TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Compact LCD Bias Supply for TFT-LCD TV Panels

FEATURES

APPLICATIONS

•

•

•

•

•

•

•

1

2

•

•

•

•

•

•

•

•

•

•

•

•

•

•

6 V to 14 V Input Voltage Range

Vs Output Voltage Range up to 19 V

Boost Converter With 3.5-A Switch Current

Boost Converter Overvoltage Protection

2.5-A Step-Down Converter With 3.3-V Fixed or

Adjustable Output

750 kHz Fixed Switching Frequency

150 mA Negative Charge Pump Driver for VGL

50 mA Positive Charge Pump for VGH

LDO Controller for Logic Supply

Gate Voltage Shaping for VGH

Temperature Sensor Output

TPS65167 - High Voltage Stress Test Vs

and VGH

TPS65167A - High Voltage Stress Test Vs only

Adjustable Sequencing

Gate Drive Signal for Isolation Switch

Short-Circuit Protection

Internal Soft-start

Thermal Shutdown

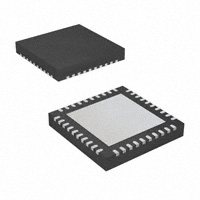

Available in 6 × 6 mm 40 Pin QFN Package

TPS65167

12 V

Boost Converter

High-Voltage Stress Test

Positive Charge Pump

Gate Voltage Shaping

Negative Charge Pump

Temperature Sensor

Vs

15 V/1.7 A

VGH

30 V/50 mA

LCD TV Panel

LCD Monitor

DESCRIPTION

The TPS65167 offers a compact power supply

solution to provide all voltages required by a LCD

panel for large size monitor and TV panel

applications running from a 12-V supply rail.

The device generates all 3 voltage rails for the TFT

LCD bias (Vs, VGL and VGH). In addition to that it

includes a step-down converter and a LDO controller

to provide two logic voltage rails. The device

incorporates a high voltage switch that can be

controlled by a logic signal from the external timing

controller (TCON). This function allows gate voltage

shaping for VGH. The device also features a high

voltage stress test where the output voltage of VGH

is set to typically 30 V and the output voltage of Vs is

programmable to any higher voltage. The high

voltage stress test is enabled by pulling the HVS pin

high. The device consists of a boost converter to

provide the source voltage Vs operating at a fixed

switching frequency of 750 kHz. A fully integrated

positive charge pump, switching automatically

between doubler and tripler mode provides an

adjustable regulated TFT gate on voltage VGH. A

negative charge pump driver provides adjustable

regulated output voltages VGL. To minimize external

components the charge pumps for VGH and VGL

operate at a fixed switching frequency of 1.5 MHz.

The device includes safety features like overvoltage

protection of the boost converter, short-circuit

protection of VGH and VGL as well as thermal

shutdown.

VGL

–5 V/150 mA

Vtemp

Buck Converter

Vlogic

3.3 V/2.5 A

LDO Controller

Vaux

1.8 V/500 mA

1

2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPAD is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2007–2008, Texas Instruments Incorporated

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION (1)

TA

High voltage Stress Test

(HVS)

ORDERING

Available on Vs and VGH

TPS65167RHAR

Available on Vs only

TPS65167ARHA

R

–40°C to 85°C

(1)

(2)

PACKAGE (2)

PACKAGE

MARKING

40 pin QFN

TPS65167A

TPS65167

The RHA package is available taped and reeled. Add R suffix to the device type (TPS65167RHAR) to

order the device taped and reeled. The RHA package has quantities of 3000 devices per reel.

For the most current package and ordering information, see the Package Option Addendum at the end

of this document, or see the TI website at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted) (1)

AVIN, VINB, SUPN, GD, BASE

VI

Voltage on pin

(2)

VALUE

UNIT

–0.3 to 16.5

V

EN, HVS, CTRL(2)

–0.3 to 6

V

FB, FBB, FBP, FBN, FBLDO, RSET(2)

–0.3 to 6

V

SW, SUP

25

V

SWB(2)

20

V

POUT, VGH, DRN(2)

36

V

(2)

TJ

Continuous power dissipation

Tstg

Operating junction temperature range

–40 to 150

°C

Storage temperature range

–65 to 150

°C

(1)

(2)

See Dissipation Rating Table

Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltage values are with respect to network ground terminal.

DISSIPATION RATINGS (1)

(1)

PACKAGE

RθJA

TA ≤ 25°C

POWER RATING

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

40 pin QFN

30°C/W

3.3 W

1.8 W

1.3 W

See the Texas Instruments Application report SLMA002 regarding thermal characteristics of the PowerPAD package.

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

VI

Input voltage range

6

14

V

TA

Operating ambient temperature

–40

85

°C

TJ

Operating junction temperature

–40

125

°C

CREG

REGOUT bypass capacitor

4.7

µF

CREF

Reference (REF) bypass capacitor

100

nF

2

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

ELECTRICAL CHARACTERISTICS

AVIN=VINB=SUPN=12V, EN=REGOUT, Vs = 15V, Vlogic = 3.3V , Vaux = 1.8V, TA = –40°C to 85°C, typical values are at

TA = 25°C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SUPPLY CURRENT

VI

IQ

UVLO

Input voltage range

6

14

Quiescent current into AVIN

Not switching, FB = FB + 5%

Quiescent current into VINB

Quiescent current into SUP

Undervoltage lockout threshold

VI falling

4.7

5.2

5.7

Undervoltage lockout threshold

VI rising

4.9

5.45

5.9

V

1.5

mA

Not switching, FBB = FBB + 5%

0.15

mA

Not switching, FB = FBB = FBN = FBP = + 5%

275

Thermal shutdown

Thermal shutdown hysteresis

µA

V

V

155

°C

5

°C

REFERENCE VOLTAGE REF

Vref

VI = 6 V to 14 V, Iref = 10 µA

Reference voltage

1.205

1.213

1.219

V

LOGIC SIGNALS CTRL, HVS

VIH

High level input voltage

6 V ≤ VIN ≤ 14 V

VIL

Low level input voltage

6 V ≤ VIN ≤ 14 V

Ilkg

Input leakage current

EN = CTRL = HVS = GND or 6 V

1.4

V

0.4

V

0.01

0.1

µA

4.8

6.2

µA

SEQUENCING GDLY/EN

EN/GDLY Charge current

V(threshold) = 1.213 V

3.6

EN/GDLY threshold

EN/GDLY pulldown resistor

1.23

V

4.5

kΩ

SWITCHING FREQUENCY

fs

Switching frequency

600

750

900

kHz

4.6

4.8

5

V

19

V

1.136

1.146

1.154

V

10

100

nA

REGULATOR REGOUT

VO

Regulator output voltage

Ireg = 1 mA

BOOST CONVERTER (Vs)

VO

Output voltage range

VFB

Feedback regulation voltage

IFB

Feedback input bias current

RDS(on)

N-MOSFET on-resistance (Q1)

I(SW) = 500 mA

160

270

mΩ

P-MOSFET on-resistance (Q2)

