Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

TMP468 9-Channel (8-Remote and 1-Local), High-Accuracy Temperature Sensor

1 Features

3 Description

•

The TMP468 device is a multi-zone, high-accuracy,

low-power temperature sensor using a two-wire,

SMBus or I2C compatible interface. Up to eight

remote diode-connected temperature zones can be

monitored simultaneously in addition to the local

temperature.

Aggregating

the

temperature

measurements across a system allows improved

performance through tighter guard bands and can

reduce board complexity. A typical use case is for

monitoring the temperature across different

processors, such as MCUs, GPUs, and FPGAs in

complex

systems

such

as

servers

and

telecommunications equipment. Advanced features

such as series resistance cancellation, programmable

non-ideality factor, programmable offset, and

programmable temperature limits are included to

provide a robust thermal monitoring solution with

improved accuracy and noise immunity.

1

•

•

•

•

•

•

•

•

•

•

8-Channel Remote Diode Temperature Sensor

Accuracy: ±0.75°C (Maximum)

Local and Remote Diode Accuracy: ±0.75°C

(Maximum)

Local Temperature Sensor Accuracy for the

DSBGA Package: ±0.35°C (Maximum)

Temperature Resolution: 0.0625°C

Supply and Logic Voltage Range: 1.7 V to 3.6 V

67-µA Operating Current (1 SPS, All Channels

Active)

0.3-µA Shutdown Current

Remote Diode: Series Resistance Cancellation,

η-Factor Correction, Offset Correction, and Diode

Fault Detection

Register Lock Function Secures Key Registers

I2C or SMBus™ Compatible Two-Wire Interface

With Pin-Programmable Address

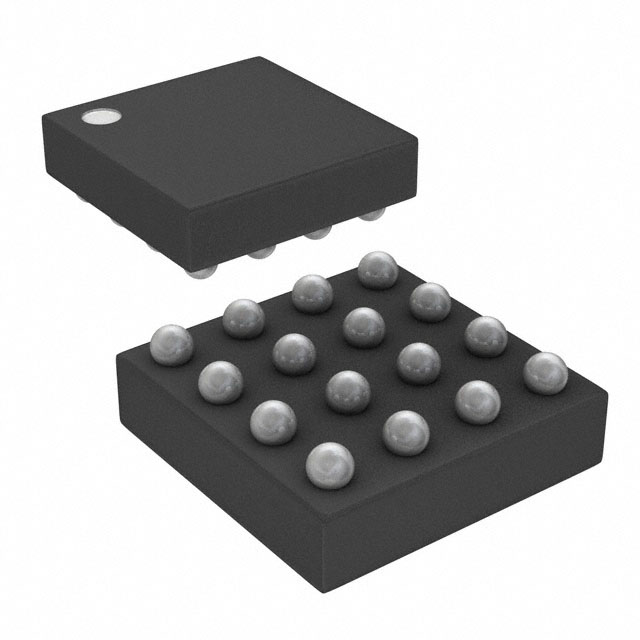

16-Bump DSBGA and 16-Pin VQFN Packages

Each of the eight remote channels (and the local

channel) can be programmed independently with two

thresholds that are triggered when the corresponding

temperature is exceeded at the measured location. In

addition, there is a programmable hysteresis setting

to avoid constant toggling around the threshold.

2 Applications

•

•

•

•

•

•

•

•

MCU, GPU, ASIC, FPGA, DSP, and CPU

Temperature Monitoring

Telecommunication Equipment

Servers and Personal Computers

Cloud Ethernet Switches

Secure Data Centers

Highly Integrated Medical Systems

Precision Instruments and Test Equipment

LED Lighting Thermal Control

The TMP468 device provides high accuracy (0.75°C)

and high resolution (0.0625°C) measurement

capabilities. The device supports low voltage rails

(1.7 V to 3.6 V), common two-wire interfaces, and is

available in a small, space efficient package (3 mm ×

3 mm or 1.6 mm × 1.6 mm) for easy integration into

computing systems. The remote junction supports a

temperature range from –55°C to +150°C.

Device Information(1)

PART NUMBER

TMP468

PACKAGE

BODY SIZE (NOM)

DSBGA (16)

1.60 mm × 1.60 mm

VQFN (16)

3.00 mm × 3.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application Schematic

Remote

Remote

Remote

Zone 4

Zone 3

Zone 2

Remote

1.7 V to 3.6 V

Zone 1

CBYPASS

RS1 RS2

CDIFF

RS1

RS2

CDIFF

RS1

RS2

CDIFF

RS1

RS2

D3

V+

CDIFF

A1

B1

C1

D1

A3

A2

B2

C2

D2

CDIFF

1

CDIFF

CDIFF

CDIFF

RS1 RS2

RS1 RS2

RS1 RS2

RS1 RS2

Remote

Remote

Remote

Remote

Zone 5

Zone 6

Zone 7

Zone 8

RSCL RSDA RT2 RT

2-Wire Interface

SMBus / I2C

Compatible

Controller

D1+ TMP468 SCL D4

D2+

C4

D3+

SDA

D4+

C3

DTHERM2

D5+

B3

D6+

THERM

D7+

Local

ADD B4

D8+

Overtemperature

Shutdown

Zone 9

GND

A4

Copyright © 2016, Texas Instruments Incorporated

See the Design Requirements section for remote diode recommendations.

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

5

6.1

6.2

6.3

6.4

6.5

6.6

6.7

5

5

5

5

6

7

8

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Two-Wire Timing Requirements ...............................

Typical Characteristics ..............................................

Detailed Description ............................................ 10

7.1 Overview ................................................................. 10

7.2 Functional Block Diagram ....................................... 10

7.3 Feature Description................................................. 11

7.4 Device Functional Modes........................................ 13

7.5 Programming........................................................... 13

7.6 Register Maps ......................................................... 19

8

Application and Implementation ........................ 29

8.1 Application Information............................................ 29

8.2 Typical Application .................................................. 30

9 Power Supply Recommendations...................... 33

10 Layout................................................................... 34

10.1 Layout Guidelines ................................................. 34

10.2 Layout Example .................................................... 35

11 Device and Documentation Support ................. 37

11.1

11.2

11.3

11.4

11.5

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

37

37

37

37

37

12 Mechanical, Packaging, and Orderable

Information ........................................................... 37

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (March 2017) to Revision B

•

Page

Updated packaging information ........................................................................................................................................... 37

Changes from Original (November 2016) to Revision A

Page

•

Added 16-pin VQFN package version throughout data sheet................................................................................................ 1

