PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

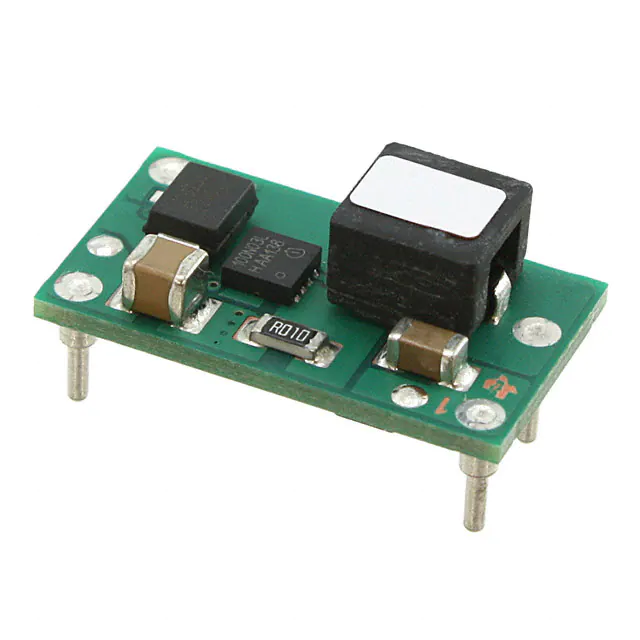

12-W, 3.3/5-V INPUT, WIDE OUTPUT ADJUSTABLE BOOST CONVERTER

Check for Samples: PTN04050C

FEATURES

APPLICATIONS

•

•

•

1

•

•

•

•

Up to 12 W Output Power

Wide Input Voltage Range

(2.95 V to 5.5 V)

Wide Output Voltage Adjust

(5 V to 15 V)

High Efficiency (Up to 90%)

Operating Temperature: –40°C to 85°C

Surface Mount Package Available

Telecommunications, Instrumentation,

and General-Purpose Applications

DESCRIPTION

The PTN04050C is a 4-pin boost-voltage regulator product. In new designs it should be considered in place of

the PT5040 series of positive step-up products. The PTN04050C is smaller and lighter than its predecessors,

and has either similar or improved electrical performance characteristics. The case-less, double-sided package,

also exhibits improved thermal characteristics, and is compatible with TI's roadmap for RoHS and lead-free

compliance.

Operating over a 2.95V to 5.5V input range, the PTN04050C provides high-efficiency, step-up voltage conversion

for loads of up to 12W. The output voltage is set using a single external resistor. The PTN04050C may be set to

any value within the range, 5V to 15V. The output voltage of the PTN04050C can be as little as 0.5V higher than

the input, allowing an output voltage of 5V, with an input voltage of 4.5V.

The PTN04050C modules are suited to a wide variety of general-purpose applications that operate off 3.3-V or 5V dc power.

STANDARD APPLICATION

VI

1

2

4

PTN04050C

(Top View)

3

CI*

100 mF

Electrolytic

(Required)

VO

RSET#

0.1 W, 1%

(Required)

GND

CO*

100 mF

Electrolytic

(Required)

GND

* See the Application Information section for capacitor recommendations.

# See the Application Information section for RSET values.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2005–2011, Texas Instruments Incorporated

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

For the most current package and ordering information, see the Package Option Addendum at the end of this datasheet, or see

the TI website at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range unless otherwise noted

all voltages with respect to GND (pin 1),

UNIT

TA

Operating free-air temperature

Over VI range

Leaded temperature (H suffix)

5 seconds

Solder reflow temperature (S suffix)

Surface temperature of module body or pins

235°C

Solder reflow temperature (Z suffix) (3)

Surface temperature of module body or pins

260°C (3)

Tstg

Storage temperature

PO

Output power

(1)

(2)

(3)

–40°C to 85°C

260°C

(2)

–55°C to 125°C

12 W

Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

This model is NOT compatible with surface-mount reflow solder process.

