Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

TPS6218x 4-V to 15-V, 6-A, 2-Phase Step-Down Converters with AEE™

1 Features

3 Description

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

The TPS6218x is a synchronous dual-phase stepdown DC-DC converter for low profile power rails. It

operates with two identical, current balanced phases

that are peak current controlled enabling use in

height limited applications.

1

•

Dual Phase Balanced Peak Current Mode

Input Voltage Range: 4 V to 15 V

Output Voltage Range: 0.9 V to 6 V

Output Current up to 6 A

Typical Quiescent Current of 28 µA

Output Voltage Accuracy of ±1% (PWM Mode)

Automatic Efficiency Enhancement (AEE™)

Phase Shifted Operation

Automatic Power Save Mode

Adjustable Soft Start

Power Good Output

Undervoltage Lockout

HICCUP Over Current Protection

Pin-to-Pin Compatible with TPS62184

Over Temperature Protection

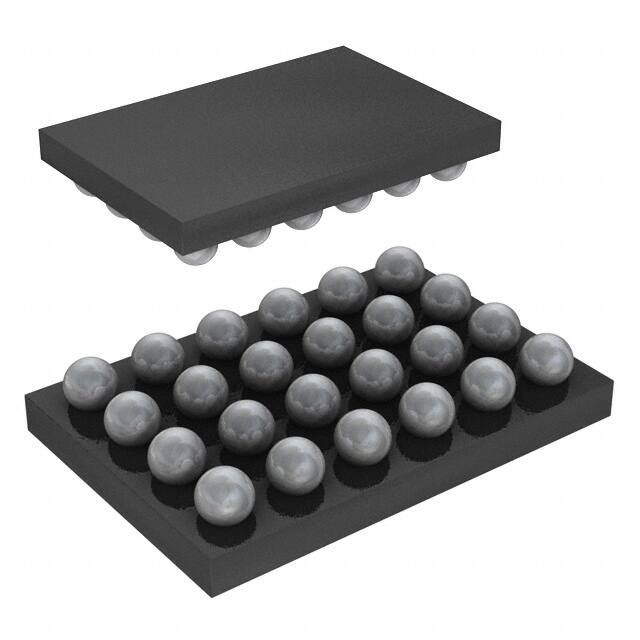

NanoFree™ 2.10 mm x 3.10 mm DSBGA

Package

Create a Custom Design Using the TPS62180

With the WEBENCH® Power Designer

2 Applications

•

•

•

•

•

•

Low Profile POL Supply

NVDC Powered Systems

Dual/Triple Cell Li-ion Battery

Ultra Portable/Embedded/Tablet PC

Computing Network Solutions

Micro Server, SSD

With a wide operating input voltage range of 4 V to

15 V, the device is ideally suited for systems powered

from multi-cell Li-Ion batteries or 12-V rails. The

output current of 6 A is continuously provided by two

phases of 3 A each, allowing the use of low profile

external components. The phases operate out of

phase, reducing switching noise significantly.

The TPS6218x automatically enters Power Save

Mode to maintain high efficiency down to very light

loads. It also incorporates an Automatic Efficiency

Enhancement (AEE™) for the entire duty cycle range.

The device features a Power Good signal, as well as

an adjustable soft start. The quiescent current is

typically 28 µA, it is able to run in 100% mode, and it

has no duty cycle limitation even at lowest output

voltage.

The TPS6218x, available in adjustable and fixed

output voltage options, is packaged in a small 24bump, 0.5 mm pitch DSBGA package.

Device Information(1)

PART NUMBER

PACKAGE

BODY SIZE (NOM)

TPS62180

DSBGA (24)

2.10 mm x 3.10 mm

TPS62182

DSBGA (24)

2.10 mm x 3.10 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

spacing

Simplified Schematic

Efficiency vs Output Current

space

22µF

1µH

4 to 15 V

VIN1

SW1

VIN2

SW2

3.3V/6A

1µH

VO

22µF

470k

TPS62182

PG

EN

2x

47µF

FB

SS/TR

GND

3.3nF

Copyright © 2017, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Device Comparison Table.....................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

3

4

7.1

7.2

7.3

7.4

7.5

7.6

4

4

4

4

5

6

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description .............................................. 7

8.1 Overview ................................................................... 7

8.2 Functional Block Diagram ......................................... 7

8.3 Feature Description................................................... 8

8.4 Device Functional Modes.......................................... 9

9

Application and Implementation ........................ 14

9.1 Application Information............................................ 14

9.2 Typical Applications ................................................ 14

9.3 TPS62180 Output Voltage Application Examples... 28

10 Power Supply Recommendations ..................... 30

11 Layout................................................................... 31

11.1 Layout Guidelines ................................................. 31

11.2 Layout Example .................................................... 31

12 Device and Documentation Support ................. 32

12.1

12.2

12.3

12.4

12.5

Device Support......................................................

Related Links ........................................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

32

32

32

32

32

13 Mechanical, Packaging, and Orderable

Information ........................................................... 32

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (August 2014) to Revision B

Page

•

Added Feature: Pin-to-Pin Compatible with TPS62184 ......................................................................................................... 1

•

Added WEBENCH® information to Features, Detailed Design Procedures, and Development Support sections................. 1

•

Changed the BODY SIZE value From: 2.14 mm x 3.14 mm To: 2.10 mm x 3.10 mm in the Device Information table ........ 1

•

Added SW1, SW2, (AC, less than 10ns) and Note (3) to the Pin voltage range in the Absolute Maximum Ratings table ... 4

•

Changed Handling Ratings To: ESD Ratings table................................................................................................................ 4

•

Added Table 1 ....................................................................................................................................................................... 9

•

Added the application note .................................................................................................................................................. 14

•

Changed the Design Requirements paragraph .................................................................................................................... 14

•

Added Note (2) to Table 6 ................................................................................................................................................... 17

•

Added Figure 31 and Figure 32............................................................................................................................................ 21

•

Added Figure 37 .................................................................................................................................................................. 22

•

Changed the Design Requirements paragraph .................................................................................................................... 24

•

Added Figure 38 and Figure 39 to the Inductor section ....................................................................................................... 24

•

Changed Figure 55 .............................................................................................................................................................. 31

Changes from Original (August 2014) to Revision A

•

2

Page

Released to Production ......................................................................................................................................................... 1

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

5 Device Comparison Table

PART NUMBER

OUTPUT VOLTAGE

TJ

TPS62180

Adjustable

-40°C to 125°C

TPS62182

3.3 V

-40°C to 125°C

Spacer

6 Pin Configuration and Functions

24-Pin DSBGA

YZF Package

(Top View - Left, Bottom View - Right)

1

2

3

4

F

E

D

C

B

A

A

B

C

D

E

F

Pin Functions

PIN (1)

DESCRIPTION

NAME

NUMBER

AGND

C4

Analog Ground. Connect on PCB directly with PGND.

