www.ti.com

Table of Contents

User’s Guide

TPS54291 Step-Down Converter Evaluation Module User's

Guide

Table of Contents

1 Introduction.............................................................................................................................................................................2

1.1 Description......................................................................................................................................................................... 2

1.2 Applications........................................................................................................................................................................2

1.3 Features............................................................................................................................................................................. 2

2 TPS54291EVM-431 Electrical Performance Specifications................................................................................................ 3

3 Schematic................................................................................................................................................................................4

3.1 Enable Jumpers (JP1 and JP2)......................................................................................................................................... 5

3.2 Error Amplifier Outputs.......................................................................................................................................................5

3.3 Test Point Descriptions.......................................................................................................................................................5

4 Test Setup................................................................................................................................................................................7

4.1 Equipment.......................................................................................................................................................................... 7

4.2 Equipment Setup................................................................................................................................................................8

4.3 Start-Up/Shutdown Procedure........................................................................................................................................... 9

4.4 Output Ripple Voltage Measurement Procedure..............................................................................................................10

4.5 Control Loop Gain and Phase Measurement Procedure................................................................................................. 10

4.6 Equipment Shutdown....................................................................................................................................................... 10

5 TPS54291EVM-431 Typical Performance Data and Characteristic Curves......................................................................11

5.1 Efficiency.......................................................................................................................................................................... 11

5.2 Line and Load Regulation.................................................................................................................................................11

5.3 Switch Node and Output Ripple Voltage.......................................................................................................................... 12

6 EVM Assembly Drawings and Layout.................................................................................................................................13

7 List of Materials.....................................................................................................................................................................16

8 Revision History................................................................................................................................................................... 16

List of Figures

Figure 3-1. TPS54291EVM-431 Schematic.................................................................................................................................4

Figure 4-1. TPS54291EVM-431 Recommended Test Setup....................................................................................................... 8

Figure 4-2. Output Ripple Measurement – Tip and Barrel Using TP3 and TP4 or TP18 and TP19............................................ 9

Figure 4-3. Control Loop Measurement Setup............................................................................................................................ 9

Figure 5-1. TPS54291EVM-431 Efficiency vs Load Current......................................................................................................11

Figure 5-2. TPS54291EVM-431 Output Voltage vs Load Current............................................................................................. 11

Figure 5-3. TPS54291EVM-431 Output Voltage Ripple............................................................................................................ 12

Figure 6-1. TPS54291EVM-431 Component Placement (Viewed from Top).............................................................................13

Figure 6-2. TPS54291EVM-431 Silkscreen (Viewed from Top).................................................................................................13

Figure 6-3. TPS54291EVM-431 Top Copper (Viewed from Top)...............................................................................................14

Figure 6-4. TPS54291EVM-431 Bottom Copper (X-Ray View from Top).................................................................................. 14

Figure 6-5. TPS54291EVM-431 Internal 1 (X-Ray View from Top)........................................................................................... 15

Figure 6-6. TPS54291EVM-431 Internal 2 (X-Ray View from Top)........................................................................................... 15

List of Tables

Table 2-1. TPS54291EVM-431 Electrical and Performance Specifications.................................................................................3

Table 3-1. Test Point Descriptions............................................................................................................................................... 5

Table 7-1. TPS54291EVM-431 Bill of Materials.........................................................................................................................16

Trademarks

All trademarks are the property of their respective owners.

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

1

�Introduction

www.ti.com

1 Introduction

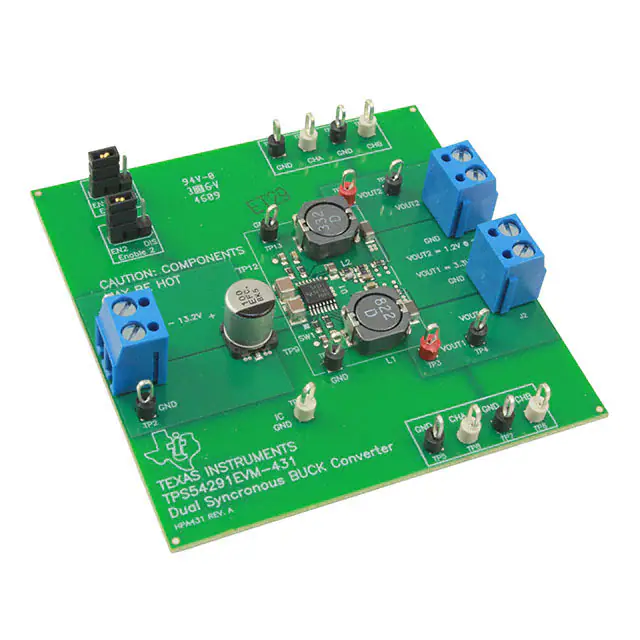

The TPS54291EVM-431 evaluation module (EVM) is a dual synchronous buck converter providing fixed 3.3-V

