SmartRF Transceiver

Evaluation Board

“TrxEB”

User’s Guide

SWRU294A

�SWRU294A

Table of Contents

TABLE OF CONTENTS ......................................................................................................................... 2

LIST OF FIGURES ................................................................................................................................. 4

LIST OF TABLES ................................................................................................................................... 4

1

INTRODUCTION .......................................................................................................................... 5

2

ABOUT THIS MANUAL ............................................................................................................... 5

3

ACRONYMS AND ABBREVIATIONS......................................................................................... 6

4

GETTING STARTED ................................................................................................................... 7

4.1

SMARTRF STUDIO ...................................................................................................................... 7

4.2

INSTALLING SMARTRF STUDIO AND USB DRIVERS ....................................................................... 7

4.2.1

Cebal USB driver ...................................................................................................................... 7

4.2.2

Virtual COM port USB driver .................................................................................................... 8

5

USING THE SMARTRF TRANSCEIVER EVALUATION BOARD ............................................. 9

5.1

ABSOLUTE MAXIMUM RATINGS.................................................................................................... 10

6

SMARTRF TRANSCEIVER EVALUATION BOARD OVERVIEW ........................................... 11

6.1

USB MCU ............................................................................................................................... 12

6.1.1

SmartRF Mode ....................................................................................................................... 13

6.1.2

UART Mode ............................................................................................................................ 13

6.1.3

Disabled Mode ........................................................................................................................ 14

6.2

MSP430 MCU ......................................................................................................................... 15

6.3

POWER SOURCES ..................................................................................................................... 15

6.3.1

Battery Power ......................................................................................................................... 16

6.3.2

USB Power ............................................................................................................................. 16

6.3.3

External Power Supply ........................................................................................................... 17

6.3.4

MSP-FET Power ..................................................................................................................... 18

6.4

LCD ......................................................................................................................................... 18

6.5

ACCELEROMETER ..................................................................................................................... 18

6.6

AMBIENT LIGHT SENSOR ........................................................................................................... 18

6.7

SERIAL FLASH........................................................................................................................... 18

6.8

BUTTONS.................................................................................................................................. 19

6.9

LEDS ....................................................................................................................................... 19

6.9.1

General Purpose LEDs ........................................................................................................... 19

6.9.2

USB LED ................................................................................................................................ 19

6.10

EM CONNECTORS..................................................................................................................... 20

6.11

BREAKOUT HEADERS AND JUMPERS .......................................................................................... 23

6.11.1 EM I/O breakout headers ....................................................................................................... 23

6.11.2 MSP430 I/O breakout ............................................................................................................. 23

6.12

CURRENT MEASUREMENT JUMPERS .......................................................................................... 26

7

CONNECTING AN EXTERNAL MCU TO SMARTRF TRXEB ................................................. 28

7.1

DISABLE MCUS ONBOARD SMARTRF TRXEB ............................................................................. 28

7.2

SELECT POWER SOURCE ........................................................................................................... 28

7.2.1

Power external MCU from SmartRF TrxEB ............................................................................ 28

7.2.2

Power SmartRF TrxEB from external power source .............................................................. 28

7.3

CONNECT SIGNALS .................................................................................................................... 29

7.3.1

Common signals ..................................................................................................................... 29

7.3.2

Transceiver GPIO signals ....................................................................................................... 29

8

SMARTRF TRXEB REV. 1.3.0 .................................................................................................. 30

8.1

BOARD OVERVIEW .................................................................................................................... 30

8.2

SOFTWARE CONSIDERATIONS.................................................................................................... 30

8.2.1

Virtual COM port over USB .................................................................................................... 30

8.2.2

Accelerometer......................................................................................................................... 30

8.3

USB MCU PIN-OUT .................................................................................................................. 31

8.4

MSP430 MCU PIN-OUT ............................................................................................................ 31

9

SMARTRF TRXEB REV. 1.5.0 .................................................................................................. 32

9.1

BOARD OVERVIEW .................................................................................................................... 32

9.2

CHANGES FROM REV. 1.3.0 ....................................................................................................... 32

Page 2/44

�SWRU294A

9.2.1

RC filter on USB MCU reset line ............................................................................................ 32

9.2.2

Accelerometer......................................................................................................................... 32

9.2.3

Silk print .................................................................................................................................. 33

9.3

USB MCU PIN-OUT .................................................................................................................. 33

9.4

MSP430 MCU PIN-OUT ............................................................................................................ 33

10

SMARTRF TRXEB REV. 1.7.0 .................................................................................................. 34

10.1

BOARD OVERVIEW .................................................................................................................... 34

10.2

CHANGES FROM REV. 1.5.0 ....................................................................................................... 34

10.2.1 Switch added to enable combo EM support ........................................................................... 34

10.2.2 Connector type for external power sources ............................................................................ 35

10.2.3 Connector type for LCD .......................................................................................................... 35

10.2.4 Ground pad between P17 and P7 .......................................................................................... 35

10.2.5 Silk print .................................................................................................................................. 36

10.3

USB MCU PIN-OUT .................................................................................................................. 36

10.4

MSP430 MCU PIN-OUT ............................................................................................................ 36

11

UPDATING THE FIRMWARE ................................................................................................... 37

11.1

FORCED BOOT RECOVERY MODE .............................................................................................. 38

11.2

BOARD RESURRECTION............................................................................................................. 39

12

FREQUENTLY ASKED QUESTIONS ....................................................................................... 41

13

REFERENCES ........................................................................................................................... 43

14

DOCUMENT HISTORY.............................................................................................................. 44

Page 3/44

�SWRU294A

List of Figures

Figure 1 – Install virtual COM port USB driver using the Windows Hardware Wizard ........................... 8

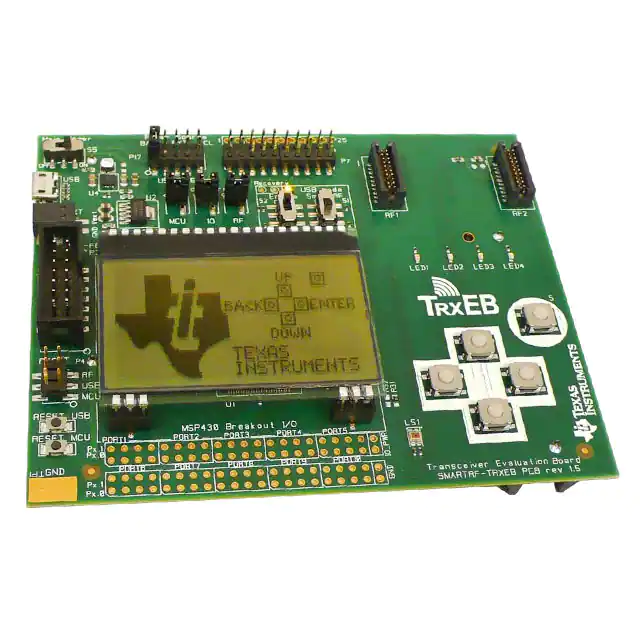

Figure 2 – SmartRF TrxEB (rev. 1.5.0) with EM connected ................................................................... 9

Figure 3 – SmartRF TrxEB architecture ................................................................................................ 11

Figure 4 – Flow chart of the USB MCU bootloader and standard firmware ......................................... 12

Figure 5 – UART lines connected between the USB MCU and the onboard MSP430 MCU. .............. 14

Figure 6 – Main power selection header (P17) and power switch (P5) ................................................ 15

Figure 7 – P17 jumper settings to power TrxEB using batteries........................................................... 16

Figure 8 – P17 jumper settings to power TrxEB via the USB cable ..................................................... 16

Figure 9 – P17 jumper settings to power TrxEB using external power supply ..................................... 17

Figure 10 – Powering TrxEB rev. ≤1.5.0 via the external power supply connector (P201) .................. 17

Figure 11 – TrxEB rev. 1.7.0 external power supply header (P1) ......................................................... 17

Figure 12 – P17 jumper settings to power EB using a MSP-FET ......................................................... 18

Figure 13 – SmartRF TrxEB EM connectors RF1 and RF2 .................................................................. 20

Figure 14 – EM interface ....................................................................................................................... 20

Figure 15 – SmartRF TrxEB I/O breakout overview ............................................................................. 23

Figure 16 – I/O connector P25A-E PCB layout ..................................................................................... 23

Figure 17 – MSP430 I/O breakout on SmartRF TrxEB ......................................................................... 23

Figure 18 – Current measurement jumpers .......................................................................................... 26

Figure 19 – Current measurement setup .............................................................................................. 26

Figure 20 – Switch and jumper settings to disable both SmartRF TrxEB MCUs .................................. 28