•

Deleted Description (cont.) section and moved text to Description section .......................................................................... 1

•

Added VQFN package and body size information to Device Information table .................................................................... 1

•

Added copyright statement to Typical Application Schematic................................................................................................ 1

•

Added RGT (VQFN) pinout diagram in the Pin Configuration and Functions section .......................................................... 4

•

Added remote junction temperature parameter and values to Recommended Operating Conditions table ......................... 5

•

Changed formatting of Thermal Information table note ......................................................................................................... 5

•

Changed TMP468 Thermal Information table package from "RGT (QFN)" to "RGT (VQFN)" .............................................. 5

•

Updated formatting of Two-Wire Timing Requirements table ............................................................................................... 7

•

Changed Timing Requirements table note parameter from tVD;DATA to tVD;DAT ........................................................................ 7

•

Added 2017 copyright to Functional Block Diagram ........................................................................................................... 10

•

Changed table headers in Continuous Conversion Times table ......................................................................................... 26

•

Added 2017 copyright to Typical Application schematic in Application Information section ................................................ 30

•

Changed η-factor setting from 1.003674 to 1.0067 in Figure 23 table note in Typical Application section ......................... 30

•

Changed conversion rate from 16 conversions/second to 1 conversion/second in the Detailed Design Procedure

section .................................................................................................................................................................................. 32

•

Changed units of Equation 7 from "µs" to "µA" .................................................................................................................... 32

2

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

5 Pin Configuration and Functions

TMP468 YFF Package

16-Pin DSBGA

Bottom View

D4+

(D1)

D8+

(D2)

V+

(D3)

SCL

(D4)

D3+

(C1)

D7+

(C2)

THERM2

(C3)

SDA

(C4)

D2+

(B1)

D6+

(B2)

THERM

(B3)

ADD

(B4)

D1+

(A1)

D5+

(A2)

D(A3)

GND

(A4)

Pin Functions

PIN

I/O

DESCRIPTION

NAME

NO.

ADD

B4

Digital input

Address select. Connect to GND, V+, SDA, or SCL.

D1+

A1

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D2+

B1

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D3+

C1

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D4+

D1

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D5+

A2

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D6+

B2

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D7+

C2

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D8+

D2

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are supported. An

unused channel must be connected to D–.

D–

A3

Analog input

Negative connection to remote temperature sensors. Common for 8 remote channels.

GND

A4

Ground

SCL

D4

Digital input

SDA

C4

THERM

B3

Digital output

Thermal shutdown or fan-control pin.

Active low; open-drain; requires a pullup resistor to a voltage between 1.7 V and 3.6 V, not necessarily

V+. If this pin is not used it may be left open or grounded.

THERM2

C3

Digital output

Second THERM output.

Active low; open-drain; requires a pullup resistor to a voltage between 1.7 V and 3.6 V, not necessarily

V+. If this pin is not used it may be left open or grounded.

V+

D3

Power supply

Positive supply voltage, 1.7 V to 3.6 V; requires 0.1-µF bypass capacitor to ground.

Supply ground connection

Serial clock line for I2C- or SMBus compatible two-wire interface.

Requires a pullup resistor to a voltage between 1.7 V and 3.6 V (not necessarily V+) if driven by an

open-drain output.

Bidirectional digital Serial data line for I2C or SMBus compatible two-wire interface. Open-drain; requires a pullup resistor

input/output

to a voltage between 1.7 V and 3.6 V, not necessarily V+.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

3

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

12

SDA

11

THERM2

10

THERM

D7+

D8+

V+

SCL

15

14

13

9

8

4

GND

D3+

Pad

7

3

D±

D4+

Thermal

6

2

D1+

D5+

5

1

D2+

D6+

16

TMP468 RGT Package

16-Pin VQFN

Top View

ADD

Not to scale

NC - No internal connection

Pin Functions

PIN

NAME

I/O

NO.

DESCRIPTION

ADD

9

Digital input

Address select. Connect to GND, V+, SDA, or SCL.

D1+

6

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D2+

5

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D3+

4

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D4+

3

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D5+

2

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D6+

1

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D7+

16

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D8+

15

Analog input

Positive connection to remote temperature sensors. A total of 8 remote channels are

supported. An unused channel must be connected to D–.

D–

7

Analog input

Negative connection to remote temperature sensors. Common for 8 remote channels.

GND

8

Ground

SCL

13

Digital input

SDA

12

THERM

10

Digital output

Thermal shutdown or fan-control pin.

Active low; open-drain; requires a pullup resistor to a voltage between 1.7 V and 3.6 V, not

necessarily V+. If this pin is not used it may be left open or grounded.

THERM2

11

Digital output

Second THERM output.

Active low; open-drain; requires a pullup resistor to a voltage between 1.7 V and 3.6 V, not

necessarily V+. If this pin is not used it may be left open or grounded.

V+

14

Power supply

Positive supply voltage, 1.7 V to 3.6 V; requires 0.1-µF bypass capacitor to ground.

4

Supply ground connection

Serial clock line for I2C or SMBus-compatible two-wire interface.

Requires a pullup resistor to a voltage between 1.7 V and 3.6 V (not necessarily V+) if driven

by an open-drain output.

Bidirectional digital Serial data line for I2C- or SMBus-compatible two-wire interface. Open-drain; requires a pullup

input/output

resistor to a voltage between 1.7 V and 3.6 V, not necessarily V+.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

Power supply

Input voltage

Input current

MIN

MAX

UNIT

V+

–0.3

6

V

THERM, THERM2, SDA, SCL, and ADD only

–0.3

6

D1+ through D8+

–0.3

((V+) + 0.3)

and ≤ 6

D– only

–0.3

0.3

SDA sink

–25

All other pins

–10

10

–55

150

°C

150

°C

150

°C

Operating temperature

Junction temperature (TJ, maximum)

Storage temperature, Tstg

(1)

–60

V

mA

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged device model (CDM), JEDEC specification JESD22-C101 (2)

±750

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

V+

Supply voltage

1.7

3.6

V

TA

Operating free-air temperature

–40

125

°C

TD

Remote junction temperature

–55

150

°C

6.4 Thermal Information

TMP468

THERMAL METRIC

(1)

RGT (VQFN)

YFF (DSBGA)

16 PINS

16 PINS

UNIT

RθJA

Junction-to-ambient thermal resistance

46

76

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

43

0.7

°C/W

RθJB

Junction-to-board thermal resistance

17

13

°C/W

ψJT

Junction-to-top characterization parameter

0.8

0.4

°C/W

ψJB

Junction-to-board characterization parameter

5

13

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

5

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

6.5 Electrical Characteristics

at TA = –40°C to +125°C and V+ = 1.7 V to 3.6 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