I(SW) = 200 mA

14

20

Ω

1

A

IMAX

Maximum P-MOSFET peak switch current

ILIM

N-MOSFET switch current limit (Q1)

Ilkg

Switch leakage current

V(SW) = 15 V

Line Regulation

6 V ≤ Vin ≤ 14 V, IO = 2 mA

Load Regulation

2 mA ≤ Iout ≤ 1.8 A

3.5

4.2

4.9

A

1

10

µA

0.006

%/V

0.06

%/A

BOOST CONVERTER (Vs) OVERVOLTAGE PROTECTION

Switch overvoltage protection

Vs rising

19.5

Switch overvoltage protection hysteresis

20.2

21

0.6

V

V

GATE DRIVE (GD) AND BOOST CONVERTER PROTECTION

I(GD)

Gate drive sink current

R(GD)

Gate drive internal pull up resistance

ton

Gate on time during short-circuit

toff

Gate off time during short-circuit

9

µA

5

kΩ

Vs < 4.8 V

1

ms

Vs < 4.8 V

60

ms

EN = high

TEMPERATURE SENSOR (TEMP)

VO

Output voltage range

1.2

Drive current

VO

TA = 85°C, I = 200 µA, device not switching,

FB = FBnominal + 5%

Output voltage at TA = 85°C

Temperature accuracy

V

µA

2.037

–6

Temperature coefficient

2.5

200

V

6

5.7

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

°C

mV/°C

3

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

ELECTRICAL CHARACTERISTICS (continued)

AVIN=VINB=SUPN=12V, EN=REGOUT, Vs = 15V, Vlogic = 3.3V , Vaux = 1.8V, TA = –40°C to 85°C, typical values are at

TA = 25°C (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

STEP-DOWN CONVERTER (Vlogic)

Output voltage range

5

V

3.3V fixed output voltage accuracy

FBB = GND

–2%

3.3

2%

V

VFB

Feedback regulation voltage

FBB connected to resistor divider,

–2%

1.213

2%

V

IFB

Feedback input bias current

10

100

nA

RDS(on)

N-MOSFET on-resistance (Q1)

200

330

mΩ

ILIM

N-MOSFET switch current limit (Q1)

3.5

4.2

A

Ilkg

Switch leakage current

V(SW) = 0 V

1

10

µA

Line regulation

6 V ≤ Vin ≤ 14 V, IO = 1.8 mA

Load regulation

1.8 mA ≤ IO ≤ 2.5 A

VO

1.5

I(SW) = 500 mA

2.8

0.006

%/V

0.06

%/A

STEP-DOWN CONVERTER FEEDBACK SELECT THRESHOLD FBB

VFB

Feedback select threshold

Adjustable version select

0.25

V

14

V

NEGATIVE CHARGE PUMP VGL

VI

Input supply range

VO

Output voltage range

VFB

Feedback regulation voltage

IFB

Feedback input bias current

RDS(on)

Q4 P-Channel switch RDS(on)

Current source voltage drop (1)

6

–36

–2

V

0

36

mV

10

100

nA

IO = 20 mA

4.4

8

Ω

I(DRVN) = 50 mA, V(FBN) = V(FBNnominal) –5%

120

I(DRVN) = 100 mA, V(FBN) = V(FBNnominal) –5%

235

mV

Line regulation

9.5 V ≤ Vin ≤ 14 V, IO = 1 mA

0.098

%/V

Load regulation

1 mA ≤ IO ≤ 100 mA, VGL = –5 V

0.055

%/mA

POSITIVE CHARGE PUMP (POUT)

VO

Output voltage range

VFB

Feedback regulation voltage

IFB

Feedback input bias current

30

CTRL = GND, VGH = open

1.187

Doubler Mode (x2); I(POUT) = 20 mA

Effective output resistance

1.238

V

10

100

nA

98

Doubler Mode (x2); I(POUT) = 50 mA

63

Tripler Mode (x3); I(POUT) = 20 mA

Ω

143

Tripler Mode (x3); I(POUT) = 50 mA

Load regulation

V

1.214

91

1 mA ≤ Iout ≤ 51 mA, VGH = 23.9 V

0.0022

%/mA

HIGH VOLTAGE SWITCH VGH

RDS(on)

I(DRN)

POUT to VGH RDS(on)

CTRL = high, POUT = 27 V, I = 20 mA

10

18

DRN to VGH RDS(on)

CTRL = low, V(DRN) = 5 V, I = 20 mA

40

60

DRN input current

CTRL = low, V(DRN) = 10 V

tdly

CTRL to VGH propagation delay

R(VGH)

VGH pull down resistance

µA

10

CTRL = high to low, POUT = 27 V, V(DRN) = GND

120

CTRL= low to high, POUT = 27 V, V(DRN) = GND

140

EN = low, I = 20 mA

Ω

ns

1

kΩ

LINEAR REGULATOR CONTROLLER Vaux

VEB

Emitter voltage range

VFB

Feedback regulation voltage

I(BASE)

Base sink current

2.3

–2%

V(BASE) = 3.3 V-1V, VFBLDO = 1.15 V

25

V(BASE) = 2.5 V-1V, VFBLDO = 1.15 V

15

Power supply rejection ratio

LDO input

Line regulation

6V ≤ Vin ≤ 14 V, I(load) = 1 mA,

Vaux = 1.6 V

Load regulation

1 mA ≤ IO ≤ 500 mA, VI = 3.3 V,

Vaux = 1.6 V

15

1.213

V

2%

mA

65

dB

0.007

%/V

0.48

%/A

HIGH VOLTAGE STRESS TEST (HVS), RHVS

(1)

4

The maximum charge pump output current is half the drive current of the internal current source or sink

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

ELECTRICAL CHARACTERISTICS (continued)

AVIN=VINB=SUPN=12V, EN=REGOUT, Vs = 15V, Vlogic = 3.3V , Vaux = 1.8V, TA = –40°C to 85°C, typical values are at

TA = 25°C (unless otherwise noted)

PARAMETER

37

36

35

TEMP

38

PGND

39

33

32

31

SW

40

PGND

TPS65167A, TPS65167, HVS = low, V(RHVS) = 5 V

SW

RHVS leakage current

GD

TPS65167A, TPS65167, HVS = high, I(HVS) = 100 µA

GND

RHVS pull down resistance

AVIN

TPS65167, HVS = high

FBLDO

34

MIN

TYP

MAX

29

30

31

V

450

650

850

Ω

100

nA

VINB

1

30

COMP

BOOT

2

29

FB

SWB

3

28

RHVS

SWB

4

27

HVS

PGND

5

26

EN

PGND

6

25

GDLY

VLOGIC

7

24

CTRL

FBB

8

23

DRN

REGOUT

9

22

VGH

21

POUT

18

19

UNIT

20

FBP

17

SUP

16

C2N

15

C2P

14

C1N

SUPN

13

C1P

12

GND

10

11

FBN

REF

Exposed

Thermal Die

(See NOTE)

DRVN

Ilkg

TEST CONDITIONS

Positive charge pump output voltage

BASE

V(POUT)

NOTE: The thermally enhance PowerPAD is connected to GND.