and 1.2-V outputs at up to 1.5 A and 2.5 A, respectively from a 12-V bus. The EVM is designed to start up from

a single supply, so no additional bias voltages are require for start-up. The module uses the TPS54291 600-kHz

dual synchronous buck converter with integral MOSFETs.

1.1 Description

The TPS54291EVM-431 is designed to use a regulated 12-V (+10% /–20%) bus to produce two regulated power

rails, 3.3 V at 1.5 A and 1.2 V at 2.5 A. TPS54291EVM-431 is designed to demonstrate the TPS54291 in a

typical 12-V bus system while providing a number of test points to evaluate the performance of the TPS54291 in

a given application. The EVM can be modified to other output voltages by changing some of the components.

1.2 Applications

•

•

•

•

•

Non-isolated point-of-load and voltage bus converters

Consumer electronics

LCD TV

Computer peripherals

Digital set top box

1.3 Features

•

•

•

•

•

•

•

•

2

12 V +10% /–20% input range

5.0-V and 3.3-V fixed output voltage, adjustable with resistor change

1.5-A (3.3 V) and 2.5-A (1.2 V) steady state current

600-kHz switching frequency (fixed by TPS54291)

Internal switching MOSFET and external rectifier diode

Double-sided 2 active layer PCB with all components on top side (test point signals routed on internal layers)

Active converter area of 1.1 square inches (0.86" × 1.28")

Convenient test points for probing switching waveforms and non-invasive loop response testing

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

TPS54291EVM-431 Electrical Performance Specifications

2 TPS54291EVM-431 Electrical Performance Specifications

Table 2-1. TPS54291EVM-431 Electrical and Performance Specifications

PARAMETER

NOTES AND CONDITIONS

MIN

NOM

MAX

UNITS

9.6

12

13.2

V

–

2.4

2.6

A

INPUT CHARACTERISTICS

VIN

Input Voltage

IIN

Input Current

VIN = Nom, IOUT = Max

No Load Input Current

VIN = Nom, IOUT = 0 A

Input UVLO

IOUT = Min to Max

VIN_UVLO

–

12

20

mA

4.0

4.2

4.4

V

OUTPUT CHARACTERISTICS

VOUT1

Output Voltage 1

VIN = Nom, IOUT = Nom

3.20

3.30

3.40

V

VOUT2

Output Voltage 2

VIN = Nom, IOUT = Nom

1.15

1.20

1.25

V

Line Regulation

VIN = Min to Max

–

–

1%

Load Regulation

IOUT = Min to Max

–

–

1%

VOUT_ripple

Output Voltage Ripple

VIN = Nom, IOUT = Max

–

–

50

mVpp

IOUT1

Output Current 1

VIN = Min to Max

0

2.5

A

IOUT2

Output Current 2

VIN = Min to Max

0

2.5

A

IOCP1

Output Over Current Channel 1

VIN = Nom, VOUT = VOUT1–5%

1.6

2.0

2.4

A

IOCP2

Output Over Current Channel 2

VIN = Nom, VOUT = VOUT2–5%

3.0

3.6

4.4

A

520

600

720

kHz

SYSTEMS CHARACTERISTICS

FSW

Switching Frequency

ηpk

Peak Efficiency

VIN = Nom

–

88%

–

η

Full Load Efficiency

VIN = Nom, IOUT1 = IOUT1 = Max

–

85%

–

Top

Operating Temperature Range

VIN = Min to Max, IOUT = Min to Max

0

25

60

°C

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

3

�Schematic

www.ti.com

+

3 Schematic

Figure 3-1. TPS54291EVM-431 Schematic

The schematic is for reference only. See Table 7-1 for specific values.

