Sample &

Buy

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

LP5560 Programmable Single-LED Driver With Simple Single-Wire Control

and Small Solution Size

1 Features

3 Description

•

•

•

The LP5560 is a programmable LED driver that can

generate variety of blinking sequences with up to

three pulses of different length per sequence. Blinking

sequences can be programmed through a single-wire

interface. Programmable parameters include on and

off times as well as rise and fall times. Default

sequence is programmed into the LP5560 to enable

the use of device in simple systems without

programming capabilities.

1

•

•

•

•

•

Wide Input-Voltage Range: 2.7 V to 5.5 V

Adjustable Output Current: 2.8 mA to 19.5 mA

Programmable Blinking Sequence with Current

Rise and Fall Time Control

Default Blinking Sequence for Simple Systems

Without Programming Capabilities

Single-Wire Interface

Constant Current High Side Output Driver

Very Low Headroom Voltage (40 mV Typical)

Ultra-Small Solution Size – No External

Components

Very low headroom voltage eliminates the need for a

boost converter. Indicator LEDs can be driven directly

from the battery. Small package size combined with

zero external components minimizes the solution

size.

2 Applications

•

•

•

•

•

•

Indicator LEDs in Cell Phones and Other Portable

Devices

Card Readers

Fuel Dispensers

Pedometers

Electronic Access Control

Where Simple Feedback is Needed

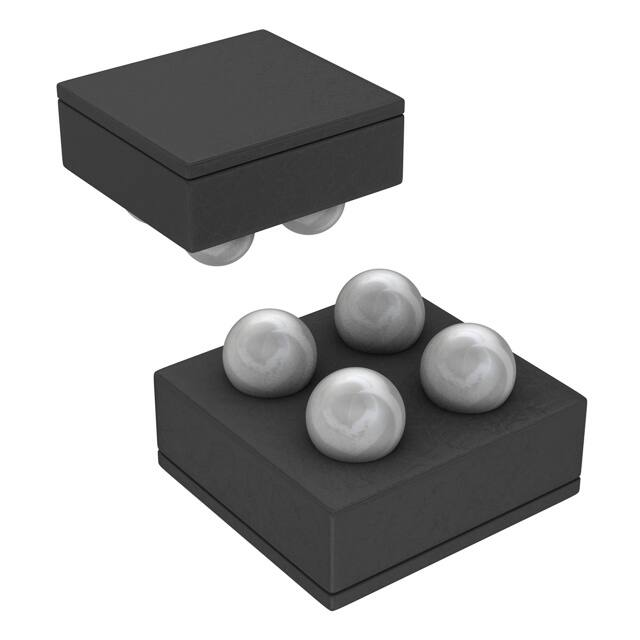

LP5560 is available in TI’s tiny 4-pin DSBGA package

with 0.4-mm pitch.

Device Information(1)

PART NUMBER

LP5560

PACKAGE

DSBGA (4)

BODY SIZE (NOM)

0.886 mm × 0.886 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application

VDD

LED

+

-

LP5560

CTRL

GND

Copyright © 2016, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

6.7

4

4

4

5

5

6

7

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Single-Wire Interface Timing Requirements .............

Typical Characteristics ..............................................

Detailed Description .............................................. 8

7.1

7.2

7.3

7.4

Overview ................................................................... 8

Functional Block Diagram ......................................... 8

Feature Description................................................... 9

Device Functional Modes........................................ 17

7.5 Programming .......................................................... 18

7.6 Registers ................................................................. 18

8

Application and Implementation ........................ 19

8.1 Application Information............................................ 19

8.2 Typical Application ................................................. 19

9 Power Supply Recommendations...................... 22

10 Layout................................................................... 22

10.1 Layout Guidelines ................................................. 22

10.2 Layout Example .................................................... 22

11 Device and Documentation Support ................. 23

11.1

11.2

11.3

11.4

11.5

11.6

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

23

23

23

23

23

23

12 Mechanical, Packaging, and Orderable

Information ........................................................... 23

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision D (June 2016) to Revision E

•

Page

Changed title of data sheet ................................................................................................................................................... 1

Changes from Revision C (May 2013) to Revision D

Page

•

Added additional Applications, Device Information and Pin Configuration and Functions sections, ESD Ratings and

Thermal Information tables, Feature Description, Device Functional Modes, Application and Implementation, Power

Supply Recommendations, Layout, Device and Documentation Support, and Mechanical, Packaging, and Orderable

Information sections................................................................................................................................................................ 1

•

Changed RθJA value from "120°C/W" to "184.3°C/W"; added additional thermal values ....................................................... 5

Changes from Revision B (April 2013) to Revision C

•

2

Page

Changed layout of National Data Sheet to TI format ........................................................................................................... 18

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

5 Pin Configuration and Functions

YFQ Package

4-Pin DSBGA

Top View

A

VDD

LED

B

GND

CTRL

1

2

Pin Functions

PIN

TYPE (1)

DESCRIPTION

NO.

