividers from output to the FB pins. The output voltage

adjustment range is between 1.5 V and 15 V. The regulation threshold at the FB pin is 1.2 V (VREF). To

calculate RFB1 and RFB2 use Equation 3, refer to Figure 26:

æ VOUT

ö

RFB2 = ç

- 1÷ ´ RFB1

è VREF

ø

(3)

The recommend value for R(FB1) is between 10 kΩ to 20 kΩ.

The Thevenin equivalent impedance of the resistive divider connected to the FB pins must be greater than 5 kΩ

for the LM5140-Q1 to detect the divider and set the channel to the adjustable output mode.

R ´ RFB2

> 5 kW

RTH = FB1

RFB1 + RFB2

(4)

If a low IQ mode is required, take care when selecting the external resistors. The extra current drawn from the

external divider is added to the LM5140-Q1 I(STANDBY) current (35 µA typical). The divider current reflected to VIN

is divided down by the ratio of VOUT/VIN. For example, if VOUT is set to 5.5 V with RFB1 10 kΩ, and RFB2 = 35.8

kΩ (use 35.7 kΩ), the input current at VIN required to supply the current in the feedback resistors is:

VOUT

VOUT

5.5 V

5.5 V

IDIVIDER =

´

=

´

= 55.04 mA

RFB1 + RFB2

VIN

10 k + 35.8 k 12 V

(5)

IVIN » I(STANDBY) + IDIVIDER » 35 mA + 55.04 m » 90.4 mA

(6)

VIN = 12 V

LOUT

VOUT

COUT

RFB2

LM5140-Q1 Transconductance Amplifier

gm 1200uS

FB

_

RFB1

VREF

+

SS

+

COMP

Figure 26. Voltage Feedback

If one output is enabled and the other disabled, VCC output will be in regulation. The HB pin voltage of the

disabled channel will charge to VCC through the boot strap diode. As a result, the HO driver bias current

(approximately 3 µA) can charge the disabled channel VOUT to approximately 2.2 V. If this is not desired, a load

resistor (100 kΩ) can be added to the output that is disabled to maintain a low voltage OFF-state.

20

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Feature Description (continued)

7.3.8 Minimum Output Voltage Adjustment

There are two limitations to the minimum output voltage adjustment range: the LM5140-Q1 voltage reference 1.2

V and the minimum switch node pulse width, tSW.

The minimum controllable voltage at the switch node (tSW) limits the voltage conversion ratio (VOUT/VIN). For

fixed-frequency PWM operation, the voltage conversion ratio must meet Equation 7:

VOUT

> t SW ´ Fsw

VIN

where

•

•

tSW is 70 ns (typical)

and Fsw is the switching frequency

(7)

If the desired voltage conversion ratio does not meet the above condition, the controller transitions from fixed

frequency operation into a pulse skipping mode to maintain regulation of the output voltage.

For example if the desired output voltage is 3.3 V with a VIN of 20 V and operating at 2.2 MHz, the voltage

conversion ratio test is in Equation 8:

3.3 V

> 70 ns ´ 2.2 MHz

20 V

0.165 > 0.154

(8)

For Wide VIN applications and lower output voltages, an alternative is to use the LM5140-Q1 with 440-kHz

oscillator frequency. Operating at 440 kHz, the limitation with the minimum ton time is less significant. For

example, if a 1.8-V output is required with a VIN of 50 V (see Equation 9):

1.8 V

> 70 ns ´ 440 kHz

50 V

0.036 > 0.0308

(9)

7.3.9 Current Sense

There are two methods to sense the inductor current of the buck converters. The first is using current sense

resistor in series with the inductor and the second is to use the DC resistance of the inductor (DCR sensing).

Figure 27 illustrates inductor current sensing using a current sense resistor. This configuration continuously

monitors the inductor current providing accurate current-limit protection. For the best current-sense accuracy and

overcurrent protection, use a low inductance ±1% tolerance current-sense resistor between the inductor and

output, with a Kelvin connection to the LM5140-Q1 sense amplifier.

