Product

Folder

Order

Now

Support &

Community

Tools &

Software

Technical

Documents

TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

TPS63805 High Current, High Efficiency Single Inductor Buck-Boost Converter

1 Features

2 Applications

•

•

1

•

•

•

•

•

•

Input Voltage Range: 1.3 V to 5.5 V

(>1.8 V for Device Start-up)

Adjustable Output Voltage Range: 1.8 V to 5 V

2-A Output Current for VIN ≥ 2.3 V, VOUT = 3.3 V

High Efficiency over the entire load range

– 11-μA Operating Quiescent Current

– Power Save Mode with Mode Selection

Peak Current Buck-Boost Mode Architecture

– Seamless Transition within Operation Modes

– Wide Output Capacitor Selection

– Forward and Reverse Current Operation

Safety- and Robust Operation Features

– Integrated Soft Start

– Over-Temperature- and Over-VoltageProtection

– True Shutdown Function with Load Disconnect

Tiny Solution Size

– 1.4 mm x 2.3 mm Package size

– Small 0.47 µH inductor, Single 22 µF Output

Capacitor

•

•

•

•

System Pre-Regulator (Smartphone, Tablet, EFT

Terminal, Telematics)

Point-of-Load Regulation (Wired Sensor,

Port/Cable Adapter and Dongle)

Fingerprint / Face-ID / Camera Sensors

(Smartphone, Electronic Smart Lock, IP Network

Camera)

RF Amplifier Supply (Smart Sensors)

Thermoelectric Device (TEC) Supply (Datacom

Optical Modules)

3 Description

The TPS63805 is a high efficiency, high output

current buck-boost converter. It is used when the

input voltage is higher, equal, or lower than the output

voltage. Output currents up to 2 A are supported over

a wide voltage range. The device limits the peak

current at 4.5 A in Boost-Mode and 3.5 A in BuckMode. The device is adjusted to the programmed

output voltage. It automatically changes from buck to

boost operation based on the input voltage. It

remains in a 3-cycle buck-boost mode when the input

voltage is approximately equal to the output voltage.

The transitions happen seamlessly and avoids

unwanted toggling within the modes. The TPS63805

comes in a 1.4 mm x 2.3 mm package. The device

works with tiny passive components to keep the

overall solution size small.

Device Information(1)

PART NUMBER

TPS63805

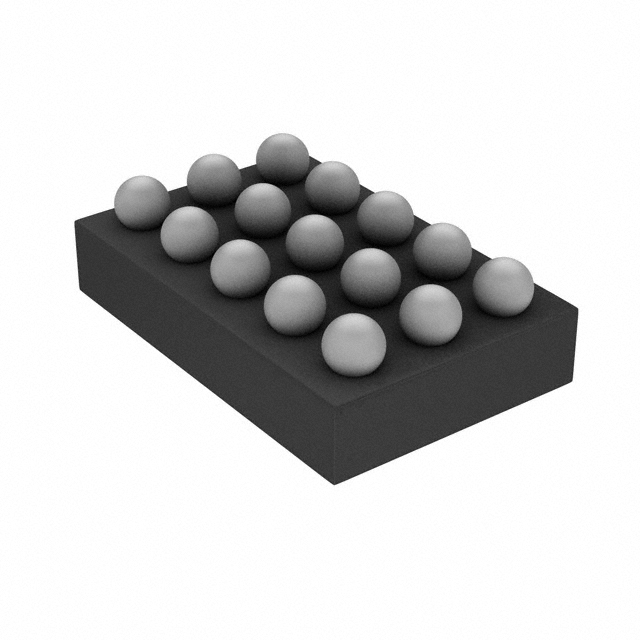

PACKAGE

3x5 Balls WCSP

(0.4mm pitch)

BODY SIZE (NOM)

2.3 mm x 1.4 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

Typical Application

Efficiency vs Output Current (VO = 3.3V)

0.47µH

1

0,96

0,92

L2

VIN

VOUT

3.3V / 2A

VOUT

22 …F

10 …F

EN

PG

MODE

FB

0,88

Efficiency

L1

VIN

1.3V t 5.5V

0,84

0,8

0,76

0,72

VIN

VIN

VIN

VIN

0,68

GND

AGND

TPS63805

0,64

0,6

100P

1m

10m

100m

Output Current (A)

=

=

=

=

2.5V

3.0V

3.7V

4.3V

1

2

D002

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Device Comparison Table.....................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

3

4

7.1

7.2

7.3

7.4

7.5

7.6

4

4

4

4

5

7

Absolute Maximum Ratings ......................................