Figure 21 – Power external MCU board by connecting it to IO_PWR and GND .................................. 28

Figure 22 – P7 with strapping to connect external MCU to SmartRF TrxEB ........................................ 29

Figure 23 – SmartRF TrxEB revision 1.3.0 overview ............................................................................ 30

Figure 24 – Accelerometer axes on SmartRF TrxEB rev. 1.3.0 ........................................................... 30

Figure 25 – SmartRF TrxEB revision 1.5.0 overview ............................................................................ 32

Figure 26 – Accelerometer axes on SmartRF TrxEB rev. ≥1.5.0 ......................................................... 32

Figure 27 – Correct silk print for MCLK and SMCLK test points ........................................................... 33

Figure 28 – SmartRF TrxEB revision 1.7.0 overview ............................................................................ 34

Figure 29 – Signal overview for switch TS3A44159 added for SmartRF TrxEB rev. 1.7.0 .................. 35

Figure 30 – Added ground pad on SmartRF TrxEB rev. 1.7.0.............................................................. 35

Figure 31 – Firmware upgrade steps in SmartRF Studio ..................................................................... 37

Figure 32 – Enter forced boot recovery mode ...................................................................................... 38

Figure 33 – Proper connection for board resurrection. ......................................................................... 39

List of Tables

Table 1 – Available features on the SmartRF TrxEB .............................................................................. 5

Table 2 – Supply voltage: Recommended operating conditions and absolute max. ratings ................ 10

Table 3 – Temperature: Recommended operating conditions and storage temperatures ................... 10

Table 4 – SmartRF TrxEB operating modes ......................................................................................... 13

Table 5 – Data rates supported by the USB MCU in UART Mode ....................................................... 13

Table 6 – USB LED state descriptions .................................................................................................. 19

Table 7 – EM connector RF1 pin-out .................................................................................................... 21

Table 8 – EM connector RF2 pin-out .................................................................................................... 22

Table 9 – MSP430 Port 1-5 pin-out ...................................................................................................... 24

Table 10 – MSP430 Port 6-10 pin-out .................................................................................................. 25

Table 11 – Component/Power segment overview ................................................................................ 27

Table 12 – Strapping overview to connect common signals to an external MCU ................................ 29

Table 13 – Strapping overview to strap CC1120 GPIO to an external MCU ........................................ 29

Table 14 – USB MCU pin-out on SmartRF TrxEB rev. 1.3.0 ................................................................ 31

Table 15 – MSP430 miscellaneous signal pin-out ................................................................................ 31

Table 16 – S1 control over TS3A44159 switch for SmartRF TrxEB rev. 1.7.0 ..................................... 35

Table 17 – USB MCU pin-out on SmartRF TrxEB rev. 1.7.0 ................................................................ 36

Page 4/44

�SWRU294A

1 Introduction

The SmartRF Transceiver Evaluation Board (SmartRF TrxEB or simply EB) is the motherboard in a

number of development kits for Low Power RF transceiver devices from Texas Instruments. The

board has a wide range of features, listed in Table 1 below.

Component

Description

MSP430 MCU

The Ultra-low Power MSP430 serves as a platform for software

development, testing and debugging.

Full-speed USB 2.0 interface Easy plug and play access to full transceiver control using

SmartRF™ Studio PC software. Integrated serial port over USB

enables communication between onboard MSP430 and PC.

64x128 pixels serial LCD

Big LCD display for demo use and user interface development.

LEDs

Four general purpose LEDs for demo use or debugging.

Serial Flash

External flash for extra storage, over-the-air upgrades and more.

Buttons

Five push-buttons for demo use and user interfacing.

Accelerometer

Three-axis highly configurable digital accelerometer for application

development and demo use.

Light Sensor

Ambient Light Sensor for application development and demo use.

Breakout pins

Easy access to GPIO pins for quick and easy debugging.

Table 1 – Available features on the SmartRF TrxEB

2 About this manual

This manual contains reference information about the SmartRF TrxEB.

Chapter 4 will give a quick introduction on how to get started with the SmartRF TrxEB. It describes

how to install SmartRF Studio and to get the required USB drivers for the evaluation board. Chapter 5

briefly explains how the EB can be used throughout a project’s development cycle. Chapter 6 gives

an overview of the various features and functionality provided by the board.

Chapter 8, 9 and 10 provide additional details about the different versions of SmartRF TrxEB, revision

1.3.0, 1.5.0 and 1.7.0, respectively. Chapter 11 gives details on how to update the EB firmware, while

a troubleshooting guide is found in chapter 12.

Appendices A, B and C contain the schematics for the different versions of SmartRF TrxEB.

The PC tools SmartRF Studio and SmartRF Flash Programmer have their own user manual.

See chapter 13 for references to relevant documents and web pages.

Page 5/44

�SWRU294A

3 Acronyms and Abbreviations

ACM

Abstract Control Model

ALS

Ambient Light Sensor

CEBAL

CC Evaluation Board Abstraction Layer

CDC

Communication Device Class

CTS

Clear to Send

CW

Continuous Wave

DK

Development Kit

DUT

Device Under Test

EB

Evaluation Board

EM

Evaluation Module

IC

Integrated Circuit

I/O

Input/Output

KB

Kibi Byte (1024 byte)

LCD

Liquid Crystal Display

LED

Light Emitting Diode

LPRF

Low Power RF

MCU

Micro Controller

MISO

Master In, Slave Out (SPI signal)

MOSI

Master Out, Slave In (SPI signal)

NA

Not Applicable / Not Available

NC

Not Connected

PER

Packet Error Rate

RF

Radio Frequency

RX

Receive

RTS

Request to Send

SoC

System on Chip

SPI

Serial Peripheral Interface

TI

Texas Instruments

TrxEB

Transceiver Evaluation Board

TX

Transmit

TRX

Transmit / Receive

UART

Universal Asynchronous Receive Transmit

USB

Universal Serial Bus

Page 6/44

�SWRU294A

4 Getting Started

Before connecting the SmartRF TrxEB to the PC via the USB connector, it is highly recommended to

install the USB drivers needed for proper communication between the TrxEB and applicable PC tools.

The drivers are bundled and installed together with SmartRF™ Studio.

4.1 SmartRF Studio

SmartRF Studio is a PC application developed for evaluation of the low power RF IC products from

Texas Instruments. The application is designed for use with SmartRF Evaluation Boards, such as

SmartRF TrxEB, and runs on Microsoft Windows operating systems.

SmartRF Studio gives the user full overview of and access to the devices’ registers for configuration

of the radio parameters and behavior. It also provides a control interface for performing operations

like sending and receiving packets and setting up a continuous wave signal. In addition, it offers a

flexible system for exporting radio register values to a user defined format for easy integration in

software.

The latest version of SmartRF Studio can be downloaded from the Texas Instruments website [1].

4.2 Installing SmartRF Studio and USB drivers

Before your PC can communicate with the SmartRF TrxEB over USB, you will need to install the USB

drivers for the EB. The latest SmartRF Studio installer [1] includes the required USB drivers both for

Windows x86 and Windows x64 platforms.

After you have downloaded SmartRF Studio from the web, extract the zip-file, run the installer and

follow the instructions. Select the complete installation to include the SmartRF Studio program, the

SmartRF Studio documentation and the USB drivers. There are two drivers needed for TrxEB: Cebal

and a virtual COM port driver.

4.2.1 Cebal USB driver

NOTE: The SmartRF TrxEB must be in “SmartRF Mode” in order to be recognized by the PC

as a Cebal device. The EB is in SmartRF Mode when hardware switches S1 and S2 are in

positions “SmartRF” and “Enable”, respectively. See section 6.1 for more information about

the SmartRF TrxEB operating modes.

SmartRF PC software such as SmartRF Studio uses a proprietary USB driver, Cebal, to communicate

with evaluation boards. Connect your SmartRF TrxEB to the computer with a USB cable, set the

mode switches to “SmartRF” and “Enable”, and turn it on. If you did a complete install of SmartRF

Studio, Windows will recognize the device automatically and the SmartRF TrxEB is ready for use!

For more information regarding the USB drivers, please consult the SmartRF Studio documentation,

the USB driver installation guide [2] or chapter 11.

Page 7/44

�SWRU294A

4.2.2 Virtual COM port USB driver

NOTE: The SmartRF TrxEB must be in “UART Mode” in order to be recognized as a virtual

COM port. The EB is in UART Mode when hardware switches S1 and S2 are in positions

“UART” and “Enable”, respectively. See section 6.1 for more information about the SmartRF

TrxEB operating modes.