EN

E4

Enable input (High = enabled, Low = disabled)

FB

B4

Output voltage feedback. Connect resistive voltage divider to this pin and AGND. On TPS62182,

connect to AGND.

PG

F4

Output power good (High = VOUT ready, Low = VOUT below nominal regulation); open drain

(requires pull-up resistor)

PGND

A3, B3, C3, D3,

E3, F3

SS/TR

D4

Common power ground.

Soft-Start and Tracking Pin. An external capacitor connected to this pin sets the internal voltage

reference rise time.

SW1

A2, B2, C2

Switch node for Phase 1 (master), connected to the internal MOSFET switches. Connect inductor 1

between SW1 and output capacitor.

SW2

D2, E2, F2

Switch node for Phase 2 (follower), connected to the internal MOSFET switches. Connect inductor 2

between SW2 and output capacitor.

VIN1

A1, B1, C1

Supply voltage for Phase 1.

VIN2

D1, E1, F1

Supply voltage for Phase 2.

A4

Output Voltage Connection

VO

(1)

For more information about connecting pins, see Detailed Description and Application Information sections.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

3

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

7 Specifications

7.1 Absolute Maximum Ratings (1)

Pin voltage range (2)

MIN

MAX

UNIT

VIN1, VIN2

–0.3

17

V

EN, PG

–0.3

VIN + 0.3

V

SW1, SW2, (DC)

–0.3

VIN + 0.3

–2

24.5

SS/TR

–0.3

VIN + 0.3,

but ≤ 7

V

FB, VO

–0.3

7

V

10

mA

SW1, SW2, (AC, less than 10ns) (3)

V

Power good sink

current

PG

Operating junction

temperature range

TJ

–40

150

°C

Storage Temperature

Range

Tstg

–65

150

°C

(1)

(2)

(3)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltages are with respect to network ground pin.

While switching.

7.2 ESD Ratings

VESD (1)

(1)

(2)

MIN

MAX

Human Body Model (HBM) ESD stress voltage (2)

–1

1

Charge device model (CDM) ESD stress voltage

–0.5

0.5

UNIT

kV

Electrostatic discharge (ESD) to measure device sensitivity and immunity to damage caused by assembly line electrostatic discharges in

to the device.

Level listed above is the passing level per ANSI, ESDA, and JEDEC JS-001. JEDEC document JEP155 states that 500-V HBM allows

safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

MIN

Supply voltage range, VIN

Output voltage range, VOUT

Maximum Output current,

IOUT(max)

0.9V ≤ VOUT ≤ 3.3V

TYP

MAX

UNIT

4

15

V

0.9

6

V

6

3.3V < VOUT

A

6

Operating junction temperature, TJ

–40

125

°C

7.4 Thermal Information

TPS6218x

THERMAL METRIC (1)

RθJA

Junction-to-ambient thermal resistance

RθJCtop

RθJB

YZF (24 PINS)

UNIT

61.5

°C/W

Junction-to-case (top) thermal resistance

0.3

°C/W

Junction-to-board thermal resistance

10.1

°C/W

ψJT

Junction-to-top characterization parameter

0.1

°C/W

ψJB

Junction-to-board characterization parameter

10.1

°C/W

RθJCbot

Junction-to-case (bottom) thermal resistance

n/a

°C/W

(1)

4

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

7.5 Electrical Characteristics

Over operating junction temperature range (TJ = –40°C to +125°C) and VIN = 4 V to 15 V.

Typical values at VIN = 12 V and TJ = 25°C (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SUPPLY

VIN

Input voltage range

4

IQ

Operating quiescent current

EN = High, IOUT = 0 mA, Device not switching,

(TJ = –40°C to +85°C)

ISD

Shutdown current

EN = Low (≤ 0.3 V), (TJ = –40°C to +85°C)

VUVLO

TSD

Undervoltage lockout threshold

(1)

Thermal shutdown

Falling input voltage

3.5

15

V

28

55

µA

2.8

15

µA

3.6

3.7

Hysteresis

300

Rising junction temperature

160

Hysteresis

V

mV

°C

20

CONTROL (EN, SS/TR, PG)

VH_EN

High-level input threshold voltage (EN)

VL_EN

Low-level input threshold voltage (EN)

ILKG_EN

Input leakage current (EN)

ISS/TR

SS/TR pin source current

VTH_PG

Power good threshold voltage

VOL_PG

Power good output low voltage

ILKG_PG

Input leakage current (PG)

0.97

0.87

EN = VIN or GND

1

1.03

V

0.9

0.93

V

0.01

1.2

µA

µA

4.5

5

5.5

Rising (%VOUT)

94%

96%

98%

Falling (%VOUT)

90%

92%

94%

0.3

V

1

100

nA

27

65

mΩ

21

45

mΩ

4.7

5.5

IPG= -2 mA

POWER SWITCH

Phase 1

High-side MOSFET ON-resistance

RDS(ON)

VIN = 7.5 V

Low-side MOSFET ON-resistance

Phase 2

Phase 1

Phase 2

ILIM

High-side MOSFET current limit

Each phase, VIN = 7.5 V

TPSD

Phase shift delay time

Phase 2 after Phase 1, PWM mode

4.0

250

A

ns

OUTPUT

VREF

Internal reference voltage

ILKG_FB

Input leakage current (FB)

VFB = 0.8 V

0.792

RDISCHARGE

Output discharge resistance

EN = Low

Output voltage range (TPS62180)

VIN ≥ VOUT

V

100

nA

60

Ω

6

3.3

PWM Mode, VIN ≥ VOUT + 1 V

1%

–1%

2%

Power Save Mode, VOUT = 0.9 V, Iload ≥ 1 mA,

L = 1 µH, COUT = 4 x 47 µF, (TJ = –40°C to +85°C)

