Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

Reference

Design

LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

LM73605/LM73606 3.5-V to 36-V, 5-A or 6-A Synchronous

Step-Down Voltage Converter

1 Features

2 Applications

•

•

•

•

1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

New product available: LM61460 60-V, 6-A

synchronous converter

Synchronous rectification

Wettable flanks QFN package (WQFN)

Low quiescent current

– 0.8 µA in shutdown (typical)

– 15 µA in active mode with no load (typical)

Wide voltage conversion range:

– tON-MIN = 60 ns (typical)

– tOFF-MIN = 70 ns (typical)

Low MOSFET ON-resistance:

– RDS_ON_HS = 53 mΩ (typical)

– RDS_ON_LS = 31 mΩ (typical)

External bias input to improve efficiency

Pin-selectable auto mode or forced PWM

operation

Adjustable frequency range: 350 kHz to 2.2 MHz

Synchronizable to external clock

Internal compensation

Power-good flag

Precision enable to program system UVLO

Flexible soft-start features:

– Start-up into pre-biased load

– Fixed or adjustable soft-start time

– Output voltage tracking

Cycle-by-cycle current limiting

Short-circuit protection with hiccup mode

Create a custom design with the WEBENCH®

power designer using LM73605 or LM73606

Simplified Schematic

L

VIN

PVIN

CIN

VOUT

Industrial distributed power applications

Test and measurement

General-purpose wide VIN applications

3 Description

The LM73605 and LM73606 family of devices are

easy-to-use

synchronous

step-down

DC/DC

converters capable of driving up to 5 A or 6 A of load

current from a supply voltage ranging from 3.5 V to

36 V. The LM73605 and LM73606 provide

exceptional efficiency and output accuracy in a very

small solution size. Peak current-mode control is

employed. Additional features such as adjustable

switching frequency, synchronization to an external

clock, power-good flag, precision enable, adjustable

soft start, and tracking provide both flexible and easyto-use solutions for a wide range of applications.

Automatic frequency foldback at light load improves

efficiency over the entire load range. Protection

features include thermal shutdown, cycle-by-cycle

current limiting, and short-circuit protection. The

devices are pin-to-pin compatible for easy current

scaling. The new product, LM61460-Q1, offers higher

efficiency, lower stand-by quiescent current, and

improved EMI performance. See the device

comparison table to compare specifications. Start a

Webench design with LM61460-Q1. Use the

LMZM33606 module for faster time to market.

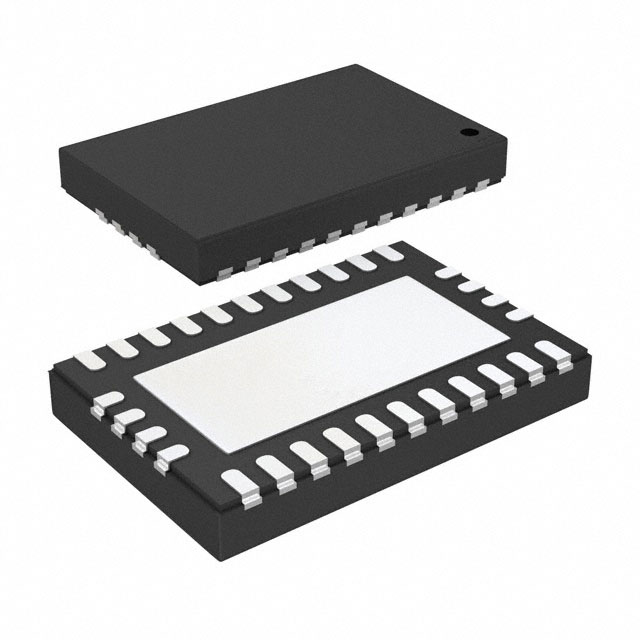

Device Information(1)

PART NUMBER

LM73605

LM73606

PACKAGE

BODY SIZE (NOM)

WQFN (30)

Wettable Flanks

6.00 mm × 4.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Efficiency versus Load Current

VOUT = 5 V, fSW = 500 kHz, Auto Mode

SW

100

CBOOT

COUT

95

EN

90

CBOOT

PGND

SS/TRK

RT

SYNC/

MODE

RFBT

FB

Efficiency (%)

85

PGOOD

BIAS

80

75

70

65

RFBB

VCC

CVCC

60

VIN = 12 V

VIN = 24 V

AGND

55

50

0.001

0.01 0.02 0.05 0.1 0.2

Load Current (A)

0.5

1

2 3 4 56

Eff_

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

5

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

5

5

5

6

6

8

8

8

9

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Timing Characteristics...............................................

Switching Characteristics ..........................................

System Characteristics .............................................

Typical Characteristics ..............................................

Detailed Description ............................................ 11

7.1 Overview ................................................................. 11

7.2 Functional Block Diagram ....................................... 11

7.3 Feature Description................................................. 12

7.4 Device Functional Modes........................................ 24

8

Application and Implementation ........................ 26

8.1 Application Information............................................ 26

8.2 Typical Application ................................................. 26

9 Power Supply Recommendations...................... 40

10 Layout................................................................... 40

10.1 Layout Guidelines ................................................. 40

10.2 Layout Example .................................................... 43

11 Device and Documentation Support ................. 44

11.1

11.2

11.3

11.4

11.5

11.6

11.7

11.8

Device Support......................................................

Documentation Support ........................................

Related Links ........................................................

Receiving Notification of Documentation Updates

Support Resources ...............................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

44

44

44

44

45

45

45

45

12 Mechanical, Packaging, and Orderable

Information ........................................................... 45

4 Revision History

Changes from Original (September 2017) to Revision A

Page

•

Added bullet point for new product......................................................................................................................................... 1

•

Added wording for new product.............................................................................................................................................. 1

2

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

5 Pin Configuration and Functions

RNP Package

30-Pin Wettable Flanks QFN (WQFN) 6 mm × 4 mm × 0.8 mm

Top View

NC

NC

NC

NC

30

29

28

27

SW

1

26

PGND

SW

2

25

PGND

SW

3

24

PGND

SW

4

23

PGND

SW

5

22

PVIN

CBOOT

6

21

PVIN

VCC

7

20

PVIN

BIAS

8

19

AGND

RT

9

18

EN

SS/TRK

10

17

SYNC/

MODE

FB

11

16

PGOOD

DAP

12

13

14

15

NC

NC

NC

NC

Pin Functions

PIN

I/O (1)

DESCRIPTION

SW

P

Switching output of the regulator. Internally connected to source of the HS FET and drain of the LS

FET. Connect to power inductor and bootstrap capacitor.

6

CBOOT

P

Bootstrap capacitor connection for HS FET driver. Connect a high-quality 470-nF capacitor from

this pin to the SW pin.

7

VCC

P

Output of internal bias supply. Used as supply to internal control circuits and drivers. Connect a

high-quality 2.2-µF capacitor from this pin to GND. TI does not recommend loading this pin by

external circuitry.

8

BIAS

P

Optional BIAS LDO supply input. TI recommends tying to VOUT when 3.3 V ≤ VOUT ≤ 18 V, or tie to

an external 3.3-V or 5-V rail if available, to improve efficiency. BIAS pin voltage must not be

greater than VIN. Tie to ground when not in use.

9

RT

A

Switching frequency setting pin. Place a resistor from this pin to ground to set the switching

frequency. If floating, the default switching frequency is 500 kHz. Do not short to ground.

NO.

NAME

1, 2, 3, 4, 5

(1)

10

SS/TRK

A

Soft-start control pin. Leave this pin floating for a fixed internal soft-start ramp. An external

capacitor can be connected from this pin to ground to extend the soft start time. A 2-µA current

sourced from this pin charges the capacitor to provide the ramp. Connect to external ramp for

tracking. Do not short to ground.

11

FB

I

Feedback input for output voltage regulation. Connect a resistor divider to set the output voltage.

Never short this pin to ground during operation.