If you are using SmartRF TrxEB in UART Mode (see section 6.1.2), a standard driver for a virtual

COM port over USB is used (USB CDC-ACM). If you did a complete install of SmartRF Studio,

Windows will recognize the device automatically. If prompted with the Windows Hardware Wizard,

select “Install the software automatically (recommended)” and click next to finish the installation. The

SmartRF TrxEB is now ready for use!

If the SmartRF TrxEB CDC-ACM driver is not found by the Hardware Wizard, make sure you have

installed the latest version of SmartRF Studio [1]. In the Windows Hardware Wizard, select “Install

from a list or specific location (Advanced)”. You will see below window.

Figure 1 – Install virtual COM port USB driver using the Windows Hardware Wizard

The driver for the Virtual COM Port (VCP) is typically located in the directory C:\Program Files\Texas

Instruments\SmartRF Tools\Drivers\vcp, where C:\Program Files\Texas Instruments\SmartRF Tools\

is the root installation directory for SmartRF Tools such as SmartRF Studio. The path may be different

if you have chosen a different installation directory for SmartRF Studio.

If the above fails, select “Don’t Search. I will choose the driver to install.” A new window will open,

asking for a location of where the drivers can be found. Locate the trxeb_cdc_uart.inf file and select

that driver for installation.

Page 8/44

�SWRU294A

5 Using the SmartRF Transceiver Evaluation Board

The SmartRF TrxEB is a flexible test and development platform that works together with RF

Evaluation Modules from Texas Instruments.

An Evaluation Module is a small RF module with RF chip, balun, matching filter, antenna, and I/O

connectors. The modules can be plugged into the SmartRF TrxEB which lets the PC take direct

control of the RF device on the EM over the USB interface.

Currently, SmartRF TrxEB supports:

-

CC1120EM

CC1121EM

CC1175EM

CC1101EM

CC1100EM

-

CC1100EEM

CC110LEM

CC113LEM

CC115LEM

CC2520EM

SmartRF TrxEB is included in e.g. the CC1120 development kit. Some of the above EMs comes in

variants combined with a RF front-end such as CC1190, CC2590, or CC2591. Such variants are

1

called combo EMs and are also supported by the SmartRF TrxEB .

Figure 2 – SmartRF TrxEB (rev. 1.5.0) with EM connected

1

Some limitations exist for boards prior to version 1.7.0.

Page 9/44

�SWRU294A

The PC software that controls the SmartRF TrxEB + EM is SmartRF Studio. Studio can be used to

perform several RF tests and measurements, e.g. to set up a CW signal and send and receive

packets.

The EB+EM can be of great help during the whole development cycle for a new RF product.

-

Perform comparative studies. Compare results obtained with EB+EM with results from your

own system.

-

Perform basic functional tests of your own hardware by connecting the radio on your board to

SmartRF TrxEB. SmartRF Studio can be used to exercise the radio.

-

Verify your own software with known good RF hardware, by simply connecting your own

microcontroller to an EM via the EB. Test the send function by transmitting packets from your

SW and receive with another board using SmartRF Studio. Then transmit using SmartRF

Studio and receive with your own software.

-

Develop code for the MSP430 MCU.

-

Use the SmartRF TrxEB as a debugger interface to the low power RF 8051-based SoCs with

IAR Embedded Workbench.

5.1 Absolute maximum ratings

The minimum and maximum operating supply voltages and absolute maximum ratings for the active

components onboard the SmartRF TrxEB are summarized in Table 2. Table 3 lists the recommended

operating temperature and storage temperature ratings. Please refer to the respective component’s

datasheet for further details.

Component

Operating voltage

Min. [V]

Max. [V]

Absolute max. rating

Min. [V]

Max. [V]

USB MCU [3]

+3.0

+3.6

-0.3

+3.9

MSP430 MCU [6]

+1.8

+3.6

-0.3

+4.1

LCD [7]

+3.0

+3.3

-0.3

+3.6

Accelerometer [8]

+1.7

+3.6

-0.3

+3.6

Ambient light sensor [9]

+2.3

+5.5

NA

+6

Serial Flash [10]

+2.7

+3.6

-0.4

+4.0

Table 2 – Supply voltage: Recommended operating conditions and absolute max. ratings

Component

Operating temperature

Storage temperature

Min. [˚C]

Max. [˚C]

0

+85

-50

+150

MSP430 MCU [6]

-40

+85

-55

+105

LCD [7]

-20

+70

-30

+80

Accelerometer [8]

-40

+85

-40

+125

Ambient light sensor [9]

-40

+85

-40

+85

Serial Flash [10]

-40

+85

-65

+150

USB MCU [3]

Min. [˚C]

Max. [˚C]

Table 3 – Temperature: Recommended operating conditions and storage temperatures

Page 10/44

�SWRU294A

6 SmartRF Transceiver Evaluation Board Overview

SmartRF TrxEB acts as the motherboard in several development kits for low power RF ICs from

Texas Instruments. The board has several user interfaces and connections to external interfaces,

allowing fast prototyping and testing of both software and hardware.

This chapter will give an overview of the general architecture of the board and describe the available

I/O. The following sub-sections will explain the I/O in more detail. Pin connections between the

evaluation board I/O and EM can be found in section 6.10.

LEDs

JTAG

debug

Light

Sensor

Buttons

Serial

Flash

LCD

Accelerometer

SPI (USCIB2)

SPI (USCIA2)

MSP430F5438A

controller

UART (USCIA0)

SPI (USCIB1)

SPI (USCIB0)

EM

GPIO

UART

(USCIA1)

Micro USB

connector

GPIO (1.7.0+ only)

USB

Controller

(CC2511)

USB

LED

Figure 3 – SmartRF TrxEB architecture

NOTE: Signal names used in this user’s guide and in the SmartRF TrxEB schematics, are

named “as seen” from the onboard MSP430 MCU. E.g. signal name “P1_3” refers to the

signal connected to MSP430 port 1, pin 3.

Page 11/44

�SWRU294A

6.1 USB MCU

The USB MCU is the CC2511F32 from Texas Instruments. Please see the CC2511 product page [3]

on the TI web for detailed information about this controller. The recommended operating condition for

the CC2511 is a supply voltage between 3.0 V and 3.6 V. The min (max) operating temperature is 0

(+85) ˚C.

The USB controller is programmed with a bootloader and the standard SmartRF TrxEB firmware

when it is shipped from the factory. A flow chart over the USB MCU bootloader and standard firmware

is shown in Figure 4.

Power-on-Reset

Hold MSP430 &

EM in reset

Forced recovery or

no/invalid application

Yes

Release MSP430

& EM reset

No

Enable Cebal

USB interface

Launch application

Recovery Mode

USB MCU Bootloader

USB MCU Standard Application

SmartRF

S1/S2 change

Determine operating

mode (S1/S2)

Disabled

UART

Release EM

reset

Release MSP430

& EM reset

Release MSP430

& EM reset

Enable Cebal

USB interface

Enable CDC-ACM

USB interface

Enter low-power

mode

SmartRF Mode

UART Mode

Disabled Mode

Figure 4 – Flow chart of the USB MCU bootloader and standard firmware

When the bootloader starts running, it will check for a valid application in the CC2511 flash memory. If

detection is successful, the application is started and the board can be operated normally. If no

application is detected (e.g. blank flash or firmware upgrade failed) the USB LED (D6) will start

blinking rapidly – indicating failure. See section 6.9.2 for more details on USB LED states.

The USB MCU bootloader will allow programming/upgrading of the USB MCU firmware over the USB

interface. No additional hardware or programmers are needed. Both SmartRF Studio and SmartRF

Flash Programmer [4] can be used for this purpose. Please refer to chapter 11 for details.

The standard firmware application has three operating modes, controlled by hardware switches S1

and S2. The three modes are named “SmartRF Mode”, “UART Mode” and “Disabled Mode”. Table 4

shows which S1 and S2 positions that give the different operation modes. The following sections will

discuss the different operating modes in more detail.

Page 12/44

�SWRU294A

S2

Enable

Enable

Disable

S1

Operating Mode

SmartRF

UART

x

Key features

- Cebal USB interface

- MSP430 disabled

- Control RF-IC using

SmartRF Mode

SmartRF PC software

UART Mode

Disabled Mode

- CDC-ACM USB interface

- MSP430 enabled

- UART bridge between PC

and MSP430

- Control RF-IC using

MSP430 or external MCU

- USB interface disabled

- MSP430 enabled

- Control RF-IC using

MSP430 or external MCU

Table 4 – SmartRF TrxEB operating modes

6.1.1 SmartRF Mode

SmartRF Mode is the standard operating mode and is obtained by setting hardware switches S1 and

S2 on the EB to “SmartRF” and “Enable”, respectively (see Table 4).

In SmartRF mode the EB is recognized over USB as a Cebal device, enabling PC software like

SmartRF Studio to configure and control the RF-IC connected to the EB’s EM connectors.