–0.35

±0.125

0.35

°C

–0.75

±0.125

0.75

°C

–1

±0.5

1

°C

–0.75

±0.125

0.75

TEMPERATURE MEASUREMENT

TA = 20°C to 30°C, V+ = 1.7 V to 2 V (DSBGA)

TLOCAL

Local temperature sensor accuracy

TA = –40°C to 125°C, V+ = 1.7 V to 2 V (DSBGA)

TA = –40°C to 100°C, V+ = 1.7 V to 3.6 V (VQFN)

TA = –40°C to 125°C, V+ = 1.7 V to 3.6 V

(DSBGA):

TA = –10°C to 50°C, TD = –55°C to 150°C

V+ = 1.7 V to 3.6 V

TREMOTE

Remote temperature sensor accuracy

(VQFN):

TA = –10°C to 85°C, TD = –55°C to 150°C

V+ = 1.7 V to 3.6 V

°C

TA = –40°C to 125°C, TD = –55°C to 150°C

V+ = 1.7 V to 3.6 V

–1

±0.5

1

Local temperature error supply sensitivity

V+ = 1.7 V to 3.6 V

–0.15

±0.05

0.15

°C/V

Remote temperature error supply sensitivity

V+ = 1.7 V to 3.6 V

–0.25

±0.1

0.25

°C/V

Temperature resolution

(local and remote)

ADC conversion time

0.0625

One-shot mode, per channel (local or remote)

16

ADC resolution

Medium

ms

Bits

120

Series resistance 1 kΩ (maximum)

45

Low

η

17

13

High

Remote sensor

source current

°C

µA

7.5

Remote transistor ideality factor

1.008

SERIAL INTERFACE (SCL, SDA)

VIH

High-level input voltage

VIL

Low-level input voltage

0.7 × (V+)

Hysteresis

200

SDA output-low sink current

VOL

Low-level output voltage

Serial bus input leakage current

V

0.3 × (V+)

20

IO = –20 mA, V+ ≥ 2 V

mA

0.15

IO = –15 mA, V+ < 2 V

0 V ≤ VIN ≤ 3.6 V

–1

Serial bus input capacitance

V

mV

0.4

V

0.2 × V+

V

1

μA

4

pF

DIGITAL INPUTS (ADD)

VIH

High-level input voltage

0.7 × (V+)

VIL

Low-level input voltage

–0.3

0.3 × (V+)

V

–1

1

μA

Input leakage current

0 V ≤ VIN ≤ 3.6 V

Input capacitance

V

4

pF

DIGITAL OUTPUTS (THERM, THERM2)

Output-low sink current

VOL = 0.4 V

VOL

Low-level output voltage

IO = –6 mA

IOH

High-level output leakage current

VO = V+

6

mA

0.15

0.4

V

1

μA

3.6

V

POWER SUPPLY

V+

IQ

Specified supply voltage range

Quiescent current

POR

Power-on-reset threshold

POH

Power-on-reset hysteresis

6

1.7

Active conversion, local sensor

240

375

Active conversion, remote sensors

400

600

15

21

Shutdown mode, serial bus inactive

0.3

4

Shutdown mode, serial bus active, fS = 400 kHz

120

Shutdown mode, serial bus active, fS = 2.56 MHz

300

Rising edge

1.5

1.65

1.2

1.35

Standby mode (between conversions)

Falling edge

1

0.2

Submit Documentation Feedback

µA

µA

µA

V

V

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

6.6 Two-Wire Timing Requirements

at TA = –40°C to +125°C and V+ = 1.7 V to 3.6 V (unless otherwise noted)

The master and the slave have the same V+ value. Values are based on statistical analysis of samples tested during initial

release.

MIN

MAX

UNIT

Fast mode

0.001

0.4

High-speed mode

0.001

2.56

Bus free time between stop and start

condition

Fast mode

1300

High-speed mode

160

tHD;STA

Hold time after repeated start condition.

After this period, the first clock is generated.

Fast mode

600

High-speed mode

160

tSU;STA

Repeated start condition setup time

Fast mode

600

High-speed mode

160

tSU;STO

Stop condition setup time

Fast mode

600

High-speed mode

160

tHD;DAT

Data hold time when SDA

tVD;DAT

Data valid time (2)

tSU;DAT

Data setup time

tLOW

SCL clock low period

tHIGH

SCL clock high period

tF – SDA

Data fall time

tF, tR – SCL

Clock fall and rise time

tR

Rise time for SCL ≤ 100 kHz

fSCL

SCL operating frequency

tBUF

ns

ns

ns

0

High-speed mode

0

130

0

900

—

—

High-speed mode

Fast mode

(1)

100

High-speed mode

1300

High-speed mode

250

Fast mode

600

High-speed mode

Fast mode

ns

ns

ns

20

Fast mode

ns

ns

60

20 × (V+ / 5.5)

300

High-speed mode

100

Fast mode

300

High-speed mode

40

Fast mode

1000

High-speed mode

Serial bus timeout

(1)

(2)

ns

Fast mode

Fast mode

MHz

Fast mode

15

20

High-speed mode

15

20

ns

ns

ns

ms

The maximum tHD;DAT can be 0.9 µs for fast mode, and is less than the maximum tVD;DAT by a transition time.

tVD;DAT = time for data signal from SCL LOW to SDA output (HIGH to LOW, depending on which is worse).

tr

t(LOW)

tf

VIH

SCL

VIL

t(BUF)

t(SU:STA)

t(HIGH)

t(HD:STA)

t(SU:STO)

t(SU:DAT)

t(HD:DAT)

VIH

SDA

VIL

P

S

S

P

Figure 1. Two-Wire Timing Diagram

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

7

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

6.7 Typical Characteristics

at TA = 25°C and V+ = 3.6 V (unless otherwise noted)

1.5

1.5

Max Limit

Max Limit

Local Temperature Error (qC)

1

Local Temperature Error (qC)

Average + 3V

0.5

Typical Units

0

-0.5

-1

Average - 3V

Min Limit

-1.5

-40

-20

0

20

40

60

80

Ambient Temperature (qC)

100

-0.5

-1

Average - 3V

-20

0

20

40

60

80

Ambient Temperature (qC)

100

120

Typical behavior of 75 VQFN devices over temperature at V+ =

1.8 V

Figure 3. Local Temperature Error vs Ambient Temperature

1.5

Average + 3V

Max Limit

Remote Temperature Error (qC)

Max Limit

Remote Temperature Error (°C)