Moisture Sensitivity Level (MSL) Rating Level-3-260C-168HR

RECOMMENDED OPERATING CONDITIONS

MIN

MAX

VI

Input voltage

2.95

5.5

UNIT

V

TA

Operating free-air temperature

–40

85

°C

PACKAGE SPECIFICATIONS

PTN04050Cx (Suffix AH, AS, and AZ)

Weight

2.8 grams

Flammability

Meets UL 94 V-O

Mechanical shock

Per Mil-STD-883D, Method 2002.3, 1 ms, 1/2 sine,

mounted

Mechanical vibration

Mil-STD-883D, Method 2007.2, 20-2000 Hz

(1)

2

500 G

(1)

Horizontal T/H (suffix AH)

20 G

(1)

Horizontal SMD (suffix AS and AZ)

15 G

(1)

Qualification limit.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

ELECTRICAL CHARACTERISTICS

operating at 25°C free-air temperature, VI = 5 V, VO = 12 V, IO = IO (max), CI = 100 μF, CO = 100 μF (unless otherwise noted)

PARAMETER

TEST CONDITIONS

PTN04050C

MIN

Over VI Range

IO

Output current

VI

Input voltage range

η

MAX

0.1

(1)

0.8

VO = 12 V

0.1

(1)

1.0

VO = 9 V

0.1

(1)

1.3

VO = 5 V

0.1

(1)

Over IO range

UNIT

A

2.4

2.95

Output adjust range

VO

TYP

VO = 15 V

5.5

5

±2

(2)

V

15

V

(3)

%VO

Set-point voltage tolerance

TA = 25°C

Temperature variation

–40°C to 85°C

Line regulation

Over VI range

±0.5

%VO

Load regulation

Over IO range

±0.5

%VO

Total Output Voltage

Variation

Includes set point, line, load

–40°C < TA < 85°C

(3)

%VO

3

%VO

±0.5

Efficiency

Output voltage ripple

(peak-to-peak)

%VO

±3

VI = 5 V, RSET = 60.4 Ω, VO = 15 V

88%

VI = 5 V, RSET = 1.33 kΩ, VO = 12 V

89%

VI = 5 V, RSET = 4.53 kΩ, VO = 9 V

90%

VI = 3.3 V, RSET = OPEN, VO = 5 V

87%

20-MHz bandwith

1.5

1 A/μs load step from 50% to 100% IOmax

Recovery time

500

μs

VO over/undershoot

2.5

%VO

Transient response

Ilim

Current limit

Iir

Inrush current

tir

Inrush current time

duration

FS

Switching frequency

CI

150 (4)

Over VI and IO ranges

External input capacitance

External output

capacitance

Calculated reliability

450

Per Telcordia SR-332, 50% stress,

TA = 40°C, ground benign

525

ms

600

100

(6)

100

(7)

560

(8)

0

100

(9)

Ceramic

Equivalent series resistance (nonceramic)

MTBF

A

1

Nonceramic

CO

%IOmax

2 (5)

10

kHz

μF

μF

(10)

mΩ

8.9

106 Hr

(1)

(2)

Operation at no load is not recommended.

The maximum VI is 5.5V or (VO- 0.5V) whichever is less. If the difference in VO to VIN is ≥ 0.5V and ≤ 1.4V, the device will operate in

asynchronous mode. In this condition, there may be multiple output voltage ripple frequencies and the total output voltage variation may

increase by up to 2%.

(3) The set-point voltage tolerance is affected by the tolerance and stability of RSET. The stated limit is unconditionally met if RSET has a

tolerance of 1% with 100 ppm/°C or better temperature stability.

(4) Boost-topology switching regulators are not short-circuit protected.

(5) The inrush current stated is in addition to the normal input current for the associated output load.

(6) An external input capacitor is required across the input (VI and GND) for proper operation. See the application information for further

guidance.

(7) An external output capacitance is required for proper operation. See the application information for further guidance.

(8) The minimum ESR limitation may result in a lower value for the output capacitance. See the application information for further guidance.

(9) When using ceramic capacitors equivalent to 100 μF, a 100 μF bulk electrolytic is also required.

(10) This is the minimum ESR for all the electrolytic (nonceramic) output capacitance. Use 17 mΩ as the minimum when using maximum

ESR values to calculate.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

3

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

PIN ASSIGNMENT

1

2

4

PTN04050C

(Top View)

3

PIN FUNCTIONS

PIN

NAME

NO.

I/O

DESCRIPTION

This is the common ground connection for the VI and VO power connections. It is also the 0 Vdc

reference for the VO Adjust control input.

GND

1

I/O

VI

2

I

The positive input voltage power node to the module, which is referenced to common GND.

