TMP144

TMP144

SBOS891B – OCTOBER 2018 – REVISED APRIL

2021

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

www.ti.com

TMP144 Low-Power, Digital Temperature Sensor With SMAART Wire™ / UART

Interface

1 Features

3 Description

•

The TMP144 digital output temperature sensor can

read temperatures to a resolution of 0.0625 °C.

•

•

•

•

•

•

•

•

Multiple Device Access (MDA):

– Global read/write operations

SMAART Wire™ / UART interface

Resolution: 12-bit or 0.0625 °C

±1 °C maximum (–10 °C to +100 °C)

±2 °C maximum (–40 °C to +125 °C)

Low quiescent current:

– 3-μA active IQ at 0.25 Hz

– 0.6-μA shutdown

Supply range: 1.4 V to 3.6 V

Push-pull digital output

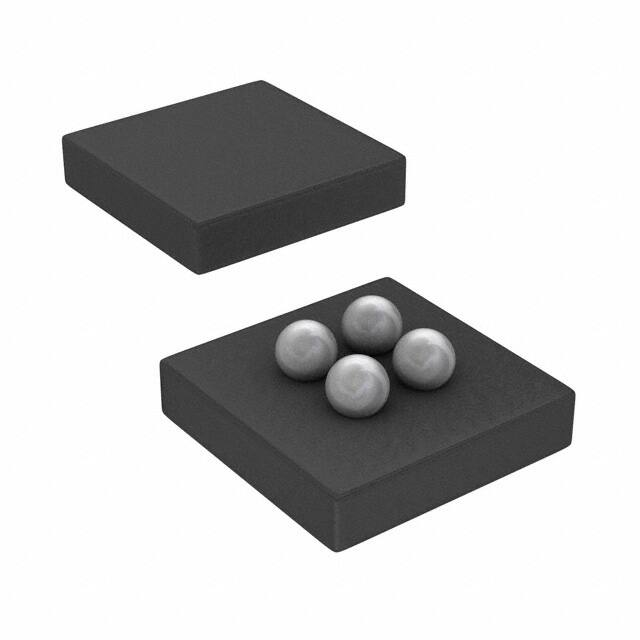

Package:

– 0.76 mm × 0.96 mm, 150-µm maximum height,

4-ball YMT (DSBGA)

– 0.76 mm × 0.96 mm, 625-µm maximum height,

4-ball YFF (DSBGA)

The device has a SMAART Wire™ / UART

interface that supports daisy-chain configurations. The

interface also supports Multiple Device Access (MDA)

commands that let the host communicate with multiple

devices on the bus simultaneously. MDA commands

are used as an alternative to sending individual

commands to each device on the bus. Up to 16

TMP144 devices can be attached together serially

and can be read by the host computer.

The TMP144 device is designed for spaceconstrained, power-sensitive applications with multiple

temperature measurement zones that must be

monitored. The device is specified for operation

over a temperature range of –40 °C to 125 °C

and is available in two different 4-ball, low-height

wafer chip-scale package (DSBGA) options. The YMT

package of the device has a height of 150 µm, which

is 40% thinner than a 0201 resistor. The thinner

YMT package can be placed under heat-dissipating

components on the system for better accuracy and

faster thermal response times.

2 Applications

•

•

•

•

•

•

•

•

Handsets

Smartphones

Tablets

LED Backlighting

HDTVs

Enterprise Servers

Notebooks

Medical

Device Information(1)

PART NUMBER

TMP144

(1)

VCC

TX

V

RX

+

TMP144

U1

GND

RX

0.76 mm x 0.96 mm

VCC

0.1µ F

0.1µ F

+

V

TX

YMT DSBGA (4)

VCC

0.1µ F

+

BODY SIZE (NOM)

0.76 mm x 0.96 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

VCC

0.1µ F

Host

PACKAGE

YFF DSBGA (4)

+

V

TX

RX

TMP144

U2

V

TX

TMP144

U(n-1)

GND

GND

RX

TX

TMP144

U(n)

GND

RX

Up to 16 TMP144 devices can be configured as a daisy-chain. (See Device Nomenclature)

Simplified Application

An©IMPORTANT

NOTICEIncorporated

at the end of this data sheet addresses availability, warranty, changes, use in

safety-critical

applications,

Copyright

2021 Texas Instruments

Submit

Document

Feedback

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Product Folder Links: TMP144

1

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications.................................................................. 4

6.1 Absolute Maximum Ratings ....................................... 4

6.2 ESD Ratings .............................................................. 4

6.3 Recommended Operating Conditions ........................4

6.4 Thermal Information ...................................................4

6.5 Electrical Characteristics ............................................4

6.6 UART Interface Timing ...............................................6

6.7 Timing Diagrams......................................................... 6

6.8 Typical Characteristics................................................ 7

7 Detailed Description........................................................8

7.1 Overview..................................................................... 8

7.2 Functional Block Diagram........................................... 8

7.3 Feature Description.....................................................9

7.4 Device Functional Modes..........................................10

7.5 SMAART Wire™ / UART Interface............................ 13

7.6 Register Maps...........................................................19

8 Application and Implementation.................................. 23

8.1 Application Information............................................. 23

8.2 Typical Application.................................................... 23

9 Power Supply Recommendations................................24

10 Layout...........................................................................25

10.1 Layout Guidelines................................................... 25

10.2 Layout Example...................................................... 25

11 Device and Documentation Support..........................26

11.1 Device Support........................................................26

11.2 Receiving Notification of Documentation Updates.. 26

11.3 Support Resources................................................. 26

11.4 Trademarks............................................................. 26

11.5 Electrostatic Discharge Caution.............................. 26

11.6 Glossary.................................................................. 26

12 Mechanical, Packaging, and Orderable

Information.................................................................... 26

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (February 2021) to Revision B (April 2021)

Page

• Removed Advanced Information note from YMT package................................................................................. 1

• Updated thermal information for YMT package.................................................................................................. 4

• Added typical value for pin capacitance............................................................................................................. 4

• Added active conversion current consumption limit values................................................................................ 4

• Added Figure 6-5 to the Typical Characteristics section.....................................................................................7

Changes from Revision * (October 2018) to Revision A (February 2021)

Page

• Changed data sheet status from Production Data to Production Mixed............................................................. 1

• Updated the numbering format for tables, figures, and cross-references throughout the document..................1

• Added Advanced Information YMT package...................................................................................................... 3

• Updated absolute max supply voltage from 3.6V to 4.0V...................................................................................4

• Updated TX pin absolute max from (V+) + 0.3 V to (V+) + 0.3 and ≤ 4 V.......................................................... 4

