Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

LMX2594 15-GHz Wideband PLLATINUM™ RF Synthesizer

With Phase Synchronization and JESD204B Support

1 Features

3 Description

•

•

The LMX2594 is a high-performance, wideband

synthesizer that can generate any frequency from 10

MHz to 15 GHz without using an internal doubler,

thus eliminating the need for sub-harmonic filters. The

high-performance PLL with figure of merit of –236

dBc/Hz and high-phase detector frequency can attain

very low in-band noise and integrated jitter. The highspeed N-divider has no pre-divider, thus significantly

reducing the amplitude and number of spurs. There is

also a programmable input multiplier to mitigate

integer boundary spurs.

1

•

•

•

•

•

•

•

•

•

10-MHz to 15-GHz output frequency

–110 dBc/Hz phase noise at 100-kHz offset with

15-GHz carrier

45-fs rms jitter at 7.5 GHz (100 Hz to 100 MHz)

Programmable output power

PLL key specifications

– Figure of merit: –236 dBc/Hz

– Normalized 1/f noise: –129 dBc/Hz

– High phase detector frequency

– 400-MHz integer mode

– 300-MHz fractional mode

– 32-bit fractional-N divider

Remove integer boundary spurs with

programmable input multiplier

Synchronization of output phase across multiple

devices

Support for SYSREF with 9-ps resolution

programmable delay

Frequency ramp and chirp generation ability for

FMCW applications

< 20-µs VCO calibration speed

3.3-V single power supply operation

The LMX2594 allows users to synchronize the output

of multiple devices and also enables applications that

need deterministic delay between input and output. A

frequency ramp generator can synthesize up to two

segments of ramp in an automatic ramp generation

option or a manual option for maximum flexibility. The

fast calibration algorithm allows changing frequencies

faster than 20 µs. The LMX2594 adds support for

generating or repeating SYSREF (compliant to

JESD204B standard) designed for low-noise clock

sources in high-speed data converters. A fine delay

adjustment (9-ps resolution) is provided in this

configuration to account for delay differences of board

traces.

The output drivers within LMX2594 deliver output

power as high as 7 dBm at 15-GHz carrier frequency.

The device runs from a single 3.3-V supply and has

integrated LDOs that eliminate the need for on-board

low noise LDOs.

2 Applications

•

•

•

•

•

•

5G and mm-Wave wireless infrastructure

Test and measurement equipment

Radar

MIMO

Phased array antennas and beam forming

High-speed data converter clocking (supports

JESD204B)

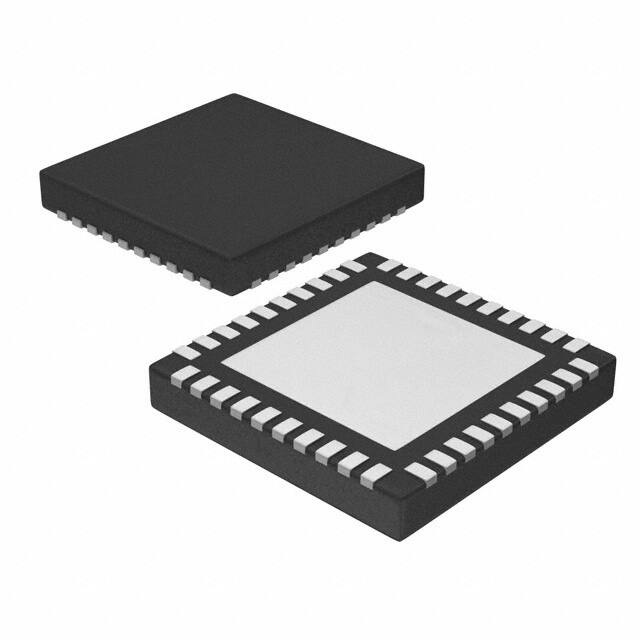

Device Information(1)

PART NUMBER

LMX2594

PACKAGE

VQFN (40)

BODY SIZE (NOM)

6.00 mm × 6.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Simplified Schematic

CPout

Phase

Detector

OSCinP

Input

signal

OSCin

Douber

OSCinM

Pre-R

Divider

Multiplier

Post-R

Divider

ϕ

Vtune

Charge

Pump

Sigma-Delta

Modulator

CSB

SCK

SDI

RFoutAP

MUX

Vcc

RFoutAM

Channel

Divider

RFoutBM

MUX

Serial Interface

Control

Loop Filter

Vcc

RFoutBP

N Divider

SYSREF

MUXout

Copyright © 2017, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

Table of Contents

1

2

3

4

5

6

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

6.1

6.2

6.3

6.4

6.5

6.6

6.7

7

1

1

1

2

6

8

Absolute Maximum Ratings ...................................... 8

ESD Ratings.............................................................. 8

Recommended Operating Conditions....................... 8

Thermal Information .................................................. 8

Electrical Characteristics........................................... 9

Timing Requirements .............................................. 11

Typical Characteristics ............................................ 14

Detailed Description ............................................ 18

7.1

7.2

7.3

7.4

Overview .................................................................

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

18

19

19

39

7.5 Programming........................................................... 40

7.6 Register Maps ......................................................... 41

8

Application and Implementation ........................ 59

8.1 Application Information............................................ 59

8.2 Typical Application .................................................. 61

9 Power Supply Recommendations...................... 64

10 Layout................................................................... 65

10.1 Layout Guidelines ................................................. 65

10.2 Layout Example .................................................... 66

11 Device and Documentation Support ................. 67

11.1

11.2

11.3

11.4

11.5

11.6

11.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

67

67

67

67

67

67

67

12 Mechanical, Packaging, and Orderable

Information ........................................................... 68

4 Revision History

Changes from Revision B (March 2018) to Revision C

Page

•

Deleted the recommended bypass capacitor values for Vcc pins 7, 11, 15, 21, 26 and 37, as these capacitor values

are not mandatory and the power supply filtering design is up to the user............................................................................ 7

•

Changed all the 'FRAC_ORDER' to 'MASH_ORDER' to avoid confusion ............................................................................. 9

•

Changed the names of timing specs to align with timing diagram: changed tCE to tES, tCS to tDCS, tCH to tCDH, and tCES

to tECS .................................................................................................................................................................................... 11

•

Changed the names of timing specs to align with timing diagram: changed tES to tCE, tCES to tECS, added tDCS and

tCDH, and changed tCS to tCR .................................................................................................................................................. 12

•

Changed the serial data input timing diagram and corrected the typo for 'SCK'.................................................................. 12

•

Deleted the note 'The CSB transition from high to low must occur when SCK is low' from the serial data input timing

diagram, because SPI mode 4 (CPOL = 1, CPHA = 1) is also supported, and SCK is held high when idle in mode 4 ..... 12

•

Added note for the serial data input timing diagram to explain the tCE requirement for mode 4 (CPOL = 1, CPHA = 1)

of SPI, because the diagram only indicated SPI mode 1 (CPOL = 0, CPHA = 0) ............................................................... 12

•

Changed the serial data readback timing diagram............................................................................................................... 13

•

Changed the note about MUXout clocking out and emphasized the effect of tCR on the readback data available time ..... 13

•

Changed the fOUT test conditions in the Closed-Loop Phase Noise at 3.5 GHz graph from: 14 GHz / 2 = 3.5 GHz to:

to 14 GHz / 4 = 3.5 GHz ...................................................................................................................................................... 15

•

Added Normalized Output Power Across OUTA_PWR With Resistor Pullup graph............................................................ 15

