Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

LP8867-Q1, LP8869-Q1 Low EMI Automotive LED Driver with 4-, 3- Channels

1 Features

2 Applications

•

•

1

•

•

•

•

AEC-Q100 Qualified for automotive applications:

– Device temperature grade 1:

–40°C to +125°C, TA

Functional safety capable

– Documentation available to aid functional

safety system design

3-, 4-Channel 120-mA current sinks

– High dimming ratio of 10 000:1 at 100 Hz

– Current matching 1% (typical)

– LED String current up to 120 mA per channel

– Outputs can be combined externally for higher

current per string

Integrated boost and SEPIC converter for LED

string power

– Input voltage operating range 4.5 V to 40 V

– Output voltage up to 45 V

– Integrated 3.3-A Switch FET

– Switching frequency 300 kHz to 2.2 MHz

– Switching synchronization input

– Spread spectrum for lower EMI

Fault detection and protection

– Fault output

– Input voltage OVP, UVLO and OCP

– Boost block SW OVP and output OVP

– LED open and short fault detection

– Power-Line FET control for battery bus

protection

– Automatic LED current reduction with external

temperature sensor

– Thermal shutdown

Simplified Schematic

VIN

4.5...40 V RISENSE

Q1

D1

L1

CIN BOOST

Backlight for:

– Automotive infotainment

– Automotive instrument clusters

– Smart mirrors

– Heads-up displays (HUD)

3 Description

The LP8867-Q1, LP8869-Q1 is an automotive highlyintegrated, low-EMI, easy-to-use LED driver with DCDC converter. The DC-DC converter supports both

boost and SEPIC mode operation. The device has

four or three high-precision current sinks that can be

combined for higher current capability.

The DC-DC converter has adaptive output voltage

control based on the LED forward voltages. This

feature minimizes the power consumption by

adjusting the voltage to the lowest sufficient level in

all conditions. For EMI reduction DC-DC supports

spread spectrum for switching frequency and an

external synchronization with dedicated pin. A widerange adjustable frequency allows the LP886x-Q1 to

avoid disturbance for sensitive frequency band.

The input voltage range for the LP886x-Q1 is from

4.5 V to 40 V to support automotive start-stop and

load dump condition. The LP886x-Q1 integrates

extensive fault detection features.

Device Information(1)

PART NUMBER

LP8867-Q1

LP8869-Q1

LED Backlight Efficiency

COUT

96

VL DO

CIN

CLDO

FB

CFB

Up to 120 mA/string

LDO

OUT1

LP8867-Q1

OUT2

RFSET

BRIGHTNESS

EN

FSET

OUT3

VLDO

SYNC

OUT4

R4

PWM

TSET

VDDIO/EN

FAULT

PGND

R3

R7

TSENSE

FAULT

R8

R1

System Efficiency (%)

SW

RTº

ISET

GND

PAD

R6

RISET

6.50 mm × 4.40 mm

100

RGS

SD

VSENSE_N

VIN

HTSSOP (20)

BODY SIZE (NOM)

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Up to 45 V

R2

PACKAGE

R5

92

88

84

80

76

VIN = 16V

VIN = 12V

VIN = 8V

VIN = 6V

72

68

80

160

240

320

Output Current (mA)

400

480

D000

NTC

VDDIO

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Device Comparison Table.....................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

3

5

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.10

7.11

7.12

5

5

5

6

6

6

6

7

7

7

7

9

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Internal LDO Electrical Characteristics .....................

Protection Electrical Characteristics .........................

Current Sinks Electrical Characteristics....................

PWM Brightness Control Electrical Characteristics ..

Boost and SEPIC Converter Characteristics ..........

Logic Interface Characteristics................................

Typical Characteristics ............................................

Detailed Description ............................................ 11

8.1

8.2

8.3

8.4

9

Overview .................................................................

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

11

12

13

25

Application and Implementation ........................ 27

9.1 Application Information............................................ 27

9.2 Typical Applications ................................................ 27

10 Power Supply Recommendations ..................... 32

11 Layout................................................................... 32

11.1 Layout Guidelines ................................................. 32

11.2 Layout Example .................................................... 33

12 Device and Documentation Support ................. 34

12.1

12.2

12.3

12.4

12.5

12.6

12.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

34

34

34

34

34

34

34

13 Mechanical, Packaging, and Orderable

Information ........................................................... 34

4 Revision History

Changes from Revision A (July 2019) to Revision B

•

Page

Added the functional safety link to the Features section........................................................................................................ 1

Changes from Original (June 2019) to Revision A

•

2

Page

Changed from Advance Information to Production Data ....................................................................................................... 1

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

5 Device Comparison Table

LP8869-Q1

LP8869C-Q1

LP8867-Q1

3

3

4

4

120 mA

120 mA

120 mA

120 mA

Yes

No

Yes

No

Number of LED channels

LED current / channel

Power Line FET Control and

Automatic Current De-rating Support

LP8867C-Q1

6 Pin Configuration and Functions

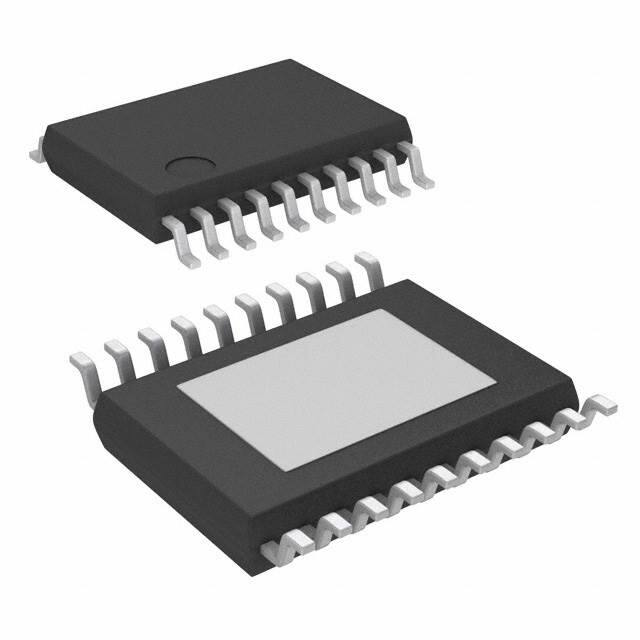

LP8867-Q1 PWP Package

20-Pin HTSSOP With Exposed Thermal Pad

Top View

VIN

1

20

VSENSE_N

LDO

2

19

SD

FSET

3

18

SW

VDDIO/EN

4

17

PGND

FAULT

5

16

FB

SYNC

6

15

OUT1

PWM

7

14

OUT2

TSENSE

8

13

OUT3

TSET

9

12

OUT4

11

GND

ISET

10

EP*

*EXPOSED PAD

LP8869-Q1 PWP Package

20-Pin HTSSOP With Exposed Thermal Pad

Top View

VIN

1

20

VSE NS E_N

LDO

2

19

SD

FSET

3

18

SW

VDDIO/EN

4

17

PGND

FAULT

5

16

FB

SYNC

6

15

OUT1

PWM

7

14

OUT2

TSENSE

8

13

OUT3

TSET

9

12

GND

ISET

10

11

GND

EP*

*EXP OSED PAD

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

3

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Pin Functions

PIN

NO.