4

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

Schematic

3.1 Enable Jumpers (JP1 and JP2)

The TPS54291EVM-431 provides separate three pin 100-mil headers and shunts for exercising the TPS54291

Enable functions. Place the JP1 shunt in the left position connects EN1 to ground and turns on Output 1 and

placing the JP2 shunt in the left position connects EN2 to ground and turns on Output 2.

3.2 Error Amplifier Outputs

The output of the TPS54291 transconductance error amplifiers (COMP1 and COMP2) are sensitive to

capacitive loading, including the typical 8-pF to 15-pF capacitance added by an oscilloscope probe. No direct

measurements of these signals should be attempted without using an external buffer to prevent loading of the

control voltage.

3.3 Test Point Descriptions

Table 3-1. Test Point Descriptions

TEST POINT

LABEL

USE

SECTION

TP1

VIN

Monitor Input Voltage

Section 3.3.1

TP2

GND

Ground for Input Voltage

Section 3.3.1

TP3

VOUT1

Monitor VOUT1 Voltage

Section 3.3.2

TP4

GND

Ground for VOUT1 Voltage

Section 3.3.2

TP5

GND

Ground for VOUT1 Channel B Loop Monitoring

Section 3.3.3

TP6

CHB

VOUT1 Channel B for Loop Monitoring

Section 3.3.3

TP7

GND

Ground for VOUT1 Channel A Loop Monitoring

Section 3.3.3

TP8

CHA

VOUT1 Channel B for Loop Monitoring

Section 3.3.3

TP9

SW1

Monitor Switching Node of Channel 1

Section 3.3.4

TP10

GND

Ground for Switch Node of Channel 1

Section 3.3.4

TP11

IC_GND

Monitor IC Ground

Section 3.3.5

TP12

SW2

Monitor Switching Node of Channel 2

Section 3.3.6

TP13

GND

Ground for Switch Node of Channel 2

Section 3.3.6

TP14

CHA

VOUT2 Channel A for Loop Monitoring

Section 3.3.7

TP15

GND

Ground for VOUT2 Channel A Loop Monitoring

Section 3.3.7

TP16

CHB

VOUT2 Channel B for Loop Monitoring

Section 3.3.7

TP17

GND

Ground for VOUT2 Channel B Loop Monitoring

Section 3.3.7

TP18

VOUT2

Monitor VOUT2 Voltage

Section 3.3.8

TP19

GND

Ground for VOUT2 Voltage

Section 3.3.8

3.3.1 Input Voltage Monitoring (TP1 and TP2)

TPS54291EVM-431 provides two test points for measuring the voltage applied to the module. This allows the

user to measure the actual module voltage without losses from input cables and connectors. All input voltage

measurements should be made between TP1 and TP2. To use TP1 and TP2, connect a voltmeter positive

terminal to TP1 and negative terminal to TP2.

3.3.2 Channel 1 Output Voltage Monitoring (TP3 and TP4)

TPS54291EVM-431 provides two test points for measuring the voltage generated by the module. This allows

the user to measure the actual module output voltage without losses from output cables and connectors. All

output voltage measurements should be made between TP3 and TP4. To use TP3 and TP4, connect a voltmeter

positive terminal to TP3 and negative terminal to TP4. For output ripple measurements, TP3 and TP4 allow a

user to limit the ground loop area by using the tip and barrel measurement technique shown in Section 4.2.2.

All output ripple measurements should be made using the tip and barrel measurement. Even this Tip and Barrel

measurement technique increases the measured switch edge noise. For improved output ripple measurement,

measure the output ripple at the output capacitor (C5).

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

5

�Schematic

www.ti.com

3.3.3 Channel 1 Loop Analysis (TP5, TP6, TP7, and TP8)

The TPS54291EVM-431 contains a 51-Ω series resistor (R1) in the feedback loop to allow for matched

impedance signal injection into the feedback for loop response analysis. An isolation transformer should be

used to apply a small (30 mV or less) signal across R1 through TP6 and TP8. By monitoring the AC injection

level at TP8 and the returned AC level at TP6, the power supply loop response can be determined.

3.3.4 Channel 1 Switching Waveforms (TP9 and TP10)

The TPS54291EVM-431 provides a surface test pad and a local ground connection (TP10) for the monitoring

of the channel 1 power stage switching waveform. Connect an oscilloscope probe to TP9 to monitor the switch

node voltage for channel 1. Test pads are used on the switch nodes to minimize radiated noise from the switch

node.