TERMINAL FUNCTIONS

TERMINAL

NAME

NO.

I/O

DESCRIPTION

VINB

1

I

Power input for the buck converter.

BOOT

2

I

This pin generates the gate drive voltage for the Buck converter. Connect a 100 nF from this pin to the

switch pin of the step-down converter SWB.

SWB

3, 4

O

Switch pin of the step-down converter

PGND

5

Power ground for the step-down converter

PGND

6

Power ground for the negative charge pump

VLOGIC

7

I

Output sense of the step-down converter

FBB

8

I

Feedback pin of the step-down converter

REGOUT

9

O

Output of the internal 5V regulator. Connect a 4.7 µF bypass capacitor to this pin.

REF

10

O

Internal reference output typically 1.213 V. Connect a 100 nF bypass capacitor to this pin.

FBN

11

I

Feedback pin of negative charge pump

SUPN

12

I

Power supply pin for the negative charge pump driver.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

5

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

TERMINAL FUNCTIONS (continued)

TERMINAL

I/O

DESCRIPTION

NAME

NO.

DRVN

13

GND

14

Power ground for the positive charge pump

C1P

15

Positive charge pump flying capacitor

C1N

16

Positive charge pump flying capacitor

C2P

17

Positive charge pump flying capacitor

C2N

18

Positive charge pump flying capacitor

SUP

19

FBP

20

Feedback of the positive charge pump

POUT

21

Output of the positive charge pump converter

VGH

22

Output of the high voltage switch and gate shaping function block

DRN

23

Termination of the low side switch of the gate voltage shaping block

CTRL

24

I

Control input for the gate voltage shaping block. Connect this pin to REGOUT if the gate voltage shaping

function is not used.

GDLY

25

O

Connecting a capacitor from this pin to GND allows to set the delay time between the boost converter Vs

and VGH. Note that VGH is controlled by CTRL as well.

EN

26

I

This is the enable pin of the boost converter Vs, negative charge pump VGL and positive charge pump

POUT. This pin is a dual function pin. EN can be held high if no start-up delay is desired or a capacitor can

be connected to this pin. The capacitor determines the start-up delay time.

HVS

27

I

Logic control input to force the device into High Voltage Stress Test. With HVS = low the high voltage stress

test disabled. With the TPS65167 and HVS = high the high voltage stress test is enabled for Vs and for

VGH. With the TPS65167A and HVS = high the high voltage stress test is enabled for Vs only.

RHVS

28

I/O

This resistor sets the voltage of the boost converter Vs when the High Voltage Stress test is enabled. (HVS

= high). With HVS = high the RHVS pin is pulled to GND which sets the voltage for the boost converter

during High Voltage Stress. When HVS is disabled (HVS = low) the RHVS pin is high impedance.

FB

29

I

COMP

30

I/O

Compensation for the regulation loop of the boost converter generating Vs. Typically a 22 nF compensation

capacitor is connected to this pin.

TEMP

31

O

This is the output of the internal device temperature sensor. The output voltage is proportional to the chip

temperature.

PGND

32, 33

SW

34, 35

I/O

Switch pin of the boost converter generating Vs

GD

36

I/O

Gate drive. This pin controls the external isolation MOSFET.

GND

37

AVIN

38

I

Analog input voltage of the device. Bypass this pin with a 0.47 µF bypass capacitor.

FBLDO

39

I

Feedback of the LDO controller

BASE

40

I/O

PowerPAD

™

6

I/O

I/O

Drive pin of the negative charge pump.

Power supply pin of the positive charge pump and control voltage for the boost regulator Vs. Connect this

pin with a short and wide PCB trace to the output of the boots converter

Feedback of the boost converter Vs

Power Ground for the boost converter Vs

Analog Ground for the internal reference

BASE drive of the external PNP transistor

Analog GND for the internal reference

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

FUNCTIONAL BLOCK DIAGRAM

Temperature

Output

C27

1nF

L1

10uH

1

C2

1uF

38

5

26

C11

4.7uF

SW

SUPN

SUP

Boost Converter

VINB

Positive Charge

Pump

x2 and x3 Mode

S

C13

10nF

C2N

REGOUT

Gate Voltage

Shaping

HVS

24 CTRL

11

VINB

Step Down

Converter

FBN

10

14

37

PGND

6

32

33

20

C9

0.33 uF

17

C10

1uF

18

DRN

23

Vlogic

7

BOOT

2

SWB

4

SWB

3

FBLDO

R4

300kW

21

22

FBB

PGND

C1P

C1N

C29

22 uF

R3

82kW

28

VGH

15

GND

C20

0.33uF

16

R8

39kW

DRVN Negative Charge SUPN

Pump Driver

BASE

D4

R7

160kW

13

PGND

C15

0.33uF

GND

C16

2.2uF

D3

REF

VGL

-5V/150 mA

FBP

C2P

EN

25 GDLY

27

C8

47 pF

R2

30kW

29

POUT

PGND

COMP

R1

365kW

C7

22 uF

FB

RHVS

D

AVIN

C6

22 uF

19

31

SUP

34

TEMP

35

9

C12

22nF 30

R6

0W

GD

12

Vin

6V to 14 V

Vs

15 V/1.5A

C5

1uF

C4

22 uF

C28

10uF

36

C25

470 nF

C1

22 uF

C3

10uF

SW

C24

1nF

D1

C26

100 pF

R5

16kW

VGH

23 V/

50 mA

C14

100nF

L2

10 uH

Vlogic

3.3V/

2.5A

D2

C19

22 uF

C18

22 uF

8

39

40

Vaux

1.5V/500mA

Q1

C21

100nF

C22

1uF

R11

1.6kW

R13

1kW

C23

10uF

R12

6.8kW

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

7

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

TYPICAL CHARACTERISTICS

Table 1. Table of Graphs

FIGURE

Main Boost Converter (Vs)

η

Efficiency boost converter

vs Load currents

Figure 1

Softstart boost converter

vs Load currents

Figure 2

PWM operation

at nominal load current

Figure 3

PWM operation

at light load current

Figure 4

Overvoltage protection

Figure 5

Short-circuit power down cycling

Figure 6

Load transient response boost converter

Figure 7

Step-Down Converter (Vlogic)

η

Efficiency buck converter

vs Load currents

Figure 8

PWM operation

at nominal load current

Figure 9

PWM operation

at light load current

Figure 10

Softstart buck converter

Figure 11

Load transient response buck converter

Figure 12

LDO Controller

Vaux

Load transient response LDO controller

Figure 13

Negative Charge Pump Driver

VGL

vs Load current - doubler stage

Figure 14

vs Load current

Figure 15

vs Temperature

Figure 16

Positive Charge Pump Driver

VGH

Temperature Sensor

VTemp

System Performance

Gate voltage shaping VGH

8

Figure 17

Power up sequencing

EN connected to REGOUT

Figure 18

Power up sequencing

External capacitor connected to EN

Figure 19

Power up sequencing

REGOUT vs VREF

Figure 20

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

EFFICIENCY BOOST CONVERTER (Vs)

vs

LOAD CURRENT

SOFTSTART BOOST CONVERTER (Vs)

vs

LOAD CURRENT

100

Vsw

90

Efficiency - %

80

Vout

VIN

70

60

VI = 12 V,

VO = 15 V

50

Input Current

40

0

500

1000

1500

VI = 12 V,

VO = 15 V,

IO = 500 mA

2000

IO - Output Current - mA

Figure 1.