–1%

3%

PWM Mode, VIN ≥ VOUT + 1 V

–1%

1%

Power Save Mode, Iload ≥ 1 mA, L = 1 µH,

COUT = 2 x 47 µF, (TJ = –40°C to +85°C)

–1%

2%

Power Save Mode, VOUT = 1.8 V, Iload ≥ 1 mA,

L = 1 µH, COUT = 4 x 47 µF, (TJ = –40°C to +85°C)

VOUT

Output voltage accuracy

(TPS62182) (2)

V

V

–1%

Power Save Mode, VOUT = 3.3 V, Iload ≥ 1 mA,

L = 1 µH, COUT = 2 x 47 µF, (TJ = –40°C to +85°C)

Feedback voltage accuracy

(TPS62180) (2)

(1)

(2)

0.808

1

0.9

Output voltage (TPS62182)

tHICCUP

0.8

Load regulation

VOUT = 3.3 V, PWM Mode operation

0.04

%/A

Line regulation

4 V ≤ VIN ≤ 15 V, VOUT = 3.3 V, IOUT = 4 A

0.01

%/V

Hiccup on time

0.9

Hiccup off time

5

ms

The minimum VIN value of 4 V is not violated by UVLO threshold and hysteresis variations.

The accuracy in Power Save Mode can be improved by increasing the output capacitor value, reducing the output voltage ripple.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

5

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

7.6 Typical Characteristics

6

Figure 1. Quiescent Current

Figure 2. Shutdown Current

Figure 3. High-Side Switch Resistance

Figure 4. Low-Side Switch Resistance

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

8 Detailed Description

8.1 Overview

The TPS6218x is a high efficiency synchronous switched mode step-down converter based on a peak current

control topology. It is designed for smallest solution size low-profile applications, converting multi-cell Li-Ion

supply voltages to output voltages of 0.9 V to 6 V. While an outer voltage loop sets the regulation threshold for

the current loop based on the actual VOUT level, the inner current loop adapts the peak inductor current for every

switching cycle. The regulation network is internally compensated. The switching frequency is set by an OFFtime control and features Power Save Mode (PSM) and AEE™ (Automatic Efficiency Enhancement) to keep the

efficiency high over the whole load current and duty cycle range. The switching frequency is set depending on

VIN and VOUT and remains unchanged for steady state operating conditions.

The TPS6218x is a dual phase converter, sharing the load current among the phases. Identical in construction,

the follower control loop is connected with a fixed delay to the master control loop. Both the phases use the

same regulation threshold and cycle-by-cycle peak current setpoint. This ensures a phase-shifted as well as

current-balanced operation. Using the advantages of the dual phase topology, a 6-A continuous output current is

provided with high performance and smallest system solution size.

While the TPS62180 offers an adjustable output voltage, the TPS62182 supports a fixed 3.3-V output voltage,

saving external components.

8.2 Functional Block Diagram

Thermal

Shutdown

PG

VIN1

VIN2

1

3

3

Power Save

Mode

PG control

VIN1

HS1

EN*

1

power

control

control logic

SS/TR

VIN

SW2

1

FB

HS2

HICCUP

follower

VO

3

HS2

phase shift

UVLO

SW1

VIN2

gate

drive

1

3

tf

1

gmout

delay

60

gm

VREF

master

EN

VIN

AEETM

tm

off-timer

HS1

VIN

7

GND

*Pin is connected to a pull down resistor internally

(see Feature Description section)

Copyright © 2017, Texas Instruments Incorporated

Figure 5. TPS62180 (Adjustable output voltage)

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

7

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

Functional Block Diagram (continued)

Thermal

Shutdown

PG

VIN1

VIN2

1

3

3

Power Save

Mode

PG control

VIN1

HS1

EN*

1

SS/TR

phase shift

VIN

VREF

gmout

delay

60

master

VIN

AEETM

1

FB*

VO

tf

1

EN

SW2

HS2

HICCUP

follower

VO

3

HS2

1

UVLO

SW1

VIN2

gate

drive

power

control

control logic

3

gm

tm

off-timer

R1

R2

HS1

VIN

7

GND

*Pin is connected to a pull down resistor internally

(see Feature Description section)

Copyright © 2017, Texas Instruments Incorporated

Figure 6. TPS62182 (Fixed output voltage)

8.3 Feature Description

8.3.1 Enable / Shutdown (EN)

The device starts operation, when VIN is present and Enable (EN) is set High. The EN threshold is 1 V for rising

and 0.9 V for falling voltages, providing a threshold accuracy of ±3%. That makes it suitable for precise switching

on and off in accurate power sequencing arrangements as well as for slowly rising EN control voltage signals

(see Using the Accurate EN Threshold for more details).

The device is disabled by pulling EN Low. A discharge resistor of about 60 Ω is then connected to the output. At

the EN pin, an internal pull down resistor of about 350 kΩ keeps the Low state, if EN gets high impedance or

floating afterwards.

The EN pin can be connected to VIN to always enable the device. A delay of 1 ms, after VIN exceeds VUVLO,

ensures safe operating conditions before the device starts switching. If VIN is already present, a soft start

sequence is initiated about 100 µs after EN is pulled High.

8.3.2 Soft Start / Tracking (SS/TR)

The soft start circuit controls the output voltage slope during startup. This avoids excessive inrush current and

ensures a controlled output voltage rise time. It also prevents unwanted voltage drop from high impedance power

sources or batteries. When EN is set to start device operation, the device starts switching and VOUT rises with a

slope, controlled by the external capacitor connected to the SS/TR pin. There is no theoretical limit for the

longest startup time. It is not recommended to leave the SS/TR pin floating, because VOUT may overshoot.

Typical startup operation is shown in Application Performance Curves.

8

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

Feature Description (continued)

The device can track an external voltage (see Tracking). The device can monotonically start into a pre-biased

output.

