Product

Folder

Sample &

Buy

Support &

Community

Tools &

Software

Technical

Documents

TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

TPS5438x Dual 3-A Non-Synchronous Converters With Integrated High-Side MOSFET

1 Features

3

•

•

The TPS54383 and TPS54386 are dual output, nonsynchronous buck converters capable of supporting

3-A output applications that operate from a 4.5-V to

28-V input supply voltage, and require output

voltages between 0.8 V and 90% of the input voltage.

1

•

•

•

•

•

•

•

•

•

•

•

•

•

4.5-V to 28-V Input Range

Output Voltage Range 0.8 V to 90% of Input

Voltage

Output Current Up to 3 A

Two Fixed Switching Frequency Versions:

– TPS54383: 300 kHz

– TPS54386: 600 kHz

Three Selectable Levels of Overcurrent Protection

(Output 2)

0.8-V 1.5% Voltage Reference

2.1-ms Internal Soft-Start

Dual PWM Outputs 180° Out-of-Phase

Ratiometric or Sequential Startup Modes

Selectable by a Single Pin

85-mΩ Internal High-Side MOSFETs

Current Mode Control

Internal Compensation (See Page 16)

Pulse-by-Pulse Overcurrent Protection

Thermal Shutdown Protection at +148°C

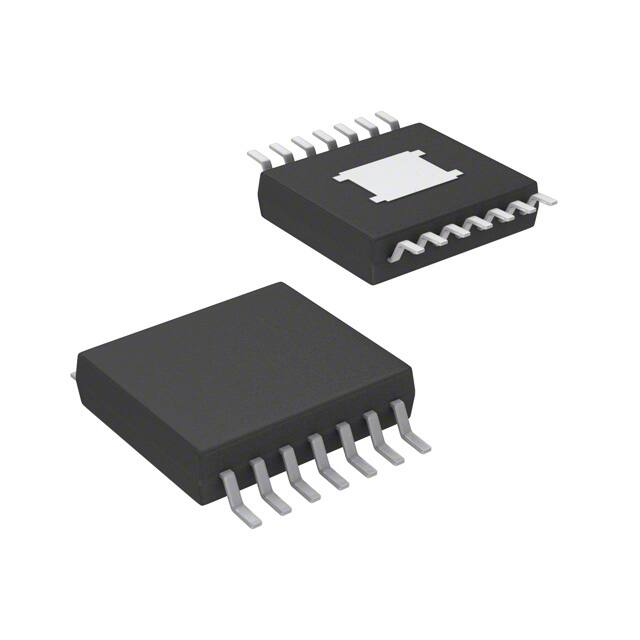

14-Pin PowerPAD™ HTSSOP package

With an internally-determined operating frequency,

soft-start time, and control loop compensation, these

converters provide many features with a minimum of

external components. Channel 1 overcurrent

protection is set at 4.5 A, while Channel 2 overcurrent

protection level is selected by connecting a pin to

ground, to BP, or left floating. The setting levels are

used to allow for scaling of external components for

applications that do not need the full load capability of

both outputs.

The outputs may be enabled independently, or may

be configured to allow either ratio-metric or sequential

startup sequencing. Additionally, the two outputs may

be powered from different sources.

Device Information(1)

PART NUMBER

TPS54383

TPS54386

PACKAGE

HTSSOP (14)

BODY SIZE (NOM)

4.40 mm × 5.00 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

2 Applications

•

•

•

•

Description

Set Top Box

Digital TV

Power for DSP

Consumer Electronics

4 Simplified Schematic

VIN

TPS54383

1

PVDD1

PVDD2 14

2

BOOT1

BOOT2 13

3

SW1

OUTPUT1

OUTPUT2

SW2 12

4

GND

BP 11

5

EN1

SEQ 10

6

EN2

7

FB1

ILIM2

9

FB2

8

GND

UDG-07123

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Simplified Schematic.............................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

1

2

3

5

7.1

7.2

7.3

7.4

7.5

7.6

5

5

5

5

6

8

Absolute Maximum Ratings .....................................

ESD Ratings ............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 11

8.1 Overview ................................................................. 11

8.2 Functional Block Diagram ....................................... 12

8.3 Feature Description................................................. 13

8.4 Device Functional Modes........................................ 29

9

Applications and Implementation ...................... 30

9.1 Application Information............................................ 30

9.2 Typical Applications ................................................ 30

10 Power Supply Recommendations ..................... 41

11 Layout................................................................... 41

11.1 Layout Guidelines ................................................. 41

11.2 Layout Example .................................................... 42

11.3 PowerPAD Package.............................................. 43

12 Device and Documentation Support ................. 44

12.1

12.2

12.3

12.4

12.5

12.6

Device Support......................................................

Documentation Support ........................................

Related Links ........................................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

44

45

45

45

45

45

13 Mechanical, Packaging, and Orderable

Information ........................................................... 46

5 Revision History

Changes from Revision B (October 2007) to Revision C

•

2

Page

Added ESD Ratings table, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section. ................................................................................................. 1

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

6 Pin Configuration and Functions

PWP Package

14-Pin HTSSOP

Bottom View

PVDD1

1

14 PVDD2

BOOT1

2

13 BOOT2

SW1

3

12 SW2

GND

4

EN1

5

10 SEQ

EN2

6

9 ILIM2

FB1

7

8 FB2

Thermal Pad

(bottom side)

11 BP

Pin Functions

PIN

NAME

BOOT1

NO.

2

I/O

DESCRIPTION

I

Input supply to the high side gate driver for Output 1. Connect a 22-nF to 82-nF capacitor from this pin

to SW1. This capacitor is charged from the BP pin voltage through an internal switch. The switch is

turned ON during the OFF time of the converter. To slow down the turn ON of the internal FET, a small

resistor (1 Ω to 3 Ω) may be placed in series with the bootstrap capacitor.

BOOT2

13

I

Input supply to the high side gate driver for Output 2. Connect a 22-nF to 82-nF capacitor from this pin

to SW2. This capacitor is charged from the BP pin voltage through an internal switch. The switch is

turned ON during the OFF time of the converter. To slow down the turn ON of the internal FET, a small

resistor (1 Ω to 3 Ω) may be placed in series with the bootstrap capacitor.

BP

11

-

Regulated voltage to charge the bootstrap capacitors. Bypass this pin to GND with a low ESR (4.7-μF

to 10-μF X7R or X5R) ceramic capacitor.

EN1

5

I

Active low enable input for Output 1. If the voltage on this pin is greater than 1.55 V, Output 1 is

disabled (high-side switch is OFF). A voltage of less than 0.9 V enables Output 1 and allows soft-start

of Output 1 to begin. An internal current source drives this pin to PVDD2 if left floating. Connect this pin

to GND for "always ON" operation.

EN2

6

I

Active low enable input for Output 2. If the voltage on this pin is greater than 1.55 V, Output 2 is

disabled (high-side switch is OFF). A voltage of less than 0.9 V enables Output 2 and allows soft-start

of Output 2 to begin. An internal current source drives this pin to PVDD2 if left floating. Connect this pin

to GND for "always ON" operation.

I

Voltage feedback pin for Output 1. The internal transconductance error amplifier adjusts the PWM for

Output 1 to regulate the voltage at this pin to the internal 0.8-V reference. A series resistor divider from

Output 1 to ground, with the center connection tied to this pin, determines the value of the regulated

output voltage. Compensation for the feedback loop is provided internally to the device. See Feedback

Loop and Inductor-Capacitor ( L-C) Filter Selection section for further information.

FB1

7

FB2

8

I

Voltage feedback pin for Output 2. The internal transconductance error amplifier adjusts the PWM for

Output 2 to regulate the voltage at this pin to the internal 0.8-V reference. A series resistor divider from

Output 2 to ground, with the center connection tied to this pin, determines the value of the regulated

Output voltage. Compensation for the feedback loop is provided internally to the device. See Feedback

Loop and Inductor-Capacitor ( L-C) Filter Selection section for further information.