The LM5140-Q1 provides two user selectable current limit levels of 48 mV and 73 mV. If the ILSET pin is

connected to VDDA, the current limit threshold is 73 mV. When the ILSET pin is connected to ground, the current

limit set point is 48 mV. The ILSET pin is monitored during power up and the setting is latched. To change the

setting, VIN power must be removed from the controller allowing the VCC voltage to drop below VCC(UVLO).

If the peak differential current signal sensed from CS to VOUT exceeds the user selectable current limit level of

48 mV or 73 mV, the current limit comparator immediately terminates the HO output for cycle-by-cycle current

limiting.

VCS

Rsense =

DI ö

æ

ç IOUTmax + 2 ÷

è

ø

where

•

•

•

VCS is user selectable threshold of 48 mV or 73 mV.

IOUTmax is the overcurrent setpoint which is set higher than the maximum load current to avoid tripping the

overcurrent comparator during load transients.

ΔI is the peak-peak inductor current.

(10)

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

21

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Feature Description (continued)

VOUT

Rsense

LOUT

COUT

LM5140-Q1 Current Sense Amplifier

Gain 12

CS

+

VOUT

_

Figure 27. Current Sense

7.3.10 DCR Current Sensing

For high-power applications which do not require high accuracy current-limit protection, DCR sensing may be

preferable. This technique provides lossless and continuous monitoring of the output current using an RC sense

network in parallel with the inductor. Using an inductor with a low DCR tolerance, the user can achieve a typical

current limit accuracy within the range of 10% to 15% at room temperature.

Components RSC and CCS in Figure 28 create a low-pass filter across the inductor to enable differential sensing

of the voltage drop across inductor DCR. When RCS × CCS is equal to LOUT/LDCR, the voltage developed across

the sense capacitor, CS, is a replica of the inductor DCR voltage waveform. Choose the capacitance of CCS to

be greater than 0.1 μF to maintain a low impedance sensing network, thus reducing the susceptibility of noise

pickup from the switch node. Carefully observe the PCB layout guidelines to ensure the noise and DC errors do

not corrupt the differential current-sense signals applied across the CS and VOUT pins.

The voltage drop across CCS in Equation 11:

1 + sLout

VCS (s ) =

Ipk ´ LDCR

LDCR

1 + sRCS CCS

VOUT

LDCR

(11)

LOUT

COUT

CCS

RCS

LM5140-Q1 Current Sense Amplifier

Gain 12

CS

+

VOUT

_

Figure 28. DCR Current Sensing

22

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Feature Description (continued)

RCSCCS = LOUT/LDCR → accurate DC and AC current sensing.

If the RC time constant is not equal to the LOUT/LDCR time constant, there is an error.

RCSCCS > LOUT/LDCR → DC level still correct, the AC amplitude is attenuated.

RCSCCS < LOUT/LDCR → DC level still correct, the AC amplitude is amplified.

7.3.11 Error Amplifier and PWM Comparator

Each channel of the LM5140-Q1 has an independent high-gain transconductance amplifier which generates an

error current proportional to the difference between the feedback voltage and an internal precision reference (1.2

V). The output of each transconductance amplifier is connected to the COMP pin allowing the user to provide

external control loop compensation. Generally for current mode control a type II network is recommended.

7.3.12 Slope Compensation

The LM5140-Q1 provides internal slope compensation to ensure stable operation with duty cycle greater than

50%. To correctly use the internal slope compensation, the inductor value must be calculated based on the

following guidelines (Equation 12 assumes an inductor ripple current of 30%):

VOUT

LOUT ³

Fsw ´ (0.3 ´ IOUT )

(12)

•

•

Lower inductor values increase the peak-to-peak inductor current, which minimizes size and cost and

improves transient response at the cost of reduced efficiency due to higher peak currents.

