Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

Reference

Design

LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

LMZ21701 1-A Nano Module With 17-V Maximum Input Voltage

1 Features

2 Applications

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1

Integrated Inductor

Miniature 3.5 mm × 3.5 mm × 1.75 mm Package

35-mm² Solution Size (Single Sided)

-40°C to 125°C Junction Temperature Range

Adjustable Output Voltage

Integrated Compensation

Adjustable Soft-Start Function

Starts into Prebiased Loads

Power Good and Enable Pins

Seamless Transition to Power-Save Mode

Up to 1000 mA Output Current

Input Voltage Range 3 V to 17 V

Output Voltage Range 0.9 V to 6 V

Efficiency up to 95 %

1.5-µA Shutdown Current

17-µA Quiescent Current

Create a Custom Design Using the LMZ21701

With WEBENCH® Power Designer

•

•

Point-of-Load Conversions from

3.3 V, 5 V, or 12 V Input Voltage

Space Constrained Applications

LDO Replacement

3 Description

The LMZ21701 nano module is an easy-to-use stepdown DC/DC solution capable of driving up to 1000mA load in space-constrained applications. Only an

input capacitor, an output capacitor, a soft-start

capacitor, and two resistors are required for basic

operation.

Device Information(1)

PART NUMBER

LMZ21701

PACKAGE

µSIP (8)

BODY SIZE (NOM)

3.50 mm × 3.50 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

space

space

space

Simplified Schematic

VIN

Efficiency for VIN = 12 V

VOUT

VIN

VOUT

EN

PG

100

90

80

LMZ21701

SS

COUT

VOS

RFBT

CSS

GND

FB

RFBB

70

Efficiency (%)

CIN

60

50

40

30

VOUT = 1.2 V

VOUT = 1.8 V

VOUT = 2.5 V

VOUT = 3.3 V

VOUT = 5 V

20

10

0

0.0001

0.001

0.01

Output Current (A)

0.1

1

D023

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

7

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description .............................................. 8

7.1

7.2

7.3

7.4

7.5

Overview ................................................................... 8

Functional Block Diagram ......................................... 9

Package Construction ............................................... 9

Feature Description................................................. 11

Device Functional Modes........................................ 12

8

Application and Implementation ........................ 13

8.1 Application Information............................................ 13

8.2 Typical Application ................................................. 13

8.3 Do's and Don'ts ...................................................... 26

9

Power Supply Recommendations...................... 26

9.1 Voltage Range ........................................................ 26

9.2 Current Capability ................................................... 26

9.3 Input Connection .................................................... 26

10 Layout................................................................... 27

10.1 Layout Guidelines ................................................. 27

10.2 Layout Example .................................................... 28

11 Device and Documentation Support ................. 31

11.1

11.2

11.3

11.4

Device Support ....................................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

31

31

31

31

12 Mechanical, Packaging, and Orderable

Information ........................................................... 31

12.1 Tape and Reel Information ................................... 32

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision D (#IMPLIED) to Revision E

Page

•

Added links for Webench and top navigator icon for TI reference design; deleted Simple Switcher branding .................... 1

•

Changed Handling Ratings to ESD Ratings .......................................................................................................................... 4

Changes from Revision C (October 2014) to Revision D

Page

•

Changed from product Preview to Production Data .............................................................................................................. 1

•

Changed to Final Limits ......................................................................................................................................................... 5

Changes from Revision B (August 2014) to Revision C

•

Added Device Information and Handling Rating tables, Feature Description, Application and Implementation Layout

Device and Documentation Support and Mechanical, Packaging, and Orderable Information, moved some curves to

Application Curves ................................................................................................................................................................. 1

Changes from Revision A (October 2013) to Revision B

•

2

Page

Updated datasheet to new TI standards ................................................................................................................................ 1

Changes from Original (August 2012) to Revision A

•

Page

Page

Changed Description .............................................................................................................................................................. 1

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

5 Pin Configuration and Functions

Figure 1. LMZ21701 in the SIL0008E Package

SIL Package

8-Pin µSIP

Top View

TOP

SS

1

FB

2

PG

3

VOUT

4

PAD

(GND)

PAD

(GND)

8

VIN

7

EN

6

VOS

5

GND

Pin Functions

PIN

NAME

NO.

I/O

DESCRIPTION

SS

1

I

Soft-start pin. An external capacitor connected to this pin sets the internal voltage reference

ramp time. It can be used for tracking and sequencing.

FB

2

I

Voltage feedback. Connect resistive voltage divider to this pin to set the output voltage.

PG

3

O

Output power good (High = VOUT ready, Low = VOUT below nominal regulation); open drain

(requires pull-up resistor; goes low impedance when EN is low).

VOUT

4

O

Output Voltage. Connected to one terminal of the integrated inductor. Connect output filter

capacitor between VOUT and PGND.

GND

5

I

Ground for the power MOSFETs and gate-drive circuitry.

VOS

6

I

Output voltage sense pin and connection for the control loop circuitry.

EN

7

I

Enable input (High = enabled, Low = disabled). Internal pull down resistor keeps logic level

low if pin is left floating.

VIN

8

I

Supply voltage for control circuitry and power stage.

PAD

Electrically connected to GND. Must be soldered to a ground copper plane to achieve

appropriate power dissipation and mechanical reliability.

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

3

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

Over operating free-air temperature range (unless otherwise noted) (1) (2)

MIN

MAX

VIN

−0.3

20

V

EN, SS

−0.3

VIN +0.3 V w/ 20 V

maximum

V

FB, PG, VOS

−0.3

7

V

10

mA

−40

125

°C

260

°C

150

°C

PG sink current

Junction temperature, TJ-MAX

Maximum lead temperature

−65

Storage temperature, Tstg

(1)

(2)

UNIT

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

If Military/Aerospace specified devices are required, contact the Texas Instruments Sales Office/ Distributors for availability and

specifications.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22C101 (2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

Over operating free-air temperature range (unless otherwise noted) (1)

Input voltage

Output voltage

Recommended load current

Junction temperature, TJ

(1)

MIN

MAX

3

17

UNIT

V

0.9

6

V

0

1000

mA

−40

125

°C

Operating Ratings indicate conditions for which the device is intended to be functional, but do not ensure specific performance limits. For

ensured specifications, see the Electrical Characteristics section.

6.4 Thermal Information

LMZ21701

THERMAL METRIC

(1)

SIL (µSIP)

UNIT

8 PINS

RθJA

Junction-to-ambient thermal resistance (2)

42.6

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

20.8

°C/W

RθJB

Junction-to-board thermal resistance

9.4

°C/W

ψJT

Junction-to-top characterization parameter

1.5

°C/W

ψJB

Junction-to-board characterization parameter

9.3

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

1.8

°C/W

(1)

(2)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Junction-to-ambient thermal resistance (RθJA) is based on 4-layer board thermal measurements, performed under the conditions and

guidelines set forth in the JEDEC standards JESD51-1 to JESD51-11. RJθA varies with PCB copper area, power dissipation, and airflow.

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

6.5 Electrical Characteristics (1)

Limits apply over the recommended operating junction temperature (TJ) range of -40°C to +125°C, unless otherwise stated.