Typical Units

D001

1.5

1

0.5

Typical Units

0

-0.5

-1

Min Limit

-25

0

25

50

75

Device Junction Temperature (°C)

100

0.5

Typical Units

0

-0.5

-1

Min Limit

-1.5

-50

125

D003

Average + 3V

1

Average - 3V

Typical behavior of 30 DSBGA devices over temperature at V+ =

1.8 V with the remote diode junction at 150°C.

-25

Average - 3V

0

25

50

75

Device Junction Temperature (qC)

100

125

Typical behavior of 75 VQFN devices over temperature at V+ =

1.8 V with the remote diode junction at 150°C.

Figure 5. Remote Temperature Error vs Device Junction

Temperature

Figure 4. Remote Temperature Error vs Device Junction

Temperature

1

40

0.8

0.6

Max Limit

Average + 3V

0.4

0.2

0

Typical Units

-0.2

-0.4

Min Limit

-0.6

Average - 3V

-0.8

Remote Temperature Error (qC)

Remote Error Power Supply Sensitivity (°C/V)

0

-1.5

-40

120

Figure 2. Local Temperature Error vs Ambient Temperature

-1

-40

0.5

Min Limit

Typical behavior of 95 DSBGA devices over temperature at V+ =

1.8 V

-1.5

-50

Average + 3V

1

D+ to V+

D+ to GND

30

20

10

0

-10

-20

-30

-40

-20

40

60

80

0

20

Device Junction Temperature (°C)

100

120

1

10

Leakage Resistance (M:)

100

Typical behavior of 30 devices over temperature with V+ from 1.8

V to 3.6 V

Figure 6. Remote Temperature Error Power Supply

Sensitivity vs Device Junction Temperature

8

Figure 7. Remote Temperature Error vs Leakage Resistance

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

Typical Characteristics (continued)

at TA = 25°C and V+ = 3.6 V (unless otherwise noted)

0.5

0

Remote Temperature Error (qC)

Remote Temperature Error (qC)

V+ = 1.8 V

V+ = 3.6 V

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

-0.4

-0.5

-5

-10

-15

-20

-25

-30

-35

-40

0

500

1000 1500 2000 2500 3000 3500 4000 4500

Series Resistance (:)

No physical capacitance during measurement

0

4

6

8

10

12

14

Differential Capacitance (nF)

16

18

20

No physical series resistance on D+, D– pins during measurement

Figure 8. Remote Temperature Error vs Series Resistance

Figure 9. Remote Temperature Error vs

Differential Capacitance

400

360

2

800

V+ = 1.8 V

V+ = 3.6 V

700

V+ = 1.8 V

V+ = 3.6 V

600

280

V+ Current (PA)

Supply Current (PA)

320

240

200

160

120

500

400

300

200

80

100

40

0

0.05 0.1

1

10

Conversion Rate (Hz)

0

1k

100

10k

100k

Frequency (Hz)

1M

10M

16 samples per second (default mode)

Figure 10. Quiescent Current vs Conversion Rate °

1

390

0.9

Shutdown Supply Current (PA)

400

380

V+ Current (PA)

Figure 11. Shutdown Quiescent Current

vs SCL Clock Frequency

370

360

350

340

330

320

310

300

1.5

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

2

2.5

3

V+ Voltage (V)

3.5

4

Figure 12. Quiescent Current vs Supply Voltage

(at Default Conversion Rate of 16 Conversions Per Second)

0

1.5

2

2.5

3

V+ Voltage (V)

3.5

4

Figure 13. Shutdown Quiescent Current vs Supply Voltage

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

9

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

7 Detailed Description

7.1 Overview

The TMP468 device is a digital temperature sensor that combines a local temperature measurement channel

and eight remote-junction temperature measurement channels in VQFN-16 or DSBGA-16 packages. The device

has a two-wire-interface that is compatible with I2C or SMBus interfaces and includes four pin-programmable bus

address options. The TMP468 is specified over a local device temperature range from –40°C to +125°C. The

TMP468 device also contains multiple registers for programming and holding configuration settings, temperature

limits, and temperature measurement results. The TMP468 pinout includes THERM and THERM2 outputs that

signal overtemperature events based on the settings of temperature limit registers.

7.2 Functional Block Diagram

V+

ADD

SCL

Serial

Interface

SDA

Register

Bank

THERM

Oscillator

Local

Thermal

BJT

Control

Logic

16 × I

D1+

D2+

6×I

MUX

D3+

D4+

V+

I

THERM2

Voltage

Reference

MUX

D5+

D6+

ADC

D7+

D8+

D-

GND

10

Copyright © 2017, Texas Instruments Incorporated

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

7.3 Feature Description

7.3.1 Temperature Measurement Data

The local and remote temperature sensors have a resolution of 13 bits (0.0625°C). Temperature data that result

from conversions within the default measurement range are represented in binary form, as shown in the

Standard Binary column of Table 1. Negative numbers are represented in two's-complement format. The

resolution of the temperature registers extends to 255.9375°C and down to –256°C, but the actual device is

limited to ranges as specified in the Electrical Characteristics table to meet the accuracy specifications. The

TMP468 device is specified for ambient temperatures ranging from –40°C to +125°C; parameters in the Absolute

Maximum Ratings table must be observed to prevent damage to the device.

Table 1. Temperature Data Format (Local and Remote Temperature)

TEMPERATURE

(°C)

(1)

LOCAL OR REMOTE TEMPERATURE REGISTER VALUE

(0.0625°C RESOLUTION)

STANDARD BINARY (1)

BINARY

HEX

–64

1110 0000 0000 0000

E0 00

–50

1110 0111 0000 0000

E7 00

–25

1111 0011 1000 0000

F3 80

–0.1250

1111 1111 1111 0000

FF F0

–0.0625

1111 1111 1111 1000

FF F8

0

0000 0000 0000 0000

00 00

0.0625

0000 0000 0000 1000

00 08

0.1250

0000 0000 0001 0000

00 10

0.1875

0000 0000 0001 1000

00 18

0.2500

0000 0000 0010 0000

00 20

0.3125

0000 0000 0010 1000

00 28

0.3750

0000 0000 0011 0000

00 30

0.4375

0000 0000 0011 1000

00 38

0.5000

0000 0000 0100 0000

00 40

0.5625

0000 0000 0100 1000

00 48

0.6250

0000 0000 0101 0000

00 50

0.6875

0000 0000 0101 1000

00 58

0.7500

0000 0000 0110 0000

00 60

0.8125

0000 0000 0110 1000

00 68

0.8750

0000 0000 0111 0000

00 70

0.9375

0000 0000 0111 1000

00 78

1

0000 0000 1000 0000

00 80

5

0000 0010 1000 0000

02 80

10

0000 0101 0000 0000

05 00

25

0000 1100 1000 0000

0C 80

50

0001 1001 0000 0000

19 00

75

0010 0101 1000 0000

25 80

100

0011 0010 0000 0000

32 00

125

0011 1110 1000 0000

3E 80

127

0011 1111 1000 0000

3F 80

150

0100 1011 0000 0000

4B 00

175

0101 0111 1000 0000

57 80

191

0101 1111 1000 0000

5F 80

Resolution is 0.0625°C per count. Negative numbers are represented in two's-complement format.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