• Added digital temperature output section for result readout with different ETM mode setting........................... 9

• Updated the communication protocol description.............................................................................................13

• Added command byte value table.................................................................................................................... 13

• Added command flow for global software reset................................................................................................14

• Added command flow for global initialization and address assignment............................................................14

• Added command flow for global clear interrupt................................................................................................ 16

• Added command flow for global read and write................................................................................................16

• Added command flow for individual read and write.......................................................................................... 17

• Updated Register Map as per new format........................................................................................................ 19

• Updated temperature result register as a 16-bit value to map to the communication protocol.........................20

• Updated configuration register as a 16-bit value to map to the communication protocol................................. 20

• Updated temperature low limit register as a 16-bit value to map to the communication protocol.....................21

• Updated temperature high limit register as a 16-bit value to map to the communication protocol................... 22

2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

5 Pin Configuration and Functions

B2

B2

B1

RX

TX

A2

A2

B1

RX

TX

A1

A1

V+

GND

V+

GND

No t to scale

No t to scale

Figure 5-2. YMT Package 4-Pin DSBGA (Top View)

Figure 5-1. YFF Package 4-Pin DSBGA (Top View)

Table 5-1. Pin Functions

PIN

(1)

NAME

NO.

GND

A2

RX

TX

V+

I/O(1)

DESCRIPTION

G

Ground

B2

I

Serial data input pin

B1

O

Serial data output pin (push-pull output)

A1

I

Supply voltage 1.4 V to 3.6 V

I = Input, O = Output, G = Ground

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

3

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

6 Specifications

6.1 Absolute Maximum Ratings

Over free-air temperature range unless otherwise noted(1)

MIN

Supply voltage

V+

Input voltage

RX

I/O current

TX

MAX

UNIT

–0.3

4.0

V

–0.3

(V+) + 0.3

and ≤ 4

V

±15

mA

Operating junction temperature, TJ

–55

150

°C

Storage temperature, Tstg

–60

150

°C

(1)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress

ratings only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

6.2 ESD Ratings

V(ESD)

(1)

(2)

Electrostatic discharge

VALUE

UNIT

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001(1)

±2000

V

Charged-device model (CDM), per JEDEC specification JESD22-C101(2)

±1000

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

V+

Supply voltage

VI/O

RX

TA

Operating ambient temperature

MIN

NOM

MAX

1.4

3.3

3.6

UNIT

V

0

V+

V

-40

125

°C

6.4 Thermal Information

TMP144

THERMAL METRIC(1)

YFF (DSBGA)

YMT (DSBGA)

4 PINS

4 PINS

188.5

167.3

℃/W

UNIT

RθJA

Junction-to-ambient thermal resistance

RθJC(top)

Junction-to-case (top) thermal resistance

2.1

0.7

℃/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

NA

NA

℃/W

RθJB

Junction-to-board thermal resistance

35.1

47.0

℃/W

ψJT

Junction-to-top characterization parameter

10.6

0.4

℃/W

ψJB

Junction-to-board characterization parameter

35.1

47.0

℃/W

(1)

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

6.5 Electrical Characteristics

Over free-air temperature range and V+ = 1.4 V to 3.6 V (unless otherwise noted); Typical specifications are at TA = 25 °C

and V+ = 3.3 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

TEMPERATURE SENSOR

TERR (1)

PSR

4

Temperature accuracy

V+ = 3.3 V, TA = –10 °C to 100 °C

±0.5

±1.0

°C

Temperature accuracy

V+ = 1.4 V to 3.6 V, TA = –40 °C to 125 °C

±1.0

±2.0

°C

DC power supply rejection

One-shot mode

±0.2

±0.5

°C/V

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

Over free-air temperature range and V+ = 1.4 V to 3.6 V (unless otherwise noted); Typical specifications are at TA = 25 °C

and V+ = 3.3 V (unless otherwise noted)

PARAMETER

TRES

Temperature resolution

tCONV

Conversion time

TEST CONDITIONS

MIN

Including sign bit

LSB

One-shot mode

MAX

UNIT

12

Bits

62.5

m°C

26

CR1 = 0, CR0 = 0 (default)

tCONV_P Conversion Period

TYP

35

ms

4

s

CR1 = 0, CR0 = 1

1

s

CR1 = 1, CR0 = 0

0.25

s

CR1 = 1, CR0 = 1

0.125

s

DIGITAL INPUT/OUTPUT

CIN

Input capacitance

VIH

Input logic high level

RX

0.7 × (V+)

5

(V+) + 0.3

–0.5

0.3 × (V+)

V

–1

1

μA

VIL

Input logic low level

RX

IIN

Input leakage current

0 ≤ VIN ≤ (V+) + 0.3V

VOL

Output low level

VOH

Output high level

pF

V

TX, V+ > 2V, IOH = 1 mA

0

0.4

V

TX, V+ < 2V, IOH = 1 mA

0

0.2 × (V+)

V

TX, V+ > 2V, IOL = 1 mA

(V+) – 0.4

V+

V

TX, V+ < 2V, IOL = 1 mA

0.8 × (V+)

V+

V

μA

POWER SUPPLY

IDD_ACTI Supply current during active

conversion

VE

V+ = 3.3V, Active Conversion, serial bus inactive

44

100

IDD_AVG Average current consumption

V+ = 3.3V, CR1 = 0, CR0 Serial bus inactive

= 0 (default)

Serial bus active

3

10

53

μA

IDD_SB

Standby current(2)

V+ = 3.3V, Serial bus inactive

2.5

9.5

μA

IDD_SD

Shutdown current

V+ = 3.3V, Serial bus inactive

0.6

5

μA

VPOR

Power-on reset threshold

voltage

Supply rising

0.9

VDD ramp time requirements

Supply rising or falling

tRAMP_V

DD

(1)

(2)

V

1

ms

Does not include effects of self heating.