NAME

TYPE (1)

DESCRIPTION

1

VIN

A

Input power pin; input voltage OVP detection pin; input current sense positive input pin.

2

LDO

A

Output of internal LDO; connect a 1-μF decoupling capacitor between this pin and noise-free ground.

Put the capacitor as close to the chip as possible.

3

FSET

A

DC-DC (boost or SEPIC) switching frequency setting resistor; for normal operation, resistor value

from 24 kΩ to 219 kΩ must be connected between this pin and ground.

4

VDDIO/EN

I

Enable input for the device as well as supply input (VDDIO) for digital pins.

5

FAULT

OD

6

SYNC

I

Input for synchronizing DC-DC converter. If synchronization is not used, connect this pin to ground to

disable spread spectrum or to VDDIO/EN to enable spread spectrum.

7

PWM

I

PWM dimming input.

8

TSENSE

A

Input for NTC resistor divider. Refer to LED Current Dimming With External Temperature Sensor for

proper connection. If unused, the pin must be left floating.

9

TSET

A

Input for NTC resistor divider. Refer to LED Current Dimming With External Temperature Sensor for

proper connection. If unused, the pin must be connected to GND.

10

ISET

A

LED current setting resistor; for normal operation, resistor value from 20 kΩ to 129 kΩ must be

connected between this pin and ground.

11

GND

G

Ground.

12

OUT4/GND

A

Current sink output for LP8867-Q1

This pin must be connected to ground if not used.

Fault signal output. If unused, the pin may be left floating.

GND pin for LP8869-Q1

13

OUT3

A

Current sink output.

This pin must be connected to ground if not used.

14

OUT2

A

Current sink output.

This pin must be connected to ground if not used.

15

OUT1

A

Current sink output.

This pin must be connected to ground if not used.

16

FB

A

DC-DC (boost or SEPIC) feedback input; for normal operation this pin must be connected to the

middle of a resistor divider between VOUT and ground using feedback resistor values greater than

5kΩ.

17

PGND

G

DC-DC (boost or SEPIC) power ground.

18

SW

A

DC-DC (boost or SEPIC) switch pin.

19

SD

A

Power-line FET control. Open Drain (current sink type) Output. If unused, the pin may be left floating.

20

VSENSE_N

A

Input current sense negative input. Connect to VIN pin when input current sense resistor is not used.

(1)

4

A: Analog pin, G: Ground pin, P: Power pin, I: Input pin, I/O: Input/Output pin, O: Output pin, OD: Open Drain pin

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1) (2)

Voltage on pins

MIN

MAX

VIN, VSENSE_N, SD, SW, FB

–0.3

50

OUT1, OUT2, OUT3, OUT4

–0.3

45

LDO, SYNC, FSET, ISET, TSENSE, TSET, PWM, VDDIO/EN, FAULT

–0.3

5.5

Continuous power dissipation (3)

UNIT

V

Internally Limited

Ambient temperature, TA (4)

–40

125

°C

Junction temperature, TJ (4)

–40

150

°C

Storage temperature, Tstg

–65

150

°C

(1)

(2)

(3)

(4)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltages are with respect to the potential at the GND pins.

Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 165°C (typical) and

disengages at TJ = 145°C (typical).

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be derated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP =

150°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to ambient thermal resistance of the

part/package in the application (RθJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (RθJA × PD-MAX).

7.2 ESD Ratings

VALUE

Human-body model (HBM), per AEC Q100-002, all pins

V(ESD)

(1)

Electrostatic discharge

Charged-device model (CDM), per AEC

Q100-011

(1)

UNIT

±2000

Corner pins (1, 10, 11 and 20)

±750

All pins

±500

V

AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

7.3 Recommended Operating Conditions

Over operating free-air temperature range (unless otherwise noted) (1)

VIN

Voltage on

pins

(1)

MIN

NOM

MAX

4.5

12

45

SW, VSENSE_N, SD

0

OUT1, OUT2, OUT3, OUT4

0

40

FB, FSET, LDO, ISET, TSENSE, TSET, VDDIO/EN, FAULT

0

5.25

SYNC, PWM

0

VDDIO/EN

UNIT

45

V

All voltages are with respect to the potential at the GND pins.

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

5

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

7.4 Thermal Information

LP886x-Q1

THERMAL METRIC (1)

PWP (HTSSOP)

UNIT

20 PINS

RθJA

Junction-to-ambient thermal resistance (2)

44.2

°C/W

RθJCtop

Junction-to-case (top) thermal resistance

26.5

°C/W

RθJB

Junction-to-board thermal resistance

22.4

°C/W

ψJT

Junction-to-top characterization parameter

0.9

°C/W

ψJB

Junction-to-board characterization parameter

22.2

°C/W

RθJCbot

Junction-to-case (bottom) thermal resistance

2.5

°C/W

(1)

(2)

For more information about traditional and new thermal metrics, see Semiconductor and IC Package Thermal Metrics.

Junction-to-ambient thermal resistance is highly application and board-layout dependent. In applications where high maximum power

dissipation exists, special care must be paid to thermal dissipation issues in board design.

7.5 Electrical Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

IQ

TEST CONDITIONS

MIN

Standby supply current

Device disabled, VVDDIO/EN = 0 V, VIN = 12 V

Active supply current

VIN = 12 V, VOUT = 26 V, output current 80

mA/channel, converter ƒSW = 300 kHz

TYP

MAX

4.5

20

UNIT

μA

5

12

mA

7.6 Internal LDO Electrical Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

VLDO

Output voltage

VDR

Dropout voltage

ISHORT

Short circuit current

IEXT

Current for external load

TEST CONDITIONS

VIN = 12 V

MIN

TYP

MAX

4.15

4.3

4.55

V

120

300

430

mV

50

UNIT

mA

5

mA

7.7 Protection Electrical Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

MIN

TYP

MAX

41

42

44

V

VOCP

VIN OCP threshold voltage, VIN VSENSEN

135

160

186

mV

VUVLO

VIN UVLO Falling threshold

3.7

3.85

4

VUVLO_HYST

VIN UVLO Rising threshold - VIN UVLO

Fallling threshold

ISENSE_N

VSENSE_N pin leakage

VSENSE_N = 45V, EN = L

0.1

3

µA

ISD_LEAK

SD pin leakage

VSD = 45V, EN = L

0.1

3

µA

ISD

SD pull down current

230

283

µA

VFB_OVP

FB threshold for BST_OVP fault

TTSD

Thermal shutdown Rising threshold

175

℃

TTSD_HYS

Thermal shutdown Rising threshold Thermal shutdown Falling threshold

VOVP

VIN OVP threshold voltage

6

Submit Documentation Feedback

TEST CONDITIONS

150

185

165

20

V

mV

2.3

150

UNIT

V

℃

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

7.8 Current Sinks Electrical Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

TYP

MAX

ILEAKAGE

Leakage current

PARAMETER

Outputs OUT1 to OUT4 , VOUTx = 45 V, EN = L

0.1

5

IMAX

Maximum current

OUT1, OUT2, OUT3, OUT4, RISET = 20 kΩ

120

IOUT

Output current accuracy

IOUT = 100 mA

IMATCH

Output current matching (1)

IOUT = 100 mA, PWM duty =100%

VLOW_COMP

Low comparator threshold

0.9

VMID_COMP

Mid comparator threshold

1.9

VHIGH_COMP

High comparator threshold

(1)

TEST CONDITIONS

MIN

−5%

µA

mA

5%

1%

5.6

UNIT

6

5%

V

V

7

V

Output Current Accuracy is the difference between the actual value of the output current and programmed value of this current.