GND

4

-

Ground pin for the device. Connect directly to Thermal Pad.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

3

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

Pin Functions (continued)

PIN

NAME

NO.

I/O

DESCRIPTION

ILIM2

9

I

Current limit adjust pin for Output 2 only. This function is intended to allow a user with asymmetrical

load currents (Output 1 load current much greater than Output 2 load current) to optimize component

scaling of the lower current output while maintaining proper component derating in a overcurrent fault

condition. The discrete levels are available as shown in Table 2. Note: An internal 2-resistor divider

(150-kΩ each) connects BP to ILIM2 and to GND.

PVDD1

1

I

Power input to the Output 1 high side MOSFET only. This pin should be locally bypassed to GND with a

low ESR ceramic capacitor of 10-μF or greater.

PVDD2

14

I

The PVDD2 pin provides power to the device control circuitry, provides the pull-up for the EN1 and EN2

pins and provides power to the Output 2 high-side MOSFET. This pin should be locally bypassed to

GND with a low ESR ceramic capacitor of 10-μF or greater. The UVLO function monitors PVDD2 and

enables the device when PVDD2 is greater than 4.1 V.

This pin configures the output startup mode. If the SEQ pin is connected to BP, then when Output 2 is

enabled, Output 1 is allowed to start after Output 2 has reached regulation; that is, sequential startup

where Output 1 is slave to Output 2. If EN2 is allowed to go high after the outputs have been operating,

then both outputs are disabled immediately, and the output voltages decay according to the load that is

present. For this sequence configuration, tie EN1 to ground.

SEQ

10

I

If the SEQ pin is connected to GND, then when Output 1 is enabled, Output 2 is allowed to start after

Output 1 has reached regulation; that is, sequential startup where Output 2 is slave to Output 1. If EN1

is allowed to go high after the outputs have been operating, then both outputs are disabled immediately,

and the output voltages decay according to the load that is present. For this sequence configuration, tie

EN2 to ground.

If left floating, Output 1 and Output 2 start ratio-metrically when both outputs are enabled at the same

time. They will soft-start at a rate determined by their final output voltage and enter regulation at the

same time. If the EN1 and EN2 pins are allowed to operate independently, then the two outputs also

operate independently

NOTE: An internal two resistor (150-kΩ each) divider connects BP to SEQ and to GND. See the

Sequence States table.

SW1

3

O

Source (switching) output for Output 1 PWM. A snubber is recommended to reduce ringing on this

node. See SW Node Ringing for further information.

SW2

12

O

Source (switching) output for Output 2 PWM. A snubber is recommended to reduce ringing on this

node. See SW Node Ringing for further information.

Thermal Pad

—

—

This pad must be tied externally to a ground plane and the GND pin.

4

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

7 Specifications

7.1 Absolute Maximum Ratings (1)

MIN

MAX

PVDD1, PVDD2, EN1, EN2

BOOT1, BOOT2

Input voltage range

VSW+ 7

SW1, SW2

–2

30

SW1, SW2 transient (< 50ns)

–3

31

BP

TJ

–0.3

6.5

FB1, FB2

–0.3

3

SW1, SW2 output current

7

A

BP load current

35

mA

–40

+150

Soldering temperature

(1)

V

6.5

SEQ, ILIM2

Operating temperature

Tstg

UNIT

30

°C

+260

Storage temperature

–55

165

°C

Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional operation should be limited to the

Recommended DC Operating Conditions detailed in this data sheet. Exposure to conditions beyond the operational limits for extended

periods of time may affect device reliability.

7.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22C101 (2)

±1500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

MIN

MAX

UNIT

VPVDD2

Input voltage

4.5

28

V

TJ

Operating junction

temperature

–40

+125

°C

7.4 Thermal Information

THERMAL METRIC

(1)

TPS54383

TPS54386

HTSSOP

UNIT

14 PINS

RθJA

Junction-to-ambient thermal resistance

48.6

RθJC(top)

Junction-to-case (top) thermal resistance

29.4

RθJB

Junction-to-board thermal resistance

25.1

ψJT

Junction-to-top characterization parameter

0.9

ψJB

Junction-to-board characterization parameter

24.9

RθJC(bot)

Junction-to-case (bottom) thermal resistance

2.4

(1)

°C/W

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

5

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

7.5 Electrical Characteristics

–40°C ≤ TJ ≤ +125°C, VPVDD1 = VPVDD2 = 12 V, unless otherwise noted.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

INPUT SUPPLY (PVDD)

VPVDD1

Input voltage range

VPVDD2

4.5

28

V

μA

IDDSDN

Shutdown

V EN1 = V EN2 = VPVDD2

70

150

IDDQ

Quiescent, non-switching

VFB = 0.9 V, Outputs off

1.8

3.0

IDDSW

Quiescent, while-switching

SW node unloaded; Measured as BP sink

current

VUVLO

Minimum turn-on voltage

PVDD2 only

VUVLO(hys)

Hysteresis

(1) (2)

tSTART

3.8

CBP = 10 μF, EN1 and EN2 go low

simultaneously

Time from startup to softstart begin

mA

5

4.1

4.4

V

400

mV

2

ms

ENABLE (EN)

V EN1

Enable threshold

V EN2

0.9

Hysteresis

I EN1

I EN2

(1)

t EN

1.2

1.5

50

Enable pull-up current

V EN1 = V EN2 = 0 V

Time from enable to soft-start begin

Other EN pin = GND

6

V

mV

12

μA

μs

10

BP REGULATOR (BP)

BP

BPLDO

IBP

(1)

Regulator voltage

8 V < PVDD2 < 28 V

Dropout voltage

PVDD2 = 4.5 V; switching, no external load on

BP

5

5.25

400

Regulator external load

IBPS

5.6

mV

2

Regulator short circuit

4.5 V < PVDD2 < 28 V

V

10

20

30

TPS54383

255

310

375

TPS54386

510

630

750

mA

OSCILLATOR

fSW

Switching frequency

(1)

tDEAD

Clock dead time

140

kHz

ns

ERROR AMPLIFIER (EA) and VOLTAGE REFERENCE (REF)

VFB1

Feedback input voltage

VFB2

IFB1

0°C < TJ < +85°C

788

–40°C < TJ < +125°C

786

Feedback input bias current

IFB2

gM1 (1)

812

812

3

Transconductance

gM2 (1)

800

50

mV

nA

μS

30

SOFT-START (SS)

TSS1

Soft-start time

TSS2

1.5

2.1

2.7

ms

OVERCURRENT PROTECTION

ICL1

Current limit channel 1

ICL2

Current limit channel 2

3.6

4.5

5.6

VILIM2 = VBP

3.6

4.5

5.6

VILIM2 = (floating)

2.4

3.0

3.6

1.15

1.50

1.75

VILIM2 = GND

VUV1

Low-level output threshold to declare a fault

VUV2

THICCUP

(1)

tON1(oc)

(1)

tON2(oc)

(1)

(1)

(2)

6

Measured at feedback pin.

A

670

mV

Hiccup timeout

10

ms

Minimum overcurrent pulse width

90

150

ns

Ensured by design. Not production tested.

When both outputs are started simultaneously, a 20-mA current source charges the BP capacitor. Faster times are possible with a lower

BP capacitor value. More information can be found in the Input UVLO and Startup section.

