www.ti.com

Table of Contents

User’s Guide

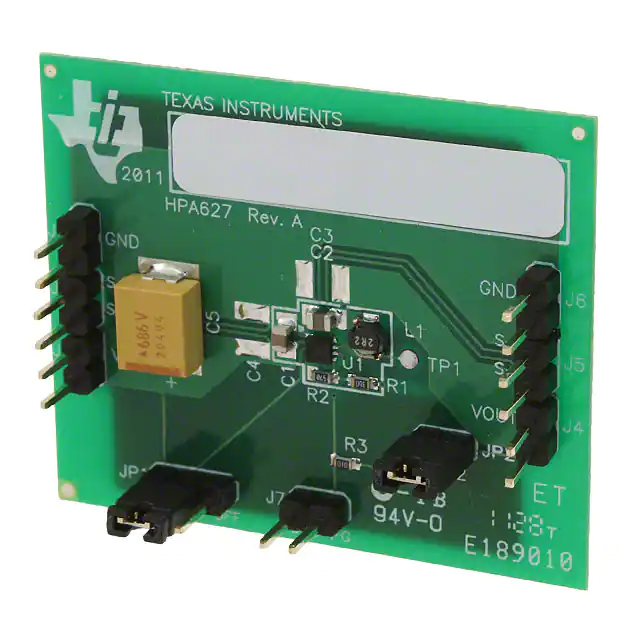

TPS621x0 Buck Converter Evaluation Module User's

Guide

ABSTRACT

This user’s guide describes the characteristics, operation, and use of the Texas Instruments TPS62160 and

TPS62170 evaluation modules (EVM). These EVMs are designed to help the user easily evaluate and test the

operation and functionality of the TPS62160 and TPS62170. This user’s guide includes setup instructions for the

hardware, printed-circuit board layouts for the EVMs, a schematic diagram, a bill of materials, and test results for

the EVMs.

Table of Contents

1 Introduction.............................................................................................................................................................................2

1.1 Background........................................................................................................................................................................ 2

1.2 Performance Specification................................................................................................................................................. 2

1.3 Modifications...................................................................................................................................................................... 2

2 Setup........................................................................................................................................................................................4

2.1 Input/Output Connector Descriptions................................................................................................................................. 4

2.2 Setup..................................................................................................................................................................................4

3 TPS621x0EVM-627 Test Results............................................................................................................................................5

4 Board Layout......................................................................................................................................................................... 11

5 Schematic and Bill of Materials...........................................................................................................................................13

5.1 Schematic........................................................................................................................................................................ 13

5.2 Bill of Materials.................................................................................................................................................................14

6 Revision History................................................................................................................................................................... 14

List of Figures

Figure 1-1. Loop Response Measurement Modification.............................................................................................................. 3

Figure 3-1. Efficiency................................................................................................................................................................... 5

Figure 3-2. Load Regulation........................................................................................................................................................ 5

Figure 3-3. Line Regulation With Iout = 0.5 A..............................................................................................................................5

Figure 3-4. Loop Response With Vin = 12 V and Iout = 0.5 A..................................................................................................... 6

Figure 3-5. Input Voltage Ripple With Vin = 12 V and Iout = 1 A................................................................................................. 6

Figure 3-6. Output Voltage Ripple With Vin = 12 V and Iout = 1 A.............................................................................................. 7

Figure 3-7. Load Transient Response With Vin = 12 V................................................................................................................7

Figure 3-8. Start-Up on Vin With 0.5-A Load............................................................................................................................... 8

Figure 3-9. Start-Up on EN with 0.5-A Load................................................................................................................................ 8

Figure 3-10. Shutdown on EN With 0.5-A Load...........................................................................................................................9

Figure 3-11. Prebias Start-Up and Shutdown on EN With 0.5-A Load........................................................................................ 9

Figure 3-12. Thermal Performance With Vin = 12 V and Iout = 1 A.......................................................................................... 10

Figure 4-1. Assembly Layer....................................................................................................................................................... 11

Figure 4-2. Top Layer Routing....................................................................................................................................................11

Figure 4-3. Bottom Layer Routing..............................................................................................................................................12

Figure 5-1. TPS621x0EVM-627 Schematic...............................................................................................................................13

List of Tables

Table 1-1. Performance Specification Summary..........................................................................................................................2

Table 5-1. TPS621x0EVM-627 Bill of Materials.........................................................................................................................14

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

1

�Introduction

www.ti.com

1 Introduction

The TPS62160 is a 1-A, synchronous, step-down converter in a 2x2-mm, 8-pin WSON package. Both fixed and

adjustable output voltage units are available.

The TPS62170 is a 0.5-A, synchronous, step-down converter in a 2x2-mm, 8-pin WSON package. Both fixed

and adjustable output voltage units are available.