Matching is the maximum difference from the average. For the constant current sinks on the part (OUTx), the following are determined:

the maximum output current (MAX), the minimum output current (MIN), and the average output current of all outputs (AVG). Matching

number is calculated: (MAX-MIN)/AVG. The typical specification provided is the most likely norm of the matching figure for all parts. LED

current sinks were characterized with 1-V headroom voltage. Note that some manufacturers have different definitions in use.

7.9 PWM Brightness Control Electrical Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

ƒPWM

PWM input frequency

tON/OFF

Minimum on/off time (1)

(1)

TEST CONDITIONS

MIN

TYP

100

MAX

20 000

0.5

UNIT

Hz

µs

This specification is not ensured by ATE.

7.10 Boost and SEPIC Converter Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

Input voltage

VOUT

Output voltage

ƒSW_MIN

Minimum switching frequency

Defined by RFSET resistor

300

ƒSW_MAX

Maximum switching frequency

Defined by RFSET resistor

2 200

tOFF

Minimum switch OFF time (1)

ƒSW ≥ 1.15 MHz

ISW_MAX

SW current limit first triggerred

tSW_MAX

SW current limit first triggerred period

ISW_LIM

SW current limit

RDSON

FET RDSON

fSYNC

External SYNC frequency

300

tSYNC_ON

External SYNC on time (1)

150

ns

tSYNC_OFF

External SYNC off time (1)

150

ns

(1)

4.5

40

6

45

UNIT

VIN

3.3

3.7

kHz

kHz

55

ns

4.1

A

3.7

A

1.6

3

3.35

240

V

s

400

mΩ

2 200

kHz

This specification is not ensured by ATE.

7.11 Logic Interface Characteristics

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

LOGIC INPUT VDDIO/EN

VIL

Input low level

VIH

Input high level

0.4

1.65

−1

Input DC current

IEN

Input transient current during VDDIO/EN

powering up

5

V

30

µA

1.2

mA

LOGIC INPUT SYNC, PWM

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

7

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Logic Interface Characteristics (continued)

Limits apply over the full operation temperature range −40°C ≤ TA ≤ +125°C , unless otherwise speicified, VIN = 12V.

PARAMETER

VIL

Input low level

VIH

Input high level

II

Input current

TEST CONDITIONS

MIN

TYP

MAX

0.2 ×

VDDIO/E

N

0.8 ×

VDDIO/E

N

−1

1

UNIT

V

μA

LOGIC OUTPUT FAULT

VOL

Output low level

Pullup current 3 mA

ILEAKAGE

Output leakage current

V = 5.5 V

8

Submit Documentation Feedback

0.3

0.5

V

1

μA

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

7.12 Typical Characteristics

480

480

400

400

Boost Output Current (mA)

Boost Output Current (mA)

Unless otherwise specified: D = NRVB460MFS, TA = 25°C

320

240

160

80

4.5

VBoost = 18V

VBoost = 26V

VBoost = 37V

5.5

6.5

7.5

Input Voltage (V)

8.5

320

240

160

VBoost = 18V

VBoost = 26V

VBoost = 37V

80

4.5

9

5.5

D005

ƒSW = 400 kHz

L = 33 μH

DC Load (PWM = 100%)

CIN and COUT = 33 µF (electrolytic) + 2 × 10 µF (ceramic)

6.5

7.5

Input Voltage (V)

8.5

9.5

10

D006

ƒSW = 1.1 MHz

L = 15 μH

DC Load (PWM = 100%)

CIN and COUT = 33 µF (electrolytic) + 10 µF (ceramic)

Figure 1. Maximum Boost Current

Figure 2. Maximum Boost Current

480

5.5

Output current mismatch (%)

Boost Output Current (mA)

5

400

320

240

160

80

4.5

VBoost = 18V

VBoost = 26V

VBoost = 37V

5.5

6.5

7.5

Input Voltage (V)

ƒSW = 2.2 MHz

L = 10 μH

CIN and COUT = 3× 10 µF (ceramic)

8.5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

30

40

50

9.5

60

70

80

90

Output Current (mA)

100

110

120

D008

D007

DC Load (PWM = 100%)

Figure 4. LED Current Sink Matching

100

96

96

92

92

Boost Efficiency (%)

Boost Efficiency (%)

Figure 3. Maximum Boost Current

100

88

84

80

76

VIN = 16V

VIN = 12V

VIN = 8V

VIN = 6V

72

68

80

160

240

320

Output Current (mA)

ƒSW = 400 kHz

L = 22 μH

CIN and COUT = 33 µF (electrolytic)

+ 2 × 10 µF (ceramic)

400

88

84

80

76

VIN = 16V

VIN = 12V

VIN = 8V

VIN = 6V

72

480

68

80

D001

DC Load (PWM = 100%)

VBOOST = 18 V

160

240

320

Output Current (mA)

ƒSW = 400 kHz

L = 22 μH

CIN and COUT = 33 µF (electrolytic)

+ 2 × 10 µF (ceramic)

Figure 5. Boost Efficiency

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

400

480

D002

DC Load (PWM = 100%)

VBOOST = 30 V

Figure 6. Boost Efficiency

Submit Documentation Feedback

9

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Typical Characteristics (continued)

100

100

96

96

92

92

Boost Efficiency (%)

Boost Efficiency (%)

Unless otherwise specified: D = NRVB460MFS, TA = 25°C

88

84

80

76

VIN = 16V

VIN = 12V

VIN = 8V

VIN = 6V

72

68

80

160

240

320

Output Current (mA)

ƒSW = 2.2 MHz

L = 4.7 μH

CIN and COUT = 3 × 10 µF (ceramic)

400

88

84

80

76

VIN = 16V

VIN = 12V

VIN = 8V

VIN = 6V

72

480

68

80

160

D003

DC Load (PWM = 100%)

VBOOST = 18 V

ƒSW = 2.2 MHz

L = 4.7 μH

CIN and COUT = 3 × 10 µF (ceramic)

Figure 7. Boost Efficiency

10

Submit Documentation Feedback

240

320

Output Current (mA)

400

480

D004

DC Load (PWM = 100%)

VBOOST = 30 V

Figure 8. Boost Efficiency

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

8 Detailed Description

8.1 Overview

The LP8867-Q1, LP8869-Q1 is a highly integrated LED driver for automotive infotainment , cluster and HUD

medium-size LCD backlight applications. It includes a DC-DC with an integrated FET, supporting both boost and

SEPIC modes, an internal LDO enabling direct connection to battery without need for a pre-regulated supply and

3 or 4 LED current sinks. The VDDIO/EN pin provides the supply voltage for digital IOs (PWM and SYNC inputs)

and at the same time enables the device.