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

Electrical Characteristics (continued)

–40°C ≤ TJ ≤ +125°C, VPVDD1 = VPVDD2 = 12 V, unless otherwise noted.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

BOOTSTRAP

RBOOT1

Bootstrap switch resistance

RBOOT2

From BP to BOOT1 or BP to BOOT2,

IEXT = 50 mA

18

TJ = +25°C, VPVDD2 = 8 V

85

–40°C < TJ < +125°C, VPVDD2 = 8 V

85

165

100

200

ns

0

%

Ω

OUTPUT STAGE (Channel 1 and Channel 2)

RDS(on)

(1)

tON(min)

(1)

MOSFET on resistance plus bond wire resistance

Minimum controllable pulse width

ISWx peak current > 1 A (3)

DMIN

Minimum Duty Cycle

VFB = 0.9 V

DMAX

Maximum Duty Cycle

ISW

Switching node leakage current (sourcing)

TPS54383 fSW = 300 kHz

90

95

TPS54386 fSW = 600 kHz

85

90

Outputs OFF

2

mΩ

%

%

12

μA

THERMAL SHUTDOWN

TSD

(1)

TSD(hys)

(3)

Shutdown temperature

(1)

148

Hysteresis

20

°C

See Figure 14 for ISWx peak current

enable threshold voltage

Active

Tie EN1 to > enable threshold voltage

for low quiescent current (BP inactive)

when V EN2 > enable threshold voltage

Ignored by the device.when V EN1 <

enable threshold voltage

GND

Sequential, Output 1 then Output 2

Tie EN2 to < enable threshold voltage

for BP to be active when V EN1 >

enable threshold voltage

Active

Tie EN2 to > enable threshold voltage

for low quiescent current (BP inactive)

when V EN1 > enable threshold voltage

(floating)

14

Independent or Ratiometric, Output 1

and Output 2

Submit Documentation Feedback

Active. EN1 and EN2 must be tied

together for Ratio-metric startup.

Active. EN1 and EN2 must be tied

together for Ratio-metric startup.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

If the SEQ pin is connected to BP, then when Output 2 is enabled, Output 1 is allowed to start approximately 400

μs after Output 2 has reached regulation; that is, sequential startup where Output 1 is slave to Output 2. If EN2 is

allowed to go high after the outputs have been operating, then both outputs are disabled immediately, and the

output voltages decay according to the load that is present.

If the SEQ pin is connected to GND, then when Output 1 is enabled, Output 2 is allowed to start approximately

400 μs after Output 1 has reached regulation; that is, sequential startup where Output 2 is slave to Output 1. If

EN1 is allowed to go high after the outputs have been operating, then both outputs are disabled immediately,

and the output voltages decay according to the load that is present.

SEQ = BP

Sequential

CH2 then CH1

SEQ = GND

Sequential

CH1 then CH2

5-V VOUT1

(2 V/div)

5-V VOUT1

(2 V/div)

3.3-V VOUT2

(2 V/div)

3.3-V VOUT2

(2 V/div)

T - Time - 1 ms/div

T - Time - 1 ms/div

Figure 18. SEQ Pin TIed to BP

Figure 19. SEQ Pin Tied to GND

NOTE

An R-C network connected to the ENx pin may be used in addition to the SEQ pin in

sequential mode to delay the startup of the first output voltage. This approach may be

necessary in systems with a large number of output voltages and elaborate voltage

sequencing requirements. See Enable and Timed Turn On of the Outputs.

If the SEQ pin is left floating, Output 1 and Output 2 each start ratiometrically when both outputs are enabled at

the same time. Output 1 and Output 2 soft-start at a rate that is determined by the respective final output

voltages and enter regulation at the same time. If the EN1 and EN2 pins are allowed to operate independently,

then the two outputs also operate independently.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

15

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

5-V VOUT1

(2 V/div)

3.3-V VOUT2

(2 V/div)

T - Time - 1 ms/div

Figure 20. SEQ Pin Floating

8.3.6 Soft-Start

Each output has a dedicated soft-start circuit. The soft-start voltage is an internal digital reference ramp to one of

two noninverting inputs of the error amplifier. The other input is the (internal) precision 0.8-V reference. The total

ramp time for the FB voltage to charge from 0 V to 0.8 V is about 2.1 ms. During a soft-start interval, the

TPS5438x output slowly increases the voltage to the noninverting input of the error amplifier. In this way, the

output voltage ramps up slowly until the voltage on the noninverting input to the error amplifier reaches the

internal 0.8 V reference voltage. At that time, the voltage at the noninverting input to the error amplifier remains

at the reference voltage.

NOTE

To avoid a disturbance in the output voltage during the stepping of the digital soft -tart, a

minimum output capacitance of 50μF is recommended. See Feedback Loop and InductorCapacitor (L-C) Filter Selection Once the filter and compensation components have been

established, laboratory measurements of the physical design should be performed to

confirm converter stability.

During the soft-start interval, pulse-by-pulse current limiting is in effect. If an overcurrent pulse is detected, six

PWM pulses are skipped to allow the inductor current to decay before another PWM pulse is applied. (See the

Output Overload Protection section.) There is no pulse skipping if a current limit pulse is not detected.

DESIGN HINT

If the rate of rise of the input voltage (PVDDx) is such that the input voltage is too low to

support the desired regulation voltage by the time Soft-Start has completed, then the

output UV circuit may trip and cause a hiccup in the output voltage. In this case, use a

timed delay startup from the ENx pin to delay the startup of the output until the PVDDx

voltage has the capability of supporting the desired regulation voltage. See Operating

Near Maximum Duty Cycle and Maximum Output Capacitance for related information.

16

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

8.3.7 Output Voltage Regulation

Each output has a dedicated feedback loop comprised of a voltage setting divider, an error amplifier, a pulse

width modulator, and a switching MOSFET. The regulation output voltage is determined by a resistor divider

connecting the output node, the FBx pin, and GND (see Figure 21). Assuming the value of the upper voltage

setting divider is known, the value of the lower divider resistor for a desired output voltage is calculated by

Equation 2.

VREF

R2 = R1´

VOUT - VREF

where

•

VREF is the internal 0.8-V reference voltage

(2)

TPS5438x

1

PVDD1

PVDD2 14

2

BOOT1

BOOT2 13

3

SW1

SW2 12

4

GND

BP 11

5

EN1

SEQ 10

6

EN2

ILIM2

9

7

FB1

FB2

8

OUTPUT1

R1

R2

UDG-07011

Figure 21. Feedback Network for Channel 1

DESIGN HINT

There is a leakage current of up to 12 μA out of the SW pin when a single output of the

TPS5438x is disabled. Keeping the series impedance of R1 + R2 less than 50 kΩ

prevents the output from floating above the reference voltage while the controller output is

in the OFF state.

8.3.8 Feedback Loop and Inductor-Capacitor (L-C) Filter Selection

In the feedback signal path, the output voltage setting divider is followed by an internal gM-type error amplifier

with a typical transconductance of 30 μS. An internal series connected R-C circuit from the gM amplifier output to

ground serves as the compensation network for the converter. The signal from the error amplifier output is then

buffered and combined with a slope compensation signal before it is mirrored to be referenced to the SW node.

Here, it is compared with the current feedback signal to create a pulse-width-modulated (PWM) signal-fed to

drive the upper MOSFET switch. A simplified equivalent circuit of the signal control path is depicted in Figure 22.

NOTE

Noise coupling from the SWx node to internal circuitry of BOOTx may impact narrow pulse

width operation, especially at load currents less than 1 A. See SW Node Ringing for

further information on reducing noise on the SWx node.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

17

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

TPS5438x

BOOT

ICOMP - ISLOPE

0.8 VREF

PWM to

Switch

x2

Error Amplifier

ISLOPE

+

+

FB

ICOMP

Offset

f(IDRAIN)

RCOMP

SW

11.5 kW

CCOMP

RCOMP

(kW)

CCOMP

(pF)

TPS54383

700

40

TPS54386

700

20

UDG-07012

Figure 22. Feedback Loop Equivalent Circuit

A more conventional small signal equivalent block diagram is shown in Figure 23. Here, the full closed loop

signal path is shown. Because the TPS5438x contains internal slope compensation and loop compensation

components, the external L-C filter must be selected appropriately so that the resulting control loop meets criteria

for stability. This approach differs from an externally-compensated controller, where the L-C filter is generally

selected first, and the compensation network is found afterwards. To find the appropriate L and C filter

combination, the Output-to-Vc signal path plots (see the next section) of gain and phase are used along with

other design criterial to aid in finding the combinations that best results in a stable feedback loop.

