TI Designs

Ultralow Power Multi-sensor Data Logger with NFC

Interface Reference Design

Design Overview

Design Features

TIDA-00524 provides a complete reference design

for asset tracking and cold chain data logging with

over 5 year battery life and a simple NFC (Near Field

Communication) interface for configuration and read

back. For maximum flexibility, the system offers the

choice of multiple sensor configurations to monitor

temperature (TMP112), ambient light (OPT3001),

and/or humidity (HDC1000).

NFC is provided by

TI’s RF430CL331H and up to 64KB of non-volatile

FRAM memory is available with the MSP430FR5969

MCU.

Design Resources

TIDA-00524

Design Folder

RF430CL331H

Product Folder

MSP430FR5969IRGZ

Product Folder

TMP112

Product Folder

HDC1000

Product Folder

OPT3001

Product Folder

TPD1E10B06

Product Folder

> 5 Year Battery Life on a CR2032 coin cell

RF430CL33xH NFC Dynamic Tag Type 4B

Compliant Communication

NFC configuration and data read back

Multiple Sensor Options

- Temperature (TMP112)

- Temperature + Ambient Light

(OPT3001)

- Temperature+ Humidity (HDC1000)

- Temperature + Humidity + Ambient

Light

Up to 64KB of non-volatile FRAM memory

Data is Date/Time stamped using RTC

Featured Applications

Block Diagram

Asset and Cold Chain Tracking

Data Loggers

Intrusion and Tamper Detection

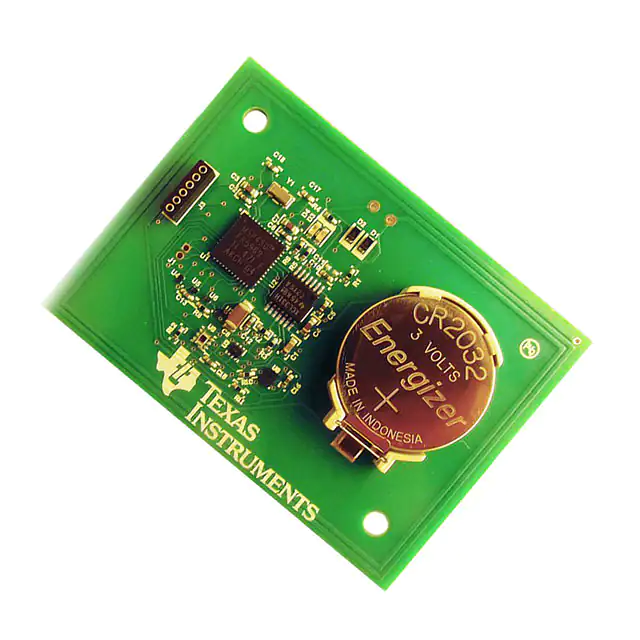

Board Image

Coin Cell Battery

(CR2032)

3.0 Volts

NFC

Enabled

Smartphone

Dynamic NFC

Transponder

(RF430CL331H)

I2C

MCU

I2C

Temperature

Sensor

(TMP112)

I2C

I2C

Humidity

Sensor

(HDC1000)

Light Sensor

(OPT3001)

TIDU821– September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

1

�www.ti.com

1

Key System Specifications

PARAMETER

SPECIFICATIONs and FEATURES

DETAILS

Operating Power Supply Range

2.2 V to 3.6 V

Section 3.1

Input power source

CR2032 Lithium-ion coin cell battery

(3.0-V nominal voltage)

Section 4.1.7

Battery life

>5 years

Section 7.4

Operating temperature

Typical Read/Write Distance

RF Protocol

Data Rate

Typical Data Throughput

NFC Operating Frequency

Measurement Interval

Memory

Wired Interface from Transponder to

Application Processor

Form Factor

Sensors

–30°C to +60°C

(limited by CR2032 coin cell operating range)

Up to 5.5 cm

ISO14443B

106-848 kbps

Write 2.0 – 5.1 KBps

Read: 3.2 – 5.8 KBps

13.56 MHz

Configurable: 1 min to 720 min

3KB SRAM for NDEF Messages (RF430CL),

64 KB FRAM (MSP430FR)

Up to 1,853 samples

2

I C Compatible

58 mm x 43 mm square PCB

Sensor: Temperature (TMP112)

Operating Temperature Range: –40°C to +125°C

Temperature Accuracy: +/-0.5°C (typ)

Sensor: Humidity Sensor (HDC1000)

Operating Temperature Range: –20°C to +85°C

Relative Humidity Accuracy: ±3% RH (typ)

Sensor: Ambient Light Sensor (OPT3001)

Operating Temperature Range: –40°C to +85°C

Relative Accuracy between gain ranges: 0.2% (typ)

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

Section 4.1.7

Section 7.2

Section 3.1.1

Section 7.3

Section 7.3

Section 3.1.1

Section 6.2

Section 6.2

Section 2

Section 5.1

Section 3.1.3

Section 3.1.4

Section 3.1.5

2

�www.ti.com

2

System Description

Cold chain management includes all of the means used to ensure a constant temperature for a product

that is not heat stable from the time it is manufactured or farmed until the time it is used. This includes

industries such as food, retail, medical, and pharmaceutical.