12–15,

27–30

NC

—

No internal connection. Connect to ground net and copper to improve heat sinking and board-level

reliability.

16

PGOOD

O

Open drain power-good flag output. Connect to suitable voltage supply through a current limiting

resistor. High = VOUT regulation OK, Low = VOUT regulation fault. PGOOD = LOW when EN = low

and VIN > 2 V.

A = Analog, O = Output, I = Input, G = Ground, P = Power

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

3

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

Pin Functions (continued)

PIN

4

I/O (1)

DESCRIPTION

SYNC/MODE

I

Synchronization input and mode setting pin. Do not float. Tie to ground if not used.

Tie to ground: auto mode, higher efficiency at light loads;

Tie to logic high: forced PWM, constant switching frequency over load;

Tie to external clock source: forced PWM, synchronize to the rising edge of the external clock.

18

EN

I

Enable input to regulator. Do not float. High = ON, Low = OFF. Can be tied to PVIN. Precision

enable input allows adjustable input voltage UVLO using external resistor divider.

19

AGND

G

Analog ground. Ground reference for internal circuitry. All electrical parameters are measured with

respect to this pin. Connect to system ground on PCB.

20–22

PVIN

P

Supply input to internal bias LDO and HS FET. Connect to input supply and input bypass

capacitors CIN. CIN must be placed right next to this pin and PGND pins on PCB, and connected

with short and wide traces.

23–26

PGND

G

Power ground, connected to the source of LS FET internally. Connect to system ground, DAP/EP,

AGND, ground side of CIN and COUT on PCB. Path to CIN must be as short as possible

EP

DAP

G

Low impedance connection to AGND. Connect to system ground on PCB. Major heat dissipation

path for the device. Must be used for heat sinking by soldering to ground copper on PCB. Thermal

vias are preferred to improve heat dissipation to other layers.

NO.

NAME

17

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

6 Specifications

6.1 Absolute Maximum Ratings

Over operating free-air temperature range of –40°C to +125°C (unless otherwise noted) (1)

MIN

MAX

PVIN to PGND

PARAMETER

–0.3

42

EN to AGND

–0.3

VIN + 0.3

FB, RT, SS/TRK to AGND

–0.3

5

PGOOD to AGND

–0.1

20

SYNC to AGND

–0.3

5.5

BIAS to AGND

–0.3

Lower of (VIN + 0.3) or 20

AGND to PGND

–0.3

0.3

SW to PGND

–0.3

VIN + 0.3

SW to PGND less than 10-ns transients

–3.5

42

CBOOT to SW

–0.3

5

VCC to AGND

–0.3

5

Junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–65

150

°C

Input voltages

Output voltages

(1)

UNIT

V

V

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22-C101 (2)

±750

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

Over operating free-air temperature range of –40°C to +125°C (unless otherwise noted) (1)

PVIN to PGND

Input voltages

Output voltage

Output current

(1)

MIN

MAX

3.5

36

UNIT

EN

0

VIN

FB

0

4.5

PGOOD

0

18

BIAS input not used

0

0.3

BIAS input used

0

Lower of (VIN + 0.3) or 18

AGND to PGND

–0.1

0.1

VOUT

1

95% of VIN

V

IOUT, LM73605

0

5

A

IOUT, LM73606

0

6

A

V

Recommended operating rating indicate conditions for which the device is intended to be functional, but do not ensure specific

performance limits. For ensured specifications, see Electrical Characteristics

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

5

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

6.4 Thermal Information

LM73605/LM73606

THERMAL METRIC (1)

RNP (WQFN)

UNIT

30 PINS

RθJA

Junction-to-ambient thermal resistance

34.3

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

14.6

°C/W

RθJB

Junction-to-board thermal resistance

7.3

°C/W

ψJT

Junction-to-top characterization parameter

0.1

°C/W

ψJB

Junction-to-board characterization parameter

7.1

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

1

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

6.5 Electrical Characteristics

Limits apply over the recommended operating junction temperature (TJ) range of –40°C to +125°C, unless otherwise stated.

Minimum and maximum limits are specified through test, design or statistical correlation. Typical values represent the most

likely parametric norm at TJ = 25°C, and are provided for reference purposes only. Unless otherwise stated, VIN = 12 V.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SUPPLY VOLTAGE (PVIN PINS)

VIN

Operating input voltage

range

ISD

Shutdown quiescent current;

measured at VIN pin (1)

VEN = 0 V

TJ = 25℃

IQ_NONSW

Operating quiescent current

from VIN (non-switching)

VEN = 2 V, VFB = 1.5 V, VBIAS = 3.3 V

external

3.5

36

V

0.8

10

µA

0.6

12

µA

1.15

V

ENABLE (EN PIN)

VEN_VCC_H

Enable input high level for

VCC output

VEN rising

VEN_VCC_L

Enable input low level for

VCC output

VEN falling

0.3

VEN_VOUT_H

Enable input high level for

VOUT

VEN rising

1.14

VEN_VOUT_HYS

Enable input hysteresis for

VOUT

VEN falling hysteresis

ILKG_EN

Enable input leakage current

VEN = 2 V

V

1.196

1.25

–100

1.4

V

mV

200

nA

INTERNAL LDO (VCC PIN, BIAS PIN)

VCC

Internal VCC voltage

VCC_UVLO

Internal VCC undervoltage

lockout

VBIAS_ON

Input changeover

IBIAS_NONSW

Operating quiescent current

from external VBIAS (nonswitching)

PWM operation

3.27

V

PFM operation

3.1

V

VCC rising

2.96

3.14

VCC falling hysteresis

–605

VBIAS rising

3.09

VBIAS falling hysteresis

–63

VEN = 2 V, VFB = 1.5 V, VBIAS = 3.3 V

external

3.27

V

mV

3.25

V

mV

21

50

µA

1.006

1.017

V

0.2

60

nA

VOLTAGE REFERENCE (FB PIN)

VFB

Feedback voltage

PWM mode

ILKG_FB

Input leakage current at FB

pin

VFB = 1 V

(1)

6

0.987

Shutdown current includes leakage current of the switching transistors.

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

Electrical Characteristics (continued)

Limits apply over the recommended operating junction temperature (TJ) range of –40°C to +125°C, unless otherwise stated.

Minimum and maximum limits are specified through test, design or statistical correlation. Typical values represent the most

likely parametric norm at TJ = 25°C, and are provided for reference purposes only. Unless otherwise stated, VIN = 12 V.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

1.6

2.2

2.7

LM73605

6

7.3

8.35

LM73606

7.4

8.7

9.85

LM73605

4.79

5.5

6.1

LM73606

5.8

6.6

7.25

UNIT

HIGH SIDE DRIVER (CBOOT PIN)

VCBOOT_UVLO

CBOOT - SW undervoltage

lockout

V

CURRENT LIMITS AND HICCUP

IHS_LIMIT

Short-circuit, high-side

current limit (2)

ILS_LIMIT

Low-side current limit (2)

INEG_LIMIT

Negative current limit

VHICCUP

Hiccup threshold on FB pin

IL_ZC

Zero cross-current limit

LM73605

–5

LM73606

–6

0.36

0.4

A

A

A

0.44

0.06

V

A

SOFT START (SS/TRK PIN)

ISSC

Soft-start charge current

RSSD

Soft-start discharge

resistance

1.8

UVLO, TSD, OCP, or EN = 0

2

2.2

1

µA

kΩ

POWER GOOD (PGOOD PIN) and OVERVOLTAGE PROTECTION

VPGOOD_OV

Power-good overvoltage

threshold

% of FB voltage

106%

110%

113%

VPGOOD_UV

Power-good undervoltage

threshold

% of FB voltage

86%

90%

93%

VPGOOD_HYS

Power-good hysteresis

% of FB voltage

VPGOOD_VALID

Minimum input voltage for

proper PGOOD function

50-µA pullup to PGOOD pin, VEN = 0 V,

TJ = 25°C

1.3

2

RPGOOD

Power-good ON-resistance

VEN = 2.5V

40

100

VEN = 0 V

30

90

1.2%

V

Ω

MOSFETS

RDS_ON_HS (3)

High-side MOSFET ONresistance

IOUT = 1 A, VBIAS = VOUT = 3.3 V

53

90

mΩ

RDS_ON_LS (3)

Low-side MOSFET ONresistance

IOUT = 1 A, VBIAS = VOUT = 3.3 V

31

55

mΩ

THERMAL SHUTDOWN

TSD (4)

(2)

(3)

(4)

Thermal shutdown threshold

Shutdown threshold

Recovery threshold

160

°C

135

°C

This current limit was measured as the internal comparator trip point. Due to inherent delays in the current limit comparator and drivers,

the peak current limit measured in closed loop with faster slew rate will be larger, and valley current limit will be lower.