ESD Ratings ............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

8.3 Feature Description................................................... 9

8.4 Device Functional Modes........................................ 12

9

Application and Implementation ........................ 17

9.1 Application Information............................................ 17

10 Power Supply Recommendations ..................... 24

11 Layout................................................................... 24

11.1 Layout Requirements ............................................ 24

11.2 Layout Example .................................................... 24

12 Device and Documentation Support ................. 25

12.1

12.2

12.3

12.4

12.5

12.6

Detailed Description .............................................. 8

8.1 Overview ................................................................... 8

8.2 Functional Block Diagram ......................................... 8

Device Support......................................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

25

25

25

25

25

25

13 Mechanical, Packaging, and Orderable

Information ........................................................... 25

4 Revision History

2

DATE

REVISION

NOTES

October 2018

A

Initial release

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

5 Device Comparison Table

PART NUMBER

VOUT

TPS63805

Adjustable

6 Pin Configuration and Functions

WCSP Package

Top View

Pin Functions table

PIN

NO

DESCRIPTION

NAME

A2, A3

VIN

Supply voltage

B2, B3

L1

Connection for inductor

A1

EN

Device Enable input. Set HIGH to enable and LOW to disable. It must not be left floating

GND

Power ground

B1

MODE

PFM/PWM mode selection. Set LOW for power safe mode, set HIGH for forced PWM mode. It must not be

left floating

C1

C2, C3

AGND

Analog ground

D2, D3

L2

Connection for inductor

E2, E3

VOUT

Power stage output

D1

FB

Voltage feedback sensing Pin

E1

PG

Power good indicator, open drain output

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

3

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

7 Specifications

7.1 Absolute Maximum Ratings

over junction temperature range (unless otherwise noted) (1)

Voltage (2)

MIN

MAX

VIN, L1, L2, EN, PFM/PWM, VOUT, FB

–0.3

6.0

L1, L2 (AC, less than 10ns)

UNIT

V

-3.0

9.0

Operating junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–65

150

°C

(1)

(2)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltage values are with respect to network ground pin.

7.2 ESD Ratings

VALUE

Electrostatic

discharge

V(ESD)

(1)

(2)

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

(1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22-C101 (2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

MIN

NOM

MAX

UNIT

VIN

Input voltage

1.3

5.5

V

VOUT

Output voltage

1.8

5.0

V

CIN

Effective capacitance connected to VIN (Ceramic-type placed close to VIN

Terminal)

L

Effective inductance

COUT

Effective capacitance connected to VOUT

TJ

Operating junction temperature

4

5

0.37

0.47

7

10

–40

μF

0.57

μH

μF

125

°C

7.4 Thermal Information

over operating free-air temperature range (unless otherwise noted)

TPS63805

THERMAL METRIC

3x5 Ball WCSP

UNIT

15 PINS

RΘJA

Junction-to-ambient thermal resistance

78.8

°C/W

RΘJC(top)

Junction-to-case (top) thermal resistance

0.6

°C/W

RΘJB

Junction-to-board thermal resistance

19.5

°C/W

ΨJT

Junction-to-top characterization parameter

0.3

°C/W

ΨJB

Junction-to-board characterization parameter

19.5

°C/W

RΘJC(bot)

Junction-to-case (bottom) thermal resistance

N/A

°C/W

4

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

7.5 Electrical Characteristics

VIN= 1.8 V to 5.5 V, VOUT = 1.8 V - 5.0 V , TJ= –40°C to +125°C, typical values are at TJ= 25°C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SUPPLY

VOUT ≥ 1.8 V

VIN

Input voltage (operation)

VIN;START

Input voltage (Device start-up)