3.3.5 TPS54291 IC Ground (TP11)

The TPS54291EVM-431 provides a test point for the IC ground. To measure IC pin voltages, connect the ground

of the oscilloscope probe to TP11.

3.3.6 Channel 2 Switching Waveforms (TP12 and TP13)

The TPS54291EVM-431 provides a surface test pad and a local ground connection (TP13) for the monitoring of

the channel 1 power stage switching waveform. Connect an oscilloscope probe to TP12 to monitor the switch

node voltage for channel 1. Test pads are used on the switch nodes to minimize radiated noise from the switch

node.

3.3.7 Channel 2 Loop Analysis (TP14, TP15, TP16, and TP17)

The TPS54291EVM-431 contains a 51-Ω series resistor (R13) in the feedback loop to allow for matched

impedance signal injection into the feedback for loop response analysis. An isolation transformer should be used

to apply a small (30 mV or less) signal across R13 through TP14 and TP16. By monitoring the AC injection level

at TP14 and the returned AC level at TP16, the power supply loop response can be determined.

3.3.8 Output Voltage Monitoring (TP18 and TP19)

The TPS54291EVM-431 provides two test points for measuring the voltage generated by the module. This

allows the user to measure the actual module output voltage without losses from output cables and connector

losses. All output voltage measurements should be made between TP18 and TP19. To use TP18 and TP19,

connect a voltmeter positive terminal to TP18 and negative terminal to TP19. For output ripple measurements,

TP18 and TP19 allow a user to limit the ground loop area by using the tip and barrel measurement technique

shown in Figure 4-2. All output ripple measurements should be made using the tip and barrel measurement.

Even this tip and barrel measurement technique increases the measured switch edge noise. For improved

output ripple measurement, measure the output ripple at the output capacitor (C17).

6

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

Test Setup

4 Test Setup

4.1 Equipment

4.1.1 Voltage Source (VIN)

The input voltage source (VIN) should be a 0-V to 15-V variable DC source capable of 2-A DC. Connect VIN to J1

as shown in Figure 4-2.

4.1.2 Meters

•

•

•

•

A1: 0-Adc to 2-Adc ammeter

V1: VIN, 0-V to 15-V voltmeter

V2: VOUT1, 0-V to 6-V voltmeter

V3: VOUT2, 0-V to 4-V voltmeter

4.1.3 Loads

LOAD1

The Output1 Load (LOAD1) should be an electronic constant current mode load capable of 0 Adc to 1.5 Adc at

3.3 V.

LOAD2

The Output2 Load (LOAD2) should be an electronic constant current mode load capable of 0 Adc to 2.5 Adc at

1.2 V.

4.1.4 Oscilloscope

A Digital or Analog Oscilloscope can be used to measure the ripple voltage on VOUT1 or VOUT2. The

oscilloscope should be set for the following for taking output ripple measurements:

• 1-MΩ impedance

• 20-MHz Bandwidth

• AC coupling

• 1-μs/division horizontal resolution

• 10-mV/division vertical resolution

TP3 and TP4 or TP18 and TP19 can be used to measure the output ripple voltages by placing the oscilloscope

probe tip through TP3 or TP18 and holding the ground barrel to TP4 or TP19 as shown in Figure 4-2. For a

hands free approach, the loop in TP4 or TP19 can be cut and opened to cradle the probe barrel. Using a leaded

ground connection can induce additional noise due to the large ground loop area.

4.1.5 Recommended Wire Gauge

VIN to J1

The connection between the source voltage, VIN, and J1 of HPA431 can carry as much as 5 Adc. The minimum

recommended wire size is AWG #16 with the total length of wire less than four feet (two feet input, two feet

return).

J2 to LOAD1

The power connection between J2 of HPA431 and LOAD1 can carry as much as 1.5 Adc. The minimum

recommended wire size is AWG #18 with the total length of wire less than two feet (two foot output, two foot

return).

J3 to LOAD2

The power connection between J3 of HPA431 and LOAD2 can carry as much as 2.5 Adc. The minimum

recommended wire size is AWG #18 with the total length of wire less than 2two feet (one foot output, one foot

return).

4.1.6 Other

FAN

This evaluation module includes components that can get hot to the touch. Because this EVM is not enclosed to

allow probing of circuit nodes, a small fan capable of 200lfm to 400 lfm is recommended to reduce component

surface temperatures to prevent user injury. The EVM should not be left unattended while powered. The EVM

should not be probed while the fan is not running.