Measured at pins

Ensured by design

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

7

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

6.6 Timing Characteristics

MIN

NOM

MAX

UNIT

CURRENT LIMITS AND HICCUP

NOC (1)

Number of switching cycles before

hiccup is tripped

128

Cycles

tOC

Overcurrent hiccup retry delay time

46

ms

3.5

6.3

ms

SOFT START (SS/TRK PIN)

tSS

CSS = OPEN, from EN rising edge to

PGOOD rising edge

Internal soft-start time

POWER GOOD (PGOOD PIN) and OVERVOLTAGE PROTECTION

tPGOOD_RISE

PGOOD rising edge deglitch delay

80

140

200

µs

tPGOOD_FALL

PGOOD falling edge deglitch delay

80

140

200

µs

MAX

UNIT

(1)

Ensured by design

6.7 Switching Characteristics

PARAMETER

TEST CONDITIONS

MIN

TYP

PWM LIMITS (SW PINS)

tON-MIN

Minimum switch on-time

60

82

tOFF-MIN

Minimum switch off-time

70

120

ns

tON-MAX

Maximum switch on-time

3

6

9

µs

HS timeout in dropout

ns

OSCILLATOR (RT and SYNC PINS)

fOSC

fADJ

Internal oscillator frequency

RT = Open

440

500

560

kHz

Minimum adjustable frequency by RT or

SYNC

RT =115 kΩ, 0.1%

315

350

385

kHz

Maximum adjustable frequency by RT or

SYNC

RT = 17.4 kΩ, 0.1%

1980

2200

2420

kHz

VSYNC_HIGH

Sync input high level threshold

VSYNC_LOW

Sync input low level threshold

2

VMODE_HIGH

Mode input high level threshold for

FPWM

VMODE_LOW

tSYNC_MIN

0.4

V

V

0.42

V

Mode input low level threshold for AUTO

mode

0.4

V

Sync input minimum ON and OFF-time

80

ns

6.8 System Characteristics

The following specifications apply to the circuit found in typical schematic with appropriate modifications from typical bill of

materials. These parameters are not tested in production and represent typical performance only. Unless otherwise stated the

following conditions apply: TA = 25°C, VIN = 12 V, VOUT = 3.3 V, fSW = 500 kHz.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

VFB_PFM

Output voltage offset at no load in

auto mode

VIN = 3.8 V to 36 V, VSYNC = 0 V, auto mode IOUT = 0

A

2%

VDROP

Minimum input to output voltage

differential to maintain specified

accuracy

VOUT = 5 V, IOUT = 3 A, fSW = 2.2 MHz

0.4

V

IQ_SW

Operating quiescent current

(switching)

VEN = 3.3 V, IOUT = 0 A, RT = open, VBIAS = VOUT =

3.3 V , RFBT = 1 Meg

15

µA

IPEAK_MIN

Minimum inductor peak current

LM73605:

VSYNC = 0, IOUT = 10 mA

1

A

LM73606:

VSYNC = 0 V, IOUT = 10 mA

1.3

IBIAS_SW

Operating quiescent current from

external VBIAS (switching)

fSW = 500 kHz, IOUT = 1 A

7

fSW = 2.2 MHz, IOUT = 1 A

25

DMAX

Maximum switch duty cycle

While in frequency foldback

tDEAD

Dead time between high-side and

low-side MOSFETs

8

Submit Documentation Feedback

mA

97.5%

4

ns

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

6.9 Typical Characteristics

Unless otherwise specified, VIN = 12 V. Curves represent most likely parametric norm at specified condition.

75

70

HS Switch

LS Switch

Shutdown Current (nA)

65

RDS-ON (m:)

60

55

50

45

40

35

30

25

20

-40

-20

0

20

40

60

80

Temperature (°C)

100

120

140

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

-40

-20

0

CHAR

Figure 1. High-Side and Low-Side Switches RDS-ON

20

40

60

Temperature (°C)

80

100

120

CHAR

Plot

Figure 2. Shutdown Quiescent Current

1.01

7.5

Temp = -40°C

Temp = 25°C

Temp = 125°C

1.009

1.008

7

1.007

Current Limits (A)

Feedback Voltage (V)

VIN = 3.5 V

VIN = 12 V

VIN = 36 V

1.006

1.005

1.004

1.003

1.002

6.5

HS

LS

6

5.5

1.001

1

3

6

9

12

15

18 21

VIN (V)

24

27

30

33

5

-40

36

-20

0

CHAR

Figure 3. Feedback Voltage

20

40

60

Temperature (°C)

80

100

120

CHAR

Figure 4. LM73605 High-Side and Low-Side Current Limits

2500

9

2250

2000

Frequency (kHz)

Current Limits (A)

8.4

7.8

HS

LS

7.2

FREQ = 350 kHz

FREQ = 1 MHz

FREQ = 2.2 MHz

1750

1500

1250

1000

750

500

6.6

250

6

-40

-20

0

20

40

60

Temperature (°C)

80

100

0

-40

120

-20

CHAR

Figure 5. LM73605 High-Side and Low-Side Current Limit

0

20

40

60

Temperature (°C)

80

100

120

CHAR

Figure 6. Switching Frequency Set by RT Resistor

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

9

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

Typical Characteristics (continued)

550

1.28

540

1.2

530

1.12

Enable Thresholds (V)

Frequency with RT Pin Floating (kHz)

Unless otherwise specified, VIN = 12 V. Curves represent most likely parametric norm at specified condition.

520

510

500

490

480

VIN = 3.5 V

VIN = 12 V

VIN = 36 V

470

460

450

-40

-20

0

20

40

60

Temperature (°C)

80

100

1.04

VEN_VOUT Rising

VEN_VOUT Falling

VEN_VCC Rising

VEN_VCC Falling

0.96

0.88

0.8

0.72

0.64

0.56

-40

120

-20

0

20

CHAR

Figure 7. Switching Frequency with RT Pin Open Circuit

40

60

80

Temperature (°C)

100

120

140

CHAR

Figure 8. Enable Thresholds

115

PGOOD Thresholds (%)

110

105

OV Tripping

OV Recovery

UV Recovery

UV Tripping

100

95

90

85

-40

-20

0

20

40

60

Temperature (°C)

80

100

120

CHAR

Figure 9. PGOOD Thresholds

10

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

7 Detailed Description

7.1 Overview

The LM73605 and LM73606 are easy-to-use synchronous step-down DC/DC converters that operate from a 3.5V to 36-V supply voltage. It is capable of delivering up to 5-A (LM73605) or 6-A (LM73606) DC load current with

exceptional efficiency and thermal performance in a very small solution size.

The LM73605 and LM73606 employs fixed-frequency peak current-mode control with configurable auto or

FPWM operation mode. Auto mode provides very high efficiency at light loads, and FPWM mode maintains

constant switching frequency over entire load range.