VIN

VREF

VC

+

_

VOUT

+

Modulator

_

Filter

Current

Feedback

Network

Compensation

Network

Figure 23. Small Signal Equivalent Block Diagram

8.3.9 Inductor-Capacitor (L-C) Selection

The following figures plot the TPS5438x Output-to-Vc gain and phase versus frequency for various duty cycles

(10%, 30%, 50%, 70%, 90%) at three (200 mA, 400 mA, 600 mA) peak-to-peak ripple current levels. The loop

response curve selected to compensate the loop is based on the duty cycle of the application and the ripple

current in the inductor. Once the curve has been selected and the inductor value has been calculated, the output

capacitor is found by calculating the L-C resonant frequency required to compensate the feedback loop. A brief

example follows the curves.

Note that the internal error amplifier compensation is optimized for output capacitors with an ESR zero frequency

between 20 kHz and 60 kHz. See the following sections for further details.

18

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

270

Duty Cycle %

Gain Phase

10

30

50

70

90

80

180

60

135

40

90

Gain - dB

225

180

135

90

40

45

45

20

20

0

0

0

0

-45

-20

100

1k

10 k

100 k

f - Frequency -Hz

-45

-90

1M

-20

100

85

225

180

70

180

135

55

135

40

90

225

40

90

45

Gain - dB

Gain - dB

60

25

45

20

0

Duty Cycle %

Gain Phase

10

30

50

70

90

10

0

-45

-20

100

1k

10 k

100 k

f - Frequency -Hz

-90

1M

270

Phase - °

80

100 k

100

270

Duty Cycle %

Gain Phase

10

30

50

70

90

10 k

Figure 25. Gain and Phase vs Frequency. TPS54383 at

400-mApp Ripple Current

Figure 24. Gain and Phase vs Frequency. TPS54383 at

200-mApp Ripple Current

100

1k

-90

1M

Figure 26. Gain and Phase vs Frequency. TPS54383 at

600-mApp Ripple Current

Phase - °

Gain - dB

60

Duty Cycle %

Gain Phase

10

30

50

70

90

225

Phase - °

80

270

100

Phase - °

100

-5

-20

100

1k

0

-45

10 k

100 k

f - Frequency - Hz

-90

1M

Figure 27. Gain and Phase vs Frequency. TPS54386 at

200-mApp Ripple Current

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

19

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

100

www.ti.com

100

270

85

225

180

70

180

135

55

135

40

90

270

225

90

45

20

Duty Cycle %

Gain Phase

10

30

50

70

90

0

-20

100

1k

0

-45

10 k

100 k

f - Frequency -Hz

-90

1M

Figure 28. Gain and Phase vs Frequency. TPS54386 at

400-mApp Ripple Current

45

25

Duty Cycle %

Gain Phase

10

30

50

70

90

10

-5

-20

100

1k

Phase - °

40

Gain - dB

Gain - dB

60

Phase - °

80

0

-45

10 k

100 k

f - Frequency - Hz

-90

1M

Figure 29. Gain and Phase vs Frequency. TPS54386 at

600-mApp Ripple Current

8.3.10 Maximum Output Capacitance

With internal pulse-by-pulse current limiting and a fixed soft-start time, there is a maximum output capacitance

which may be used before startup problems begin to occur. If the output capacitance is large enough so that the

device enters a current limit protection mode during startup, then there is a possibility that the output will never

reach regulation. Instead, the TPS5438x simply shuts down and attempts a restart as if the output were shortcircuited to ground. The maximum output capacitance (including bypass capacitance distributed at the load) is

given by Equation 3:

R1

VREF (1 + R2 ) ´ TS

tSS

R1

1

+

)

COUTmax =

ICLx - VREF (1 + R2 ) (1 RLOAD

VREF

2 ´ VIN ´ L

(3)

8.3.11 Minimum Output Capacitance

Ensure the value of capacitance selected for closed loop stability is compatible with the requirements of SoftStart .

8.3.12 Modifying The Feedback Loop

Within the limits of the internal compensation, there is flexibility in the selection of the inductor and output

capacitor values. A smaller inductor increases ripple current, and raises the resonant frequency, thereby

incerasing the required amount of output capacitance. A smaller capacitor could also be used, increasing the

resonant frequency, and increasing the overall loop bandwidth—perhaps at the expense of adequate phase

margin.

The internal compensation of the TPS54x8x is designed for capacitors with an ESR zero frequency between

20kHz and 60kHz. It is possible, with additional feedback compensation components, to use capacitors with

higher or lower ESR zero frequencies. For either case, the components C1 and R3 (ref.Figure 30 ) are added to

re-compensate the feedback loop for stability. In this configuration a low frequency pole is followed by a higher

frequency zero. The placement of this pole-zero pair is dependent on the type of output capacitor used, and the

desired closed loop frequency response.

20

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

TPS5438x

1

PVDD1

PVDD2 14

2

BOOT1

BOOT2 13

3

SW1

SW2 12

4

GND

BP 11

5

EN1

SEQ 10

6

EN2

ILIM2

9

7

FB1

FB2

8

OUTPUT1

C2

R1

C1

R2

R3

UDG-07013

Figure 30. Optional Loop Compensation Components

NOTE

Once the filter and compensation components have been established, laboratory

measurements of the physical design should be performed to confirm converter stability.

8.3.12.1 Using High-ESR Output Capacitors

If a high-ESR capacitor is used in the output filter, a zero appears in the loop response that could lead to

instability. To compensate, a small R-C series connected network is placed in parallel with the lower voltage

setting divider resistor (see Figure 30). The values of the components are determined such that a pole is placed

at the same frequency as the ESR zero and a new zero is placed at a frequency location conducive to good loop

stability.

The value of the resistor is calculated using a ratio of impedances to match the ratio of ESR zero frequency to

the desired zero frequency.

R3 =

R2

æ æ fZERO(desired)

çç

ç ç fESR(zero)

èè

ö ö

÷ - 1÷

÷ ÷

ø ø

where:

•

•

f ESR(zero) is the ESR zero frequency of the output capacitor.

f ZERO(desired) is the desired frequency of the zero added to the feedback. This frequency should be placed

between 20 kHz and 60 kHz to ensure good loop stability.

(4)

The value of the capacitor is calculated in Equation 5.

C1 =

1

2p ´ REQ ´ fESR(zero)

where:

•

REQ is an equivalent impedance created by the parallel combination of the voltage setting divider resistors (R1

and R2) in series with R3.

(5)

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

21

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

REQ = R3 +

www.ti.com

1

ææ 1 ö æ 1 öö

çç ÷ + ç

÷÷

è è R1 ø è R2 ø ø

(6)

8.3.12.2 Using All Ceramic Output Capacitors

With low ESR ceramic capacitors, there may not be enough phase margin at the crossover frequency. In this

case, (see Figure 30) resistor R3 is set equal to 1/2 R2. This lowers the gain by 6 dB, reduce the crossover

frequency, and improve phase margin.

The value of C1 is found by determining the frequency to place the low frequency pole. The minimum frequency

to place the pole is 1 kHz. Any lower, and the time constant will be too slow and interfere with the internal softstart (see Soft-Start). The upper bound for the pole frequency is determined by the operating frequency of the

converter. It is 3 kHz for the TPS54x83, and 6 kHz for the TPS54x86. C1 is then found from Equation 7. Keep

component tolerances in mind when selecting the desired pole frequency.

C1 =

1

2p ´ REQ ´ fPOLE(desired)

where:

•

•

f POLE(desired)is the desired pole frequency between 1 kHz and 3 kHz (TPS54x83) or 1 kHz and 6 kHz

(TPS54x86).

REQ is an equivalent impedance created by the parallel combination of the voltage setting divider resistors (R1

and R2) in series with R3.