Minimum and Maximum limits are specified through test, design or statistical correlation. Typical values represent the most

likely parametric norm at TJ = 25°C, and are provided for reference purposes only. Unless otherwise stated the following

conditions apply: VIN = 12 V.

TYP (2)

MAX (1)

EN = high, IOUT = 0 mA, TJ = -40°C to

85°C

device not switching

17

25

μA

EN = high, IOUT = 0 mA, TJ = -40°C to

125°C

device not switching

17

28

μA

EN = low, TJ = -40°C to 85°C

1.5

4

μA

EN = low, TJ = -40°C to 125°C

1.5

5

μA

2.8

2.9

3

V

0.125

0.18

0.26

V

PARAMETER

TEST CONDITIONS

MIN (1)

UNIT

SYSTEM PARAMETERS

IQ

Operating quiescent current

ISD

Shutdown current

VINUVLO

Input under voltage lock out rising

threshold

VINUVLO-HYS

Input under voltage lock out

hysteresis

TSD

Thermal shutdown

TSD-HYST

Thermal shutdown hysteresis

Rising Threshold

160

°C

30

°C

CONTROL

VIH,

ENABLE

Enable logic HIGH voltage

0.9

VIL, ENABLE

Enable logic LOW voltage

ILKG

Input leakage current

EN = VIN or GND

VTH_PG

Power Good threshold voltage

Rising (% VOUT)

Falling (% VOUT)

V

0.3

V

0.01

1

μA

92%

95%

98%

87%

90%

93%

VOL_PG

Power Good output low voltage

IPG = -2 mA

0.07

0.3

V

ILKG_PG

Power Good leakage current

VPG = 1.8 V

1

400

nA

ISS

Softstart Pin source current

2.84

3.2

μA

2.5

POWER STAGE

RDS(ON)

High-Side MOSFET ON

Resistance

VIN ≥ 6 V

82

VIN = 3 V

120

Low-Side MOSFET ON

Resistance

VIN ≥ 6 V

40

VIN = 3 V

50

mΩ

mΩ

L

Integrated power inductor value

2.2

μH

DCR

Integrated power inductor DC

resistance

92

mΩ

ICL-HS

High-Side MOSFET Current Limit

TA = 25°C

ICL-LS

Low-Side MOSFET Current Limit

TA = 25°C

1.2

A

ICL-DC

Output (DC) current limit

VOUT = 5 V, TA = 85°C

1.3

A

(1)

(2)

1.4

1.8

2.2

A

Min and Max limits are 100% production tested at 25°C. Limits over the operating temperature range are ensured through correlation

using Statistical Quality Control (SQC) methods. Limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Typical numbers are at 25°C and represent the most likely parametric norm.

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

5

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Electrical Characteristics(1) (continued)

Limits apply over the recommended operating junction temperature (TJ) range of -40°C to +125°C, unless otherwise stated.

Minimum and Maximum limits are specified through test, design or statistical correlation. Typical values represent the most

likely parametric norm at TJ = 25°C, and are provided for reference purposes only. Unless otherwise stated the following

conditions apply: VIN = 12 V.

PARAMETER

TEST CONDITIONS

MIN (1)

TYP (2)

MAX (1)

0.7869

0.803

0.8191

V

1

100

nA

UNIT

OUTPUT

VREF

Internal reference voltage

IFB

Feedback pin leakage current

VFB = 0.8 V

VOUT

Light load initial voltage accuracy

Power save mode, COUT = 22 µF, TA =

-40°C to 85°C, 1% FB Resistors

VOUT

Load regulation

VOUT = 3.3 V

PWM mode operation

0.05%

/A

VOUT

Line regulation

3 V ≤ VIN ≤ 17 V, VOUT= 3.3 V, IOUT =

1000 mA

PWM mode operation

0.02%

/V

-2.3%

2.8%

SYSTEM CHARACTERISTICS

η

6

Full Load Efficiency

VOUT = 3.3 V, IOUT = 1000 mA

93%

Light Load Efficiency

VOUT = 3.3 V, IOUT = 1 mA

72%

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

6.6 Typical Characteristics

Unless otherwise specified the following conditions apply: VIN = 12 V, TA = 25°C

0.7

2-LAYER 70 µm (2 oz) Cu

4-LAYER 70 µm (2 oz) Cu

90

VIN = 3.3 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.6

80

Power Dissipation (W)

Thermal Resistance J-A (°C/W)

100

70

60

50

40

0.5

0.4

0.3

0.2

0.1

30

20

0

0

5

10

Copper Area (cm2)

15

20

0

0.1

0.2

0.3

D012

VOUT = 1.2 V

Figure 2. Package Thermal Resistance vs. Board Copper

Area

0.4 0.5 0.6

Load Current (A)

0.7

0.8

0.9

1

005

TA = 85ºC

Figure 3. Power Dissipation

0.7

0.7

VIN = 3.3 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.5

VIN = 3.3 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.6

Power Dissipation (W)

Power Dissipation (W)

0.6

0.4

0.3

0.2

0.1

0.5

0.4

0.3

0.2

0.1

0

0

0

0.1

0.2

0.3

VOUT = 1.8 V

0.4 0.5 0.6

Load Current (A)

0.7

0.8

0.9

1

0

0.1

0.2

TA = 85ºC

VOUT = 2.5 V

Figure 4. Power Dissipation

0.4 0.5 0.6

Load Current (A)

0.7

0.8

0.9

1

D007

TA = 85ºC

Figure 5. Power Dissipation

0.7

0.7

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.5

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.6

Power Dissipation (W)

0.6

Power Dissipation (W)

0.3

D006

0.4

0.3

0.2

0.5

0.4

0.3

0.2

0.1

0.1

0

0

0

0.1

0.2

VOUT = 3.3 V

0.3

0.4 0.5 0.6

Load Current (A)

0.7

0.8

TA = 85ºC

0.9

1

0

0.1

0.2

D008

VOUT = 5.0 V

Figure 6. Power Dissipation

0.3

0.4 0.5 0.6

Load Current (A)

0.7

0.8

0.9

1

D009

TA = 85ºC

Figure 7. Power Dissipation

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

7

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Typical Characteristics (continued)

Unless otherwise specified the following conditions apply: VIN = 12 V, TA = 25°C

6

4

IOUT = 0.25 A

IOUT = 0.5 A

IOUT = 1 A

IOUT = 0.25 A

IOUT = 0.5 A

IOUT = 1 A

3.6

Output Voltage (V)

Output Voltage (V)

5.5

3.8

5

4.5

4

3.4

3.2

3

2.8

2.6

2.4

3.5

2.2

3

2

3

3.5

VOUT = 5.0 V

4

4.5

5

Input Voltage (V)

5.5

6

3

3.1

3.2

TA = 85ºC

3.4 3.5 3.6

Input Voltage (V)

VOUT = 3.3 V

Figure 8. Dropout

3.7

3.8

3.9

4

D010

TA = 85ºC

Figure 9. Dropout

80

100

Evaluation Board

EN 55022 Class B Limit

EN 55022 Class A Limit

70

Peak Emissions

Quasi Peak Limit

Average Limit

90

Conducted Emissions (dBµV)