•

Changed "Vtune" to "Indirect Vtune" when LD_TYPE = 1 ................................................................................................... 21

•

Changed description for LD_TYPE. .................................................................................................................................... 21

•

Added description of Indirect Vtune. ................................................................................................................................... 22

•

Added description for the 'no assist' mode, mphasized the effect of VCO_SEL, VCO_DACISET_STRT and

VCO_CAPCTRL_STRT under 'no assist' mode, and added recommended values for these registers .............................. 23

•

Added description for the 'full assist' mode to allow the user to set VCO amplitude and capcode using linear

interpolation under certain conditions................................................................................................................................... 23

•

Changed OUTx_PWR Recommendations for Resistor Pullup table ................................................................................... 25

•

Added description for category 3 of SYNC feature stating that FCAL_EN needs to be 1. .................................................. 29

•

Changed description of MASH_SEED ................................................................................................................................ 29

2

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

Revision History (continued)

•

Added 10-ms wait time before re-programming register R0 in recommended initial power-up sequence ......................... 40

•

Added the General Programming Requirements section based on frequently asked questions......................................... 40

•

Changed register R4 in the register map to: exposed ACAL_CMP_DLY ........................................................................... 41

•

Changed the register R20[14] value from 0 to 1 in the full register map to match the R20 register description ................ 41

•

Changed the default value of R25 to align with register map of LMX2595. This change has no impact on the LMX2594. 42

•

Changed the R0[14] register field name in the register map from VCO_PHASE_SYNC_EN to VCO_PHASE_SYNC.

to align with the rest of the data sheet ................................................................................................................................. 46

•

Added recommended value for register CAL_CLK_DIV when lock time is not of concern.................................................. 46

•

Changed the typo for register 'VCO_DACISET' in the register map. Bit 0 of this register was not included in the

map. The full register map and register description were correct ........................................................................................ 48

•

Added description to the R4[15:8]: ACAL_CMP_DLY register............................................................................................. 48

•

Deleted the bit description '0: disabled; 1: enabled' for register 'PLL_N' ............................................................................. 49

•

Added description to the R60[15:0] LD_DLY register .......................................................................................................... 51

•

Changed the R31[14] register name from CHDIV_DIV2 to SEG1_EN to align with the naming in the TICS Pro GUI ....... 53

•

Changed the R105[1:0] field name from RAMP_NEXT_TRIG to RAMP1_NEXT_TRIG ..................................................... 58

•

Added the Bias Levels of Pins table..................................................................................................................................... 64

Changes from Revision A (August 2017) to Revision B

Page

•

Changed all the VCO Gain typical values in the Electrical Characteristics table. This is due to improved

measurement methods and NOT a change in the device itself ........................................................................................... 11

•

Moved the high-level output voltage parameter VCC – 0.4 value from the MAX column to the MIN.................................... 11

•

Moved the high-level output current parameter 0.4 value from the MIN column to the MAX .............................................. 11

•

Changed bulleted text: data is clocked out on MUXout, not SDI pin ................................................................................... 13

•

Added comment that OSCin is clocked on rising edges of the signal. and reformatted with bulleted list ........................... 19

•

Added description of the state machine clock ..................................................................................................................... 20

•

Changed example from: 200 MHz / 232 to: 200 MHz / (232 – 1) .......................................................................................... 21

•

Changed LD_DLY description in Table 4 and removed duplicated text in the Lock Detect section .................................... 21

•

Changed name from VCO_AMPCAL to VCO_DACISET_STRT ........................................................................................ 23

•

Added more programmable settings to Table 5 ................................................................................................................... 23

•

Changed VCO Gain table..................................................................................................................................................... 24

•

Added that OUTx_PWR states 32 to 47 are redundant and reworded section ................................................................... 25

•

Added term "IncludedDivide" for clarity ............................................................................................................................... 26

•

Changed Fixed Diagram to show SEG0, SEG1, SEG2, and SEG3 ................................................................................... 27

•

Changed included channel divide to IncludedDivide and 2 X SEG0 to 2 X SEG1. Also clarified IncludedDivide

calculations ........................................................................................................................................................................... 29

•

Added more description on conditions for phase adust ....................................................................................................... 29

•

Changed text from: (VCO_PHASE_SYNC = 1) to: (VCO_PHASE_SYNC = 0) ................................................................. 29

•

Changed text so the user does not incorrectly assume that MASH_SEED varies from part ot part ................................... 30

•

Changed the RAMP_THRESH programming from: 0 to ± 232 to: 0 to ± 233 – 1 .................................................................. 30

•

Removed comment that RAMP_TRIG_CAL only applies in automatic ramping mode........................................................ 30

•

Changed the RAMP_LOW and _HIGH programming from: 0 to ± 231 to: 0 to ± 233 – 1...................................................... 30

•

Changed description to be in terms of state machine cycles ............................................................................................... 31

•

Changed RAMP_MODE to RAMP_MANUAL in the Manual Pin Ramping and Automatic Ramping sections .................... 31

•

Added that the RampCLK pin input is reclocked to the phase detector frequency.............................................................. 31

•

Added that RampDir rising edges should be targeted away from rising edges of RampCLK pin........................................ 31

•

Changed programming enumerations for RAMP0_INC and RAMP1_INC .......................................................................... 33

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

3

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

•

Changed programming enumerations for RAMP_THRESH, RAMPx_LEN, and RAMP1_INC............................................ 34

•

Changed Figure 29 .............................................................................................................................................................. 34

•

Changed SysRef description ................................................................................................................................................ 35

•

Added divide by 2 to figure................................................................................................................................................... 35

•

Changed some entries in the table ...................................................................................................................................... 35

•

Changed fINTERPOLATOR SYSREF setup equation in Table 18 .............................................................................................. 35

•

Changed SysRef delay from: 224 and 225 to: 225 and 226 ................................................................................................ 36

•

Changed "generator" mode to "master" mode. They mean the same thing ........................................................................ 36

•

Changed description for SYSREF_DIV ................................................................................................................................ 36

•

Changed Figure 31 .............................................................................................................................................................. 37

•

Changed wording for repeater mode and master mode....................................................................................................... 38

•

Changed description of a few of the steps ........................................................................................................................... 39

•

Changed typo in R17 and R19 ............................................................................................................................................ 48

•

Deleted reference to VCO_SEL_STRT_EN. This is always 1 ............................................................................................. 48

•

Added VCO_SEL_STRT_EN reference. This is always 1 ................................................................................................... 48

•

Changed the enumerations 0-3 and added content to the INPIN_LVL field description ..................................................... 50

•

Added Divide by 1' to SYSREF_DIV_PRE register description. Also fixed the name misspelling ...................................... 52

•

Deleted redundant formula for Fout and also clarified SYSREF_DIV starts at 4 and counts by 2 ...................................... 52

•

Deleted reference to VCO_CAPCTRL_EN, which is always 1, and clarified....................................................................... 54

•

Changed text from: fMAX to: fHIGH ........................................................................................................................................... 55

•

Changed text from: RAMP_LIMIT_LOW=232 - (fLOW - fVCO) / fPD × 16777216 to: RAMP_LIMIT_LOW=233 - 16777216

x (fVCO - fLOW) / fPD ................................................................................................................................................................ 55

•

Removed the OSCin Configuration table and added content to the OSCin Configuration section...................................... 59

•

Changed pin 27 recommendation from 10 µF to 1 µF in Figure 51 ..................................................................................... 61

Changes from Original (March 2017) to Revision A

Page

•

Added DAP pin described as "Die Attach Pad"...................................................................................................................... 7