Quiescent current between conversions

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

5

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

6.6 UART Interface Timing

Over free-air temperature range and V+ = 1.4 V to 3.6 V (unless otherwise noted)

UART (8N1)

MIN

Baud Rate

4.8

MAX

UNIT

114

kbps

tR

Data rise time

0.5%

Baud

tF

Data fall time

0.5%

Baud

±1

Baud

Jitter

6.7 Timing Diagrams

BaudTYP

Jitter -

tR

tF

Jitter +

Figure 6-1. SMAART Wire™ / UART Interface Timing Diagram

6

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

6.8 Typical Characteristics

12

9

V+ = 1.4 V

V+ = 1.8 V

V+ = 3.6 V

10

7

8

6

ISD (mA)

IQ (mA)

V+ = 1.8 V

V+ = 3.6 V

8

6

5

4

3

4

2

2

1

0

0

-60 -40 -20

0

20

40

60

80

-60 -40 -20

100 120 140 160

0

40

60

80

100 120 140 160

Temperature (°C)

Temperature (°C)

Figure 6-3. Shutdown Current vs. Temperature

Figure 6-2. Typical Quiescent Current vs. Temperature

27.5

1

V+ = 1.4 V

V+ = 1.8 V

V+ = 3.6 V

27

26.5

26

25.5

25

24.5

V+ = 3.3 V

V+ = 1.8 V

0.8

0.6

Temperature Error (qC)

Conversion Time (ms)

20

0.4

0.2

0

-0.2

-0.4

-0.6

24

-0.8

23.5

-60 -40 -20

0

20

40

60

80

100 120 140 160

Temperature (°C)

Figure 6-4. Conversion Time vs. Temperature

-1

-40

-15

10

35

60

Temperature (qC)

85

110 125

TMP1

Figure 6-5. Temperature Error vs. Temperature (YFF Package)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

7

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7 Detailed Description

7.1 Overview

The TMP144 is a digital output temperature sensor in a wafer chip-scale package (WCSP) that is designed for

thermal management and thermal profiling. The TMP144 includes a SMAART Wire™ / UART interface that can

communicate in a daisy-chain loop with up to 16 devices on a single bus. The interface requires two pins from

the host: the first device in the daisy-chain receives data from the host and the last device in the daisy-chain

returns data to the host, closing the loop. In addition, the TMP144 can do multiple device access (MDA)

commands that allow multiple TMP144 devices to respond to a single global bus command. MDA commands

reduce communication time and power in a bus that contains multiple TMP144 devices. The operation of

TMP144, is specified over a temperature range of –40 °C to 125 °C.

The TMP144 can also configure the bus in a transparent mode, where the input from the host is sent directly

to the next device in the chain without delay. Additionally, the TMP144 can disconnect the chain and create a

serial communication controlled by each TMP144 on the bus, thereby allowing each device to have configurable

addressing and interrupt capabilities. The input pin, RX, is a high-impedance node. The output pin, TX, has an

internal push-pull output stage that can drive the host to GND or V+.

After an initialization sequence, each device on the bus is programmed with its own unique interface address

based upon its position in the chain, that allows it to respond to its own address. The devices can also respond

to general commands that permit the user to read or write to all devices on the bus without the need to send

individual addresses and commands to each device.

The temperature sensor in the TMP144 is the chip itself. Thermal paths run through the package bumps as

well as the package. The lower thermal resistance of metal and the low height of the devices, causes the

bumps and the topside to provide the dominant thermal paths to the sensing element on the device. To maintain

accuracy in applications that require air or surface temperature measurement, care should be taken to isolate

the package from ambient air temperature. A thermally-conductive adhesive can help to achieve accurate

surface temperature measurement.

7.2 Functional Block Diagram

V+

Rx

SW

Tx

Serial

Interface

Register

Bank

Oscillator

Control

Logic

Reset

Internal

Thermal

BJT

Temperature

Sensor

Circuitry

ADC

GND

8

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7.3 Feature Description

7.3.1 Power Up

After power-up or general-call reset, the TMP144 immediately starts a conversion as shown in Figure 7-1. The

active conversion time (tACT) of the device is 26 ms (typical) and the first result is available after the conversion is

complete in the temperature result register.

tACT

tCONV

Start of

Conversion

Startup

Figure 7-1. Conversion Start

7.3.2 Digital Temperature Output

The TMP144 by default provides a 12-bit digital output for each temperature conversion, which is stored in

the temperature result register. The host application needs to read two bytes to obtain the data. Additionally,

the application may program the ETM bit in the configuration register to get a 13-bit digital output. Table 7-1

summarizes the temperature output format. One LSB equals 0.0625 °C resolution.

Table 7-1. Temperature Data Format

TEMPERATURE (°C)

DIGITAL OUTPUT (ETM = 0)

DIGITAL OUTPUT (ETM = 1)

BINARY (T11-T0)

HEX

BINARY (T12-T0)

HEX

+150

0111 1111 1111

7FF

0 1001 0110 0000

0960

+127.9375

0111 1111 1111

7FF

0 0111 1111 1111

07FF

+125

0111 1101 0000

7D0

0 0111 1101 0000

07D0

+100

0110 0100 0000

640

0 0110 0100 0000

0640

+80

0101 0000 0000

500

0 0101 0000 0000

0500

+75

0100 1011 0000

4B0

0 0100 1011 0000

04B0

+50

0011 0010 0000

320

0 0011 0010 0000

0320

+25

0001 1001 0000

190

0 0001 1001 0000

0190

+0.0625

0000 0000 0001

001

0 0000 0000 0001

0001

0

0000 0000 0000

000

0 0000 0000 0000

0000

-0.0625

1111 1111 1111

FFF

1 1111 1111 1111

1FFF

-25

1110 0111 0000

E70

1 1110 0111 0000

1E70

-40

1101 1000 0000

D80

1 1101 1000 0000

1D80

7.3.3 Timeout Function

A timeout mechanism is implemented on the TMP144 to allow for re-synchronization of the SMAART Wire™

interface if synchronization between the host and the TMP144 is lost for 28 ms (typical). If the timeout period

expires between the calibration byte and the command byte, between the command byte and a data byte, or

between any data bytes, the TMP144 resets the SMAART Wire™ interface circuitry and waits for the baud rate

calibration command to restart. Every time a byte is transmitted on the SMAART Wire™ interface, this timeout

period restarts.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

9

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7.4 Device Functional Modes

7.4.1 Continuous Conversion Mode

When the TMP144 is in Continuous Conversion mode (M1 = 1), continuous conversions are performed at a rate

determined by the conversion rate bits, CR[1:0], in the configuration register. The TMP144 performs a single

conversion, then powers down and waits for the appropriate delay set by CR[1:0].

7.4.2 Shutdown Mode

Shutdown mode saves maximum power by shutting down all device circuitry other than the serial interface,

reducing the current consumption to typically less than 0.5 μA. Shutdown mode is enabled when bits M[1:0] in

the configuration register are set as "00". If there is an active conversion ongoing, the device completes the

ongoing conversion, updates the temperature result register and shuts down.