(7)

REQ = R3 +

1

ææ 1 ö æ 1 öö

çç ÷ + ç

÷÷

è è R1 ø è R2 ø ø

(8)

If it is necessary to increase phase margin, place a capacitor in parallel with the upper voltage setting divider

resistor (Ref. C2 in Equation 9).

C2 =

1

R1

´ 1+

2p ´ fC ´ R1

æ (R2 ´ R3 ) ö

çç

÷÷

è (R2 + R3 ) ø

where

•

f

C

is the unity gain crossover frequency, (approximately 50 kHz for most designs following these guidelines)

(9)

8.3.13 Example: TPS54386 Buck Converter Operating at 12-V Input, 3.3-V Output and 400-mA(P-P) Ripple

Current

First, the steady state duty cycle is calculated. Assuming the rectifier diode has a voltage drop of 0.5 V, the duty

cycle is approximated using Equation 10.

VOUT + VDIODE

3.3 + 0.5

= 30%

d=

=

VIN + VDIODE

12 + 0.5

(10)

The filter inductor is then calculated; see Equation 11.

V - VOUT

12 - 3.3

1

L = IN

´ d ´ TS =

´ 0.3 ´

= 10.9 mH

0.4

600000

DIL

22

Submit Documentation Feedback

(11)

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

A custom-designed inductor may be used for the application, or a standard value close to the calculated value

may be used. For this example, a standard 10-μH inductor is used. Using Figure 28, find the 30% duty cycle

curve. The 30% duty cycle curve has a down slope from low frequency and rises at approximately 6 kHz. This

curve is the resonant frequency that must be compensated. Any frequency wthin an octave of the peak may be

used in calculating the capacitor value. In this example, 6 kHz is used.

1

C=

2

L ´ (2 ´ p ´ fRES )

1

=

10 ´ 10

-6

2

= 70 mF

´ (2 ´ 3.14 ´ 6000 )

(12)

A 68-μF capacitor should be used as a bulk capacitor, with up to 10 μF of ceramic bypass capacitance. To

ensure the ESR zero does not significantly impact the loop response, the ESR of the bulk capacitor should be

placed a decade above the resonant frequency.

RESR <

1

1

=

» 40 mW

2 ´ p ´ 10 ´ fRES ´ C 2 ´ 3.14 ´ 10 ´ 6000 ´ 68 ´ (10 )-6

(13)

The resulting loop gain and phase are shown in Figure 31. Based on measurement, loop crossover is 45 kHz

with a phase margin of 60 degrees.

80

180

70

135

Phase

60

90

45

40

0

30

20

Phase - °

Gain - dB

50

-45

10

-90

0

Gain

-135

-10

-20

100

1k

10 k

100 k

f - Frequency - Hz

-180

1M

Figure 31. Gain and Phase vs Frequency. Example Loop Result

8.3.14 Bootstrap for the N-Channel MOSFET

A bootstrap circuit provides a voltage source higher than the input voltage and of sufficient energy to fully

enhance the switching MOSFET each switching cycle. The PWM duty cycle is limited to a maximum of 90%,

allowing an external bootstrap capacitor to charge through an internal synchronous switch (between BP and

BOOTx) during every cycle. When the PWM switch is commanded to turn ON, the energy used to drive the

MOSFET gate is derived from the voltage on this capacitor.

To allow the bootstrap capacitor to charge each switching cycle, an internal pulldown MOSFET (from SW to

GND) is turned ON for approximately 140 ns at the beginning of each switching cycle. In this way, if, during light

load operation, there is insufficient energy for the SW node to drive to ground naturally, this MOSFET forces the

SW node toward ground and allow the bootstrap capacitor to charge.

Because this is a charge transfer circuit, care must be taken in selecting the value of the bootstrap capacitor. It

must be sized such that the energy stored in the capacitor on a per cycle basis is greater than the gate charge

requirement of the MOSFET being used.

DESIGN HINT

For the bootstrap capacitor, use a ceramic capacitor with a value between 22 nF and 82

nF.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

23

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

NOTE

For 5-V input applications, connect PVDDx to BP directly. This connection bypasses the

internal control circuit regulator and provides maximum voltage to the gate drive circuitry.

In this configuration, shutdown mode IDDSDN will be the same as quiescent IDDQ.

8.3.15 Light Load Operation

There is no special circuitry for pulse skipping at light loads. The normal characteristic of a nonsynchronous

converter is to operate in the discontinuous conduction mode (DCM) at an average load current less than onehalf of the inductor peak-to-peak ripple current. Note that the amplitude of the ripple current is a function of input

voltage, output voltage, inductor value, and operating frequency, as shown in Equation 14.

1 VIN - VOUT

IDCM = ´

´ d ´ TS

2

L

(14)

Further, during discontinuous mode operation the commanded pulse width may become narrower than the

capability of the converter to resolve. To maintain the output voltage within regulation, skipping switching pulses

at light load conditions is a natural by-product of that mode. This condition may occur if the output capacitor is

charged to a value greater than the output regulation voltage, and there is insufficient load to discharge the

capacitor. A by-product of pulse skipping is an increase in the peak-to-peak output ripple voltage.

SW Waveform

SW Waveform

VOUT

Ripple

VOUT

Ripple

Skipping

VIN = 12 V

VOUT = 5 V

Inductor

Current

Steady State

VIN = 12 V

VOUT = 5 V

Inductor

Current

Figure 32. Steady State

Figure 33. Skipping

DESIGN HINT

If additional output capacitance is required to reduce the output voltage ripple during DCM

operation, be sure to recheck Feedback Loop and Inductor-Capacitor (L-C) Filter Selection

and Maximum Output Capacitance sections.

8.3.16 SW Node Ringing

A portion of the control circuitry is referenced to the SW node. To ensure jitter-free operation, it is necessary to

decrease the voltage waveform ringing at the SW node to less than 5 volts peak and of a duration of less than

30-ns. In addition to following good printed circuit board (PCB) layout practices, there are a couple of design

techniques for reducing ringing and noise.

8.3.16.1 SW Node Snubber

Voltage ringing observable at the SW node is caused by fast switching edges and parasitic inductance and

capacitance. If the ringing results in excessive voltage on the SW node, or erratic operation of the converter, an

R-C snubber may be used to dampen the ringing and ensure proper operation over the full load range.

24

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

DESIGN HINT

A series-connected R-C snubber (C = between 330 pF and 1 nF, R = 10 Ω) connected

from SW to GND reduces the ringing on the SW node.

8.3.16.2 Bootstrap Resistor

A small resistor in series with the bootstrap capacitor reduces the turn-on time of the internal MOSFET, thereby

reducing the rising edge ringing of the SW node.

DESIGN HINT

A resistor with a value between 1Ω and 3Ω may be placed in series with the bootstrap

capacitor to reduce ringing on the SW node.

DESIGN HINT

Placeholders for these components should be placed on the initial prototype PCBs in case

they are needed.

8.3.17 Output Overload Protection

In the event of an overcurrent during soft-start on either output (such as starting into an output short), pulse-bypulse current limiting and PWM frequency division are in effect for that output until the internal soft-start timer

ends. At the end of the soft-start time, a UV condition is declared and a fault is declared. During this fault

condition, both PWM outputs are disabled and the small pulldown MOSFETs (from SWx to GND) are turned ON.

This process ensures that both outputs discharge to GND in the event that overcurrent is on one output while the

other is not loaded. The converter then enters a hiccup mode timeout before attempting to restart. "Frequency

Division" means if an overcurrent pulse is detected, six clock cycles are skipped before a next PWM pulse is

initiated, effectively dividing the operating frequency by six and preventing excessive current build up in the

inductor.

In the event of an overcurrent on either output after the output reaches regulation, pulse-by-pulse current limit is

in effect for that output. In addition, an output undervoltage (UV) comparator monitors the FBx voltage (that

follows the output voltage) to declare a fault if the output drops below 85% of regulation. During this fault

condition, both PWM outputs are disabled and the small pulldown MOSFETs (from SWx to GND) are turned ON.