This design implements a cold chain monitoring system which measures temperature, light, and

humidity, then logs the sensor data to non-volatile(FRAM) memory. The design includes a Near Field

Communication (NFC) interface for wireless communication and is powered from a CR2032 coin cell

battery with a focus on low power to maximize the battery lifetime.

The MSP430FR5969 microcontroller communicates with all of the sensor devices via an I2C compatible

interface. The MSP430FR5969 also communicates with the RF430CL331H NFC transponder via this

interface. This board does not include any physical user interface, such as switches. An NFC enabled

smartphone can be used to send configuration to the board. This includes configuration of the RealTime Clock (RTC), both time and date, polling interval, Fahrenheit/Celsius, and sensor mode

(temperature (mode 0), temperature and light (mode 1), temperature and humidity (mode 2),

temperature, light, and humidity (mode 3). In addition, control commands to start measurements, stop

measurements, clear data, and reset can also be sent to the board via NFC.

To ensure the lowest power operation, the power rail for the MSP430 and all I2C compatible devices

has been separated. The power rail to the I2C compatible devices is controlled by the MSP430, so the

devices are only powered as needed during sensor measurements or RF communication. When idle,

the MSP430 is in low power mode and the power rail to the devices is off, resulting in current

consumption under 1 uA.

3

Block Diagram

Coin Cell Battery

(CR2032)

3.0 Volts

NFC

Enabled

Smartphone

Dynamic NFC

Transponder

(RF430CL331H)

I2C

MCU

I2C

Temperature

Sensor

(TMP112)

I2C

I2C

Humidity Sensor

(HDC1000)

Light Sensor

(OPT3001)

Figure 1: System Block Diagram

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

3

�www.ti.com

3.1

Highlighted Products

The Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design features the

following devices:

RF430CL331H

- Dynamic NFC Interface Transponder

MSP430FR5969IRGZ

- FRAM Mixed Signal Microcontroller

TMP112

- High-Accuracy, Low-Power, Digital Temperature Sensor With I2C/SMBus™ Compatible

Interface

HDC1000

- Low Power, 3% Accuracy Digital Humidity Sensor

OPT3001

- Ambient Light Sensor

TPD1E10B06

- Single Channel ESD in 0402 package with 10 pF Capacitance and 6-V Breakdown

For more information on each of these devices, see the respective product folders at www.ti.com

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

4

�www.ti.com

3.1.1 RF430CL331H Description

The TI Dynamic NFC/RFID Interface Transponder RF430CL331H is an NFC Tag Type 4 device that

combines a contactless NFC/RFID interface and a wired I2C compatible interface to connect the device

to a host. The NDEF message can be written and read from the integrated I 2C compatible serial

communication interface and can also be accessed and updated over a contactless interface using the

integrated ISO/IEC 14443 Type B compliant RF interface that supports up to 848 kbps.

The device requests responses to NFC Type 4 commands on demand from the host controller and

stores only a portion of the NDEF message in its buffer at any one time. This allows NDEF message

size to be limited only by the memory capacity of the host controller and specification limitations.

Support of read caching, prefetching, and write automatic acknowledgment features allows for greater

data throughput.

This device enables NFC connection handover for an alternative carrier like Bluetooth ®, Bluetooth ®

Low Energy (BLE), or Wi-Fi as an easy and intuitive pairing process or authentication process with only

a tap. As a general NFC interface, the RF430CL331H enables end equipment to communicate with the

fast growing infrastructure of NFC-enabled smart phones, tablets, and notebooks.

Figure 2: RF430CL331H Block Diagram

3.1.1.1 RF430CL331H Features

NFC Type 4B Tag Platform and ISO/IEC 14443B

I2C Interface to Write and Read NDEF Messages to Internal SRAM

3KB of SRAM for NDEF Message Buffer

Supports up to 847 kbps • Supports NDEF Messages Up To 64KB

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

5

�www.ti.com

3.1.2 MSP430FR5969IRGZ Description

The MSP430™ ultra-low-power (ULP) FRAM platform combines uniquely embedded FRAM and a

holistic ultra-low-power system architecture, allowing innovators to increase performance at lowered

energy budgets. FRAM technology combines the speed, flexibility, and endurance of SRAM with the

stability and reliability of flash at much lower power. The MSP430 ULP FRAM portfolio consists of a

diverse set of devices featuring FRAM, the ULP 16-bit MSP430 CPU, and intelligent peripherals

targeted for various applications. The ULP architecture showcases seven low-power modes, optimized

to achieve extended battery life in energy-challenged applications.