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

7

�Test Setup

www.ti.com

4.2 Equipment Setup

Shown in Figure 4-1 is the basic recommended test setup to evaluate the TPS54291EVM-431. Note that

although the return for J1, J2, and JP3 is the same system ground, the connections should remain separate as

shown in Figure 4-1.

4.2.1 Procedure

1. Working at an ESD workstation, make sure that any wrist straps, bootstraps, or mats are connected

referencing the user to earth ground before power is applied to the EVM. An electrostatic smock and safety

glasses should also be worn.

2. Prior to connecting the DC input source, VIN, it is advisable to limit the source current from VIN to 2.0-A

maximum. Make sure VIN is initially set to 0 V and connected as shown in Figure 4-1.

3. Connect the ammeter A1 (0-A to 5-A range) between VIN and J1 as shown in Figure 4-1.

4. Connect voltmeter V1 to TP1 and TP2 as shown in Figure 4-1.

5. Connect LOAD1 to J2 as shown in Figure 4-1. Set LOAD1 to constant current mode to sink 0 Adc before VIN

is applied.

6. Connect voltmeter V2 across TP3 and TP4 as shown in Figure 4-1.

7. Connect LOAD2 to J3 as shown in Figure 4-1. Set LOAD2 to constant current mode to sink 0 Adc before VIN

is applied.

8. Connect voltmeter V3 across TP18 and TP19 as shown in Figure 4-1.

9. Place a fan as shown in Figure 4-2 and turn it on, making sure air is flowing across the EVM.

4.2.2 Diagram

FAN

Oscilloscope

1MW, AC

20mV / div

20MHz

+

-

See Tip and Barrel

Measurement for

Vout ripple

V3

+

+

-

LOAD2

1.2V @

2.5A

A1

-

-

-

VVIN

+

V1

+

LOAD1

3.3V @

1.5A

-

+

V2

Figure 4-1. TPS54291EVM-431 Recommended Test Setup

8

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

Test Setup

Metal Ground Barrel

Probe Tip

TP3 /

TP4 /

TP18

TP19

Tip and Barrel Vout ripple

measurement

Figure 4-2. Output Ripple Measurement – Tip and Barrel Using TP3 and TP4 or TP18 and TP19

Network

Analyzer

FAN

Isolation

Transformer

+

V3

+

+

A1

-

-

-

VVIN

+

V1

LOAD2

1.2V @

2.5A

+

LOAD1

3.3V @

1.5A

-

+

V2

Figure 4-3. Control Loop Measurement Setup

4.3 Start-Up/Shutdown Procedure

1.

2.

3.

4.

Increase VIN from 0 Vdc to 12 Vdc.

Vary LOAD1 from 0 Adc to 1.5 Adc.

Vary LOAD2 from 0 Adc to 2.5 Adc.

Vary VIN from 9.6 Vdc to 13.2 Vdc.

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

9

�Test Setup

www.ti.com

5. Decrease VIN to 0 Vdc.

6. Decrease LOAD1 to 0 A.

7. Decrease LOAD2 to 0 A.

4.4 Output Ripple Voltage Measurement Procedure

See Section 5.3 for more information on measuring output ripple.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Increase VIN from 0 Vdc to 12 Vdc.

Adjust LOAD1 to desired load between 0 Adc and 1.5 Adc.

Adjust LOAD2 to desired load between 0 Adc and 2.5 Adc.

Adjust VIN to desired load between 9.6 Vdc and 13.2 Vdc.

Connect an oscilloscope probe to TP3 and TP4 or TP18 and TP19 as shown in Figure 4-2.

Measure output ripple.

Decrease VIN to 0 Vdc.

Decrease LOAD1 to 0 A.

Decrease LOAD2 to 0 A.

4.5 Control Loop Gain and Phase Measurement Procedure

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Connect a 1-kHz to 1-MHz isolation transformer to TP6 and TP8 as shown in Figure 4-3

Connect the input signal amplitude measurement probe (Channel A) to TP8 as shown in Figure 4-3.

Connect output signal amplitude measurement probe (Channel B) to TP6 as shown in Figure 4-3.

Connect ground lead of Channel A and Channel B to TP5 and TP7 as shown in Figure 4-3.

Inject 30-mV or less signal across R1 through an isolation transformer.