Figure 2.

PWM OPERATION AT NOMINAL LOAD CURRENT

PWM OPERATION AT LIGHT LOAD CURRENT

Vsw

Vsw

Vout

Vout

VI = 12 V,

VO = 15 V/50 mA

Inductor Current

Inductor Current

VI = 12 V,

VO = 15 V/1A

Figure 3.

Figure 4.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

9

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

OVER VOLTAGE PROTECTION

SHORT-CIRCUIT POWER DOWN CYCLING

Vsw

Vout

VI = 15 V,

VO = shorted to GND,

Peak current depends mainly

on input power supply

VI = 15 V,

VO = 15 V/500 mA

VOUT with 15 V Offset

Vout

Vsw

Input Current

Figure 5.

Figure 6.

LOAD TRANSIENT RESPONSE BOOST CONVERTER

EFFICIENCY BUCK CONVERTER

vs

LOAD CURRENT

90

VI = 12 V,

VO = 3.3 V

85

Vout

VI = 12 V,

VS = 15 V,

560 mA to 1.46 A

Output Current

Efficiency - %

80

75

70

65

60

55

50

0

1500

500

1000

IO - Output Current - mA

Figure 7.

10

Submit Documentation Feedback

2000

Figure 8.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

PWM OPERATION AT NOMINAL LOAD CURRENT

PWM OPERATION AT LIGHT LOAD CURRENT

Vsw

Vsw

Vout

Vout

Inductor Current

Inductor Current

VI = 12 V,

VO = 3.3 V/50 mA

VI = 12 V,

VO = 3.3 V/2.5 A

Figure 9.

Figure 10.

SOFTSTART BUCK CONVERTER Vlogic

LOAD TRANSIENT RESPONSE BUCK CONVERTER

Vout

Vsw

Vout

VI = 12 V,

VS = 3.3 V,

3.3 V fixed output voltage

136 mA to 1.8 A

VIN

Input Current

Output Current

VI = 12 V,

VO = 3.3 V fixed,

IO = 500 mA

Figure 11.

Figure 12.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

11

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

LOAD TRANSIENT RESPONSE LDO CONTROLLER

VGL vs LOAD CURRENT

-4.3

VGL = -5 V,

VIN = 7 V,

VIN = 7.5 V,

VIN = 8 V

-4.4

Vaux

-4.5

-4.6

Cout = 22 mF,

50 mA to 530 mA

Increasing VIN

-4.7

VGL - V

VI = 12 V,

VS = 1.6 V,

Output Current

-4.8

-4.9

-5

-5.1

-5.2

0.091

0.081

0.071

0.061

0.051

0.041

0.031

0.021

0.011

0.001

-5.3

IO - Output Current - A

Figure 13.

Figure 14.

VGH vs LOAD CURRENT – DOUBLER STAGE

Vtemp vs TEMPERATURE

2.4

24

VS = 15 V,

VGH = 24 V

23.8

2.3

2.2

23.6

2

23.2

TA = 85°C

23

TA = 25°C

22.8

Vtemp - V

VGH - V

Itemp = 200 mA,

All Outputs no Load

2.1

TA = -40°C

23.4

VI = 12 V,

1.9

1.8

1.7

1.6

22.6

1.5

22.4

1.4

22.2

1.3

22

0

0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1

IO - Output Current - A

1.2

-40

-20

0

20

40 60

80 100 120

TA - Free-Air Temperature - °C

Figure 15.

12

Submit Documentation Feedback

140

Figure 16.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

GATE VOLTAGE SHAPING VGH

CTRL

POWER-UP SEQUENCING

Vlogic

Vaux

VI = 12 V,

GDLY = 10 nF

EN = REGOUT

Vs

VGH

VGH

VGL

DRN = 10 kW to VS,

VGH = 470 pF Capacitive Load

to Represent Panel

1 ms/div

4 ms/div

Figure 17.

Figure 18.

POWER-UP SEQUENCING

POWER-UP SEQUENCING

REGOUT vs VREF

VI = 12 V,

GDLY = 10 nF,

EN = 22 nF to GND

Vlogic

CTRL

Vaux

VGH

Vs

VGH

VGL

200 ms/div

2 ms/div

Figure 19.

Figure 20.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

13

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

APPLICATION INFORMATION

TEMP

200 mA

AVIN

Temperature

Sensor

Vref

1.213V

UVLO

Undervoltage

lockout

5.35V typ

Regulator

4.8V typ

REGOUT

Start Buck Converter

GND

Thermal

Shutdown latch

155oC typ

30 mA

Start LDO Controller

REF

Control

Start negative

charge pump

EN

Ichg

Vref

EN

AVIN

3.5k

Start Boost

converter, and

positive charge

5k

EN

VREF

Power Good

Buck Converter

GD

Idischg

Control

EN

Ichg

GDLY

Vref

FBB

Control

Power Good

Boost Converter

FB

Enable Gate voltage

shaping block

3.5k

EN

Figure 21. Control Block TPS65167

Regulator REGOUT and Reference REF

The 4.8 V regulator REGOUT and reference REF is always on as long as the input voltage is above the device

undervoltage lockout of typically 5.2 V. To ensure a correct start-up, the reference voltage REF needs to come

up faster than the regulator voltage REGOUT. In other words as REF = 1.213 V then REGOUT must remain

< 4.25 V to assure proper start-up (Figure 22).

14

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

CTRL

VGH

200 ms/div

Figure 22. Power-up Sequencing (REGOUT vs VREF)

This is implemented by connecting a 4.7 µF bypass capacitor to REGOUT and a 100 nF bypass capacitor to the

REF pin. If the bypass capacitor on the REF pin is selected larger than 100 nF, then the bypass capacitor on

REGOUT needs to be increased accordingly. Refer to Table 2 to properly select a bypass capacitor.

The REF pin provides a reference output which is used to regulate the negative charge pump. In order to have a

stable reference voltage, a 100 nF bypass capacitor is required, which needs to be connected directly from REF

to GND (pin 37) for best noise immunity. The reference output has a current capability of 30 µA which must not

be exceeded. Therefore, the feedback resistor value from FBN to REF must not be smaller than 40 kΩ.

