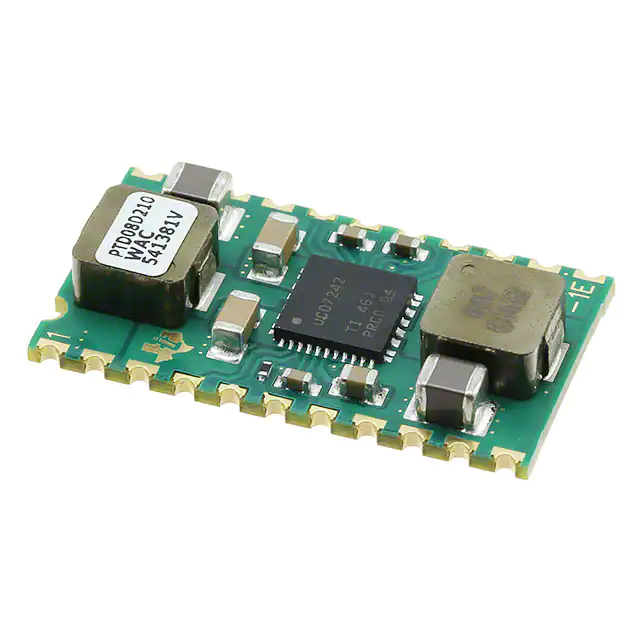

PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

DUAL 10-A OUTPUTS, 4.75-V to 14-V INPUT, NON-ISOLATED,

DIGITAL POWERTRAIN™ MODULE

Check for Samples: PTD08D210W

FEATURES

DESCRIPTION

•

•

•

The PTD08D210W is a high-performance dual 10-A

output, non-isolated digital PowerTrain module. This

module is the power conversion section of a digital

power system which incorporates TI's UCD7242

MOSFET/driver IC. The PTD08D210W must be used

in conjunction with a digital power controller such as

the UCD9240, UCD9220 or UCD9110 family. The

PTD08D210W receives control signals from the

digital controller and provides parametric and status

information back to the digital controller. Together,

PowerTrain modules and a digital power controller

form a sophisticated, robust, and easily configured

power management solution.

1

2

•

•

•

•

•

Dual 10-A Outputs

4.75-V to 14-V Input Voltage

Programmable Wide-Output Voltage

(0.7 V to 3.6 V)

Efficiencies up to 96%

Digital I/O

– PWM signal

– Fault Flag (FF)

– Sychronous Rectifier Enable (SRE)

Analog I/O

– Temperature

– Output currrent

Safety Agency Approvals: (Pending)

– UL/IEC/CSA-C22.2 60950-1

Operating Temperature: –40°C to 85°C

APPLICATIONS

•

Digital Power Systems

using UCD9XXX Digital Controllers

Operating from an input voltage range of 4.75 V to

14 V, the PTD08D210W provides step-down power

conversion to a wide range of output voltages from,

0.7 V to 3.6 V. The wide input voltage range makes

the PTD08D210W particularly suitable for advanced

computing and server applications that utilize a

loosely regulated 8-V, 9.6-V or 12-V intermediate

distribution bus. Additionally, the wide input voltage

range increases design flexibility by supporting

operation with tightly regulated 5-V or 12-V

intermediate bus architectures.

The module incorporates output over-current and

temperature monitoring which protects against most

load faults. Output current and module temperature

signals are provided for the digital controller to permit

user defined over-current and over-temperature

warning and fault scerarios.

The module uses single-sided, pin-less surface

mount construction to provide a low profile and

compact footprint. The package is lead (Pb) - free

and RoHS compatible.

1

2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

POWERTRAIN is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009–2010, Texas Instruments Incorporated

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

Standard PTD08D210W Application

18

4

17

5

15

7

PWM-A

PWM-B

SRE-A

SRE-B

FF-A

FF-B

Digital

Lines

to/from

Digital

Controller

VOA 22

VI

AGND

PGND

PGND

VOB

AGND

CI2

22 mF

(Required)

GND

ISENSE-B

+

CI1

330 mF

(Recommended)

COA2

330 mF

(Recommended)

PGND 19

ISENSE-A

2

VI

COA1

+

47 mF

(Required)

PGND 20

PTD08D210W

TSENSE

VI

PGND

1

VOA

VOA 21

3

16

14

6

12

13

8

9

VOB 10

VOB 11

GND

COB1

+

47 mF

(Required)

COA2

330 mF

(Recommended)

GND

Analog

Lines

to

Digital

Controller

UDG-09155

2

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

ORDERING INFORMATION

For the most current package and ordering information, see the Package Option Addendum at the end of this datasheet, or see

the TI website at www.ti.com.