8.3.3 Power Good (PG)

The TPS6218x has a built in power good (PG) function. The PG pin goes High, when the output voltage has

reached its nominal value. Otherwise, including when disabled, in UVLO or in thermal shutdown, PG is Low. The

PG pin is an open drain output that requires a pull-up resistor and can sink typically 2 mA. If not used, the PG pin

can be left floating or grounded.

space

Table 1. Power Good Pin Logic Table

PG Logic Status

Device Information

Enable (EN=High)

High Z

VFB ≥ VTH_PG

Low

√

VFB ≤ VTH_PG

√

√

Shutdown (EN=Low)

UVLO

0.7V < VIN < VUVLO

Thermal Shutdown

TJ > TSD

Power Supply Removal

VIN < 0.7V

√

√

√

space

8.3.4 Undervoltage Lockout (UVLO)

The undervoltage lockout (UVLO) prevents misoperation of the device, if the input voltage drops below the UVLO

threshold. It is set to 3.6 V typically with a hysteresis of typically 300mV. (See also Device Functional Modes).

8.3.5 Thermal Shutdown

The junction temperature TJ of the device is monitored by an internal temperature sensor. If TJ exceeds 160°C

(typ.), the device goes in thermal shutdown with a hysteresis of typically 20°C. Both the power FETs are turned

off, the discharge resistor is connected to the output and the PG pin goes Low. Once TJ has decreased enough,

the device resumes normal operation with Soft Start.

8.4 Device Functional Modes

8.4.1 Pulse Width Modulation (PWM) Operation

The TPS6218x is based on a predictive OFF-time peak current control topology, operating with PWM in

continuous conduction mode for heavier loads. Since the OFF-time is automatically adjusted according to the

actual VIN and VOUT, it provides highest efficiency over the entire input and output voltage range. The OFF-time is

calculated as:

spacing

é V

ù

tOFF = ê IN 500ns ú + 50ns

ë 5VOUT

û

(1)

spacing

While the OFF-time is predicted, the ON-time is set depending on the converter's duty cycle and calculated as:

spacing

t ON =

t OFF × VOUT

V IN - VOUT

(2)

spacing

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

9

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

Device Functional Modes (continued)

Thereby the switching frequency is fixed for a given input and output voltage and is calculated as:

spacing

f SW =

1- D

1

=

tOFF

tOFF

æ VOUT

çç1 VIN

è

ö

÷÷

ø

(3)

spacing

Both the master and follower phases regulate to the same level of VOUT with separate current loops, using the

same peak current setpoint, cycle by cycle. This provides excellent peak current balancing, independent of

inductor dc resistance matching. Since the follower phase operates with a fixed delay to the master phase, also

cycle by cycle, phase shifted operation is obtained.

The device features an automatic transition into Power Save Mode, entered at light loads, running in

discontinuous conduction mode (DCM).

8.4.2 Power Save Mode (PSM) Operation

As the load current decreases, the converter enters Power Save Mode operation. During PSM, the converter

operates with a reduced switching frequency maintaining highest efficiency due to minimum quiescent current.

Power Save Mode is based on a fixed peak current architecture, where the peak current (IPEAK) is set depending

on VIN, VOUT, and L. After each single pulse, a pause time until the internal VOUT_Low level threshold is reached

completes the switching cycle in PSM.

The switching frequency for PSM in one phase operation is calculated as :

spacing

f PSM =

2 I OUT × VOUT (VIN - VOUT )

2

L × I PEAK

× VIN

(4)

spacing

Equation 4 shows the linear relationship of output current and switching frequency. Typical values of the fixed

peak current are shown in Figure 7.

space

Figure 7. Typical Fixed Peak Current (IPEAK) in Power Save Mode

space

If the load decreases to very light loads and only one phase is needed, either phase (master or follower) might

be active. The load current level at which Power Save Mode is entered is calculated as follows:

spacing

10

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

Device Functional Modes (continued)

I load ( PSM ) = DI L

(5)

spacing

Equation 7 is used to calculate ΔIL.

8.4.3 Minimum Duty Cycle and 100% Mode Operation

When the input voltage comes close to the output voltage, the device enters 100% mode and both high-side

FETs are continuously switched on as long as VOUT remains below its setpoint. The minimum VIN to maintain

output voltage regulation is calculated as:

spacing

éR

ù

VIN (min) = VOUT (min) + I OUT ê DS (ON ) + DCRL1 // DCRL 2 ú

ë 2

û

(6)

spacing

This allows the conversion of small input to output voltage differences, for example for the longest operation time

in battery powered applications. In 100% duty cycle mode, the low-side FET is switched off.

While the maximum ON-time is not limited, the AEE feature, explained in the next section, secures a minimum

ON-time of about 100 ns.

8.4.4 Automatic Efficiency Enhancement (AEE™)

AEE™ provides highest efficiency over the entire input voltage and output voltage range by automatically

adjusting the converter's switching frequency. This is achieved by setting the predictive off-time of the converter.

The efficiency of a switched mode converter is determined by the power losses during the conversion. The

efficiency decreases, if VOUT decreases and/or VIN increases. In order to keep the efficiency high over the entire

duty cycle range (VOUT/VIN ratio), the switching frequency is adjusted while maintaining the ripple current. The

following equation shows the relation between the inductor ripple current, switching frequency and duty cycle.

spacing

æ 1- D

DI L = VOUT × çç

è L × f SW

ö

÷÷ = VOUT

ø

æ VOUT

ç1VIN

×ç

ç L × f SW

ç

è

ö

÷

÷

÷

÷

ø

(7)

spacing

Efficiency increases by decreasing switching losses, preserving high efficiency for varying duty cycles, while the

ripple current amplitude remains low enough to deliver the full output current without reaching current limit. The

AEE™ feature provides an efficiency enhancement for various duty cycles, especially for lower Vout values,

where fixed frequency converters suffer from a significant efficiency drop. Furthermore, this feature compensates

for the very small duty cycles of high VIN to low VOUT conversion, which limits the control range in other

topologies.

Figure 8 shows the typical switching frequency over the input voltage range.

space

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

11

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

Device Functional Modes (continued)

Figure 8. Typical Switching Frequency vs Input Voltage

space

8.4.5 Phase-Shifted Operation

While, for a buck converter, the input current source provides the average current that is needed to support the

output current, an input capacitance is needed to support pulse currents. One of the natural benefits of a two- (or

multi-) phase converter is the possibility to operate out of phase, which decreases the pulse currents and

switching noise. In PWM mode, the TPS6218x devices run with a fixed delay of typically 250 ns between the

phases. This ensures that the phases run phase-delayed, limiting input RMS current and corresponding noise. If

in PSM, both phases run, the phase delay is about 100 ns.