VIN;LOAD

Minimum input voltage for full load,

once started

IOUT = 2 A, VOUT = 3.3 V, TJ =

25°C

2.3

V

IQ;VIN

Quiescent current into VIN

TJ = 25°C, EN = VIN = 3.6 V, VOUT =

3.3 V, not switching

11

μA

ISD

Shutdown current into VIN

EN = low, -40°C ≤ TJ ≤ 85°C, VIN =

3.6 V, VOUT = 0 V

Undervoltage lockout threshold

VIN falling, VOUT ≥ 1.8 V, once

started

1.2

1.6

UVLO

Undervoltage lockout threshold

VIN rising

TSD

Thermal shutdown

Temperature rising

TSD;HYST

Thermal shutdown hysteresis

VIVP

Input Overvoltage Protection

1.3

5.5

V

1.8

5.5

V

5.50

0.01

0.6

µA

1.25

1.29

V

1.7

1.79

V

150

°C

20

°C

5.66

5.78

V

SOFT-START, POWER GOOD

tSS

Soft-start, Current limit ramp time

TJ = 25°C, from 0 V to 0.95xVOUT,

VIN = 3.6 V, VOUT = 3.3 V, no load

0.6

ms

tEN;DELAY

Delay from EN-edge until rising

VOUT

TJ = 25°C, VIN = 3.6 V

100

μs

LOGIC SIGNALS EN, MODE

VTHR;EN

Threshold Voltage rising for EN-Pin

1.07

1.1

1.13

V

VTHF;EN

Threshold Voltage falling for EN-Pin

0.97

1

1.03

V

VIH

High-level input voltage

VIL

Low-level input voltage

VPG;rising

Power Good threshold voltage

VPG;falling

1.2

V

0.4

VOUT rising, referenced to VOUT

nominal

95%

VOUT falling, referenced to VOUT

nominal

90%

VPG;Low

Power Good low-level output voltage ISINK = 1 mA

tPG;delay

Power Good delay time

Ilkg

Input leakage current

0.4

VFB falling

40

0.01

V

V

µS

0.2

µA

5.0

V

0.6

µA

OUTPUT

VOUT

Output Voltage

1.8

EN = low, -40°C ≤ TJ ≤ 85°C, VIN =

0.0 V, VOUT = 3.3 V

ISD

Shutdown current into VOUT

VFB

Feedback Regulation Voltage

VFB

Feedback Voltage accuracy

PWM mode

–1%

1%

VFB

Feedback Voltage accuracy

PFM mode

–1%

3%

VOVP

Overvoltage Protection

Clamping Voltage to protect the

device output

5.50

5.66

5.78

V

ISKIP

Peak Inductor Current to enter PFMVIN = 3.6 V; VOUT = 3.3 V

Mode

550

700

900

mA

IFB

Feedback Input Bias Current

VFB = 500 mV

10

100

nA

Peak Current Limit, Boost Mode

VIN ≥ 2.5V

3.5

4.8

5.8

A

Peak Current Limit, Buck-Boost

Mode

VIN ≥ 2.5V

4.5

A

Peak Current Limit, Buck Mode

VIN ≥ 2.5V

3.5

A

Peak Current Limit for Reverse

Operation

VIN = 3.6 V, VOUT = 3.3 V

-0.75

A

IPK

IPK;Reverse

0.01

500

-0.5

mV

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

5

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

Electrical Characteristics (continued)

VIN= 1.8 V to 5.5 V, VOUT = 1.8 V - 5.0 V , TJ= –40°C to +125°C, typical values are at TJ= 25°C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

Buck

RDS;ON

High-side FET on-resistance

VIN = 3 V, VOUT = 3.3 V

47

mΩ

Low-side FET on-resistance

VIN = 3 V, VOUT = 3.3 V

30

mΩ

Boost

RDS;ON

High-side FET on-resistance

VIN = 3 V, VOUT = 3.3 V

43

mΩ

Low-side FET on-resistance

VIN = 3 V, VOUT = 3.3 V

18

mΩ

fSW

Inductor Switching Frequency, Boost VIN = 2.3V, VOUT = 3.3V, no Load,

Mode

MODE = HIGH, TJ = 25°C

2.1

MHz

fSW

Inductor Switching Frequency, Buck

Mode

2.7

MHz

fSW

Inductor Switching Frequency, Buck- VIN = 3.3V, VOUT = 3.3V, no Load,

Boost Mode

MODE = HIGH, TJ = 25°C

1.4

MHz

Line regulation

VIN = 2.4 V to 5.5 V, VOUT = 3.3V,

IOUT = 2 A

0.5%

Load regulation

VIN= 3.6 V, VOUT = 3.3V, IOUT = 0 A

to 2 A, PWM Mode

0.5%

6

VIN = 4.3, VOUT = 3.3V, no Load,

MODE = HIGH, TJ = 25°C

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

7.6 Typical Characteristics

16

1.4

VI = 1.8V

VI = 3.6V

VI = 5.5V

1

12

0.8

10

0.6

8

0.4

6

0.2

4

0

2

-0.2

-40

-20

0

VI = 1.8V

VI = 3.6V

VI = 5.5V

14

IQ [PA]

ISD [PA]

1.2

20

40

60

80

Temperature [°C]

100

120

140

0

-40

-20

D001

fsw_

EN = LOW

MODE = LOW

Figure 1. Shutdown Current vs. Temperature

0

20

40

60

80

Temperature [°C]

100

120

140

D001

fsw_

VO = 3.3V, 0mA load, not switching

Figure 2. Quiescent Current vs Temperature

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

7

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

8 Detailed Description

8.1 Overview

The TPS63805 Buck-Boost converter uses 4 internal switches to maintain synchronous power conversion at all

possible operating conditions. This enables the device to keep high efficiency over a wide input voltage and

output load range. To regulate the output voltage at all possible input voltage conditions, the device automatically

transits between buck, buck-boost and boost operation as required by the configuration. In buck and boost

modes, it always uses one active switch, one rectifying switch, one switch on, and one switch held off. Therefore,

it operates as a buck converter when the input voltage is higher than the output voltage, and as a boost

converter when the input voltage is lower than the output voltage. When the input voltage is close to the output

voltage, it operates in a 3-cycle buck-boost operation. In this mode all 4 switches are active (seeBuck-Boost

Operation) The RMS current through the switches and the inductor is kept at a minimum, to minimize switching

and conduction losses. Controlling the switches this way allows the converter to always keep high efficiency over

the complete input voltage range. The device provides a seamless transition between all modes.