Table 2. Bypass Capacitor Selection

REGOUT

Type/Rating

REF

Type

Option 1

4.7 µF

Option 2

10 µF

X7R or X5R/10V

100 nF

x7R or X5R

X7R or X5R/10V

220 nF or 100 nF

x7R or X5R

Temperature Sensor Output TEMP

The device provides a temperature sensor output measuring the actual chip temperature. This pin has an analog

output capable of driving 200 µA. The TEMP pin requires a 1 nF output capacitor to provide a stable output

voltage. At 85°C, the typical output voltage is 2.037 V with a temperature coefficient of 5.9 mV/°C. See Figure 16

for the output characteristic of the temperature output.

Thermal Shutdown

A thermal shutdown is implemented to prevent damages due to excessive die temperatures. Once the thermal

shutdown is exceeded, the device enters shutdown. The device can be enabled again by cycling the EN pin or

input voltage to ground.

Undervoltage Lockout

To avoid mis-operation of the device at low input voltages an undervoltage lockout is included which shuts down

the device at voltages lower than 5.2 V.

Short circuit protection (all outputs)

All the outputs have a short circuit protection implemented.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

15

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Boost converter Vs: A short circuit is detected when the voltage on SUP, that is connected to the output falls

typically below 4.5V. Then the isolation switch is opened by pulling GD high. After a delay of typically 60mS the

isolation switch is closed again and restarts the output automatically. See Figure 6.

Buck converter Vlogic: During a short circuit even the output current is typically limited to the buck converter

switch current limit of 3.5A and the switching frequency is reduced.

Negative charge pump VGL: As the output falls below the power good limit threshold the output current is limited

to the softstart current limit of the negative charge pump.

Positive charge pump output VGH: As the output POUT falls below its power good threshold then the internal

gate voltage shaping switch opens disconnecting the load from POUT. As the output POUT exceeds the power

good threshold again the internal switch of the gate voltage shaping block is closed again. The VGH output

cycles as long as the short circuit event remains.

LDO controller VAUX: During a short circuit event the maximum output current is given by the gain of the

external transistor. Depending on the selected output transistor the power dissipation of the external transistor

might be exceeded during a short circuit event. Using a base series resistor protects the IC during a short circuit

event.

Start-Up Sequencing

The device has an adjustable start-up sequencing to provide correct sequencing as required by LCD. When the

input voltage exceeds the undervoltage lockout threshold, then the step-down converter and LDO controller

start-up at the same time. As the enable signal (EN) goes high, the negative charge pump starts up followed by

the boost converter Vs starting at the same time as the positive charge pump. See the typical curves shown in

Figure 18, Figure 19, and Figure 23.

AVIN =UVLOVhys

AVIN = UVLO

VIN

VLOGIC

Vaux

td

VGH

EN

with CTRL=high

POUT

Vs

VGL

GDLY

GD

Figure 23. Power Up Sequencing

16

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Enable EN

The enable is a dual function pin. It can be used as a standard enable pin that enables the device once it is

pulled high by a logic signal or connected to the REGOUT pin.

The enable can not be connected directly to Vin due to its maximum voltage rating!

If no logic control signal is available, it is also possible to connect a capacitor to this pin to set the delay time td

as shown in Figure 23 and Figure 19.

Delay GDLY

The capacitor connected to GDLY sets the delay time from the point when the boost converter Vs reaches its

nominal value to the enable of the gate voltage shaping block.

Setting the Delay Times GDLY, EN delay

Connecting an external capacitor to the GDLY and EN pin sets the delay time. To set the delay time, the external

capacitor is charged with a constant current source of typically 5 µA. The delay time is terminated when the

capacitor voltage has reached the threshold voltage of Vth = 1.230 V. The external delay capacitor is calculated:

5 mA x td

5 mA x td

Cdly =

=

Vref

1.23 V

(1)

with td = Desired delay time

Example for setting a delay time of 2.3 mS

5 mA x 2.3 ms

Cdly =

= 9.3 nF Þ Cdly = 10 nF

1.23 V

(2)

Boost Converter

The main boost converter operates in Pulse Width Modulation (PWM) and at a fixed switching frequency of 750

kHz The converter uses a unique fast response, voltage-mode controller scheme with feed-forward input voltage

. This achieves excellent line and load regulation (0.2% A load regulation typical) and allows the use of small

external components. To add higher flexibility to the selection of external component values the device uses

external loop compensation. Although the boost converter looks like a non-synchronous boost converter topology

operating in discontinuous conduction mode at light load, the device will maintain continuous conduction even at

light load currents. This is achieved with a novel architecture using an external Schottky diode with an integrated

MOSFET in parallel connected between SW and SUP. See the Functional Block Diagram. The intention of this

MOSFET is to allow the current to go below ground that occurs at light load conditions. For this purpose, a small

integrated P-Channel MOSFET with typically 10 Ω RDS(on) is sufficient. When the inductor current is positive, the

external Schottky diode with the lower forward voltage will carry the current. This causes the converter to operate

with a fixed frequency in continuous conduction mode over the entire load current range. This avoids the ringing

on the switch pin as seen with standard non-synchronous boost converter, and allows a simpler compensation

for the boost converter.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

17

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

AVIN

GD

5 kW

IDLY

SW

SW

IDLY

Softstart

Vref

M2

SS

750kHz

Oszillator

70 W

SUP

Current limit

and

Soft Start

EN

Comparator

Control Logic

M1

COMP

GM Amplifier

PGND

Sawtooth

Generator

FB

VFB

1.154V

GM Amplifier

Low Gain

Overvoltage

Comparator

OVP

PGND

Vref

SUP

VFB

1.154

RHVS

HVS

Figure 24. Block Diagram Boost Converter

Softstart (Boost Converter)

The main boost converter has an internal softstart to prevent high inrush current during start-up. The device

incorporates a digital softstart increasing the current limit in digital current limit steps. See Figure 2 for the typical

softstart timing.

High Voltage Stress Test (Boost converter and positive charge pump)

The TPS65167 and TPS65167A incorporates a high voltage stress test where the output voltage of the boost

converter Vs and the positive charge pump POUT is set to a higher voltage compared to the nominal

programmed output voltage. The High Voltage Stress test is enabled by pulling the HVS pin to high. With HVS =

high, the voltage on POUT, respectively VGH, remains unchanged with the TPS65167A and the TPS65167

regulates to a fixed output voltage of 30 V. The boost converter Vs is programmed to a higher voltage

determined by the resistor connected to RHVS. With HVS = high the RHVS pin is pulled to GND which sets the

voltage for the boost converter during the High Voltage Stress Test. The output voltage for the boost converter

during high voltage stress test is calculated as:

R1 + R2//R3

R1 + R2//R3

VsHVS = VFB

= 1.146V

R2//R3

R2//R3

R3 =

18

R1 x R2

æ VsHSV

ö

- 1÷ x R2 - R1

ç

V

è FB

ø

Submit Documentation Feedback

(3)

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

With:

VsHVS = Boost converter output voltage with HVS = high

VFB = 1.146 V

Overvoltage Protection

The main boost converter has an overvoltage protection of the main switch M1 if the feedback pin (FB) is floating

or shorted to GND causing the output voltage to rise. In such an event, the output voltage is monitored with the

overvoltage protection comparator on the SUP pin. As soon as the comparator trips at typically at 20 V then the

boost converter stops switching. The output voltage will fall below the overvoltage threshold and the converter

continues to operate. See Figure 4.