The device is internally compensated, which reduces design time and the number of external components. The

switching frequency is programmable from 350 kHz to 2.2 MHz by an external resistor. The LM73605 and

LM73606 can also synchronize to an external clock within the same frequency range. The wide switching

frequency range allows the device to be optimized for a wide range of system requirements. It can be optimized

for small solution size with higher frequency; or for high efficiency with lower switching frequency. The LM73605

and LM73606 have very low quiescent current, which is critical for battery-operated systems. It allows for a wide

range of voltage conversion ratios due to very small minimum on-time (tON-MIN) and minimum off-time (tOFF-MIN).

Automated frequency foldback is employed at very high or low duty cycles to further extend the operating range.

The LM73605 and LM73606 also feature a power-good (PGOOD) flag, precision enable, internal or adjustable

soft start, pre-biased start-up, and output voltage tracking. Protection features include thermal shutdown,

undervoltage lockout (UVLO), cycle-by-cycle current limiting, and short-circuit hiccup protection. It provides

flexible and easy-to-use solutions for a wide range of applications.

The family requires very few external components and has a pin out designed for simple, optimum PCB layout

for enhanced EMI and thermal performance. The LM73605 and LM73606 devices are available in a 30-pin

WQFN leadless package.

7.2 Functional Block Diagram

VCC

ENABLE

ISSC

BIAS

LDO

Internal

SS

CBOOT

VCC

SS/TRK

HS I Sense

ICMD +

EA

REF

VBOOT VSW

+

±

RC

FB

FB

OV/UV

Detector

± +

UVLO

UVLO

CC

VSW

PFM

Detector

CONTROL LOGIC

SW

PGood

Hiccup

Detector

Slope Comp

Oscillator

TSD

± +

PGOOD

PVIN

VBOOT

Precision

Enable

CLK

ILIMIT

AGND

FPWM

RT

SYNC/

MODE

LS I Sense

PGND

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

11

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

7.3 Feature Description

7.3.1 Synchronous Step-Down Regulator

The LM73605 and LM73606 are synchronous buck converters with both power MOSFETs integrated in the

device. Figure 10 shows a simplified schematic for synchronous and non-synchronous buck converters. The

synchronous buck integrates both high-side (HS) and low-side (LS) power MOSFETs. The non-synchronous

buck integrates HS MOSFET and works with a discrete power diode as LS rectifier.

VIN

VIN

Synchronous

Buck

L

SW

CIN

VOUT

COUT

VIN

VIN

Non Synchronous

Buck

SW

L

CIN

VOUT

COUT

PGND

PGND

Figure 10. Simplified Synchronous versus Non-synchronous Buck Converters

A

•

•

•

•

•

•

synchronous converter with integrated HS and LS MOSFETs offers benefits such as the following:

Less design effort

Lower external component count

Reduced total solution size

Higher efficiency at heavier load

Easier PCB design

More control flexibility

The main advantage of a synchronous converter is that the voltage drop across the LS MOSFET is lower than

the voltage drop across the power diode of a non-synchronous converter. Lower voltage drop translates into less

power dissipation and higher efficiency. The LM73605 and LM73606 integrate HS and LS MOSFETs with very

low on-time resistance to improve efficiency. It is especially beneficial when the output voltage is low. Because

the LS MOSFET is integrated into these devices, at light loads a synchronous converter has the flexibility to

operate in either discontinuous or continuous conduction mode.

An integrated LS MOSFET also allows the controller to obtain inductor current information when the LS switch is

on. It allows the control loop to make more complex decisions based on HS and LS currents. It allows the

LM73605 and LM73606 to have peak and valley cycle-by-cycle current limiting for more robust protection.

7.3.2 Auto Mode and FPWM Mode

The LM73605 and LM73606 have pin-configurable auto mode or FPWM options.

In auto mode, the device operates in diode emulation mode (DEM) at light loads. In DEM, inductor current stops

flowing when it reaches 0 A. This is also referred to as discontinuous conduction mode (DCM). This is the same

behavior as the non-synchronous regulator, with higher efficiency. At heavier load, when the inductor current

valley is above 0 A, the device operates in continuous conduction mode (CCM), where the switching frequency is

fixed and set by RT pin.

In auto mode, the peak inductor current has a minimum limit, IPEAK_MIN, in the LM73605 and LM73606. When

peak current reaches IPEAK_MIN, the switching frequency reduces to regulate the required load current. Switching

frequency lowers when load reduces. This is when the device operates in pulse frequency modulation (PFM).

PFM further improves efficiency by reducing switching losses. Light load efficiency is especially important for

battery-operated systems.

In forced PWM (FPWM) mode, the device operates in CCM regardless of load with the frequency set by RT pin

or synchronization input. Inductor current can go negative at light loads. At light loads, the efficiency is lower than

auto mode, due to higher conduction losses and switching losses. In FPWM, the device has fixed switching

frequency over the entire load range, which is beneficial to noise sensitive applications.

12

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

Feature Description (continued)

Figure 11 shows the inductor current waveforms in each mode with heavy load, light load, and very light load.

The difference between the two modes is at lighter loads where inductor current valley reaches zero.

Auto Mode

IL

FPWM Mode

IL

CCM

CCM

Heavy

Loads

t

Light

Loads

t

IL

IL

CCM

DCM

t

IL

t

IL

PFM

CCM

Very Light

Loads

t

t

Figure 11. Inductor Current Waveforms at Auto Mode and FPWM Mode with Different Loads

In CCM, the inductor current peak-to-peak ripple can be estimated by Equation 1:

ILripple =

(VIN VOUT )

V

u OUT

fSW u L

VIN

(1)

The average or DC value of the inductor current equals the load current, or output current IOUT, in steady state.

Peak inductor current can be calculated by Equation 2:

IPEAK = IOUT + ILripple / 2

(2)

Valley inductor current can be calculated by Equation 3:

IVALLEY = IOUT – ILripple / 2

(3)

In auto mode, the CCM-to-DCM boundary condition is when IVALLEY = 0 A. When ILripple ≥ IPEAK_MIN, the load

current at the DCM boundary condition can be found by Equation 4. When the peak-to-peak ripple current is

smaller than ILripple ≥ IPEAK-MIN, the PFM boundary is reached first.

IOUT_DCM = ILripple / 2

when

•

ILripple ≥ IPEAK_MIN

(4)

In auto mode, the PFM operation boundary condition is when IPEAK = IPEAK_MIN. Frequency foldback occurs when

peak current drops to IPEAK_MIN, regardless of whether it is in CCM or DCM operation. When current ripple is

small, ILripple < IPEAK_MIN, the peak current reaches IPEAK_MIN when it is still in CCM. The output current at CCM

PFM boundary can be found by Equation 5:

IOUT_CCM_PFM = IPEAK_MIN – ILripple / 2

when

•

ILripple < IPEAK_MIN

(5)

The current ripple increases with reduced frequency if load reduces. When valley current reaches zero, the

frequency continues to fold back with constant peak current and discontinuous current.

In FPWM mode, there is no IPEAK-MIN limit. The peak current is defined by Equation 2 at light loads and heavy

loads.

Mode setting only affects operation at light loads. There is no difference if load current is above the DCM and

PFM boundary conditions discussed above.

See the Frequency Synchronization and Mode Setting section for mode setting options in the LM73605 and

LM73606.

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

13

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

Feature Description (continued)

7.3.3 Fixed-Frequency Peak Current-Mode Control

The LM73605 and LM73606 synchronous switched mode voltage regulator employs fixed frequency peak current

mode control with advanced features. The fixed switching frequency is controlled by an internal clock. To get

accurate DC load regulation, a voltage feedback loop is implemented to generate peak current command. The

HS switch is turned on at the rising edge of the clock. As shown in Figure 12, during the HS switch on-time, tON,

the SW pin voltage, VSW, swings up to approximately VIN, and the inductor current, IL, increases with a linear

slope. The HS switch is turned off when the inductor current reaches the peak current command. During the HS

switch off-time, tOFF, the LS switch is turned on. Inductor current discharges through the LS switch, which forces

the VSW to swing below ground by the voltage drop across the LS switch. The LS switch is turned off at the next

clock cycle, before the HS switch is turned on. The regulation loop adjusts the peak current command to

maintain a constant output voltage.