VO Adjust

3

I

A 1% resistor must be connected between this pin and GND (pin 1) to set the output voltage. If left

open-circuit, the output voltage will default to its minimum adjust value. The temperature stability of the

resistor should be 100 ppm/°C (or better). The set-point range is 5 V to 15 V. The standard resistor

value for a number of common output voltages is provided in the application information.

VO

4

O

The regulated positive power output with respect to the GND node.

4

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

TYPICAL CHARACTERISTICS (3.3-V INPUT) (1)

EFFICIENCY

vs

OUTPUT CURRENT

OUTPUT VOLTAGE RIPPLE

vs

OUTPUT CURRENT

90

VO = 9 V

VO = 12 V

VO = 15 V

70

VO = 15 V

150

120

VO = 9 V

90

VO = 12 V

60

VO = 5 V

30

VO = 9 V

1.2

0.8

0

0.8

0.4

1.6

1.2

2

2.4

0

0

0.8

0.4

1.2

1.6

2

2.4

0

1.6

1.2

2

IO - Output Current - A

Figure 1.

Figure 2.

Figure 3.

TEMPERATURE DERATING

vs

OUTPUT CURRENT

TEMPERATURE DERATING

vs

OUTPUT CURRENT

TEMPERATURE DERATING

vs

OUTPUT CURRENT

Ambient Temperature - °C

80

Airflow:

70

200 LFM

60

100 LFM

50

60 LFM

Nat conv

40

VO = 5 V

30

90

80

Airflow:

200 LFM

70

100 LFM

60

60 LFM

50

Nat conv

40

VO = 9 V

1

1.5

2

20

2.5

80

Airflow:

200 LFM

70

100 LFM

60

60 LFM

50

Nat conv

40

VO = 12 V

30

30

0.5

2.4

IO - Output Current - A

90

0

0.8

0.4

IO - Output Current - A

90

20

VO = 5 V

0.4

0

60

VO = 12 V

1.6

Ambient Temperature - °C

Efficiency - %

2

VO = 15 V

PD - Power Dissipation - W

VO - Output Voltage Ripple - VPP (mV)

VO = 5 V

Ambient Temperature - °C

POWER DISSIPATION

vs

OUTPUT CURRENT

180

100

80

(2)

0

0.3

IO - Output Current - A

0.6

0.9

1.2

Figure 4.

20

0

0.2

0.4

0.6

0.8

1

IO - Output Current - A

IO - Output Current - A

Figure 5.

Figure 6.

TEMPERATURE DERATING

vs

OUTPUT CURRENT

Ambient Temperature - °C

90

80

Airflow:

200 LFM

70

100 LFM

60

60 LFM

50

Nat conv

40

VO = 15 V

30

20

0

0.2

0.4

0.6

0.8

IO - Output Current - A

Figure 7.

(1)

(2)

The electrical characteristic data has been developed from actual products tested at 25°C. This data is considered typical for the

converter. Applies to Figure 1, Figure 2, and Figure 3.

The Safe Operating Area curves represent the conditions at which internal components are at or below the manufacturer's maximum

operating temperatures. Derating limits apply to modules soldered directly to a 100 mm x 100 mm double-sided PCB with 2 oz. copper.

Applies to Figure 4, Figure 5, Figure 6, and Figure 7.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

5

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

TYPICAL CHARACTERISTICS (5-V INPUT) (1)

EFFICIENCY

vs

OUTPUT CURRENT

OUTPUT VOLTAGE RIPPLE

vs

OUTPUT CURRENT

90

VO = 12 V

VO = 15 V

70

VO = 15 V

120

VO = 12 V

90

60

VO = 9 V

30

0

60

0

0.2

0.4

0.8

0.6

1

1.2

0

0.2

IO - Output Current - A

0

0.2

0.4

0.8

0.6

1

1.2

IO - Output Current - A

TEMPERATURE DERATING

vs

OUTPUT CURRENT

TEMPERATURE DERATING

vs

OUTPUT CURRENT

TEMPERATURE DERATING

vs

OUTPUT CURRENT

90

80

Airflow:

200 LFM

70

Ambient Temperature - °C

Ambient Temperature - °C

0

1.2

90

100 LFM

60 LFM

60

Nat conv

50

40

VO = 9 V

80

Airflow:

200 LFM

70

100 LFM

60

60 LFM

50

Nat conv

40

VO = 12 V

30

0

VO = 9 V

0.3

Figure 10.