Sweep frequency from 1 kHz to 1 MHz with 1-0Hz or lower post filter.

æ C hannelB ö

20 ´ LOG ç

÷

è ChannelA ø .

Control loop gain can be measured by

The control loop phase is measured by the phase difference between Channel A and Channel B.

The control loop for Channel 2 can be measured by making the following substitutions:

a. Change TP6 to TP16.

b. Change TP8 to TP14.

c. Change TP5 to TP17.

d. Change TP7 to TP15.

Disconnect the isolation transformer before making any other measurements (signal injection into feedback

can interfere with the accuracy of other measurements).

4.6 Equipment Shutdown

1.

2.

3.

4.

5.

10

Shut down the oscilloscope.

Shut down VIN.

Shut down LOAD1.

Shut down LOAD2.

Shut down the fan.

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

TPS54291EVM-431 Typical Performance Data and Characteristic Curves

5 TPS54291EVM-431 Typical Performance Data and Characteristic Curves

Figure 5-1 through Figure 5-3 present typical performance curves for the TPS54291EVM-431. Since actual

performance data can be affected by measurement techniques and environmental variables, these curves are

presented for reference and can differ from actual field measurements.

5.1 Efficiency

100

90

8V

8V

12 V

95

12 V

85

14 V

85

η - Efficiency - %

η - Efficiency - %

90

80

75

80

14 V

75

70

70

65

65

60

0

0.2

0.4

0.6

0.8

1

1.2

ILOAD - Load Current - A

1.4

60

1.6

0

0.5

1

1.5

2

ILOAD - Load Current - A

2.5

3

VIN = 9.6-13.2V, VOUT1 = 3.3V IOUT1 = 0-1.5A, VOUT2 = 1.2V IOUT2 = 0-2.5A

Figure 5-1. TPS54291EVM-431 Efficiency vs Load Current

5.2 Line and Load Regulation

1.212

3.35

3.33

14 V

VO - Output Voltage - V

VO - Output Voltage - V

12 V

3.31

8V

3.29

1.206

14 V

1.2

12 V

8V

1.194

3.27

3.25

1.188

0

0.2

0.4

0.6

0.8

1

1.2

ILOAD - Load Current - A

1.4

1.6

0

0.5

1

1.5

2

ILOAD - Load Current - A

2.5

3

VIN = 9.6 V–13.2 V, VOUT1 = 3.2 V IOUT1 = 0 A–1.5 A, VOUT2 = 1.2 V IOUT2 = 0 A–2.5 A

Figure 5-2. TPS54291EVM-431 Output Voltage vs Load Current

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

11

�TPS54291EVM-431 Typical Performance Data and Characteristic Curves

www.ti.com

5.3 Switch Node and Output Ripple Voltage

VIN = 13.2 V, VOUT1 = 3.3 A, IOUT2 = 1.2 V IOUT2 = 2.5 A

Ch1: TP3 (VOUT1), Ch2: TP18 (VOUT2), Ch3: TP9 (SW1), Ch4: TP12 (SW2)

Figure 5-3. TPS54291EVM-431 Output Voltage Ripple

12

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

EVM Assembly Drawings and Layout

6 EVM Assembly Drawings and Layout

Figure 6-1 through Figure 6-6 show the designs of the TPS54291EVM-431 printed circuit board. The EVM has

been designed using a 4-layer, 2-oz copper-clad circuit board 3.0 inch × 3.0 inch with all components in a

0.86-inch × 1.28-inch active area on the top side and all active traces to the top and bottom layers to allow the

user to easily view, probe, and evaluate the TPS54291 control IC in a practical double-sided application. Moving

components to both sides of the PCB or using additional internal layers can offer additional size reduction for

space constrained systems.

Figure 6-1. TPS54291EVM-431 Component Placement (Viewed from Top)

Figure 6-2. TPS54291EVM-431 Silkscreen (Viewed from Top)

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

13

�EVM Assembly Drawings and Layout

www.ti.com

Figure 6-3. TPS54291EVM-431 Top Copper (Viewed from Top)

Figure 6-4. TPS54291EVM-431 Bottom Copper (X-Ray View from Top)

14

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�www.ti.com

EVM Assembly Drawings and Layout

Figure 6-5. TPS54291EVM-431 Internal 1 (X-Ray View from Top)

Figure 6-6. TPS54291EVM-431 Internal 2 (X-Ray View from Top)

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

TPS54291 Step-Down Converter Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

15

�List of Materials

www.ti.com

7 List of Materials

Table 7-1 lists the EVM components as configured according to the schematic shown in Figure 3-1.