Radiated Emissions (dBµV/m)

3.3

D011

60

50

40

30

20

10

80

70

60

50

40

30

20

10

0

0

200

VIN= 12 V

400

600

Frequency (MHz)

800

1000

0

0.1

1

VOUT = 3.3 V

IOUT = 1 A

10

Frequency (MHz)

D004

VIN= 12 V

Lf = 2.2 µH

Figure 10. Radiated EMI on EVM

VOUT = 3.3 V

Cf = 1.0 µF

100

D003

IOUT = 1 A

Figure 11. Conducted EMI on EVM

7 Detailed Description

7.1 Overview

The LMZ21701 Nano Module is an easy-to-use step-down DC/DC solution capable of driving up to 1000 mA load

in space-constrained applications. Only an input capacitor, an output capacitor, a softstart capacitor, and two

resistors are required for basic operation. The Nano Module comes in 8-pin DFN footprint package with an

integrated inductor. The LMZ21701 architecture is based on DCS-Control™ (Direct Control with Seamless

Transition into Power Save Mode). This architecture combines the fast transient response and stability of

hysteretic type converters along with the accurate DC output regulation of voltage mode and current mode

regulators.

The LMZ21701 architecture uses pulse width modulation (PWM) mode for medium and heavy load requirements

and Power Save Mode (PSM) at light loads for high efficiency. In PWM mode the switching frequency is

controlled over the input voltage range. The value depends on the output voltage setting and is typically reduced

at low output voltages to achieve higher efficiency. In PSM the switching frequency decreases linearly with the

load current. Since the architecture of the device supports both operation modes (PWM and PSM) in a single

circuit building block, the transition between the modes of operation is seamless with minimal effect on the output

voltage.

8

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

7.2 Functional Block Diagram

HIGH SIDE

SWITCH

INDUCTOR

VIN

VOUT

2.2µH

LDO

BYPASS

5V LDO

UVLO

HIGH SIDE

CURRENT

LIMIT

HIGH SIDE DRIVER

WITH INTERNAL BOOTSTRAP

LOW SIDE

DRIVER

EN

400kŸ

CONTROL LOGIC

THERMAL

SHUTDOWN

SS

PG

LOW SIDE

SWITCH

LOW SIDE

CURRENT

LIMIT

ZERO

CURRENT

DETECT

SOFTSTART

CURRENT AND

TRACKING

VOS

DIRECT CONTROL

&

COMPENSATION

tON TIMER

6.6V

CLAMP

25pF

CFF

+

GND

FB

+

COMPARATOR

ERROR

AMPLIFIER

VREF

+

-

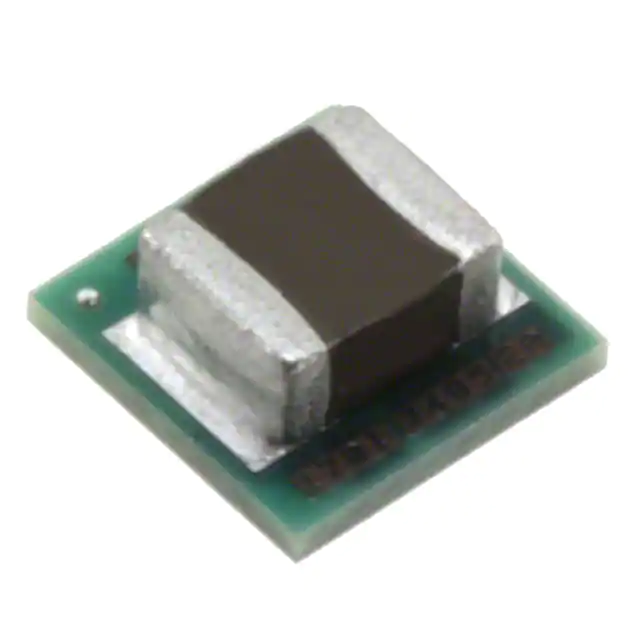

7.3 Package Construction

In order to achieve a small solution size the LMZ21701 Nano Module comes in an innovative MicroSiP™

package. The construction consists of a synchronous buck converter IC embedded inside an FR-4 laminate

substrate, with a power inductor mounted on top of the substrate material. See Figure 12 and Figure 13 below.

The bottom (landing pads) of the package resemble a typical 8-pin DFN package. See the Mechanical drawings

at the end of the datasheet for details on the recommended landing pattern and solder paste stencil information.

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

9

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Package Construction (continued)

Figure 12. LMZ21701 in the SIL0008E Package

INDUCTOR

FR-4 LAMINATE

SUBSTRATE

BOTTOM

COPPER PATTERN

EMBEDDED BUCK IC

Figure 13. LMZ21701 Package Construction Cross Section

(Illustration Only, Not to Scale)

10

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

7.4 Feature Description

7.4.1 Input Undervoltage Lockout

The LMZ21701 features input undervoltage lockout (UVLO) circuit. It monitors the input voltage level and

prevents the device from switching the power MOSFETs if VIN is not high enough. The typical VIN UVLO rising

threshold is 2.9 V with 180 mV of hysteresis.

7.4.2 Enable Input (EN)

The enable pin (EN) is weakly pulled down internally through a 400-kΩ resistor to keep EN logic low when the

pin is floating. The pull-down resistor is not connected when EN is set high. Once the voltage on the enable pin

(EN) is set high the Nano Module will start operation. If EN is set low ( < 0.3 V ) the LMZ21701 will enter

shutdown mode. The typical shutdown quiescent current is 1.5 μA.

7.4.3 Soft Start and Tracking Function (SS)

When EN is set high for device operation the LMZ21701 start switching after 50-μs delay, and the output voltage

starts rising. The VOUT rising slope is controlled by the external capacitor CSS connected to the softstart (SS) pin.

The Nano Module has a 2.9 μA constant current source internally connected to the SS pin to program the

softstart time TSS:

TSS = CSS × 1.25 V / 2.9 μA

(1)

The soft-start capacitor voltage is reset to zero volts when EN is pulled low and when the thermal protection is

active.

If tracking function is desired, the SS pin can be used to track external voltage. If the applied external tracking

voltage is between 100 mV and 1.2 V, the FB voltage will follow SS according to the following relationship:

VFB = 0.64 x VSS

(2)

7.4.4 Power Good Function (PG)

The LMZ21701 features a power good function which can be used for sequencing of multiple rails. The PG pin is

an open-drain output and requires a pull-up resistor RPG to VOUT (or any other external voltage less than 7 V).

When the Nano Module is enabled and UVLO is satisfied, the power good function starts monitoring the output

voltage. The PG pin is kept at logic low if the output has not reached the proper regulation voltage. Refer to the

Electrical Characteristics table for the PG voltage thresholds. The PG pin can sink 2 mA of current which sets the

minimum limit of the RPG resistance value:

RPG-MIN= VPULL-UP / 2 mA

(3)

The PG pin goes low impedance if the device is disabled or the thermal protection is active.