The switching frequency on the DC-DC converter is set by a resistor connected to the FSET pin. The maximum

voltage of the DC-DC is set by a resistive divider connected to the FB pin. For the best efficiency, the output

voltage is adapted automatically to the minimum necessary level needed to drive the LED strings. This is done

by monitoring LEDs' cathode voltage in real time. For EMI reduction, two optional features are available:

• Spread spectrum, which reduces EMI noise around the switching frequency and its harmonic frequencies

• DC-DC can be synchronized to an external frequency connected to SYNC pin

The 3 or 4 constant current outputs OUT1, OUT2, OUT3, and OUT4 provide LED current up to 120 mA. Value

for the current per OUT pin is set with a resistor connected to ISET pin. Current sinks that are not used must be

connected to ground. Grounded current sink is disabled and excluded from boost adaptive voltage detection

loop.

Brightness is controlled with the PWM input. Frequency range for the input PWM is from 100 Hz to 20 kHz. LED

output PWM behavior follows the input PWM so the output frequency is equal to the input frequency.

LP886x-Q1 has extensive fault detection features:

• LED open and short detection

• VIN input overvoltage protection

• VIN input undervoltage protection

• VIN input overcurrent protection

• VBoost output overvoltage protection

• SW overvoltage protection

• Thermal shutdown in case of chip overheated

Fault condition is indicated through the FAULT output pin.

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

11

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

8.2 Functional Block Diagram

RISENSE

VIN

L

Q

RGS

CIN

CIN BOOST

VIN

VSENSE_N

D

COUT

SD

POWER-LINE FET CONTROL

LDO

LDO

CLDO

SW

SYNC

RFSET

PGND

BOOST

CONTROLLER

FSET

FB

RISET

4 x LED

CURRENT

SINK

ISET

TSET

CURRENT

SETTING

OUT2

NTC

TSENSE

OUT3

PWM

OUT4

tº

VDDIO/EN

FAULT

VDDIO

OUT1

GND

DIGITAL BLOCKS

(FSM, ADAPTIVE VOLTAGE

CONTROL, SAFETY LOGIC

etc.)

ANALOG BLOCKS

(CLOCK GENERATOR, VREF,

TSD etc.)

EXPOSED PAD

12

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

8.3 Feature Description

8.3.1 Integrated DC-DC Converter

The LP886x-Q1 DC-DC converter generates supply voltage for the LEDs and can operate in boost mode or in

SEPIC mode. The output voltage, switching frequency are all configured by external resistors.

For detailed boost application, refer to Typical Application for 4 LED Strings

For detailed SEPIC application, refer to SEPIC Mode Application

8.3.1.1 DC-DC Converter Parameter Configuration

The LP886x-Q1 converter is a current-peak mode DC-DC converter, where the switch FET's current and the

output voltage feedback are measured and controlled. The block diagram is shown in Figure 9.

D

VIN

VOUT

CIN

COUT

R1

SW

OCP

ADAPTIVE

VOLTAGE

CONTROL

RC

filter

FB

R2

LIGHT

LOAD

S R

R

-

GM

OVP

R

CURRENT

SENSE

R

PGND

+

SYNC

FSET

GM

FSET

CTRL

BOOST

OSCILLATOR

RFSET

OFF/BLANK

TIME

PULSE

GENERATOR

BLANK

TIME

CURRENT

RAMP

GENERATOR

Figure 9. DC-DC converter in Boost Application

8.3.1.1.1 Switching Frequency

Switching frequency is adjustable between 300 kHz and 2.2 MHz with RFSET resistor as Equation 1:

ƒSW = 67600 / (RFSET + 6.4)

where

•

•

ƒSW is switching frequency, kHz

RFSET is frequency setting resistor, kΩ

(1)

For example, if RFSET is set to 163 kΩ, fSW will be 400 kHz.

In most cases, lower switching frequency has higher system efficiency and lower internal temperature increase.

8.3.1.1.2 Spread Spectrum and External SYNC

LP886x-Q1 has an optional spread spectrum feature (±3% from central frequency, 1-kHz modulation frequency)

which reduces EMI noise at the switching frequency and its harmonic frequencies. If SYNC pin level is low,

spread spectrum function is disabled. If SYNC pin level is high, spread spectrum function is enabled.

LP886x-Q1 DC-DC converter can be driven by an external SYNC signal between 300 kHz and 2.2 MHz. When

external synchronization is used, spread spectrum is not available. If the external synchronization input

disappears, DC-DC continues operation at the frequency defined by RFSET resistor and spread spectrum function

will be enabled/disabled depending on the final SYNC pin level.

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

13

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Feature Description (continued)

External SYNC frequency must be 1.2 to 1.5 times higher than the frequency defined by RFSET resistor. In

external SYNC configuration, minimum frequency setting with RFSET could go as low as 250 kHz to support 300kHz switching with external clock.

Table 1. DC-DC Synchronization Mode

SYNC PIN INPUT

MODE

Low

Spread spectrum disabled

High

Spread spectrum enabled

300 to 2200 kHz frequency

Spread spectrum disabled, external synchronization mode

8.3.1.1.3 Recommended Component Value and Internal Parameters

The LP886x-Q1 DC-DC converter has an internal compensation network to ensure the stability. There's no

external component needed for compensation. It's strongly recommended that the inductance value and the

boost input and output capacitors value follow the requirement of Table 2. Also, the DC-DC internal parameters

are chosen automatically according to the selected switching frequency (see Table 2) to ensure stability.

Table 2. Boost Converter Parameters (1)

FREQUENCY (kHz)

TYPICAL

INDUCTANCE (µH)

TYPICAL BOOST INPUT

AND OUTPUT CAPACITORS (µF)

MINIMUM SWITCH

OFF TIME (ns) (2)

BLANK

TIME (ns)

1

300 to 480

22 or 33

2 ×10 (cer.) + 33 (electr.)

150

95

2

480 to 1150

15

10 (cer.) + 33 (electr.)

60

95

3

1150 to 1650

10

3 × 10 (cer.)

40

95

4

1650 to 2200

4.7 or 10

3 × 10 (cer.)

40

70

RANGE

(1)

(2)

Parameters are for reference only

Due to current sensing comparator delay the actual minimum off time is 6 ns (typical) longer than in the table.

8.3.1.1.4 DC-DC Converter Switching Current Limit

The LP886x-Q1 DC-DC converter has an internal SW FET inside chip's SW pin. The internal FET current is

limited to 3.35 A (typical). The DC-DC converter will sense the internal FET current, and turn off the internal FET

cycle-by-cycle when the internal FET current reaches the limit.

To support start transient condition, the current limit could be automatically increased to 3.7 A for a short period

of 1.6 seconds when a 3.35-A limit is reached.

NOTE

Application condition where the 3.35-A limit is exceeded continuously is not allowed. In

this case the current limit would be 3.35 A for 1.6 seconds followed by 3.7-A limit for 1.6

seconds, and this 3.2-second period repeats.

8.3.1.1.5 DC-DC Converter Light Load Mode

LP886x-Q1 DC-DC converter will enter into light load mode in below condition:

• VIN voltage is very close to VOUT

• Loading current is very low

• PWM pulse width is very short

When DC-DC converter enters into light load mode, DC-DC converter stops switching occasionally to make sure

boost output voltage won't rise up too much. It could also be called as PFM mode, since the DC-DC converter

switching frequency will change in this mode.