This design ensures that both outputs discharge to GND, in the event that overcurrent is on one output while the

other is not loaded. The converter then enters a hiccup mode timeout before attempting to restart.

The overcurrent threshold for Output 1 is set nominally at 4.5 A. The overcurrent level of Output 2 is determined

by the state of the ILIM2 pin. The ILIM setting of Output 2 is not latched in place and may be changed during

operation of the converter.

Table 2. Current Limit Threshold Adjustment for

Output 2

ILIM2 Connection

OCP Threshold for Output 2

BP

4.5 A nominal setting

(floating)

3.0 A nominal setting

GND

1.5 A nominal setting

DESIGN HINT

The OCP threshold refers to the peak current in the internal switch. Be sure to add onehalf of the peak inductor ripple current to the dc load current in determining how close the

actual operating point is to the OCP threshold

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

25

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

8.3.18 Operating Near Maximum Duty Cycle

If the TPS5438x operates at maximum duty cycle, and if the input voltage is insufficient to support the output

voltage (at full load or during a load current transient), then there is a possibility that the output voltage will fall

from regulation and trip the output UV comparator. If this should occur, the TPS5438x protection circuitry will

declare a fault and enter a shut down-and-restart cycle.

DESIGN HINT

Ensure that under ALL conditions of line and load regulation, there is sufficient duty cycle

to maintain output voltage regulation.

To calculate the operating duty cycle, use Equation 15.

d=

VOUT + VDIODE

VIN + VDIODE

where

•

VDIODE is the voltage drop of the rectifier diode

(15)

8.3.19 Dual Supply Operation

It is possible to operate a TPS5438x from two supply voltages. If this application is desired, then the sequencing

of the supplies must be such that PVDD2 is above the UVLO voltage before PVDD1 begins to rise. This level

requirement ensures that the internal regulator and the control circuitry are in operation before PVDD1 supplies

energy to the output. In addition, Output 1 must be held in the disabled state (EN1 high) until there is sufficient

voltage on PVDD1 to support Output 1 in regulation. (See the Operating Near Maximum Duty Cycle section.)

The preferred sequence of events is:

1. PVDD2 rises above the input UVLO voltage

2. PVDD1 rises with Output 1 disabled until PVDD1 rises above level to support Output 1 regulation.

With these two conditions satisfied, there is no restriction on PVDD2 to be greater than, or less than PVDD1.

DESIGN HINT

An R-C delay on EN1 may be used to delay the startup of Output1 for a long enough

period of time to ensure that PVDD1 can support Output 1 load.

8.3.20 Cascading Supply Operation

It is possible to source PVDD1 from Output 2 as depicted in Figure 34 and Figure 35. This configuration may be

preferred if the input voltage is high, relative to the voltage on Output 1.

26

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

VIN

TPS54383

1

PVDD1

PVDD2 14

2

BOOT1

BOOT2 13

3

SW1

SW2 12

4

GND

BP 11

5

EN1

SEQ 10

6

EN2

ILIM2

9

7

FB1

FB2

8

OUTPUT2

OUTPUT1

UDG-07015

Figure 34. Schematic Showing Cascading PVDD1 from Output 2

PVDD2

Output2

PVDD1

Output1

T - Time

Figure 35. Waveforms Resulting from Cascading PVDD1 from Output 2

In this configuration, the following conditions must be maintained:

1. Output 2 must be of a voltage high enough to maintain regulation of Output 1 under all load conditions.

2. The sum of the current drawn by Output 2 load plus the current into PVDD1 must be less than the overload

protection current level of Output 2.

3. The method of output sequencing must be such that the voltage on Output 2 is sufficient to support Output 1

before Output 1 is enabled. This requrement may be accomplished by:

(a) a delay of the enable function

(b) selecting sequential sequencing of Output 1 starting after Output 2 is in regulation

8.3.21 Multiphase Operation

The TPS5438x is not designed to operate as a two-channel multiphase converter. See http://www.power.ti.com

for appropriate device selection.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

27

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

8.3.22 Bypass and FIltering

As with any integrated circuit, supply bypassing is important for jitter-free operation. To improve the noise

immunity of the converter, ceramic bypass capacitors must be placed as close to the package as possible.

1. PVDD1 to GND: Use a 10-μF ceramic capacitor

2. PVDD2 to GND: Use a 10-μF ceramic capacitor

3. BP to GND: Use a 4.7-μF to 10-μF ceramic capacitor

8.3.23 Overtemperature Protection and Junction Temperature Rise

The overtemperature thermal protection limits the maximum power to be dissipated at a given operating ambient

temperature. In other words, at a given device power dissipation, the maximum ambient operating temperature is

limited by the maximum allowable junction operating temperature. The device junction temperature is a function

of power dissipation, and the thermal impedance from the junction to the ambient. If the internal die temperature

should reach the thermal shutdown level, the TPS5438x shuts off both PWMs and remains in this state until the

die temperature drops below the hysteresis value, at which time the device restarts.

The first step to determine the device junction temperature is to calculate the power dissipation. The power

dissipation is dominated by the two switching MOSFETs and the BP internal regulator. The power dissipated by

each MOSFET is composed of conduction losses and output (switching) losses incurred while driving the

external rectifier diode. To find the conduction loss, first find the RMS current through the upper switch MOSFET.

2

æ

æ (D I

2

OUTPUTx )

IRMS(outputx) = D ´ ç (IOUTPUTx ) + ç

çç

ç

12

è

è

öö

÷÷

÷ ÷÷

øø

where

•

•

•

D is the duty cycle

IOUTPUTx is the dc output current

ΔIOUTPUTx is the peak ripple current in the inductor for Outputx

(16)

Notice the impact of the operating duty cycle on the result.

Multiplying the result by the RDS(on) of the MOSFET gives the conduction loss.

PD(cond) = IRMS(outputx)2 ´ RDS(on)

(17)

The switching loss is approximated by:

2

PD(SW) =

(VIN) ´ CJ ´ fS

2

where

•

•

where CJ is the prallel capacitance of the rectifier diode and snubber (if any)

fS is the switching frequency

(18)

The total power dissipation is found by summing the power loss for both MOSFETs plus the loss in the internal

regulator.

PD = PD(cond)output1 + PD(SW )output1 + PD(cond)output2 + PD(SW )output2 + VIN ´ Iq

(19)

The temperature rise of the device junction depends on the thermal impedance from junction to the mounting pad

(See the Thermal Information table for performance on the standard test board), plus the thermal impedance

from the thermal pad to ambient. The thermal impedance from the thermal pad to ambient depends on the PCB

layout (PowerPAD interface to the PCB, the exposed pad area) and airflow (if any). See the Layout Guidelines

section.

The operating junction temperature is shown in Equation 20.

(

TJ = TA + PD ´ qTH(pkg) + qTH(pad-amb)

28

Submit Documentation Feedback

)

(20)

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

8.3.24 Power Derating

The TPS5438x delivers full current at ambient temperatures up to +85°C if the thermal impedance from the

thermal pad maintains the junction temperature below the thermal shutdown level. At higher ambient

temperatures, the device power dissipation must be reduced to maintain the junction temperature at or below the

thermal shutdown level. Figure 36 illustrates the power derating for elevated ambient temperature under various

airflow conditions. Note that these curves assume that the PowerPAD is properly soldered to the recommended

thermal pad. (See the Related Documentation section for further information.)