Figure 3: MSP430FR5969 Block Diagram

3.1.2.1 MSP430FR5969IRGZ Features

•

•

•

Embedded Microcontroller

– 16-Bit RISC Architecture up to 16-MHz Clock

– Wide Supply Voltage Range (1.8 V to 3.6 V)

Optimized Ultralow-Power Modes

Ultralow-Power Ferroelectric RAM (FRAM)

– Up to 64KB Nonvolatile Memory

– Ultralow-Power Writes

– Fast Write at 125 ns Per Word (64KB in 4 ms)

– Unified Memory = Program + Data + Storage in one single space

– 1015 Write Cycle Endurance

– Radiation Resistant and Nonmagnetic

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

6

�www.ti.com

•

•

•

•

•

•

•

•

•

•

•

•

•

Intelligent Digital Peripherals

– 32-Bit Hardware Multiplier (MPY)

– Three-Channel Internal DMA

– Real-Time Clock (RTC) With Calendar and Alarm Functions

– Five 16-Bit Timers With up to Seven Capture/Compare Registers Each

– 16-Bit Cyclic Redundancy Checker (CRC)

• High-Performance Analog

– 16-Channel Analog Comparator

– 14-Channel 12-Bit Analog-to-Digital Converter (ADC) with Internal Reference and Sampleand-Hold

200 ksps at 75-µA Consumption

Multifunction Input/Output Ports

– All Pins Support Capacitive Touch Capability With No Need for External Components

– Accessible Bit-, Byte-, and Word-Wise (in Pairs)

– Edge-Selectable Wake From LPM on All Ports

– Programmable Pullup and Pulldown on All Ports

Code Security and Encryption

– 128-Bit or 256-Bit AES Security Encryption and Decryption Coprocessor (MSP430FR59xx

Only)

– Random Number Seed for Random Number Generation Algorithms

Enhanced Serial Communication

– eUSCI_A0 and eUSCI_A1 Support

UART With Automatic Baud-Rate Detection

IrDA Encode and Decode

SPI at Rates up to 10 Mbps

– eUSCI_B0 Supports

I2C compatible interface with Multiple Slave Addressing

SPI at Rates up to 8 Mbps

– Hardware UART and I2C Bootstrap Loader (BSL)

Flexible Clock System

– Fixed-Frequency DCO With 10 Selectable Factory-Trimmed Frequencies

– Low-Power Low-Frequency Internal Clock Source (VLO)

– 32-kHz Crystals (LFXT)

– High-Frequency Crystals (HFXT)

Development Tools and Software

– Professional Development Environments

– Development Kit (MSP TS430RGZ48C)

For Complete Module Descriptions, see the SP430FR58xx, MSP430FR59xx, MSP430FR68xx, and

MSP430FR69xx Family User's Guide (SLAU367)

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

7

�www.ti.com

3.1.3 TMP112 Description

The TMP112 device is a digital temperature sensor ideal for NTC/PTC thermistor replacement where

high accuracy is required. The device offers an accuracy of ±0.5°C without requiring calibration or

external component signal conditioning. IC temperature sensors are highly linear and do not require

complex calculations or lookup tables to derive the temperature. The calibration for improved accuracy

feature allows users to calibrate for accuracy as good as ±0.17°C. The on-chip 12-bit ADC offers

resolutions down to 0.0625°C.

The TMP112 device features SMBus™, two-wire and I2C interface compatibility, and allows up to four

devices on one bus. The device also features a SMBus alert function. The device is specified to

operate over supply voltages from 1.4 V to 3.6 V with the maximum quiescent current of 10 µA over the

full operating range.

The 1.6-mm × 1.6-mm SOT563 package is 68% smaller footprint than an SOT23 package. The

temperature sensor in the TMP112 device is the chip itself. Thermal paths run through the package

leads as well as the plastic package. The package leads provide the primary thermal path because of

the lower thermal resistance of the metal.

The TMP112 is ideal for temperature measurement in communication, computer, consumer,

environmental, industrial, and instrumentation applications. It is specified for operation over a

temperature range of –40°C to +125°C.

Figure 4 TMP112 Block Diagram

3.1.3.1 TMP112 Features

SOT563 Package (1.6 mm × 1.6 mm) is 68% smaller footprint than SOT23

Accuracy Without Calibration:

- 0.5°C (max) from 0°C to +65°C

- 1.0°C (max) from –40°C to +125°C

Low Quiescent Current:

- 10 µA Active (max), 1 µA Shutdown (max)

Supply Range: 1.4 V to 3.6 V

Resolution: 12 Bits

Digital Output: SMBus™, Two-Wire and I2C Interface Compatibility

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

8

�www.ti.com

3.1.4 HDC1000 Description

The HDC1000 is a digital humidity sensor with an integrated temperature sensor that provides excellent

measurement accuracy at very low power. The device measures humidity based on a novel capacitive

sensor. The humidity and temperature sensors are factory calibrated. The innovative WLCSP (Wafer

Level Chip Scale Package) simplifies board design with the use of an ultra-compact package. The

HDC1000 is functional within the full –40°C to 125°C temperature range.