0.3

0.6

0.9

1.2

Figure 11.

6

1

0.6

Figure 9.

IO - Output Current - A

(2)

0.8

0.6

0.9

Figure 8.

30

(1)

0.4

VO = 12 V

1.2

IO - Output Current - A

90

80

VO = 15 V

1.5

150

Ambient Temperature - °C

Efficiency - %

1.8

PD - Power Dissipoation - W

VO - Output Voltage Ripple - VPP (mV)

VO = 9 V

20

POWER DISSIPATION

vs

OUTPUT CURRENT

180

100

80

(2)

20

Airflow:

200 LFM

70

100 LFM

60

60 LFM

50

Nat conv

40

VO = 15 V

30

0

0.2

0.4

0.6

0.8

IO - Output Current - A

Figure 12.

1

20

0

0.2

0.4

0.6

0.8

IO - Output Current - A

Figure 13.

The electrical characteristic data has been developed from actual products tested at 25°C. This data is considered typical for the

converter. Applies to Figure 8, Figure 9, and Figure 10.

The Safe Operating Area curves represent the conditions at which internal components are at or below the manufacturer's maximum

operating temperatures. Derating limits apply to modules soldered directly to a 100-mm x 100-mm, double-sided PCB with 2 oz. copper.

Applies to Figure 11, Figure 12, and Figure 13.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

APPLICATION INFORMATION

Adjusting the Output Voltage of the PTN04050C Wide-Output Adjust Power Modules

General

A resistor must be connected between the VO Adjust control (pin 3) and GND (pin 1) to set the output voltage of

the PTN04050C product. The adjustment range is from 5 V to 15 V. If pin 3 is left open, the output voltage

defaults to the lowest value.

Table 1 gives the standard resistor value for several common voltages, along with the actual output voltage that

the value provides. For other output voltages, the value of the required resistor can be calculated using

Equation 1. Alternatively, RSET can be simply selected from the range of values given in Table 2. Figure 14

shows the placement of the required resistor.

RSET = 15 kW ´

2V

VO - 5 V

- 2.94 kW

(1)

Table 1. Standard Values of RSET for Common Output

Voltages

VO

(Required)

RSET

(Standard Value)

VO

(Actual)

5.0 V

Open

5.00 V

9.0 V

4.53 kΩ

9.01 V

12.0 V

1.33 kΩ

12.03 V

15.0 V

60.4 Ω

14.99 V

VI

2

PTN04050C

VO

VI

VO

Adj

GND

1

CI

100 mF

(Required)

4

3

RSET

0.01 W

1%

GND

CO

100 mF

(Required)

GND

(1)

A 0.05-W rated resistor may be used. The tolerance should be 1%, with a temperature stability of 100 ppm/°C (or

better). Place the resistor as close to the regulator as possible. Connect the resistor directly between pins 3 and 1

using dedicated PCB traces.

(2)

Never connect capacitors from VO Adjust to GND or VO . Any capacitance added to the VO Adjust pin affects the

stability of the regulator.