DATASHEET TABLE OF CONTENTS

DATASHEET SECTION

PAGE NUMBER

ENVIRONMENTAL AND ABSOLUTE MAXIMUM RATINGS

3

ELECTRICAL CHARACTERISTICS TABLE

4

TERMINAL FUNCTIONS

5

TYPICAL CHARACTERISTICS (VI = 12V)

6

TYPICAL CHARACTERISTICS (VI = 5V)

8

TYPICAL APPLICATION SCHEMATIC

10

GRAPHICAL USER INTERFACE VALUES

11

TAPE & REEL AND TRAY DRAWINGS

12

ENVIRONMENTAL AND ABSOLUTE MAXIMUM RATINGS

(Voltages are with respect to GND)

UNIT

VI

Input voltage

TA

Operating temperature range

Over VI range

Treflow

Solder reflow temperature

Surface temperature of module body

Tstg

16

260 (1)

Storage temperature

–55 to 125

Mechanical shock

Per Mil-STD-883D, Method 2002.3, 1 msec, 1/2 sine, mounted

275

Mechanical vibration

Mil-STD-883D, Method 2007.2, 20-2000 Hz

10

Weight

MTBF

(1)

(2)

V

–40 to 85

Reliability

Per Telcordia SR-332, 50% stress, TA = 40°C, ground benign

Flammability

Meets UL94V-O

°C

(2)

G

3.9

grams

13.3

106 Hr

During reflow do not elevate peak temperature of the module or internal components above the stated maximum.

The shipping tray or tape and reel cannot be used to bake parts at temperatures higher than 65°C.

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

3

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

ELECTRICAL CHARACTERISTICS

PTD08D210W

TA= 25°C, FSW= 750kHz, VI= 12 V, VO= 1.2 V, CI1= 330 µF, CI2= 22 µF ceramic, CO1= 47 µF ceramic, CO2= 330 µF, IO= IO(max),

single output (unless otherwise stated)

PARAMETER

TEST CONDITIONS

PTD08D210W

MIN

IO

Output current

Over VO range

VI

Input voltage range

VOADJ

Output voltage adjust range

Efficiency

h

25°C, natural convection

10

A

Over IO range

4.75

14

V

Over IO range

0.7

3.6 (1)

V

IO = 10 A,

fs = 750 kHz

VO Ripple (peak-to-peak)

20-MHz bandwidth

IB

Bias current

PWM & SRE to AGND

VIH

High-level input voltage

VIL

Low-level input voltage

VO = 3.3 V

92.8%

VO = 2.5 V

91.4%

VO = 1.8 V

89.1%

VO = 1.5 V

87.7%

VO = 1.2 V

85.6%

VO = 1.0 V

84.0%

11

Standby

SRE & PWM input levels

VOL

Frequency range

500 (1)

Pulse width limits

20

Accuracy, -40°C ≤ TA ≤ 85°C

-5

ILIM

Gain, 3A ≤ IO ≤ 10A

188

0

Offset, IO = 0A, VO = 1.2V

3.3

CO

External output capacitance

Ceramic

Equivalent series resistance (non-ceramic)

(1)

(2)

(3)

(4)

(5)

(6)

4

0.6

22

(3)

47

(4)

Nonceramic

Ceramic

1 (6)

V

A

3.5

V

200

212

mV/A

0.3

0.76

10

Nonceramic

°C

mV

15 (2)

0.15

Capacitance Value

°C

720

0

Range

External input capacitance

125

mV/°C

Output Impedance

CI

kHz

10

Low-level output voltage, IFAULT = 4mA

Overcurrent threshold; Reset, followed by auto-recovery

IOUT output

1000

5

Slope

2.7

V

ns

-40

High-level output voltage, IFAULT = 4mA

FAULT output

mA

5.5

0.8

Offset, TA = 25°C

VOH

mVPP

6

2.0

Range

TEMP output

MAX

0

VOPP

PWM input

TYP

UNIT

330

(3)

330

(4)

V

kΩ

µF

5000 (5)

µF

mΩ

When operating at 12V input and 500kHz, VO is limited to ≤ 2.0V.