The onboard MSP430 microcontroller is in this operating mode held in reset by the USB MCU.

6.1.2 UART Mode

UART Mode is obtained by setting hardware switches S1 and S2 on the EB to “UART” and “Enable”,

respectively (see Table 4).

In UART mode, the EB is recognized over USB as a virtual serial port (CDC-ACM). The USB MCU

works as a UART bridge between the onboard MSP430 and the PC. The hardware connection

between the USB MCU and the MSP430 is shown in Figure 5. The supported data rates are listed in

Table 5.

It is not possible to use SmartRF Studio or other PC software to communicate with a connected RF-IC

when operating in UART Mode. To communicate with a connected RF-IC, the onboard MSP430 or an

external MCU must be programmed with custom firmware. Please refer to the MSP430 User’s Guide

[5] for more information about the MSP430 MCU.

Data rate [baud]

9 600

38 400

56 700

115 200

Table 5 – Data rates supported by the USB MCU in UART Mode

Page 13/44

�SWRU294A

CTS

USB_UART_RTS

RTS

RTS

USB_UART_CTS

CTS

RXD

USB_UART_TXD

TXD

TXD

USB_UART_RXD

RXD

CC2511

MSP430 I/O

breakout

P4.4

P2.7

P5.6

P5.7

MSP430

Figure 5 – UART lines connected between the USB MCU and the onboard MSP430 MCU.

CTS and RTS lines are dotted to indicate that the USB MCU standard firmware only

implements a two-line UART interface to the MSP430 MCU.

NOTE: Figure 5 shows the four hardware connected UART lines between the USB MCU and

the MSP430 MCU. The MSP430 does not support hardware flow control (RTS and CTS

lines). Such support must be manually implemented in the MSP430 software. To ease

MSP430 application development, the standard USB MCU firmware uses a two-line UART

interface to the MSP430, i.e. hardware flow control is not implemented.

6.1.3 Disabled Mode

Disabled Mode is obtained by setting hardware switch S2 on the EB to “Disable” position (see Table

4). The position of S1 is disregarded by the USB MCU when S2 is in the “Disable” position.

In Disabled Mode, the USB MCU is in power-down mode and no USB communication is possible

between a PC and the EB. It is however still possible to power the EB via the USB cable, see section

6.3.2.

Page 14/44

�SWRU294A

6.2 MSP430 MCU

The SmartRF TrxEB is equipped with an MSP430F5438A micro controller from Texas Instruments.

Please see the MSP430F5438A product page [6] on the TI website for detailed information about this

controller.

All of the EB’s user interface peripherals are available to the MSP430 (Figure 3 on page 11).

Excluding the EM, the list of available peripherals consists of

-

LCD

5x Buttons

4x LEDs

Ambient Light Sensor

Accelerometer

SPI Flash.

The recommended operating condition for the MSP430 is a supply voltage (VCC) between 1.8 V and

3.6 V. The min (max) operating temperature is -40 (+85) ˚C.

NOTE: The onboard MSP430 MCU is held in reset by the USB MCU in SmartRF Mode. In

order to use the MSP430, make sure the USB MCU is set to Disabled Mode or UART Mode.

See section 6.1 for details.

6.3 Power Sources

There are four possible solutions for applying power to the SmartRF TrxEB; batteries, USB bus,

external power supply and MSP-FET. The power source can be selected using the power source

selection jumpers on header P17 (Figure 6). The main power supply switch (S5) turns off all power

sources.

Figure 6 – Main power selection header (P17) and power switch (P5)

WARNING! Do not use multiple power sources to power the SmartRF TrxEB at the same

time. Doing so may lead to excessive currents, causing onboard components to break.

WARNING! When using the SmartRF TrxEB with a MSP430 debugger (e.g. MSPFET430UIF), while powering the EB with a different power source (batteries, USB or external

power supply), a jumper should short circuit pin 9-10 of header P17 (“LCL”). This will prevent

the MSP-FET from supplying power to the EB.

Page 15/44

�SWRU294A

6.3.1 Battery Power

The SmartRF TrxEB includes a battery holder for two 1.5 V AA batteries on the reverse side of the

PCB. Normal AA batteries can be used and the onboard regulator supplies 3.3 V to the board. The

power source selection jumpers should short circuit pin 1-2 (“BATT”) and 9-10 (“LCL”) of header P17,

see Figure 7.

Figure 7 – P17 jumper settings to power TrxEB using batteries

The maximum current consumption is limited by the regulator to 800 mA.

6.3.2 USB Power

When the SmartRF TrxEB is connected to a PC via a USB cable, it can draw power from the USB

bus. The onboard voltage regulator supplies approximately 3.3 V to the board. The power source

selection jumpers should short circuit pin 3-4 (“USB”) and 9-10 (“LCL”) of header P17 (Figure 8).

Figure 8 – P17 jumper settings to power TrxEB via the USB cable

2

The maximum current consumption is limited by the regulator to 1500 mA .

2

Note that most USB power sources are limited to 500 mA.

Page 16/44

�SWRU294A

6.3.3 External Power Supply

The SmartRF TrxEB has a connector for powering the board using an external power supply. The

power source selection jumpers should short circuit pin 5-6 (“EXT”) and 9-10 (“LCL”) of header P16 as

shown in Figure 9.

Figure 9 – P17 jumper settings to power TrxEB using external power supply

WARNING! When using an external power source, all onboard voltage regulators are

bypassed. There is a risk of damaging the onboard components if the applied voltage on the

external power connector/header is lower than -0.3 V or higher than 3.6 V (combined

absolute maximum ratings for onboard components. See section 5.1 for further information.

6.3.3.1 SmartRF TrxEB revision ≤1.5.0

The external supply’s ground should be connected to pin 2 of P201. Apply a voltage in the range from

3.0 V to 3.3 V to pin 1 (see Figure 10). Pin 1 and pin 2 of P201 are marked “Vext” and “GND”,

respectively, on SmartRF TrxEB revision 1.5.0.

Pin 1: Vext

Pin 2: GND

Figure 10 – Powering TrxEB rev. ≤1.5.0 via the external power supply connector (P201)

6.3.3.2 SmartRF TrxEB revision 1.7.0

The external supply’s ground should be connected to the TrxEB ground, e.g. to the ground pad in the

bottom left corner of the EB. Connect the positive supply connector to either of the two pins on the

external power header P1 (Figure 11). The applied voltage must be in the range from 3.0 V to 3.3 V.

Figure 11 – TrxEB rev. 1.7.0 external power supply header (P1)

Page 17/44

�SWRU294A

6.3.4 MSP-FET Power

The SmartRF TrxEB can be powered via an MSP430 debugger such as MSP-FET430UIF. The power

source selection jumpers should in that case short circuit pin 7-8 of header P17 (Figure 12). Note that

the MSP-FET will not power the EB if pin 9-10 of header P17 (“LCL”) is short circuited.

Figure 12 – P17 jumper settings to power EB using a MSP-FET

6.4 LCD

The SmartRF TrxEB comes with a 128x64 pixels display from Electronic Assembly (DOGM128E-6)

[7]. The LCD display is available to the onboard MSP430 via an SPI interface, enabling software

development of user interfaces and demo use. The LCD display shares SPI interface with the serial

flash device (section 6.7).

The recommended operating condition for the LCD display is a supply voltage between 3.0 V and 3.3

V. The min (max) operating temperature is -20 (+70) ˚C.

6.5 Accelerometer

The SmartRF TrxEB is equipped with a digital accelerometer from VTI Technologies (CMA3000-D01)

[8]. The accelerometer is available to the onboard MSP430 MCU via an SPI interface and has a

dedicated interrupt line to the MCU. The onboard accelerometer is suitable for application

development, prototyping and demo use. See sections 8.2.2 and 9.2.2 for details on accelerometer

axis orientation for EB revision 1.3.0 and ≥1.5.0, respectively.

The recommended operating condition for the accelerometer is a supply voltage between 1.7 V and

3.6 V. The min (max) operating temperature is -40 (+85) ˚C.

6.6 Ambient Light Sensor

The SmartRF TrxEB has an analog SFH 5711 ambient light sensor from Osram [9] that is available to

the onboard MSP430, enabling quick application development for demo use and prototyping. The

light sensor is placed outside the bottom right corner of the LCD display.

The recommended operating condition for the ambient light sensor is a supply voltage between 2.3 V

and 5.5 V. The min (max) operating temperature is -40 (+85) ˚C.

6.7 Serial Flash

SmartRF TrxEB has a M25PE20 flash device – a paged 256 KB serial flash memory from Micron [10].