VSW

SW Voltage

D = tON / TSW

VIN

tON

tOFF

0

-VD

t

TSW

Inductor Current

IL

IL-PEAK

IOUT

ILripple

IL-VALLEY

t

0

Figure 12. SW Voltage and Inductor Current Waveforms in CCM

Duty cycle D is defined by the on-time of the HS switch over the switching period:

D = tON / TSW

where

•

TSW = 1 / fSW is the switching period

(6)

In an ideal buck converter where losses are ignored, D is proportional to the output voltage and inverse

proportional to the input voltage: D = VOUT ⁄ VIN.

When the LM73605 and LM73606 are set to operate in auto mode, the LS switch is turned off when its current

reaches zero ampere before the next clock cycle comes. Both HS switch and LS switch are off before the HS

switch is turned on at the next clock cycle.

7.3.4 Adjustable Output Voltage

The voltage regulation loop in the LM73605 and LM73606 regulate the FB pin voltage to be the same as the

internal reference voltage. The output voltage of the LM73605 and LM73606 is set by a resistor divider to

program the ratio from VOUT to VFB. The resistor divider is connected from the output to ground with the mid-point

connecting to the FB pin.

VOUT

RFBT

FB

RFBB

Figure 13. Output Voltage Setting by Resistor Divider

14

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

Feature Description (continued)

The internal voltage reference and feedback loop produce precise voltage regulation over temperature. TI

recommends using divider resistors with 1% tolerance or better, and with temperature coefficient of 100 ppm or

lower. Typically, RFBT = 10 kΩ to 100 kΩ is recommended. Larger RFBT and RFBB values reduce the quiescent

current going through the divider, which help maintain high efficiency at very light load. Larger divider values also

make the feedback path more susceptible to noise. If efficiency at very light load is critical in a certain

application, RFBT up to 1 MΩ can be used.

RFBB can be calculated by Equation 7:

VFB

RFBB

RFBT

VOUT VFB

(7)

The minimum programmable VOUT equals VFB, with RFBB open. The maximum VOUT is limited by the maximum

duty cycle at a given frequency:

DMAX = 1 – (tOFF-MIN / TSW)

where

•

•

tOFF-MIN is the minimum off time of the HS switch

TSW = 1 / fSW is the switching period

(8)

Ideally, without frequency foldback, VOUT_MAX = VIN_MIN × DMAX.

Power losses in the circuit reduces the maximum output voltage. The LM73605 and LM73606 fold back switching

frequency under tOFF_MIN condition to further extend VOUT_MAX. The device maintains output regulation with lower

input voltage. The minimum foldback frequency is limited by the maximum HS on-time, tON_MAX. Maximum output

voltage with frequency foldback can be estimated by:

VOUT _ MAX

VIN_MIN u

tON

tON

MAX

MAX

tOFF-MIN

IOUT u (RDS_ON_HS

DCR)

(9)

The voltage drops on the HS MOSFET and inductor DCR have been taken into account in Equation 9. The

switching losses were not included.

If the resistor divider is not connected properly, the output voltage cannot be regulated because the feedback

loop cannot obtain correct output voltage information. If the FB pin is shorted to ground or disconnected, the

output voltage is driven close to VIN. The load connected to the output can be damaged under this condition. Do

not short FB to ground or leave it open circuit during operation.

The FB pin is a noise sensitive node. It is important to place the resistor divider as close as possible to the FB

pin, and route the feedback node with a short and thin trace. The trace connecting VOUT to RFBT can be long, but

it must be routed away from the noisy area of the PCB. For more layout recommendations, see the Layout

section.

7.3.5 Enable and UVLO

The LM73605 and LM73606 regulate output voltage when the VCC voltage is higher than the undervoltage lock

out (UVLO) level, VCC_UVLO, and the EN voltage is higher than VEN_VOUT_H.

The internal LDO output voltage VCC is turned on when the EN voltage is higher than VEN_VCC_H. The precision

enable circuitry is also turned on when VCC is above UVLO. Normal operation of the LM73605 and LM73606

with regulated output voltage is enabled when the EN voltage is greater than VEN_VOUT_H. When the EN voltage is

less than VEN_VCC_L, the device is in shutdown mode. The internal dividers make sure VEN_VOUT_H is always

higher than VEN_VCC_H.

The EN pin cannot be left floating. The simplest way to enable the operation of the LM73605 and LM73606 is to

connect the EN pin to PVIN, which allows self-start-up of the LM73605 and LM73606 when VIN rises. Use of a

pullup resistor between PVIN and EN pins helps reduce noise coupling from PVIN pin to the EN pin.

Many applications benefit from employing an enable divider to establish a customized system UVLO. This can be

used either for sequencing, system timing requirement, or to reduce the occurrence of deep discharge of a

battery power source. Figure 14 shows how to use a resistor divider to set a system UVLO level. An external

logic output can also be used to drive the EN pin for system sequencing.

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

15

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

Feature Description (continued)

VIN

RENT

ENABLE

RENB

Figure 14. System UVLO

With a selected RENT, the RENB can be calculated by:

RENB =

VEN _ VOUT _ H

VIN _ ON _ H

VEN_VOUT_H

RENT

where

•

VIN_ON_H is the desired supply voltage threshold to turn on this device

(10)

Note that the divider adds to supply quiescent current by VIN / (RENT + RENB). Small RENT and RENB values add

more quiescent current loss. However, large divider values make the node more sensitive to noise. RENT in the

hundreds of kΩ range is a good starting point.

7.3.6 Internal LDO, VCC_UVLO, and BIAS Input

The LM73605 and LM73606 integrate an internal LDO, generating VCC voltage for control circuitry and MOSFET

drivers. The VCC pin must have a 1-µF to 4.7-µF bypass capacitor placed as close as possible to the pin and

properly grounded. Do not load the VCC pin or short it to ground during operation. Shorting VCC pin to ground

during operation can damage the device.

The UVLO on VCC voltage, VCC_UVLO, turns off the regulation when VCC voltage is too low. It prevents the

LM73605 and LM73606 from operating until the VCC voltage is enough for the internal circuitry. Hysteresis on

VCC_UVLO prevents the part from turning off during power up if VIN droops due to input current demands. The LDO

generates VCC voltage from one of the two inputs: the supply voltage VIN, or the BIAS input. When BIAS is tied

to ground, the LDO input is VIN. When BIAS is tied to a voltage higher than 3.3 V, the LDO input is VBIAS. BIAS

voltage must be lower than both VIN and 18 V.

The BIAS input is designed to reduce the LDO power loss. The LDO power loss is:

PLOSS_LDO = ILDO × (VIN_LDO – VOUT_LDO)

(11)

The higher the difference between the input and output voltages of the LDO, the more loss occurs to supply the

same LDO output current. The BIAS input provides an option to supply the LDO with a lower voltage than VIN, to

reduce the difference of the input and output voltages of the LDO and reduce power loss. For example, if the

LDO current is 10 mA at a certain frequency with VIN = 24 V and VOUT = 5 V. The LDO loss with BIAS tied to

ground is equal to 10 mA × (24 V – 3.27 V) = 207.3 mW, while the loss with BIAS tied to VOUT is equal to 10 mA

× (5 – 3.27) = 17.3 mW.

The efficiency improvement is more significant at light and mid loads because the LDO loss is a higher

percentage in the total loss. The improvements is more significant with higher switching frequency because the

LDO current is higher at higher switching frequency. The improvement is more significant when VIN » VOUT

because the voltage difference is higher.

Figure 15 and Figure 16 show efficiency improvement with bias tied to VOUT in a VOUT = 5 V and fSW = 2200 kHz

application, in auto mode and FPWM mode, respectively.