NAME

A1

VDD

P

Power supply pin

A2

LED

A

Current source output

B1

GND

G

Ground

B2

CTRL

DI

Single-wire interface input

(1)

A: Analog Pin D: Digital Pin G: Ground Pin P: Power Pin I: Input Pin

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

3

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1) (2) (3)

MIN

MAX

UNIT

Voltage on VDD pin

−0.3

6

V

Voltage on other pins (CTRL,LED) (4)

−0.3

VDD + 0.3 V with

6 V maximum

V

Continuous power dissipation (5)

Internally Limited

Junction temperature, TJ-MAX

−65

Storage temperature, Tstg

(1)

(2)

(3)

(4)

(5)

125

°C

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltages are with respect to the potential at the GND pins.

If Military/Aerospace specified devices are required, contact the Texas Instruments Sales Office/ Distributors for availability and

specifications. Voltage

Undervoltage lockout (UVLO) shuts down the LED driver with VIN drops to 2.3 V (typical). Power-on reset (POR) trips at VIN = 2 V

(typical).

Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 160°C (typical) and

disengages at TJ=140°C (typical).

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic

discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

(1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22-C101 (2)

±1000

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted) (1) (2)

MIN

Voltage on power pin (VDD)

NOM

MAX

UNIT

2.7

5.5

V

Junction temperature, TJ

−30

125

°C

Ambient temperature, TA (1)

−30

85

°C

(1)

(2)

4

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be derated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP =

125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to ambient thermal resistance of the

part/package in the application (RθJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (RθJA × PD-MAX).

All voltages are with respect to the potential at the GND pin.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

6.4 Thermal Information

LP5560

THERMAL METRIC (1)

YFQ (DSBGA)

UNIT

4 PINS

RθJA

Junction-to-ambient thermal resistance

RθJC(top)

Junction-to-case (top) thermal resistance

RθJB

Junction-to-board thermal resistance

ψJT

Junction-to-top characterization parameter

ψJB

Junction-to-board characterization parameter

(1)

184.3

°C/W

1.8

°C/W

103.2

°C/W

9.1

°C/W

103.1

°C/W

For more information about traditional and new thermal metrics, see Semiconductor and IC Package Thermal Metrics.

6.5 Electrical Characteristics

Unless otherwise specified: VIN = 3.6 V, CTRL = 3.6 V, VLED = 3.1 V; typical limits are for TA = 25°C, and minimum and

maximum limits apply over the operating ambient temperature range (−30°C < TA < +85°C). (1) (2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

ISD

Shutdown supply current

CTRL = 0 V

0.4

0.75

IQ

Quiescent supply current

ILED = 0 mA

25

30

ILED

LED output current

ISET = 0

2.26

2.8

3.34

ISET = 1 (default)

4.61

5.3

5.99

ISET = 2

6.78

7.8

8.82

ISET = 3

8.87

10.2

11.53

ISET = 4

10.96

12.6

14.24

ISET = 5

13.5

15.0

16.5

ISET = 6

15.05

17.3

19.55

ISET = 7

16.96

19.5

22.04

2.7 V ≤ VIN ≤ 4.5 V

ΔILED%/ΔVIN

Line regulation

ΔILED%/ΔVLED (3)

Load regulation

VHR

Headroom voltage (4)

VIH

Logic input high level

VIN = 2.7 V to 5.5 V

VIL

Logic input low level

VIN = 2.7 V to 5.5 V

ICTRL

CTRL pin leakage current

CTRL = 1.8 V

T_cycle_H

LED On time

T_cycle_L

LED OFF time

IDX = 5.3 mA, Vƒ = 2.5 V

(6)

Trise

LED current rise time

Tfall

LED current fall time (6)

Fade resolution

Rise/fall time resolution

(1)

(2)

(3)

(4)

(5)

(6)

–3%

3%

1.7 V ≤ VLED ≤ 3.4 V, ILED = 5.3 mA

0.6

ILED = 5.3 mA

40

ILED = 19.5 mA

40

Adjustable (5), TA = 25°C

See (5)

UNIT

µA

mA

%/1V

100

1.1

mV

V

0.6

V

400

nA

13.2

3009.6

ms

26.4

6019.2

ms

0

1584

ms

0

1584

ms

105.6

ms

All voltages are with respect to the potential at the GND pins.