Figure 5: HDC1000 Block Diagram

3.1.4.1 HDC1000 Features

•

•

•

•

•

•

•

•

•

•

Relative humidity (RH) operating range 0% to 100%

14-bit measurement resolution

Relative humidity accuracy ±3%

Temperature range

– Operating –20°C to +85°C

– Functional –40°C to +125°C

Temperature accuracy ±0.2°C

200 nA sleep mode current

Average supply current:

– 820 nA at 1 sps, 11 bit RH measurement

– 1.2 µA at 1 sps, 11 bit RH and temperature measurement

Supply voltage 3 V to 5 V

Tiny 2 mm × 1.6 mm device footprint

I2C interface

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

9

�www.ti.com

3.1.5 OPT3001 Description

The OPT3001 is a sensor that measures the intensity of visible light. The spectral response of the

sensor tightly matches the photonic response of the human eye and includes significant infrared

rejection. Measurements can be made from 0.01 lux up to 83k lux without manually selecting full-scale

ranges by using the built-in, full-scale setting feature. This capability allows light measurement over a

23-bit effective dynamic range.

The digital operation is flexible for system integration. Measurements can be either continuous or

single-shot. The control and interrupt system features autonomous operation, allowing the processor to

sleep while the sensor searches for appropriate wake-up events to report via the interrupt pin. The

digital output is reported over an I2C- and SMBus-compatible, two-wire serial interface.

The low power consumption and low power-supply voltage capability of the OPT3001 enhance the

battery life of battery-powered systems.

Figure 6: OPT3001 Block Diagram

3.1.5.1 OPT3001 Features

•

•

•

•

•

•

•

•

•

•

•

•

Precision Optical Filtering to Match Human Eye:

Rejects > 99% (typ) of IR

Automatic Full-Scale Setting Feature Simplifies Software and Ensures Proper Configuration

Measurements: 0.01 lux to 83k lux

23-Bit Effective Dynamic Range with Automatic Gain Ranging

12 Binary-Weighted Full-Scale Range Settings: < 0.2% (typ) Matching Between Ranges

Low Operating Current: 1.8 µA (typ)

Operating Temperature Range: –40°C to +85°C

Wide Power-Supply Range: 1.6 V to 3.6 V

5.5-V Tolerant I/O

Flexible Interrupt System

Small-Form Factor: 2.0 mm × 2.0 mm × 0.65 mm

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

10

�www.ti.com

3.1.6 TPD1E10B06 Description

The TPD1E10B06 device is a single-channel electrostatic discharge (ESD) transient voltage

suppression (TVS) diode in a small 0402 package. This TVS protection product offers ±30-kV contact

ESD, ±30-kV IEC air-gap protection, and has an ESD clamp circuit with a back-to-back TVS diode for

bipolar or bidirectional signal support.

Figure 7: TPD1E10B06 Block Diagram

3.1.7 TPD1E10B06 Features

•

•

•

•

•

•

•

•

•

•

Provides System Level ESD Protection for Low-voltage IO Interface

IEC 61000-4-2 Level 4

– ±30 kV (Air-Gap Discharge)

– ±30 kV (Contact Discharge)

IEC 61000-4-5 (Surge): 6 A (8/20 µs)

IO Capacitance 12 pF (typ)

RDYN 0.4 Ω (typ)

DC Breakdown Voltage ±6 V (Min)

Ultra Low Leakage Current 100 nA (Max)

10 V Clamping Voltage (Max at IPP = 1 A)

Industrial Temperature Range: –40°C to +125°C

Space Saving 0402 Footprint (1.0 mm × 0.6 mm × 0.5 mm)

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

11

�www.ti.com

4

4.1

System Design Theory

Component Selection

4.1.1 Dynamic Interface Transponder

The RF430CL331H Dynamic NFC Interface Transponder is an NFC Tag Type 4B device that combines

a wireless NFC interface and a wired I2C interface to connect the device to a host. The device utilizes a

3KB SRAM buffer to receive commands from an NFC enabled reader/writer and also communicate

back the response. The integrated ISO14443B-compliant RF interface supports data rates from 106

kbps to 848 kbps. The RF430CL331H was chosen to allow for a low cost, dual interface (wired and

wireless) transponder which allows for communication to/from a host controller. This functionality is not

possible with a standard passive NFC transponder (wireless only).

4.1.2 Microcontroller Selection

The MSP430 ultra-low-power (ULP) FRAM platform combines uniquely embedded FRAM and a holistic

ultra-low-power system architecture, allowing innovators to increase performance at lowered energy

budgets. FRAM technology combines the speed, flexibility, and endurance of SRAM with the stability

and reliability of flash at much lower power. The MSP430FR5969 was chosen for the large (64kB)

amount of non-volatile memory along with ultra-low power operation, which is especially important for

applications such as data loggers where the system is in low power mode a majority of the time.

4.1.3 Digital Temperature Sensor

The TMP112 digital temperature sensor device was chosen for this TI Design to provide high accuracy

temperature measurements, while requiring miniscule power and board space. The TMP112 device is a

digital output temperature sensor in a 1.6 mm x 1.6 mm footprint SOT563 package. It is specified for

operation over a temperature range of –40°C to +125°C and it offers an accuracy of ±0.5°C without

requiring calibration or external component signal conditioning. Its maximum quiescent current is 10 µA

over the full operating range.