16

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

0.001

VOUT = 5 V

100

VIN = 12 V BIAS = VOUT

VIN = 12 V BIAS = GND

VIN = 24 V BIAS = VOUT

VIN = 24 V BIAS = GND

80

Efficiency (%)

Efficiency (%)

Feature Description (continued)

VIN = 12 V BIAS = VOUT

VIN = 12 V BIAS = GND

VIN = 24 V BIAS = VOUT

VIN = 24 V BIAS = GND

0.01 0.02 0.05 0.1 0.2

Load Current (A)

0.5

1

60

40

20

2 3 4 56

0

0.001

0.01 0.02 0.05 0.1 0.2 0.5

Load Current (A)

EFF_

fSW = 2200 kHz

Auto Mode

Figure 15. LM73606 Efficiency Comparison With Bias =

VOUT to Bias = GND in Auto Mode

VOUT = 5 V

fSW = 2200 kHz

1

2 3 4 5 7 10

EFF_

FPWM Mode

Figure 16. LM73606 Efficiency Comparison With Bias =

VOUT to Bias = GND in FPWM Mode

TI recommends tying the BIAS pin to VOUT when VOUT is equal to or greater than 3.3 V and no greater than 18 V.

Tie the BIAS pin to ground when not in use. A ceramic capacitor, CBIAS, can be used from the BIAS pin to ground

for bypassing. If VOUT has high frequency noise or spikes during transients or fault conditions, a resistor (1 to 10

Ω) connected between VOUT to BIAS can be used together with CBIAS for filtering.

VCC (V)

The VCC voltage is typically 3.27 V. When the LM73605 and LM73606 are operating in PFM mode with

frequency foldback, VCC voltage is reduced to 3.1 V (typical) to further decrease the quiescent current and

improve efficiency at very light loads. Figure 17 shows an example of VCC voltage change with mode change.

3.5

3.4

3.3

3.2

3.1

3

2.9

2.8

2.7

2.6

2.5

2.4

2.3

2.2

2.1

2

0.001

Auto Mode

FPWM Mode

0.01 0.02 0.05 0.1 0.2

Load Current (A)

VOUT = 5 V

0.5

1

fSW = 500 kHz

2 3 45

VCC_

VIN = 12 V

Figure 17. VCC Voltage versus Load Current

VCC voltage has an internal UVLO threshold, VCC_UVLO. When VCC voltage is higher than VCC_UVLO rising

threshold, the device is active and in normal operation if VEN > VEN_VOUT_H. If VCC voltage droops below

VCC_UVLO falling threshold, the VOUT is shut down.

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

17

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

Feature Description (continued)

7.3.7 Soft Start and Voltage Tracking

The LM73605 and LM73606 feature controlled output voltage ramp during start-up. The soft-start feature reduces

inrush current during start-up and improves system performance and reliability.

If the SS/TRK pin is floating, the LM73605 and LM73606 start up following the fixed internal soft-start ramp.

If longer soft-start time is desired, an external capacitor can be added from SS/TRK pin to ground. There is a 2µA (typical) internal current source, ISSC, to charge the external capacitor. For a desired soft-start time tSS,

capacitance of CSS can be found by Equation 12.

CSS = ISSC × tSS

where

•

•

•

CSS = soft-start capacitor value (F)

ISSC = soft-start charging current (A)

tSS = desired soft-start time or times

(12)

The FB voltage always follows the lower potential of the internal voltage ramp or the voltage on the SS/TRK pin.

Thus, the soft-start time can only be extended longer than the internal soft-start time by connecting CSS. Use CSS

to extend soft-start time when there are a large amount of output capacitors, the output voltage is high, or the

output is heavily loaded during start-up.

LM73605 and LM73606 are operating in diode emulation mode during start-up regardless of mode setting. The

device is capable of starting up into pre-biased output conditions. During start-up, the device sets the minimum

inductor current to zero to avoid back charging the input capacitors.

LM73605 and LM73606 can track an external voltage ramp applied to the SS/TRK pin, if the ramp is slower than

the internal soft-start ramp. The external ramp final voltage after start-up must be greater than 1.5 V to avoid

noise interfering with the reference voltage. Figure 18 shows how to use resistor divider to set VOUT to follow an

external ramp.

EXT RAMP

RTRT

SS/TRK

RTRB

Figure 18. Soft-start Tracking External Ramp

VOUT tracking also provides the option of ramping up faster than the internal start-up ramp. The FB voltage

always follows the lower potential of the internal voltage ramp and the voltage on the SS/TRK pin. Figure 19

shows the case when VOUT ramps slower than the internal ramp, while Figure 20 shows when VOUT ramps faster

than the internal ramp. If the tracking ramp is delayed after the internal ramp is completed, VFB follows the

tracking ramp even if it is faster than the internal ramp. Faster start-up time may result in large inductor current

during start-up. Use with special care.

Enable

Internal SS Ramp

Ext Tracking Signal to SS pin

VOUT

Figure 19. Tracking With Longer Start-up Time Than the Internal Ramp

18

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

Feature Description (continued)

Enable

Internal SS Ramp

Ext Tracking Signal to SS pin

VOUT

Figure 20. Tracking With Shorter Start-up Time Than the Internal Ramp

The SS/TRK pin is discharged to ground by an internal pulldown resistor RSSD when the output voltage is

shutting down, such as in the event of UVLO, thermal shutdown, hiccup, or VEN = 0. If a large CSS is used, and

the time when VEN = 0 V is very short, the CSS may not be fully discharged before the next soft start. Under this

condition, the FB voltage follows the internal ramp slew rate until the voltage on CSS is reached, then follow the

slew rate defined by CSS.

7.3.8 Adjustable Switching Frequency

The internal oscillator frequency is controlled by the impedance on the RT pin. If the RT pin is open circuit, the

LM73605 and LM73606 operate at their default switching frequency, 500 kHz. The RT pin is not designed to be

connected directly to ground. To program the switching frequency by RT resistor, Equation 13, or Figure 21, or

Table 1 can be used to find the resistance value.

RT (k:) =

1

fSW (kHz) u 2.675 u 10 -5 0.0007

(13)

120

110

100

90

RT (k:)

80

70

60

50

40

30

20

10

200

400

600

800 1000 1200 1400 1600 1800 2000 2200

Frequency (kHz)

RT_F

Figure 21. RT Resistance versus Switching Frequency

Table 1. Typical Frequency Setting Resistance

SWITCHING FREQUENCY fSW (kHz)

RT RESISTANCE (kΩ)

350

115

400

100

500

78.7 (or open)

750

52.3

1000

39.2

1500

26.1

2000

19.1

2200

17.4

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

19

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

The choice of switching frequency is usually a compromise between conversion efficiency and the size of the

solution. Lower switching frequency has lower switching losses (including gate charge losses, switch transition

losses, and so forth) and usually results in higher overall efficiency. However, higher switching frequency allows

the use of smaller power inductor and output capacitors, hence a more compact design. Lower inductance also

helps transient response (higher large signal slew rate of inductor current), and has lower DCR. The optimal

switching frequency is usually a trade-off in a given application and thus needs to be determined on a case-bycase basis. The following are factors that need to be taken into account:

• Input voltage range

• Output voltage

• Most frequent load current level or levels

• External component choices

• Solution size/cost requirements

• Efficiency

• Thermal management requirements

The choice of switching frequency can also be limited whether an operating condition triggers tON-MIN or tOFF-MIN.

Minimum on-time, tON-MIN, is the smallest time that the HS switch can be on. Minimum off-time, tOFF-MIN, is the

smallest duration that the HS switch can be off.