•

Added H2 Spec for 11 GHz ................................................................................................................................................... 9

•

Clarified that output power assumes that load is matched and losses are de-embedded..................................................... 9

•

Changed "SDA" pin name mispelled. Should be "SDI". Also fixed in timing diagrams. Also added CE Pin ...................... 11

•

Swapped SDI and SCK in diagram ..................................................................................................................................... 12

•

Added graphs and reordered ............................................................................................................................................... 14

•

Added 12-GHz VCO frequency for PLL Noise Metrics Plot ................................................................................................ 14

•

Added Phase Noise plots vs. Temperature ......................................................................................................................... 15

•

Added Phase noise vs. Fpd Graph ..................................................................................................................................... 16

•

Moved second paragraph of Readback into Lock Detect section; deleted last paragraph of Readback (was in wrong

place) .................................................................................................................................................................................... 22

•

Changed table to allow 11.5 GHz max frequency for divides >6 ......................................................................................... 24

•

Added Recommendations table .......................................................................................................................................... 25

•

Changed the IncludedDivide table........................................................................................................................................ 26

•

Added section on fine tune adjustments ............................................................................................................................. 30

•

Changed graphic and description......................................................................................................................................... 35

•

Added SYSREF_EN = 1 if and only if OUTB_MUX=2 ........................................................................................................ 36

•

Changed SysRef Example Description and Pictures .......................................................................................................... 38

•

Added recommendation to make fInterpolator a multiple of fOSC .............................................................................................. 39

•

Added SEG1_EN.................................................................................................................................................................. 42

•

Added INPIN_IGNORE, INPIN_LVL, and INPIN_HYST ...................................................................................................... 43

4

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

•

Removed RAMP0_FL from register map ............................................................................................................................. 45

•

Changed address for VCO_DACISET_STRT and VCO_CAPCTRL .................................................................................. 48

•

Clarified MASH_RESET_N. 0 = RESET (integer mode), 1 = Fractional mode .................................................................. 49

•

Changed OUT_ISEL to OUTI_SET ..................................................................................................................................... 50

•

Added SYSREF_EN=1 when OUTB_MUX=2 ..................................................................................................................... 50

•

Added section for input register descriptions ...................................................................................................................... 50

•

Added description for SEG1_EN ......................................................................................................................................... 53

•

Fixed TYPO table to match main register map. ................................................................................................................... 53

•

Added SEG1_EN.................................................................................................................................................................. 53

•

Corrected RAMP_BURST_TRIG description to match other place in data sheet................................................................ 56

•

Removed duplicate error in R101[2] .................................................................................................................................... 57

•

Changed RAMP1_INC from RAMP0 to RAMP1 .................................................................................................................. 57

•

Clarified that the delay was in state machine cycles............................................................................................................ 57

•

Swapped 1 and 3 in the R110[10:9] description .................................................................................................................. 58

•

Fixed pin names in schematic ............................................................................................................................................. 61

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

5

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

5 Pin Configuration and Functions

GND

RampDir

VbiasVARAC

GND

Vtune

VrefVCO

VccVCO

VregVCO

GND

GND

RHA Package

40-Pin VQFN

Top View

CE

RampClk

GND

VrefVCO2

VbiasVCO

SysRefReq

GND

VbiasVCO2

SYNC

VccVCO2

GND

GND

GND

VccDIG

CSB

OSCinP

RFoutAP

OSCinM

RFoutAM

6

Submit Documentation Feedback

MUXout

RFoutBP

RFoutBM

SDI

SCK

VccMASH

GND

GND

CPout

VccBUF

VccCP

VregIN

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

Pin Functions

PIN

NO.

1

NAME

I/O

DESCRIPTION

CE

Input

GND

Ground

VCO ground.

3

VbiasVCO

Bypass

VCO bias. Requires a 10-µF capacitor connected to VCO ground. Place close to pin.

5

SYNC

Input

6, 14

GND

Ground

Digital ground.

7

VccDIG

Supply

Digital supply. TI recommends bypassing with decoupling capacitor to digital ground.

8

OSCinP

Input

Reference input clock (+). High-impedance self-biasing pin. Requires AC-coupling capacitor.

(0.1 µF recommended)

9

OSCinM

Input

Reference input clock (–). High impedance self-biasing pin. Requires AC-coupling capacitor.

(0.1 µF recommended)

10

VregIN

Bypass

Input reference path regulator output. Requires a 1-µF capacitor connected to ground. Place

close to pin.

11

VccCP

Supply

Charge pump supply. TI recommends bypassing with decoupling capacitor to charge pump

ground.

12

CPout

Output

Charge pump output. TI recommends connecting C1 of loop filter close to pin.

13

GND

Ground

Charge pump ground.

15

VccMASH

Supply

Digital supply. TI recommends bypassing with decoupling capacitor to digital ground.

16

SCK

Input

SPI clock. High impedance CMOS input. 1.8-V to 3.3-V logic.

17

SDI

Input

SPI data. High impedance CMOS input. 1.8-V to 3.3-V logic.

18

RFoutBM

Output

Differential output B (–). Requires a pullup (typically 50-Ω resistor) connected to Vcc as close

to the pin as possible. Can be used as an output signal or SYSREF output.

19

RFoutBP

Output

Differential output B (+). Requires a pullup (typically 50-Ω resistor) connected to Vcc as close

to the pin as possible. Can be used as an output signal or SYSREF output.

2, 4, 25, 31,

34, 39, 40

Chip enable input. Active HIGH powers on the device.

Phase synchronization pin. Has programmable threshold.

20

MUXout

Output

Multiplexed output pin — lock detect, readback, diagnostics, ramp status.

21

VccBUF

Supply

Output buffer supply. TI recommends bypassing with decoupling capacitor to RFout ground.

22

RFoutAM

Output

Differential output A (–). Requires connecting a 50-Ω resistor pullup to Vcc as close to the

pin as possible.

23

RFoutAP

Output

Differential output A (+). Requires connecting a 50-Ω resistor pullup to Vcc as close to the

pin as possible.

24

CSB

Input

SPI latch. Chip Select Bar. High-impedance CMOS input. 1.8-V to 3.3-V logic.

26

VccVCO2

Supply

VCO supply. TI recommends bypassing with decoupling capacitor to VCO ground.

27

VbiasVCO2

Bypass

VCO bias. Requires a 1-µF capacitor connected to VCO ground.

28

SysRefReq

Input

29

VrefVCO2

Bypass

30

RampClk

Input

Input pin for ramping mode that can be used to clock the ramp in manual ramping mode or

as a trigger input.

32

RampDir

Input

Input pin for ramping mode that can be used to change ramp direction in manual ramping

mode or as a trigger input.

33

VbiasVARAC

Bypass

35

Vtune

Input

36

VrefVCO

Bypass

VCO supply reference. Requires a 10-µF capacitor connected to VCO ground.

37

VccVCO

Supply

VCO supply. Recommend bypassing with decoupling capacitor to ground.

38

VregVCO

Bypass

VCO regulator node. Requires a 1-µF capacitor connected to ground.

GND

Ground

Die Attached Pad. Used for RFout ground.

DAP

SYSREF request input for JESD204B support.

VCO supply reference. Requires a 10-µF capacitor connected to VCO ground.

VCO Varactor bias. Requires a 10-µF capacitor connected to VCO ground.

VCO tuning voltage input.