Table 7-1. TPS54291EVM-431 Bill of Materials

QTY

REFDES

VALUE

DESCRIPTION

SIZE

PART NUMBER

MFR

1

C1

100 μF

Capacitor, Aluminum, 25 V, ±20%

0.328 × 0.390 inch

EEEFC1E101P

Panasonic

1

C12

4.7 μF

Capacitor, Ceramic, 10 V, X5R, 20%

0805

Std

Std

2

C2, C14

22 μF

Capacitor, Ceramic, 6.3 V, X5R, 20%

1206

C3216X5R0J226M

TDK

2

C3, C13

470 pF

Capacitor, Ceramic, 25 V, X7R, 20%

0603

Std

Std

2

C4, C11

0.047 μF

Capacitor, Ceramic, 25 V, X7R, 20%

0603

Std

Std

2

C5, C10

10 μF

Capacitor, Ceramic, 25 V, X5R, 20%

1210

C3225X5R1E106M

TDK

1

C6

1.8 nF

Capacitor, Ceramic, 25 V, X7R, 20%

0603

Std

Std

1

C7

15 pF

Capacitor, Ceramic, 25 V, C0G, 20%

0603

Std

Std

1

C8

47 pF

Capacitor, Ceramic, 25 V, C0G, 20%

0603

Std

Std

1

C9

1.2 nF

Capacitor, Ceramic, 25 V, X7R, 20%

0603

Std

Std

3

J1, J2, J3

ED1609-ND

Terminal Block, 2-pin, 15-A, 5.1 mm

0.40 × 0.35 inch

ED120/2DS

OST

2

JP1, JP2

PEC03SAAN

Header, 3-pin, 100-mil spacing

0.100 inch × 3

PEC03SAAN

Sullins

1

L1

8.2 μH

Inductor, SMT, 4.38 A, 20 mΩ

0.402 × 0.394 inch

MSS1048-822L

Coilcraft

1

L2

3.3 μH

Inductor, SMT, 4.38 A, 20 mΩ

0.402 × 0.394 inch

MSS1048-332L

Coilcraft

2

R1, R8

51

Resistor, Chip, 1/16W, 5%

0603

Std

Std

1

R10

40.2 k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

2

R2, R11

10

Resistor, Chip, 1/16W, 5%

0603

Std

Std

2

R3, R12

20.5 k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

R4

6.49 k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

2

R5, R9

0

Resistor, Chip, 1/16W, 5%

0603

Std

Std

1

R6

53.6 k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

R7

18.7 k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

3

TP1, TP3, TP18

5010

TP2, TP4, TP5, TP7,

TP10, TP13, TP15

Test Point, Red, Thru Hole

0.125 × 0.125 inch

5010

Keystone

9

TP17, TP19, TP6,

TP8, TP11, TP14

5011

Test Point, Black, Thru Hole

0.125 × 0.125 inch

5011

Keystone

5

TP16

5012

Test Point, White, Thru Hole

0.125 × 0.125 inch

5012

Keystone

0

TP9, TP12

None

Test point, 40 mil SMT

None

None

None

1

U1

TPS54291PWP

IC, 2.5-A/1.5-A, 600-Hz, Dual Output Fully

Synchronous Buck Converter W/Integrated

FET

CSP

TPS54291PWP

TI

2

—

Shunt, 100-mil, Black

0.100

929950-00

3M

1

—

PCB, 3 inch × 3 inch × 0.063 inch

HPA431

Any

8 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision * (January 2010) to Revision A (October 2021)

Page

• Updated the numbering format for tables, figures, and cross-references throughout the document. ................2

• Updated the user's guide title............................................................................................................................. 2

• Edited the user's guide for clarity........................................................................................................................2

16

TPS54291 Step-Down Converter Evaluation Module User's Guide

SLVU356A – JANUARY 2010 – REVISED OCTOBER 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

�IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, regulatory or other requirements.

These resources are subject to change without notice. TI grants you permission to use these resources only for development of an

application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license

is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you

will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these

resources.

TI’s products are provided subject to TI’s Terms of Sale or other applicable terms available either on ti.com or provided in conjunction with

such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2022, Texas Instruments Incorporated