11

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

Both local and remote temperature data use two bytes for data storage with a two's-complement format for

negative numbers. The high byte stores the temperature with 2°C resolution. The second or low byte stores the

decimal fraction value of the temperature and allows a higher measurement resolution, as shown in Table 1. The

measurement resolution for both the local and the remote channels is 0.0625°C.

7.3.2 Series Resistance Cancellation

Series resistance cancellation automatically eliminates the temperature error caused by the resistance of the

routing to the remote transistor or by the resistors of the optional external low-pass filter. A total up to 1-kΩ series

resistance can be cancelled by the TMP468 device, which eliminates the need for additional characterization and

temperature offset correction. See Figure 8 for details on the effects of series resistance on sensed remote

temperature error.

7.3.3 Differential Input Capacitance

The TMP468 device tolerates differential input capacitance of up to 1000 pF with minimal change in temperature

error. The effect of capacitance on the sensed remote temperature error is illustrated in Figure 9.

7.3.4 Sensor Fault

The TMP468 device can sense a fault at the D+ resulting from an incorrect diode connection. The TMP468

device can also sense an open circuit. Short-circuit conditions return a value of –256°C. The detection circuitry

consists of a voltage comparator that trips when the voltage at D+ exceeds (V+) – 0.3 V (typical). The

comparator output is continuously checked during a conversion. If a fault is detected, then the RxOP bit in the

Remote Channel Status register is set to 1.

When not using the remote sensor with the TMP468 device, the corresponding D+ and D– inputs must be

connected together to prevent meaningless fault warnings.

7.3.5

THERM Functions

Operation of the THERM (pin B3) and THERM2 (pin C3) interrupt pins are shown in Figure 14.

The hysteresis value is stored in the THERM Hysteresis register and applies to both the THERM and THERM2

interrupts.

Temperature Conversion Complete

150

140

130

Temperature (°C)

120

110

THERM Limit

100

THERM Limit - Hysteresis

90

THERM2 Limit

80

THERM2 Limit - Hysteresis

70

Measured

Temperature

60

50

Time

THERM2

THERM

Figure 14. THERM and THERM2 Interrupt Operation

12

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

7.4 Device Functional Modes

7.4.1 Shutdown Mode (SD)

The TMP468 shutdown mode enables the user to save maximum power by shutting down all device circuitry

other than the serial interface, and reducing current consumption to typically less than 0.3 μA; see Figure 13.

Shutdown mode is enabled when the shutdown bit (SD, bit 5) of the Configuration Register is HIGH; the device

shuts down immediately once the current conversion is complete. When the SD bit is LOW, the device maintains

a continuous-conversion state.

7.5 Programming

7.5.1 Serial Interface

The TMP468 device operates only as a slave device on the two-wire bus (I2C or SMBus). Connections to either

bus are made using the open-drain I/O lines, SDA, and SCL. The SDA and SCL pins feature integrated spike

suppression filters and Schmitt triggers to minimize the effects of input spikes and bus noise. The TMP468

device supports the transmission protocol for fast (1 kHz to 400 kHz) and high-speed (1 kHz to 2.56 MHz)

modes. All data bytes are transmitted MSB first.

While the TMP468 device is unpowered bus traffic on SDA and SCL may continue without any adverse effects to

the communication or to the TMP468 device itself. As the TMP468 device is powering up, the device does not

load the bus, and as a result the bus traffic may continue undisturbed.

7.5.1.1 Bus Overview

The TMP468 device is compatible with the I2C or SMBus interface. In I2C or SMBus protocol, the device that

initiates the transfer is called a master, and the devices controlled by the master are slaves. The bus must be

controlled by a master device that generates the serial clock (SCL), controls the bus access, and generates the

start and stop conditions.

To address a specific device, a start condition is initiated. A start condition is indicated by pulling the data line

(SDA) from a high-to-low logic level when SCL is high. All slaves on the bus shift in the slave address byte, with

the last bit indicating whether a read or write operation is intended. During the ninth clock pulse, the addressed

slave responds to the master by generating an acknowledge (ACK) bit and pulling SDA low.

Data transfer is then initiated and sent over eight clock pulses followed by an acknowledge bit (ACK). During

data transfer, SDA must remain stable when SCL is high. A change in SDA when SCL is high is interpreted as a

control signal. The TMP468 device has a word register structure (16-bit wide), with data writes always requiring

two bytes. Data transfer occurs during the ACK at the end of the second byte.

After all data are transferred, the master generates a stop condition. A stop condition is indicated by pulling SDA

from low to high when SCL is high.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

13

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

Programming (continued)

7.5.1.2 Bus Definitions

The TMP468 device has a two-wire interface that is compatible with the I2C or SMBus interface. Figure 15

through Figure 20 illustrate the timing for various operations on the TMP468 device. The bus definitions are as

follows:

Bus Idle:

Both SDA and SCL lines remain high.

Start Data Transfer: A change in the state of the SDA line (from high to low) when the SCL line is high defines

a start condition. Each data transfer initiates with a start condition.

Stop Data Transfer: A change in the state of the SDA line (from low to high) when the SCL line is high defines

a stop condition. Each data transfer terminates with a repeated start or stop condition.

Data Transfer: The number of data bytes transferred between a start and stop condition is not limited and is

determined by the master device. The receiver acknowledges the data transfer.

Acknowledge: Each receiving device, when addressed, is obliged to generate an acknowledge bit. A device

that acknowledges must pull down the SDA line during the acknowledge clock pulse in such a way

that the SDA line is stable low during the high period of the acknowledge clock pulse. Take setup

and hold times into account. On a master receive, data transfer termination can be signaled by the

master generating a not-acknowledge on the last byte that is transmitted by the slave.