14

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

8.3.1.2 Adaptive Voltage Control

The LP886x-Q1 DC/DC converter generates the supply voltage for the LEDs. During normal operation, boost

output voltage is adjusted automatically based on the LED cathode (OUTx pin) voltages. This is called adaptive

boost control. Only the active LED outputs are monitored to control the adaptive boost voltage. Any LED strings

with open or short faults are removed from the adaptive voltage control loop. The OUTx pin voltages are

periodically monitored by the control loop. The boost voltage is raised if any of the OUTx voltage falls below the

VLOW_COMP threshold. The boost voltage is also lowered if all OUTx voltages are higher than VLOW_COMP

threshold. The boost voltage keeps unchanged when one of OUTx voltage touches the VLOW_COMP threshold. In

normal operation, the lowest voltage among the OUTx pins is around VLOW_COMP, and boost voltage stays

constant. VLOW_COMP level is the minimum voltage which could guarantee proper LED current sink operation. See

Figure 10 for how the boost voltage automatically scales based on the OUT1-4 pin voltage.

Boost

decreases voltage

No actions

OUT 1-4

VOLTAGE

The lowest channel

voltage touches

VLOW_COMP threshold

No output is close to

VLOW_COMP threshold

Boost

Increases voltage

One output is lower than

VLOW_COMP threshold

Normal

Conditions

OUT4

OUT3

OUT2

OUT1

OUT4

OUT3

OUT2

OUT1

OUT4

OUT3

OUT2

OUT1

VLOW_COMP

Dynamic

Conditions

Figure 10. Adaptive Boost Voltage Control Loop Function

8.3.1.2.1 Using Two-Divider

VBOOST_MAX voltage should be chosen based on the maximum voltage required for LED strings. Recommended

maximum voltage is about 3 to 5-V higher than maximum LED string voltage. DC-DC output voltage is adjusted

automatically based on LED cathode voltage. The maximum, minimum and initial boost voltages can be

calculated with Equation 2:

·

§V

VBOOST ¨ BG K u 0.0387 ¸ u R1 VBG

© R2

¹

where

•

•

•

•

•

•

VBG = 1.2 V

R2 recommended value is 10 kΩ to 200 kΩ

R1/R2 recommended value is 5 to 10

K = 1 for maximum adaptive boost voltage (typical)

K = 0 for minimum adaptive boost voltage (typical)

K = 0.88 for initial boost voltage (typical)

(2)

For example, if R1 is set to 750 kΩ and R2 is set to 130 kΩ, VBOOST will be in the range of 8.1 V to 37.1 V.

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

15

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

VOUT

COUT

R1

R2

+

GM

±

VBG

FB

+

VOVP

BSTOV P

±

Curren t DA C

(38.7uA Full-Scale)

Figure 11. FB External Two-Divider Resistors

8.3.1.2.2 Using T-Divider

Alternatively, a T-divider can be used if resistance less than 100 kΩ is required for the external resistive divider.

Then the maximum, minimum and initial boost voltages can be calculated with

§ R1u R3

·

VBOOST = ¨

+R1+R3 ¸ K u 0.0387 +

© R2

¹

§ R1 ·

+1¸ u VBG

¨

© R2 ¹

where

•

•

•

•

•

•

VBG = 1.2 V

R2 recommended value is 10 kΩ to 200 kΩ

R1/R2 recommended value is 5 to 10

K = 1 for maximum adaptive boost voltage (typical)

K = 0 for minimum adaptive boost voltage (typical)

K = 0.88 for initial boost voltage (typical)

(3)

For example, if R1 is set to 100 kΩ, R2 is set to 10 kΩ and R3 is set to 60 kΩ, VBOOST will be in the range of 13.2

V to 42.6 V.

16

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

VOUT

COUT

R1

+

GM

±

VBG

R3

FB

R2

+

VOVP

BSTOV P

±

Curren t DA C

(38.7uA Full-Scale)

Figure 12. FB External T-divider Resistors

8.3.1.2.3 Feedback Capacitor

When operating with no electrolytic capacitor in boost output, which is a typical case when boost frequency is in

the 1.15-MHz to 2.2-MHz range, a feedback capacitor needs to be put in parallel with R1 to ensure the loop

stability. The value of the capacitor is recommended to be:

CFB =

1

2S fzR1

where

•

fz = 20 kHz

(4)

For example, if R1 is set to 750 kΩ, CFB needs to be around 11 pF.

VOUT

COUT

C FB

R1

R2

Optiona l

R3

+

GM

±

VBG

FB

+

VOVP

BSTOV P

±

Curren t DA C

(38.7uA Full-Scale)

Figure 13. FB External Resistors With Capacitor When Operating With No Electrolytic Capacitor In Boost

Output

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

17

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

8.3.2 Internal LDO

The internal LDO regulator converts the input voltage at VIN to a 4.3-V output voltage for internal use. Connect a

minimum of 1-µF ceramic capacitor from LDO pin to ground, as close to the LDO pin as possible.

8.3.3 LED Current Sinks

8.3.3.1 LED Output Configuration

LP886x-Q1 detects LED output configuration during start-up. Any current sink output connected to ground is

disabled and excluded from the adaptive voltage control of the DC-DC converter and fault detections.

If more current is needed, LP886x-Q1's output could also be connected together to support the high current LED.

8.3.3.2 LED Current Setting

The output current of the LED outputs is controlled with external RISET resistor. RISET value for the target LED

current per channel can be calculated using Equation 5:

ILED = 2000 u

VBG

RISET

where

•

•

•

VBG = 1.2 V

RISET is current setting resistor, kΩ

ILED is output current per OUTx pin, mA

(5)

For example, if RISET is set to 20 kΩ, ILED will be 120 mA per channel.

8.3.3.3 Brightness Control

LP886x-Q1 controls the brightness of the display with conventional PWM. Output PWM directly follows the input

PWM. Input PWM frequency can be in the range of 100 Hz to 20 kHz.

8.3.4 Power-Line FET Control

The LP886x-Q1 has a power-line FET control feature. It has a control pin (SD) for driving the gate of an external

power-line P-Channel MOSFET. This feature grants LP886x-Q1 the ability to immediately cut-off the power part

of backlight system when failure occurs, protecting other parallel power systems from being impacted. In

addition, the feature could smooth the inrush current during powering-up by turning on the power-line FET

gradually. In SOFT START state, the SD pin slowly increases the sink current until it reaches 230 μA. An

example schematic is shown in Figure 14.

The value of RGS should follow the rules below

• ISD_MAX × RGS should be less than the power-line FET's maximum acceptable Source-Gate voltage

• ISD_MIN × RGS should be greater than the minimum power-line FET's Source-Gate voltage which could ensure

a low On-State Resistance.

A 20-kΩ RGS is chosen in typical application which generates a 4.6 V difference on power-line FET's SourceGate voltage.

VIN

RISENSE

Q1

L1

CIN BOOST

RGS

SW

SD

VSENSE_N

VIN

CIN

Figure 14. Power-Line FET Control Schematics

18

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

The LP886x-Q1 turns off the power-line FET and prevents the possible boost and LEDs leakage when the device

is disabled or in FAULT RECOVERY state.

Power-line FET control is an optional feature. Leave SD pin NC and don't use power-line FET when this feature

is not needed.