7.4.3 One-Shot Mode

The TMP144 features a One-Shot Temperature Measurement mode. When the device is in Shutdown mode,

writing 01 to bits M[1:0] in the configuration register, starts a single temperature conversion. During the

conversion, the bits M[1:0] read 01. The device returns to the shutdown state at the completion of the single

conversion. After the conversion, bits M[1:0] read 00. This feature is useful for reducing power consumption in

the TMP144 when continuous temperature monitoring is not required.

As a result of the short conversion time, the TMP144 can achieve a higher conversion rate. A single conversion

typically takes 26 ms and an individual read can take place in less than 300 μs. When using One-Shot mode, 30

or more conversions per second are possible.

7.4.4 Extended Temperature Mode

At power on, the TMP144 operates with a 12-bit temperature output. However, the TMP144 can be programmed

to operate in Extended Temperature mode, by setting the ETM bit in the configuration register as '1'. When

operating in extended temperature mode, the temperature result and temperature limit registers will be 13-bit

instead of 12-bit. This extra bit increases the range of the measurement. As shown in Table 7-1, with a 12-bit

temperature, the maximum value is 7FFh or 127.9 °C. With a 13-bit temperature value, however, the maximum

value is FFFh or 255.9 °C.

When the extended temperature mode is enabled, the EM bit for the temperature high limit register and

temperature low limit registers is usable by the application. TI recommends that the user update the THIGH

and TLOW register limits because the added bit will effectively left shift and double the register value. This will

double the corresponding temperature limit. However, if the application exits the ETM mode, by changing the bit

from 1 to 0, this bit is not cleared. As a result, the limit will be right-shifted by 1 bit and halved unless the register

values are updated by the application.

The ETM bit value is considered at the end of every conversion cycle, but the limit registers can be updated

immediately after setting the bit to 1.

7.4.5 Temperature Alert Function

The TMP144 contains a temperature alert function that monitors the device temperature and compares the result

to the values stored in the temperature limit registers to determine if the device temperature is within these

set limits. As shown in Figure 7-2, if the result of the temperature conversion is greater than the value in the

temperature high limit register, the flag-high bit (FH) in the configuration register is set to '1'. If the result of the

temperature conversion register is less than the value in the temperature low limit register, the flag-low (FL) in

10

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

the configuration register is set to '1'. The clearing of the flag bits depends on the setting of the latch bit (LC) in

the configuration register.

THIGH

Measured

Temperature

TLOW

FH Bit

(Transparent Mode)

FL Bit

(Transparent Mode)

FH Bit

(Latch Mode)

FL Bit

(Latch Mode)

Time

Read of Configuration Register

Figure 7-2. Temperature Flag Functional Diagram

The LC bit in the configuration register when set to '1' is used to latch the value of the flag bits (FH and FL) until

the host issues a read command to the configuration register. The flag bits are set to '0' when a read command

is received by the device.

The LC bit when configured as '0', configures the device to operate in transparent mode, where the flag bits (FH

and FL) are cleared only when the result of the temperature conversion is within the temperature limits.

7.4.6 Interrupt Functionality

The TMP144 interrupts the host by disconnecting the bus and issuing an interrupt request by holding the bus low

if all of following conditions are met as shown in Figure 7-3.

•

•

•

INT_EN in the configuration register is set to 1;

The temperature result of the last conversion is greater than the value in the temperature high limit register or

less than the value in the temperature low limit register (also indicated by a 1 in either FH or FL, respectively);

The bus is logic high and idle for more than 28 ms.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

11

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

RX

RX

Host

RX

TX

RX

TX

TX

TX

Interface Logic

Interface Logic

Interface Logic

Device(1)

Device(2)

Device(N)

Figure 7-3. TMP144 Daisy-Chain: Bus Status During an Interrupt Request (Logic Low) From Second

Device

The interrupt on the bus is latched regardless of the status of LC. Writing a 1 to INT_EN automatically sets the

LC bit. The TMP144 holds the bus low until one of the following events happen:

•

•

•

Global Interrupt Clear command is received.

Global Software Reset command is received.

A power-on reset event occurs.

Each of these events clears the INT_EN. The TMP144 does not issue future interrupts until the host writes sets

the INT_EN in the configuration register to re-enable future interrupts.

In a system with enabled interrupts, it is possible for a TMP144 on the bus to issue an interrupt at the same

time that the host starts a communication sequence. To avoid this scenario, TI recommends that the host should

check the status on the receiving side of the bus after transmitting the calibration byte. If it is 1, then the host can

continue with the communication. If it is 0, one of the TMP144 devices on the bus is issuing an alert and the host

must transmit a Global Interrupt Clear command.

12

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7.5 SMAART Wire™ / UART Interface

The TMP144 uses a TI proprietary, one-wire UART-compatible communication protocol called SMAART Wire™.

The TMP144 has two dedicated pins for communication:TX and RX. Usually, these two pins are connected

internally and the signal on the RX propagates to the TX, unless the device must send data on the bus or during

address assignment and alert procedures.

The interface has built-in timeouts (typically 28 ms) that return the interface to a known state if communication is

disrupted.

7.5.1 Communication Protocol

Each communication of the SMAART Wire™ / UART protocol consists of 8-bit word, transferred least significant

bit (LSB) first. Each 8-bit word begins with a Start bit that is logic low, and ends with a Stop bit that is logic high.

By using a Start bit and Stop bit for each 8-bit word, the TMP144 can calibrate each word and keep synchronous

communication throughout the process.

The steps for the SMAART Wire™ / UART communication protocol are:

1. The host sends a Start bit to start the communication process.

2. The host sends the calibration byte (55h) to allow the TMP144 to sync to the baud rate of the host.

3. The host sends a Stop bit after the calibration byte.

4. The host sends a second Start bit, followed by the command register byte and a Stop bit.

5. The host sends a third Start bit, followed by the data byte only for writes.

6. The host will send the data byte(s) if the instruction is a write command.

7. The host sends a Stop bit to finish the process.

Note

The device will break the chain and send the data byte(s) if the instruction sent in the command

register is a read command.

The sequence is shown in Figure 7-4.