8.2 Functional Block Diagram

L

L1

L2

VOUT

VIN

CIN

COUT

Current

Sensor

Gate

Driver

Gate

Driver

Device

Control

Device

Control

VIN

VMAX Switch

VOUT

PG

Device

Control

EN

+

Ref

1.1V

Device Control

FB

+

±

VIN

MODE

VOUT

GND

Power Safe Mode

Protection

Current Limit

Buck/Boost Control

Off-time calculation

Soft-Start

±

+

±

Gate

Driver

Ref

500mV

Power

Good

AGND

L1, L2

8

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

8.3 Feature Description

8.3.1 Control Loop Description

TPS63805 uses a peak current mode control architecture. It has an inner current loop where it measures the

peak current of the boost High-Side MOSFET and compares it to a reference current. This current is the output

of the outer voltage loop. It measures the output voltage via the FB-Pin and compares it with the internal voltage

reference. That means, the outer voltage loop measures the voltage error (VREF-VFB) and transforms it into the

system current demand (IREF) for the inner Current Loop.

Figure 3 shows the simplified schematic of the control loop. The Error Amplifier and its Type-2 compensation

represent the voltage loop. Its voltage output is converted into ther reference current IREF and fed into the

current comparator.

The Scheme shows as well the Skip-Comparator handling the Power Safe Mode (PFM) to achieve high

Efficiency at light loads. See Power Save Mode Operation for further details.

VIN

L1

IPK

±

IREF

+

FB

VEA

+

Ref

500mV

Gate

Driver

±

+

ISKIP

±

Figure 3. Control Loop Architecture Scheme

8.3.2 Precise Device Enable: Threshold- or delayed Enable

The Enable-Pin is a digital input to enable or disable the device by applying a high- or low-level. The device

enters shutdown when EN is set low. In addition, this input features a precise threshold and can be used as a

comparator that enables/disables the part at a defined threshold. This allows to drive the state by a slowly

changing voltage and enables the use of an external RC network to achieve a precise power-up delay. The

enable pin can also be used with an external voltage divider to set a user-defined minimum supply voltage. For

proper operation, the EN pin must be terminated and must not be left floating.

VTHRESHOLD

VDELAY

R4

R4

EN

R5

EN

C5

Figure 4. Circuit Example how to use the Precise Device Enable feature

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

9

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

Feature Description (continued)

8.3.3 Mode Selection (PFM/PWM)

The Mode-Pin is a digital input to enable the automatic PWM/PFM Mode that features highest efficiency by

allowing Pulse-Frequency-Modulation for lower output currents. This mode is enabled by applying a low level.

The device can be forced in PWM operation regardless of the output current to achieve minimum output ripple by

applying a high level. This pin must not be left floating

8.3.4 Undervoltage Lockout (UVLO)

To avoid mis-operation of the device at low input voltages, an undervoltage lockout is included. It activates the

device once the input voltage (VI) has risen the UVLOrising value. Once active, the device allows operation down

to even smaller input voltages which is determined by the UVLOfalling. This behavior requires VO to be higher than

the minimum value of 1.8V.

UVLOrising

UVLOfalling

VIN

Device

active

Figure 5. Rising and falling Undervoltage Lockout behavior

10

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

Feature Description (continued)

8.3.5 Softstart

To minimize inrush current and output voltage overshoot during start-up, the device features a controlled soft

start-up. After device enable, the device starts all internal reference and control circuits within the enable delay

time Tdelay. After that, the maximum switch current limit raises monotonic from zero mA to the current limit. The

loop stops switching once VO is reached. This allows a quick output voltage raise for small capacitors at the

output. The bigger the output capacitor, the longer it takes to settle Vout. A potential load during start is

lengthening the ramp as well. The raise of the current limit allows smallest inrush current for no-load conditions,

as well as the possibility to start into high loads at start-up.

VIN

EN

Current

Limit

Inductor

Current

0.95 x VOUT

VOUT

Power

Good

Tde lay

Tramp

TStart-up

Figure 6. Device Start-up Scheme

8.3.6 Adjustable Output Voltage

The devices output voltage is adjusted by applying an external resistive divider between VO, FB-Terminal and

GND. This allows to program the output voltage in the recommended range. The divider should provide a lowside resistor of less than 100 KΩ. The high-side resistor is chosen accordingly.