8.4.6 Current Limit, Current Balancing, and Short Circuit Protection

Each phase has a separate integrated peak current limit. While its minimum value limits the output current of the

phase, the maximum number gives the current that must be considered to flow in any operating case. If the

current limit of a phase is reached, the peak current setpoint is unable to increase further. The device provides its

maximum output current. Detecting this heavy load or short circuit condition for about 0.9 ms, the device

switches off for about 5 ms and then restarts again with a soft start cycle. As long as the overload condition is

present, the device hiccups that way, limiting the output power.

The two phases are peak current balanced with a variation within about ±10% at 6-A output current (see

Figure 9). Since the control topology does not depend on inductor or output current measurements, the current

balancing accuracy is independent of inductor matching (binning) and does not need matched power routing.

space

12

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

Device Functional Modes (continued)

Figure 9. Typical Current Balancing vs Load Current

space

8.4.7 Tracking

VOUT can track a voltage that is applied at the SS/TR pin. The tracking range at the SS/TR pin is 50 mV to 1.2 V

and the FB pin voltage tracks this as given in Equation 8:

spacing

VFB » 0.64 × VSS / TR

(8)

spacing

Due to the factor of about 0.64, the minimum output voltage for tracking is 1.25 V. Once the SS/TR pin voltage

reaches about 1.2 V, the internal voltage is clamped to the internal feedback voltage and the device goes to

normal regulation. This works for falling tracking voltage as well. If, in this case, the SS/TR voltage decreases,

the device does not sink current from the output. Thus, the resulting decrease of the output voltage may be

slower than the SS/TR pin voltage if the load is light. When driving the SS/TR pin with an external voltage, do not

exceed the voltage rating of the SS/TR pin which is VIN+0.3 V.

Note: If the voltage at the FB pin is below its typical value of 0.8 V, the output voltage accuracy may have a

wider tolerance than specified.

8.4.8 Operation with Fixed VOUT

The TPS62182 provides a fixed output voltage of 3.3 V (±1%). In this case, the feedback divider is integrated

and the FB pin is internally connected to GND with a resistor of about 350 kΩ. It is recommended to connect the

FB pin to PCB ground to improve thermal behavior.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

13

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

The TPS62180/2 are switched mode step-down converters, able to convert a 4-V to 15-V input voltage into a

lower 0.9-V to 6-V output voltage, providing up to 6 A. It needs a minimum amount of external components. Apart

from the LC output filter and the input capacitors only an optional pull-up resistor for Power Good (PG) and a

small capacitor for adjustable soft start are used. The TPS62180 with an adjustable output voltage needs an

additional resistive divider to set the output voltage level.

9.2 Typical Applications

9.2.1 Typical TPS62180 Application

C1

L1

VIN1

4 to 15 V

VOUT/6A

SW1

L2

VIN2

SW2

VO

C2

470k

TPS62180

C3

PG

EN

FB

SS/TR

GND

C5

C4

R1

VFB

R2

Copyright © 2017, Texas Instruments Incorporated

Figure 10. Typical 4-V to 15-V Input, 6A Converter

spacing

9.2.1.1 Design Requirements

The design guideline provides a component selection to operate the device within the recommended operating

conditions. The component selection is given in Table 2 and gives a total solution size of about 99 mm2 with a

maximum height of 2.1 mm:

spacing

Table 2. Components Used for Application Characteristics

REFERENCE NAME

DESCRIPTION / VALUE

MANUFACTURER

TPS62180YZF

2 phase step down converter, 2 x 3 mm WCSP

Texas Instruments

L1, L2

Inductor XFL4020-102ME, 1 µH ±20%, 4 x 4 x 2.1 mm

Coilcraft

C1, C2

Ceramic capacitor GRM21BR61E226ME44, 2 x 22 µF, 25 V, X5R, 0805

muRata

C3, C4

Ceramic capacitor GRM21BR60J476ME15, 2 x 47 µF, 6.3 V, X5R, 0805

muRata

C5

Ceramic capacitor, 3.3 nF

Standard

R1

Chip resistor, value depending on VOUT

Standard

R2

Chip resistor, value depending on VOUT

Standard

R3

Chip resistor, 470 kΩ, 0603, 1/16 W, 1%

Standard

14

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

9.2.1.2 Detailed Design Procedure

9.2.1.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the TPS62180 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

9.2.1.2.2 Programming the Output Voltage

The output voltage of the TPS62180 is programmed using an external resistive divider. While the voltage at the

FB pin is regulated to 0.8 V, the output voltage range is specified from 0.9 up to 6 V. The value of the output

voltage is set by selection of the resistive divider (from VOUT to FB to AGND) from Equation 9.

spacing

R1 VOUT

=

-1

R2 VFB

(9)

spacing

The current through those resistors contributes to the light load efficiency, which makes larger resistor values

beneficial. However, to get sufficient noise immunity these values should not be oversized. Using this, the

resistor values are calculated by converting Equation 9 as follows:

spacing

R2 =

VFB 0.8V

=

= 160kW

I FB 5mA

(10)

spacing

Inserting the R2 value in Equation 11, R1 can be obtained.

spacing

æV

ö

R1 = R2 × çç OUT - 1÷÷

è VFB

ø

(11)

spacing

Calculating for VOUT = 3.3 V gives R1 = 500 kΩ. Using standard resistor values R1 = 470 kΩ and R2 = 150 kΩ are

chosen.

For applications requiring lowest current consumption, the use of fixed output voltage options is recommended.

Using the TPS62182, the FB pin can be left floating, but it is recommended to connect it to AGND which

decreases thermal resistance.

In case the FB pin of the adjustable output voltage version gets opened or an over voltage appears at the output,

an internal clamp limits the output voltage to about 7.4 V.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

15

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

9.2.1.2.3 Output Filter Selection

Since the TPS6218x is compensated internally, it is optimized for a range of external component values, which is

specified below. Table 3 and Table 4 are used to simplify the output filter component selection. Checked cells

represent combinations that are proven for stability by simulation and lab test. Further combinations should be

checked for each individual application.

Table 3. Recommended LC Output Filter Combinations for VOUT ≥ 1.8 V (1)

2 x 47 µF

4 x 47 µF

6 x 47 µF

8 x 47 µF

√

√

√

√

0.47 µH

1.0 µH

1.5 µH

(1)

The values in the table are the nominal values of inductors and ceramic capacitors. The effective capacitance can vary by +20 and

–60%.