In CCM operation, tON-MIN and tOFF_MIN limit the voltage conversion range given a selected switching frequency,

fSW. The minimum duty cycle allowed is:

DMIN = tON-MIN × fSW

(14)

The maximum duty cycle allowed is:

DMAX = 1 – tOFF-MIN × fSW

(15)

Given an output voltage, the choice of the switching frequency affects the allowed input voltage range, solution

size and efficiency. The maximum operational supply voltage can be found by:

VIN_MAX = VOUT / (fSW × tON-MIN)

(16)

At lower supply voltage, the switching frequency decreases once tOFF-MIN is tripped. The minimum VIN without

frequency foldback can be approximated by:

VIN_MIN = VOUT / (1 – fSW × tOFF-MIN)

(17)

With a desired VOUT, the range of allowed VIN is narrower with higher switching frequency.

The LM73605 and LM73606 have an advanced frequency foldback algorithm under both tON_MIN and tOFF_MIN

conditions. With frequency foldback, stable output voltage regulation is extended to wider range of supply

voltages.

At very high VIN conditions where tON-MIN limitation is met, the switching frequency reduces to allow higher VIN

while maintaining VOUT regulation. Note that the peak-to-peak inductor current ripple will increase with higher VIN

and lower frequency. TI does not recommend designing the circuit to operate with tON_MIN under typical

conditions.

At very low VIN conditions, where tOFF-MIN limitation is met, the switching frequency decreases until tON-MAX

condition is met. Such frequency foldback mechanism allows the LM73605 and LM73606 to have very low

dropout voltage regardless of frequency setting.

7.3.9 Frequency Synchronization and Mode Setting

The LM73605 and LM73606 switching action can synchronize to an external clock from 350 kHz to 2.2 MHz. TI

recommends connecting the external clock to the SYNC/MODE pin with an appropriate termination resistor.

Ground the SYNC/MODE pin if not used.

SYNC/

MODE

EXT CLOCK

RSYNC

Figure 22. Frequency Synchronization

20

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

Recommendations for the external clock include a high level no lower than 2 V, low level no higher than 0.4 V,

duty cycle between 10% and 90%, and both positive and negative pulse width no shorter than 80 ns. When the

external clock fails at logic high or low, the LM73605 and LM73606 switch at the frequency programmed by the

RT resistor after a time-out period. TI recommends connecting a resistor to the RT pin such that the internal

oscillator frequency is the same as the external clock frequency. This allows the regulator to continue operating

at approximately the same switching frequency if the external clock fails with the same control loop behavior.

The SYNC/MODE pin is also used as an operation mode control input.

• To set the operation in auto mode, connect SYNC/MODE pin to ground, or a logic signal lower than 0.3 V.

• To set the operation in FPWM mode, connect SYNC/MODE pin to a bias voltage or logic signal greater than

0.6 V.

• When the LM73605 and LM73606 are synchronized to an external clock, the operation mode is FPWM.

Table 2 summarizes the operation mode and features according to the SYNC/MODE input signal. For more

details, see the Active Mode and Auto Mode and FPWM Mode sections.

Table 2. SYNC/MODE Pin Settings and Operation Modes

SYNC/MODE

INPUT

SWITCHING

FREQUENCY

OPERATING

MODE

LIGHT LOAD BEHAVIOR

•

Logic low

Set by RT resistor

Logic high

Set by RT resistor

External clock

Set by external

clock

Auto mode

FPWM mode

•

No negative inductor current, device operates in discontinuous conduction mode

(DCM) when current valley reaches 0 A.

Minimum peak inductor current is limited at IPEAK_MIN; device operates in pulse

frequency modulation (PFM) mode when peak current reaches IPEAK_MIN.

Switching frequency reduces in PFM mode.

•

•

•

Fixed frequency continuous conduction mode (CCM) regardless of load

Inductor current have negative portion at light loads

No IPEAK_MIN

•

7.3.10 Internal Compensation and CFF

The LM73605 and LM73606 are internally compensated. The internal compensation is designed such that the

loop response is stable over a wide operating frequency and output voltage range. The internal R-C values are

500 kΩ and 30 pF, respectively.

When large resistance value (MΩ) is used for RFBT, the pole formed by an internal parasitic capacitor and RFBT

can be low enough to reduce the phase margin. If only low ESR output capacitors (ceramic types) are used for

COUT, the control loop can have low phase margin. To provide a phase boost an external feedforward capacitor

(CFF) can be added in parallel with RFBT. Choose the CFF capacitor to provide most phase boost at the estimated

crossover frequency fX:

fX =

K

VOUT u COUT

where

•

•

K = 20.27 with LM73605

K = 24.16 with LM73606

(18)

Select COUT so that the fX is no higher than 1/6 of the switching frequency. Typically, fX / fSW = 1/10 to 1/8

provides a good combination of stability and performance.

Place the external feedforward capacitor in parallel with the top resistor divider RFBT when additional phase boost

is needed.

VOUT

RFBT

CFF

FB

RFBB

Figure 23. Feedforward Capacitor for Loop Compensation

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

21

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

The feedforward capacitor CFF in parallel with RFBT places an additional zero before the crossover frequency of

the control loop to boost phase margin. The zero frequency can be found by Equation 19:

fZ-CFF = 1 / (2π × RFBT × CFF)

(19)

An additional pole is also introduced with CFF at the frequency of:

fP-CFF = 1 / (2π × CFF × (RFBT // RFBB))

(20)

Select the CFF so that the bandwidth of the control loop without the CFF is centered between fZ-CFF and fP-CFF. The

zero at fZ-CFF adds phase boost at the crossover frequency and improves transient response. The pole at fP-CFF

helps maintain proper gain margin at frequency beyond the crossover.

The need of CFF depends on RFBT and COUT. Typically, choose RFBT ≤ 100 kΩ. CFF may not be required, because

the internal parasitic pole is at higher frequency. If COUT has larger ESR, and ESR zero fZ-ESR = 1 / (2π × ESR ×

COUT) is low enough to provide phase boost around the crossover frequency, do not use CFF. Equation 21 was

tested for ceramic output capacitors:

CFF =

1

u

2 u S u fx

1

RFBT u (RFBT // RFBB )

(21)

The CFF creates a time constant with RFBT that couples in the attenuated output voltage ripple to the FB node. If

the CFF value is too large, it can couple too much ripple to the FB and affect VOUT regulation. It can also couple

too much transient voltage deviation and falsely trigger PGOOD flag.

7.3.11 Bootstrap Capacitor and VBOOT-UVLO

The driver of the HS switch requires a bias voltage higher than the VIN voltage. The capacitor, CBOOT in the

Simplified Schematic, connected between CBOOT and SW pins works as a charge pump to boost voltage on the

CBOOT pin to (VSW + VCC). A boot diode is integrated on the die to minimize external component count. TI

recommends a high-quality 0.47-µF, 6.3-V or higher voltage ceramic capacitor for CBOOT. The VBOOT_UVLO

threshold is designed to maintain proper HS switch operation. If the CBOOT is not charged above this voltage with

respect to SW, the device initiates a charging sequence using the LS switch before turning on the HS switch.

7.3.12 Power-Good and Overvoltage Protection

The LM73605 and LM73606 have a built-in power-good (PGOOD) flag to indicate whether the output voltage is

at an appropriate level or not. The PGOOD flag can be used for start-up sequencing of multiple rails. The

PGOOD pin is an open-drain output that requires a pullup resistor to an appropriate logic voltage (any voltage

below 15 V). The pin can sink 5 mA of current and maintain its specified logic low level. A typical pullup resistor

value is 10 kΩ to 100 kΩ. When the FB voltage is higher than VPGOOD-OV or lower than VPGOOD-UV threshold, the

PGOOD internal switch is turned on, and the PGOOD pin voltage is pulled low. When the FB is within the range,

the PGOOD switch is turned off, and the pin is pulled up to the voltage connected to the pullup resistor. The

PGOOD function also has a deglitch timer for about 140 µs for each transition. If it is desired to pull up PGOOD

pin to a voltage higher than 15 V, a resistor divider can be used to divide the voltage down.