8.3.7 Over Temperature Protection - Thermal Shutdown

The device has a built-in temperature sensor which monitors the IC temperature. If the temperature exceeds the

threshold, the device stops operating. As soon as the IC temperature has decreased below the programmed

threshold, it starts operating again. There is a built-in hysteresis to avoid unstable operation at IC temperatures at

the over-temperature threshold.

8.3.8 Input Overvoltage - Reverse-Boost Protection (IVP)

TPS63805 can operate in reverse mode where the device transfers energy from the output back to the input. If

the source would not be able to sink that current, potentially charge can build up uncontrolled and VIN rises. To

protect the device and other components from that scenario, the device features an Input Voltage Protection

(IVP) for reverse Boost Operation. Once the input voltage is above the threshold, the converter stops switching.

The PG signal goes low to indicate that behavior.

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

11

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

Feature Description (continued)

8.3.9 Output Overvoltage Protection (OVP)

In case of a broken feedback-path connection the device can loose VO information and is not able to regulate. To

avoid a uncontrolled boosting of VO, TPS63805 features an Output Overvoltage Protection. It measures the

voltage on VOUT-Pin and stops switching when VO is greater than the threshold avoid harm of the converter and

of other components.

8.3.10 Power Good Indicator

The power good goes high-impedance once the output is above 95% of the nominal voltage, and is driven low

once the output voltage falls below typically 90% of the nominal voltage. This feature also indicates Overvoltage

and device shutdown cases as shown in the table The PG pin is an open-drain output and is specified to sink up

to 1 mA. The power good output requires a pull-up resistor connecting to any voltage rail less than 5.5 V. The

PG signal can be used for sequencing of multiple rails by connecting it to the EN pin of other converters. Leave

the PG pin unconnected when not used.

Table 1. Power Good Indicator Truth Table

Logic Signals

EN

VOUT

VIN

OVP

IVP

PG LOGIC STATUS

X

< 1.8V

< UVLO_R

X

X

undefined

LOW

X

> UVLO_F

X

X

LOW

HIGH

VOUT < 0.9 *

target-VOUT

> 1.3V

X

X

LOW

HIGH

X

> UVLO_F

HIGH

X

LOW

HIGH

X

> UVLO_F

X

HIGH

LOW

HIGH

VOUT > 0.95 *

target-VOUT

> UVLO_F

LOW

LOW

HIGH Z

8.4 Device Functional Modes

8.4.1 Peak Current Mode Architecture

The TPS63805 is based on a Peak Current Mode Architecture. The Error Amplifier provides a peak current target

(voltage that is translated into a equivalent current, see Figure 3 ), based on the current demand from the voltage

loop. This target is compared with the actual inductor current during the ON-time. The ON-time is ended once the

inductor current is equal to the current target and OFF-time is initiated. The OFF-time is calculated by the control

and a function of VI and VO.

12

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

Device Functional Modes (continued)

IPEAK

VEAmp

IPK-PK

TON

IIND

TOFF

0

time

Figure 7. Peak Current Architecture Operation

8.4.1.1 Reverse Current Operation, Negative Current

When the TPS63805 is forced to PWM operation (MODE = HIGH), the device current can flow in reverse

direction. This happens by the negative current capability of the TPS63805. The Error Amplifier provides a peak

current target (voltage that is translated into a equivalent current, see Figure 3 ), even so the target has a

negative value. The maximum average current is even more negative than the peak current.

time

0

IPEAK

VEAmp

IIND

IAVG

IPK-PK

Figure 8. Peak Current Operation, Reverse Current

8.4.1.2 Boost Operation

When VI is smaller than VO (and the voltages are not close enough to trigger Buck-Boost operation), TPS63805

operates in Boost Mode where the Boost High-Side & Low-Side Switches are active. The Buck High-Side Switch

is always turned on, the Buck Low-Side Switch is always turned off. This lets TPS63805 operate as a classical

Boost Converter.

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

13

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

Device Functional Modes (continued)

IPEAK

VEAmp

IIND

TON

TOFF

Figure 9. Peak Current Boost Operation

8.4.1.3 Buck-Boost Operation

When VI is close to VO, TPS63805 operates in Buck-Boost Mode, where all switches are active and the device

repeats 3-cycles

• TON: Boost Charge Phase where Boost Low-Side and Buck High-Side are closed and inductor current is built

up

• TOFF: Buck Discharge Phase where Boost High-Side and Buck Low-Side are closed and inductor is

discharged

• TCOM: VI connected to VO where all High-Side switches are closed and input is connected to output

IPEAK

VEAmp

IIND

TON

TCOM

TOFF

TCOM

Figure 10. Peak Current Buck-Boost Operation

8.4.1.4 Buck Operation

When VI is greater than VO (and the voltages are not close enough to trigger Buck-Boost operation), TPS63805

operates in Buck Mode where the Buck High-Side & Low-Side Switches are active. The Boost High-Side Switch

is always turned on, the Boost Low-Side Switch is always turned off. This lets TPS63805 operate as a classical

Buck Converter.