1.1 Background

The TPS62160EVM-627 (HPA627-001) uses the TPS62160 adjustable version and is set to a 3.3-V output. The

EVM operates with full-rated performance with an input voltage between 3.7 V and 17 V.

The TPS62170EVM-627 (HPA627-002) uses the TPS62170 adjustable version and is set to a 3.3-V output. The

EVM operates with full-rated performance with an input voltage between 3.7 V and 17 V.

1.2 Performance Specification

Table 1-1 provides a summary of the TPS621x0EVM-627 performance specifications. All specifications are given

for an ambient temperature of 25°C.

Table 1-1. Performance Specification Summary

Specification

Test Conditions

Input Voltage

Min

Typ

Max

17

V

3.327

3.427

V

3.7

3.227

Unit

Output Voltage

PWM Mode of Operation

Output Current

TPS62160EVM-627

0

1000

mA

TPS62170EVM-627

0

500

mA

Peak Efficiency

93.1%

Soft-Start Time

180

µs

1.3 Modifications

The printed-circuit board (PCB) for this EVM is designed to accommodate both the fixed and adjustable voltage

versions of this integrated circuit (IC). Additional input and output capacitors can also be added. Finally, the loop

response of the IC can be measured.

1.3.1 Fixed Output Operation

U1 can be replaced with the fixed-voltage version of the IC for evaluation. For fixed-voltage version operation,

replace R2 with a 0-Ω resistor and remove R1.

1.3.2 Input and Output Capacitors

C4 is provided for an additional input capacitor. This capacitor is not required for proper operation but can be

used to reduce the input voltage ripple.

C3 is provided for an additional output capacitor. This capacitor is not required for proper operation but can

be used to reduce the output voltage ripple and to improve the load transient response. The total output

capacitance must remain within the recommended range in the data sheet for proper operation.

1.3.3 Loop Response Measurement

The loop response of the TPS621x0EVM-627 can be measured with two simple changes to the circuitry. First,

install a 10-Ω resistor across the pads in the middle of the back of the PCB. The pads are spaced to allow

installation of 0805- or 0603-sized resistors. Second, cut the short section of trace between the via on the output

voltage and the trace that connects to the VOS pin via. These changes are shown in Figure 1-1. With these

changes, an ac signal (10-mV, peak-to-peak amplitude recommended) can be injected into the control loop

across the added resistor.

2

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�www.ti.com

Introduction

Added Resistor

Cut This Trace

Figure 1-1. Loop Response Measurement Modification

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

3

�Setup

www.ti.com

2 Setup

This section describes how to properly use the TPS621x0EVM-627.

2.1 Input/Output Connector Descriptions

J1 – VIN

Positive input connection from the input supply for the EVM.

J2 – S+/S-

Input voltage sense connections. Measure the input voltage at this point.

J3 – GND

Return connection from the input supply for the EVM.

J4 – VOUT

Output voltage connection.

J5 – S+/S-

Output voltage sense connections. Measure the output voltage at this point.

J6 – GND

Output return connection.

J7 – PG/GND

The PG output appears on pin 1 of this header with a convenient ground on pin 2.

JP1 – EN

EN pin input jumper. Place the supplied jumper across ON and EN to turn on the IC. Place the jumper across OFF

and EN to turn off the IC.

JP2 – PG Pullup

Voltage

PG pin pullup voltage jumper. Place the supplied jumper on JP2 to connect the PG pin pullup resistor to Vout.

Alternatively, the jumper can be removed and a different voltage can be supplied on pin 1 to pull up the PG pin to a

different level. This externally applied voltage must remain below 7 V.

2.2 Setup

To operate the EVM, set jumpers JP1 through JP2 to the desired positions per Section 2.1. Connect the input

supply to J1 and J3 and connect the load to J4 and J6.

4

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�www.ti.com

TPS621x0EVM-627 Test Results

3 TPS621x0EVM-627 Test Results

This section provides test results of the TPS621x0EVM-627.

100

95

VIN = 5 V

90

VIN = 9 V

85

Efficiency (%)

80

75

VIN = 12 V

70

VIN = 15 V

VIN = 17 V

65

60

55

50

45

40

0.1

1

10

100

1000

Current (mA)

Figure 3-1. Efficiency

0.5

VIN = 15 V

0.4

VIN = 17 V

Load Regulation (%)

0.3

VIN = 12 V

0.2

0.1

VIN = 9 V

0

VIN = 5 V

-0.1

-0.2

0.1

1

10

Current (mA)

100

1000

Figure 3-2. Load Regulation

0.15

Line Regulation (%)

0.1

0.05

0

-0.05

-0.1

3

5

7

9

11

VI - Input Voltage - (V)

13

15

17

Figure 3-3. Line Regulation With Iout = 0.5 A

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

5

�TPS621x0EVM-627 Test Results

www.ti.com

60

180

Gain - dB

150

40

120

30

90

20

60

10

30

Gain

0

0

-10

-30

-20

-60

-30

-90

-40

-120

-50

Phase - deg.