The device gives the MSP430 access to extra flash, enabling over-the-air upgrades and more. The

serial device shares SPI bus with the LCD display (section 6.4).

The recommended operating condition for the serial flash device is a supply voltage between 2.7 V

and 3.6 V. The min (max) operating temperature is -40 (+85) ˚C.

Page 18/44

�SWRU294A

6.8 Buttons

There are 7 buttons on the SmartRF TrxEB. Status of BTN_LEFT, BTN_RIGHT, BTN_UP,

BTN_DOWN and BTN_SELECT can be read by the onboard MSP430. These buttons are intended

for user interfacing and development of demo applications.

The RESET MCU button resets the MSP430 MCU by pulling its reset line low (MCU_RESET_N). The

RESET USB button similarly resets the USB controller (pulling USB_RESET_N low). Note that the

standard firmware on the USB controller will reset the EM and MSP430 during startup, so pushing the

RESET USB button also resets the controller on the EM board and the MSP430.

6.9 LEDs

6.9.1 General Purpose LEDs

The four LEDs D3, D4, D5, D7 can be controlled from the onboard MSP430 and are suitable for demo

use and debugging. The LEDs are active low.

6.9.2 USB LED

LED D6 (USB LED) is controlled by the USB controller and is used to indicate the status of the EB.

The USB LED has several states, listed in Table 6.

USB LED state

Description

OFF

Power is turned off, the USB controller is in Disabled

Mode or the software on the USB controller is corrupt.

ON

SmartRF Mode: The standard firmware is running and

a RF-IC has been detected.

UART Mode: The standard firmware is running. The

USB LED is quickly toggled OFF/ON when UART traffic.

This is typically seen as slight variations in emitted

intensity.

BLINKING (100 ms ON – 900 ms OFF) SmartRF Mode: No RF-IC is detected.

BLINKING (1 Hz)

The USB MCU has entered the boot recovery mode.

See chapter 11 for further details.

BLINKING (10 Hz)

The bootloader on the USB MCU could not find a valid

application to boot. Basic USB services are available

and both SmartRF Studio and SmartRF Flash

Programmer can be used to program an application to

the USB controller’s flash. See chapter 11 for further

details.

Table 6 – USB LED state descriptions

Page 19/44

�SWRU294A

6.10 EM Connectors

The EM connectors (TFM-110-02-S-D-A from Samtec), shown in Figure 13, are used for connecting

an EM board to the SmartRF TrxEB. The connectors RF1 and RF2 are the main interface and are

designed to avoid incorrect mounting of the EM board.

Figure 13 – SmartRF TrxEB EM connectors RF1 and RF2

The signals from the EM are primarily connected to the MSP430 on the TrxEB. Some of the signals

are also connected to the USB controller in order to allow control of the RF device from the PC with

SmartRF Studio. The figure below (Figure 14) illustrates how the signals are connected to the

MSP430 and which serial peripheral modules on the MSP430 that can potentially be used for

communication with the EM.

The main serial interface to the EM (transceiver) is over SPI using USCIB0. To support some of the

network processors and other EMs with alternative pin-out, some of the signals from the EM are

connected to both USCIB1 (for SPI) and USCIA0 (for UART). If the serial peripheral modules are not

needed, the same pins on the MSP430 can be used as general purpose IOs.

Also note that most of the general purpose control signals from the EM (i.e. the signals not used for

serial communication) are connected to interrupt capable pins on the MSP430 (port 1 and 2).

UART (USCIA0)

MSP430F5438A

controller

SPI (USCIB1)

EM

SPI (USCIB0)

GPIO

UART

(USCIA1)

switch*

GPIO

USB

Controller

(CC2511)

Figure 14 – EM interface

(*) Note that the switch is only present on rev 1.7.0 and newer of the TrxEB (see 10.2.1)

The pin-out of the EM connectors is given in Table 7 and Table 8 below. The signals from the EM

connectors are all accessible from either the EM I/O breakout headers (see section 6.11.1) and/or the

MSP430 I/O breakout (section 6.11.2).

Page 20/44

�SWRU294A

EM pin

Signal name

Description

Breakout

header

MSP430

RF1.1

GND

Ground

RF1.2

NC

Not connected

RF1.3

P1_4 / RF_SPI1_CS_N

GPIO signal to EM board / Alt. SPI P7.5

P1.4

RF1.4

P1_1

GPIO signal to EM board

P7.2

P1.1

RF1.5

P8_2

GPIO signal to EM board

P7.13

P8.2

RF1.6

P1_5

GPIO signal to EM board

P7.6

P1.5

RF1.7

RF_UART_TXD / RF_SPI1_MISO

2-line UART to EM board / Alt. SPI P7.9

RF1.8

(breakout)

GPIO signal

RF1.9

RF_UART_RXD / RF_SPI1_MOSI

2-line UART to EM board / Alt. SPI P7.7

P3.5 / P3.7

RF1.10

P1_7

GPIO signal to EM board

P7.8

P1.7

RF1.11

P8_3

GPIO signal to EM board

P7.15

P8.3

RF1.12

P1_3

GPIO signal to EM board

P7.4

P1.3

RF1.13

(breakout)

GPIO signal

P25A.2

RF1.14

RF_SPI0_CS_N

EM SPI Chip Select

P7.14

P3.0

RF1.15

P8_4

GPIO signal to EM board

P7.17

P8.4

RF1.16

RF_SPI0_SCLK

EM SPI Clock

P7.12

P3.3

RF1.17

P8_5

GPIO signal to EM board

P7.19

P8.5

RF1.18

RF_SPI0_MOSI

EM SPI MOSI

P7.16

P3.1

RF1.19

GND

Ground

P7.20

RF1.20

RF_SPI0_MISO

EM_SPI_MISO

P7.18

Table 7 – EM connector RF1 pin-out

Page 21/44

P3.4 / P5.4

P25A.1

P3.2

�SWRU294A

EM pin

Signal name

Description

RF2.1

NC

Not connected

RF2.2

GND

Ground

RF2.3

NC

Not connected

RF2.4

NC

Not connected

RF2.5

NC

Not connected

RF2.6

(breakout)

GPIO signal

RF2.7

RF_PWR

EM power

RF2.8

(breakout)

GPIO signal

RF2.9

RF_PWR

EM power

Breakout

header

MSP430

P25C.1

P25C.2

RF2.10 (breakout)

GPIO signal

P25D.1

RF2.11 (breakout)

GPIO signal

P25B.1

RF2.12 (breakout)

GPIO signal

P25D.2

RF2.13 (breakout)

GPIO signal

P25B.2

RF2.14 (breakout)

GPIO signal

P25E.1

RF2.15 RF_RESET_N

Signal used to reset EM board

P7.10

P8.0

RF2.16 NC

Not connected

RF2.17 P8_1

GPIO signal to EM board

P7.11

P8.1

RF2.18 P1_2 / RF_SPI1_SCLK

GPIO signal to EM board / Alt. SPI

P7.3

P1.2 / P5.5

RF2.19 P1_0

GPIO signal to EM board

P7.1

P1.0

RF2.20 GND (NC on rev < 1.7.0)

Ground

Table 8 – EM connector RF2 pin-out

Page 22/44

�SWRU294A

6.11 Breakout Headers and Jumpers

Header P7 and P25A-E give access to main EM connector pins, while P11, P14, P16 and P18-P24

give access to the MSP430 I/O (section 6.11.2). Some signals can be accessed from both the EM I/O

breakout headers and the MSP430 I/O breakout as indicated by Figure 15.

EM Connectors

RF1

RF2

MSP430

MCU

MSP430 I/O Breakout

EM I/O Breakout

P7, P25

Figure 15 – SmartRF TrxEB I/O breakout overview

6.11.1

EM I/O breakout headers

The EM I/O breakout headers on SmartRF TrxEB consist of header P7 and I/O connector P25. P25 is

made out of five 2-pin connectors (P25A-E). The layout of these connectors is shown in Figure 16.

Table 7 and Table 8 in section 6.10 shows how the EM I/O connector headers are mapped to EM

connector RF1 and RF2, respectively.

P25A

1 2

P25B P25C P25D P25E

1 2 1 2 1 2 1 2

Figure 16 – I/O connector P25A-E PCB layout

6.11.2

MSP430 I/O breakout

MSP430 ports 1-10 are on SmartRF TrxEB available through the MSP430 I/O breakout shown in

Figure 17. Table 9 lists I/O breakout for ports 1-5, while Table 10 covers ports 6-10. Both tables

indicate if the given MSP430 pin is connected to an EM connector pin. For additional info on the

MSP430 pin-out on SmartRF TrxEB, please refer to section 8.4.