Note: During high voltage stress test the overvoltage protection is disabled.

Input Capacitor Selection VINB, SUP, SUPN, AVIN, Inductor Input Terminal

For good input voltage filtering, low ESR ceramic capacitors are recommended. The TPS65167 has an analog

input AVIN as well as a power supply input SUP powering all the internal rails. A 1-µF bypass capacitor is

required as close as possible from AVIN to GND as well as from SUP to GND. The SUPN pin needs to be

bypassed with a 470-nF capacitor. Depending on the overall load current two or three 22-µF input capacitors are

required. For better input voltage filtering, the input capacitor values can be increased. To reduce the power

losses across the external isolation switch a filter capacitance at the input terminal of the inductor is required. To

minimize possible audible noise problems, two 10-µF capacitors in parallel are recommended. More capacitance

will further reduce the ripple current across the isolation switch. See Table 3 and the typical applications for input

capacitor recommendations.

Table 3. Input Capacitor Selection

CAPACITOR

COMPONENT SUPPLIER

COMMENTS

22 µF/16 V

Taiyo Yuden EMK316BJ226ML

Pin VINB

2 ×10 µF/25 V

Taiyo Yuden TMK316BJ106KL

Pin VINB (alternative)

2 ×10 µF/25 V

Taiyo Yuden TMK316BJ106KL

Inductor input terminal

1 µF/35 V

Taiyo Yuden GMK107BJ105KA

Pin SUP

1 µF/25 V

Taiyo Yuden TMK107BJ105KA

Pin AVIN

470 nF/25 V

Taiyo Yuden TMK107BJ474MA

Pin SUPN

x

Boost Converter Design Procedure

The first step in the design procedure is to verify whether the maximum possible output current of the boost

converter supports the specific application requirements. To simplify the calculation, the fastest approach is to

estimate the converter efficiency by taking the efficiency numbers from the provided efficiency curves or to use a

worst case assumption for the expected efficiency, e.g., 80%. With the efficiency number it is possible to

calculate the steady state values of the application.

Vin h

D +1*

Vout

1. Converter Duty Cycle:

ǒ

Ǔ

Iout + Isw * Vin D

2 ƒs L

2. Maximum output current:

I

I swpeak + Vin D ) out

2

ƒs

L

1

*D

3. Peak switch current:

(1 * D)

With Isw = converter switch current (minimum switch current limit = 3.5 A)

fs = converter switching frequency (typical 750 kHz)

L = Selected inductor value

η = Estimated converter efficiency (use the number from the efficiency curves or 0.8 as an estimation)

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

19

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

The peak switch current is the steady state peak switch current the integrated switch, inductor and external

Schottky diode has to be able to handle. The calculation must be done for the minimum input voltage where the

peak switch current is highest. Note that the maximum output power of the device is limited by the power

dissipation of the package.

Inductor Selection (Boost Converter)

The TPS65167 typically operates with a 10-µH inductor. Main parameter for the inductor selection is the

saturation current of the inductor which should be higher than the peak switch current as calculated above with

additional margin to cover for heavy load transients. The alternative more conservative approach is to choose the

inductor with saturation current at least as high as the minimum switch current limit of 3.5 A. The second

important parameter is the inductor dc resistance. The lower the dc resistance the higher the efficiency of the

converter. The converter efficiency can vary between 2% to 10% when choosing different inductors. Possible

inductors are shown in Table 4.

Table 4. Inductor Selection Boost Converter

INDUCTOR VALUE

COMPONENT SUPPLIER

DIMENSIONS in mm

Isat/DCR

10 µH

Sumida CDRH8D43-100

8.3 × 8.3 × 4.5

4 A/29 mΩ

10 µH

Wuerth 744066100

10 × 10 × 3.8

4 A/25 mΩ

10 µH

Coilcraft DO3316P-103

12.95 × 9.4 × 5.5

3.9 A/38 mΩ

Output Capacitor Selection (Boost Converter)

For best output voltage filtering, a low ESR output capacitor is recommended. Ceramic capacitors have a low

ESR value and work best with the TPS65167. Three 22-µF or six 10-µF ceramic output capacitors in parallel are

sufficient for most applications. More capacitors can be added to improve the load transient regulation. See

Table 5 for the selection of the output capacitor.

Table 5. Output Capacitor Selection

CAPACITOR

COMPONENT SUPPLIER

6 × 10 µF/25 V

Taiyo Yuden TMK316BJ106KL

3 × 22 µF/25 V

TDK C4532X7R1E226M

COMMENTS

Alternative solution

Rectifier Diode Selection (Boost Converter)

To achieve high efficiency, a Schottky diode should be used. The reverse voltage rating should be higher than

the maximum output voltage of the converter. The current rating for the Schottky diode is calculated as the off

time of the converter times the peak switch current of the application. The minimum switch current of the

converter can be used as a worst case calculation.

Vin

Iavg = (1 - D ) x Isw =

x 3.5 A

Vout

with Isw=minimum switch current of the TPS65167 (3.5 A)

Usually a Schottky diode with 2 A maximum average rectified forward current rating is sufficient for most of the

applications. Secondly, the Schottky rectifier has to be able to dissipate the power. The dissipated power is the

average rectified forward current times the diode forward voltage.

P D + I avg VF + Isw (1 * D) VF + I sw + Vin

VF

Vout

with Isw = minimum switch current of 3.5 A

(worst case calculation)

Table 6. Rectifier Diode Selection (Boost Converter)

20

Avg.

Or

Vforward

RθJA

SIZE

COMPONENT SUPPLIER

3A

20 V

0.36 at 3 A

46°C/W

S.C.

MBRS320, International Rectifier

2A

20 V

0.44 V at 2 A

75°C/W

SMB

SL22, Vishay Semiconductor

2A

20 V

0.5 at 2 A

75°C/W

SMB

SS22, Fairchild Semiconductor

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Setting the Output Voltage and Selecting the Feed-forward Capacitor (Boost Converter)

The output voltage is set by the external resistor divider and is calculated as:

V out + 1.146 V

ǒ1 ) R1

Ǔ

R2

(4)

Across the upper resistor a bypass capacitor is required to speed up the circuit during load transients. The

capacitor is calculated as:

1

1

C8 +

+

2 p ƒ z R1

2 p 10000 R1

(5)

A value coming closest to the calculated value should be used.

Compensation (COMP)

The regulator loop can be compensated by adjusting the external components connected to the COMP pin. The

COMP pin is the output of the internal transconductance error amplifier. A single capacitor connected to this pin

sets the low frequency gain. A 22-nF capacitor is sufficient for most of the applications. Adding a series resistor

sets an additional zero and increases the high frequency gain. The formula below calculates at what frequency

the resistor will increase the high frequency gain.