8.3.5 LED Current Dimming With External Temperature Sensor

The LP886x-Q1 has an optional feature to decrease automatically LED current when LED overheating is

detected with an external NTC sensor. An example of the behavior is shown in Figure 15. When the NTC

temperature reaches T1, the LP886x-Q1 starts to decrease the LED current. When the LED current has reduced

to 17.5% of the nominal value, current turns off until temperature returns to the operation range.

LED CURRENT

100%

17.5%

T1

NTC TEMPERATURE

T2

Figure 15. Temperature-Based LED Current Dimming Functionality

VBG

ISET_SCALED

1:2000

ISET

+

LED OUT

RISET

VDD

ILED

R3

ITSENSE

R4

LED DRIVER

TSET

TSENSE

RT

R7

R5

ITSENSE

R6

NTC

Figure 16. Temperature-Based LED Current Dimming Implementation

When TSET pin is grounded and TSENSE is floated, this feature is disabled. LED current is set by RISET resistor:

ILED = 2000 u

VBG

RISET

where

•

•

•

VBG = 1.2 V

RISET is current setting resistor, kΩ

ILED is output current per OUTx pin, mA

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

(6)

Submit Documentation Feedback

19

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

When external NTC is connected, the TSENSE pin current decreases LED output current. Temperature T1 and

de-rate slope are defined by external resistors as explained below.

Parallel resistance of the NTC sensor RT and resistor R4 is calculated by formula:

RT u R6

RT R6

RII

(7)

TSET voltage can be calculated with Equation 8:

VTSET

VDD u

R5

R4 R5

(8)

TSENSE pin current is calculated by Equation 9:

VTSET

ITSENSE

RII

VDD u

RII

RII R3

RII2

R7

RII R3

where

•

VDD is the bias voltage of the resistor group. It's recommended to connect with chip's internal LDO output (pin

2)

(9)

ISET pin current defined by RISET is:

VBG

ISET _ SCALED

RISET

(10)

For Equation 11, ITSENSE current must be limited between 0 and ISET_SCALED. If ITSENSE > ISET_SCALED then set

ITSENSE = ISET_SCALED. If ITSENSE < 0 then set ITSENSE = 0.

LED driver output current is:

ILED = (ISET_SCALED – ITSENSE ) x 2 000

(11)

When current is lower than 17.5% of the nominal value, the current is set to 0 (the cut-off point).

An Excel® calculator is available for calculating the component values for a specific NTC and target thermal

profile (contact TI E2E™ support forums ). Figure 17 shows an example thermal profile implementation.

20

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

120

0.06

100

0.05

80

0.04

60

0.03

40

0.02

LED current

20

TSENSE Current (mA)

LED Current (mA)

www.ti.com

0.01

TSENSE current

0.00

0

60

70

80

90

100

110

120

Temperature (ž&

C006

NTC – 10 kΩ at 25ºC

RISET = 24 kΩ

R2 = 10 kΩ

R4 = 100 kΩ

VDD = 4.3 V

R1 = 10 kΩ

R3 = 2 kΩ

R5 = 7.5 kΩ

Figure 17. Calculation Example

8.3.6 Fault Detections and Protection

The LP886x-Q1 has fault detection for LED open and short, VIN input overvoltage protection (VIN_OVP) , VIN

undervoltage protection (VIN_UVLO), VIN overcurrent protection (VIN_OCP) , Boost output overvoltage

protection (BST_OVP), SW overvoltage protection (SW_OVP) and thermal shutdown (TSD).

8.3.6.1 Supply Fault and Protection

8.3.6.1.1 VIN Undervoltage Fault (VIN_UVLO)

The LP886x-Q1 device supports VIN undervoltage protection. The VIN undervoltage falling threshold is 3.85-V

typical and rising threshold is 4-V typical. If during operation of the LP886x-Q1 device, the VIN pin voltage falls

below the VIN undervoltage falling threshold, the boost, LED outputs, and power-line FET will be turned off, and

the device will enter FAULT RECOVERY mode. The FAULT pin will be pulled low. The LP886x-Q1 will exit

FAULT RECOVERY mode after 100 ms and try the start-up sequence again. VIN_UVLO fault detection is

available in SOFT START, BOOST START, and NORMAL state.

8.3.6.1.2 VIN Overvoltage Fault (VIN_OVP)

The LP886x-Q1 device supports VIN overvoltage protection. The VIN overvoltage threshold is 43-V typical. If

during LP886x-Q1 operation, VIN pin voltage rises above the VIN overvoltage threshold, the boost, LED outputs

and the power-line FET will be turned off, and the device will enter FAULT RECOVERY mode. The FAULT pin

will be pulled low. The LP886x-Q1 will exit FAULT RECOVERY mode after 100 ms and try the start-up sequence

again. VIN_OVP fault detection is available in SOFT START, BOOST START and NORMAL state.

8.3.6.1.3 VIN Overcurrent Fault (VIN_OCP)

The LP886x-Q1 device supports VIN overcurrent protection. If during LP886x-Q1 operation, voltage drop

between VIN pin and VSENSE_N pin rises above 160-mV typical, the boost, LED outputs and the power-line

FET will be turned off, and the device will enter FAULT RECOVERY mode. The FAULT pin will be pulled low.

The LP886x-Q1 will exit FAULT RECOVERY mode after 100 ms and try the start-up sequence again. VIN_OCP

fault detection is available in SOFT START, BOOST START, and NORMAL state.

A 30-mΩ resistor is recommended to put between VIN pin and VSENSE_N pin, which will set the VIN

overcurrent threshold to 5.3 A.

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

21

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

8.3.6.2 Boost Fault and Protection

8.3.6.2.1 Boost Overvoltage Fault (BST_OVP)

The LP886x-Q1 device supports boost overvoltage protection. If during LP886x-Q1 operation, the FB pin voltage

exceeds the VFB_OVP threshold, which is 2.3-V typical, the boost, LED outputs and the power-line FET will be

turned off, and the device will enter FAULT RECOVERY mode. The FAULT pin will be pulled low. The LP886xQ1 will exit FAULT RECOVERY mode after 100 ms and try the start-up sequence again. BST_OVP fault

detection is available in NORMAL state.

Calculating back from FB pin voltage threshold to boost output OVP voltage threshold, the value is not a static

threshold, but a dynamic threshold changing with the current target boost adaptive voltage:

§ R1 ·

VBOOST_OVP = VBOOST + ¨

+1¸ u ( VFB_OVP

© R2 ¹

VBG )

where

•

•

•

•

VBOOST is the current target boost adaptive voltage, which in most time is the current largest LED string forward

voltage among multiple strings + 0.9 V in steady state

VFB_OVP = 2.3 V

VBG = 1.2 V

R1 and R2 is the resistor value of FB external network in Using Two-Divider and Using T-Divider

(12)

For example, if R1 is set to 750 kΩ and R2 is set to 130 kΩ, VBOOST will report OVP when the boost voltage is 7.4

V above target boost voltage.

This equation holds true in both two-divider FB external network and T-divider FB external network.

8.3.6.2.2 SW Overvoltage Fault (SW_OVP)

Besides boost overvoltage protection, the LP886x-Q1 supports SW pin overvoltage protection to further protect

the boost system from overvoltage scenario. If during LP886x-Q1 operation, the SW pin voltage exceeds the

VSW_OVP threshold, which is 49-V typical, the boost, LED outputs and the power-line FET are turned off, and the

device will enter FAULT RECOVERY mode. The FAULT pin will be pulled low. The LP886x-Q1 will exit FAULT

RECOVERY mode after 100 ms and try the start-up sequence again. SW_OVP fault detection is available in

SOFT START, BOOST START and NORMAL state.