Figure 17 – MSP430 I/O breakout on SmartRF TrxEB

Page 23/44

�SWRU294A

MSP430 Signal Name

Description

EM pin

P1.0

P1_0

Unused GPIO

RF2.19

P1.1

P1_1

GPIO signal to EM board

RF1.4

P1.2

P1_2 / RF_SPI1_SCLK

Alternative EM SPI Clock

RF2.18

P1.3

P1_3

GPIO signal to EM board

RF1.12

P1.4

P1_4 / RF_SPI1_CS_N

Alternative EM SPI Chip Select

RF1.3

P1.5

P1_5

GPIO signal to EM board

RF1.6

P1.6

P1_6

Unused GPIO

P1.7

P1_7

GPIO signal to EM board

P2.0

ACC_INT

Accelerometer interrupt line

P2.1

BTN_LEFT

Left button input line

P2.2

BTN_RIGHT

Right button input line

P2.3

BTN_SELECT

Select button input line

P2.4

BTN_UP

Up button input line

P2.5

BTN_DOWN

Down button input line

P2.6

P2_6

Unused GPIO

P2.7

USB_UART_CTS

CTS line to USB MCU

P3.0

RF_SPI0_CS_N

EM SPI Chip Select

RF1.14

P3.1

RF_SPI0_MOSI

EM SPI MOSI

RF1.18

P3.2

RF_SPI0_MISO

EM SPI MISO

RF1.20

P3.3

RF_SPI0_SCLK

EM SPI Clock

RF1.16

P3.4

RF_UART_TXD / RF_SPI1_MISO

2-line UART to EM board

RF1.7

P3.5

RF_UART_RXD / RF_SPI1_MOSI

2-line UART to EM board

RF1.9

P3.6

LCD_BL

LCD backlight module enable line 3

P3.7

RF_UART_RXD / RF_SPI1_MOSI

Alternative EM SPI MOSI

P4.0

LED_1

General purpose LED 1 line

P4.1

LED_2

General purpose LED 2 line

P4.2

LED_3

General purpose LED 3 line

P4.3

LED_4

General purpose LED 4 line

P4.4

USB_UART_RTS

RTS line to USB MCU

P4.5

P4_5

Unused GPIO

P4.6

P4_6

Unused GPIO

P4.7

P4_7

Unused GPIO

P5.0

P5_0

GPIO or VREF+

P5.1

P5_1

GPIO or VREF-

P5.2

P5_2 / XT2IN

Unused GPIO / External crystal oscillator line

P5.3

P5_3 / XT2OUT

Unused GPIO / External crystal oscillator line

P5.4

RF_UART_TXD / RF_SPI1_MISO

Alternative EM SPI MISO

RF1.7

P5.5

P1_2 / RF_SPI1_SCLK

Alternative EM SPI Clock

RF2.18

P5.6

USB_UART_TXD

TXD line to USB MCU

P5.7

USB_UART_RXD

RXD line to USB MCU

RF1.10

RF1.9

Table 9 – MSP430 Port 1-5 pin-out

3

LCD backlight module is not included. Additional components needed to use backlight module.

Page 24/44

�SWRU294A

MSP430 Signal Name

Description

P6.0

ACC_PWR

Accelerometer power, enable high

P6.1

ALS_PWR

Ambient light sensor power, enable high

P6.2

ALS_OUT

Ambient light sensor output line

P6.3

P6_3

Unused GPIO

P6.4

P6_4

Unused GPIO

P6.5

P6_5

Unused GPIO

P6.6

P6_6

Unused GPIO

P6.7

P6_7

Unused GPIO

P7.0

P7_0 / XIN

External crystal oscillator line

P7.1

P7_1 / XOUT

External crystal oscillator line

P7.2

FLASH_RESET_N

Serial flash reset line, active low

P7.3

LCD_RESET_N

LCD reset line, active low

P7.4

P7_4

Unused GPIO

P7.5

P7_5

Unused GPIO

P7.6

FLASH_PWR

Serial flash power, enable high

P7.7

LCD_PWR

LCD power, enable high

P8.0

RF_RESET_N

Signal used to reset EM board

RF2.15

P8.1

P8_1

GPIO signal to EM board

RF2.17

P8.2

P8_2

GPIO signal to EM board

RF1.5

P8.3

P8_3

GPIO signal to EM board

RF1.11

P8.4

P8_4

GPIO signal to EM board

RF1.15

P8.5

P8_5

GPIO signal to EM board

RF1.17

P8.6

FLASH_CS_N

SPI Chip Select for serial flash, active low

P8.7

ACC_CS_N

SPI Chip Select for accelerometer, active low

P9.0

IO_SPI1_SCLK

SPI Clock (interface used by accelerometer)

P9.1

IO_SPI0_MOSI

SPI MOSI (interface shared by LCD, serial flash)

P9.2

IO_SPI0_MISO

SPI MISO (interface shared by LCD, serial flash)

P9.3

IO_SPI0_SCLK

SPI SCLK (interface shared by LCD, serial flash)

P9.4

IO_SPI1_MOSI

SPI MOSI (interface used by accelerometer)

P9.5

IO_SPI1_MISO

SPI MISO (interface used by accelerometer)

P9.6

LCD_CS_N

SPI Chip Select for LCD, active low

P9.7

LCD_MODE

LCD mode select signal [7]

P10.0

P10_0

Unused GPIO

P10.1

P10_1

Unused GPIO

P10.2

P10_2

Unused GPIO

P10.3

P10_3

Unused GPIO

P10.4

P10_4

Unused GPIO

P10.5

P10_5

Unused GPIO

P10.6

P10_6

Unused GPIO

P10.7

P10_7

Unused GPIO

Table 10 – MSP430 Port 6-10 pin-out

Page 25/44

EM pin

�SWRU294A

6.12 Current Measurement Jumpers

SmartRF TrxEB has three current measurement jumpers, MCU_PWR, IO_PWR and RF_PWR, as

shown in Figure 18. By removing one of the jumpers, an ammeter can easily be connected to the

board and perform current consumption measurements on the different segments of the EB. Similarly,

a separate, regulated power supply for the EM can be connected. Table 11 shows an overview of

what onboard components are connected to which power segment.

Figure 18 – Current measurement jumpers

If the EM is powered by a different source than the rest of the board, the same voltage should be

used on the EM as on the EB. The digital signals between the EB and the EM are not isolated from

each other, and different voltage levels can cause excessive current consumption or erroneous

interaction between the EB and the EM.

NOTE: On SmartRF TrxEB revision 1.3.0, the “IO” and “RF” labels in the silk print are

switched around. For all revisions, IO and RF current should be measured on the jumpers

indicated by the silk print in Figure 18. See chapter 8 for details about EB revision 1.3.0.

Figure 19 – Current measurement setup

Page 26/44

�SWRU294A

Component

Default power

Alternative power

Evaluation Module

RF_PWR

NA

MSP430 MCU

MCU_PWR

NA

USB MCU

IO_PWR

NA

General Purpose LEDs IO_PWR

NA

USB LED

IO_PWR

NA

Accelerometer

MCU_PWR (MSP430 P6.0)

NA

Ambient Light Sensor

MCU_PWR (MSP430 P6.1)

NA

SPI Flash

MCU_PWR (MSP430 P7.6)

IO_PWR (swap R17/R18)

LCD

MCU_PWR (MSP430 P7.7)

IO_PWR (swap R29/R30)

Table 11 – Component/Power segment overview

Page 27/44

�SWRU294A

7 Connecting an external MCU to SmartRF TrxEB

You can easily connect an external MCU to a SmartRF TrxEB and use it to control the EM board

mounted on the TrxEB. This chapter gives a quick overview over the signals that must be connected

to enable your external MCU to control the EM.

7.1 Disable MCUs onboard SmartRF TrxEB

To avoid any signal conflicts between the MCUs onboard the SmartRF TrxEB (MSP430 and USB

MCU) and the external MCU, both onboard MCUs should be disabled.

Disable the USB MCU by setting mode selection switch S2 to “Disable” position (Figure 20a).

To hold the onboard MSP430 MCU in reset state, short circuit pins 1-2 on header P4 as shown in

Figure 20b. An alternative, more power efficient option is to program the onboard MSP430 with you

own, custom software which configures the MSP430 pins to minimize current consumption and makes

the MSP430 enter a low-power mode [5].

a) Disable USB MCU

b) Hold MSP430 in reset

Figure 20 – Switch and jumper settings to disable both SmartRF TrxEB MCUs

7.2 Select power source

When connecting an external MCU board to the SmartRF TrxEB, there are typically two options for

powering the boards, both consisting of sharing a power source. The first is to let the external MCU

board draw power from the SmartRF TrxEB; the second is to power the SmartRF TrxEB from an

external power source. It is in both cases important that the voltage levels on shared signals are the

same.