1

1

9

9

SCL

SDA

1

Start by

Master

0

0

1

0

A1 A0 R/W

P7 P6 P5 P4 P3 P2 P1 P0

ACK

ACK Stop

by

by

by

Frame 2

Device

Device Master

Pointer Byte

from Master

Frame 1

Serial Bus Address

Byte from Master

Figure 15. Two-Wire Timing Diagram for Write Pointer Byte

1

9

1

9

SCL

SDA

1

0

0

1

0

A1

A0

R/W

Frame 1

Serial Bus Address Byte

from Master

SCL

(continued)

SDA

(continued)

1

P7

9

D15 D14 D13 D12 D11 D10

D9

Frame 3

Word MSB from Master

P6

P5

ACK

by

Device

Start by

Master

D8

P3

P2

P1

P0

ACK

by

Device

Frame 2

Pointer Byte from Master

1

D7

ACK

by

Device

P4

9

D6

D5

D4

D3

D2

D1

Frame 4

Word LSB from Master

D0

ACK

by

Device

Stop

by

Master

Figure 16. Two-Wire Timing Diagram for Write Pointer Byte and Value Word

14

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

Programming (continued)

1

9

1

9

SCL

SDA

1

Start by

Master

(1)

0

A1 A0 R/W

0

1

Frame 1

Serial Bus Address

Byte from Master

P7 P6 P5 P4 P3 P2 P1 P0

ACK

ACK

by

by

Frame 2

Device

Device

Pointer Byte

from Master

1

SCL

(continued)

SDA

(continued)

0

1

Repeat

Start by

Master

9

0

0

0

1

1

9

D15 D14 D13 D12 D11 D10 D9 D8

NACK Stop

ACK

by

by

by

Frame 4

Master Master

Device

Data Byte 1 from

Device

A1 A0 R/W

Frame 3

Serial Bus Address

Byte from Master

The master must leave SDA high to terminate a single-byte read operation.

Figure 17. Two-Wire Timing Diagram for Pointer Set Followed by a Repeat Start and Single-Byte Read

Format

1

9

1

9

SCL

SDA

SCL

(continued)

SDA

(continued)

1

Start by

Master

0

0

1

0

A1 A0 R/W

Frame 1

Serial Bus Address

Byte from Master

P7 P6 P5 P4 P3 P2 P1 P0

ACK

ACK

by

by

Frame 2

Device

Device

Pointer Byte

from Master

1

1

Repeat

Start by

Master

9

0

0

1

0

1

9

1

9

D15 D14 D13 D12 D11 D10 D9 D8

D7 D6 D5 D4 D3 D2 D1 D0

NACK Stop

ACK

ACK

by

by

by

by

Frame 4

Frame 5

Master Master

Device

Master

Data Byte 1 from

Data Byte 2 from

Device

Device

A1 A0 R/W

Frame 3

Serial Bus Address

Byte from Master

Figure 18. Two-Wire Timing Diagram for Pointer Byte Set Followed by a Repeat Start and Word (TwoByte) Read

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

15

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

Programming (continued)

1

9

1

9

SCL

SDA

1

Start by

Master

SCL

(continued)

SDA

(continued)

0

1

0

A1 A0 R/W

1

Repeat

Start by

Master

80h Block

ReadP4

AutoP3

Increment

Pointer

P7

P6 P5

P2 P1

P0

ACK

by

Device

Frame 1

Serial Bus Address

Byte from Master

1

SCL

(continued)

SDA

(continued)

0

9

0

0

1

0

ACK

by

Device

Frame 2

Pointer Byte from

Master

1

9

1

9

D15 D14 D13 D12 D11 D10 D9 D8

D7 D6 D5 D4 D3 D2 D1 D0

ACK

ACK

ACK

by

by

by

Frame 4

Frame 5

Device

Master

Master

Word 1 MSB from

Word 1 LSB from

Device

Device

A1 A0 R/W

Frame 3

Serial Bus Address

Byte from Master

1

9

1

9

D15 D14 D13 D12 D11 D10 D9 D8

Frame (2N + 2)

Word N MSB from

Device

D7 D6 D5 D4 D3 D2 D1 D0

ACK

NACK Stop

by

by

by

Frame (2N + 3)

Master

Master Master

Word N LSB from

Device

Figure 19. Two-Wire Timing Diagram for Pointer Byte Set Followed by a Repeat Start and Multiple-Word

(N-Word) Read

1

9

1

9

1

9

SCL

1

SDA

Start by

Master

SCL

(continued)

SDA

(continued)

0

0

1

0

D15 D14 D13 D12 D11 D10 D9 D8

D7 D6 D5 D4 D3 D2 D1 D0

ACK

ACK

ACK

by

by

by

Frame 4

Frame 5

Device

Master

Master

Word 1 MSB from

Word 1 LSB from

Device

Device

A1 A0 R/W

Frame 3

Serial Bus Address

Byte from Master

1

9

1

9

D15 D14 D13 D12 D11 D10 D9 D8

Frame (2N + 2)

Word N MSB from

Device

D7 D6 D5 D4 D3 D2 D1 D0

ACK

NACK Stop

by

by

by

Frame (2N + 3)

Master

Master Master

Word N LSB from

Device

Figure 20. Two-Wire Timing Diagram for Multiple-Word (N-Word) Read Without a Pointer Byte Set

16

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

Programming (continued)

7.5.1.3 Serial Bus Address

To communicate with the TMP468 device, the master must first address slave devices using a slave address

byte. The slave address byte consists of seven address bits and a direction bit indicating the intent of executing a

read or write operation. The TMP468 device allows up to four devices to be addressed on a single bus. The

assigned device address depends on the ADD pin connection as described in Table 2.

Table 2. TMP468 Slave Address Options

ADD PIN CONNECTION

SLAVE ADDRESS

BINARY

HEX

GND

1001000

48

V+

1001001

49

SDA

1001010

4A

SCL

1001011

4B

7.5.1.4 Read and Write Operations

Accessing a particular register on the TMP468 device is accomplished by writing the appropriate value to the

pointer register. The value for the pointer register is the first byte transferred after the slave address byte with the

R/W bit low. Every write operation to the TMP468 device requires a value for the pointer register (see Figure 16).

The TMP468 registers can be accessed with block or single register reads. Block reads are only supported for

pointer values 80h to 88h. Registers at 80h through 88h mirror the Remote and Local Temperature registers (00h

to 08h). Pointer values 00h to 08h are for single register reads.

7.5.1.4.1 Single Register Reads

When reading from the TMP468 device, the last value stored in the pointer register by a write operation is used

to determine which register is read by a read operation. To change which register is read for a read operation, a

new value must be written to the pointer register. This transaction is accomplished by issuing a slave address

byte with the R/W bit low, followed by the pointer register byte; no additional data are required. The master can

then generate a start condition and send the slave address byte with the R/W bit high to initiate the read

command; see Figure 17 through Figure 19 for details of this sequence.