Table 4. Recommended LC Output Filter Combinations for VOUT < 1.8 V (1)

2 x 47 µF

4 x 47 µF

6 x 47 µF

√

√

8 x 47 µF

0.68 µH

1.0 µH

1.5 µH

(1)

The values in the table are nominal values of inductors and ceramic capacitors. The effective capacitance can vary by +20 and –40%.

For the output capacitors, a voltage rating of 6.3 V and an X5R dielectric are chosen. If space allows for higher

voltage rated capacitors in larger case sizes, the dc bias effect is lowered and the effective capacitance value

increases.

9.2.1.2.4 Inductor Selection

The TPS6218x is designed to work with two inductors of 1 µH nominal. They have to be selected for adequate

saturation current and a low dc resistance (DCR). The minimum inductor current rating IL(min) that is needed

under static load conditions is calculated using Equation 12 and Equation 13. A current imbalance of 10% at

most is incorporated.

spacing

I peak (max) = I L (min) =

1.1× I OUT (max)

2

+

DI L (max)

2

(12)

spacing

spacing

DI L (max)

V

æ

ç 1 - OUT

VIN (max)

= VOUT × ç

ç L(min) × f SW

ç

è

ö

÷

÷

÷

÷

ø

(13)

spacing

This calculation gives the minimum saturation current of the inductor needed and an additional margin of about

20% is recommended to cover dynamic overshoot due to load transients. For low profile solutions, the physical

inductor size and the power losses have to be traded off. Smallest solution size (for example with chip inductors)

are less efficient than bigger inductors with lower losses due to lower DCR and/or core losses. The following

inductors have been tested with the TPS6218x:

16

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

Table 5. List of Inductors

TYPE

INDUCTANCE

[µH]

CURRENT RATING

MIN/TYP [A] (1)

DCR MAX

[mΩ]

DIMENSIONS (LxBxH) [mm]

MANUFACTURER

DFE201612E-1R0M

1 ±20%

4.0/4.4

48

2.0 x 1.6 x 1.2

TOKO

TOKO

DFE252012F-1R0M

1 ±20%

4.7/5.3

40

2.5 x 2.0 x 1.2

DFE252012P-1R0M

1 ±20%

3.8/4.5

42

2.5 x 2.0 x 1.2

TOKO

PIFE32251B-1R0MS

1 ±20%

4.2/4.7

42

3.2 x 2.5 x 1.2

CYNTEC

PIME031B-1R0MS

1 ±20%

4.5/5.4

55

3.7 x 3.3 x 1.2

CYNTEC

PISB25201T-1R0MS

1 ±20%

3.6/3.9

62

2.5 x 2.0 x 1.0

CYNTEC

IHLP1212AB-11

1 ±20%

/5.0

37.5

3.6 x 3.0 x 1.2

VISHAY

(1)

IHLP1212AE-11

1 ±20%

/5.3

33

3.6 x 3.0 x 1.5

VISHAY

XFL4015-122ME_

1.2±20%

/4.5

20.7

4.0 x 4.0 x 1.5

COILCRAFT

XFL4020-102ME_

1 ±20%

/5.4

11.9

4.0 x 4.0 x 2.1

COILCRAFT

TFM201610-GHM

1 ±20%

3.6/3.8

60

2.0 x 1.6 x 1.0

TDK

TFM252010-GHM

1 ±20%

3.5/4.0

56

2.5 x 2.0 x 1.0

TDK

ISAT at 30% drop of inductance (ΔIL/IL).

The TPS6218x is not designed to operate with only one inductor.

9.2.1.2.5 Output Capacitor Selection

The TPS6218x provides a wide output voltage range of 0.9 V to 6 V. While stability is a critical criteria for the

output filter selection, the output capacitor value also determines transient response behavior, ripple and

accuracy of VOUT. Table 6 gives recommendations to achieve various transient design targets using 1-µH

inductors and small sized output capacitors (see Table 2).

Table 6. Recommended Output Capacitor Values

OUTPUT

VOLTAGE [V]

0.9 (2)

1.8

3.3

(1)

(2)

(3)

LOAD STEP [A]

(NOMINAL) CAPACITOR VALUE (1)

2-6-2 (3)

2-6-2

2-6-2

(3)

(3)

TYPICAL TRANSIENT RESPONSE ACCURACY

±mV

±%

4 x 47 µF

90

10

6 x 47 µF

70

8

2 x 47 µF

150

8

4 x 47 µF

120

7

8 x 47 µF

90

5

2 x 47 µF

170

5

4 x 47 µF

135

4

8 x 47 µF

100

3

Ceramic capacitors have a dc bias effect where the effective capacitance differs significantly from the nominal value, depending on

package size, voltage rating and dielectric material.

For output voltages < 1.8V an additional feedforward capacitor of 82pF, parallel to R1 is recommended to increase stability margin at

heavy load steps.

The transient load step is tested with 1-µs/step rising/falling slopes.

spacing

The architecture of the TPS6218x allows the use of tiny ceramic output capacitors with low equivalent series

resistance (ESR). These capacitors provide low output voltage ripple and are recommended. To keep its low

resistance up to high frequencies and to get narrow capacitance variation with temperature, it is recommended to

use X7R or X5R dielectrics. Using even higher values than demanded for stability and transient response has

further advantages like smaller voltage ripple and tighter dc output accuracy in Power Save Mode.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

17

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

9.2.1.2.6 Input Capacitor Selection

The input current of a buck converter is pulsating. Therefore, a low ESR input capacitor is required to prevent

large voltage transients and provide peak currents. The recommended value for most applications is 2 x 22 µF,

split between the VIN1 and VIN2 inputs and placed as close as possible to these pins and PGND pins. If

additional capacitance is needed, it can be added as bulk capacitance. To ensure proper operation, the effective

capacitance at the VIN pins must not fall below 2 x 2 µF (close) + 10 µF bulk (effective capacitances).

Low ESR multilayer ceramic capacitors are recommended for best filtering. Increasing with input voltage, the dc

bias effect reduces the nominal capacitance value significantly. To decrease input ripple current further, larger

values of input capacitors can be used.