14

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

Device Functional Modes (continued)

IPEAK

VEAmp

IIND

TON

TOFF

Figure 11. Peak Current Buck Operation

8.4.2 Power Save Mode Operation

Besides Continuos Conduction (PWM) Mode, TPS63805 features Power Safe (PFM) Mode operation to achieve

high efficiency at light load currents. This is implented by pausing the switching operation depending on the load

current.

The Skip Comparator manages the switching or pause operation. It compares the current demand signal from

the Voltage Loop IREF with the skip threshold ISKIP as shown in Figure 3. If the current demand is lower than the

skip value, the comparator pauses switching operation. If the current demand goes higher (due to falling VO) the

comparator activates the current loop and allows switching according to the loop behavior. Whenever the current

loop has risen VO by bringing charge to the output, the Voltage loop output IREF (respectively VEA) decreases.

When IREF falls below ISKIP-Hysteresis, it automatically goes into pause again.

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

15

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

Device Functional Modes (continued)

ICOIL

VO

ISKIP

VEA

/ IREF

Hysteresis

SKIP

Yes/No

Switching

Pause

t

Figure 12. Power Safe Mode Operation Curves

8.4.2.1 Current Limit Operation

For limiting current and protecting the device and the application, the maximum peak inductor current is limited

internally on the IC. It is measured at the Buck High-Side Switch which turns into an input current detection. To

provide a certain load current across all Operation Modes, the Boost & Buck-Boost peak current limit is higher

than in Buck Mode. It limits the input current and allows no further increase of the delivered current. When using

the device in this Mode, it behaves similar to a current source.

The current limit depends on the operation Mode (Buck, Buck-Boost or Boost Mode) and is listed in the section

Electrical Characteristics

16

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

The TPS63805 is a high efficiency, high current Buck-Boost converter suitable for application where the input

voltage is higher, lower or equal to the output voltage.

9.1.1 Typical Application

L1

0.47µH

L1

VIN

1.3V t 5.5V

VIN

L2

VOUT = 3.3V

VIN

VOUT

R3

100kQ

C1

10 …F

EN

PG

MODE

FB

R1

511kQ

C2

22 …F

R2

91kQ

GND

AGND

TPS63805

Figure 13. 3.3VOUT Typical Application

9.1.1.1 Design Requirements

The design guideline provides a component selection to operate the device within the recommended operating

conditions.

Table 2 shows the list of components for the Application Characteristic Curves.

Table 2. Components for Application Characteristic Curves (1)

REFERENCE

DESCRIPTION

Part Number

MANUFACTURER

TPS63805 2A Buck-Boost Converter (15-ball

WCSP)

TPS63805YFF

Texas Instruments

L1

0.47µH, 4mmx4mmx1.5mm, 5.4A, 7.6mΩ

XFL4015-471ME

Coilcraft

C1

10µF, 0603, Ceramic Capacitor, ±20%, 6.3V

GRM188R60J106ME84

Murata

C2

22uF, 0603, Ceramic Capacitor, ±20%, 6.3V

GRM188R60J226MEA05

Murata

R1

511kΩ, 0603 Resistor, 1%, 100mW

Standard

Standard

R2

91kΩ, 0603 Resistor, 1%, 100mW

Standard

Standard

R3

100kΩ, 0603 Resistor, 1%, 100mW

Standard

Standard

(1)

See Third-Party Products Discalimer

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

17

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

9.1.1.2 Detailed Design Procedure

The first step is the selection of the output filter components. To simplify this process outlines possible inductor

and capacitor value combinations.

9.1.1.2.1

Output Capacitor

For the output capacitor, use of a small ceramic capacitors placed as close as possible to the VOUT and PGND

pins of the IC is recommended. The recommended nominal output capacitor value is a single 22µF for all

programmed output voltages ≤ 4 V. Above that voltage 2x22 µFcapacitors are recommended. It is key to make

sure that the effective capacitance is given according the recommended value in Recommended Operating

Conditions. In general, consider DC-bias effects resulting in less effective capacitance. The choice of the output

capacitance is mainly a tradeoff between size and transient behavior as higher capacitance reduces transient

response over/undershoot.

There is no upper limit for the output capacitance value.

9.1.1.2.2

Input Capacitor Selection

A 10 μF input capacitor is recommended to improve line transient behavior of the regulator and EMI behavior of

the total power supply circuit. An X5R or X7R ceramic capacitor placed as close as possible to the VIN and

PGND pins of the IC is recommended. This capacitance can be increased without limit. If the input supply is

located more than a few inches from the TPS63805 converter additional bulk capacitance may be required in

addition to the ceramic bypass capacitors. An electrolytic or tantalum capacitor with a value of 47 μF is a typical

choice.