4.1.4 Humidity Sensor

The HDC1000 humidity sensor device was chosen to enable humidity measurements in the Ultralow

Power Multi-sensor Data Logger with NFC Interface Reference Design. This humidity sensor is

functional within the full –40°C to +125°C temperature range. The sensor element of the HDC1000 is

placed on the bottom part of the device, which makes the HDC1000 robust against dirt, dust, and other

environmental contaminants.

4.1.5 Light Sensor

The OPT3001 light sensor device was chosen to enable ambient light measurements in the Ultralow

Power Multi-sensor Data Logger with NFC Interface Reference Design.

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

12

�www.ti.com

4.1.6 ESD Protection

The TPD1E10B06 Single Channel ESD protection device was chosen to protect the Spy Bi-Wire (2wire JTAG) programming interface. The device offers over ±30 KV IEC air-gap, over ±30 KV contact

ESD protection, and has an ESD clamp circuit with a back-to-back diode for bipolar or bidirectional

signal support. The 10 pF line capacitance is suitable for a wide range of applications supporting data

rates up to 400 Mbps. The 0402 package is industry standard and convenient for component placement

in space saving applications. The TPD1E10B06 is characterized for operation over ambient air

temperature of –40°C to +125°C.

4.1.7 Coin Cell Battery

The CR2032 lithium-ion coin cell battery was chosen as the power source of this design due to its

ability of providing long shelf life, continuous voltage supply (220 mAh at 3 V) and its great availability

on the market. Also, the CR2032 is commonly used in small, low power applications like this data

logger due to its small form factor (20 mm diameter x 3.2 mm thickness) and low cost. The CR2032

operating temperature range is –30°C to +60°C. Among all the integrated circuits and electrical

components in the Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

board the CR2032 have the narrower temperature range. Therefore, the specified operating

temperature range of the data loggers is –30°C to +60°C.

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

13

�www.ti.com

5

5.1

Getting Started Hardware

Hardware Overview

The Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design is shown in Figure

8 Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design. This design is 59 mm x 43

mm and includes two mounting holes on opposing corners to allow for mounting the board in specific

test environments.

Figure 8 Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

All components are located on the top side of the PCB. The antenna coil wraps around the edge and

uses both top and bottom layers. The board has been designed for use with a CR2032 battery with the

Battery holder (B1). J3 is used for programming and debug of the MSP430 microcontroller.

5.2

Programming the board

An MSP-FET must be used to program the Reference Design board. The appropriate connections

between the Reference Design hardware and the MSP-FET programming tool are shown in Table 1.

For convenience, the pinout diagram of the MSP-FET debugger is shown in Figure 9: MSP- FET JTAG

Connector Pinout. Once the electrical connections between the Reference Design board and the MSPFET are complete, then Code Composer Studio can be used to program the board.

Table 1: TIDA-00524 and MSP-FET JTAG Connector Pin Numbers and Names

TIDA-00524 J3 Pin

Number

1

2

3

4

5

6

TIDA-00524 J3 Pin

Name

NC

VCC

SBWTCK

SBWTDIO

GND

NC

MSP-FET Pin

Number

2

7

1

9

-

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

MSP-FET Pin

Name

VCC_TOOL

TCK

TDO/TDI

GND

14

�www.ti.com

Figure 9: MSP- FET JTAG Connector Pinout

5.3

Configuring Reference Board using NFC enabled Phone/Tablet

The Data logger comes pre-programed and ready to be configured. Using a NFC enabled smart

phone, confirm that NFC is turned on in the settings. Next present the data logger to the back of the

phone. The welcome message, as shown in Figure 10: Welcome Message, should be read out and

displayed. The welcome message list default settings as well as all supported commands. This

message will always be displayed below all logged measurements for quick reference.

Figure 10: Welcome Message

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

15

�www.ti.com

Configure the time, date, polling interval, and mode using the commands listed in Table 2. Once

configured, start the data logger. To read the logged measurements at any time, just present an NFC

enabled phone. Readings will appear as shown in Figure 11.

Table 2: Data Logger Commands

Control Commands

ST

SP

CD

RE

Configuration Commands

TI HH:MM:SS

DA MM/DD/YY

PI xxx

TM x

MO x

Description

Start data logging with current settings.

Stop/Pause data logging.

Clears data while keeping all settings.

Clears data and returns all settings to default.

Set Time in 24 hour format. Ex: “TI 14:30:00” (2:30 pm)

Set Date. Ex: “DA 09/01/15”

Set Polling interval in minutes. Ex: “PI 45”

Temperature Mode. Ex: “TM C” for Celsius

Set Data logging Mode. Ex: “MO 3”

Figure 11: Data Logged Measurements (Mode 3)

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

16

�www.ti.com

6

6.1

Getting Started Firmware

High Level Controller Overview

Upon power up, the firmware runs a check to determine the previous state of the data logger. Since

our MSP430F5969 uses FRAM, which acts like non-volatile RAM, all previous states, settings, and

measurements are preserved. If the data logger has never been initialized, the welcome message is

written. This feature of FRAM also allows for easy detection of a previous power loss. If the firmware

determines that power was lost while logging, a warning message will be added. Time and date will be

reset because there is no way to determine the length of the power loss. The Controller state diagram

in Figure 12 shows the high level flow.