9.2.1.2.7 Soft Start Capacitor Selection

The TPS6218x provides a user programmable soft start time. A constant current source of 5 µA, internally

connected to the SS/TR pin, allows control of the startup slope by connecting a capacitor to this pin. The current

source charges the capacitor and the soft start time is given by:

spacing

CSS = t SS ×

5mA

1.25V

(14)

spacing

where CSS is the soft-start capacitance required at the SS/TR pin and tss is the resulting soft-start ramp time.

spacing

The SS/TR pin should not be left floating and a minimum capacitance of 220 pF is recommended. Using

Equation 14, and inserting tSS = 750 µs, a value of 3 nF is calculated. 3.3 nF is chosen as a standard value for

this example.

18

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

9.2.1.3 Application Performance Curves

VIN = 12 V, VOUT = 3.3 V, TA = 25°C, (unless otherwise noted)

VOUT = 6 V

VOUT = 6 V

Figure 11. Efficiency vs Load Current

VOUT = 3.3 V

Figure 12. Efficiency vs Input Voltage

VOUT = 3.3 V

Figure 13. Efficiency vs Load Current

VOUT = 1.8 V

Figure 14. Efficiency vs Input Voltage

VOUT = 1.8 V

Figure 15. Efficiency vs Load Current

Figure 16. Efficiency vs Input Voltage

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

19

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

VOUT = 0.9 V

20

VOUT = 0.9 V

Figure 17. Efficiency vs Load Current

Figure 18. Efficiency vs Input Voltage

Figure 19. Output Voltage vs Output Current (Load

regulation)

Figure 20. Output Voltage vs Input Voltage (Line

regulation)

Figure 21. Maximum Output Current vs Input Voltage

Figure 22. Switching Frequency vs Output Current

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

Figure 23. Startup into 33 Ω (100 mA)

Figure 24. Startup into 1 Ω (3.3 A)

Figure 25. Startup into 0.5 Ω (6.6 A)

Figure 26. Output Discharge (No load)

IOUT = 3 A

IOUT = 100 mA

Figure 27. Typical Operation (PWM)

Figure 28. Typical Operation (PSM)

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

21

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

Figure 29. Load Transient Response (PSM-PWM)

VOUT = 1.8 V

COUT = 6x47 µF

VOUT = 1.8 V

Figure 31. Transient Response to a load step of 1-6A

(1A/µs)

RLOAD = 0.33 Ω

Submit Documentation Feedback

COUT = 6x47 µF

additional CFF = 82

pF

Figure 32. Transient Response to a load step of 1-6A

(1A/µs)

RLOAD = 0.33 Ω

Figure 33. HICCUP at Overload Condition

22

Figure 30. Load Transient Response (PWM-PWM)

Figure 34. HICCUP at Overload Condition

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

Figure 35. HICCUP at Short Circuit

Figure 36. HICCUP at Short Circuit

Figure 37. Maximum Ambient Temperature

space

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

23

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

9.2.2 TPS62180 Low Profile Solution

This design example is based on Figure 10 again, providing a very small (see Figure 38) and low profile solution,

using low profile inductors.

9.2.2.1 Design Requirements

The input parameters used for this design are given in Table 7 and give a total solution size of about 72mm2,

using inductors with a maximum height of 1.2 mm:

space

Table 7. Components Used for Application Characteristics

REFERENCE NAME

DESCRIPTION / VALUE

MANUFACTURER

TPS62180YZF

2 phase step down converter, 2 x 3 mm WCSP

Texas Instruments

L1, L2

Inductor DFE252012P, 1 µH ±20%, 2.5 x 2 x 1.2 mm

Toko

CIN

Ceramic capacitor GRM21BR61E226ME44, 2 x 22 µF, 25 V, X5R, 0805

muRata

COUT

Ceramic capacitor GRM21BR60J476ME15, 2 x 47 µF, 6.3 V, X5R, 0805

muRata

CSS

Ceramic capacitor, 10 nF

Standard

R1

Chip resistor, value depending on VOUT

Standard

R2

Chip resistor, value depending on VOUT

Standard

R3

Chip resistor, 470 kΩ, 0603, 1/16 W, 1%

Standard

space

9.2.2.2 Detailed Design Procedure

As opposed to the previous example, the solution size, including height, is limited and the soft start time is

longer. This is achieved by using smaller inductors, as well as using a different soft start capacitor.

9.2.2.2.1 Inductor

Using Table 5, the 1-µH DFE252012P is chosen with dimensions of 2.5 x 2.0 x 1.2 mm. The larger DCR of 42

mΩ maximum causes some efficiency drop (see comparison below).

space

Figure 38. Ultra Small Solution Size

Figure 39. Efficiency vs Inductor Size/Type

space

24

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

9.2.2.2.2 Input and Output Capacitors

Since electrical design parameters are unchanged, the same values as chosen in the previous example are used

for these capacitors.

9.2.2.2.3 Soft Start Capacitor

Using Equation 14 again, and inserting tSS = 2.5 ms gives a capacitance of 10 nF, which is chosen.

9.2.2.2.4 Using the Accurate EN Threshold

The TPS6218x provides a very accurate EN threshold voltage. This can be used to switch on the device

according to a VIN or another voltage level by using a resistive divider as shown below.

space

VIN

VIN

REN1

EN

REN2

Figure 40. Resistive Divider for Controlled EN Threshold

space

The values of REN1 and REN2, needed to set EN = High at a specific VIN can be calculated according to

Kirchhoff's laws, shown in Equation 15 and used in the following example:

space

VIN = VEN _ threshold ×

REN 1 + REN 2

REN 2

(15)

space

For a typical 8-V input rail, the device turn on target value is set to 5.5 V. The current through the resistive divider

is set to 10 µA, which indicates a total resistance of about 800 kΩ. Appropriate standard resistor values, fitting

Equation 15, are REN1 = 680 kΩ and REN2 = 150 kΩ. As a result, the device switches on, when VIN has reached

5.5 V and the current through the divider is 9.6 µA. The device switches off at a threshold of 0.9 V. Using

Equation 15 again, this case gives a level of VIN = 5.0 V.