Higher inductance values decrease the peak-to-peak inductor current, which increases efficiency by reducing

the RMS current at the cost of requiring larger output capacitors to meet load-transient specifications.

7.4 Device Functional Modes

7.4.1 Hiccup Mode Current Limiting

The LM5140-Q1 includes an optional hiccup mode protection function that is enabled when a capacitor is

connected to the RES pin. In normal operation the RES capacitor is discharged to ground. If 512 cycles of cycleby-cycle current limiting occur on a either channel, the SS pin capacitor of that channel is pulled low and the HO

and LO outputs are disabled (refer to Figure 29). A 20-μA current source begins to charge the RES capacitor.

When the RES pin charges to 1.2 V, the RES pin is pulled low and the SS capacitor begins to charge. The 512

cycle hiccup counter is reset if 4 consecutive switching cycles occur without exceeding the current limit threshold.

Separate hiccup counters are provided for each channel, but the RES pin is shared by both channels. One

channel can be in the hiccup protection mode while the other operates normally. In the event that both channels

are in an overcurrent condition triggering hiccup protection, the last hiccup counter to expire pulls RES low and

starts the RES capacitor charging cycle. Both channels then restart together when RES=1.2 V. If RES is

connected to VDDA at power up, the hiccup function is disabled for both channels.

The controller is in forced PWM (FPWM) continuous conduciton mode when the DEMB pin is connected to

VDDA. In this mode the SS pin is clamped to a level 200 mV above the feedback voltage to the internal error

amplifier. This ensures that SS can be pulled low quickly during a brief overcurrent event and prevent overshoot

of VOUT when the overcurrent condition is removed.

If DEMB=0 V, the controller operates in diode emulation with light loads (discontinous conduction mode) and the

SS pin is allowed to charge to VDDA. This reduces the quiescent current of the LM5140-Q1. If 32 or more cycleby-cycle current limit events occur, the SS pin is clamped to 200 mV above the feedback voltage to the internal

error amplifier until the hiccup counter is reset. Thus, if a momentary overload occurs that causes at least 32

cycles of current limiting, the SS capacitor voltage is slightly higher than the FB voltage and controls VOUT

during recovery.

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

23

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

Device Functional Modes (continued)

Current Limit

Detected

1.2 V RES Threshold

I RES = 20 mA

RES

0V

ISS = 20 mA

SS

1.2 V REF

HO/HOL

LO/LOL

t RES

tSS

Current Limit persists

during 512

consecutive cycles

Figure 29. Hiccup Mode

7.4.2 Standby Mode

The LM5140-Q1 operates with peak current mode control such that the feedback compensation voltage is

proportional to the peak inductor current. During no-load or light load conditions, the output capacitor discharges

very slowly. As a result the compensation voltage does not demand a driver output pulses on a cycle-by-cycle

basis. When the LM5140-Q1 controller detects that there have been 16 missing switching cycles, it enters

Standby Mode and switches to a low IQ state to reduce the current drawn from VIN. For the LM5140-Q1 to go

into a Standby Mode, the controller must be programmed for diode emulation (DEMB pin < 0.4 V). The typical IQ

in Standby Mode is 35 µA with VOUT1 regulating at 3.3 V and VOUT2 disabled. With VOUT1 disabled and

VOUT2 regulating to 5 V, the Standby Mode current is 42 μA. With both channels in standby mode (VOUT1 =

3.3 V and VOUT2 = 5 V) the VIN current is 75 μA. Using external feedback resistors add additional load to VOUT

and significantly increase the Standby Mode VIN current.

7.4.3 Soft Start

The soft-start feature allows the regulator to gradually reach the steady-state operating point, thus reducing startup stresses and surges. The LM5140-Q1 regulates the FB pin to the SS pin voltage or the internal 1.2-V

reference, whichever is lower. At the beginning of the soft-start sequence when SS = 0 V, the internal 20-μA softstart current source gradually increases the voltage on an external soft-start capacitor connected to the SS pin,

resulting in a gradual rise of the FB and output voltages.