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

7

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

UNIT

VCC

Power supply voltage

–0.3

3.6

V

TJ

Junction temperature

–40

150

°C

Tstg

Storage temperature

–65

150

°C

(1)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22C101 (2)

±750

UNIT

V

JEDEC document JEP155 states that 500 V HBM allows safe manufacturing with a standard ESD control process. Manufacturing with

less than 500 V HBM is possible with the necessary precautions. Pins listed as ±XXX V may actually have higher performance.

JEDEC document JEP157 states that 250 V CDM allows safe manufacturing with a standard ESD control process. Manufacturing with

less than 250 V CDM is possible with the necessary precautions. Pins listed as ±YYY V may actually have higher performance.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

VCC

Power supply voltage

3.15

3.3

3.45

V

TA

Ambient temperature

–40

25

85

°C

TJ

Junction temperature

125

°C

6.4 Thermal Information

LMX2594

THERMAL METRIC (1)

RHA (VQFN)

UNIT

40 PINS

RθJA

Junction-to-ambient thermal resistance

RθJC(top)

Junction-to-case (top) thermal resistance

30.5

°C/W

15.3

°C/W

RθJB

ψJT

Junction-to-board thermal resistance

5.4

°C/W

Junction-to-top characterization parameter

0.2

°C/W

ψJB

Junction-to-board characterization parameter

5.3

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

0.9

°C/W

(1)

(2)

8

(2)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report (SPRA953).

DAP

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

6.5 Electrical Characteristics

3.15 V ≤ VCC ≤ 3.45 V, –40°C ≤ TA ≤ +85°C. Typical values are at VCC = 3.3 V, 25°C (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

3.15

3.3

3.45

V

POWER SUPPLY

VCC

Supply voltage

OUTA_PD = 0, OUTB_PD = 1

OUTA_MUX = OUTB_MUX = 1

OUTA_PWR = 31, CPG=7

fOSC= fPD = 100 MHz, fVCO = fOUT = 14 GHz

pOUT = 3 dBm with 50-Ω resistor pullup

340

Power-on reset current

RESET=1

170

Power-down current

POWERDOWN=1

Supply current

ICC

mA

5

OUTPUT CHARACTERISTICS

pOUT

Xtalk

H2

Single-ended output power (1) (2)

fOUT = 8 GHz

5

fOUT = 15 GHz

2

1-nH inductor pullup

OUTx_PWR = 50

fOUT = 8 GHz

10

fOUT = 15 GHz

7

Isolation between outputs A and OUTA_MUX = VCO

B. Measured on output A

OUTB_MUX = channel divider

Second harmonic

(2)

Third harmonic (2)

H3

50-Ω resistor pullup

OUTx_PWR = 50

dBm

–50

OUTA_MUX = VCO

fVCO = 8 GHz

–20

OUTA_MUX = VCO

fVCO = 11 GHz

–30

OUTA_MUX = VCO

fVCO = 8 GHz

–50

dBc

dBc

dBc

INPUT SIGNAL PATH

OSC_2X = 0

5

1400

OSC_2X = 1

5

200

fOSCin

Reference input frequency

vOSCin

Reference input voltage

AC-coupled required

Input range

fMULT

Multiplier frequency (only

applies when multiplier is

enabled)

(3)

Output range

0.2

2

30

70

180

250

MHz

Vpp

MHz

PHASE DETECTOR AND CHARGE PUMP

Phase detector frequency (3)

fPD

Charge-pump leakage current

ICPout

Effective charge pump current.

This is the sum of the up and

down currents

Integer mode

MASH_ORDER = 0

0.125

400

Fractional mode

MASH_ORDER= 1, 2,

3

5

300

MASH_ORDER = 4

5

Normalized PLL 1/f noise

PNPLL_flat Normalized PLL noise floor

(1)

(2)

(3)

(4)

240

CPG = 0

15

CPG = 4

3

CPG = 1

6

CPG = 5

9

CPG = 3

12

CPG = 7

PNPLL_1/f

MHz

nA

mA

15

fPD = 100 MHz, fVCO = 12 GHz (4) (4) (4) (4)

–129

dBc/Hz

–236

dBc/Hz

Single ended output power obtained after de-embedding microstrip trace losses and matching with a manual tuner. Unused port

terminated to 50 ohm load.

Output power, spurs, and harmonics can vary based on board layout and components.

For lower VCO frequencies, the N divider minimum value can limit the phase-detector frequency.

The PLL noise contribution is measured using a clean reference and a wide loop bandwidth and is composed into flicker and flat

components. PLL_flat = PLL_FOM + 20 × log(Fvco/Fpd) + 10 × log(Fpd / 1Hz). PLL_flicker (offset) = PLL_flicker_Norm + 20 × log(Fvco

/ 1GHz) – 10 × log(offset / 10kHz). Once these two components are found, the total PLL noise can be calculated as PLL_Noise = 10 ×

log(10 PLL_Flat / 10 + 10 PLL_flicker / 10 )

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

9

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

Electrical Characteristics (continued)

3.15 V ≤ VCC ≤ 3.45 V, –40°C ≤ TA ≤ +85°C. Typical values are at VCC = 3.3 V, 25°C (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

VCO CHARACTERISTICS

VCO1

fVCO = 8 GHz

VCO2

fVCO = 9.2 GHz

VCO3

fVCO = 10.3 GHz

PNVCO

VCO phase noise

VCO4

fVCO = 11.3 GHz

VCO5

fVCO = 12.5 GHz

VCO6

fVCO = 13.3 GHz

VCO7

fVCO = 14.5 GHz

tVCOCAL

(5)

10

VCO calibration speed

Switch across the entire

frequency band

fOSC = 200 MHz, fPD =

100 MHz (5)

10 kHz

–80

100 kHz

–107

1 MHz

–128

10 MHz

–148

90 MHz

–157

10 kHz

–79

100 kHz

–105

1 MHz

–127

10 MHz

–147

90 MHz

–157

10 kHz

–77

100 kHz

–104

1 MHz

–126

10 MHz

–147

90 MHz

–157

10 kHz

–76

100 kHz

–103

1 MHz

–125

10 MHz

–145

90 MHz

–158

10 kHz

–74

100 kHz

–100

1 MHz

–123

10 MHz

–144

90 MHz

–157

10 kHz

–73

100 kHz

–100

1 MHz

–122

10 MHz

–143

90 MHz

–155

10 kHz

–73

100 kHz

–99

1 MHz

–121

10 MHz

–143

90 MHz

–152

No assist

50

Partial assist

35

Close frequency

20

Full assist

dBc/Hz

µs

5

See Application and Implementation for more details on the different VCO calibration modes.