7.2.1 Power external MCU from SmartRF TrxEB

Power the external MCU board by connecting it to IO_PWR (P9) and GND (P6) on SmartRF TrxEB,

shown in Figure 21.

Figure 21 – Power external MCU board by connecting it to IO_PWR and GND

7.2.2 Power SmartRF TrxEB from external power source

Connect the power from the external power source to the external power source connector on

SmartRF TrxEB and set the power source selection jumpers accordingly. Please see section 6.3.3 for

a detailed description on how to power the SmartRF TrxEB from an external power source.

NOTE: When powering the SmartRF TrxEB from an external power source, the TrxEB main

power switch must be in on position for the EB to be powered up.

Page 28/44

�SWRU294A

7.3 Connect signals

7.3.1 Common signals

Table 12 shows the common signals needed to communicate with transceivers on a mounted EM

board. Figure 22 shows where the signals listed Table 12 and Table 13 can be found on the P7 EM

I/O breakout header on SmartRF TrxEB.

TrxEB Signal Name TrxEB breakout pin Description

RF_RESET_N

P7.10

Signal used to reset EM board

RF_SPI0_SCLK

P7.12

EM SPI interface clock signal

RF_SPI0_CS_N

P7.14

EM SPI interface chip select signal, active low

RF_SPI0_MOSI

P7.16

EM SPI interface MOSI signal

RF_SPI0_MISO

P7.18

EM SPI interface MISO signal

GND

P7.20

Common ground for EB and external MCU board

Table 12 – Strapping overview to connect common signals to an external MCU

7.3.2 Transceiver GPIO signals

The CC1120 GPIO pins available through the EM connectors on the SmartRF TrxEB are listed in

Table 13. Figure 22 shows where the signals listed Table 12 and Table 13 can be found on the P7

EM I/O breakout header on SmartRF TrxEB. On SmartRF TrxEB rev. 1.7.0, silk print indicates where

the most important EM I/O signals on header P7 are located.

NOTE: Transceiver EM boards from Texas Instruments share much of the same GPIO

routing to the EM connectors. However, the number of GPIO signals available depends on

the transceiver. Please refer to the schematics of your EM board for further details on the

available GPIO.

TrxEB Signal Name

TrxEB Breakout Pin Description

P1_7

P7.8

Transceiver GPIO0

RF_SPI0_MISO

P7.18

Transceiver GPIO1 (Shared with EM SPI MISO)

P1_3

P7.4

Transceiver GPIO2

P1_2 / RF_SPI1_SCLK P7.3

Transceiver GPIO3

Table 13 – Strapping overview to strap CC1120 GPIO to an external MCU

GPIO3

GND

SPI MISO

SPI MOSI

SPI CSn

SPI SCLK

GPIO2

GPIO0

RESET

Figure 22 – P7 with strapping to connect external MCU to SmartRF TrxEB

Page 29/44

�SWRU294A

8 SmartRF TrxEB rev. 1.3.0

8.1 Board Overview

Figure 23 – SmartRF TrxEB revision 1.3.0 overview

8.2 Software Considerations

8.2.1 Virtual COM port over USB

The onboard MSP430 MCU can communicate with a PC over a virtual serial port when the USB MCU

is in UART Mode (described in section 6.1.2). When developing MSP430 code to communicate via

the USB MCU, keep in mind that the standard USB MCU firmware only supports a two-line UART

interface (see section 6.1.2 for further details).

8.2.2 Accelerometer

The onboard MSP430 MCU has access to accelerometer A1. On SmartRF TrxEB revision 1.3.0, the

accelerometer axes are as shown in Figure 24.

X

Z

Y

Figure 24 – Accelerometer axes on SmartRF TrxEB rev. 1.3.0

Page 30/44

�SWRU294A

8.3 USB MCU pin-out

Table 14 shows how the USB MCU’s pins are connected to the different functionalities on EB revision

1.3.0.

CC2511 Signal name

Description

EM pin

P0.0

MCU_RESET_N

Signal used to reset MSP430 MCU

P0.1

RF_RESET_N

Signal used to reset EM board

RF2.15

P0.2

RF_SPI0_CS_N

EM SPI Chip Select

RF1.14

P0.3

RF_SPI0_SCLK

EM SPI Clock

RF1.16

P0.4

RF_SPI0_MOSI

EM SPI MOSI

RF1.18

P0.5

RF_SPI0_MISO

EM SPI MISO

RF1.20

P1.0

USB_PULLUP

Enable USB Interface pull-up resistor

P1.1

P1_3

CC Debug Clock

P1.2

USB_UART_RTS

MSP430 UART (CC2511 CTS)

P1.3

USB_UART_CTS

MSP430 UART (CC2511 RTS)

P1.4

USB_UART_TXD

MSP430 UART (CC2511 RXD)

P1.5

USB_UART_RXD

MSP430 UART (CC2511 TXD)

P1.6

USB_ENABLE

Switch S2 input

P1.7

P1_7

CC Debug Data

P2.0

RF_UART_RXD / RF_SPI1_MOSI GPIO signal to EM board

P2.1

USB_DBG_DD

CC2511 CC Debug Interface Data

P2.2

USB_DBG_DC

CC2511 CC Debug Interface Clock

P2.3

USB_MODE

Switch S1 input

P2.4

USB_LED

USB LED and Forced Recovery signal

RF1.12

RF1.10

RF1.9

Table 14 – USB MCU pin-out on SmartRF TrxEB rev. 1.3.0

8.4 MSP430 MCU pin-out

For details on the pin-out for MSP430 port 1-10, please refer to Table 9 and Table 10 in section

6.11.2. Table 15 below shows the MSP430 pin-out not listed in section 6.11.2.

MSP430 Signal Name

Description

P11.0

ACLK

MSP430 ACLK output to test point TP5

P11.1

MCLK

MSP430 MCLK output to test point TP6

P11.2

SMCLK

MSP430 SMCLK output to test point TP7

VCORE VCORE

MSP430 VCORE output to test point TP8

PJ.0

TDO

JTAG Test Data Out

PJ.1

TDI

JTAG Test Data In

PJ.2

TMS

JTAG Test Mode Select

PJ.3

TCK

JTAG Test Clock

Table 15 – MSP430 miscellaneous signal pin-out

Page 31/44

�SWRU294A

9 SmartRF TrxEB rev. 1.5.0

9.1 Board Overview

Figure 25 – SmartRF TrxEB revision 1.5.0 overview

9.2 Changes from rev. 1.3.0

9.2.1 RC filter on USB MCU reset line

The pull-up resistor R22 on the USB MCU’s reset line (USB_RESET_N) has been removed. It is

replaced by a RC filter (R22 and C50) to remove ripple during reset line state transitions. See the

schematics for EB revision 1.5.0 for more details.

9.2.2 Accelerometer

The onboard accelerometer (A1) has been rotated 180 degrees compared to EB revision 1.3.0. The

accelerometer axes are given in Figure 26. Silk print has been added on the EB backside indicating

the accelerometer axes.

Y

Z

X

Figure 26 – Accelerometer axes on SmartRF TrxEB rev. ≥1.5.0

Page 32/44

�SWRU294A

9.2.3 Silk print

Silk print text “IO” and “RF” near board current measurement jumpers P10 and P15 were on EB

revision 1.3.0 placed next to the wrong jumper. This has been corrected as seen in Figure 27.

Silk print text “MCLK” and “SMCLK” near test points TP6 and TP7 were on EB revision 1.3.0

swapped, and placed next to the wrong test point. This has been corrected as seen in Figure 27.

Figure 27 – Correct silk print for MCLK and SMCLK test points

Silk print has been added to the backside for EB revision 1.5.0. The silk print indicates the orientation

of the accelerometer axes (see section 9.2.1) and power source jumper configurations (see section

6.3).

9.3 USB MCU pin-out

Same as revision 1.3.0, see section 8.3.

9.4 MSP430 MCU pin-out

Same as revision 1.3.0, see section 8.4.

Page 33/44

�SWRU294A

10 SmartRF TrxEB rev. 1.7.0

10.1 Board Overview

EM IO

Breakout header

Power source

selection header

Main power

switch

EM connectors

USB connector

USB LED

External power

supply connector

Mode selection

switces

Jumpers for current

measurement

General purpose

LEDs

MSP430 debug

connector

Accelerometer

USB MCU

CC2511

SPI flash

256 kByte

CC2511 debug

connector

General purpose

buttons

Reset header

Ambient Light

Sensor

Reset buttons

MSP430F5438A

MSP430 IO

breakout

LCD

Figure 28 – SmartRF TrxEB revision 1.7.0 overview

10.2 Changes from rev. 1.5.0

10.2.1

Switch added to enable combo EM support

In order to support all combo EMs (e.g. CC1101-CC1190), a switch (TS3A44159) has been added in

EB revision 1.7.0. The switch is placed between the four UART lines between the USB MCU and the

MSP430 as shown in Figure 29. Hardware switch S1 controls the switch as given in Table 16.