7.4.5 Output Voltage Setting

The output voltage of the LMZ21701 is set by a resistive divider from VOUT to GND, connected to the feedback

(FB) pin. The output voltage can be set between 0.9 V and 6 V. The voltage at the FB pin is regulated to 0.8 V.

The recommended minimum divider current is 2 μA. This sets a maximum limit on the bottom feedback resistor

RFBB. Its value must not exceed 400 kΩ. The top feedback resistor RFBT can be calculated using the following

formula:

RFBT = RFBB x (VOUT/ 0.8 – 1)

(4)

7.4.6 Output Current Limit and Output Short Circuit Protection

The LMZ21701 has integrated protection against heavy loads and output short circuit events. Both, the high-side

FET and low-side FET have current monitoring circuitry. If the current limit threshold of the high-side FET is

reached , the high-side FET will be turned off and the low-side FET will be turned on to ramp down the inductor

current. Once the current through the low-side FET has decreased below a safe level, the high-side device will

be allowed to turn on again. The actual DC output current depends on the input voltage, output voltage, and

switching frequency. Refer to the Application Curves section for more information.

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

11

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Feature Description (continued)

7.4.7 Thermal Protection

The nano module monitors its junction temperature (Tj) and shuts itself off if the it gets too hot. The thermal

shutdown threshold for the junction is typically 160 °C. Both, high-side and low-side FETs are turned off until the

junction temperature has decreased under the hysteresis level, typically 30 °C below the shutdown temperature.

7.5 Device Functional Modes

7.5.1 PWM Mode Operation

The LMZ21701 operates in PWM mode when the output current is greater than half the inductor ripple current.

The frequency variation in PWM mode is controlled and depends on the VIN and VOUT settings. Refer to the

Application Curves section for switching frequency graphs for several typical output voltage settings. As the load

current is decreased and the valley of the inductor current ripple reaches 0 A the device enters PSM operation to

maintain high efficiency.

7.5.2 PSM Operation

Once the load current decreases and the valley of the inductor current reaches 0 A, the LMZ21701 transitions to

power save mode of operation. The device will remain in PSM as long as the inductor current is discontinuous.

The switching frequency will decrease linearly with the load current. If VIN decreases to about 15 % above VOUT

the device will not enter PSM and will maintain output regulation in PWM mode.

12

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LMZ21701 is a step down DC-to-DC converter. It is used to convert higher DC voltage to a regulated lower

DC voltage with maximum load current of 1 A. The following design procedure can be used to select components

for the LMZ21701. Alternatively, the WEBENCH® software can be used to select from a large database of

components, run electrical simulations, and optimize the design for specific performance. Please go to

webench.ti.com to access the WEBENCH® tool.

8.2 Typical Application

For a quick start, the following component values can be used as a design starting point for several typical output

voltage rails and 1 A of output load current.

VOUT

VIN

VIN

VOUT

EN

PG

RPG

LMZ21701

CIN

COUT

VOS

SS

RFBT

CSS

GND

FB

RFBB

COMPONENT VALUES FOR VOUT=1.2V

CIN

22µF

COUT

22µF

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

RFBT

41.2k

1%

RFBB

82.5k

1%

RPG

10k

1%

• 25V

X7R or X5R

Figure 14. Typical Applications Circuit

Figure 15. External Component Values

( VOUT = 1.2 V )

COMPONENT VALUES FOR VOUT=1.8V

COMPONENT VALUES FOR VOUT=2.5V

CIN

X7R or X5R

CIN

22µF

• 10V

X7R or X5R

COUT

22µF

• 10V

X7R or X5R

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

1%

RFBT

357k

1%

118k

1%

RFBB

169k

1%

10k

1%

RPG

10k

1%

22µF

COUT

22µF

CSS

3300pF

RFBT

147k

RFBB

RPG

• 25V

• 25V

X7R or X5R

Figure 16. External Component Values

( VOUT = 1.8 V )

Figure 17. External Component Values

( VOUT = 2.5 V )

COMPONENT VALUES FOR VOUT=3.3V

COMPONENT VALUES FOR VOUT=5.0V

CIN

X7R or X5R

CIN

22µF

• 10V

X7R or X5R

COUT

22µF

• 10V

X7R or X5R

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

1%

RFBT

232k

1%

383k

1%

RFBB

44.2k

1%

10k

1%

RPG

10k

1%

22µF

COUT

22µF

CSS

3300pF

RFBT

1.21M

RFBB

RPG

• 25V

Figure 18. External Component Values

( VOUT = 3.3 V )

• 25V

X7R or X5R

Figure 19. External Component Values

( VOUT = 5.0 V )

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

13

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Typical Application (continued)

8.2.1 Design Requirements

The design procedure requires a few typical design parameters. See Table 1 below.

Table 1. Design Parameters

DESIGN PARAMETER

VALUE

Input Voltage (VIN)

Range from 3.0 V to 17 V

Output Voltage (VOUT)

Range from 0.9 V to 6 V

Output Current (IOUT)

Up to 1000 mA

Softstart time (TSS)

Minimum of 0.5 ms recommended

8.2.2 Detailed Design Procedure

8.2.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the LMZ21701 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

8.2.2.2 Input Capacitor (CIN)

Low ESR multi-layer ceramic capacitors (MLCC) are recommended for the input capacitor of the LMZ21701.

Using a ≥ 10 µF ceramic input capacitor in ≥ 0805 (2012 metric) case size with 25-V rating typically provides

sufficient VIN bypass. Use of multiple capacitors can also be considered. Ceramic capacitors with X5R and X7R

temperature characteristics are recommended. These provide an optimal balance between small size, cost,

reliability, and performance for applications with limited space. The DC voltage bias characteristics of the

capacitors must be considered when selecting the DC voltage rating and case size of these components. The

effective capacitance of an MLCC is typically reduced by the DC voltage bias applied across its terminals.

Selecting a part with larger capacitance, larger case size, or higher voltage rating can compensate for the

capacitance loss due to the DC voltage bias effect. For example, a 10-µF, X7R, 25-V rated capacitor used under

12-V DC bias may have approximately 8-µF effective capacitance in a 1210 (3225 metric) case size and about 6

µF in a 1206 (3216 metric) case size. As another example, a 10-µF, X7R, 16-V rated capacitor in a 1210 (3225

metric) case size used at 12-V DC bias may have approximately 5.5 µF effective capacitance. Check the

capacitor specifications published by the manufacturer.

8.2.2.3 Output Capacitor (COUT)

Similarly to the input capacitor, it is recommended to use low ESR multi-layer ceramic capacitors for COUT.

Ceramic capacitors with X5R and X7R temperature characteristics are recommended. Use 10 µF or larger value

and consider the DC voltage bias characteristics of the capacitor when choosing the case size and voltage

rating. For stability, the output capacitor should be in the 10 µF – 200 µF effective capacitance range.

14

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

8.2.2.4 Soft-start Capacitor (CSS)

The softstart capacitor is chosen according to the desired softstart time. As described in the Softstart and

Tracking Function section the softstart time TSS = CSS x 1.25 V / 2.9 μA.