1.8

LFM = 250

1.6

PD - Power Dissipation - W

LFM = 500

1.4

LFM = 0

1.2

LFM = 150

1.0

0.8

0.6

LFM

0

150

250

500

0.4

0.2

0

0

20

40

60

80

100

120

TA - Ambient Temperature - °C

140

Figure 36. Power Dissipation vs Ambient Temperature. Power Derating Curves

8.4 Device Functional Modes

8.4.1 Minimum Input Voltage

The TPS5438x is recommended to operate with input voltages above 4.5 V. The typical UVLO threshold is 4.1 V

at PVDD2 and the device may operate at PVDD2 voltages down to the UVLO voltage. PVDD2 is used for input

voltage UVLO protection because it is the power supply for the BP regulator. The device will operate with PVDD1

voltages even lower as long as PVDD2 is above its UVLO threshold. With VPVDD2 below the UVLO voltage

threshold the device will not switch. If either ENx pins is pulled below 0.9 V, when VPVDD2 passes the UVLO

threshold the BP regulator turns on and begins charging the BP capacitor. After VBP is greater than 4 V,

depending on the state of the SEQ pin, the channel corresponding to the low ENx pin will become active. When

a channel becomes active switching is enabled and the soft-start sequence is initiated. The TPS5438x starts

linearly ramping up an internal soft-start reference voltage of the active channel from 0 V to its final value over

the internal soft-start time period. The designer should make sure the input voltage is sufficient to support the

output voltage of the active channels.

8.4.2 ENx Control

The enable start threshold voltage is 1.2 V typical. With ENx held above the 1.2 V threshold voltage the

correspondeng cahnnel of the TPS548x is disabled and switching is inhibited even if PVDD2 is above its UVLO

threshold. The quiescent current is reduced in this state. When the first ENx pin voltage is decreased below the

threshold while V(PVDD2) is above the UVLO threshold the BP regulator turns on and begins charging the BP

capacitor. After VBP is greater than 4 V, depending on the state of the SEQ pin, the channel corresponding to the

low ENx pin will become active. If the second ENx pin voltage is decreased below the threshold after VBP is

greater than 4 V, again depending on the state of the SEQ pin, the corresponding channel will become active

immediately. When a channel becomes active switching is enabled and the slow-start sequence is initiated. The

TPS548x starts linearly ramping up the internal soft-start reference voltage of the active channel from 0 V to its

final value over the internal slow-start time period. If both channels are active the start-up sequence is

deteremined by the stat of the SEQ pin. The designer should make sure the input voltage is sufficient to support

the output voltageof the active channels.

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

29

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

www.ti.com

9 Applications and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

The TPS5438x is a dual 28-V, 3-A, step down regulator with an integrated high-side MOSFETs. This device is

typically used to convert a higher DC voltage to a lower DC voltage with a maximum available output current of 3

A on each channel. Example applications are: High Density Point-of-Load Regulators for Set-top Box, Digital TV,

Power for DSP and other Consumer Electronics.

9.2 Typical Applications

9.2.1 12-V to 5-V and 3.3-V Converter

The following example illustrates a design process and component selection for a 12-V to 5-V and 3.3-V dual

non-synchronous buck regulator using the TPS54383 converter.

+

+

+

Figure 37. Design Example Schematic

9.2.1.1 Design Requirements

PARAMETER

NOTES AND CONDITIONS

MIN

NOM

MAX

UNIT

6.9

V

INPUT CHARACTERISTICS

VIN

Input voltage

12.0

13.2

IIN

Input current

VIN = nom, IOUT = max

1.6

2.0

A

No load input current

VIN = nom, IOUT = 0 A

12

20

mA

OUTPUT CHARACTERISTICS

VOUT1

Output voltage 1

VIN = nom, IOUT = nom

4.8

5.0

5.2

VOUT2

Output voltage 2

VIN = nom, IOUT = nom

3.2

3.3

3.4

Line regulation

VIN = min to max

1%

Load regulation

IOUT = min to max

1%

30

Submit Documentation Feedback

V

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

Typical Applications (continued)

PARAMETER

VOUT(ripple

NOTES AND CONDITIONS

MIN

NOM

MAX

UNIT

50

mVPP

Output voltage ripple

VIN = nom, IOUT = max

IOUT1

Output current 1

VIN = min to max

0

2.0

IOUT2

Output current 2

VIN = min to max

0

2.0

IOCP1

Output overcurrent channel

1

VIN = nom, VOUT = VOUT1 = 5%

2.4

3

3.5

IOCP2

Output overcurrent channel

2

VIN = nom, VOUT = VOUT2 = 5%

2.4

3

3.5

Transient response ΔVOUT

from load transient

ΔIOUT = 1 A @ 3 A/μs

)

A

200

mV

1

ms

Transient response settling

time

SYSTEM CHARACTERISTICS

fSW

Switching frequency

η

Full load efficiency

250

TJ

Operating temperature

range

310

370

kHz

60

°C

85%

0

25

Table 3. Design Example List of Materials

QTY

REFERENCE

DESIGNATOR

VALUE

DESCRIPTION

SIZE

PART NUMBER

MANUFACTURER

1

C1

100 μF

Capacitor, Aluminum, 25V, 20%

E-can

EEEFC1E101P

2

C10, C11

10 μF

Capacitor, Ceramic, 25V, X5R 20%

1210

C3216X5R1E106M TDK

1

C12

4.7 μF

Capacitor, Ceramic, 10V, X5R 20%

0805

Std

Std

2

C14, C16

470 pF

Capacitor, Ceramic, 25V, X7R, 20%

0603

Std

Std

1

C15

6.8 nF

Capacitor, Ceramic, 25V, X7R, 20%

0603

Std

Std

100 μF

Capacitor, Aluminum, 10V, 20%, FC

Series

F-can

EEEFC1A101P

Panasonic

Panasonic

1

C17, C5

4

C3, C4, C18, C19 10 μF

Capacitor, Ceramic, 6.3V, X5R 20%

0805

C2012X5R0J106M

TDK

1

C8

10 nF

Capacitor, Ceramic, 25V, X7R, 20%

0603

Std

Std

2

C9, C13

0.033 μF

Capacitor, Ceramic, 25V, X7R, 20%

0603

Std

Std

2

D1, D2

MBRS320

Diode, Schottky, 3-A, 30-V

SMC

MBRS330T3

On Semi

MSS1278-153ML

Coilcraft

2

L1, L2

22 μH

Inductor, Power, 6.8A, 0.038 Ω

0.484 x

0.484

2

R2, R9

20 kΩ

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

R5

422 Ω

Resistor, Chip, 1/16W, 1%

0603

Std

Std

2

R6, R10

10 Ω

Resistor, Chip, 1/16W, 5%

0603

Std

Std

1

R8

698 Ω

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

R4

3.83 kΩ

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

R7

6.34 kΩ

Resistor, Chip, 1/16W, 1%

0603

Std

Std

TPS54383 DC-DC Switching Converter

w/ FET

HTSSOP

TPS54383PWP

-14

1

U1

TI

9.2.1.2 Detailed Design Procedure

Use the following design procedure to select component values for the TPS5438x.

9.2.1.2.1 Duty Cycle Estimation

The first step is to estimate the duty cycle of each switching FET.

Dmax »

VOUT + VFD

VIN(min) + VFD

(21)

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

31

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

Dmin »

www.ti.com

VOUT + VFD

VIN(max) + VFD

(22)

Using an assumed forward drop of 0.5 V for a schottky rectifier diode, the Channel 1 duty cycle is approximately

40.1% (minimum) to 48.7% (maximum) while the Channel 2 duty cycle is approximately 27.7% (minimum) to

32.2% (maximum).

9.2.1.2.2 Inductor Selection

The peak-to-peak ripple is limited to 30% of the maximum output current. This places the peak current far

enough from the minimum overcurrent trip level to ensure reliable operation.

For both Channel 1 and Channel 2, the maximum inductor ripple current is 600 mA. The inductor size is

estimated in Equation 23.

L min »

VIN(max) - VOUT

1

´ D min ´

ILRIP(max)

fSW

(23)

The inductor values are

• L1 = 18.3 μH

• L2 = 15.3 μH

The next higher standard inductor value of 22 μH is used for both inductors.

The resulting ripple currents are :

IRIPPLE »

VIN(max) - VOUT

L

´ Dmin ´

1

fSW

(24)

Peak-to-peak ripple currents of 0.498 A and 0.416 A are estimated for Channel 1 and Channel 2 respectively.