Minimum and Maximum limits are specified by design, test, or statistical analysis. Typical numbers are not ensured, but do represent the

most likely norm.

ILED = LED output current, VLED = LED forward voltage.

For LED output pin, headroom voltage is defined as the voltage across the internal current source when the LED current has dropped

10% from the value measured at VIN – 0.5 V. If headroom voltage requirement is not met, LED current regulation is compromised.

Specified by design.

LED current ramp-up and ramp-down uses a combined PWM-current adjustment.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

5

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

6.6 Single-Wire Interface Timing Requirements

See

(1) (2)

and Figure 1

MIN

MAX

UNIT

TC_ON

Command pulse on time

15

µs

TC_OFF

Command pulse off time

30

µs

TT_ON

Minimum training pulse on time (3)

200

µs

TT_OFF

Minimum training pulse off time (4)

200

µs

TCAL

Calibration pulse length

0.35

T ENTER

Command entering period

500

T ENTER+T BLANK

Command entering period + Blank period

(1)

(2)

(3)

(4)

8

ms

µs

1500

µs

Specified by design.

Minimum and Maximum limits are specified by design, test, or statistical analysis. Typical numbers are not ensured, but do represent the

most likely norm.

All CTRL signal high times between calibration pulse and training end are considered as training pulse on times.

All CTRL signal low times between calibration pulse and training end are considered as training pulse off times.

TC_ON

TCAL

CTRL

TT_OFF

C

TC_OFF

TENTER

I

R1

TT_ON

TBLANK

TENTER

Figure 1. Interface Timing

6

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

6.7 Typical Characteristics

TJ = 25°C. Unless otherwise noted, typical characteristics apply to the Functional Block Diagram with: VIN = 3.6 V, RISET =

24 kΩ, CIN = 100 nF.

50

QUIESCENT CURRENT ( A)

SHUTDOWN CURRENT ( A)

1.0

0.8

0.6

+25°C

+85°C

0.4

-30°C

0.2

0.0

45

40

30

3.0

3.5 4.0 4.5 5.0

INPUT VOLTAGE (V)

5.5

6.0

+25°C

20

15

10

5

2.5

Figure 2. Standby Current vs VIN

3.0

3.5 4.0 4.5 5.0 5.5

INPUT VOLTAGE (V)

6.0

Figure 3. Quiescent Current vs VIN

6.6

23

6.3

22

6.0

5.7

+85°C

LED CURRENT (mA)

LED CURRENT (mA)

+85°C

25

0

2.5

5.4

5.1

-30°C

4.8

+25°C

4.5

4.2

3.6

2.5

21

+85°C

20

19

-30°C

18

+25°C

17

16

3.9

15

3.0

3.5 4.0 4.5 5.0 5.5

INPUT VOLTAGE (V)

6.0

2.5

5 mA

3.0

3.5 4.0 4.5 5.0 5.5

INPUT VOLTAGE (V)

6.0

20 mA

Figure 4. LED Current vs Input Voltage

Figure 5. LED Current vs Input Voltage

25.0

7

22.5

LED CURRENT (mA)

6

LED CURRENT (mA)

-30°C

35

5

4

3

2

20.0

17.5

15.0

12.5

10.0

7.5

5.0

1

2.5

0.0

0

0.0

0.1

0.2

0.3

0.4

HEADROOM VOLTAGE (V)

0.5

5 mA

0.0

0.1

0.2

0.3

0.4

HEADROOM VOLTAGE (V)

0.5

20 mA

Figure 6. IOUT vs Headroom Voltage

Figure 7. IOUT vs Headroom Voltage

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

7

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

7 Detailed Description

7.1 Overview

The LP5560 is a programmable LED driver with a single-wire interface. It is designed to drive a single indicator

LED with different blinking sequences. Up to three pulses with different on and off times can be programmed into

the device. LED current rise and fall times can also be independently controlled. Blinking sequence is stored into

volatile memory, thus removing input voltage VIN resets the memory into default state.