Power Up

Data logger

Memory

Initialized?

No

Yes

Data logger in

Reset State?

No

Data logger Init

Yes

Load Default Settings:

Mode: Temp Only

Temp Mode: Fahrenheit

Time: 12:00:00 AM

Date: 1/1/2015

Polling Interval: 10 minutes

Default State: Stopped

Power Lost State

Write power lost message

Time and Date Reset

Reset all data Pointers

Write welcome message to

Data logger memory

Wait for Command.

Command

Received?

No

Control

Commands

Configuration

Commands

Set Mode

MO x

RE

Reset

Restore default settings

Set Time

TI hh:mm:ss

ST

Start

Enable Data Logging

Set Date

DA mm:dd:yy

SP

Stop

Disable Data Logging

Set Polling Interval

1-720 minutes.

PI xxx

CD

Clear Data

Keeps all settings

Set Temperature Mode

Fahrenheit or Celsius

TM x

Process Command State

Figure 12: Controller State Diagram

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

17

�www.ti.com

6.2

Data logger

The data logger is triggered by an alarm from the real-time clock (RTC). Once triggered, it checks if

there is still memory space available. If so, depending on the mode selected, it calls the respective

drivers for each sensor. These measurements are packaged along with a time stamp and stored in the

data logger memory block. The data logger state diagram is show in Figure 13. There is 46KB of data

logger memory space. Table 3 shows the number of measurements possible in each mode.

Wake from RTC

Alarm

Data logger

Memory Full?

Disable Data logging

Sleep

Data Logger

Mode

Mode 0

Mode 1

Mode 2

Mode 3

Get Temperature

Get Temperature

Get Temperature

Get Temperature

Get Lux

Get Humidity

Get Lux

Get Humidity

Store Sample in

Data logger Memory

Sleep

Figure 13: Data Logger State Diagram

Table 3: Number of measurements available in memory

Mode

Size

Number of samples

Notes

0

25 bytes

1853

-

1

36 bytes

1286

2

34 bytes

1362

Low lux measurements could adjust the

size down to 34 bytes

-

3

45 bytes

1029

Low lux measurements could adjust the

size down to 43 bytes

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

18

�www.ti.com

6.3

NFC Overview

The NFC Forum defines a data format for NFC messages called NDEF (NFC Data Exchange Format).

Utilization of a common data format allows for all NFC compliant devices to exchange data in a “well

known” format. NDEF allows for many different record types ranging from simple text records, URL,

Vcard, and Bluetooth Connection Handover just to name a few. In this application, we are using simple

text records to display the measurements. Figure 14 shows an example of a NDEF tag application

mapping.

Figure 14: NDEF tag Application Mapping Example

There is a state machine in the NFC stack that emulates this NDEF memory structure. The

RF430CL331H generates requests for each file as required to respond to the NFC reader. The

RF430CL331H supports files up to 64KB. This enables streaming of all the measurements in a single

NDEF message, preventing the need to tap the phone more than once or needing custom applications.

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

19

�www.ti.com

7

7.1

Test Data

Temperature Characterization

Figure 15 shows the test setup for temperature testing. For this test, two data loggers were placed in a

Delta 9064 Environmental Test Chamber. Data logger # 1 was configured to log every 5 minutes, in

Temperature reading mode only (Mode 0). Data logger #2 was configured to log every 5 minutes, in

Temperature + Humidity + Light Mode (Mode 3). Data logger #2 was added to the test to confirm that

the accuracy of TMP112 readings won’t be affected when other sensors are in use at the same time.

Figure 15: Delta 9064 Environmental Test Chamber and Test Setup

Two tests were performed. For test #1, the test chamber was programmed to do temperature steps

every 10°C, from 0°C to 60°C. For test #2, the chamber was programed to decrease from 0°C to -30°C

at a -10°C step rate. Table 4 shows the data logger readings for these two tests. These readings

confirm the accuracy of TMP112 in this design is around +/- 0.2°C (typ), +/- 1.0°C (max), without

calibration.

Table 4: TMP112 Temperature Reading Results

Oven Temperature (°C)

-30.0

-20.0

-10.0

0.0

10.0

20.0

30.0

40.0

50.0

60.0

TMP112 Temperature (°C)

Data logger #1

-30.0

-20.1

-10.0

0.0

09.8

19.8

29.6

39.7

49.7

59.2

TMP112 Temperature (°C)

Data logger #2

-29.6

-19.8

-9.6

0.0

10.0

20.0

29.8

39.8

49.8

59.0

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

20

�www.ti.com

7.2

Read/Write Distance

Table 5 shows the measured communication range with some common NFC enabled phone/tablet

devices. This data assumes a parallel orientation between the reader antenna and the tag antenna

which provides the maximum magnetic field coupling.

Table 5: Communication Range

Device

Nexus 4

Nexus 5

Nexus 10

7.3

Communication Range

4.5 cm

4.5 cm

5.5 cm

Data Throughput

Data throughput varies based on the NFC reader/writer implementation of each tested device. The

conditions for the data throughput testing are listed in Table 6 along with the test results for several

NFC compliant devices.

