User's Guide

SNVA265A – November 2007 – Revised April 2013

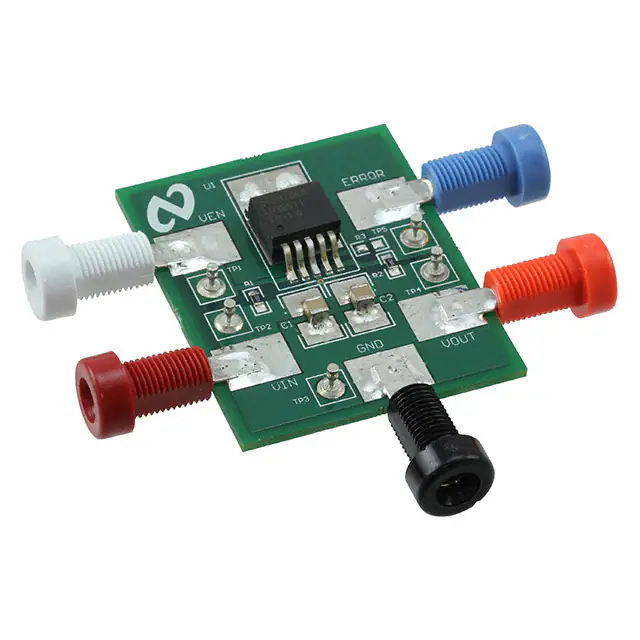

AN-1675 LP38511TS-1.8 Evaluation Board

1

Introduction

This board is designed to enable the evaluation of the LP38511TS-1.8 Voltage Regulator. Each board is

assembled and tested in the factory. This evaluation board has the TO-263 5–lead package mounted.

2

General Description

The LP38511 is a linear regulator capable of supplying up to 800 mA of output current, and incorporates

Enable and Error flag features.

The device has been designed to work with 10 µF ceramic input and output capacitors. Footprints areas

for CIN and COUT will allow for a variety of sizes.

3

Operation

The input voltage, applied between VIN and GND, should be at least 2.25V, and no higher than 5.5V.

Loads can be connected to VOUT with reference to GND.

Test points are provided on the board to allow monitoring of VOUT, VIN, Enable, and ERROR signals during

operation

If the application does not require the Enable function, the EN pin should be connected to directly to the

adjacent VIN pin.

4

Enable Operation

The Enable On threshold is typically 1.2V, and typically has 200mV of hysteresis. The voltage signal

should rise and fall cleanly, and promptly, through these thresholds.

The Enable pin (EN) has no internal pull-up or pull-down to establish a default condition and, as a result,

this pin must be terminated either actively or passively.

Figure 1. VOUT vs. VEN

All trademarks are the property of their respective owners.

SNVA265A – November 2007 – Revised April 2013

Submit Documentation Feedback

AN-1675 LP38511TS-1.8 Evaluation Board

Copyright © 2007–2013, Texas Instruments Incorporated

1

�ERROR Flag

www.ti.com

If the Enable pin is driven from a single ended device (such as the collector of a discrete transistor) a pullup resistor to VIN, or a pull-down resistor to ground, will be required for proper operation. A 1 kΩ to 100 kΩ

resistor can be used as the pull-up or pull-down resistor to establish default condition for the EN pin. The

resistor value selected should be appropriate to swamp out any leakage in the external single ended

device, as well as any stray capacitance.

If the Enable pin is driven from a source that actively pulls high and low (such as a CMOS rail to rail

comparator output), the pull-up, or pull-down, resistor is not required.

If the application does not require the Enable function, the EN pin should be connected to directly to the

adjacent VIN pin.

The status of the Enable pin also affects the behavior of the ERROR Flag. While the Enable pin is high

the regulator control loop will be active and the ERROR Flag will report the status of the output voltage.

When the Enable pin is taken low the regulator control loop is shutdown, the output is turned off, and the

internal logic will immediately force the ERROR Flag pin low.

Figure 2. Enable Threshold

5

ERROR Flag

When the LP38511 Enable pin is high, the ERROR Flag pin will produce a logic low signal when the

output drops by more than 10% (typical) from the nominal output voltage. The drop in output voltage may

be due to low input voltage, current limiting, or thermal limiting. This flag has a built in hysteresis. The

output voltage will need to rise to within 5% of the nominal output voltage for the ERROR Flag to return to

a logic high state. It should also be noted that when the Enable pin is pulled low, the ERROR Flag pin is

forced to be low as well.

The internal ERROR flag comparator has an open drain output stage. Hence, the ERROR pin requires an

external pull-up resistor. The value of the pull-up resistor should be in the range of 2 kΩ to 100 kΩ, and

should be connected to the LP38511 output voltage pin. The ERROR Flag pin should not be pulled-up to

any voltage source higher than VIN as current flow through an internal parasitic diode may cause

unexpected behavior. When the input voltage is less than typically 1.25V the status of the ERROR flag

output will not be reliable. The ERROR Flag pin must be connected to ground if this function is not used.

The timing diagram in Figure 4 shows the relationship between the ERROR flag and the output voltage

when the pull-up resistor is connected to the output voltage pin.

The timing diagram in Figure 5 shows the relationship between the ERROR flag and the output voltage

when the pull-up resistor is connected to the input voltage pin.

6

Power Dissipation

The TO-263 package alone has a junction to ambient thermal resistance (θJA) rating of 60°C/W. When

mounted on the LP38511TS evaluation board the θJA rating is approximately 30°C/W.