The high-side LED driver has very low headroom voltage requirement and can drive most indicator LEDs directly

from battery voltage. A single CTRL pin is used to control the device on and off and to change settings of the

device. A default blinking sequence is programmed into the LP5560 to enable use of the devices in simply

applications without programming capabilities.

7.2 Functional Block Diagram

VDD

POR

CTRL

UVLO

State Machine

LED CONTROL

Single-Wire

Interface

Volatile

Program Memory

OSCILLATOR

IBIAS

BANDGAP

TSD

LED

Default Sequence

GND

Copyright © 2016, Texas Instruments Incorporated

8

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

7.3 Feature Description

7.3.1 LED Driver Headroom Voltage

The current source is connected internally between the VDD and LED output pins. The voltage across the

current source, (VVDD − VLED), is referred as headroom voltage (VHR). The current source requires a sufficient

amount of headroom voltage to be present across it in order to regulate the output current properly. The LP5560

headroom voltage requirement is 40 mV (typical) and does not depend on the current setting.

7.3.2 Single-Wire Interface

The LP5560 has one digital control input (CTRL). Threshold levels of CTRL input are fixed to support control

from low-voltage controller. The CTRL signal is used to control the mode of the circuit. The rising edge of the

CTRL signal activates the circuit and starts a command entering period. During the command entering period all

rising edges are counted. After command entering period there is a blank period when no rising edges are

allowed. If there are any rising edges during blank period these are not detected. User must take care not to start

the training sequence before blank period has elapsed or the training sequence is corrupted.

If CTRL is left high after command entering period, the consequent command is performed right after the blank

period. In case of run once command CTRL pin can be set low after the command entering period and execution

of the command starts once CTRL pin is pulled high after blank period.

CTRL

LED

Command

entering

period

Blank

period

Command

execution

starts

Figure 8. Single-Wire Interface

The LP5560 has four different commands. Command depends on the number of rising edges during command

entering period. If there are more than 4 rising edges during command entering period command is ignored. Note

that even in this case blank period needs to elapse before next command can be given.

Table 1. LP5560 Commands

COMMAND

NUMBER OF RISING EDGES DURING COMMAND

ENTERING PERIOD

Run

1

Training start

2

Training end

3

Run once

4

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

9

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

7.3.2.1 Run Command

One rising edge of the CTRL signal within command entering period is interpreted as a run command. The CTRL

pin must be kept high during blank period. If the CTRL pin is pulled low during command entering period or blank

period device goes to stand by. In run mode (mode bit = 1) blinking sequence is started right after Blank period

and it is repeated as long as CTRL signal is kept high. When the CTRL signal is set low device goes into standby

mode (Figure 9).

CTRL

To Standby

LED

Command

entering

period

Blank

period

Programmed

sequence

Figure 9. Run Mode

In follow mode (mode bit = 0) LED is turned on right after a blank period, and it stays on as long as CTRL is kept

high. When CTRL signal is set low LED is turned off and device goes into standby mode (Figure 10).

CTRL

To Standby

LED

Command

entering

period

Blank

period

Figure 10. Follow Mode

7.3.2.2 Training Start Command

Two rising edges of CTRL signal within command entering period is interpreted as training start command.

Training start command starts training sequence. Different blinking sequences can be trained into device in

training mode. Training mode is described in more details in Training Mode.

7.3.2.3 Training End Command

Three rising edges of CTRL signal within command entering period is interpreted as training end command.

Training end is used to stop the training sequence.

7.3.2.4 Run-Once Command

Four rising edges of the CTRL signal within command entering period is interpreted as a run-once command.

Programmed blinking sequence is performed once after a run-once command. If CTRL is kept high after

command entering period the programmed blinking sequence starts right after the blank period has elapsed

(Figure 11). The CTRL signal must stay high as long as programmed blinking sequence is executed. If CTRL is

set low during execution of blinking sequence, device goes to standby and execution of blinking sequence is

stopped.

10

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

CTRL

To Standby

Programmed

sequence

LED

Command

entering

period

Blank

period

Figure 11. Run-Once Command

If CTRL signal is low after command entering period, blinking sequence is executed once the CTRL is set high

(Figure 12).