A minimum CSS value of 1000 pF is required for monotonic VOUT ramp up.

8.2.2.5 Power Good Resistor (RPG)

If the Power Good function is used, a pull up resistor RPG is necessary from the PG pin to an external pull-up

voltage.

The minimum RPG value is restricted by the pull down current capability of the internal pull down device.

RPG-MIN= VPULL-UP / 2 mA

(5)

The maximum RPG value is based on the maximum PG leakage current and the minimum “logic high” level

system requirements:

RPG-MAX= (VPULL-UP – VLOGIC-HIGH) / ILKG_PG

(6)

8.2.2.6 Feedback Resistors (RFBB and RFBT)

The feedback resistors RFBB and RFBT set the desired output voltage. Choose RFBB less than 400 kΩ and

calculate the value for RFBT using the following formula:

RFBT = RFBB x (VOUT/ 0.8 – 1)

(7)

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

15

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

8.2.3 Application Curves

8.2.3.1 VOUT = 1.2 V

VOUT

VIN

VIN

VOUT

EN

PG

COMPONENT VALUES FOR VOUT=1.2V

RPG

LMZ21701

CIN

SS

COUT

VOS

RFBT

CSS

GND

FB

RFBB

CIN

22µF

• 25V

X7R or X5R

COUT

22µF

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

RFBT

41.2k

1%

RFBB

82.5k

1%

RPG

10k

1%

Figure 20. Typical Applications Circuit

Figure 21. External Component Values

(VOUT = 1.2 V)

100

0.6

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

90

0.5

Power Dissipation (W)

80

Efficiency (%)

70

60

50

40

30

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

20

10

0

0.0001

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.4

0.3

0.2

0.1

0.0

0.0

0.001

0.01

Load Current (A)

0.1

0.1

1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Load Current (A)

D013

1.0

C001

Figure 23. Power Dissipation VOUT = 1.2 V

Figure 22. Efficiency VOUT = 1.2 V

ILOAD 500mA/Div

PGOOD 1V/Div

ILOAD 500mA/Div

VOUT 500mV/Div

VOUT 20mV/Div AC

ENABLE 500mV/Div

1ms/Div

20MHz BW

Figure 24. Load Transient VOUT = 1.2 V

16

1ms/Div

20MHz BW

Submit Documentation Feedback

Figure 25. Startup VOUT = 1.2 V

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

COUT1 = 22 F 10V 0805 X5R

Taiyo Yuden MK212BJ226MG-T

VOUT RIPPLE

VOUT RIPPLE

COUT = 22 F 10V 0805 X5R

WITH 500MHz SCOPE BANDWIDTH

COUT2 = 3x1000pF 0805 NP0

Johanson Dielectrics 500R15N102JV4T

Taiyo Yuden MK212BJ226MG-T

50mV/Div

10mV/Div

1µs/Div

20MHz BW

Figure 26. 20 MHz Oscilloscope Bandwidth

Output Voltage Ripple VOUT = 1.2 V

500MHz BW

Figure 27. 500 MHz Oscilloscope Bandwidth, 3x1000 pF

additional output capacitance

Output Voltage Ripple and HF Noise VOUT = 1.2 V

1.8

VOUT=1.2V

2.0

1.5

1.0

0.5

TYPICAL DC CURRENT LIMIT (A)

SWITCHING FREQUENCY (MHz)

2.5

0.0

1.6

1.4

1.2

1.0

0.8

0.6

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

18

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

C001

Figure 28. Typical Switching Frequency at 1000 mA Load

VOUT = 1.2 V

18

C001

Figure 29. Typical Current Limit VOUT = 1.2 V, TA = 85 °C

1.206

1.2

1.202

VIN = 12 V

VIN = 15 V

VIN = 17 V

1.0

Output Current (A)

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

1.204

Output Voltage (V)

1µs/Div

1.2

1.198

1.196

1.194

0.8

0.6

0.4

VIN = 3.3 V

VIN = 5 V

VIN = 12 V

VIN = 17 V

0.2

1.192

0.0

1.19

0.0001

60

0.001

0.01

Load Current (A)

0.1

1

D014

Figure 30. Line and Load Regulation VOUT = 1.2 V

70

80

90

100

110

120

Ambient Temperature (ƒC)

130

C001

Figure 31. Thermal Derating for θJA = 47 ºC/W, VOUT = 1.2 V

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

17

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

8.2.3.2 VOUT = 1.8 V

VOUT

VIN

VIN

VOUT

EN

PG

COMPONENT VALUES FOR VOUT=1.8V

RPG

LMZ21701

CIN

SS

COUT

VOS

RFBT

CSS

GND

FB

RFBB

CIN

22µF

COUT

22µF

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

RFBT

147k

1%

RFBB

118k

1%

RPG

10k

1%

Figure 32. Typical Applications Circuit

0.6

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

90

0.5

Power Dissipation (W)

80

Efficiency (%)

70

60

50

40

30

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

10

0

0.0001

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.4

0.3

0.2

0.1

0.0

0.0

0.001

0.01

Load Current (A)

0.1

X7R or X5R

Figure 33. External Component Values

(VOUT = 1.8 V)

100

20

• 25V

0.1

1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Load Current (A)

D015

1.0

C001

Figure 35. Power Dissipation VOUT = 1.8 V

Figure 34. Efficiency VOUT = 1.8 V

ILOAD 500mA/Div

PGOOD 1V/Div

ILOAD 500mA/Div

VOUT 1V/Div

VOUT 20mV/Div AC

ENABLE 500mV/Div

1ms/Div

20MHz BW

Figure 36. Load Transient VOUT = 1.8 V

18

1ms/Div

20MHz BW

Submit Documentation Feedback

Figure 37. Startup VOUT = 1.8 V

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

COUT1 = 22 F 10V 0805 X5R

Taiyo Yuden MK212BJ226MG-T

VOUT RIPPLE

VOUT RIPPLE

COUT = 22 F 10V 0805 X5R

WITH 500MHz SCOPE BANDWIDTH

COUT2 = 3x1000pF 0805 NP0

Johanson Dielectrics 500R15N102JV4T

Taiyo Yuden MK212BJ226MG-T

10mV/Div

50mV/Div

1µs/Div

20MHz BW

Figure 38. 20 MHz Oscilloscope Bandwidth

Output Voltage Ripple VOUT = 1.8 V

500MHz BW

Figure 39. 500 MHz Oscilloscope Bandwidth, 3x1000 pF

additional output capacitance

Output Voltage Ripple and HF Noise VOUT = 1.8 V

1.8

VOUT=1.8V

2.0

1.5

1.0

0.5

TYPICAL DC CURRENT LIMIT (A)

SWITCHING FREQUENCY (MHz)

2.5

0.0

1.6

1.4

1.2

1.0

0.8

0.6

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

18

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

C001

Figure 40. Typical Switching Frequency at 1000 mA Load

VOUT = 1.8 V

18

C001

Figure 41. Typical Current Limit VOUT = 1.8 V, TA = 85 °C

1.81

1.2

1.806

VIN = 12 V

VIN = 15 V

VIN = 17 V

1.0

Output Current (A)