Figure 14. PTN04050C VO Adjust Resistor Placement

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

7

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

Table 2. PTN04050C Output Voltage Set-Point Resistor Values

8

VO

RSET

VO

RSET

VO

RSET

5V

Open

10 V

3.06 kΩ

12.6 V

1.01 kΩ

5.2 V

147 kΩ

10.1 V

2.94 kΩ

12.7 V

956 Ω

5.4 V

72 kΩ

10.2 V

2.83 kΩ

12.8 V

906 Ω

5.6 V

47 kΩ

10.3 V

2.72 kΩ

12.9 V

857 Ω

5.8 V

34.5 kΩ

10.4 V

2.62 kΩ

13 V

810 Ω

6V

27 kΩ

10.5 V

2.52 kΩ

13.1 V

764 Ω

6.2 V

22 kΩ

10.6 V

2.42 kΩ

13.2 V

719 Ω

6.4 V

18.5 kΩ

10.7 V

2.32 kΩ

13.3 V

674 Ω

6.6 V

15.8 kΩ

10.8 V

2.23 kΩ

13.4 V

631 Ω

6.8 V

13.7 kΩ

10.9 V

2.15 kΩ

13.5 V

589 Ω

7V

12 kΩ

11 V

2.06 kΩ

13.6 V

548 Ω

7.2 V

10.7 kΩ

11.1 V

1.98 kΩ

13.7 V

508 Ω

7.4 V

9.56 kΩ

11.2 V

1.89 kΩ

13.8 V

469 Ω

7.6 V

8.60 kΩ

11.3 V

1.82 kΩ

13.9 V

431 Ω

7.8 V

7.77 kΩ

11.4 V

1.75 kΩ

14 V

393 Ω

8V

7.06 kΩ

11.5 V

1.67 kΩ

14.1 V

357 Ω

8.2 V

6.44 kΩ

11.6 V

1.60 kΩ

14.2 V

321 Ω

8.4 V

5.88 kΩ

11.7 V

1.54 kΩ

14.3 V

286 Ω

8.6 V

5.39 kΩ

11.8 V

1.47 kΩ

14.4 V

251 Ω

8.8 V

4.95 kΩ

11.9 V

1.41 kΩ

14.5 V

218 Ω

9V

4.56 kΩ

12 V

1.35 kΩ

14.6 V

185 Ω

9.2 V

4.20 kΩ

12.1 V

1.29 kΩ

14.7 V

153 Ω

9.4 V

3.88 kΩ

12.2 V

1.23 kΩ

14.8 V

121 Ω

9.6 V

3.58 kΩ

12.3 V

1.17 kΩ

14.9 V

90 Ω

9.8 V

3.31 kΩ

12.4 V

1.11 kΩ

15 V

60 Ω

9.9 V

3.18 kΩ

12.5 V

1.06 kΩ

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

CAPACITOR RECOMMENDATIONS FOR PTN04050C WIDE-OUTPUT

ADJUST POWER MODULES

Input Capacitor

The minimum required input capacitance is 100 μF. The minimum ripple current rating for any nonceramic

capacitance must be greater than 250 mA rms. The ripple current rating of electrolytic capacitors is a major

consideration when they are used at the input. This ripple current requirement can be reduced by placing

ceramic capacitors at the input, in addition to the minimum required capacitance.

When specifying regular tantalum capacitors for use at the input, a minimum voltage rating of 2 X (maximum dc

voltage + ac ripple) is highly recommended. This is standard practice to ensure reliability. Polymer-tantalum

capacitors are not affected by this requirement. (Please verify voltage derating for the polymer-tantalum

capacitors from the vendors.)

Output Capacitor

The minimum capacitance required to insure stability is a 100 μF. A combination of both ceramic and electrolytictype capacitors should be used. The minimum ripple current rating for the nonceramic capacitance must be at

least 150 mA rms. When using ceramic capacitors equivalent to 100 μF, a 100 μF bulk electrolytic is also

required. The stability of the module and voltage tolerances are compromised if the capacitor is not placed near

the output pin. A high-quality, computer-grade electrolytic capacitor is adequate. Ceramic capacitance should

also be located within 0.5 inches (1,27 cm) of the output pin.

For applications with load transients (sudden changes in load current), the regulator response improves with

additional capacitance. Additional electrolytic capacitors should be located close to the load circuit. These

capacitors provide decoupling over the frequency range, 2 kHz to 150 kHz. Aluminum electrolytic capacitors are

suitable for ambient temperatures above 0°C. For operation below 0°C, tantalum or OS-CON type capacitors are

recommended. When using one or more nonceramic capacitors, the calculated equivalent ESR should be no

lower than 10 mΩ (17 mΩ using the manufacturer's maximum ESR for a single capacitor). A list of capacitors

and vendors are identified in Table 3, the recommended capacitor table.

Ceramic Capacitors

Above 150 kHz the performance of aluminum electrolytic capacitors becomes less effective. To further reduce

the reflected input ripple current, or the output transient response, multilayer ceramic capacitors must be added.

Ceramic capacitors have low ESR and their resonant frequency is higher than the bandwidth of the regulator.

When placed at the output, their combined ESR is not critical as long as the total value of ceramic capacitance

does not exceed 100 μF.

Note: If only ceramics are used on the output bus, then a 100 μF electrolytic is required for stabilization.