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

Electrical Characteristics (continued)

3.15 V ≤ VCC ≤ 3.45 V, –40°C ≤ TA ≤ +85°C. Typical values are at VCC = 3.3 V, 25°C (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

8 GHz

KVCO

VCO gain

MAX

UNIT

92

9.2 GHz

91

10.3 GHz

115

11.3 GHz

121

12.5 GHz

195

13.3 GHz

190

14.5 GHz

213

|ΔTCL|

Allowable temperature drift

when VCO is not recalibrated

RAMP_EN = 0 or RAMP_MANUAL= 1

125

H2

VCO second harmonic

fVCO = 8 GHz, divider disabled

–20

H3

VCO third haromonic

fVCO = 8 GHz, divider disabled

–50

MHz/V

°C

dBc

SYNC PIN AND PHASE ALIGNMENT

fOSCinSY

NC

Maximum usable OSCin with

sync pin (Figure 27)

Category 3

0

100

Categories1 and 2

0

1400

MHz

DIGITAL INTERFACE

Applies to SLK, SDI, CSB, CE, RampDir, RampClk, MUXout, SYNC (CMOS Mode), SysRefReq (CMOS Mode)

VIH

High-level input voltage

1.4

Vcc

VIL

IIH

Low-level input voltage

0

0.4

V

High-level input current

–25

25

µA

IIL

Low-level input current

–25

25

µA

VOH

High-level output voltage

VOL

Low-level output voltage

Load current = –10 mA

MUXout pin

V

VCC – 0.4

V

Load current = 10 mA

0.4

V

6.6 Timing Requirements

(3.15 V ≤ VCC ≤ 3.45 V, –40°C ≤ TA ≤ +85°C, except as specified. Nominal values are at VCC = 3.3 V, TA = 25°C)

MIN

NOM

MAX

UNIT

SYNC, SYSRefReq, RampClk, and RampDIR Pins

tSETUP

Setup time for pin relative to

OSCin rising edge

SYNC pin

2.5

SysRefReq pin

2.5

tHOLD

Hold time for SYNC pin

relative to OSCin rising edge

SYNC pin

2

SysRefReq pin

2

ns

ns

DIGITAL INTERFACE WRITE SPECIFICATIONS

fSPIWrite

SPI write speed

tCWL + tCWH > 13.333 ns

tCE

Clock to enable low time

5

ns

tDCS

Data to clock setup time

2

ns

tCDH

Clock to data hold time

2

ns

tCWH

Clock pulse width high

5

ns

tCWL

Clock pulse width low

5

ns

tECS

Enable to clock setup time

5

ns

tEWH

Enable pulse width high

2

ns

See Figure 1

75

MHz

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

11

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

Timing Requirements (continued)

(3.15 V ≤ VCC ≤ 3.45 V, –40°C ≤ TA ≤ +85°C, except as specified. Nominal values are at VCC = 3.3 V, TA = 25°C)

MIN

NOM

MAX

UNIT

50

MHz

DIGITAL INTERFACE READBACK SPECIFICATIONS

fSPIReadback

SPI readback speed

tCE

Clock to enable low time

10

ns

tDCS

Data to clock setup time

2

ns

tCDH

Clock to data hold time

2

ns

tCR

Clock falling edge to

available readback data wait

time.

tCWH

Clock pulse width high

10

ns

tCWL

Clock pulse width low

10

ns

tECS

Enable to clock setup time

10

ns

tEWH

Enable pulse width high

10

ns

See Figure 2

0

10

ns

SCK

tCWL

tCWH

tCDH

SDI

R/W

A6

A5 ~ A1

A0

D15

D14 ~ D2

D1

D0

tDCS

tCE

tECS

tEWH

CSB

Figure 1. Serial Data Input Timing Diagram

There are several other considerations for writing on the SPI:

• The R/W bit must be set to 0.

• The data on SDI pin is clocked into a shift register on each rising edge on the SCK pin.

• The CSB must be held low for data to be clocked. Device will ignore clock pulses if CSB is held high.

• When SCK and SDI lines are shared between devices, TI recommends to hold the CSB line high on the

device that is not to be clocked.

• Note that tCE is only a valid spec if CPOL (Clock Polarity) = 0 and CPHA (Clock Phase) = 0 is used for SPI

protocol. For SPI mode (CPOL = 1 and CPHA = 1), the minimum distance required between the last rising

edge of clock and the rising edge of CSB is tCE + clock_period/2.

12

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

SCK

tCWL

tCWH

tCDH

R/W

SDI

A6

A5 ~ A1

A0

tDCS

tCR

D15

MUXout

D14 ~ D2

D1

D0

tECS

tCE

tEWH

CSB

Figure 2. Serial Data Readback Timing Diagram

There are several other considerations for SPI readback:

• The R/W bit must be set to 1.

• The MUXout pin will always be low for the address portion of the transaction.

• The data on MUXout is clocked out at tCR after the falling edge of SCK. In other words, the readback data will

be available at the MUXout pin tCR after the clock falling edge.

• The data portion of the transition on the SDI line is always ignored.

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

13

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

-30

1: 100 Hz -84.0 dBc/Hz

-40

2: 1 kHz

-94.5 dBc/Hz

-50

3: 10 kHz -104.8 dBc/Hz

-60

4: 100 kHz -107.5 dBc/Hz

5: 1 MHz -114.7 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 15.0 GHz

-4.1 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

-141.8 dBc/Hz

-150.2 dBc/Hz

-148.6 dBc/Hz

-147.6 dBc/Hz

Phase Noise (dBc/Hz)

Phase Noise (dBc/Hz)

6.7 Typical Characteristics

1*10^6

1*10^7

1*10^8

Offset (Hz)

fOSC = 100 MHz

fPD = 200 MHz

fOSC = 100 MHz

fPD = 200 MHz

-145.6 dBc/Hz

-154.5 dBc/Hz

-158.8 dBc/Hz

-159.1 dBc/Hz

1*10^6

1*10^7

1*10^8

Offset (Hz)

fOSC = 100 MHz

fPD = 200 MHz

fOSC = 100 MHz

fPD = 200 MHz

Phase Noise (dBc/Hz)

Phase Noise (dBc/Hz)

1*10^6

1*10^7

fOSC = 100 MHz

fPD = 200 MHz

1*10^8

14

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

1*10^6

-147.4 dBc/Hz

-154.7 dBc/Hz

-155.2 dBc/Hz

-155.0 dBc/Hz

1*10^7

1*10^8

D005

Jitter = 46.9 fs (100 Hz - 100 MHz)

-30

1: 100 Hz -90.1 dBc/Hz

-40

2: 1 kHz -100.4 dBc/Hz

-50

3: 10 kHz -110.6 dBc/Hz

-60

4: 100 kHz -113.7 dBc/Hz

5: 1 MHz -125.1 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 7.5 GHz

5.3 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

Jitter = 46.87 fs (100 Hz - 100 MHz)

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

1*10^6

-149.3 dBc/Hz

-154.8 dBc/Hz

-155.1 dBc/Hz

-148.5 dBc/Hz

1*10^7

1*10^8

Offset (Hz)

D001

Figure 7. Closed-Loop Phase Noise at 8 GHz

D003

Figure 6. Closed-Loop Phase Noise at 9 GHz

-148.3 dBc/Hz

-155.2 dBc/Hz

-157.1 dBc/Hz

-148.2 dBc/Hz

Offset (Hz)

1*10^8

Offset (Hz)

Figure 5. Closed-Loop Phase Noise at 11 GHz

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

1*10^7

Jitter = 52.6 fs (100 Hz - 100 MHz)

-30

1: 100 Hz -88.3 dBc/Hz

-40

2: 1 kHz

-98.5 dBc/Hz

-50

3: 10 kHz -108.9 dBc/Hz

-60

4: 100 kHz -111.4 dBc/Hz

5: 1 MHz -123.1 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 9.0 GHz

1.6 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

D004

Jitter = 46.8 fs (100 Hz - 100 MHz)

-30

1: 100 Hz -89.6 dBc/Hz

-40

2: 1 kHz

-99.8 dBc/Hz

-50

3: 10 kHz -110.1 dBc/Hz

-60

4: 100 kHz -113.4 dBc/Hz

5: 1 MHz -123.1 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 8.0 GHz

5.0 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

1*10^6

-143.2 dBc/Hz

-151.5 dBc/Hz

-153.8 dBc/Hz

-153.8 dBc/Hz

Figure 4. Closed-Loop Phase Noise at 13 GHz

Phase Noise (dBc/Hz)