• Data Rate: 106 kbps

• Payload size: 24 KBytes

• Start/End Time marks: Req B command / Deselect response

Table 6: Data Throughput

Device

Nexus 4

Nexus 5

Nexus 10

Write Throughput

4.6 KBps

3.1 KBps

5.1 KBps

Read Throughput

4.8 KBps

3.3 KBps

5.8 KBps

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

21

�www.ti.com

7.4

Battery Life

In order to achieve very long battery life, there are some parameters which must be considered. The

main parameters that affect the estimated battery life of the entire system are:

• Capacity rating of the battery in milliamp-hours (mAh)

• Average off-state current consumption (nA)

• Off-state durations

• Average on-state current consumption (mA)

• On-state durations

( 1 ) describes the estimated battery life of the system in units most convenient to this TI Design:

𝐵𝑎𝑡𝑡𝑒𝑟𝑦 𝑙𝑖𝑓𝑒 (𝑦𝑒𝑎𝑟𝑠) =

𝐵𝑎𝑡𝑡𝑒𝑟𝑦 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦(𝑚𝐴ℎ)

1 𝑦𝑒𝑎𝑟

×

× 85% 𝑑𝑒𝑟𝑎𝑡𝑖𝑛𝑔 𝑓𝑎𝑐𝑡𝑜𝑟

𝐼𝑜𝑛 (𝑚𝐴) × 𝑡𝑜𝑛 (𝑠) + 𝐼𝑜𝑓𝑓 (𝑛𝐴) × 𝑡𝑜𝑓𝑓 (𝑠) × 10−6

8760 ℎ𝑜𝑢𝑟𝑠

(𝑡𝑜𝑛 (𝑠) + 𝑡𝑜𝑓𝑓 (𝑠))

(1)

Figure 16 can be used to estimate the CR2032 battery life of the Ultralow power Multi-sensor Data

Logger with NFC Interface Reference Design on every mode.

Figure 16: Battery Life Estimation

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

22

�www.ti.com

7.5

Antenna Characteristics

Figure 17 shows the resonant frequency measurement of this reference board. Antenna inductance

and resulting Q value calculations are also shown in Figure 18. Antenna tuning is necessary in order to

keep the antenna resonant at or very close to the NFC operating frequency of 13.56 MHz to maximize

data and power transfer. For further information regarding antenna tuning, see SLOA197.

Figure 17: Resonant Frequency

Inductance (L) = 1.92uH

BW = f2 - f1

Q=

Q=

𝑓𝑟𝑒𝑞

𝐵𝑊

13.66𝑀𝐻𝑧

448.9𝑘𝐻𝑧

Q = 30.4

Figure 18: Q value Calculation

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

23

�www.ti.com

8

8.1

Design Files

Schematics

To download the Schematics for each board, see the design files at http://www.ti.com/tool/TIDA-00524

Figure 19: Ultra Low Power Multi-sensor Data Logger with NFC Interface Schematic

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

24

�www.ti.com

8.2

Layout Guidelines

To enable a low cost PCB, this design uses a 2-layer PCB. The bottom layer contains a ground pour

and signal routing and the top layer contains signal routing only. In order to maximize the RF

performance and reduce the PCB dimensions, the antenna coil is wrapped around the outside edge of

the PCB and components are placed in the middle of the PCB. It is important to provide spacing

between the antenna coil and any large metallic components such as batteries or ground pours.

For all of the TI products used in this TI Design, ensure that care is taken to adhere to the layout

guidelines given in the respective datasheets.

8.3

Bill of Materials

To download the Bill of Materials for each board, see the design files at http://www.ti.com/tool/TIDA00524

8.3.1 Layout Prints

To download the Layout Prints for each board, see the design files at http://www.ti.com/tool/TIDA00524

8.4

Altium Project

To download the Altium project files for each board, see the design files at http://www.ti.com/tool/TIDA00524

8.5

Gerber files

To download the Gerber files for each board, see the design files at http://www.ti.com/tool/TIDA-00524

8.6

Assembly Drawings

To download the Assembly Drawings for each board, see the design files at

http://www.ti.com/tool/TIDA-00524

9

Software Files

To download the software files for this reference design, please see the link at

http://www.ti.com/tool/TIDA-00524

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

25

�www.ti.com

10 References

For additional references, see the following:

1. MSP430FR5969 Data Sheet, MSP430FR59xx Mixed-Signal Microcontrollers (SLAS704)

2. TMP112 Data Sheet, High-Accuracy, Low-Power, Digital Temperature Sensor With SMBus™ and

Two Wire Serial Interface in SOT563 (SBOS473)

3. TPD1E10B06 Data Sheet, Single Channel ESD Protection Device in 0402 Package (SLLSEB1)

4. HDC1000 Data Sheet, Low Power, 3% Accuracy Digital Humidity Sensor with Integrated

Temperature Sensor (SNAS643)

5. OPT3001 Data Sheet, Digital Ambient Light Sensor (ALS) with High Precision Human Eye

Response (SBOS681B)

6. NFC Forum Specifications: http://nfc-forum.org/our-work/specifications-and-application-documents/

11 About the Author

EDDIE LACOST is a NFC/RFID Applications Specialist at Texas Instruments where he is responsible

for developing reference design solutions and supporting customer applications for the NFC/RFID

market. Eddie brings to this role experience in low frequency and high frequency RFID/NFC, antenna

design, and mixed signal design. Eddie earned his Bachelor of Science (BS) in Technical Management

from DeVry University in Irving, TX.