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

1.808

Output Voltage (V)

1µs/Div

1.804

1.802

1.8

1.798

1.796

0.8

0.6

0.4

VIN = 3.3 V

VIN = 5 V

VIN = 12 V

VIN = 17 V

0.2

1.794

1.792

0.0

1.79

0.0001

60

0.001

0.01

Load Current (A)

0.1

1

D016

Figure 42. Line and Load Regulation VOUT = 1.8 V

70

80

90

100

110

120

Ambient Temperature (ƒC)

130

C001

Figure 43. Thermal Derating for θJA= 47ºC/W VOUT = 1.8 V

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

19

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

8.2.3.3 VOUT = 2.5 V

VOUT

VIN

VIN

VOUT

EN

PG

COMPONENT VALUES FOR VOUT=2.5V

RPG

LMZ21701

CIN

SS

COUT

VOS

RFBT

CSS

GND

FB

RFBB

CIN

22µF

COUT

22µF

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

RFBT

357k

1%

RFBB

169k

1%

RPG

10k

1%

Figure 44. Typical Applications Circuit

0.6

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

90

0.5

Power Dissipation (W)

80

Efficiency (%)

70

60

50

40

30

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

10

0

0.0001

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.4

0.3

0.2

0.1

0.0

0.0

0.001

0.01

Load Current (A)

X7R or X5R

Figure 45. External Component Values

(VOUT = 2.5 V)

100

20

• 25V

0.1

0.1

1

D017

Figure 46. Efficiency VOUT = 2.5 V

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Load Current (A)

1.0

C001

Figure 47. Power Dissipation VOUT = 2.5 V

ILOAD 500mA/Div

PGOOD 2V/Div

ILOAD 500mA/Div

VOUT 1V/Div

VOUT 20mV/Div AC

ENABLE 500mV/Div

1ms/Div

20MHz BW

1ms/Div

20MHz BW

Figure 48. Load Transient VOUT = 2.5 V

20

Submit Documentation Feedback

Figure 49. Startup VOUT = 2.5 V

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

COUT1 = 22 F 10V 0805 X5R

Taiyo Yuden MK212BJ226MG-T

VOUT RIPPLE

VOUT RIPPLE

COUT = 22 F 10V 0805 X5R

WITH 500MHz SCOPE BANDWIDTH

COUT2 = 3x1000pF 0805 NP0

Johanson Dielectrics 500R15N102JV4T

Taiyo Yuden MK212BJ226MG-T

10mV/Div

50mV/Div

1µs/Div

20MHz BW

Figure 50. 20MHz Oscilloscope Bandwidth

Output Voltage Ripple VOUT = 2.5 V

500MHz BW

Figure 51. 500 MHz Oscilloscope Bandwidth, 3x1000 pF

additional output capacitance

Output Voltage Ripple and HF Noise VOUT = 2.5 V

1.8

VOUT=2.5V

2.0

1.5

1.0

0.5

TYPICAL DC CURRENT LIMIT (A)

SWITCHING FREQUENCY (MHz)

2.5

0.0

1.6

1.4

1.2

1.0

0.8

0.6

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

18

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

C001

Figure 52. Typical Switching Frequency at 1000 mA Load

VOUT = 2.5 V

18

C001

Figure 53. Typical Current Limit VOUT = 2.5 V, TA = 85 °C

2.5

1.2

2.496

VIN = 12 V

VIN = 15 V

VIN = 17 V

1.0

Output Current (A)

VIN = 3 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5 V

2.498

Output Voltage (V)

1µs/Div

2.494

2.492

2.49

2.488

2.486

0.8

0.6

0.4

VIN = 5 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.2

2.484

2.482

0.0

2.48

0.0001

60

0.001

0.01

Load Current (A)

0.1

1

D018

Figure 54. Line and Load Regulation VOUT = 2.5 V

70

80

90

100

110

120

Ambient Temperature (ƒC)

130

C001

Figure 55. Thermal Derating for θJA = 47 ºC/W, VOUT = 2.5 V

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

21

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

8.2.3.4 VOUT = 3.3 V

VOUT

VIN

VIN

VOUT

EN

PG

COMPONENT VALUES FOR VOUT=3.3V

RPG

LMZ21701

CIN

SS

COUT

VOS

RFBT

CSS

GND

FB

RFBB

CIN

22µF

COUT

22µF

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

RFBT

1.21M

1%

RFBB

383k

1%

RPG

10k

1%

Figure 56. Typical Applications Circuit

0.6

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

90

0.5

Power Dissipation (W)

80

Efficiency (%)

70

60

50

40

30

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

10

0

0.0001

0.4

0.3

0.2

0.1

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.0

0.0

0.001

0.01

Load Current (A)

0.1

X7R or X5R

Figure 57. External Component Values

(VOUT = 3.3 V)

100

20

• 25V

0.1

1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Load Current (A)

D019

1.0

C001

Figure 59. Power Dissipation VOUT = 3.3 V

Figure 58. Efficiency VOUT = 3.3 V

ILOAD 500mA/Div

VOUT 1V/Div

ILOAD 500mA/Div

PGOOD 2V/Div

VOUT 20mV/Div AC

ENABLE 500mV/Div

1ms/Div

20MHz BW

1ms/Div

20MHz BW

Figure 60. Load Transient VOUT = 3.3 V

22

Submit Documentation Feedback

Figure 61. Startup VOUT = 3.3 V

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

COUT1 = 22 F 10V 0805 X5R

Taiyo Yuden MK212BJ226MG-T

VOUT RIPPLE

VOUT RIPPLE

COUT = 22 F 10V 0805 X5R

WITH 500MHz SCOPE BANDWIDTH

COUT2 = 3x1000pF 0805 NP0

Johanson Dielectrics 500R15N102JV4T

Taiyo Yuden MK212BJ226MG-T

10mV/Div

50mV/Div

1µs/Div

20MHz BW

Figure 62. 20 MHz Oscilloscope Bandwidth

Output Voltage Ripple VOUT = 3.3 V

500MHz BW

Figure 63. 500 MHz Oscilloscope Bandwidth, 3x1000 pF

additional output capacitance

Output Voltage Ripple and HF Noise VOUT = 3.3 V

1.8

VOUT=3.3V

2.0

1.5

1.0

0.5

TYPICAL DC CURRENT LIMIT (A)

SWITCHING FREQUENCY (MHz)

2.5

0.0

1.6

1.4

1.2

1.0

0.8

0.6

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

18

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

C001

Figure 64. Typical Switching Frequency at 1000 mA Load

VOUT = 3.3 V

18

C001

Figure 65. Typical Current Limit VOUT = 3.3 V, TA = 85 °C

3.316

1.2

VIN = 4.5 V

VIN = 5 V

VIN = 9 V

3.314

VIN = 12 V

VIN = 15 V

VIN = 17 V

1.0

Output Current (A)

3.312

Output Voltage (V)

1µs/Div

3.31

3.308

3.306

3.304

0.8

0.6

0.4

VIN = 5 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.2

3.302

0.0

3.3

0.0001

60

0.001

0.01

Load Current (A)