Phase Noise (dBc/Hz)

Figure 3. Closed-Loop Phase Noise at 15 GHz

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

Offset (Hz)

D002

Jitter = 55.8 fs (100 Hz - 100 MHz)

-30

1: 100 Hz -87.1 dBc/Hz

-40

2: 1 kHz -97.2 dBc/Hz

-50

3: 10 kHz -107.2 dBc/Hz

-60

4: 100 kHz -109.4 dBc/Hz

5: 1 MHz -121.8 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 11.0 GHz

-0.3 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

-30

1: 100 Hz -85.5 dBc/Hz

-40

2: 1 kHz -95.6 dBc/Hz

-50

3: 10 kHz -105.6 dBc/Hz

-60

4: 100 kHz -108.7 dBc/Hz

5: 1 MHz -117.3 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 13.0 GHz

0.1 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

fOSC = 100 MHz

fPD = 200 MHz

D011

Jitter = 44.1 fs (100 Hz - 100 MHz)

Figure 8. Closed-Loop Phase Noise at 7.5 GHz

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

-30

1: 100 Hz -96.7 dBc/Hz

-40

2: 1 kHz -106.8 dBc/Hz

-50

3: 10 kHz -117.0 dBc/Hz

-60

4: 100 kHz -119.7 dBc/Hz

5: 1 MHz -130.6 dBc/Hz

-70

-80

-90

-100

-110

-120

-130

-140

-150

-160

-170

-180 3.5 GHz

1.3 dBm

-190

1*10^2

1*10^3

1*10^4

1*10^5

6: 10 MHz

7: 40 MHz

8: 95 MHz

9: 100 MHz

12.1

12.08

12.06

12.04

12.02

11.98

1*10^6

1*10^7

1*10^8

D012

fOUT = 14 GHz / 4 = 3.5 GHz

Jitter = 49.4 fs (100 Hz - 100 MHz)

15

14.5

14

13.5

13

12.5

12

11.5

11

10.5

10

9.5

9

8.5

8

7.5

7

11.96

-500 -400 -300 -200 -100 0

100

Time (Ps)

200

300

400

500

D010

Figure 10. VCO Ramping 12-GHz to 12.125-GHz Calibration

Free

8.5

8

Frequency (GHz)

7.5

7

6.5

6

5.5

1: -2.1 Ps

2: 2.9 Ps

3: 3.7 Ps

4: 17.7 Ps

5: 31.5 Ps

5

4.5

4

0

1

2

3

4

5

6

Time (ms)

7

8

9

3.5

-10

10

-5

-84

7.5

-88

Phase Noise (dBc/Hz)

-80

8

7

6.5

6

5.5

1: -200 ns 3.4745 GHz

2: 400 ns 7.4476 GHz

3: 1.1 Ps 7.4437 GHz

4: 10.2 Ps 7.0531 GHz

5: 25 Ps 7.0382 GHz

4

3.5

-10

-5

0

5

10

15

20

Time (Ps)

10

25

30

35

15

20

Time (Ps)

25

30

35

40

D008

Figure 12. VCO Unassisted Calibration

8.5

4.5

5

3.7177 GHz

7.5832 GHz

7.5845 GHz

6.9996 GHz

6.9991 GHz

CalTime = 33.6 µs = 5.8 µs (Core) + 14 µs (Fcal) + 13.8 µs

(Ampcal)

fOSC = 200 MHz, fPD = 100 MHz, fVCO = 7.5 - 14 GHz, CHDIV = 2

Figure 11. VCO Ramping 7.5-GHz to 15-GHz Triangle Wave

With VCO Calibration

5

0

D013

The glitches in the plot are due to the inability of the measurement

equipment to track the VCO while calibrating.

Frequency (GHz)

2: 2 Ps 12.1255 GHz

12.12

Figure 9. Closed-Loop Phase Noise at 3.5 GHz

Frequency (GHz)

1: -95.988 ns 12.0006 GHz

12.14

12

Offset (Hz)

fOSC = 100 MHz

fPD = 200 MHz

fVCO = 14 GHz

12.16

-149.5 dBc/Hz

-150.9 dBc/Hz

-151.1 dBc/Hz

-127.8 dBc/Hz

Frequency (GHz)

Phase Noise (dBc/Hz)

Typical Characteristics (continued)

Flicker (PLL 1/f =-129.2 dBc/Hz)

Flat (FOM = -236.2 dBc/Hz)

Modeled Phase Noise

Measurement

-92

-96

-100

-104

-108

-112

-116

40

D009

CalTime = 25.2 µs = 1.3 µs (Core) + 9.1 µs (Fcal) +14.8 µs

(Ampcal)

fOSC = 200 MHz, fPD = 100 MHz, fVCO = 7.5 GHz - 14 GHz, CHDIV

=2

Figure 13. VCO Calibration With Partial Assist

-120

100

1000

10000

Offset (Hz)

fVCO = 12 GHz

100000

D014

fPD = 100 MHz

Figure 14. Calculation of PLL Noise Metrics

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

15

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

Typical Characteristics (continued)

-80

-80

Fpd=100 MHz

Fpd=200 MHz

Fpd=400 MHz

-88

-96

Phase Noise (dBc/Hz)

Phase Noise (dBc/Hz)

-96

-104

-112

-120

-128

-136

-104

-112

-120

-128

-136

-144

-144

-152

-152

-160

100

1000

10000

100000

Offset (Hz)

1000000

Ta=25

Ta=-40

Ta=85

-88

-160

10000

1E+7 5E+7

fOSC = 200 MHz

fVCO = 14.8 GHz

Power (dBm)

Phase Noise Variation (dB)

0.8

0.4

0

-0.4

-0.8

-1.2

-1.6

100000

1000000

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1E+72E+7 5E+71E+8

Offset (Hz)

Resistor Pull-up

Inductor Pull-Up

3

4

5

D017

6

7

8

9 10 11 12

Output Frequency (GHz)

Single-Ended Output

13

14

15

D018

OUTx_PWR = 50

Figure 18. Output Power Across Frequency

0

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Ta=-40

Ta=25

Ta=85

-1

Normalized Output Power (dB)

Power (dBm)

Figure 17. CHANGE in 8-GHz VCO Phase Noise Over

Temperature

-2

-3

-4

-5

-6

-7

-8

-9

RF_out = 8 GHz

-10

3

4

5

6

7

8

9 10 11

Frequency (GHz)

12

13

14

15

0

D019

Single-ended output with resistor pullup and OUTx_PWR = 50.

Note that Near 13.3 to 14.3 GHz, output power can be impacted at

hot temperature. See the Application Information section for more

information.

Figure 19. Output Power vs Temperature

16

D016

Figure 16. VCO Phase Noise Over Temperature

Ta=25

Ta=-40

Ta=85

1.2

1E+72E+7 5E+71E+8

fVCO = 8 GHz, Narrow Loop Bandwidth ( 1), the input frequency to this divider is limited to 250 MHz.

7.3.2.5 State Machine Clock

The state machine clock is a divided down version of the OSCin signal that is used internally in the device. This

divide value is 1, 2, 4, or 8, and is determined by CAL_CLK_DIV programming word (described in the

Programming section). This state machine clock impacts various features like the lock detect delay, VCO

calibration, and ramping. The state machine clock is calculated as fsmclk = fOSC / 2CAL_CLK_DIV.