The current limit threshold is the sum of IO and the peak inductor ripple current.

A 22 µF ceramic input capacitor is required for proper operation. An additional 330 µF bulk capacitor rated for a minimum of 500mA rms

of ripple current is recommended. When operating at frequencies > 500kHz the 22 µF ceramic capacitor is only recommended. Refer to

the UCD9240 controller datasheet and user interface for application specific capacitor specifications.

A 47 µF ceramic output capacitor is required for basic operation. An additional 330 µF bulk capacitor is recommended for improved

transient response. Refer to the UCD9240 controller datasheet and user interface for application specific capacitor specifications.

5,000 µF is the calculated maximum output capacitance given a 1V/msec output voltage rise time. Additional capacitance or increasing

the output voltage rise rate may trigger the overcurrent threshold at start-up. Refer to the UCD9240 controller datasheet and user

interface for application specific capacitor specifications.

This is the minimum ESR for all non-ceramic output capacitance. Refer to the UCD9240 controller datasheet and user interface for

application specific capacitor specifications.

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

TERMINAL FUNCTIONS

TERMINAL

NAME

VI

PGND

NO.

1, 2

DESCRIPTION

The positive input voltage power node to the module, which is referenced to common GND.

3, 8, 9, 19,

The common ground connection for the VI and VO power connections.

20

VOA

21, 22

The regulated positive power A output with respect to GND.

VOB

10, 11

The regulated positive power B output with respect to GND.

ISENSE-A

14

Current sense A output. The voltage level on this pin represents the average output current of the module.

ISENSE-B

6

Current sense B output. The voltage level on this pin represents the average output current of the module.

PWM-A

18

This is the PWM A input pin. It is a high impedance digital input that accepts 3.3-V or 5-V logic level signals up to

1 MHz.

PWM-B

4

This is the PWM B input pin. It is a high impedance digital input that accepts 3.3-V or 5-V logic level signals up to

1 MHz.

FF-A

15

Current limit fault flag A. The Fault signal is a 3.3-V digital output which is latched high after an over-current

condition. The Fault is reset after a complete PWM cycle without an over-current condition (falling edge of the

PWM).

FF-B

7

Current limit fault flag A. The Fault signal is a 3.3-V digital output which is latched high after an over-current

condition. The Fault is reset after a complete PWM cycle without an over-current condition (falling edge of the

PWM).

SRE-A

17

Synchronous Rectifier Enable A. This pin is a high impedance digital input. A 3.3 V or 5 V logic level signals is used

to enable the synchronous rectifier switch. When this signal is high, the module will source and sink output current.

When this signal is low, the module will only source current.

SRE-B

5

Synchronous Rectifier Enable B. This pin is a high impedance digital input. A 3.3 V or 5 V logic level signals is used

to enable the synchronous rectifier switch. When this signal is high, the module will source and sink output current.

When this signal is low, the module will only source current.

AGND

12, 13

TSENSE

16

Thermal

Pad

Analog ground return. It is the 0 Vdc reference for the control inputs.

Temperature sense output. The voltage level on this pin represents the temperature of the module.

This pad is electrically connected to PGND and is the primary thermal conduction cooling path for the module. This

pad should be soldered to a grounded copper pad on the host board. For optimum cooling performance, the

grounded copper pad should also be tied with multiple vias to the host board internal ground plane. See the Land

Pattern drawing for package EFS for recommended pad dimensions.