8.3.6.3 LED Fault and Protection (LED_OPEN and LED_SHORT)

Every LED current sink has 3 comparators for LED fault detections.

OUT#

VHIGH_COMP

HIG H_COMP

VMID_COMP

MID_COMP

VLOW_COMP

LOW_COMP

CURRENT/PWM

CONTROL

Figure 18. Comparators for LED Fault Detection

Figure 19 shows cases which generates LED faults. Any LED faults will pull the Fault pin low.

During normal operation, boost voltage is raised if any of the used LED outputs falls below the VLOW_COMP

threshold. Open LED fault is detected if boost output voltage has reached the maximum and at least one LED

output is still below the threshold. The open string is then disconnected from the boost adaptive control loop and

its output is disabled.

22

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

Shorted LED fault is detected if one or more LED outputs are above the VHIGH_COMP threshold (typical 6 V) and at

least one LED output is inside the normal operation window (between VLOW_COMP and VMID_COMP, typical 0.9 V

and 1.9 V). The shorted string is disconnected from the boost adaptive control loop and its output is disabled.

LED Open fault detection and LED Short fault detection are available only in NORMAL state.

No actions

OUT1~4 PIN

VOLTAGE

Open LED fault

when

VBOOST = MAX

Short LED fault

(at least one channel between

LOW_COMP and MID COMP)

Open LED Fault

Short LED Fault

VHIGH_COMP

VMID_COMP

Normal Condition

OUT4

OUT3

OUT2

OUT1

OUT4

OUT3

OUT2

OUT1

OUT4

OUT3

OUT2

OUT1

VLOW_COMP

Fault Condition

Figure 19. Protection and DC-DC Voltage Adaptation Algorithms

If LED fault is detected, the device continues normal operation and only the faulty string is disabled. The fault is

indicated via the FAULT pin which can be released by toggling VDDIO/EN pin low for a short period of 2 µs to 20

µs. LEDs are turned off for this period but the device stays in NORMAL state. If VDDIO/EN is low longer, the

device goes to STANDBY and restarts when EN goes high again.

This means if the system doesn't want to simply disable the device because of LED faults. It could clear the LED

faults by toggling VDDIO/EN pin low for a short period of 2 µs to 20 µs.

8.3.6.4 Thermal Fault and Protection (TSD)

If the die temperature of LP886x-Q1 reaches the thermal shutdown threshold TTSD, which is 165°C typical, the

boost, power-line FET and LED outputs are turned off to protect the device from damage. The FAULT pin will be

pulled low. The LP886x-Q1 will exit FAULT RECOVERY mode after 100 ms and try the start-up sequence again.

Only if the die temperature drops lower than TTSD - TTSD_HYS, which is 145°C typical, the device could start-up

normally. TSD fault detection is available in SOFT START, BOOST START and NORMAL state.

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

23

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

8.3.6.5 Overview of the Fault and Protection Schemes

A summary of the LP886x-Q1 fault detection behavior is shown in Table 3. Detected faults (excluding LED open or short) cause device to enter FAULT

RECOVERY state. In FAULT_RECOVERY the DC-DC and LED current sinks of the device are disabled, and the FAULT pin is pulled low. The device will

exit FAULT RECOVERY mode after 100 ms and try the start-up sequence again. When recovery is successful and device enters into NORMAL state, the

FAULT pin is released high.

Table 3. Fault Detections

FAULT/

PROTECTION

VIN overvoltage

protection

FAULT

PIN

Enter FAULT_

RECOVERY

STATE

ACTIVE STATE

ACTION

VIN > 43 V

Yes

Yes

SOFT START, BOOST

START, NORMAL

Device enters into FAULT RECOVERY state, and restarts after

100 ms

FAULT NAME

VIN_OVP

CONDITION

VIN undervoltage

protection

VIN_UVLO

Effective when VIN <

3.85 V

Released when VIN >4

V

Yes

Yes

SOFT START, BOOST

START, NORMAL

Device enters into FAULT RECOVERY state, and restarts after

100 ms

VIN overcurrent

protection

VIN_OCP

VIN-VSENSE_N >

160mV

Yes

Yes

SOFT START, BOOST

START, NORMAL

Device enters into FAULT RECOVERY state, and restarts after

100 ms

NORMAL

Open string is removed from the DC-DC voltage control loop

and output is disabled.

Fault pin low could be released by toggling VDDIO/EN pin, If

VDDIO/EN is low for a period of 2 µs to 20 µs, LEDs are turned

off for this period but device stays in NORMAL.

LED _OPEN

Adaptive Voltage is

max. and

any OUTx voltage <

0.9 V

Shorted LED fault

LED_SHORT

One of OUTx voltage

is [0.9 V, 1.9 V] and

any OUTx voltage > 6

V

Yes

No

NORMAL

Short string is removed from the DC-DC voltage control loop

and output is disabled.

Fault pin low could be released by toggling VDDIO/EN pin, If

VDDIO/EN is low for a period of 2 µs to 20 µs, LEDs are turned

off for this period but device stays NORMAL.

Boost overvoltage

protection

BST_OVP

VFB > 2.3 V

Yes

Yes

NORMAL

Fault is detected if boost overvoltage condition duration is more

than 560 ms

Device enters into FAULT RECOVERY state, and restarts after

100 ms

SW overvoltage

protection

SW_OVP

VSW > 49 V

Yes

Yes

SOFT START, BOOST

START, NORMAL

Device enters into FAULT RECOVERY state, and restarts after

100 ms

Effective when Tj >

165 ºC

Released when Tj <

145 ºC

Yes

Yes

SOFT START, BOOST

START, NORMAL

Device enters into FAULT RECOVERY state, and restarts until

TSD fault is released

Open LED fault

Thermal protection

24

TSD

Yes

No

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

8.4 Device Functional Modes

8.4.1 STANDBY State

The LP886x-Q1 enters STANDBY state when the VIN voltage powers on and voltage is higher than VINUVLO

rising threshold, which is 4-V typical. In STANDBY state, the device is able to detect VDDIO/EN signal. When

VDDIO/EN is pulled high, the internal LDO wakes up and the device enters into SOFT START state. The device

will re-enter the STANDBY state when VDDIO/EN is pulled low for more than 50 µs.

8.4.2 SOFT START State

In SOFT START state, Power-line FET is enabled, and boost input and output capacitors are charged to VIN

level. VIN_OCP, VIN_OVP, VIN_UVLO, SW_OVP and TSD fault are active. After 65 ms, the device enters into

BOOST START state.

8.4.3 BOOST START State

In BOOST START state, DC-DC controller is turned on and boost voltage is ramped to initial boost voltage level

with reduced current limit. VIN_OCP, VIN_OVP, VIN_UVLO, SW_OVP and TSD fault are active in this state.

After 50 ms, LED outputs do a one-time detection on grounded outputs. Grounded outputs are disabled and

excluded from the adaptive voltage control loop. Then the device enters into NORMAL state.

8.4.4 NORMAL State

In NORMAL state, LED drivers are enabled when PWM signal is high. All faults are active in this state. Fault pin

will be released high in the start of NORMAL state if recovering from FAULT RECOVERY state and no fault is

available.