If repeated reads from the same register are desired, continually sending the pointer register bytes is not

necessary because the TMP468 device retains the pointer register value until the value is changed by the next

write operation. The register bytes are sent by the MSB first, followed by the LSB. If only one byte is read (MSB),

a consecutive read of TMP468 device results in the MSB being transmitted first. The LSB can only be accessed

through two-byte reads.

The master terminates a read operation by issuing a not-acknowledge (NACK) command at the end of the last

byte to be read or transmitting a stop condition. For a single-byte operation, the master must leave the SDA line

high during the acknowledge time of the first byte that is read from the slave.

The TMP468 register structure has a word (two-byte) length, so every write transaction must have an even

number of bytes (MSB and LSB) following the pointer register value (see Figure 16). Data transfers occur during

the ACK at the end of the second byte or LSB. If the transaction does not finish, signaled by the ACK at the end

of the second byte, then the data is ignored and not loaded into the TMP468 register. Read transactions do not

have the same restrictions and may be terminated at the end of the last MSB.

7.5.1.4.2 Block Register Reads

The TMP468 supports block mode reads at address 80h through 88h for temperature results alone. Setting the

pointer register to 80h signals to the TMP468 device that a block of more than two bytes must be transmitted

before a stop is issued. In this mode, the TMP468 device auto increments the internal pointer. After the 18 bytes

of temperature data are transmitted, the internal pointer resets to 80h. If the transmission is terminated before

register 88h is read, the pointer increments so a consecutive read (without a pointer set) can access the next

register.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

17

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

7.5.1.5 Timeout Function

The TMP468 device resets the serial interface if either SCL or SDA are held low for 17.5 ms (typical) between a

start and stop condition. If the TMP468 device is holding the bus low, the device releases the bus and waits for a

start condition. To avoid activating the timeout function, maintain a communication speed of at least 1 kHz for the

SCL operating frequency.

7.5.1.6 High-Speed Mode

For the two-wire bus to operate at frequencies above 1 MHz, the master device must issue a high-speed mode

(HS-mode) master code (0000 1xxx) as the first byte after a start condition to switch the bus to high-speed

operation. The TMP468 device does not acknowledge the master code byte, but switches the input filters on

SDA and SCL and the output filter on SDA to operate in HS-mode, allowing transfers up to 2.56 MHz. After the

HS-mode master code is issued, the master transmits a two-wire slave address to initiate a data transfer

operation. The bus continues to operate in HS-mode until a stop condition occurs on the bus. Upon receiving the

stop condition, the TMP468 device switches the input and output filters back to fast mode.

7.5.2 TMP468 Register Reset

The TMP468 registers can be software reset by setting bit 15 of the Software Reset register (20h) to 1. This

software reset restores the power-on-reset state to all TMP468 registers and aborts any conversion in progress.

7.5.3 Lock Register

All of the configuration and limit registers may be locked for writes (making the registers write-protected), which

decreases the chance of software runaway from issuing false changes to these registers. The Lock column in

Table 3 identifies which registers may be locked. Lock mode does not effect read operations. To activate the lock

mode, Lock Register C4h must be set to 0x5CA6. The lock only remains active while the TMP468 device is

powered up. Because the TMP468 device does not contain nonvolatile memory, the settings of the configuration

and limit registers are lost once a power cycle occurs regardless if the registers are locked or unlocked.

In lock mode, the TMP468 device ignores a write operation to configuration and limit registers except for Lock

Register C4h. The TMP468 device does not acknowledge the data bytes during a write operation to a locked

register. To unlock the TMP468 registers, write 0xEB19 to register C4h. The TMP468 device powers up in locked

mode, so the registers must be unlocked before the registers accept writes of new data.

18

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

7.6 Register Maps

Table 3. TMP468 Register Map

PTR

POR

LOCK

(HEX)

(HEX)

(Y/N)

TMP468 FUNCTIONAL REGISTER - BIT DESCRIPTION

00

0000

N/A

LT12

LT11

LT10

LT9

LT8

LT7

LT6

LT5

LT4

LT3

LT2

01

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

02

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

03

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

04

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

05

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

06

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

07

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

08

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

20

0000

N/A

RST

0

0

0

0

0

21

N/A

N/A

R8TH

R7TH

R6TH

R5TH

R4TH

R3TH

R2TH

22

N/A

N/A

R8TH2

R7TH2

R6TH2

R5TH2

R4TH2

R3TH2

R2TH2

23

N/A

N/A

R8OPN

R7OPN

R6OPN

R5OPN

R4OPN

R3OPN

R2OPN

R1OPN

REGISTER DESCRIPTION

30

15

REN8

14

REN7

13

REN6

12

REN5

11

REN4

10

REN3

9

3

2

1

0

LT1

LT0

0 (1)

0

0

Local Temperature

RT1

RT0

0

0

0

Remote Temperature 1

RT1

RT0

0

0

0

Remote Temperature 2

RT1

RT0

0

0

0

Remote Temperature 3

RT2

RT1

RT0

0

0

0

Remote Temperature 4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 8

0

0

0

0

0

0

0

0

0

0

Software Reset Register

R1TH

LTH

0

0

0

0

0

0

0

THERM Status

R1TH2

LTH2

0

0

0

0

0

0

0

THERM2 Status

0

0

0

0

0

0

0

0

Remote Channel OPEN Status

Configuration Register (Enables,

OneShot, ShutDown, ConvRate,

BUSY)

REN2

8

REN1

7

LEN

6

5

0F9C

Y

38

0080

Y

0

HYS11

HYS10

HYS9

HYS8

HYS7

HYS6

HYS5

39

7FC0

Y

LTH1_12

LTH1_11

LTH1_10

LTH1_09

LTH1_08

LTH1_07

LTH1_06

LTH1_05

3A

7FC0

Y

LTH2_12

LTH2_11

LTH2_10

LTH2_09

LTH2_08

LTH2_07

LTH2_06

LTH2_05

LTH2_04

LTH2_03

0

40

0000

Y

ROS12

ROS12 (2)

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

4

OS

SD

CR2

CR1

CR0

BUSY

0

HYS4

0

0

0

0

0

0

0

THERM Hysteresis

LTH1_04

LTH1_03

0

0

0

0

0

0

Local Temperature THERM Limit

0

0

0

0

0

Local Temperature THERM2 Limit

ROS1

ROS0

0

0

0

Remote Temperature 1 Offset

Remote Temperature 1 η-Factor

Correction

41

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

42

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 1 THERM Limit

43

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 1 THERM2 Limit

48

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote Temperature 2 Offset

Remote Temperature 2 η-Factor

Correction

49

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

4A

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 2 THERM Limit

4B

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 2 THERM2 Limit

50

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote Temperature 3 Offset

Remote Temperature 3 η-Factor

Correction

51

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

52

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 3 THERM Limit

53

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 3 THERM2 limit

58

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote temperature 4 Offset

0

Remote Temperature 4 η-Factor

Correction

59

(1)

(2)

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

Register bits highlighted in purple are reserved for future use and always report 0; writes to these bits are ignored.