XX

XX

VI

1

VI

2

PGND

3

PWM-B

4

BOTTOM VIEW

1

TOP VIEW

22

VO-A

22

VO-A

21

2

21

PGND

20

3

PGND

19

4

PWM-A

18

5

20

19

SRE-B

5

ISENSE-B

6

17

SRE-A

17

6

FF-B

7

16

TSENSE

16

7

PGND

8

FF-A

15

PGND

VO-B

VO-B

9

10

11

18

15

8

Thermal

Pad

14

ISENSE-A

14

13

AGND

13

10

AGND

12

11

12

9

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

5

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

TYPICAL CHARACTERISTICS (VI = 12 V)

. (1) (2)

100

100

100

VO = 3.3 V

VO = 1.8 V

90

VO = 1.2 V

VO = 0.8 V

70

60

80

VO = 1.8 V

VO = 1.2 V

70

VO = 0.8 V

60

VI = 12 V

fSW = 500 kHz

4

6

8

10

4

6

6

8

VO = 1.2 V

VO = 1.8 V

2.0

VO = 2.5 V

1.5

VO = 3.3 V

1.0

VO = 1.2 V

4

6

8

10

0

2

4

6

8

VO = 1.2 V

0

10

8

200 LFM

60

100 LFM

50

Natural Convection

400 LFM

70

200 LFM

60

100 LFM

50

40

Natural Convection

30

VI = 12 V

fSW = 500 kHz

0

1

200 LFM

60

100 LFM

50

40

Natural Convection

2

3

4

5

VI = 12 V

fSW = 1 MHz

PD(VOA)+PD(VOB)

20

20

5

70

30

VI = 12 V

fSW = 750 kHz

PD(VOA)+PD(VOB)

20

10

80

TA – Ambient Temperature – °C

TA – Ambient Temperature – °C

70

Figure 7. Safe Operating Area

6

90

80

80

PD – Total Power Dissipation – W

4

400 LFM

400 LFM

4

2

Figure 6. Power Dissipation

90

90

3

1.0

IO – Output Current – A

Figure 5. Power Dissipation

2

VO = 3.3 V

VO = 0.8 V

Figure 4. Power Dissipation

PD(VOA)+PD(VOB)

1.5

0

IO – Output Current – A

30

VO = 2.5 V

VO = 0.8 V

IO – Output Current – A

40

VO = 1.8 V

2.0

0.5

0.5

0

2

VI = 12 V

fSW = 1 MHz

2.5

PD – Power Dissipation – W

1.0

10

3.0

VI = 12 V

fSW = 750 kHz

2.5

VO = 1.8 V

1

4

Figure 3. Efficiency

2.0

0

2

Figure 2. Efficiency

0

TA – Ambient Temperature – °C

0

Figure 1. Efficiency

VO = 0.8 V

6

10

IO – Output Current – A

0.5

(2)

8

IO – Output Current – A

PD – Power Dissipation – W

PD – Power Dissipation – W

2

3.0

0

60

IO – Output Current – A

VI = 12 V

fSW = 500 kHz

1.5

VO = 0.8 V

40

0

3.0

2.5

VO = 1.2 V

VI = 12 V

fSW = 1 MHz

40

2

VO = 1.8 V

70

VI = 12 V

fSW = 750 kHz

40

0

80

50

50

50

(1)

h – Efficiency – %

h – Efficiency – %

80

VO = 3.3 V

VO = 2.5 V

90

90

h – Efficiency – %

VO = 2.5 V

0

1

2

3

4

PD – Total Power Dissipation – W

PD – Total Power Dissipation – W

Figure 8. Safe Operating Area

Figure 9. Safe Operating Area

5

The electrical characteristic data (Figure 1 through Figure 6) has been developed from actual products tested at 25°C. This data is

considered typical for the converter.

The temperature derating curves (Figure 7 through Figure 9) represent the conditions at which internal components are at or below the

manufacturer's maximum operating temperatures. Derating limits apply to modules soldered directly to a 100-mm x 100-mm,

double-sided PCB with 2-oz. copper. See the Safe Operating Area application section of this datasheet.