Figure 47 to Figure 50 show thresholds and appropriate device behavior with a startup time of about 800 µs.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

25

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

9.2.2.3 Application Performance Curves

VIN = 12 V, VOUT = 3.3 V, TA = 25°C, (unless otherwise noted)

Figure 41. Efficiency vs Load Current

VIN = 8 V, IOUT = 4 A

26

Figure 42. Efficiency vs Input Voltage

CSS = 10 nF

Figure 43. Typical Operation (PWM)

Figure 44. Startup into 1 Ω (3.3 A)

Figure 45. Load Transient Response (PSM-PWM)

Figure 46. Load Transient Response (PWM-PWM)

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

VIN = 5.5 V (Rising), VIN = 5.0 V (Falling)

Figure 47. Accurate EN Threshold

VIN = 5.5 V (Rising)

Figure 48. Accurate EN Threshold Showing VOUT

VIN = 5.0 V (Falling)

Figure 49. Accurate EN Threshold

Figure 50. Accurate EN Threshold

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

27

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

9.3 TPS62180 Output Voltage Application Examples

This section provides typical schematics for commonly used output voltage values.

9.3.1 Application Schematic Examples

space

22µF

1µH

VIN1

4 to 15 V

SW1

0.9V/6A

1µH

VIN2

SW2

VO

22µF

470k

TPS62180

PG

EN

20k

FB

SS/TR

GND

3.3nF

4x

47µF

160k

Copyright © 2017, Texas Instruments Incorporated

Figure 51. 0.9-V/6-A Power Supply

space

22µF

1µH

VIN1

4 to 15 V

SW1

1.8V/6A

1µH

VIN2

SW2

VO

22µF

470k

TPS62180

PG

EN

2x

47µF

FB

SS/TR

3.3nF

200k

GND

160k

Copyright © 2017, Texas Instruments Incorporated

Figure 52. 1.8-V/6-A Power Supply

space

28

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

TPS62180 Output Voltage Application Examples (continued)

22µF

1µH

VIN1

4 to 15 V

SW1

3.3V/6A

1µH

VIN2

SW2

VO

22µF

470k

TPS62180

PG

EN

470k

2x

47µF

FB

SS/TR

GND

3.3nF

150k

Copyright © 2017, Texas Instruments Incorporated

Figure 53. 3.3-V/6-A Power Supply

space

22µF

1µH

VIN1

(4) to 15 V

SW1

5V/6A

1µH

VIN2

SW2

VO

22µF

470k

TPS62180

PG

EN

430k

FB

SS/TR

GND

3.3nF

4x

47µF

82k

Copyright © 2017, Texas Instruments Incorporated

Figure 54. 5-V/6-A Power Supply

9.3.2 Design Requirements

Based on Figure 10, the schematics shown in Figure 51 through Figure 54 show different output voltage divider

values to get different VOUT. Another design target is to have about 5-µA current through the divider.

9.3.3 External Component Selection

The values for the voltage divider are derived using the procedure given in Programming the Output Voltage.

While Equation 10 and Equation 11 are used to calculate R2 and R1, the values are aligned with standard

resistor values.

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

29

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

10 Power Supply Recommendations

The TPS6218x are designed to operate from a 4-V to 15-V input voltage supply. The input power supply's output

current needs to be rated according to the output voltage and the output current of the power rail application.

30

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�TPS62180, TPS62182

www.ti.com

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

11 Layout

11.1 Layout Guidelines

The PCB layout of the TPS6218x demands careful attention to ensure proper operation, thermal profile, low

noise emission and to achieve best performance. A poor layout can lead to issues like poor regulation, stability

and accuracy weaknesses, increased EMI radiation and noise sensitivity. While the TPS6218x provides very high

power density, the PCB layout also contributes significantly to the thermal performance.

11.1.1 PCB Layout

A recommended PCB layout for the TPS62180 dual phase solution is shown below. It ensures best electrical and

optimized thermal performance considering the following important topics:

• The input capacitors must be placed as close as possible to the appropriate pins of the device. This provides

low resistive and inductive paths for the high di/dt input current. The input capacitance is split, as is the VIN

connection, to avoid interference between the input lines.

• The SW node connection from the IC to the inductor conducts high currents. It should be kept short and can

be designed in parallel with an internal or bottom layer plane, to provide low resistance and enhanced thermal

behavior.

• The VOUT regulation loop is closed with COUT and its ground connection. If a ground layer or plane is used, a

direct connection by vias, as shown, is recommended. Otherwise the connection of COUT to GND must be

short for good load regulation.

• The FB node is sensitive to dv/dt signals. Therefore the resistive divider should be placed close to the FB pin,

avoiding long trace distance. Using the TPS62182 (fixed output voltage version), the FB pin can be left

floating, but it is good practice and recommended to connect it to AGND for best thermal characteristics.

11.2 Layout Example

space

L1

VOUT

C3

VIN

C1

C2

R1

C5 R2

GND

C4

VOUT

L2

Figure 55. TPS62180 Board Layout

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

Submit Documentation Feedback

31

�TPS62180, TPS62182

SLVSBB8B – AUGUST 2014 – REVISED MAY 2017

www.ti.com

12 Device and Documentation Support

12.1 Device Support

12.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

12.2 Related Links

The table below lists quick access links. Categories include technical documents, support and community

resources, tools and software, and quick access to sample or buy.

Table 8. Related Links

PARTS

PRODUCT FOLDER

SAMPLE & BUY

TECHNICAL

DOCUMENTS

TOOLS &

SOFTWARE

SUPPORT &

COMMUNITY

TPS62180

Click here

Click here

Click here

Click here

Click here

TPS62182

Click here

Click here

Click here

Click here

Click here

12.3 Trademarks

AEE, NanoFree are trademarks of Texas Instruments.

WEBENCH is a registered trademark of Texas Instruments.

12.4 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

12.5 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

13 Mechanical, Packaging, and Orderable Information

The following pages include mechanical packaging and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

32

Submit Documentation Feedback

Copyright © 2014–2017, Texas Instruments Incorporated

Product Folder Links: TPS62180 TPS62182

�PACKAGE OPTION ADDENDUM

www.ti.com

3-Jun-2022

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

Samples

(4/5)

(6)

TPS62180YZFR

ACTIVE

DSBGA

YZF

24

3000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

ELC180

Samples

TPS62180YZFT

ACTIVE

DSBGA

YZF

24

250

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

ELC180

Samples

TPS62182YZFR

ACTIVE

DSBGA

YZF

24

3000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

ELC182

Samples

TPS62182YZFT

ACTIVE

DSBGA

YZF

24

250

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

ELC182

Samples

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of