S

1

0

1

0

1

0

1

0

P

S

P

C0 C1 C2 C3 C4 C5 C6 C7

Calibration Byte (55h)

S D0 D1 D2 D3 D4 D5 D6 D7

Command with Address Pointer

P

S D8 D9 D10 D11D12 D13D14 D15 P

Register Data (8-bit)

Register Data (8-bit)

S = Start condition of SMAART Wire¡ protocol

P = Stop condition of SMAART Wire¡ protocol

Figure 7-4. Generic Communication Write Bitstream

Driven by TMP144

S

1

0

1

0

1

0

1

0

P

S

C0 C1 C2 C3 C4 C5 C6 C7

Calibration Byte (55h)

P

S D0 D1 D2 D3 D4 D5 D6 D7

Command with Address Pointer

P

S D8 D9 D10 D11D12 D13 D14 D15 P

Register Data (8-bit)

Register Data (8-bit)

1-bit default delay for

bus direction change

S = Start condition of SMAART Wire¡ protocol

P = Stop condition of SMAART Wire¡ protocol

Figure 7-5. Generic Communication Read Bitstream

The command byte is decoded by the TMP144 to determine the format of the subsequent communication

operation. Table 7-2 lists the command register byte values.

Table 7-2. Command Byte Value

COMMAND

OPERATION

COMMAND BYTE ENCODING

HEX VALUE

C7 (MSB)

C6

C5

C4

C3

C2

C1

C0 (LSB)

GLBL

IN3/ID3

IN2/ID2

IN1/ID1

IN0/ID0

P1

P0

R/W

Global software

reset

1

0

1

1

0

1

0

0

B4

Global

initialization

1

0

0

0

1

1

0

0

8C

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

13

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

Table 7-2. Command Byte Value (continued)

COMMAND

OPERATION

COMMAND BYTE ENCODING

HEX VALUE

C7 (MSB)

C6

C5

C4

C3

C2

C1

C0 (LSB)

GLBL

IN3/ID3

IN2/ID2

IN1/ID1

IN0/ID0

P1

P0

R/W

Global address

assignment

1

0

0

1

0

0

0

0

90

Global clear

interrupt

1

0

1

0

1

0

0

1

A9

Global write

1

1

1

1

0

P1

P0

0

Based on P[1:0]

Global read

1

1

1

1

0

P1

P0

1

Based on P[1:0]

Individual write

0

ID3

ID2

ID1

ID0

P1

P0

0

Based on ID[3:0] and

P[1:0]

Individual read

0

ID3

ID2

ID1

ID0

P1

P0

1

Based on ID[3:0] and

P[1:0]

7.5.2 Global Software Reset

The host can initiate a global software reset command (C[7:0] = 10110100) to all TMP144 devices in the

daisy-chain as shown in Figure 7-6. Upon receiving this command, the TMP144 resets all of its internal registers

except for the device ID and reconnects the bus. If the bus is broken before the initiation of this command,

all TMP144 devices before the broken bus point receive the command. If the host intends to initiate a global

software reset across all TMP144 devices in the chain, this command must be transmitted multiple times until it

echoes back to the host.

S

1

0

1

0

1

0

1

0

S

P

R/W

P0

P1

0

0

1

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

0

1

1

0

GLBL

1

P

Command Byte

Calibration Byte (55h)

Figure 7-6. Global Software Reset Command Flow

7.5.3 Global Initialization and Address Assignment Sequence

At device power-up, every TMP144 in the daisy-chain is connected in transparent mode, as shown in Figure 7-7.

RX

RX

Host

RX

TX

RX

TX

TX

TX

Interface Logic

Interface Logic

Interface Logic

Device(1)

Device(2)

Device(N)

Figure 7-7. TMP144 Daisy-Chain: Bus Status at Start of Global Initialization

14

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

As shown in Figure 7-8, the host must send the initialization command (C[7:0] = 10001100) for the bus to

program its internal address, depending on the number of devices on the bus.

Host TX

S

1

0

1

0

1

0

1

0

P

R/W

P0

P1

0

0

1

S

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

Calibration Byte (55h)

1

0

GLBL

0

0

1

P

Command Byte

Device-1

TX

S

1

0

1

0

1

0

1

0

P

S

0

0

1

1

0

0

0

1

P

Device-2

TX

S

1

0

1

0

1

0

1

0

P

S

0

0

1

1

0

0

0

1

P

S

1

0

0

0

1

0

0

1

P

Host TX

S

0

0

0

0

1

0

0

1

Devices

in Pass

Through

P

Address Assignment Command (90h)

Device-1

TX

Device 1 (TX) Device 2 (RX)

Device-2

TX

Host TX

Device-1

TX

Device-2

TX

S

0

1

0

0

1

0

0

1

P

Device 2 (TX) Device 3 (RX)

Figure 7-8. Global Initialization and Address Assignment Command Flow

Each TMP144 in the chain interprets the initialization command byte and disconnects the chain, as shown in

Figure 7-9.

RX

TX

RX

TX

RX

TX

RX

TX

Host

Interface Logic

Interface Logic

Interface Logic

Device(1)

Device(2)

Device(N)

Figure 7-9. TMP144 Daisy-Chain: Bus Status at Start of Address Assignment

The host must then send the address assignment command, consisting of C[7:4] = 1001 and C[3:0] = 0000,

where C[3:0] represents the address of the first device in the chain. This word is stored internally as its device

ID. The first device increments the unit in the device address and then reconnects the bus, as shown in Figure

7-10. This address is then sent to the next device in the chain.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

15

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

RX

RX

RX

TX

Host

RX

TX

TX

TX

Interface Logic

Interface Logic

Interface Logic

Device(1)

Device(2)

Device(N)

Figure 7-10. TMP144 Daisy-Chain: Bus Status After First Device Address Assignment

After all devices on the chain have received the respective addresses, the host receives the last programmed

address on the chain + 1. The host can use this information to determine the total number of devices in the chain

and the respective address of each device.

After the initialization sequence, every device can be addressed individually or through global commands. This

global initialization sequence is a requirement and must be performed before any other communication.

7.5.4 Global Clear Interrupt

The host can initiate a global clear interrupt command (C[7:0] = 10101001) to all TMP144 devices in the

daisy-chain as shown in Figure 7-11. Upon receiving this command, the TMP144 disables future interrupts

(bit-11 in the Configuration Register is set to 0). If a TMP144 previously broke the bus connection and sent

an interrupt (logic low on the bus), the device now stops holding the bus low. The device sends the baud rate

calibration command and clear interrupt command to the next TMP144 in the chain, then reconnects the bus.

In the case of multiple devices having active interrupts, the clear interrupt command propagates through the

daisy-chain, disables all interrupts, and reconnects the bus across all devices.

0

1

S

1

1

0

0

1

0

R/W

P0

P1

1

0

0

S

P

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

0

1

1

0

GLBL

1

P

Command Byte

Calibration Byte (55h)

Figure 7-11. Global Clear Interrupt Command Flow

7.5.5 Global Read and Write

The host can initiate a global read or write command to all TMP144s in the daisy-chain by sending the read/write

command, consisting of C[7:3] = 11110 and C[2:1] to indicate the data register pointer P[1:0], as shown in Table

7-3. A global write command is indicated by C[0] = 0. The host must transfer at least one more byte of data for

the register, and every TMP144 in the daisy-chain updates the appropriate register as shown in Figure 7-12.