VPU

RPGT

PGOOD

RPGB

Figure 24. Divider for PGOOD Pullup Voltage

With a given pullup voltage VPU, select a desired voltage on the PGOOD pin, VPG. With a selected RPGT, the

RPGB can be found by:

RPGB =

VPG

RPGT

VPU VPG

(22)

When the device is disabled, the output voltage is low, and the PGOOD flag indicates logic low as long as VIN >

2 V.

22

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

7.3.13 Overcurrent and Short-Circuit Protection

The LM73605 and LM73606 are protected from overcurrent conditions with cycle-by-cycle current limiting on

both HS and LS MOSFETs.

The HS switch is turned off when HS current goes beyond the peak current limit, IHS-LIMIT. The LS switch can only

be turned off when LS current is below LS current limit, ILS-LIMIT. If the LS switch current is higher than ILS-LIMIT at

the end of a switching cycle, the switching cycle is extended until the LS current reduces below the limit.

Current limiting on both HS and LS switches provides tighter control of the maximum DC inductor current, or

output current. They also help prevent runaway current at extreme conditions. With the LM73605 and LM73606,

the maximum output current is always limited to:

IDC_LIMIT = (IHS_LIMIT + ILS_LIMIT) / 2

(23)

The LM73605 and LM73606 employ hiccup current protection at extreme overload conditions, including shortcircuit condition. Hiccup is only activated when VOUT droops below 40% (typical) of the regulation voltage and

stays below for 128 consecutive switching cycles. Under overcurrent conditions when VOUT has not fallen below

40% of regulation, the LM73605 and LM73606 continue operation with cycle-by-cycle HS and LS current limiting.

Hiccup is disabled during soft start. When hiccup is triggered, the device turns off VOUT regulation and re-tries

soft start after a re-try delay time, TOC = 46 ms (typical). The long wait time allows the device, and the load, to

cool down under such fault conditions. If the fault condition still exists when re-try, hiccup shuts down the device

and repeats the wait and re-try cycle. If the fault condition has been removed, the device starts up normally.

If tracking was used for initial sequencing, the device restarts using the internal soft-start ramp. Hiccup mode

helps reduce the device power dissipation and die temperature under severe overcurrent conditions and short

circuits. It improves system reliability and prolongs the life span of the device.

In FPWM mode, negative current protection is implemented to protect the switches from extreme negative

currents. When LS switch current reaches INEG-LIMIT, LS switch turns off, and HS switch turns on to conduct the

negative current. HS switch is turned off once its current reaches 0 A.

7.3.14 Thermal Shutdown

Thermal shutdown protection prevents the device from extreme junction temperature. The device is turned off

when the junction temperature exceeds 160°C (typical). After thermal shutdown occurs, hysteresis prevents the

device from switching until the junction temperature drops to approximately 135°C. When the junction

temperature falls below 135°C, the LM73605 and LM73606 restart.

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

Submit Documentation Feedback

23

�LM73605, LM73606

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

www.ti.com

7.4 Device Functional Modes

7.4.1 Shutdown Mode

The EN pin provides electrical on/off control of the device. When the EN pin voltage is below VEN_VCC_L, the

device is in shutdown mode. The LDO output voltage VCC = 0 V and the output voltage VOUT = 0 V. In shutdown

mode, the quiescent current drops to a very low value.

7.4.2 Standby Mode

The internal LDO has a lower EN threshold than that required to start the regulator. When the EN pin voltage is

above VEN_VCC_H, the internal LDO regulates the VCC voltage. The precision enable circuitry is turned on once

VCC is above VCC_UVLO. The device is in standby mode if EN voltage is below VEN_VOUT_H. The internal MOSFETs

remains in tri-state unless the voltage on EN pin goes beyond VEN_VOUT_H threshold. The LM73605 and LM73606

also employs UVLO protection. If the VCC voltage is below the VCC_UVLO level, the output of the regulator is

turned off.

7.4.3 Active Mode

The LM73605 and LM73606 are in active mode when the EN voltage is above VEN_VOUT_H, and VCC is above

VCC_UVLO. The simplest way to enable the operation of the LM73605 and LM73606 is to pull up the EN pin to

PVIN, which allows self-start-up when the input voltage ramps up.

In active mode, depending on the load current and mode setting, the LM73605 and LM73606 are in one of four

modes:

1. CCM with fixed switching frequency when load current is above half of the peak-to-peak inductor current

ripple

2. DCM with fixed switching frequency when load current is lower than half of the peak-to-peak inductor current

ripple in CCM operation

3. PFM when switching frequency is decreased at very light load

4. Under overcurrent or overtemperature conditions, the device operates in one of the fault protection modes

See Table 2 for mode-setting details.

7.4.3.1 CCM Mode

In CCM operation, inductor current has a continuous triangular waveform. The HS switch is on at the beginning

of a switching cycle and the LS switch is turned off the end of each switching cycle. In auto mode, the LM73605

and LM73606 operate in CCM when the load current is higher than ½ of the peak-to-peak inductor current

(ILripple). In FPWM mode, the LM73605 and LM73606 operate in CCM, regardless of load.

In CCM operation, the switching frequency is typically constant, unless tON-MIN, tOFF-MIN, or IPEAK-MIN conditions are

met. The constant switching frequency is determined by RT pin setting, or the external synchronization clock

frequency. The duty cycle is also constant in CCM: D = VOUT / VIN if loss is ignored, regardless of load. The

peak-to-peak inductor ripple is constant with the same VIN and VOUT, regardless of load.

With very high or very low supply voltages, when the tON-MIN or tOFF-MIN condition is met, the frequency reduces to

maintain VOUT regulation with even higher or lower VIN, respectively. When the IPEAK_MIN condition is met in auto

mode, the switching frequency folds back to provide higher efficiency. IPEAK_MIN is disabled in FPWM mode.

7.4.3.2 DCM Mode

DCM operation only happens in auto mode when the load current is lower than half of the CCM inductor current

ripple, and peak current is higher than IPEAK-MIN. There is no DCM in FPWM mode. DCM is also known as diode

emulation mode. The LS FET is turned off when the inductor current ramps to 0 A. DCM has the same switching

frequency as CCM, which is set by the RT pin. Duty cycle and peak current reduces with lighter load in DCM.

DCM is more efficient than FPWM under the same condition, because of lower switching losses and lower

conduction losses. When the peak current reduces to IPEAK_MIN at lighter load, the LM73605 and LM73606

operate in PFM mode.

24

Submit Documentation Feedback

Copyright © 2017–2020, Texas Instruments Incorporated

Product Folder Links: LM73605 LM73606

�LM73605, LM73606

www.ti.com

SNVSAH5A – SEPTEMBER 2017 – REVISED MAY 2020

Device Functional Modes (continued)

7.4.3.3 PFM Mode

Pulse-frequency-modulation (PFM) mode is activated when peak current is lower than IPEAK-MIN, only in auto

mode. Peak current is kept constant and VOUT is regulated by frequency. Efficiency is greatly improved by

lowered switching losses, especially at very light loads.

In PFM operation, a small DC positive offset appears on VOUT. The lower the frequency is folded back in PFM,

the more the DC offset is on VOUT. See the VOUT regulation curves in the Application Curves. If the DC offset on

VOUT is not acceptable, a dummy load at VOUT, or lower RFBT and RFBB resistance values can be used to reduce

the offset. Alternatively, the device can be run in FPWM mode where the switching frequency is constant, and no

offset is added to affect the VOUT accuracy unless tON_MIN is reached.

7.4.3.4 Fault Protection Mode

The LM73605 and LM73606 have hiccup current protection at extreme overload and short circuit conditions.

Hiccup is activated when VOUT droops below 40% (typical) of the regulation voltage and stays for 128

consecutive switching cycles. Hiccup is disabled during soft start. In hiccup, the device turns off VOUT and re-tries

soft start after 46-ms wait time. Cycle repeats until overcurrent fault condition has been removed. Hiccup mode

helps reduce the device power dissipation and die temperature under severe overcurrent conditions and short

circuits. It improves system reliability and prolongs the life span of the device.