0.1

1

D020

Figure 66. Line and Load Regulation VOUT = 3.3 V

70

80

90

100

110

120

Ambient Temperature (ƒC)

130

C001

Figure 67. Thermal Derating for θJA = 47 ºC/W, VOUT = 3.3 V

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

23

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

8.2.3.5 VOUT = 5.0 V

VOUT

VIN

VIN

VOUT

EN

PG

COMPONENT VALUES FOR VOUT=5.0V

RPG

LMZ21701

CIN

SS

COUT

VOS

RFBT

CSS

GND

FB

RFBB

CIN

22µF

COUT

22µF

• 10V

X7R or X5R

CSS

3300pF

• 10V

X7R or X5R

RFBT

232k

1%

RFBB

44.2k

1%

RPG

10k

1%

Figure 68. Typical Applications Circuit

0.6

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

90

0.5

Power Dissipation (W)

80

Efficiency (%)

70

60

50

40

30

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

10

0

0.0001

0.4

0.3

0.2

0.1

0.0

0.0

0.001

0.01

Load Current (A)

0.1

X7R or X5R

Figure 69. External Component Values

(VOUT = 5.0 V)

100

20

• 25V

0.1

1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Load Current (A)

D021

1.0

C001

Figure 71. Power Dissipation VOUT = 5.0 V

Figure 70. Efficiency VOUT = 5.0 V

ILOAD 500mA/Div

VOUT 2V/Div

ILOAD 500mA/Div

PGOOD 5V/Div

VOUT 20mV/Div AC

ENABLE 500mV/Div

1ms/Div

20MHz BW

1ms/Div

20MHz BW

Figure 73. Startup VOUT = 5.0 V

Figure 72. Load Transient VOUT = 5.0 V

24

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

COUT1 = 22 F 10V 0805 X5R

Taiyo Yuden MK212BJ226MG-T

VOUT RIPPLE

VOUT RIPPLE

COUT = 22 F 10V 0805 X5R

WITH 500MHz SCOPE BANDWIDTH

COUT2 = 3x1000pF 0805 NP0

Johanson Dielectrics 500R15N102JV4T

Taiyo Yuden MK212BJ226MG-T

10mV/Div

50mV/Div

1µs/Div

20MHz BW

Figure 74. 20MHz Oscilloscope Bandwidth

Output Voltage Ripple VOUT = 5.0 V

500MHz BW

Figure 75. 500 MHz Oscilloscope Bandwidth, 3x1000 pF

additional output capacitance

Output Voltage Ripple and HF Noise VOUT = 5.0 V

1.8

2.0

1.5

1.0

0.5

VOUT=5.0V

TYPICAL DC CURRENT LIMIT (A)

SWITCHING FREQUENCY (MHz)

2.5

0.0

1.6

1.4

1.2

1.0

0.8

0.6

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

18

0

2

4

6

8

10

12

14

16

INPUT VOLTAGE (V)

C001

18

C001

Figure 76. Typical Switching Frequency at 1000 mA Load

VOUT = 5 V

Figure 77. Typical Current Limit VOUT = 5 V, TA = 85°C

5.05

1.2

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

5.04

5.035

1.0

Output Current (A)

5.045

Output Voltage (V)

1µs/Div

5.03

5.025

5.02

5.015

5.01

5.005

0.8

0.6

0.4

VIN = 9 V

VIN = 12 V

VIN = 15 V

VIN = 17 V

0.2

5

4.995

0.0

4.99

0.0001

60

0.001

0.01

Load Current (A)

0.1

1

D022

Figure 78. Line and Load Regulation VOUT = 5 V

70

80

90

100

110

120

Ambient Temperature (ƒC)

130

C001

Figure 79. Thermal Derating for θJA= 47 ºC/W, VOUT = 5 V

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

25

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

8.3 Do's and Don'ts

● DO NOT exceed the Absolute Maximum Ratings.

● DO NOT exceed the Recommended Operating Conditions.

● DO NOT exceed the ESD Ratings.

● DO follow the Detailed Design Procedure.

● DO follow the PCB Layout Guidelines and Layout Example.

● DO follow the Power Supply Recommendations.

● DO visit the TI E2E Community Support Forum to have your questions answered and designs reviewed.

9 Power Supply Recommendations

9.1 Voltage Range

The voltage of the input supply must not exceed the Absolute Maximum Ratings and the Recommended

Operating Conditions of the LMZ21701.

9.2 Current Capability

The input supply must be able to supply the required input current to the LMZ21701 converter. The required

input current depends on the application's minimum required input voltage (VIN-MIN), the required output power

(VOUT × IOUT-MAX), and the converter efficiency (η).

IIN = VOUT x IOUT-MAX / (VIN-MIN x η)

For example, for a design with 10-V minimum input voltage, 5-V output, and 1-A maximum load, considering 90%

conversion efficiency, the required input current is 0.556 A.

9.3 Input Connection

Long input connection cables can cause issues with the normal operation of any buck converter.

9.3.1 Voltage Drops

Using long input wires to connect the supply to the input of any converter adds impedance in series with the

input supply. This impedance can cause a voltage drop at the VIN pin of the converter when the output of the

converter is loaded. If the input voltage is near the minimum operating voltage, this added voltage drop can

cause the converter to drop out or reset. If long wires are used during testing, it is recommended to add some

bulk (for example, electrolytic) capacitance at the input of the converter.

9.3.2 Stability

The added inductance of long input cables together with the ceramic (and low ESR) input capacitor can result in

an under damped RLC network at the input of the Buck converter. This can cause oscillations on the input and

instability. If long wires are used, it is recommended to add some electrolytic capacitance in parallel with the

ceramic input capacitor. The electrolytic capacitor's ESR will improve the damping.

Use an electrolytic capacitor with CELECTROLYTIC≥ 4 × CCERAMIC and ESRELECTROLYTIC≈ √ (LCABLE / CCERAMIC)

For example, two cables (one for VIN and one for GND), each 1 meter (~3 ft) long with ~1-mm diameter (18

AWG), placed 1 cm (~0.4 in) apart will form a rectangular loop resulting in about 1.2 µH of inductance. The

inductance in this example can be decreased to almost half if the input wires are twisted. Based on a 22 µF

ceramic input capacitor, the recommended parallel CELECTROLYTIC is ≥ 88 µF. Using a 100 µF capacitor will be

sufficient. The recommended ESRELECTROLYTIC≈ 0.23 Ω or larger, based on about 1.2 µH of inductance and 22

µF of ceramic input capacitance.

See application note SNVA489C for more details on input filter design.

26

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

10 Layout

10.1 Layout Guidelines

The PCB layout is critical for the proper operation of any DC/DC switching converter. Although using modules

can simplify the PCB layout process, care should still be taken to minimize the inductance in the high di/dt loops

and to protect sensitive nodes. The following guidelines should be followed when designing a board layout with

the LMZ21701:

10.1.1 Minimize the High di/dt Loop Area

The input capacitor, the VIN terminal, and the GND terminal of the LMZ21701 form a high di/dt loop. Place the

input capacitor as close as possible to the VIN and GND terminals of the module IC. This minimizes the area of

the high di/dt loop and results in lower inductance in the switching current path. Lower inductance in the

switching current path translates to lower voltage spikes on the internal switch node and lower noise on the

output voltage. Make the copper traces between the input capacitor and the VIN and GND terminals wide and

short for better current handling and minimized parasitic inductance.