Tantalum Capacitors

Tantalum type capacitors may be used at the output, and are recommended for applications where the ambient

operating temperature can be less than 0°C. The AVX TPS, Sprague 593D/594/595, and Kemet

T495/T510/T520 capacitors series are suggested over many other tantalum types due to their rated surge, power

dissipation, and ripple current capability. As a caution, many general-purpose tantalum capacitors have

considerably higher ESR, reduced power dissipation, and lower ripple current capability. These capacitors are

also less reliable as they have lower power dissipation and surge current ratings. Tantalum capacitors that do not

have a stated ESR or surge current rating are not recommended for power applications. When specifying OSCON and polymer tantalum capacitors for the output, the minimum ESR limit is encountered well before the

maximum capacitance value is reached.

Capacitor Table

The capacitor table, Table 3, identifies the characteristics of capacitors from various vendors with acceptable

ESR and ripple current (rms) ratings. The recommended number of capacitors required at both the input and

output buses is identified for each capacitor type. This is not an extensive capacitor list. Capacitors from other

vendors are available with comparable specifications. Those listed are for guidance. The rms current rating and

ESR (at 100 kHz) are critical parameters necessary to insure both optimum regulator performance and long

capacitor life.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

9

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

Designing for Load Transients

The transient response of the dc/dc converter has been characterized using a load transient with a di/dt of

1 A/µs. The typical voltage deviation for this load transient is given in the data sheet specification table using the

required value of output capacitance. As the di/dt of a transient is increased, the response of a converter's

regulation circuit ultimately depends on its output capacitor decoupling network. This is an inherent limitation of

any dc/dc converter once the speed of the transient exceeds its bandwidth capability. If the target application

specifies a higher di/dt or lower voltage deviation, the requirement can only be met with additional output

capacitor decoupling. In these cases, special attention must be paid to the type, value, and ESR of the

capacitors selected.

If the transient performance requirements exceed those specified in the data sheet, the selection of output

capacitors becomes more important. Obey the minimum ESR and maximum capacitance limits specified in the

Electrical Characteristics table.

Table 3. Recommended Input/Output Capacitors

CAPACITOR CHARACTERISTICS

WORKIN

G

VOLTAGE

(V)

VALUE

(µF)

EQUIVALENT

SERIES

RESISTANCE

(ESR) (Ω)

85°C

MAXIMUM

RIPPLE

CURRENT

(Irms) (mA)

Panasonic FC( Radial)

25

180

0.117

Panasonic FC (SMD)

25

100

0.30

United Chemi-Con PXA (SMD)

16

150

PS

25

LXZ

CAPACITOR VENDOR/

COMPONENT

SERIES

(1)

QUANTITY

VENDOR

NUMBER

PHYSICAL

SIZE

(mm)

INPUT

BUS

OUTPUT

BUS

555

8 X 11

1

1

EEUFC1E181

450

8 X 10,2

1

1

EEVFC1E101P

0.026

3430

10 X 7,7

1

1

PXA16VC151MJ80TP (VO≤13V)

100

0.020

4320

10 X 12,5

1

1

25PS100MJ12

25

100

0.250

290

6,3 X 11,5

1

1

LXZ25VB101M6X11LL

MVY(SMD)

35

100

0.300

450

8 X 10

1

1

MVY35VC101MH10TP

Nichicon UWG (SMD)

50

100

0.300

500

10 X 10

1

1

UWG1H101MNR1GS

F559 (Tantalum)

10

100

0.055

2000

7,7 X 4,3

1

HD

25

100

0.130

405

6,3 X 11

1

1

UHD1E101MER

Sanyo OS-CON SVP (SMD)

20

100

0.024

2500

8 X 12

1

1

20SVP100M

SP

16

100

0.032

2890

10 X 5

1

1

(2)

1

1

(2)

(2)

1

20

100

0.085

1543

7,3X 6,1X

3.5

20

100

0.200

> 817

7,3X 6,1X

3.5

1

1

(2)

Murata X5R Ceramic

6.3

100

0.002

>1000

3225

1

1

(2)

TDK X5R Ceramic

6.3

100

0.002

>1000

3225

1

1

(2)

Murata X5R Ceramic

16

47

0.002

>1000

3225

2

≤2

(2)

AVX Tantalum TPS (SMD)

Kemet X5R Ceramic

6.3

47

0.002

>1000

3225

2

≤2

(2)