7.3.3 PLL Phase Detector and Charge Pump

The phase detector compares the outputs of the Post-R divider and N-divider, and generates a correction current

corresponding to the phase error until the two signals are aligned in-phase. This charge-pump current is software

programmable to many different levels, allowing modification of the closed-loop bandwidth of the PLL. See the

Application Information section for more information.

20

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

Feature Description (continued)

7.3.4 N-Divider and Fractional Circuitry

The N-divider includes fractional compensation and can achieve any fractional denominator from 1 to (232 – 1).

The integer portion of N is the whole part of the N-divider value, and the fractional portion, Nfrac = NUM / DEN, is

the remaining fraction. In general, the total N-divider value is determined by N + NUM / DEN. The N, NUM and

DEN are software programmable. The higher the denominator, the finer the resolution step of the output. For

example, even when using fPD = 200 MHz, the output can increment in steps of 200 MHz / (232 – 1) = 0.047 Hz.

Equation 2 shows the relationship between the phase detector and VCO frequencies. Note that in SYNC mode,

there is an extra divider that is not shown in Equation 2.

NUM ·

§

fVCO fpd u ¨ N

DEN ¸¹

©

(2)

The sigma-delta modulator that controls this fractional division is also programmable from integer mode to fourth

order. To make the fractional spurs consistent, the modulator is reset any time that the R0 register is

programmed.

The N-divider has minimum value restrictions based on the modulator order and VCO frequency. Furthermore,

the PFD_DLY_SEL bit must be programmed in accordance to the Table 2.

Table 2. Minimum N-Divider Restrictions

MASH_ORDER

fVCO (MHz)

MINIMUM N

PFD_DLY_SEL

≤ 12500

28

1

> 12500

32

2

≤ 10000

28

1

10000-12500

32

2

>12250

36

3

≤ 10000

32

2

>10000

36

3

≤ 10000

36

3

>10000

40

4

≤ 10000

44

5

>10000

48

6

0

1

2

3

4

7.3.5 MUXout Pin

The MUXout pin can be used to readback programmable states of the device or for lock detect.

Table 3. MUXout Pin Configurations

MUXOUT_SEL

FUNCTION

0

Readback

1

Lock Detect

7.3.5.1 Lock Detect

The MUXout pin can be configured for lock detect done in by reading back the rb_LD_VTUNE field or using the

pin as shown in the Table 4.

Table 4. Configuring the MUXout Pin for Lock Detect

FIELD

PROGRAMMING

DESCRIPTION

LD_TYPE

0 = VCO Calibration Status

1 = Indirect Vtune

Select Lock Detect Type.

LD_DLY

0 to 65535

Only valid for Vtune lock detect. This is a delay in state machine cycles.

OUT_MUTE

0 = Disabled

1 = Enabled

Turns off outputs when lock detect is low.

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

21

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

VCO calibration status lock detect works by indicating a low signal on the MUXout pin whenever the VCO is

calibrating or the LD_DLY counter is running. The delay from the LD_DLY is added to the true VCO calibration

time (tVCOCAL), so it can be used to account for the analog lock time of the PLL.

Indirect Vtune lock detect is based on internally generated voltage that is related to (but not the same as) the

Vtune voltage of the charge pump. It indicates a high signal on MUXout pin or reads back state 2 of

rb_LD_VTUNE when the device is locked.

7.3.5.2 Readback

The MUXout pin can be configured to read back useful information from the device. Common uses for readback

are:

1. Read back registers to ensure that they have been programmed to the correct value.

2. Read back the lock detect status to determine if the PLL is in lock.

3. Read back VCO calibration information so that it can be used to improve the lock time.

4. Read back information to help troubleshoot.

7.3.6 VCO (Voltage-Controlled Oscillator)

The LMX2594 includes a fully integrated VCO. The VCO takes the voltage from the loop filter and converts this

into a frequency. The VCO frequency is related to the other frequencies is shown in Equation 3:

fVCO = fPD × N divider

(3)

7.3.6.1 VCO Calibration

To reduce the VCO tuning gain and therefore improve the VCO phase-noise performance, the VCO frequency

range is divided into several different frequency bands. The entire range, 7.5 to 15 GHz, covers an octave that

allows the divider to take care of frequencies below the lower bound. This creates the need for frequency

calibration to determine the correct frequency band given a desired output frequency. The frequency calibration

routine is activated any time that the R0 register is programmed with the FCAL_EN = 1. It is important that a

valid OSCin signal must present before VCO calibration begins.

The VCO also has an internal amplitude calibration algorithm to optimize the phase noise which is also activated

any time the R0 register is programmed.

The optimum internal settings for this are temperature dependent. If the temperature is allowed to drift too much

without being recalibrated, some minor phase noise degradation could result. The maximum allowable drift for

continuous lock, ΔTCL, is stated in the electrical specifications. For this device, a number of 125°C means the

device never loses lock if the device is operated under the Recommended Operating Conditions.

22

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

The LMX2594 allows the user to assist the VCO calibration. In general, there are three kinds of assistance, as

shown in Table 5:

Table 5. Assisting the VCO Calibration Speed

ASSISTANCE LEVEL

DESCRIPTION

PROGRAMMABLE SETTINGS

No assist

User does nothing to improve VCO calibration speed, but the user-specified

VCO_SEL, VCO_DACISET_STRT and VCO_CAPCTRL_STRT values do

affect the starting point of VCO calibration. For oscillation to start up

properly and for VCO to calibrate correctly, TI recommends setting

VCO_SEL = 7, VCO_DACISET_STRT = 300 and VCO_CAPCTRL_STRT =

183 for all frequencies except 11.9 GHz ~ 12.1 GHz. For frequencies within

11.9 ~ 12.1 GHz, user must use VCO_SEL = 4 for proper VCO calibration.

QUICK_RECAL_EN=0

VCO_SEL_FORCE=0

VCO_DACISET_FORCE=0

VCO_CAPCTRL_FORCE=0

Partial assist

Upon every frequency change, before the FCAL_EN bit is checked, the

user provides the initial starting point for the VCO core (VCO_SEL), band

(VCO_CAPCTRL_STRT), and amplitude (VCO_DACISET_STRT) based on

Table 6.

QUICK_RECAL_EN=0

VCO_SEL_FORCE=0

VCO_DACISET_FORCE=0

VCO_CAPCTRL_FORCE=0

Upon initialization of the device, user enables QUICK_RECAL_EN bit.

Close Frequency Assist The VCO uses the current VCO_CAPCTRL and VCO_DACISET_STRT

settings as the initial starting point.

QUICK_RECAL_EN=1

VCO_SEL_FORCE=0

VCO_DACISET_FORCE=0

VCO_CAPCTRL_FORCE=0

The user forces the VCO core (VCO_SEL), amplitude settings

(VCO_DACISET), and frequency band (VCO_CAPCTRL) and manually

sets the value. If the two frequency points are no more than 5MHz apart

and on the same VCO core, the user can set the VCO amplitude and

capcode for any frequency between those two points using linear

interpolation.

QUICK_RECAL_EN=0

VCO_SEL_FORCE=1

VCO_DACISET_FORCE=1

VCO_CAPCTRL_FORCE=1

Full assist

To do the partial assist for the VCO calibration, follow this procedure:

1. Determine the VCO Core

Find a VCO Core that includes the desired VCO frequency. If at the boundary of two cores, choose one

based on phase noise or performance.