S

1

0

1

0

1

0

1

0

P

S

R/W

P0

P1

0

P0

P1

D0

D1

D2

D3

D4

0

1

GLBL

1

1

1

P

D13

D14

D15

P

Command Byte

Calibration Byte (55h)

S

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

D5

D6

D7

P

S

D8

D9

D10

D11

D12

Data Byte-2

Data Byte-1

Figure 7-12. Global Write Command Flow

16

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

A global read command is indicated by C[0] = 1. As shown in Figure 7-13, the TMP144 with the device ID of

0000 then breaks the bus connection, transmits the data from the register indicated by bits C[2:1] (corresponding

to data register pointer P[1:0]), and then reconnects the bus. The TMP144 with the device ID of 0001 then

repeats the same sequence, followed by the rest of the TMP144 devices in the daisy-chain.

0

1

S

Host TX

1

0

0

1

1

0

S

P

R/W

P0

P1

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

1

P0

P1

0

0

1

S

1

0

1

1

1

P

P

Command Byte

Calibration Byte (55h)

Host RX

1

GLBL

0

1

1

0

S

P

1

P1

P0

0

1

1

1

1

D11

D12

D13

D14

D15

Devices

in Pass

Through

Host TX

S

Host RX

D0

D1

D2

D4

D3

D5

D6

D7

D9

D8

S

P

D10

Device-1 Data Byte-1

P

Device-1 Data Byte-2

Host TX

D0

S

Host RX

D1

D2

D3

D5

D4

D6

D7

P

D8

S

D10

D9

D12

D11

D13

D14

D15

P

Device-2 Data Byte-2

Device-2 Data Byte-1

Figure 7-13. Global Read Command Flow

Table 7-3. Pointer Addresses

P1

P0

REGISTER

0

0

Temperature register (read-only)

0

1

Configuration register (read/write)

1

0

TLOW register (read/write)

1

1

THIGH register (read/write)

7.5.6 Individual Read and Write

The host can initiate an individual read and write command to a particular TMP144 device in the daisy-chain by

sending the read/write command. The read/write command consists of these parameters:

•

•

•

•

C[7] = 0 (Individual device access)

C[6:3] = the device ID (ID[3:0])

C[2:1] = the data register pointer (P[1:0]); see Table 7-3

C[0] = indicates read/write control

As shown in Figure 7-14, an individual device write command is indicated by C[0] = 0. The host must transfer

at least one more byte of data for the register indicated by bits C[2:1]. The TMP144 in the daisy-chain that

corresponds to the device ID noted by bits C[6:3] then updates the appropriate register.

S

1

0

1

1

0

0

1

0

P

S

R/W

P0

P1

0

P0

P1

D0

D1

D2

D3

D4

ID0

ID1

GLBL

ID2

ID3

0

P

D13

D14

D15

P

Command Byte

Calibration Byte (55h)

S

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

D5

D6

D7

P

S

D8

Host Data Byte-1

D9

D10

D11

D12

Host Data Byte-2

Figure 7-14. Individual Write Command Flow

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

17

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

As shown in Figure 7-15, an individual device read command is indicated by C[0] = 1. As shown in Figure 7-16,

the TMP144 in the daisy-chain that corresponds to the device ID pointed by bits C[6:3] then breaks the bus,

transmits the data from the register pointed by bits C[2:1], and reconnects the bus.

S

Host TX

1

0

1

0

1

0

1

0

P

S

R/W

P0

P1

1

P0

P1

ID1

ID0

GLBL

ID2

ID3

0

P

Command Byte

Calibration Byte (55h)

Host RX

IN0/ID0 IN1/ID1 IN2/ID2 IN3/ID3

S

1

0

1

0

1

0

1

0

P

S

1

P0

P1

ID0

ID1

ID2

ID3

0

P

S

D0

D1

D2

D3

D4

D5

D6

D7

P

S

D8

D9

D10

D11

D12

D13

D14

D15

P

Devices

in Pass

Through

Host TX

Host RX

Device-1 Data Byte-1

Device-1 Data Byte-2

Figure 7-15. Individual Read Command Flow

RX

TX

RX

TX

RX

TX

RX

TX

Host

Interface Logic

Interface Logic

Interface Logic

Device(1)

Device(2)

Device(N)

Figure 7-16. TMP144 Daisy-Chain: Bus Status During Individual Read Operation of Second Device

18

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7.6 Register Maps

Figure 7-17 shows the internal register structure of the TMP144. Communications between the registers are

transferred through the interface in LSB-first order. The 8-bit command register as shown in , is used to

determine the address pointer for the register that the host device wants to access.

Command

Register

Temperature

Register

Configuration

Register

RX

I/O

Control

Interface

Temperature Low

Limit Register

TX

Temperature High

Limit Register

Figure 7-17. Internal Register Structure

Table 7-4. Register Map

ADDRESS

POINTER P[1:0]

TYPE

RESET

ACRONYM

REGISTER NAME

SECTION

00

R

0000h

Temp_Result

Temperature result register

Go

01

R/W

0200h

Configuration

Configuration Register

Go

10

R/W

3C00h

Tlow_limit

Temperature low limit register

Go

11

R/W

F600h

Thigh_limit

Temperature high limit register

Go

Table 7-5. Register Section/Block Access Type Codes

Access Type

Code

Description

R

R

Read

RC

R

Read

C

to Clear

R

Read

-0

Returns 0s

W

W

Write

W0CP

W

W

0C

0 to clear

P

Requires privileged access

Read Type

R-0

Write Type

Reset or Default Value

-n

Value after reset or the default value

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

19

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7.6.1 Temperature Result Register (P[1:0] = 00) [reset = 0000h]

The temperature result register stores the results of the conversion in 12-bit or 13-bit format, depending on the

state of the ETM bit in the configuration register. Negative numbers are represented in two's complement format.

Following power-up or reset the temperature result register reads 0 °C, until the first conversion is complete.

When the ETM bit is configured as '0', the temperature result register of the device is configured as 12-bit value

with the least significant bit always reading '0'. One LSB for the temperature result equals 0.0625 °C.