TDK X5R Ceramic

6.3

47

0.002

>1000

3225

2

≤2

(2)

Murata X5R Ceramic

6.3

47

0.002

>1000

3225

2

≤2

(2)

TDK X5R Ceramic

16

22

0.002

>1000

3225

5

≤5

(2)

Murata X7R Ceramic

25

22

0.002

>1000

3225

5

Kemet X7R Ceramic

16

22

0.002

>1000

3225

5

(1)

(2)

10

≤5

≤5

(2)

F551A107MN (VO≤ 5V)

16SP100M (VO≤ 14V)

TPSV107M020R0085

(VO ≤ 10 V)

TPSV107M020R0200

(VO ≤ 10 V)

GRM32ER60J107M

(VO ≤ 5.5 V)

C3225X5R0J107MT

(VO ≤ 5.5 V)

GRM32ER61C476M

C1210C476K9PAC

(VO ≤ 5.5 V)

C3225X5R0J476MT

(VO ≤ 5.5 V)

GRM422X5R476M6.3

(VO ≤ 5.5 V)

C3225X5R1E2265KT/MT

GRM32ER61C226K

C1210C226K3PAC

Capacitor Supplier Verification

1. Verify availability of capacitors identified in this table. Capacitor suppliers may recommend alternative part numbers because of

limited availability or obsolete products. In some instances, the capacitor product life cycle may be in decline and have short-term

consideration for obsolescence.

RoHS, Lead-free and Material Details

2. Consult capacitor suppliers regarding material composition, RoHS status, lead-free status, and manufacturing process requirements.

Component designators or part number deviations may occur if material composition or soldering requirements change.

The maximum voltage rating of the capacitor must be selected for the desired set-point voltage (VO). To operate at a higher output

voltage, select a capacitor with a higher voltage rating.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

Power-Up Characteristics

When configured per the standard application, the PTN04050C power module produces a regulated output

voltage following the application of a valid input source voltage. During power up, internal soft-start circuitry slows

the rate that the output voltage rises, thereby limiting the amount of in-rush current drawn from the input

source.Figure 15 shows the power-up waveforms for a PTN04050C, operating from a 5-V input and with the

output voltage adjusted to 12 V. The waveforms were measured with a 1-A resistive load.

VO (5 V/div)

VI (2 V/div)

II (2 A/div)

t - Time = 10 ms/div

Figure 15. Power-Up Waveforms

Overtemperature Protection

A thermal shutdown mechanism protects the module's internal circuitry against excessively high temperatures. A

rise in temperature may be the result of a drop in airflow, a high ambient temperature, or a sustained overcurrent

condition. If the junction temperature of the internal control IC rises excessively, the module turns its boost

operation off. Although the module is off, an output voltage of approximately (VI – 300 mV) is still present. The

module restarts boost operation when the sensed temperature decreases by approximately 10 degrees.

Note: Overtemperature protection is a last resort mechanism to prevent damage to the module. It should not be

relied on as permanent protection against thermal stress. Always operate the module within its temperature

derated limits, for the worst-case operating conditions of output current, ambient temperature, and airflow.

Operating the module above these limits, albeit below the thermal shutdown temperature, reduces the long-term

reliability of the module.

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

11

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

Boost Topology

With boost regulators an output voltage of approximately (VI - 300 mV) is present whenever the input voltage to

the module is below the minimum input voltage range, or during an overtemperature condition. Also, a boost

regulator cannot provide inherent short-circuit protection. This is due to the fact that there is a dc path from the

input to the output even when the PWM and FET are not operating. This is shown in the boost topology diagram

in Figure 16.

VI

VO

PWM

IC

Figure 16. Typical Boost Converter Topology

Optional Input/Output Filters

Power modules include internal input and output ceramic capacitors in all their designs. However, some

applications require much lower levels of either input reflected or output ripple/noise. This section describes

various filters and design techniques found to be successful in reducing both input and output ripple/noise.

Input/Output Capacitors

A first step toward reducing output ripple and noise is to add one or more 22-μF ceramic capacitors, such as C4

shown in Figure 17. Ceramic capacitors should be placed close to the output power terminals. A single 22-μF

capacitor reduces the output ripple/noise by 10% to 30% for modules with a rated output current of less than 3 A.

(Note: C3 is recommended to improve the regulators transient response and does not reduce output ripple and

noise.)