2

AN-1675 LP38511TS-1.8 Evaluation Board

SNVA265A – November 2007 – Revised April 2013

Submit Documentation Feedback

Copyright © 2007–2013, Texas Instruments Incorporated

�Power Dissipation

www.ti.com

Although there is only approximately 0.28 square inches of copper area immediately under the tab, the top

copper surface area is extended to additional copper area on the bottom of the board by nine thermal

vias.

With the 30°C/W thermal rating the LP38511TS evaluation board will deliver the rated 3A output current if

VIN = 2.5V, VOUT = 1.8V, and TA ≤ 25°C.

Figure 3. Maximum Power Dissipation vs. Ambient Temperature

~2.50V

~2.25V

VIN

~1.55V

~1.25V

Load

Transient

Power-Up

NOM

~90%

~85%

Line

Transient

Power-Down

VOUT

1.80V

VERROR

Figure 4. ERROR Flag when Pull-Up is from VOUT

SNVA265A – November 2007 – Revised April 2013

Submit Documentation Feedback

AN-1675 LP38511TS-1.8 Evaluation Board

Copyright © 2007–2013, Texas Instruments Incorporated

3

�Connection Diagram

www.ti.com

~2.50V

~2.25V

VIN

~1.55V

~1.25V

Load

Transient

Power-Up

NOM

~90%

~85%

Line

Transient

Power-Down

VOUT

~2.50V

VERROR

~1.25V

Figure 5. ERROR Flag when Pull-Up is from VIN

7

Connection Diagram

IN 2

GND 3

OUT 4

ERROR 5

8

TAB

IS

GND

LP38511TS-1.8

EN 1

Schematic Diagram

TP1

VIN

VERROR

TP5 TP3 TP4

VERR GND VOUT

TP2

VEN

J5

R2

10 k:

VIN

J2

IN (2)

C1

10 PF

Ceramic

R1

10 k:

VEN

GND

VOUT

C2

10 PF

Ceramic

LP38511TS-1.8

EN (1)

J1

J4

(4) OUT

(5) ERROR

GND (3)

J3

Figure 6. Evaluation Board Schematic

4

AN-1675 LP38511TS-1.8 Evaluation Board

SNVA265A – November 2007 – Revised April 2013

Submit Documentation Feedback

Copyright © 2007–2013, Texas Instruments Incorporated

�PCB Layout

www.ti.com

9

PCB Layout

Figure 7. Evaluation Board Component and Pin Layout

10

Bill of Materials

ID

Name

Description

Manufacturer

Part Number

U1

U1

LP38511

Texas Instruments

LP38511TS-1.8 NOPB

C1

CIN

10 µF, 10%, MLCC, 10V, X7R, 1210

AVX

1210ZC106KAT2A

C2

COUT

10 µF, 10%, MLCC, 10V, X7R, 1210

AXV

1210ZC106KAT2A

J1

VEN

Banana Jack : Insulated Solder

Terminal ; White

108–0901–001

J2

VIN

Banana Jack : Insulated Solder

Terminal ; Red

108–0902–001

J3

GND

Banana Jack : Insulated Solder

Terminal ; Black

J4

VOUT

Banana Jack : Insulated Solder

Terminal ; Orange

108–0906–001

J5

VERR

Banana Jack : Insulated Solder

Terminal ; Blue

108–0910–001

R1

—

Resistor: 10 kΩ ±1%; 0805

Vishay Dale

CRCW 0805 1002 F

R2

—

Resistor: 10 kΩ ±1%; 0805

Vishay Dale

CRCW 0805 1002 F

R3

—

Not Installed

N/A

N/A

TP1

TPEN

Turret Terminal :

Mounting Hole Diameter = 0.062”

Keystone

1593-2

TP2

TPIN

TP3

TPGND

TP4

TPOUT

TP5

TPBIAS

SNVA265A – November 2007 – Revised April 2013

Submit Documentation Feedback

Johnson Components

108–0903–001

AN-1675 LP38511TS-1.8 Evaluation Board

Copyright © 2007–2013, Texas Instruments Incorporated

5

�Bill of Materials

6

www.ti.com

AN-1675 LP38511TS-1.8 Evaluation Board

SNVA265A – November 2007 – Revised April 2013

Submit Documentation Feedback

Copyright © 2007–2013, Texas Instruments Incorporated

�IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products

Applications

Audio

www.ti.com/audio

Automotive and Transportation

www.ti.com/automotive

Amplifiers

amplifier.ti.com

Communications and Telecom

www.ti.com/communications

Data Converters

dataconverter.ti.com

Computers and Peripherals

www.ti.com/computers

DLP® Products

www.dlp.com

Consumer Electronics

www.ti.com/consumer-apps

DSP

dsp.ti.com

Energy and Lighting

www.ti.com/energy

Clocks and Timers

www.ti.com/clocks

Industrial

www.ti.com/industrial

Interface

interface.ti.com

Medical

www.ti.com/medical

Logic

logic.ti.com

Security

www.ti.com/security

Power Mgmt

power.ti.com

Space, Avionics and Defense

www.ti.com/space-avionics-defense

Microcontrollers

microcontroller.ti.com

Video and Imaging

www.ti.com/video

RFID

www.ti-rfid.com

OMAP Applications Processors

www.ti.com/omap

TI E2E Community

e2e.ti.com

Wireless Connectivity

www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