Table 7-6. Temperature Result Register (ETM = 0)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

T[11:0]

EM

Reserved

R-000h

R-0

R-0h

0

Table 7-7. Temperature Result Register (ETM = 0) Field Description

Bit

15:4

3

2:0

Field

Type

Reset

Description

T[11:0]

R

000h

12-bit temperature result after last conversion

EM

R

0

Extended mode bit

Reserved

R

0h

Reserved

When the ETM bit is configured as '1', the temperature result register of the device is configured as 13-bit value.

One LSB for the temperature result equals 0.0625 °C.

Table 7-8. Temperature Result Register (ETM = 1)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

T[12:0]

Reserved

R-0000h

R-0h

0

Table 7-9. Temperature Result Register (ETM = 1) Field Description

Bit

15:13

2:0

Field

Type

Reset

Description

T[12:0]

R

0000h

13-bit temperature result after last conversion

Reserved

R

0h

Reserved

7.6.2 Configuration Register (P[1:0] = 01) [reset = 0200h]

The configuration register is used to store bits that control the operational modes of the temperature sensors and

read the status of alert flags. Read/write operations are performed LSB first.

Return to Register Map.

Table 7-10. Configuration Register

15

14

13

12

11

10

9

8

7

6

5

4

3

INT_E

N

CR[1:0]

FH

FL

LC

M[1:0]

ETM

Reserved

R/W-0

R/W-0

R-0

R-0

R/W-0

R/W-10

R/W-0

R-00h

2

1

0

Table 7-11. Configuration Register Field Description

20

Bit

Field

Type

Reset

Description

15

INT_EN

R/W

0

Interrupt enable bit

0 = Interrupt is disabled

1 = Interrupt is enabled

14:13

CR[1:0]

R/W

0

Conversion rate select

00 = 0.25 Hz conversion rate (default)

01 = 1 Hz conversion rate

10 = 4 Hz conversion rate

11 = 8 Hz conversion rate

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

Table 7-11. Configuration Register Field Description (continued)

Bit

Field

Type

Reset

Description

12

FH

R

0

Flag high temperature

0 = High temperature limit not crossed

1 = High temperature limit crossed

11

FL

R

0

Flag low temperature

0 = Low temperature limit not crossed

1 = Low temperature limit crossed

10

LC

R/W

0

Latch control bit

0 = Flag bits are cleared on read

1 = Flag bits are latched

9:8

M[1:0]

R/W

10

Conversion mode select

00 = Shutdown mode

01 = One shot conversion mode

1x = Continuous conversion mode

ETM

R/W

0

Extended temperature mode select

0 = Mode is disabled

1 = Mode is enabled

Reserved

R

0

Reserved

7

6:0

7.6.3 Temperature Low Limit Register (P[1:0] = 10) [reset = F600h]

The temperature low limit register is used to store the low temperature threshold for the device low limit flag. The

default power up reset value is -10 °C. The power on default value is valid only when ETM = 0. At the end of

each temperature conversion, the device compares the temperature result with the temperature low limit register.

If the temperature result is less than the threshold set in this register, the FL bit in the configuration register is

set.

When the ETM bit in the configuration register is updated, it is strongly recommended that the user update the

low limit register.

Note

When the ETM bit is set to 0, any writes to the EM bit will be ignored.

Table 7-12. Temperature Low Limit Register (ETM = 0)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

L[11:0]

EM

Reserved

R/W-F60h

R/W-0

R-0h

0

Table 7-13. Temperature Low Limit Register (ETM = 0) Field Description

Bit

15:4

3

2:0

Field

Type

Reset

Description

L[11:0]

R/W

F60h

12-bit temperature low limit threshold

EM

R/W

0

Don't care when ETM = 0

Reserved

R

0h

Reserved

Table 7-14. Temperature Low Limit Register (ETM = 1)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

L[12:0]

Reserved

R/W-F600h

R-0h

0

Table 7-15. Temperature Low Limit Register (ETM = 1) Field Description

Bit

Field

Type

Reset

Description

15:3

L[12:0]

R/W

F600h

13-bit temperature low limit threshold

2:0

Reserved

R

0h

Reserved

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

21

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

7.6.4 Temperature High Limit Register (P[1:0] = 11) [reset = 3C00h]

The temperature high limit register is used to store the high temperature threshold for the device high limit flag.

The default power up reset value is +60 °C. The power on default value is valid only when ETM = 0. At the

end of each temperature conversion, the device compares the temperature result with the temperature high limit

register. If the temperature result is greater than the threshold set in this register, the FH bit in the configuration

register is set.

When the ETM bit in the configuration register is updated, it is strongly recommended that the user update the

high limit register.

Note

When the ETM bit is set to 0, any writes to the EM bit will be ignored.

Table 7-16. Temperature High Limit Register (ETM = 0)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

H[11:0]

EM

Reserved

R/W-3C0h

R/W-0

R-0h

0

Table 7-17. Temperature High Limit Register (ETM = 0) Field Description

Bit

15:4

3

2:0

Field

Type

Reset

Description

H[11:1]

R/W

3C0h

12-bit temperature high limit threshold

EM

R/W

0

Don't care when ETM = 0

Reserved

R

0h

Reserved

Table 7-18. Temperature High Limit Register (ETM = 1)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

H[12:0]

Reserved

R/W-3C00h

R-0h

0

Table 7-19. Temperature High Limit Register (ETM = 1) Field Description

Bit

22

Field

Type

Reset

Description

15:3

H[12:0]

R/W

3C00h

13-bit temperature high limit threshold

2:0

Reserved

R

0h

Reserved

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

8 Application and Implementation

Note

Information in the following applications sections is not part of the TI component specification,

and TI does not warrant its accuracy or completeness. TI’s customers are responsible for

determining suitability of components for their purposes, as well as validating and testing their design

implementation to confirm system functionality.

8.1 Application Information

The TMP144 devices are typically used to for thermal management of multiple hotspots. The MDA commands

make it easy to manage multiple devices at the same time, which reduces communication time and power. The

WCSP package enables the device to be placed in space-constrained designs and allows the device to have a

fast thermal response.

8.2 Typical Application

Figure 8-1 shows typical connections for TMP144 devices in a daisy-chain configuration.

Figure 8-1. Typical Application With Multiple Devices

8.2.1 Design Requirements

Multiple devices are connected in this typical application. The key design requirements are discussed in the

following sections.

8.2.2 Detailed Design Procedure

8.2.2.1 Trace Length

The maximum trace or cable length between two TMP144 devices can vary because of the effective resistance

and capacitance of the type of cable used in a customer application. Design the trace or cable such that timing

specifications in Timing Diagrams can be satisfied for each TMP144 device in the daisy-chain.