CTRL

To Standby

Programmed

sequence

LED

Command

entering

period

Blank

period

Figure 12. Delayed Run-Once Command

If device is in follow mode (mode bit is 0) the run-once command turns the LED on, and it is kept on as long as

CTRL is held high.

7.3.3 Training Mode

Figure 17 shows an example of a full training sequence with three pulses. Training mode starts with a training

start command. Training start command is followed by blank time during which no rising edges are allowed.

Blank time is followed by calibration pulse. Calibration pulse length (TCAL) defines the speed of the training

sequence and can vary from 350 µs to 8 ms. During parameter settings register values are incremented at speed

defined by TCAL. For example, if calibration pulse length is 1 ms and current setting pulse length is 3.3 ms, the

current-setting value is 3 (current-set register is incremented 3 times). If the parameter-setting pulse is shorter

than the calibration pulse, then the corresponding parameter is set to 0.

The next rising edge after calibration pulse starts LED driver current setting (I). LED driver current is recorded

once CTRL is pulled low. Note that there are empty low times before and after current setting pulse. For the

following pulses both CTRL high and CTRL low times are used to set the parameters. Next the CTRL high time

defines the LED current rise time setting for pulse 1 (R1). When R1 setting is started mode bit is set to 0. This

sets the LP5560 device into follow mode. Mode bit is set to 1 after first off time has been saved into register. This

means that at least one full pulse must be trained into memory to set the device into run mode.

CTRL low time after R1 defines the LED on time for pulse 1 (ON1). CTRL high time after ON1 sets the LED

current fall time (F1). CTRL low time after F1 sets pulse 1 off time (OFF1). Once rising edge of CTRL is detected

after first off time setting mode bit is set to 1 (run mode) and the number of pulses register (NOP[1:0]) is set to 1.

This indicates that one full pulse has been trained into memory.

Rise, on, fall, and off times for pulse 2 and 3 are set the same way as for pulse 1. Note that NOP register is

always incremented after OFFx time setting. This means that all pulse parameters (rise, on, fall, and off times)

must be trained for each pulse make it valid. The training sequence is ended with training end command.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

11

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

7.3.3.1 Ending the Training Sequence

A training end command can be given at any time of the training sequence except during blank time. Outcome of

the training sequence depends on the place of the training end command. If a training end command is given

after any of the off-time setting (OFF1, OFF2 or OFF3), mode bit is set to 1, and the corresponding number of

pulses are stored into memory. If a training end command is given after any of the other pulse parameters (Rx,

ONx or Fx) that pulse is ignored. For example, if training end command is given after ON2 pulse 2 is ignored and

blinking sequence includes only pulse 1.

7.3.3.2 Reset to Default

If a training end command is given right after a training start command, the LP5560 is reset back to factory

defaults (Figure 13). In this case the mode bit is set to 1 (run mode) with the factory-set default blinking

sequence.

Training start

command

Training

end

command

Blank period

CTRL

Figure 13. Reset to Default

7.3.3.3 Changing the LED Current

The LP5560 devices allows changing the LED output current without the need to reprogram the previously

programmed blinking sequence. This is done by giving the training end command after current setting

(Figure 14). In this case only the current setting changes. If a blinking sequence was programmed into the

LP5560 device it remains unchanged. If mode bit was 0 (follow mode) before the training sequence it remains 0.

Training

start

command

Training

end

command

Blank

Period

CTRL

C

I

Figure 14. Current Programming Sequence

7.3.3.4 Entering Follow Mode

Mode bit can be set to 0 (follow mode) in two ways. If training end command is given after calibration pulse mode

bit is set to 0 (follow mode) and the previously set LED output current setting remains unchanged (Figure 15).

Training

start

command

CTRL

Training

end

command

Blank

Period

C

Figure 15. Entering Follow Mode

If training end command is given after R1, ON1 or F1 mode bit is set to 0 (follow mode) and new current setting

is stored to current register (Figure 16). If a training end command is given after F1 CTRL low time before

training end command needs to be less than minimum training pulse off time (200 µs). Otherwise off time OFF1

is set to minimum value, and pulse 1 is stored into memory.