The controller is in the forced PWM (FPWM) mode when the DEMB pin is connected to VDDA. In this mode, the

SS pin is clamped at 200 mV above the feedback voltage to the internal error amplifier. This ensures that SS can

be pulled low quickly during brief overcurrent events and prevent overshoot of VOUT during recovery. SS can be

pulled low with an external circuit to stop switching, but this is not recommended. Pulling SS low results in COMP

being pulled down internally as well. If the controller is operating in FPWM mode (DEMB = VDDA), LO remains

on and the low-side MOSFET discharges the VOUT capacitor resulting in large negative inductor current. When

the LM5140-Q1 pulls SS low internally due to a fault condition, the LO gate driver is disabled.

7.4.4 Diode Emulation

A fully synchronous buck regulator implemented with a free-wheel MOSFET rather than a diode has the

capability to sink current from the output in certain conditions such as light load, overvoltage, and prebias startup. The LM5140-Q1 provides a diode emulation feature that can be enabled to prevent reverse (drain to source)

current flow in the low-side free-wheel MOSFET. When configured for diode emulation, the low-side MOSFET is

disabled when reverse current flow is detected. The benefit of this configuration is lower power loss at no load or

24

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Device Functional Modes (continued)

light load conditions and the ability to turn on into a prebiased output without discharging the output. The

negative effect of diode emulation is degraded light load transient response times. Enabling the diode emulation

feature is recommended to allow discontinuous conduction operation. The diode emulation feature is configured

with the DEMB pin. To enable diode emulation, connect the DEMB pin to ground or leave the pin floating. If

continuous conduction operation is desired, the DEMB pin must be tied to VDDA.

7.4.5 High and low-side Drivers

The LM5140-Q1 contains a N-channel MOSFET gate drivers and an associated high-side level shifter to drive

the external N-channel MOSFET. The high-side gate driver works in conjunction with an external bootstrap diode

DBST, and bootstrap capacitor CBST, refer to Figure 30. During the on-time of the low-side MOSFET, the SW pin

voltage is approximately 0 V and CBST is charged from VCC through the DBST. A 0.1-μF or larger ceramic

capacitor, connected with short traces between the BST and SW pin, is recommended.

The LO and HO outputs are controlled with an adaptive dead-time methodology which ensures that both outputs

(HO and LO) are never enabled at the same time, preventing cross conduction. When the controller commands

LO to be enabled, the adaptive dead-time logic first disables HO and waits for the HO-SW voltage to drop below

2.5 V typical. LO is then enabled after a small delay (HO fall to LO rise delay). Similarly, the HO turn-on is

delayed until the LO voltage has dropped below 2.5 V. HO is then enabled after a small delay (LO fall to HO rise

delay). This technique ensures adequate dead-time for any size N-channel MOSFET device or parallel MOSFET

configurations. Caution is advised when adding series gate resistors, as this may decrease the effective deadtime. Eachof the high and low-side drivers have an independent driver source and sink output pins. This allows

the user to adjust drive strength to optimize the switching losses for maximum efficiency and control the slew rate

for reduced EMI. The selected N-channel high-side MOSFET determines the appropriate boost capacitance

values CBST in the Figure 30 according to Equation 13.

QG

CBST =

DVBST

where

•

•

QG is the total gate charge of the high-side MOSFET

and ΔVBST is the voltage variation allowed on the high-side MOSFET driver after turnon.

(13)

Choose ΔVBST such that the available gate-drive voltage is not significantly degraded when determining CBST. A

typical range of ΔVBST is 100 mV to 300 mV. The bootstrap capacitor must be a low-ESR ceramic capacitor. A

minimum value of 0.1 µF to 0.47 µF is best in most cases. Take care when choosing the high-side and low-side

MOSFET devices with logic level gate thresholds.