Switching regulators draw current from the input line in pulses at their operating frequency. The amount of

reflected (input) ripple/noise generated is directly proportional to the equivalent source impedance of the power

source including the impedance of any input lines. The addition of C1, minimum 22-μF ceramic capacitor, near

the input power pins, reduces reflected conducted ripple/noise by 30% to 50%.

PTN04050C

VI

2

VO

VI

GND

1

C1

22 mF

Ceramic

C2*

100 mF

(Required)

VO

4

Adj

3

RSET

C3*

100 mF

(Required)

GND

C4

22 mF

Ceramic

GND

* See the Application Information section for suggested value and type.

Figure 17. Adding High-Frequency Bypass Capacitors To The Input and Output

12

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PTN04050C

www.ti.com

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

π Filters

If a further reduction in ripple/noise level is required for an application, higher order filters must be used. A π (pi)

filter, employing a ferrite bead (Fair-Rite Part Number 2673000701 or equivalent) in series with the input or

output terminals of the regulator reduces the ripple/noise by at least 20 db (see Figure 18 and Figure 19). In

order for the inductor to be effective in reduction of ripple and noise, ceramic capacitors are required. (Note: for

additional information on vendors and component suggestions, see the capacitor recommendations for the

PTN04050C.)

These inductors plus ceramic capacitors form an excellent filter because of the rejection at the switching

frequency (650 kHz - 1 MHz). The placement of this filter is critical. It must be located as close as possible to the

input or output pins to be effective. The ferrite bead is small (12,5 mm X 3 mm) and has low dc resistance. FairRite also manufactures a surface-mount bead (Part No. 2773021447), through hole (Part Number 2673000701)

rated to 5 A. Inductors in the range of 1 μH to 5 μH can be used in place of the ferrite inductor bead.

VI

L1

1 - 5 mH

2

PTN04050C

VI

VO

GND

1

C1

22 mF

Ceramic

L2

1 - 5 mH

4

VO

Adj

3

C2*

100 mF

(Required)

RSET

C4

22 mF

Ceramic

C3*

100 mF

(Required)

GND

C5

†

GND

* See the Application Information section for suggested value and type.

† Recommended for applications with load transients.

Figure 18. Adding π Filters

45

40

Attenuation − dB

35

1 MHz

30

25

600 kHz

20

15

10

0

0.5

1

1.5

2

Load Current − A

2.5

3

Figure 19. π-Filter Attenuation vs. Load Current

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

13

�PTN04050C

SLTS251A – SEPTEMBER 2005 – REVISED FEBRUARY 2011

www.ti.com

REVISION HISTORY

Changes from Original (September 2005) to Revision A

Page

•

Changed the Abs Max Ratings Storage temperature from: -40°C to 125°C To: -55°C to 125°C ........................................ 2

•

Changed Note 2 of the ELECTRICAL CHARACTERISTICS table ...................................................................................... 3

14

Submit Documentation Feedback

Copyright © 2005–2011, Texas Instruments Incorporated

Product Folder Links: PTN04050C

�PACKAGE OPTION ADDENDUM

www.ti.com

19-Dec-2019

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

Lead/Ball Finish

MSL Peak Temp

(2)

(6)

(3)

Op Temp (°C)

Device Marking

(4/5)

PTN04050CAD

ACTIVE

ThroughHole Module

EUU

4

56

RoHS (In

Work) & Green

(In Work)

SN

N / A for Pkg Type

-40 to 85

PTN04050CAH

ACTIVE

ThroughHole Module

EUU

4

56

RoHS (In

Work) & Green

(In Work)

SN

N / A for Pkg Type

-40 to 85

PTN04050CAS

ACTIVE

Surface

Mount Module

EUV

4

56

Non-RoHS

& Green

(In Work)

SNPB

Level-1-235C-UNLIM/

Level-3-260C-168HRS

-40 to 85

PTN04050CAZ

ACTIVE

Surface

Mount Module

EUV

4

56

RoHS (In

Work) & Green

(In Work)

SNAGCU

Level-3-260C-168 HR

-40 to 85

PTN04050CAZT

ACTIVE

Surface

Mount Module

EUV

4

250

RoHS (In

Work) & Green

(In Work)

SNAGCU

Level-3-260C-168 HR

-40 to 85

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of