12

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

Training

Blank

start

period

command

CTRL

Training

end

command

C

I

R1

Figure 16. Entering Follow Mode With New Current Setting

7.3.3.5 Timeout

If during training CTRL stays constant for more than 127 × TCAL time this is interpreted as timeout. For example,

if calibration pulse length TCAL is 1 ms, timeout time is 127 ms. Timeout ends the training sequence. Timeout is

considered as a false training, and it is a good practice to always give a complete training sequence after timeout

to ensure correct data is stored into memory.

Training

Blank

start

period

command

CTRL

Training

end

command

C

R1 ON1 F1 OFF1 R2

I

ON2

F2

OFF2

R3

ON3

F3

OFF3

Figure 17. Full Training Sequence

7.3.4 LED Output Current Setting

The LED output current can be set from 2.8 mA to 19.5 mA in 7 steps. Duration of the current setting pulse (I)

defines the current setting.

Table 2. LED Current Setting

CURRENT SETTING

LED CURRENT (mA)

0

2.8

1

5.3 default

2

7.8

3

10.2

4

12.6

5

15.0

6

17.3

7

19.5

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

13

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

7.3.5 Rise and Fall Time Settings

Rise and fall times of each pulse can be programmed independently. Rise and fall time can be set from 0 to

1584 ms with 105.6 ms steps. Rise and fall times are generated using a combined PWM and current control.

Ramp has 32 PWM steps. For the first 8 steps LED current is decreased to 12.5%. For the remaining steps

current is set to 100%. Each step is 3.3 ms long. This results in the minimum ramp time of 3.3 ms × 32 = 105.6

ms. When ramp time is increased each PWM step is done multiple times. When setting rise and fall times they

are always rounded down. For example if calibration pulse length is 1 ms and rise time setting pulse is 2.9 ms

rise time is set to 2 which is 211.2 ms. Rise and fall times can be set to zero by giving pulse that is shorter than

calibration pulse.

Table 3. Rise and Fall Time Settings

RAMP SETTING

14

RAMP TIME (ms)

0

0

1

105.6

2

211.2

3

316.8

4

422.4

5

528 default

6

633.6

7

739.2

8

844.8

9

950.4

10

1056

11

1161.6

12

1267.2

13

1372.8

14

1478.4

15

1584

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

7.3.6 LED ON-Time Setting

LED on time has 5-bit control. On time can be controlled from 13.2 ms to 3009.6 ms in 31 steps. Step size is not

constant to increase resolution on shorter ON times. With longer on times also the step size is increased. Table 4

shows the available on times.

Table 4. LED ON-Time Setting

SETTING

LED ON TIME (ms)

0

13.2

1

26.4

2

52.8

3

105.6

4

158.4

5

211.2

6

264

7

316.8

8

369.6

9

435.6

10

501.6 default

11

594

12

699.6

13

805.2

14

910.8

15

1016.4

16

1122

17

1227.6

18

1353

19

1478.4

20

1603.8

21

1729.2

22

1854.6

23

1980

24

2105.4

25

2230.8

26

2356.2

27

2481.6

28

2613.6

29

2745.6

30

2877.6

31

3009.6

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

15

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

7.3.7 LED OFF-Time Setting

LED off time has also 5-bit control. Off time can be controlled from 26.4 ms to 6019.2 ms in 31 steps. Off time is

always twice as long as on time with same setting.

Table 5. LED OFF-Time Setting

16

SETTING

LED OFF TIME (ms)

0

26.4

1

52.8

2

105.6

3

211.2

4

316.8

5

422.4

6

528

7

633.6

8

739.2

9

871.2

10

1003.2

11

1188

12

1399.2

13

1610.4 default

14

1821.6

15

2032.8

16

2244

17

2455.2

18

2706

19

2956.8

20

3207.6

21

3458.4

22

3709.2

23

3960

24

4210.8

25

4461.6

26

4712.4

27

4963.2

28

5227.2

29

5491.2

30

5755.2

31

6019.2

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

7.4 Device Functional Modes

POWER-ON RESET When input voltage is applied to VDD pin device goes through power on reset (POR).

During POR defaults are set into control registers.

STANDBY: After POR device goes to standby. This is the low power mode when all the internal blocks are shut

down.

COMMAND ENTERING PERIOD + BLANK PERIOD: Rising edge of the CTRL signal activates the circuit and

starts a command entering period. During the command entering period all rising edges are

counted. After command entering period there is a blank period when no rising edges are allowed.

RUN:

If mode bit is 1 (run mode) and run command has been detected device goes into run mode. In run

mode LP5560 generates the programmed blinking sequence.