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

TYPICAL CHARACTERISTICS (VI = 5 V)

. (1) (2)

100

100

VO = 3.3 V

VO = 1.8 V

VO = 0.8 V

VO = 1.2 V

70

60

80

VO = 1.8 V

VO = 0.8 V

70

VO = 1.2 V

60

50

50

6

8

10

4

6

8

2.0

1.5

1.0

VO = 1.8 V

VO = 2.5 V

2.0

1.5

1.0

VO = 1.8 V

0.5

4

6

2.0

1.5

1.0

VO = 1.8 V

0.5

VO = 1.2 V

VO = 1.2 V

VO = 0.8 V

0

8

VO = 3.3 V

VO = 2.5 V

VO = 0.8 V

VO = 0.8 V

2

VI = 5 V

fSW = 1 MHz

2.5

VO = 3.3 V

PD – Power Dissipation – W

VO = 2.5 V

0

10

2

4

6

8

0

10

0

2

4

6

8

IO – Output Current – A

IO – Output Current – A

IO – Output Current – A

Figure 13. Power Dissipation

Figure 14. Power Dissipation

Figure 15. Power Dissipation

90

400 LFM

400 LFM

80

TA – Ambient Temperature – °C

80

70

200 LFM

60

100 LFM

50

40

Natural Convection

200 LFM

60

VI = 5 V

fSW = 500 kHz

PD(VOA)+PD(VOB)

100 LFM

50

40

Natural Convection

1

2

3

4

5

PD – Total Power Dissipation – W

Figure 16. Safe Operating Area

0

1

2

3

4

PD – Total Power Dissipation – W

Figure 17. Safe Operating Area

70

200 LFM

60

100 LFM

50

40

Natural Convection

30

VI = 5 V

fSW = 750 kHz

PD(VOA)+PD(VOB)

20

400 LFM

80

70

30

30

10

90

TA – Ambient Temperature – °C

90

10

3.0

VI = 5 V

fSW = 750 kHz

2.5

0

TA – Ambient Temperature – °C

8

Figure 12. Efficiency

VO = 1.2 V

(2)

6

Figure 11. Efficiency

VO = 3.3 V

0

4

Figure 10. Efficiency

3.0

20

2

IO – Output Current – A

0.5

(1)

0

10

IO – Output Current – A

PD – Power Dissipation – W

PD – Power Dissipation – W

2

IO – Output Current – A

VI = 5 V

fSW = 500 kHz

0

60

40

0

3.0

2.5

VO = 1.2 V

70

VI = 5 V

fSW = 1 MHz

40

4

VO = 1.8 V

VO = 0.8 V

VI = 5 V

fSW = 750 kHz

40

2

80

50

VI = 5 V

fSW = 500 kHz

0

VO = 3.3 V

90

h – Efficiency – %

h – Efficiency – %

80

VO = 2.5 V

VO = 3.3 V

90

90

h – Efficiency – %

100

VO = 2.5 V

VO = 2.5 V

VI = 5 V

fSW = 1 MHz

PD(VOA)+PD(VOB)

5

20

0

1

2

3

4

5

PD – Total Power Dissipation – W

Figure 18. Safe Operating Area

The electrical characteristic data (Figure 10 through Figure 15) has been developed from actual products tested at 25°C. This data is

considered typical for the converter.

The temperature derating curves (Figure 16 through Figure 18) represent the conditions at which internal components are at or below

the manufacturer's maximum operating temperatures. Derating limits apply to modules soldered directly to a 100-mm x 100-mm,

double-sided PCB with 2-oz. copper. See the Safe Operating Area application section of this datasheet.

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

7

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

TYPICAL CHARACTERISTICS

CURRENT SENSE OUTPUT

vs

OUTPUT CURRENT

CURRENT SENSE OUTPUT

vs

OUTPUT CURRENT

1.2

1.0

0.8

0.6

0.4

0.2

VTSENSE – Temperature Sense Output Voltage – V

1.6

1.4

0

VI = 5 V

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0

8

2.0

2.0

VI = 12 V

1.8

VISENSE – Current Sense Output Voltage – V

VISENSE – Current Sense Output Voltage – V

2.0

TEMPERATURE SENSE

vs

JUNCTION TEMPERATURE

2

4

6

8

10

0

2

4

6

8

10

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

–50

–25

0

25

50

75

100

IO – Output Current – A

IO – Output Current – A

TJ – Junction Temperature – °C

Figure 19.

Figure 20.

Figure 21.