Register bits highlighted in green show sign extended values.

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

19

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

Register Maps (continued)

Table 3. TMP468 Register Map (continued)

PTR

POR

LOCK

(HEX)

(HEX)

(Y/N)

15

14

13

12

11

TMP468 FUNCTIONAL REGISTER - BIT DESCRIPTION

10

9

8

7

6

5

4

3

2

1

0

5A

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 4 THERM Limit

5B

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 4 THERM2 Limit

60

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote Temperature 5 Offset

Remote Temperature 5 η-Factor

Correction

REGISTER DESCRIPTION

20

61

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

62

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 5 THERM Limit

63

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 5 THERM2 Limit

68

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote Temperature 6 Offset

Remote Temperature 6 η-Factor

Correction

69

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

6A

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 6 THERM Limit

6B

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 6 THERM2 Limit

70

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote Temperature 7 Offset

71

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

Remote Temperature 7 η-Factor

Correction

72

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 7 THERM Limit

73

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 7 THERM2 Limit

78

0000

Y

ROS12

ROS12

ROS10

ROS9

ROS8

ROS7

ROS6

ROS5

ROS4

ROS3

ROS2

ROS1

ROS0

0

0

0

Remote Temperature 8 Offset

79

0000

Y

RNC7

RNC6

RNC5

RNC4

RNC3

RNC2

RNC1

RNC0

0

0

0

0

0

0

0

0

Remote Temperature 8 η-Factor

Correction

7A

7FC0

Y

RTH1_12

RTH1_11

RTH1_10

RTH1_09

RTH1_08

RTH1_07

RTH1_06

RTH1_05

RTH1_04

RTH1_03

0

0

0

0

0

0

Remote Temperature 8 THERM Limit

7B

7FC0

Y

RTH2_12

RTH2_11

RTH2_10

RTH2_09

RTH2_08

RTH2_07

RTH2_06

RTH2_05

RTH2_04

RTH2_03

0

0

0

0

0

0

Remote Temperature 8 THERM2 Limit

80

0000

N/A

LT12

LT11

LT10

LT9

LT8

LT7

LT6

LT5

LT4

LT3

LT2

LT1

LT0

0

0

0

Local Temperature (Block Read

Range - Auto Increment Pointer

Register)

81

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 1 (Block Read

Range - Auto Increment Pointer

Register)

82

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 2 (Block Read

Range - Auto Increment Pointer

Register)

83

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 3 (Block Read

Range - Auto Increment Pointer

Register)

84

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 4 (Block Read

Range - Auto Increment Pointer

Register)

85

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 5 (Block Read

Range - Auto Increment Pointer

Register)

86

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 6 (Block Read

Range - Auto Increment Pointer

Register)

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

�TMP468

www.ti.com

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

Register Maps (continued)

Table 3. TMP468 Register Map (continued)

PTR

POR

LOCK

(HEX)

(HEX)

(Y/N)

15

14

13

12

11

TMP468 FUNCTIONAL REGISTER - BIT DESCRIPTION

10

9

8

7

6

5

4

3

2

1

0

87

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 7 (Block Read

Range - Auto Increment Pointer

Register)

88

0000

N/A

RT12

RT11

RT10

RT9

RT8

RT7

RT6

RT5

RT4

RT3

RT2

RT1

RT0

0

0

0

Remote Temperature 8 (Block Read

Range - Auto Increment Pointer

Register)

C4

8000

N/A

REGISTER DESCRIPTION

Write 0x5CA6 to lock registers and 0xEB19 to unlock registers

Lock Register. This locks the registers

after initialization.

Read back: locked 0x8000; unlocked 0x0000

FE

5449

N/A

0

1

0

1

0

1

0

0

0

1

0

0

1

0

0

1

Manufacturers Identification Register

FF

0468

N/A

0

0

0

0

0

1

0

0

0

1

1

0

1

0

0

0

Device Identification/Revision Register

Submit Documentation Feedback

Copyright © 2016–2017, Texas Instruments Incorporated

Product Folder Links: TMP468

21

�TMP468

SBOS762B – NOVEMBER 2016 – REVISED JUNE 2017

www.ti.com

7.6.1 Register Information

The TMP468 device contains multiple registers for holding configuration information, temperature measurement

results, and status information. These registers are described in Figure 21 and Table 3.

7.6.1.1 Pointer Register

shows the internal register structure of the TMP468 device. The 8-bit pointer register addresses a given data

register. The pointer register identifies which of the data registers must respond to a read or write command on

the two-wire bus. This register is set with every write command. A write command must be issued to set the

proper value in the pointer register before executing a read command. Table 3 describes the pointer register and

the internal structure of the TMP468 registers. The power-on-reset (POR) value of the pointer register is 00h

(0000 0000b). Table 3 lists a summary of the pointer values for the different registers. Writing data to unassigned

pointer values are ignored and does not affect the operation of the device. Reading an unassigned register

returns undefined data and is ACKed.

Pointer Register

SDA

SCL

Serial

Interface

Local Temp

2

Remote Temp 1

2

Remote Temp 2

2

Remote Temp 3

2

Remote Temp 4

2

Remote Temp 5

2

Remote Temp 6

2

Remote Temp 7

2

Remote Temp 8

2

THERM Status

THERM2 Status

Remote Open Status

Manufacturer ID

Device ID

Local THERM Limit

Local THERM2 Limit

Remote 5 Offset

Remote 5 K -factor

Remote 5 THERM

Remote 5 THERM2

Remote 1 Offset

Remote 1 K -factor

Remote 1 THERM

Remote 1 THERM2

Remote 6 Offset

Remote 6 K -factor

Remote 6 THERM

Remote 6 THERM2

Remote 2 Offset

Remote 2 K -factor

Remote 2 THERM

Remote 2 THERM2

Remote 7 Offset

Remote 7 K -factor