VCC

DBST

HB

CBST

HO

RHO

HOL

RHOL

SW

VCC

CVCC

LO

RLO

LOL

RLOL

PGND

Figure 30. Drivers

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

25

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM5140-Q1 is a synchronous buck controller used to convert a higher input voltage to two lower output

voltages. The following design procedure can be used to select external component values. Alternately, the

WEBENCH® software may be used to generate a complete design. The WEBENCH software uses an iterative

design procedure and accesses a comprehensive database of components when generating a design. This

section presents a simplified discussion of the design process. In addition to the WEBENCH software the

LM5140ADESIGN-CALC.XIXS quick start Excel calculator is available at www.ti.com.

8.2 Typical Application

VIN

VCC

VIN

HB1

OUT1

HB2

HO2

HO1

HOL1

HOL2

SW1

SW2

LO1

LOL1

PGND1

LM5140-Q1

OUT2

LO2

LOL2

PGND2

PG1

VIN

VCC

EN1

ILSET

CS1

VOUT1

VCC

VIN

EN2

PG2

SYNOUT

SYNIN

CS2

VOUT2

VCCX

COMP1

COMP2

FB2

FB1

OSC AGND SS1 RES SS2 DEMB VDDA

VCC

VCC

Figure 31. 12-V to 3.3-V and 5-V Converter

26

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

�LM5140-Q1

www.ti.com

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

Typical Application (continued)

8.2.1 Design Requirements

For this design example, the intended input, output and performance parameters are shown in Table 1.

Table 1. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

Input voltage range (steady-state)

8 V to 18 V

Transient

42 V

Cold crank

3.8 V

Output voltage

3.3 V

Output current

6A

Operating frequency

2.2 MHz

Output voltage regulation

± 1%

Standby current, one output enabled, no-load

< 35 µA

Shutdown current

9 µA

8.2.2 Detailed Design Procedure

• Buck Inductor calculation

• Peak inductor current calculation

• Current Sense resistor

• Output capacitor

• Input filter design

• MOSFET selection

• Control Loop design

8.2.2.1 Inductor Calculation

For peak current mode control, sub-harmonic oscillation occurs with a duty cycle greater than 50% and is

characterized by alternating wide and narrow pulses at the SW pin. By adding a slope compensating ramp equal

to at least one-half the inductor current down-slope, any tendency toward sub-harmonic oscillation is damped

within one switching cycle. For design simplification, the LM5140-Q1 has an internal slope compensation ramp

added to the current sense signal.

For the slope compensation ramp to dampen sub-harmonic oscillation, the inductor value should be calculated

based on the following guidelines (Equation 14 assumes an inductor ripple current 30%):

LOUT ³

•

•

VOUT

Fsw ´ (0.3 ´ IOUT )

(14)

Lower inductor values increase the peak-to-peak inductor current, which minimizes size and cost and

improves transient response at the expense of reduced efficiency due to higher peak currents.

Higher inductance values decrease the peak-to-peak inductor current, which increases efficiency by reducing

the RMS current but requires larger output capacitors to meet load-transient specifications.

3.3 V

L=

= 0.833 mH

2.2 MHz ´ (0.3 ´ 6 A )

(15)

A standard inductor value of 1.5 µH is selected.

VOUT 3.3 V

=

= 0.413

VINmin

8V

(16)

VOUT 3.3 V

=

=

= 0.183

VINmax 18 V

(17)

Dmax =

Dmin

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: LM5140-Q1

27

�LM5140-Q1

SNVSA02A – JANUARY 2016 – REVISED DECEMBER 2016

www.ti.com

The maximum peak-to-peak inductor current is calculated in Equation 18 through Equation 21:

DI =

DI =

VINmax - VOUT Dmin

´

LOUT

Fsw

(18)

18 V - 3.3 V

0.183

´

= 0.815 Apk

1.5 mH

2.2 MHz

(19)

DI

Ipk = IOUT +

2

0.815

Ipk = 6A +

= 6.41 Apk

2

(20)

(21)