2. Calculate the VCO CapCode as follows:

VCO_CAPCTRL_STRT = round (CCoreMin – (CCoreMin – CCoreMax) × (fVCO – fCoreMin) / (fCoreMax – fCoreMin))

3. Get the VCO amplitude setting from Table 6.

VCO_DACISET_STRT = round (ACoreMin + (ACoreMax – ACoreMin) × (fVCO – fCoreMin)/(fCoreMax – fCoreMin))

Table 6. VCO Core Ranges

VCO CORE

fCoreMin

fCoreMax

CCoreMin

CCoreMax

ACoreMin

ACoreMax

VCO1

7500

8600

164

12

299

240

VCO2

8600

9800

165

16

356

247

VCO3

9800

10800

158

19

324

224

VCO4

10800

12000

140

0

383

244

VCO5

12000

12900

183

36

205

146

VCO6

12900

13900

155

6

242

163

VCO7

13900

15000

175

19

323

244

SPACE

NOTE

In the range of 11900 MHz to 12100 MHz, VCO assistance cannot be used, and the

settings must be: VCO_SEL = 4, VCO_DACISET_STRT = 300, and

VCO_CAPCTRL_STRT = 1. Outside this range, in the partial assist for the VCO

calibration, the VCO calibration runs. This means that if the settings are incorrect, the

VCO still locks with the correct settings. The only consequence is that the calibration time

might be a little longer. The closer the calibration settings are to the true final settings, the

faster the VCO calibration will be.

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

23

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

7.3.6.2 Determining the VCO Gain

The VCO gain varies between the seven cores and is the lowest at the lowest end of the band and highest at the

highest end of each band. For a more accurate estimation, use Table 7:

Table 7. VCO Gain

CORE

f1

f2

Kvco1

Kvco2

VCO1

7500

8600

73

114

VCO2

8600

9800

61

121

VCO3

9800

10800

98

132

VCO4

10800

12000

106

141

VCO5

12000

12900

170

215

VCO6

12900

13900

172

218

VCO7

13900

15000

182

239

Based on Table 7, Equation 4 can estimate the VCO gain for an arbitrary VCO frequency of fVCO:

Kvco = Kvco1 + (Kvco2 – Kvco1) × (fVCO – f1) / (f2 – f1)

(4)

7.3.7 Channel Divider

To go below the VCO lower bound of 7.5 GHz, the channel divider can be used. The channel divider consists of

four segments, and the total division value is equal to the multiplication of them. Therefore, not all values are

valid.

VCO

1/2

Divide by

2 or 3

Divide by

2,4,6,8

Divide by

2,4,6,8,16

MUX

RFoutA

MUX

RFoutB

MUX

Figure 24. Channel Divider

When the channel divider is used, there are limitations on the values. Table 8 shows how these values are

implemented and which segments are used.

24

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

�LMX2594

www.ti.com

SNAS696C – MARCH 2017 – REVISED APRIL 2019

Table 8. Channel Divider Segments

EQUIVALENT

DIVISION

VALUE

FREQUENCY

LIMITATION

OutMin (MHz)

OutMax (MHz)

CHDIV[4:0]

SEG0

SEG1

SEG2

SEG3

3750

7500

0

2

1

1

1

1875

3750

1

2

2

1

1

6

1250

2500

2

2

3

1

1

2

4

None

8

937.5

1437.5

3

2

2

2

1

12

625

958.333

4

2

3

2

1

16

468.75

718.75

5

2

2

4

1

24

312.5

479.167

6

2

2

6

1

32

234.375

359.375

7

2

2

8

1

48

156.25

239.583

8

2

3

8

1

64

117.1875

179.6875

9

2

2

8

2

72

fVCO ≤ 11.5 GHz

104.167

159.722

10

2

3

6

2

96

78.125

119.792

11

2

3

8

2

128

58.594

89.844

12

2

2

8

4

192

39.0625

59.896

13

2

2

8

6

256

29.297

44.922

14

2

2

8

8

384

19.531

29.948

15

2

3

8

8

512

14.648

22.461

16

2

2

8

16

768

9.766

14.974

17

2

3

8

16

n/a

n/a

18-31

n/a

n/a

n/a

n/a

Invalid

n/a

The channel divider is powered up whenever an output (OUTx_MUX) is selected to the channel divider or

SysRef, regardless of whether it is powered down or not. When an output is not used, TI recommends selecting

the VCO output to ensure that the channel divider is not unnecessarily powered up.

Table 9. Channel Divider

OUTA MUX

OUTB MUX

CHANNEL DIVIDER

Channel Divider

X

Powered up

X

Channel Divider or SYSREF

Powered up

All Other Cases

Powered down

7.3.8 Output Buffer

The RF output buffer type is open collector and requires an external pullup to Vcc. This component may be a 50Ω resistor to target 50-Ω output impedance match, or an inductor for higher output power at the expense of the

output impedance being far from 50 Ω. If inductor is used, it is recommended to follow with resistive pad for

better impedance matching. The current to the output buffer increases for states 0 to 31 and then again from

states 48 to 63. States 32 to 47 are redundant and mimic states 16 to 31. If using a resistor, limit the

OUTx_PWR setting to 50. Higher settings may actually reduce power due to the voltage drop across the resistor.

Table 10. OUTx_PWR Recommendations for Resistor Pullup

RECOMMENDATION

fOUT

COMMENTS

HIGHEST POWER

LOWEST NOISE

FLOOR

10 MHz ≤ fOUT < 13.3 GHz

OUTx_PWR = 50

OUTx_PWR = 50

-

13.3 GHz ≤ fOUT ≤ 14.3 GHz

OUTx_PWR = 15

OUTx_PWR = 15

TI recommends to set OUTx_PWR ≤ 15 to avoid

the power drop at hot temperature.

14.3 GHz < fOUT ≤ 15 GHz

OUTx_PWR = 31

OUTx_PWR = 20

-

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated

Product Folder Links: LMX2594

25

�LMX2594

SNAS696C – MARCH 2017 – REVISED APRIL 2019

www.ti.com

7.3.9 Power-Down Modes

The LMX2594 can be powered up and down using the CE pin or the POWERDOWN bit. When the device comes

out of the powered down state, either by resuming the POWERDOWN bit to zero or by pulling back CE pin

HIGH, register R0 must be programmed with FCAL_EN high again to re-calibrate the device.

7.3.10 Phase Synchronization

7.3.10.1 General Concept

The SYNC pin allows one to synchronize the LMX2594 such that the delay from the rising edge of the OSCin

signal to the output signal is deterministic. Initially, the devices are locked to the input, but are not synchronized.

The user sends a synchronization pulse that is reclocked to the next rising edge of the OSCin pulse. After a

given time, t1, the phase relationship from OSCin to fOUT will be deterministic. This time is dominated by the sum

of the VCO calibration time, the analog setting time of the PLL loop, and the MASH_RST_CNT if used in

fractional mode.

...

Device 1

SYNC

...

Device 2

...

...

fOSC

t2

t1

Figure 25. Devices Are Now Synchronized to OSCin Signal

When the SYNC feature is enabled, part of the channel divide may be included in the feedback path. This will be

referred to as IncludedDivide

Table 11. IncludedDivide With VCO_PHASE_SYNC = 1

OUTx_MUX

OUTA_MUX = OUTB_MUX = 1 ("VCO")

All Other Valid Conditions

26

CHANNEL DIVIDER

INCLUDEDDIVIDE

Don't Care

1

Divisible by 3, but NOT 24 or 192

SEG0 × SEG1 = 6

All other values

SEG0 × SEG1 = 4

Submit Documentation Feedback

Copyright © 2017–2019, Texas Instruments Incorporated