FOLLOW MODE: If mode bit is 0 (follow mode) and run command or run once command has been detected

LP5560 goes into follow mode. In follow mode LED stays on as long as CTRL pin is held high.

RUN-ONCE MODE: If run once command has been detected and mode bit is 1 (run mode) device goes into

run-once mode. In run-once mode LP5560 generates the programmed blinking sequence once.

CTRL must be high as long as blinking sequence is running.

TRAINING: If training start command has been detected device goes into training mode. In training mode a

new blinking sequence can be programmed into the device.

Power On Reset

Stand By

Rising edge at CTRL

CTRL = LOW

CTRL = LOW

Run Mode

Follow Mode

Training end

or timeout

Command

entering

period

+

Blank period

CTRL = LOW

Training

Start

Command

Run

Command,

Mode = 1

Run Command

or Run Once

Command,

Mode = 0

CTRL = High

Mode = 0

Run Once

Command,

CTRL = low,

Wait for CTRL

Run Once

Command,

CTRL = High,

Mode = 1

Training Mode

Run Once Mode

CTRL = High

Mode = 1

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

17

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

7.5 Programming

7.5.1 Default Sequence

Default blinking sequence is programmed into the LP5560 to enable the use of a device in simple systems

without programming capabilities. Default sequence has a single pulse with parameters as follows:

I = 5.3 mA; R1 = 528 ms; ON1 = 501.6 ms; F1 = 528; OFF1 = 1610.4 ms

7.6 Registers

7.6.1 Control Registers

Control registers are shown only for a reference. There is no direct way to write or read these registers. Register

values are set in the training mode as described earlier in the document.

Table 6. Control Registers

7

6

MODE

18

5

4

3

2

1

F1[3:0]

R1[3:0]

F2[3:0]

R2[3:0]

F3[3:0]

R3[3:0]

NOP[1:0]

0

ON1[4:0]

I_LED[2:0]

OFF1[4:0]

n/a

ON2[4:0]

n/a

OFF2[4:0]

n/a

ON3[4:0]

n/a

OFF3[4:0]

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LP5560 is a programmable LED driver designed to generate variety of blinking sequences for indicator

LEDs. It can drive single LED with up to 19.5 mA output current. Very low headroom voltage allows driving most

indicator LEDs straight from a single Li-ion battery. Default blinking sequence with one pulse is programmed into

the LP5560 to enable the use of device in simple systems without programming capabilities. Pulling CTRL signal

high starts the default blinking sequence. Different blinking sequences with up to three pulses can be

programmed into the LP5560 through a single-wire interface. Programmable parameters include on and off times

as well as rise and fall times.

8.2 Typical Application

A1

VIN = 2.7 V to 5.5 V

VDD

LED

A2

ILED = 2.8 mA to 19.5 mA

LP5560

CTRL

B2

CTRL

GND

B1

Copyright © 2016, Texas Instruments Incorporated

Figure 18. LP5560 Typical Application

8.2.1 Design Requirements

In this example LP5560 is used to drive a blue 0406-size indicator LED with a 5.3-mA output current. For this

example, use the parameters listed in Table 7.

Table 7. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

LED Output Current

5.3 mA

Maximum LED forward voltage at 5 mA

3.1 V

VIN voltage

from 3.2 V to 5.5 V

8.2.2 Detailed Design Procedure

8.2.2.1 Step-by-Step Design Procedure

To design in the LP5560 use the following simple design steps:

• Define the input voltage range of the system. For the LP5560 device the maximum input voltage must not

exceed 5.5 V. The minimum input voltage is critical parameter for LED selection.

• Define the LED current. LED current affects the LED forward voltage and must be taken into account when

selecting the LED for the application.

• Choose a LED which maximum forward voltage with desired LED current is less than minimum input voltage 100 mV. This ensures that there is always enough headroom voltage available for the LED driver.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

19

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

8.2.2.2 Running the Default Blinking Sequence

To run the default blinking sequence apply input voltage to VDD pin. Allow the VDD voltage settle before pulling

the CTRL pin high. It is not recommended to connect the CTRL and VDD lines together. When CTRL line is

pulled high the LP5560 starts to generate the default blinking sequence. Figure 19 shows the LP5560 generating

default sequence. Rise and fall times are generated using a combined PWM and current control. Ramp has 32

PWM steps. For the first 8 steps LED current is decreased to 12.5%. For the remaining steps current is set to

100%. Each step is 3.3 ms long. This result’s the minimum ramp time of 3.3 ms × 32 = 105.6 ms. Figure 22

shows LED current with minimum rise time. When ramp time is increased each PWM step is done multiple times.