With the USB MCU in UART Mode (see section 6.1.2), the switch connects COMx lines to NCx lines

resulting in the same behavior as for older revisions of SmartRF TrxEB. In SmartRF Mode (see

section 6.1.1), COMx lines are connected to NOx giving the USB MCU extra access to the EM

interface, enabling support of combo EMs in SmartRF Studio.

Page 34/44

�SWRU294A

(CTS) P1.2

CC2511_CTS

COM1

NC1

USB_UART_RTS

P4.4 (RTS)

(RTS) P1.3

CC2511_RTS

COM2

NC2

USB_UART_CTS

P2.7 (CTS)

(RXD) P1.4

CC2511_RX

COM3

NC3

USB_UART_TXD

P5.6 (TXD)

(TXD) P1.5

CC2511_TX

COM4

NC4

USB_UART_RXD

P5.7 (RXD)

Switch

TS3A44159

CC2511

SMARTRF

GND

MSP430

NO1

P1_2 / RF_SPI1_SCLK

RF2.18

NO2

P1_4 / RF_SPI1_CS_N

RF1.3

IN1-2

NO3

RF_UART_TXD / RF_SPI1_MISO

RF1.9

IN3-4

NO4

RF_UART_RXD / RF_SPI1_MOSI

RF1.7

IO_PWR

S1

MSP430 I/O

breakout

P18.5

P14.8

P19.7

P19.8

UART

EM I/O

breakout

P7.3

P7.5

P7.7

P7.9

EM Interface

Figure 29 – Signal overview for switch TS3A44159 added for SmartRF TrxEB rev. 1.7.0

S1 position Switch TS3A44159 connection

UART

COMx ↔ NCx

SMARTRF

COMx ↔ NOx

Table 16 – S1 control over TS3A44159 switch for SmartRF TrxEB rev. 1.7.0

10.2.2

Connector type for external power sources

On SmartRF TrxEB rev. 1.7.0, the external power source connector has been switched to a two-pin

header (P1). See section 6.3.3.2 for more details on how to power SmartRF TrxEB rev. 1.7.0 using an

external power supply.

10.2.3

Connector type for LCD

SmartRF TrxEB rev. 1.7.0 comes with a different LCD connector type than previous revisions to

ensure proper connection to the LCD.

WARNING! The LCD connector on SmartRF TrxEB rev. 1.7.0 is very tight. Be extremely

cautious when removing the LCD display to avoid the LCD display from breaking.

10.2.4

Ground pad between P17 and P7

A new ground pad has been added between the power source header (P17) and the EM I/O breakout

header (P7) to ease connection of probes with these headers. The new ground pad is shown in

Figure 30.

Figure 30 – Added ground pad on SmartRF TrxEB rev. 1.7.0.

Page 35/44

�SWRU294A

10.2.5

Silk print

There has been made several minor additions to the silk print on SmartRF TrxEB 1.7.0, e.g. EM I/O

breakout pins on header P7 are now marked (see Figure 30).

10.3 USB MCU pin-out

Table 17 shows how the USB MCU’s pins are connected to the different functionalities on EB revision

1.7.0. Changes from previous EB revision are in bold.

CC2511 Signal name

Description

P0.0

MCU_RESET_N Signal used to reset MSP430 MCU

P0.1

RF_RESET_N

Signal used to reset EM board

RF2.15

P0.2

RF_SPI0_CS_N

EM SPI Chip Select

RF1.14

P0.3

RF_SPI0_SCLK

EM SPI Clock

RF1.16

P0.4

RF_SPI0_MOSI

EM SPI MOSI (Master Out, Slave In)

RF1.18

P0.5

RF_SPI0_MISO

EM SPI MISO (Master in, slave out)

RF1.20

P1.0

USB_PULLUP

Enable USB Interface pull-up resistor

P1.1

P1_3

CC Debug Clock

P1.2

CC2511_CTS

MSP430 UART / GPIO connected to EM board RF2.18

P1.3

CC2511_RTS

MSP430 UART / GPIO connected to EM board RF1.3 4

P1.4

CC2511_RX

MSP430 UART / GPIO connected to EM board RF1.9 4

P1.5

CC2511_TX

MSP430 UART / GPIO connected to EM board RF1.7 4

P1.6

USB_ENABLE

Switch S2 input

P1.7

P1_7

CC Debug Data

RF1.10

P2.0

TP3

GPIO connected to test point TP3

NC

P2.1

USB_DBG_DD

CC2511 CC Debug Interface Data

P2.2

USB_DBG_DC

CC2511 CC Debug Interface Clock

P2.3

USB_MODE

Switch S1 input

P2.4

USB_LED

USB LED and Forced Recovery signal

Table 17 – USB MCU pin-out on SmartRF TrxEB rev. 1.7.0

10.4 MSP430 MCU pin-out

Same as revision 1.3.0, see section 8.4.

4

EM pin

USB MCU pin is GPIO connected to the EM board in SmartRF Mode (section 6.1.1).

Page 36/44

RF1.12

4

�SWRU294A

11 Updating the firmware

NOTE: This chapter only describes how to program the firmware on the USB controller on

the TrxEB. To program the MSP430, use the MSP-FET430UIF tool and connect it to the

FET430 connector on the EB. Programming can be done using IAR EW430, CCS or

SmartRF Flash Programmer.

Updating the EB firmware is done automatically by SmartRF Studio and SmartRF Flash Programmer

if an old or incompatible firmware version is found on the USB MCU. SmartRF Flash Programmer also

allows manual programming of the EB firmware. Please refer to the respective user’s guides for

detailed instructions. A simple step-by-step guide for updating the USB MCU firmware using SmartRF

Studio is provided below.

1.

2.

3.

4.

Turn off the evaluation board (EB).

Disconnect any connected evaluation module (EM).

Plug in the USB cable and turn the power switch on.

The SmartRF TrxEB device should appear in the SmartRF Studio main window as seen in

Figure 31a.

5. Double click the TrxEB device. SmartRF Studio will prompt if you wish to update the EB

firmware (Figure 31b).

6. Confirm that you wish to update the EB firmware and wait for the upgrade process to

complete (Figure 31c). This may take several seconds.

7. The EB will re-appear as a connected device in the SmartRF Studio window when the update

is completed.

a)

b)

c)

Figure 31 – Firmware upgrade steps in SmartRF Studio

Page 37/44

�SWRU294A

11.1 Forced Boot Recovery Mode

If the firmware update fails and the evaluation board appears to be dead, there is a way to force the

board to only run the bootloader and stop all further execution. No attempts will be made to start the

EB firmware.

1. Turn the EB power off.

2. Rev. 1.3.0: Ground the USB LED test point shown in Figure 32a.

Rev. ≥1.5.0: Ground the USB LED test point with the GND test point in Figure 32b.

3. While doing as explained in the second step, turn the EB power on.

When the board is powered up, the bootloader will not attempt to start the firmware and it will remain

in control of the board. LED D6 (USB LED) will be blinking with a 1 second interval, indicating that the

bootloader is running. You can use the USB LED state as an indicator to whether you have a working

bootloader or not.

When the bootloader is running, the only functionality that is offered from SmartRF Studio and

SmartRF Flash Programmer is to load a new version of the standard firmware.

b) Revision ≥1.5.0

a) Revision 1.3.0

Figure 32 – Enter forced boot recovery mode

Page 38/44

�SWRU294A

11.2 Board Resurrection

If the forced boot recovery method above also fails, the board might be faulty or the flash on the

CC2511 device has been inadvertently deleted. If the latter has happened, you can try to reprogram

the boot loader on the CC2511. This will require that you have a CC Debugger [11].

First, you will have to remove the LCD from the TrxEB to get access to the debug connector for the

CC2511 (P200). The LCD might be difficult to remove and can easily break if you use excessive

force. Once the LCD is removed, connect the CC Debugger to P200 with the small flat-cable and

adapter board included with the debugger.

Next, apply power to the TrxEB board from a suitable power source (e.g. USB). Then connect the CC

Debugger to the PC via a USB cable and press the reset button on the debugger. The GREEN LED

on the debugger should now be turned on to indicate that it has detected the CC2511 device on the

TrxEB. If the RED LED is turned on, verify that the voltage level on the TrxEB is 3.3V and that the

debugger is connected correctly (note the orientation of pin 1 on the debugger cable).

Figure 33 – Proper connection for board resurrection.