1

ƒz +

2 p C12 R6

(6)

Lower input voltages require a higher gain and; therefore, a lower compensation capacitor value. See the typical

applications for the appropriate component selection.

Gate Drive Pin (GD) and Isolation Switch Selection

The external isolation switch disconnects the output of the boost converter once the device is turned off. The

external isolation switch also provides a short-circuit protection of Vs by turning off the switch in case of a

short-circuit. The Gate Drive (GD) allows control of an external isolation MOSFET switch. GD pin is pulled low

when the input voltage is above the undervoltage lockout threshold (UVLO) and when enable (EN) is high. The

gate drive has an internal pull up resistor to AVIN of typically 5 kΩ. In order to minimize inrush current during

start-up, the gate drive pin is pulled low by an internal 10µA current sink. To further reduce this inrush current,

typically a 1-nF capacitor can be connected from pin GD to the boost converter inductor. A standard P-Channel

MOSFET with a current rating close to the minimum boost converter switch current limit of 3.5 A is sufficient.

Table 7 shows two examples coming in a small SOT23 package. The worst case power dissipation of the

isolation switch is calculated as the minimum switch current limit × RDS(on) of the MOSFET. A standard SOT23

package or similar is able to provide sufficient power dissipation.

Table 7. Isolation Switch Selection

COMPONENT SUPPLIER

CURRENT RATING

International Rectifier IRLML5203

3A

Siliconix SI2343

3.1 A

Step-Down Converter

The non-synchronous step-down converter operates at a fixed switching frequency using a fast response voltage

mode topology withfeed-forward input voltage. This topology allows simple internal compensation and it is

designed to operate with ceramic output capacitors. The converter drives an internal 2.8-A N-Channel MOSFET

switch. The MOSFET driver is referenced to the switch pin SWB. The N-Channel MOSFET requires a gate drive

voltage higher than the switch pin to turn the N-Channel MOSFET on. This is accomplished by a boost strap gate

drive circuit running of the step-down converter switch pin. When the switch pin SWB is at ground, the boot strap

capacitor is charged to 8 V. This way the N-Channel Gate drive voltage is typically around 8 V.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

21

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Regulator

8V

VINB

BOOT

Q3

VINB

SWB

Control Logic

SWB

Current limit

Vref

Error Amplifier

Vref

FBB

Vref

Compensation

and

Softstart

Vlogic

select

Fixed 3.3V/adj

Sawtooth

Generator

Fixed 3.3V

Clock /2

Logic

0.9V

Clock

Clock /4

0.6V

Clock

750 kHz

Clock select for short circuit

and softstart

Figure 25. Block Diagram Buck Converter

Soft-start (Step-Down Converter)

To avoid high inrush current during start-up, an internal soft-start is implemented. When the step-down converter

is enabled, its reference voltage slowly rises from zero to its power good threshold of typically 90% of Vref. When

the reference voltage reaches this power good threshold, the error amplifier is released to its normal operation

with its normal duty cycle. To further limit the inrush current during soft-start, the converter frequency is set to

1/4th of the switching frequency fs and th of fs determined by the comparator that monitors the feedback voltage.

See the internal block diagram. The softstart is typically completed within 1 ms.

Setting the Output Voltage, Adjustable or Fixed 3.3V (step-down converter)

The device supports a fixed 3.3-V output voltage when the feedback FBB is connected to GND. When using the

external voltage divider any other output voltage can be programmed.

To set the adjustable output voltage of the step-down converter, use an external voltage divider to set the output

voltage. The output voltage is calculated as:

V out + 1.213 V

R9 Ǔ

ǒ1 ) R10

(7)

with R10 ≈ 1.2 kΩ and internal reference voltage V(ref)typ = 1.213 V

At load currents < 1 mA, the device operates in discontinuous conduction mode. When the load current is

reduced to zero, the output voltage rises slightly above the nominal output voltage. At zero load current, the

device skips clock cycles but does not completely stops switching thus the output voltage sits slightly above the

nominal output voltage. Therefore, the lower feedback resistor is selected to be around 1.2 kΩ to have always

around 1 mA minimum load current.

22

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Selecting the Feed-forward Capacitor (step-down converter)

The feed-forward capacitor across the upper feedback resistor divider form a zero around 170 kHz and is

calculated as:

1

1

C17 =

=

= 468 pF = 470 pF

2 x p x 170kHz x R9

2 x p x 170kHz x 2k

(8)

The capacitor value closest to the calculated value is selected.

Inductor Selection (step-down converter)

The TPS65167 operates typically with a 10-µH inductor value. For high efficiencies, the inductor should have a

low dc resistance to minimize conduction losses. This needs to be considered when selecting the appropriate

inductor. To avoid saturation of the inductor, the inductor should be rated at least for the maximum output current

of the converter plus the inductor ripple current that will be calculated as:

1 * Vout

DI

Vin

DI L + Vout

I Lmax + I outmax ) L

2

L ƒ

(9)

With:

f = Switching Frequency (750 kHz)

L = Inductor Value (typically 10 µH)

ΔIL= Peak to Peak inductor ripple current

ILax = Maximum Inductor current

The highest inductor current occurs at maximum Vin. A more conservative approach is to select the inductor

current rating just for the minimum switch current limit of 2.8 A.

Table 8. Inductor Selection (Step down converter)

INDUCTOR VALUE

COMPONENT SUPPLIER

DIMENSIONS in mm

Sat/DCR

10 µH

Sumida CDRH8D43-100

8.3 × 8.3 × 4.5

4 A/29 mΩ

10 µH

Wuerth 744066100

10 × 10 × 3.8

4 A/25 mΩ

10 µH

Coilcraft DO3316P-103

12.95 × 9.4 × 5.51

3.9 A/38 mΩ

Rectifier Diode Selection (step-down converter)

To achieve high efficiency, a Schottky diode should be used. The reverse voltage rating should be higher than

the maximum output voltage of the step-down converter. The averaged rectified forward current that the Schottky

diode must be rated is calculated as the off time of the step-down converter times the minimum switch current of

the TPS65167:

D + Vout

Vin

(10)

I avg + (1 * D)

Isw + 1 * Vout

Vin

2.8 A

with Isw = minimum switch current of the TPS65167 (2.8 A)

A Schottky diode with 2 A maximum average rectified forward current rating is sufficient for most of the

applications. The Schottky rectifier has to be able to dissipate the power. The dissipated power is the average

rectified forward current times the diode forward voltage.

P D + I avg VF + Isw (1 * D) VF

with Isw = minimum switch current of the TPS65167 (2.8 A)

Table 9. Rectifier Diode Selection step-down Converter

CURRENT RATING Avg.

Or

Vforward

RθJA

SIZE

COMPONENT SUPPLIER

3A

20V

0.36 at 3A

46°C/W

S.C.