JOHN CRUTCHFIELD is a NFC/RFID Applications Specialist at Texas Instruments where he is

responsible for developing reference software and supporting customer applications for the NFC/RFID

and Car Access markets. John brings to this role experience in low frequency and high frequency

RFID/NFC software, embedded design, and mixed signal design. John earned his Bachelor of Science

(BS) in Electrical Engineering from the University of Florida.

MAYRIM VERDEJO is an Applications Engineer at Texas Instruments (TI). She assists customers in

designing TI temperature sensors into end products which require precise temperature measurement.

To accelerate engineer’s time-to-market, she develops evaluation boards and demos showcasing TI

temperature sensors. Mayrim responds to technical inquiries on E2E and directly supports customers in

debugging technical issues via phone, email and on-site visits. She compiles product information and

training material for customers and internal TI staff which involves writing reference designs,

applications notes and product presentation slides. Mayrim graduated from the University of Puerto

Rico, Mayagüez, where she earned a Bachelor of Science in Electrical Engineering.

TIDU821 - September 2015Ultralow Power Multi-sensor Data Logger with NFC Interface Reference Design

Copyright © 2015, Texas Instruments Incorporated

26

�IMPORTANT NOTICE FOR TI REFERENCE DESIGNS

Texas Instruments Incorporated ("TI") reference designs are solely intended to assist designers (“Buyers”) who are developing systems that

incorporate TI semiconductor products (also referred to herein as “components”). Buyer understands and agrees that Buyer remains

responsible for using its independent analysis, evaluation and judgment in designing Buyer’s systems and products.

TI reference designs have been created using standard laboratory conditions and engineering practices. TI has not conducted any

testing other than that specifically described in the published documentation for a particular reference design. TI may make

corrections, enhancements, improvements and other changes to its reference designs.

Buyers are authorized to use TI reference designs with the TI component(s) identified in each particular reference design and to modify the

reference design in the development of their end products. HOWEVER, NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL

OR OTHERWISE TO ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY THIRD PARTY TECHNOLOGY

OR INTELLECTUAL PROPERTY RIGHT, IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right,

or other intellectual property right relating to any combination, machine, or process in which TI components or services are used.

Information published by TI regarding third-party products or services does not constitute a license to use such products or services, or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

TI REFERENCE DESIGNS ARE PROVIDED "AS IS". TI MAKES NO WARRANTIES OR REPRESENTATIONS WITH REGARD TO THE

REFERENCE DESIGNS OR USE OF THE REFERENCE DESIGNS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING ACCURACY OR

COMPLETENESS. TI DISCLAIMS ANY WARRANTY OF TITLE AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, QUIET ENJOYMENT, QUIET POSSESSION, AND NON-INFRINGEMENT OF ANY THIRD PARTY

INTELLECTUAL PROPERTY RIGHTS WITH REGARD TO TI REFERENCE DESIGNS OR USE THEREOF. TI SHALL NOT BE LIABLE

FOR AND SHALL NOT DEFEND OR INDEMNIFY BUYERS AGAINST ANY THIRD PARTY INFRINGEMENT CLAIM THAT RELATES TO

OR IS BASED ON A COMBINATION OF COMPONENTS PROVIDED IN A TI REFERENCE DESIGN. IN NO EVENT SHALL TI BE

LIABLE FOR ANY ACTUAL, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES, HOWEVER CAUSED, ON ANY

THEORY OF LIABILITY AND WHETHER OR NOT TI HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, ARISING IN

ANY WAY OUT OF TI REFERENCE DESIGNS OR BUYER’S USE OF TI REFERENCE DESIGNS.

TI reserves the right to make corrections, enhancements, improvements and other changes to its semiconductor products and services per

JESD46, latest issue, and to discontinue any product or service per JESD48, latest issue. Buyers should obtain the latest relevant

information before placing orders and should verify that such information is current and complete. All semiconductor products are sold

subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques for TI components are used to the extent TI

deems necessary to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not

necessarily performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

Reproduction of significant portions of TI information in TI data books, data sheets or reference designs is permissible only if reproduction is

without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for

such altered documentation. Information of third parties may be subject to additional restrictions.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards that

anticipate dangerous failures, monitor failures and their consequences, lessen the likelihood of dangerous failures and take appropriate

remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use of any TI components in

Buyer’s safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed an agreement specifically governing such use.

Only those TI components that TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components that

have not been so designated is solely at Buyer's risk, and Buyer is solely responsible for compliance with all legal and regulatory

requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