The RMS current through an inductor is approximated by Equation 25.

IL(rms ) =

(IL(avg) ) + 121 (IRIPPLE )2

2

(25)

and is approximately 2.0 A for both channels.

The peak inductor current is found using:

IL(peak ) » IOUT(max) +

1

IRIPPLE

2

(26)

An inductor with a minimum RMS current rating of 2.0 A and minimum saturation current rating of 2.25 A is

required. A Coilcraft MSS1278-223ML 22-μH, 6.8-A inductor is selected.

9.2.1.2.3 Rectifier Diode Selection

A schottky diode is selected as a rectifier diode for its low forward voltage drop. Allowing 20% over VIN for

ringing on the switch node, the required minimum reverse break-down voltage of the rectifier diode is:

V(BR )R(min ) ³ 1.2 ´ VIN

(27)

The diode must have reverse breakdown voltage greater than 15.8 V, therefore a 20-V device is used.

The average current in the rectifier diode is estimated by Equation 28.

ID(avg) » IOUT(max ) ´ (1 - D )

(28)

For this design, 1.2-A (average) and 2.25 A (peak) is estimated for Channel 1 and 1.5-A (average) and 2.21-A

(peak) for Channel 2.

32

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

An MBRS320, 20-V, 3-A diode in an SMC package is selected for both channels. This diode has a forward

voltage drop of 0.4 V at 2 A.

The power dissipation in the diode is estimated by Equation 29.

PD (m ax ) » VFM ´ ID (avg )

(29)

For this design, the full load power dissipation is estimated to be 480 mW in D1, and 580 mW in D2.

9.2.1.2.4 Output Capacitor Selection

The TPS54383's internal compensation limits the selection of the output capacitors. From Figure 25, the internal

compensation has a double zero resonance at about 3 kHz. The output capacitor is selected by Equation 30.

COUT =

1

2

2

4 ´ p ´ (fRES ) ´ L

(30)

Solving for COUT using

• fRES = 3 kHz

• L = 22 μH

The resulting is COUT = 128 μF. The output ripple voltage of the converter is composed of the ripple voltage

across the output capacitance and the ripple voltage across the ESR of the output capacitor. To find the

maximum ESR allowable to meet the output ripple requirements the total ripple is partitioned, and the equation

manipulated to find the ESR.

ESR(max) =

VRIPPLE(tot) - VRIPPLE(cap)

IRIPPLE

=

VRIPPLE(tot)

IRIPPLE

-

D

fS ´ C OUT

(31)

Based on 128 μF of capacitance, 300-kHz switching frequency and 50-mV ripple voltage plus rounding up the

ripple current to 0.5 A, and the duty cycle to 50%, the capacitive portion of the ripple voltage is 6.5 mV, leaving a

maximum allowable ESR of 87 mΩ.

To meet the ripple voltage requirements, a low-cost 100-μF electrolytic capacitor with 400 mΩ ESR (C5, C17)

and two 10-μF ceramic capacitors (C3 and C4; and C18 and C19) with 2.5-mΩ ESR are selected. From the

datasheets for the ceramic capacitors, the parallel combination provides an impedance of 28 mΩ @ 300 kHz for

14 mV of ripple.

9.2.1.2.5 Voltage Setting

The primary feedback divider resistors (R2, R9) from VOUT to FB should be between 10 kΩ and 50 kΩ to

maintain a balance between power dissipation and noise sensitivity. For this design, 20 kΩ is selected.

The lower resistors, R4 and R7 are found using the following equations.

R4 =

R7 =

•

•

•

•

VFB ´ R2

VOUT1 - VFB

(32)

VFB ´ R9

VOUT2 - VFB

(33)

R2 = R9 = 20 kΩ

VFB = 0.80 V

R4= 3.80 kΩ (3.83 kΩ standard value is used)

R7= 6.40 kΩ (6.34 kΩ standard value is used)

9.2.1.2.6 Compensation Capacitors

Checking the ESR zero of the output capacitors:

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

Submit Documentation Feedback

33

�TPS54383, TPS54386

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

fESR(zero) =

•

•

•

www.ti.com

1

2 ´ p ´ C ´ ESR

C = 100 μF

ESR = 400 mΩ

ESR(zero) = 3980 Hz

(34)

Since the ESR zero of the main output capacitor is less than 20 kHz, an R-C filter is added in parallel with R4

and R7 to compensate for the electrolytic capacitors' ESR and add a zero approximately 40 kHz.

R5 =

•

•

•

•

•

•

R4

æ æ fZERO(desired)

çç

ç ç fESR(zero)

èè

fESR(zero) = 4 kHz

fESR(desired) = 40 kHz

R4 = 3.83 kΩ

R5 = 424Ω (422Ω selected)

R7 = 6.34 kΩ

R8 = 702Ω (698Ω selected)

REQ = R5 +

•

•

•

C8 =

•

•

ö ö

÷ - 1÷

÷ ÷

ø ø

(35)

1

ææ 1 ö æ 1 öö

çç

÷+ç

÷÷

è è R2 ø è R4 ø ø

R2 = R9 = 20 kΩ

REQ1 = 3.63 kΩ

REQ2 = 5.51 kΩ

(36)

1

2 ´ p ´ REQ ´ fESR(zero)

C8 = 10.9 nF (10 nF selected)

C15 = 7.22 nF (6800 pF selected)

(37)

9.2.1.2.7 Input Capacitor Selection

The TPS54383 datasheet recommends a minimum 10-μF ceramic input capacitor on each PVDD pin. These

capacitor must be capable of handling the RMS ripple current of the converter. The RMS current in the input

capacitors is estimated by Equation 38.

2

æ

æ

2 ç (D IOUTPUTx )

ç

IRMS(outputx) = D ´ (IOUTPUTx ) +

çç

ç

12

è

è

•

öö

÷÷

÷ ÷÷

øø

(38)

IRMS(CIN) = 0.43 A

One 1210 10-μF, 25 V, X5R ceramic capacitor with 2-mΩ ESR and a 2-A RMS current rating are selected for

each PVDD input. Higher voltage capacitors are selected to minimize capacitance loss at the DC bias voltage to

ensure the capacitors maintain sufficient capacitance at the working voltage.

9.2.1.2.8 Boot Strap Capacitor

To ensure proper charging of the high-side FET gate and limit the ripple voltage on the boost capacitor, a 33-nF

boot strap capacitor is used.

9.2.1.2.9 ILIM

Current limit must be set above the peak inductor current IL(peak). Comparing IL(peak) to the available minimum

current limits, ILIM is connected to BP for the highest current limit level.

34

Submit Documentation Feedback

Copyright © 2007–2014, Texas Instruments Incorporated

Product Folder Links: TPS54383 TPS54386

�TPS54383, TPS54386

www.ti.com

SLUS774C – AUGUST 2007 – REVISED DECEMBER 2014

9.2.1.2.10 SEQ

The SEQ pin is left floating, leaving the enable pins to function independently. If the enable pins are tied

together, the two supplies start-up ratiometrically. Alternatively, SEQ could be connected to BP or GND to

provide sequential start-up.

9.2.1.2.11 Power Dissipation

The power dissipation in the TPS54383 is composed of FET conduction losses, switching losses and internal

regulator losses. The RMS FET current is found using Equation 39.

2

æ

æ

2 ç (D IOUTPUTx )

ç

IRMS(outputx) = D ´ (IOUTPUTx ) +

çç

ç

12

è

è

öö

÷÷

÷ ÷÷

øø

(39)

This results in 1.05-A RMS for Channel 1 and 0.87-A RMS for Channel 2.

Conduction losses are estimated by:

2

(

PCON = RDS(on ) ´ IQSW (rms )

)

(40)

Conduction losses of 198 mW and 136 mW are estimated for Channel 1 and Channel 2 respectively.

The switching losses are estimated in Equation 41.

PSW

(V

»

IN(max

2

) ) ´ (C

DJ

+ COSS )´ fSW

2

(41)