9.1.1.2.3 Inductor Selection

The inductor selection is affected by several parameter like inductor ripple current, output voltage ripple,

transition point into Power Save Mode, and efficiency. See Table 3 for typical inductors.

Table 3. List of Recommended Inductors (1)

(1)

INDUCTOR VALUE

COMPONENT SUPPLIER

SIZE (LxWxH mm)

Isat/DCR

0.47uH

XFL4015-471ME

4 x 4 x 1.5

5.4A/7.6mΩ

0.47µH

Toko, DFE201612E

2.0 x 1.6 x 1.2

5.5A/26mΩ

See Third-party Products Disclaimer

For high efficiencies, the inductor should have a low dc resistance to minimize conduction losses. Especially at

high-switching frequencies, the core material has a high impact on efficiency. When using small chip inductors,

the efficiency is reduced mainly due to higher inductor core losses. This needs to be considered when selecting

the appropriate inductor. The inductor value determines the inductor ripple current. The larger the inductor value,

the smaller the inductor ripple current and the lower the conduction losses of the converter. Conversely, larger

inductor values cause a slower load transient response. To avoid saturation of the inductor, the peak current for

the inductor in steady state operation is calculated using Equation 2. Only the equation which defines the switch

current in boost mode is shown, because this provides the highest value of current and represents the critical

current value for selecting the right inductor.

Duty Cycle Boost

IPEAK

D=

V

-V

IN

OUT

V

OUT

(1)

Iout

Vin ´ D

=

+

η ´ (1 - D)

2 ´ f ´ L

(2)

Where,

• D =Duty Cycle in Boost mode

• f = Converter switching frequency (typical 2.5 MHz)

• L = Inductor value

• η = Estimated converter efficiency (use the number from the efficiency curves or 0.90 as an assumption)

18

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

NOTE

The calculation must be done for the minimum input voltage which is possible to have in

boost mode

Calculating the maximum inductor current using the actual operating conditions gives the minimum saturation

current of the inductor needed. It's recommended to choose an inductor with a saturation current 20% higher

than the value calculated using Equation 2. Possible inductors are listed in Table 3.

9.1.1.2.4 Setting The Output Voltage

The output voltage is set by an external resistor divider. The resistor divider must be connected between VOUT,

FB and GND. The feedback Voltage is 500 mV nominal. The low-side resistor R2 (between FB and GND) should

not exceed 100 kΩ. The high-side resistor (between FB and VOUT) R1 is calculated by Equation 3.

æV

ö

R1 = R2 × ç OUT - 1÷

è VFB

ø

(3)

Table 4. Resistor selection for typ. voltages

VOUT

R1

R2

2.5 V

365 kΩ

91 kΩ

3.3 V

511 kΩ

91 kΩ

3.6 V

562 kΩ

91 kΩ

5V

806 kΩ

91 kΩ

9.1.1.3 Application Curves

100

3.5

95

3

90

85

Efficiency [%]

Max. IO [A]

2.5

2

80

75

70

VI

VI

VI

VI

VI

VI

VI

VI

65

1.5

60

55

1

50

0.0001

0.5

VO = 3.3V

0

1

1.5

2

2.5

3

3.5

VI [V]

VO = 3.3

4

4.5

5

5.5

0.001

0.01

0.05

IO [A]

0.2

=

=

=

=

=

=

=

=

0.5 1

1.3V

1.8V

2.3V

2.9V

3.3V

3.7V

4.3V

5V

2 3

TA = 25°C, MODE

= LOW

Figure 15. Efficiency vs. Output Current

D001

fsw_

iout

TA = 25°C

Figure 14. Typical Output Current Capability vs. Input

Voltage

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

19

�TPS63805

www.ti.com

100

100

90

95

80

90

70

85

60

80

Efficiency [%]

Efficiency [%]

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

50

40

VI

VI

VI

VI

VI

VI

VI

VI

30

20

10

0

0.0001

0.001

0.01

0.05

IO [A]

VO = 3.3V

0.2

=

=

=

=

=

=

=

=

0.5 1

1.3V

1.8V

2.3V

2.9V

3.3V

3.7V

4.3V

5V

2 3

TA = 25°C, MODE

= HIGH

75

70

60

55

50

0.0001

no Load, MODE = HIGH

Figure 18. Switching Waveforms, PWM Boost Operation

VI = 4.3V, VO = 3.3V

no Load, MODE = HIGH

Figure 20. Switching Waveforms, PWM Buck Operation

20

0.001

VO = 1.8V

Figure 16. Efficiency vs. Output Current

VI = 2.3V, VO = 3.3V

VI

VI

VI

VI

VI

VI

VI

VI

65

0.01

0.05

IO [A]