Submit Documentation Feedback

125

150

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

APPLICATION INFORMATION

Determining the Safe Operating Area

3.0

2.5

PD – Power Dissipation – W

The Safe Operating Area (SOA) curves for the

PTD08D210W are determined by the total power

dissipation of the module, the maximum ambient

temperature, and the minimum available airflow of the

application. Operation below the application airflow

curve is considered a thermally safe design. For a

given SOA, refer to the Power Dissipation curves for

the same input voltage and switching frequency to

determine each output's power dissipation. Add the

power dissipation of VOA and VOB to get the total power

dissipation. The total power dissipation can then be

used to determine the safe operating area for the

application.

VI = 12 V

fSW = 750 kHz

VO = 1.8 V

2.0

VO = 2.5 V

1.5

VO = 3.3 V

1.0

VO = 1.2 V

0.5

VO = 0.8 V

0

0

2

4

6

8

10

IO – Output Current – A

90

400 LFM

TA – Ambient Temperature – °C

80

70

60

200 LFM

50

For example, consider an application operating from a

12-V input and a 750-kHz switching frequency,

requiring 1.2 V @ 10 A and 3.3 V @ 6 A outputs. In

order to determine the safe operating area the power

dissipation for each of the outputs must first be

determined. Using the VI = 12 V, fSW = 750 kHz Power

Dissipation graph, the power dissipation for the 1.2 V

@ 10 A output is 2 W and the power dissipation for the

3.3 V @ 6 A output is 1.5 W. Adding the power

dissipation for both outputs results in a total power

dissipation of 3.5 W. The safe operating area can then

be determined using the VI = 12V, fSW = 750 kHz SOA

graph, the amount of airflow of the application and the

3.5-W total power dissipation. At 3.5 W and 400 LFM,

the application can operate up to 85°C, but when no

airflow is available the maximum ambient temperature

is limited to less than 71°C.

100 LFM

40

Natural Convection

30

VI = 12 V

fSW = 750 kHz

PD(VOA)+PD(VOB)

20

0

1

2

3

3.5

4

5

PD – Total Power Dissipation – W

NOTE

•

•

Graphs above have been replicated from the Typical Characteristics section for this example

The maximum output current for either output must not exceed 10 A.

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

9

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

Digital Power

Figure 22 shows the UCD9220 power supply controller working with a single PTD08D210W, dual-output module

regulating two independent power supplies. The loop for each power supply is created by the respective voltage

outputs feeding into the Error ADC differential inputs, and completed by DPWM outputs feeding the

PTD08D210W module.

VIN

5

3

35

33

34

V33A

BPCap

Vin/Iin

V33FB

4

V33D

41

+3.3 V

FLT-1A

SRE-1A

CS-1A

FAULT-1B

26

27

28

29

30

31

43

44

45

UCD9220

SRE-2A

TMUX-0

CS-2A

PowerGood

FAULT-3A

TCK

DPWM-3A

SRE-3A

TDO/SYNC-OUT

TDI/SYNC-IN

CS-3A

TMS

Temp

6

VOA 22

VOA

VOUT-A

21

18 PWM-A

PGND 20

9

17 SRE-A

PGND 19

42

7

14 Isense-A

PTD08D210W

7

FF-B

VOB 11

2

4

PWM-B

VOB 10

8

5

SRE-B

PGND

8

14

6

Isense-B

PGND

9

13

18

VOUT-B

15

3

AGND AGND Tsense

12

13

16

25

16

17

1

46

37

TRST

EAP1

ADDR-0

EAN1

ADDR-1

Vtrack

ADCref

VIN

12

TMUX-1

EAP2

36

48

DPWM-2A

GPIO-2

PowerPad

24

FAULT-2A

GPIO-1

VIN

PGND

EAN2

38

39

40

49

22

23

PMBus-CNTL

DGND1

21

CS-1B

PMBus-Alert

AGND2

20

32

19

SRE-1B

PMBus-Data

47

11

DPWM-1B

PMBus-CLK

AGND1

10

2

15 FF-A

DPWM-1A

RESET

1

UDG-09173

Figure 22. Typical Dual-Output Application Schematic

Note: A low dropout linear regulator such as the TI TPS715A33 can provide the 3.3-V bias power to the UCD9220.