8.4.5 FAULT RECOVERY State

Non-LED faults can trigger fault recovery state. LED drivers, boost converter and power-line FET are all disabled.

After 100 ms, the device attempts to restart from SOFT START state if VDDIO/EN is still high.

8.4.6 State Diagram and Timing Diagram for Start-up and Shutdown

VIN > VUVLO

STANDBY

VDDIO / EN = 1

VDDIO / EN = 0

SOFT START

65 ms

BOOST START

50 ms

FAULT

FAULT

100 ms

FAULT RECOVERY

LED OUTPUT

CONFIGURATION

DETECTION

(1st time power-up only)

FAULT

NORMAL

VDDIO / EN = 0

Figure 20. State Diagram

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

25

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Device Functional Modes (continued)

T=50 s

t>500 s

VIN

LDO

VDDIO/EN

SYNC

Headroom adaptation

VOUT=VIN level ± diode drop

VOUT

PWM OUT

IQ

Active mode

SOFT

START

BOOST

START

Figure 21. Timing Diagram for the Typical Start-Up and Shutdown

26

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

The LP886x-Q1 is designed for automotive applications. The input voltage (VIN) is intended to be connected to

the automotive battery, which supports voltage range from 4.5 V to 40 V. Device internal circuitry is powered

from the integrated LDO.

The LP886x-Q1 uses a simple four-wire control:

• VDDIO/EN for enable

• PWM input for brightness control

• SYNC pin for boost synchronisation (optional)

• FAULT output to indicate fault condition (optional)

9.2 Typical Applications

9.2.1 Typical Application for 4 LED Strings

Figure 22 shows the typical application for LP886x-Q1 which supports 4 LED strings, 100 mA per string with a

boost switching frequency of 400 kHz.

VIN

5...28 V

RISENSE

L1

Q1

D1

Up to 34V

COUT

CIN BOOST

R2

SW

RGS

R1

SD

VSENSE_N

FB

VIN

CIN

CLDO

LDO

OUT1

LP8867-Q1

OUT2

RFSET

FSET

BRIGHTNESS

VDDIO/EN

SYNC

OUT4

PWM

TSET

TSENSE

VDDIO/EN

FAULT

FAULT

R8

VLDO

OUT3

PGND

R4

R7

ISET

GND

PAD

R3

RTf

R6

R5

NTC

RISET

VDDIO/EN

Figure 22. Four Strings 100 mA per String Configuration

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

Submit Documentation Feedback

27

�LP8867-Q1, LP8869-Q1

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

www.ti.com

Typical Applications (continued)

9.2.2 Design Requirements

Table 4. Design Requirements Table

DESIGN PARAMETER

VALUE

VIN voltage range

5 V – 28 V

LED string

4P8S LEDs (30 V max)

LED string current

100 mA

Maximum boost voltage

34 V

Boost switching frequency

400 kHz

External boost sync

not used

Boost spread spectrum

enabled

L1

33 μH

CIN

100 µF, 50 V

CIN BOOST

2 × (10 µF, 50-V ceramic) + 33 µF, 50-V electrolytic

COUT

2 × (10 µF, 50-V ceramic) + 33 µF, 50-V electrolytic

CLDO

1 µF, 10 V

RISET

24 kΩ

RFSET

160 kΩ

R1

685 kΩ

R2

130 kΩ

R8

10 kΩ

9.2.3 Detailed Design Procedure

9.2.3.1 Inductor Selection

There are two main considerations when choosing an inductor; the inductor must not saturate, and the inductor

current ripple must be small enough to achieve the desired output voltage ripple. Different saturation current

rating specifications are followed by different manufacturers so attention must be given to details. Saturation

current ratings are typically specified at 25°C. However, ratings at the maximum ambient temperature of

application should be requested from the manufacturer. Shielded inductors radiate less noise and are preferred.

The saturation current must be greater than the sum of the maximum load current, and the worst case averageto-peak inductor current. Equation 13 shows the worst case conditions

IOUTMAX

+ IRIPPLE For Boost

'¶

(VOUT - VIN) VIN

x

Where IRIPPLE =

(2 x L x f)

VOUT

ISAT >

Where D =

•

•

•

•

•

•

•

(VOUT ± VIN)

(VOUT)

DQG '¶ = (1 - D)

IRIPPLE - peak inductor current

IOUTMAX - maximum load current

VIN - minimum input voltage in application

L - min inductor value including worst case tolerances

f - minimum switching frequency

VOUT - output voltage

D - Duty Cycle for CCM Operation

(13)

As a result, the inductor should be selected according to the ISAT. A more conservative and recommended

approach is to choose an inductor that has a saturation current rating greater than the maximum current limit. A

saturation current rating of at least 4.1 A is recommended for most applications. See Table 2 for recommended

inductance value for the different switching frequency ranges. The inductor’s resistance should be less than

300 mΩ for good efficiency.

28

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

Product Folder Links: LP8867-Q1 LP8869-Q1

�LP8867-Q1, LP8869-Q1

www.ti.com

SNVSB83B – JUNE 2019 – REVISED JANUARY 2020

See detailed information in Understanding Boost Power Stages in Switch Mode Power Supplies.

Power Stage Desinger Tool can be used for the boost calculation.

9.2.3.2 Output Capacitor Selection

A ceramic capacitor with 2 × VMAX BOOST or more voltage rating is recommended for the output capacitor. The

DC-bias effect can reduce the effective capacitance by up to 80%, which needs to be considered in capacitance

value selection. If the selected ceramic capacitors' voltage rating is less than 2 × VMAX BOOST, an alternative way

is to increase the number of ceramic capacitors. Capacitance recommendations for different switching

frequencies are shown in Table 2. To minimize audible noise of ceramic capacitors their physical size should

typically be minimized.

9.2.3.3 Input Capacitor Selection

A ceramic capacitor with 2 × VIN MAX or more voltage rating is recommended for the input capacitor. The DC-bias

effect can reduce the effective capacitance by up to 80%, which needs to be considered in capacitance value

selection. If the selected ceramic capacitors' voltage rating is less than 2 × VMAX BOOST, an alternative way is to

increase the number of ceramic capacitors. Capacitance recommendations for different boost switching

frequencies are shown in Table 2.

9.2.3.4 LDO Output Capacitor

A ceramic capacitor with at least 10-V voltage rating is recommended for the output capacitor of the LDO. The

DC-bias effect can reduce the effective capacitance by up to 80%, which needs to be considered in capacitance

value selection. Typically a 1-µF capacitor is sufficient.

9.2.3.5 Diode

A Schottky diode should be used for the boost output diode. Do not use ordinary rectifier diodes, because slow

switching speeds and long recovery times degrade the efficiency and the load regulation. Diode rating for peak

repetitive current should be greater than inductor peak current (up to 4.1 A) to ensure reliable operation in boost

mode. Average current rating should be greater than the maximum output current. Schottky diodes with a low

forward drop and fast switching speeds are ideal for increasing efficiency. Choose a reverse breakdown voltage

of the Schottky diode significantly larger than the output voltage. The junction capacitance of Schottky diodes are

also very important. Big junction capacitance leads to huge reverse current and big noise when boost is

switching. A