0.2

=

=

=

=

=

=

=

=

0.5 1

1.3V

1.8V

2.3V

2.9V

3.3V

3.7V

4.3V

5V

2 3

TA = 25°C, MODE

= LOW

Figure 17. Efficiency vs. Output Current

VI = 3.3V, VO = 3.3V

no Load, MODE = HIGH

Figure 19. Switching Waveforms, PWM Buck-Boost

Operation

VI = 4.3V, VO = 3.3V

no Load, MODE = LOW

Figure 21. Switching Waveforms, PFM Boost Operation

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

VI = 4.3V, VO = 3.3V

no Load, MODE = LOW

Figure 22. Switching Waveforms, PFM Buck-Boost

Operation

VI = 3.8V, VO = 3.3V

10mA load, MODE = LOW

Figure 24. Start-up Behavior from rising Enable

VI = 3.8V, VO = 3.3V

1A load, MODE = LOW

Figure 26. Softstart Waveforms in PFM Mode

VI = 4.3V, VO = 3.3V

no Load, MODE = LOW

Figure 23. Switching Waveforms, PFM Buck Operation

VI = 3.8V, VO = 3.3V

10mA load, MODE = LOW

Figure 25. Softstart Waveforms in PFM Mode

VI = 3.8V, VO = 3.3V

10mA load, MODE = HIGH

Figure 27. Softstart Waveforms in forced PWM Mode

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

21

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

VO = 3.3V

www.ti.com

0mA load, MODE = HIGH

VO = 3.3V

Figure 29. Linesweep Waveforms

Figure 28. Linesweep Waveforms

VO = 3.3V

0mA load, MODE = HIGH

VO = 3.3V

Figure 30. Linestep Waveforms

VI = 4.3V, VO = 3.3V

VO = 200mV/div

1A load, MODE = HIGH

Figure 31. Linestep Waveforms

VI = 3.0V, VO = 3.3V

Figure 32. 1A-Loadstep Waveforms

22

1A load, MODE = HIGH

Submit Documentation Feedback

VO = 200mV/div

Figure 33. 1A-Loadstep Waveforms

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

VI = 4.3V, VO = 3.3V

VO = 500mV/div

VI = 3.0V, VO = 3.3V

Figure 34. 2A-Loadstep Waveforms

VO = 500mV/div

Figure 35. 2A-Loadstep Waveforms

3.5

VI falling

VI rising

3.25

Inductor Switching Frequency [MHz]

3

2.75

2.5

2.25

2

1.75

1.5

1.25

1

0.75

0.5

1

VO = 3.3V

1.5

2

2.5

3

3.5

VI [V]

4

4.5

5

5.5

6

D001

fsw_

no Load

TA = 25°C, MODE = HIGH

Figure 36. Typical Inductor Switching Frequency vs. Input Voltage

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

23

�TPS63805

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

www.ti.com

10 Power Supply Recommendations

The TPS63805 device family has no special requirements for its input power supply. The input power supply

output current needs to be rated according to the supply voltage, output voltage and output current of the

TPS63805.

11 Layout

11.1 Layout Requirements

The PCB layout is an important step to maintain the high performance of the TPS63805 devices.

• Place input and output capacitors as close as possible to the IC. Traces need to be kept short. Routing wide

and direct traces to the input and output capacitor results in low trace resistance and low parasitic inductance.

• Separate AGND and PGND: Do not connect AGND and PGND directly at the IC! See Figure 37 as an

example.

• Use a common-power GND but connect AGND & PGND through a via at a different layer.

• Use separate traces for the supply voltage of the power stage; and, the supply voltage of the analog stage.

• The sense trace connected to FB is signal trace. Keep these traces away from L1 and L2 nodes.

11.2 Layout Example

Figure 37. TPS63805 Example Layout

24

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

�TPS63805

www.ti.com

SLVSDS9A – JULY 2018 – REVISED OCTOBER 2018

12 Device and Documentation Support

12.1 Device Support

12.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

12.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

12.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

12.4 Trademarks

E2E is a trademark of Texas Instruments.

12.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

12.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

13 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

Product Folder Links: TPS63805

25

�PACKAGE OPTION ADDENDUM

www.ti.com

20-Oct-2018

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

Lead/Ball Finish

MSL Peak Temp

(2)

(6)

(3)

Op Temp (°C)

Device Marking

(4/5)

TPS63805YFFR

ACTIVE

DSBGA

YFF

15

3000

Green (RoHS

& no Sb/Br)

SNAGCU

Level-1-260C-UNLIM

-40 to 125

TPS63805

TPS63805YFFT

ACTIVE

DSBGA

YFF

15

250

Green (RoHS

& no Sb/Br)

SNAGCU

Level-1-260C-UNLIM

-40 to 125

TPS63805

XPS63805YFFT

ACTIVE

DSBGA

YFF

15

250

TBD

Call TI

Call TI

-40 to 125

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of