10

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

Figure 23 shows the UCD9220 power supply controller working with a single PTD08D210W power module. The

dual outputs of the PTD08D210W have been paralleled, allowing up to 20A of output current. When operating

the PTD08D210W in parallel configuration the dual inputs must be tied together and driven from a single output

of the digital power controller. Multiple PTD08D210W modules must not be paralleled.

VIN

3

35

33

34

V33A

BPCap

Vin/Iin

V33FB

4

V33D

41

+3.3 V

RESET

FLT-1A

SRE-1A

CS-1A

FAULT-1B

27

28

29

30

31

43

44

45

UCD9220

SRE-2A

TMUX-0

CS-2A

PowerGood

FAULT-3A

TCK

DPWM-3A

SRE-3A

TDO/SYNC-OUT

TDI/SYNC-IN

CS-3A

TMS

Temp

VOA 22

VOA

21

VOUT

12

9

18 PWM-A

PGND 20

17 SRE-A

PGND 19

42

7

14 Isense-A

PTD08D210W

7

FF-B

VOB 11

2

4

PWM-B

VOB 10

8

5 SRE-B

PGND

9

14

6

PGND

8

13

18

Isense-B

15

3

AGND AGND Tsense

12

13

16

25

16

17

1

46

37

TRST

EAP1

ADDR-0

EAN1

ADDR-1

Vtrack

ADCref

VIN

6

TMUX-1

EAP2

36

48

DPWM-2A

GPIO-2

PowerPad

26

FAULT-2A

GPIO-1

VIN

PGND

EAN2

38

39

40

49

24

PMBus-CNTL

DGND1

22

23

CS-1B

PMBus-Alert

AGND2

20

21

SRE-1B

PMBus-Data

32

19

47

11

DPWM-1B

PMBus-CLK

AGND1

10

2

15 FF-A

DPWM-1A

5

1

UDG-01001

Figure 23. Typical Paralleled-Output Application Schematic

Note 1: A low dropout linear regulator such as the TI TPS715A33 can provide the 3.3-V bias power to the UCD9220.

Note 2: An OR-gate such as the TI 74LVC1G32 should be used to sense a fault signal on either FF-A or FF-B.

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

11

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

UCD9240 Graphical User Interface (GUI)

When using the UCD92x0 digital controller along with digital PowerTrain modules to design a digital power

system, several internal parameters of the modules are required to run the Fusion Digital Power Designer GUI.

See the plant parameters below for the PTD08D210W digital PowerTrain modules.

Table 1. PTD08D210W Plant Parameters

PTD08D210W Plant Parameters

L (µH)

DCR (mΩ)

RDS(on)-high (mΩ)

RDS(on)-low (mΩ)

0.47

2.6

15.5

6.5

Internal output capacitance is present on the digital PowerTrain modules themselves. When using the GUI

interface this capacitance information must be included along with any additional external capacitance. See the

capacitor parameters below for the PTD08D210W digital PowerTrain modules.

Table 2. PTD08D210W Capacitor Parameters

PTD08D210W Capacitor Parameters

12

C (µF)

ESR (mΩ)

ESL (nH)

Quantity

47

1.5

2.5

1

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

TAPE & REEL

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

13

�PTD08D210W

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

www.ti.com

TRAY

14

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

�PTD08D210W

www.ti.com

SLTS295B – DECEMBER 2009 – REVISED DECEMBER 2010

REVISION HISTORY

Changes from Revision A (FEBRUARY 2010) to Revision B

•

Page

Added Caution regarding paralleling multiple modules. ..................................................................................................... 11

Submit Documentation Feedback

Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): PTD08D210W

15

�PACKAGE OPTION ADDENDUM

www.ti.com

19-Dec-2019

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

Lead/Ball Finish

MSL Peak Temp

(2)

(6)

(3)

Op Temp (°C)

Device Marking

(4/5)

PTD08D210WAC

ACTIVE

DIP MODULE

EFS

22

36

RoHS (In

Work) & Green

(In Work)

Call TI

Level-3-260C-168 HR

-40 to 85

PTD08D210WACT

ACTIVE

DIP MODULE

EFS

22

250

RoHS (In

Work) & Green

(In Work)

Call TI

Level-3-260C-168 HR

-40 to 85

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of