10.1.2 Protect the Sensitive Nodes in the Circuit

The feedback node is a sensitive circuit which can pick up noise. Make the feedback node as small as possible.

This can be achieved by placing the feedback divider as close as possible to the IC. Use thin traces to the

feedback pin in order to minimize the parasitic capacitance to other nodes. The feedback network carries very

small current and thick traces are not necessary. Another sensitive node to protect is the VOS pin. Use a thin

and short trace from the VOUT terminal of the output capacitor to the VOS pin. The VOS pin is right next to the

GND terminal. For very noisy systems, a small (0402 or 0201) 0.1 µF capacitor can be placed from VOS to GND

to filter high frequency noise on the VOS line.

10.1.3 Provide Thermal Path and Shielding

Using the available layers in the PCB can help provide additional shielding and improved thermal performance.

Large unbroken GND copper areas provide good thermal and return current paths. Flood unused PCB area with

GND copper. Use thermal vias to connect the GND copper between layers.

The required board area for proper thermal dissipation can be estimated using the power dissipation curves for

the desired output voltage and the package thermal resistance vs. board area curve. Refer to the power

dissipation graphs in the Typical Characteristics section. Using the power dissipation (PDISS) for the designed

input and output voltage and the max operating ambient temperature TA for the application, estimate the required

thermal resistance RθJA with the following expression.

RθJA - REQUIRED≤ (125ºC - TA) / PDISS

(8)

Then use Figure 80 to estimate the board copper area required to achieve the calculated thermal resistance.

Thermal Resistance J-A (°C/W)

100

2-LAYER 70 µm (2 oz) Cu

4-LAYER 70 µm (2 oz) Cu

90

80

70

60

50

40

30

20

0

5

10

Copper Area (cm2)

15

20

D012

Figure 80. Package Thermal Resistance vs. Board Copper Area

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

27

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Layout Guidelines (continued)

For example, for a design with 12-V input, 5-V output, and 1-A load the power dissipation according to Figure 7

is 0.53 W.

For 85°C ambient temperature, the RθJA-REQUIRED is ≤ (125°C – 85°C) / 0.53 W, or ≤ 75°C/W. Looking at

Figure 80 the minimum copper area required to achieve this thermal resistance with a 4-layer board and 70 µm

(2 oz) copper is approximately 3 cm².

10.2 Layout Example

The following example is for a 4-layer board. Layers 2 and 4 provide additional shielding and thermal path. If a 2layer board is used, apply the Layer 1 and Layer 3 copper patterns for the top and bottom layers, respectively.

28

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

GND VIAS TO MINIMIZE INDUCTANCE IN

THE di/dt LOOP

GND

PLACE THE INPUT CAPACITOR AS CLOSE

AS POSSIBLE TO THE MODULE VIN AND

GND PINS

VIN

Layout Example (continued)

VIN EN VOS GND

GND

SS FB PG VOUT

LAYER 1

VOUT

PLACE THE FEEDBACK DIVIDER AS CLOSE

AS POSSIBLE TO THE MODULE TO KEEP

THE FB NODE SMALL

LAYER 2

UNBROKEN GND PLANE FOR THERMAL

PERFORMANCE AND SHIELDING

ENABLE CONNECTION

VOS CONNECTION t KEEP AWAY FROM

NOISE SOURCES

LAYER 3

CONNECTION TO THE SOFTSTART

CAPACITOR

POWER GOOD FLAG CONNECTION

UNBROKEN GND PLANE FOR THERMAL

PERFORMANCE AND SHIELDING

LAYER 4

Figure 81. Layout example

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

29

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

Layout Example (continued)

10.2.1 High Density Layout Example for Space Constrained Applications

10.2.1.1 35 mm² Solution Size (Single Sided)

The following layout example uses 0805 case size components for the input and output capacitors and 0402

case size components for the rest of the passives.

LAYER 1

SS

VIN

FB

EN

LAYER 2

VIN

PG

VOS

VOUT

GND

GND

VOUT

GND

GND

LAYER 3

LAYER 4

VOS

VOUT

Figure 82. 35 mm² Solution Size (Single Sided)

30

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

11 Device and Documentation Support

11.1 Device Support

Visit the TI E2E Community Support Forum to have your questions answered and designs reviewed.

11.1.1 Development Support

11.1.1.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the LMZ21701 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

11.2 Trademarks

DCS-Control, MicroSiP are trademarks of Texas Instruments.

WEBENCH is a registered trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

11.3 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.4 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

31

�LMZ21701

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

www.ti.com

12.1 Tape and Reel Information

REEL DIMENSIONS

TAPE DIMENSIONS

K0

P1

B0 W

Reel

Diameter

Cavity

A0

B0

K0

W

P1

A0

Dimension designed to accommodate the component width

Dimension designed to accommodate the component length

Dimension designed to accommodate the component thickness

Overall width of the carrier tape

Pitch between successive cavity centers

Reel Width (W1)

QUADRANT ASSIGNMENTS FOR PIN 1 ORIENTATION IN TAPE

Sprocket Holes

Q1

Q2

Q1

Q2

Q3

Q4

Q3

Q4

User Direction of Feed

Pocket Quadrants

32

Device

Package

Type

Package

Drawing

Pins

SPQ

Reel

Diameter

(mm)

Reel

Width W1

(mm)

A0

(mm)

B0

(mm)

K0

(mm)

P1

(mm)

W

(mm)

Pin1

Quadrant

LMZ21701SILR

uSiP

SIL

8

3000

330.0

12.4

3.75

3.75

2.2

8.0

12.0

Q2

LMZ21701SILT

uSiP

SIL

8

250

178.0

13.2

3.75

3.75

2.2

8.0

12.0

Q2

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

�LMZ21701

www.ti.com

SNVS853E – AUGUST 2012 – REVISED AUGUST 2018

TAPE AND REEL BOX DIMENSIONS

Width (mm)

W

L

H

Device

Package Type

Package Drawing

Pins

SPQ

Length (mm)

Width (mm)

Height (mm)

LMZ21701SILR

uSiP

SIL

8

3000

383.0

353.0

58.0

LMZ21701SILT

uSiP

SIL

8

250

223.0

194.0

35.0

Submit Documentation Feedback

Copyright © 2012–2018, Texas Instruments Incorporated

Product Folder Links: LMZ21701

33

����PACKAGE OPTION ADDENDUM

www.ti.com

22-Feb-2021

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

(3)

Device Marking

(4/5)

(6)

LMZ21701SILR

ACTIVE

uSiP

SIL

8

3000

RoHS & Green

NIAU

Level-3-260C-168 HR

-40 to 125

1701 7485 EA

LMZ21701SILT

ACTIVE

uSiP

SIL

8

250

RoHS & Green

NIAU

Level-3-260C-168 HR

-40 to 125

1701 7485 EA

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of