In the default sequence rise and fall times are set to 528 ms.

8.2.2.3 Programming New Blinking Sequence to the Memory

Figure 22 shows an example of a training sequence which programs a new blinking sequence into the LP5560

memory. This example has a single pulse with 105.6 ms rise time, 105.6 ms on time, 105.6 ms fall time and

211.2 ms off time. LED current is set to 5.3 mA. Training sequence is started by giving a training start command

(two rising edges within 500 µs). First pulse after a training start command is the calibration pulse which

determines the speed of the training sequence. Note that there must always be at least 1500 µs from the first

rising edge of the training start command before calibration pulse can be given. Second pulse after the

calibration pulse is the LED current setting. Note that there are empty low times before and after current setting

pulse. For the following pulses both CTRL high and CTRL low times are used to set the parameters. Next CTRL

high time defines LED current rise time setting for pulse 1 (R1). CTRL low time after R1 defines the LED on time

for pulse 1 (ON1). CTRL high time after ON1 sets the LED current fall time (F1). CTRL low time after F1 sets

pulse 1 off time (OFF1). The training sequence is finished with a training stop command (three rising edges

within 500 µs). Figure 23 show the LED current after programming the new pulse into the LP5560 memory.

Figure 24 and Figure 25 show another example of a training sequence with three pulses and the resulting

blinking sequence. In this example all three pulses have different rise, on, fall, and off times. LED current is set to

10.2 mA. Figure 26 show how this sequence is run only once using the run-once command. Even though the

CTRL is held high for a long time the blinking sequence is only executed one time because a run-once command

(four rising edges within 500 µs) is given at the beginning of the frame.

8.2.3 Application Curves

Figure 19. Default Blinking Sequence

20

Submit Documentation Feedback

Figure 20. LED Rise Time Set to 105.6 ms

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

Figure 21. LED Rise Time Set to 0 ms

Figure 22. Example Training Sequence with One Pulse

Figure 23. Example Blinking Sequence with One Pulse

Figure 24. Example Training Sequence with Three Pulses

Figure 25. Example Blinking Sequence with Three Pulses

Figure 26. Run-Once Command

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

21

�LP5560

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

www.ti.com

9 Power Supply Recommendations

The LP5560 is designed to operate from an input voltage supply range between 2.7 V and 5.5 V. This input

supply must be well regulated. If the input voltage has high noise content TI recommends adding a dedicated

ceramic bypass capacitor close to the VDD and GND pins. Depending on the selected LED it may be necessary

to increase the minimum input voltage. The minimum input voltage must always be 100 mV higher than the LED

maximum forward voltage.

10 Layout

10.1 Layout Guidelines

•

•

•

•

Normally the LP5560 device does not require any external components except for the LED. However, in a

noisy environment a small 0.1-µF bypass capacitor can be connected between VIN and GND pins.

TI recommends routing the pins in a 45-degree angle to avoid component rotation during soldering process.

Use traces with similar width for all pins. This makes the exposed copper area similar for all pins and

improves the soldering reliability.

Obtain the minimum clearance and trace width from the manufacturer of the PCB used for the board.

10.2 Layout Example

VIA to VDD

Optional

bypass capacitor

VIA to GND

VDD

LED

GND

CTRL

0.1 F

To control

signal

VIA to

GND

Figure 27. LP5560 Layout Example

22

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

�LP5560

www.ti.com

SNVS873E – AUGUST 2012 – REVISED NOVEMBER 2016

11 Device and Documentation Support

11.1 Documentation Support

11.1.1 Related Documentation

For additional information, see the following:

AN-1112 DSBGA Wafer Level Chip Scale Package

11.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

11.4 Trademarks

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

11.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

11.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Documentation Feedback

Copyright © 2012–2016, Texas Instruments Incorporated

Product Folder Links: LP5560

23

�PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

(3)

Device Marking

(4/5)

(6)

LP5560TME/NOPB

ACTIVE

DSBGA

YFQ

4

250

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-30 to 85

LP5560TMX/NOPB

ACTIVE

DSBGA

YFQ

4

3000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-30 to 85

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of