Phase

50

-150

-60

1k

10k

100k

-180

1M

f - Frequency - Hz

Figure 3-4. Loop Response With Vin = 12 V and Iout = 0.5 A

Vin (AC Coupled) 20 mV/div

Iind 500 mA/div

SW 10 V/div

t - Time - 200 ns/div

Figure 3-5. Input Voltage Ripple With Vin = 12 V and Iout = 1 A

6

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�www.ti.com

TPS621x0EVM-627 Test Results

Vout (AC Coupled) 10 mV/div

Iind 500 mA/div

SW 10 V/div

t - Time - 500 ns/div

Figure 3-6. Output Voltage Ripple With Vin = 12 V and Iout = 1 A

Vout (AC Coupled) 20 mV/div

Iout 500 mA/div

500 mA to 750 mA Load step

t - Time - 2 ms/div

Figure 3-7. Load Transient Response With Vin = 12 V

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

7

�TPS621x0EVM-627 Test Results

www.ti.com

Vin 5 V/div

EN 5 V/div

PG 2 V/div

Vout 1 V/div

t - Time - 50 ms/div

Figure 3-8. Start-Up on Vin With 0.5-A Load

Vin 10 V/div

EN 10 V/div

PG 2 V/div

Vout 1 V/div

t - Time - 50 ms/div

Figure 3-9. Start-Up on EN with 0.5-A Load

8

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�www.ti.com

TPS621x0EVM-627 Test Results

Vin 10 V/div

EN 10 V/div

PG 2 V/div

Vout 1 V/div

t - Time - 200 ms/div

Figure 3-10. Shutdown on EN With 0.5-A Load

Vin 10 V/div

EN 2 V/div

PG 2 V/div

Vout 1 V/div

1.5 V Pre-bias

t - Time - 100 ms/div

Figure 3-11. Prebias Start-Up and Shutdown on EN With 0.5-A Load

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

9

�TPS621x0EVM-627 Test Results

www.ti.com

Figure 3-12. Thermal Performance With Vin = 12 V and Iout = 1 A

10

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�www.ti.com

Board Layout

4 Board Layout

This section provides the TPS621x0EVM-627 board layout and illustrations.

Figure 4-1. Assembly Layer

Figure 4-2. Top Layer Routing

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

11

�Board Layout

www.ti.com

Figure 4-3. Bottom Layer Routing

12

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�www.ti.com

Schematic and Bill of Materials

5 Schematic and Bill of Materials

This section provides the TPS621x0EVM-627 schematic and bill of materials.

+

5.1 Schematic

Figure 5-1. TPS621x0EVM-627 Schematic

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

13

�Schematic and Bill of Materials

www.ti.com

5.2 Bill of Materials

Table 5-1. TPS621x0EVM-627 Bill of Materials

Count

-001

-002

RefDes

Value

Description

Size

Part Number

MFR

1

1

C1

10 µF

Capacitor, Ceramic, 25V, X5R, 20%

0805

Std

Std

1

1

C2

22 µF

Capacitor, Ceramic, 6.3V, X5R, 20%

0805

Std

Std

1

1

C5

68 µF

Capacitor, Tantalum, 35V, 68uF, ±20%

7361[V]

TPSV686M035R0150

AVX

1

1

L1

2.2 µH

Inductor, SMT, 2.2 uH, 1.4A, 60-milliohm

2.80 X 3.00 mm

VLF3012ST-2R2M1R4

TDK

1

1

R1

1.21M

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

1

R2

383k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

1

R3

100k

Resistor, Chip, 1/16W, 1%

0603

Std

Std

1

0

U1

TPS62160DSG

IC, 17V 1A Buck Converter

2 x 2 mm WSON

TPS62160DSG

TI

0

1

U1

TPS62170DSG

IC, 17V 0.5A Buck Converter

2 x 2 mm WSON

TPS62170DSG

TI

6 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision * (October 2011) to Revision A (June 2021)

Page

• Updated user's guide title................................................................................................................................... 2

• Updated the numbering format for tables, figures, and cross-references throughout the document. ................2

14

TPS621x0 Buck Converter Evaluation Module User's Guide

Copyright © 2021 Texas Instruments Incorporated

SLVU483A – OCTOBER 2011 – REVISED JUNE 2021

Submit Document Feedback

�IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, regulatory or other requirements.

These resources are subject to change without notice. TI grants you permission to use these resources only for development of an

application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license

is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you

will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these

resources.

TI’s products are provided subject to TI’s Terms of Sale or other applicable terms available either on ti.com or provided in conjunction with

such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2022, Texas Instruments Incorporated