8.2.2.2 Voltage Drop Effect

Take into account the voltage drop that occurs along the supply and ground lines as a result of the currents of

all the devices on the line. This voltage drop occurs as a result of multiple devices simultaneously consuming

current through the combined resistance of the common wire, connectors, and solder contacts. Make sure that

the supply on the last device does not fall below the minimum operating supply of 1.4 V.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

23

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

8.2.2.3 Power Supply Noise Filtering

To reduce power supply noise, a 0.1-μF bypass capacitor is used for each TMP144 device. Depending on the

environment, additional bypass capacitors (for example, 1 nF) may be required.

8.2.3 Application Curves

12

10

3

V+ = 1.4 V

V+ = 1.8 V

V+ = 3.6 V

2.5

2

1.5

Temperature Error (qC)

IQ (mA)

8

6

4

2

1

0.5

0

-0.5

-1

-1.5

0

-60 -40 -20

0

20

40

60

80

-2

100 120 140 160

-2.5

Temperature (°C)

-3

-60

-40

-20

0

20

40

60

80

100

120

140

Temperature (qC)

Figure 8-2. Typical Quiescent Current vs.

Temperature

Figure 8-3. Temperature Error vs. Temperature

9 Power Supply Recommendations

The TMP144 operates on a power-supply range from 1.4 V to 3.6 V. The device is trimmed for operation at a

3.3-V supply, but the TMP144 can measure temperature accurately in the full supply range.

The TMP144 is a very low-power device and generates very low noise on the supply bus. Applying a bypass

capacitor to the V+ pin of the TMP144 can further reduce any noise the TMP144 might propagate to other

components. Use a CF capacitor with a value greater than 0.1 μF as shown in Figure 9-1. Place the bypass

capacitor as close to the supply and ground pins of the device as possible for best results.

VCC

CF

• 0.1 PF

+

V

RX

TX

GND

Figure 9-1. Power Supply Noise Reduction With a Bypass Capacitor

24

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

10 Layout

10.1 Layout Guidelines

Mount the TMP144 to a PCB as shown in Figure 10-1. Obtaining acceptable performance with alternate layout

schemes is possible, however this layout produces good results and is intended as a guideline:

•

•

•

•

Bypass the V+ pin to ground with a low-ESR ceramic bypass-capacitor. The typical recommended bypass

capacitance is a 0.1-μF ceramic capacitor with a X5R or X7R dielectric. The optimum placement is closest

to the V+ and GND pins of the device. Take care to minimize the loop area formed by the bypass-capacitor

connection, the V+ pin, and the GND pin of the IC. Alternatively, the bypass capacitor can also be grounded

through a via connected to the GND plane.

Use larger copper area pads to reduce self-heating and lower thermal resistance to the environment.

If possible, use PCB boards with thick copper layers.

If possible, do not use stain to protect the IC because stain can increase thermal resistance.

10.2 Layout Example

VIA to power plane

VIA to ground plane

B2/

RX

B1/

TX

A2/

GND

A1/

V+

0.1µ F

Figure 10-1. Layout Example

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

25

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

11 Device and Documentation Support

11.1 Device Support

11.1.1 Device Nomenclature

daisychain

A method of propagating signals along a bus in which the devices are connected in series and the

signal passed from one device to the next. The daisy-chain scheme permits assignment of device

priorities based on the electrical position of the device on the bus.

11.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.3 Support Resources

TI E2E™ support forums are an engineer's go-to source for fast, verified answers and design help — straight

from the experts. Search existing answers or ask your own question to get the quick design help you need.

Linked content is provided "AS IS" by the respective contributors. They do not constitute TI specifications and do

not necessarily reflect TI's views; see TI's Terms of Use.

11.4 Trademarks

SMAART Wire™ and TI E2E™ are trademarks of Texas Instruments.

All trademarks are the property of their respective owners.

11.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

11.6 Glossary

TI Glossary

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

26

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

PACKAGE OUTLINE

YMT0004

PicoStar TM - 0.15 mm max height

SCALE 20.000

PicoStar

B

E

0.4 TYP

A

2

1

PIN A1

CORNER

A

0.2 TYP

D

SYMM

0.4

TYP

B

0.15 MAX

4X

0.015

0.26

0.20

C A B

SYMM

C

SEATING PLANE

0.018

0.008

4225388/B 08/2020

PicoStar is a trademark of Texas Instruments.

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

www.ti.com

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

27

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

EXAMPLE BOARD LAYOUT

YMT0004

PicoStar TM - 0.15 mm max height

PicoStar

(0.4) TYP

4X (

2

1

0.23)

A

(0.2) TYP

SYMM

B

SYMM

LAND PATTERN EXAMPLE

EXPOSED METAL SHOWN

SCALE:60X

( 0.23)

METAL

SOLDER MASK

OPENING

0.05 MAX

EXPOSED

METAL

0.05 MIN

METAL UNDER

SOLDER MASK

EXPOSED

METAL

( 0.23)

SOLDER MASK

OPENING

NON-SOLDER MASK

DEFINED

(PREFERRED)

SOLDER MASK

DEFINED

SOLDER MASK DETAILS

NOT TO SCALE

4225388/B 08/2020

NOTES: (continued)

3. Final dimensions may vary due to manufacturing tolerance considerations and also routing constraints.

For more information, see Texas Instruments literature number SLUA271 (www.ti.com/lit/slua271).

www.ti.com

28

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

�TMP144

www.ti.com

SBOS891B – OCTOBER 2018 – REVISED APRIL 2021

EXAMPLE STENCIL DESIGN

YMT0004

PicoStar TM - 0.15 mm max height

PicoStar

(0.4) TYP

2

1

4X ( 0.21)

A

(0.2) TYP

SYMM

METAL

TYP

B

(R0.05) TYP

SYMM

SOLDER PASTE EXAMPLE

BASED ON 0.075 mm THICK STENCIL

SCALE:60X

4225388/B 08/2020

NOTES: (continued)

4. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release.

www.ti.com

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TMP144

29

�PACKAGE OPTION ADDENDUM

www.ti.com

22-Apr-2021

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TMP144YFFR

ACTIVE

DSBGA

YFF

4

3000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

C2

TMP144YFFT

ACTIVE

DSBGA

YFF

4

250

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

C2

TMP144YMTR

ACTIVE

PICOSTAR

YMT

4

3000

RoHS & Green

Call TI

Level-1-260C-UNLIM

-40 to 125

TMP144YMTT

ACTIVE

PICOSTAR

YMT

4

250

RoHS & Green

Call TI

Level-1-260C-UNLIM

-40 to 125

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of