MBRS320, International Rectifier

2A

20V

0.44V at 2A

75°C/W

SMB

SL22, Vishay Semiconductor

2A

20V

0.5 at 2A

75°C/W

SMB

SS22, Fairchild Semiconductor

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

23

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Output Capacitor Selection (step-down converter)

The device is designed to work with ceramic output capacitors. Two 22-µF output capacitors are sufficient for

most of the applications. Larger output capacitance improves the load transient response.

Table 10. Output Capacitor Selection step-down Converter

CAPACITOR

VOLTAGE RATING

COMPONENT SUPPLIER

2 × 22 µF/6.3 V

6.3 V

Taiyo Yuden JMK212BJ226MG

Positive Charge Pump

The positive charge pump is a fully integrated charge pump switching automatically its gain between doubler and

tripler mode. As shown in Figure 26, the input voltage of the positive charge pump is the SUP pin, that is

connected to the output of the main boost converter Vs.

FBP

OSC

750kHz

SUP

IDRVP

Control Logic

Automatic

Gain select

(doubler or

tripler mode)

Vref

1.213 V

C1N

Q4

C1P

Softstart

Q6

SUP = Vs

POUT

D3

Q3

D0

D1

C2P

D2

Q5

C2N

PGND

Figure 26. Positive Charge Pump Block Diagram

The charge pump requires two 330 nF flying capacitors and a 1 µF output capacitance for stable operation. The

positive charge pump also supports a high voltage stress test by pulling the HVS pin high. This programs the

output voltage to a fixed output voltage of 30 V (TPS65167 only) by using a internal voltage divider. The

TPS65167A has this function disabled. In normal operation the HVS pin is pulled low and the output voltage is

programmed with the external voltage divider.

V out + 1.213 V

R4 + R5

ǒ

ǒ1 ) R4

Ǔ

R5

Ǔ

Vout

* 1 + R5

V FB

(11)

ǒ

Ǔ

Vout

*1

1.213

(12)

To minimize noise and leakage current sensitivity, keeping the lower feedback divider resistor R5 in the 20 kΩ

range is recommended. A 100 pF feed-forward capacitor across the upper feedback resistor R4 is typically

required. For the capacitor selection, see Table 11.

24

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

Table 11. Output Capacitor Selection Positive Charge Pump

CAPACITOR

COMPONENT SUPPLIER

COMMENT

330 nF/35 V

Taiyo Yuden GMK212BJ334KG

Flying capacitor C9, C20

1 µF/35 V

Taiyo Yuden GMK107BJ105KA

Output capacitor on POUT

High Voltage Switch Control (Gate Voltage Shaping)

The TPS65167 has a high voltage switch integrated to provide gate voltage modulation of VGH. If this feature is

not required, then the CTRL pin has to be pulled high or connected to VIN. When the device is disabled or the

input voltage is below the undervoltage lockout (UVLO), then both switches Q4 and Q5 are off, and VGH is

discharge by a 1-kΩ resistor over Q8, as shown in Figure 27.

FB

Power Good

FBP

Power Good

FBN

Power Good

UVLO

EN

POUT

CTRL

Vref

GDLY

3.5kW

Q4

I DLY

EN

VGH

Control

Voltage

clamp

5.8V max

CTRL = high Q4 on Q5 off

CTRL = low Q4 off Q5 on

EN = low Q4 and Q5 off,

Q8 on

1kW

Q5

AVIN

Q8

DRN

Vs

Vs

R13

10kW

R11

10kW

R10

1 kW

Option 1

R12

10kW

Option 2

Option 3

Figure 27. High Voltage Switch (Gate Voltage Shaping) Block TPS65167

To implement gate voltage shaping, the control signal from the LCD timing controller (TCON) is connected to

CTRL. The CTRL pin is activated once the device is enabled, the input voltage is above the under voltage

lockout, all the output voltages (Vs, VGL, VGH) are in regulation and the delay time set by the GDLY pin passed

by. As soon as one of the outputs is pulled below its Power Good level, Q4 and Q5 are turned off, and VGH is

discharged via a 1-kΩ resistor over Q8.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

25

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

With CTRL=high, Q4 is turned on, and the charge pump output voltage is present at VGH. When the CTRL pin is

pulled low, then Q4 is turned off, and Q5 is turned on discharging VGH. The slope and time for discharging VGH

is determined by the LC Display capacitance and the termination on DRN. It is not required or recommended to

connect an additional output capacitor on VGH. There are three options available to terminate the DRN pin. The

chosen solution depends mainly on the LC Display capacitance and required overall converter efficiency.

td

VH

VGH

VL

CTRL

T

Timing:

1. td is set by the capacitor CE

2.The slope is set by the resistor RE

3. VL is set by the voltage applied to VD

Figure 28. High Voltage Switch (Gate Voltage Shaping) Timing Diagram

Option 1 in Figure 27 discharges VGH to Vs. The lower the resistor the faster the discharge.

Option 3 in Figure 27 constantly draws current from Vs due to the voltage divider connected to Vs. The

advantage of this solution is that the low level voltage VL is given by the voltage divider assuming the feedback

resistor values are small and allow to discharge the LC Display capacitance during the time, toff. Therefore, the

solution is not recommended for large display panels since the feedback divider resistors needs to be selected

too low which draws too much current from Vs.

Option 2 does not draw any current from Vs and; therefore, is better in terms of converter efficiency. The voltage

level VL where VGH is discharge to is determined by the LC Display capacitance, the resistor connected to DRN

and the off time, toff. The lower the resistor value connected to DRN the lower the discharge voltage level VL.

Adding any additional output capacitance to VGH is not recommend. If more capacitance is required, it needs to

be added to POUT instead.

High Voltage Stress Test (positive charge pump)

The TPS65167 incorporates a high voltage stress test where the output voltage of the boost converter Vs and

the positive charge pump POUT are set to a higher output voltage compared to the nominal programmed output

voltage. The High Voltage Stress test is enabled by pulling HVS pin to high. This sets POUT, respectively VGH

to 30 V, and the output voltage of the boost converter Vs is programmed to a higher voltage determined by the

resistor connected to RHVS. With HVS = high, the RHVS pin is pulled to GND which sets the voltage for the

boost converter during High Voltage Stress.

The TPS65167A has the high voltage stress test for the positive charge pump POUT disabled. The high voltage

stress test function is only enabled for the boost converter Vs.

Negative Charge Pump Driver

The negative charge pump provides a regulated output voltage set by the external resistor divider. The negative

charge pump inverts the input voltage applied to the SUPN pin and regulates it to the programmed voltage.

26

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

SUPN

OSC

750kHz

Control

Logic

Softstart

Q7

DRVN

IDRVN

PGND

FBN

Vref

0V

Figure 29. Negative Charge Pump Block TPS65167

The output voltage is VGL = (–Vin) + Vdrop. Vdrop is the voltage drop across the external diodes and internal

charge pump MOSFETs.

Setting the output voltage:

V out + *VREF R7 + *1.213 V

R8

|Vout|

|V out|

R7 + R8

+ R8

1.213

V REF

R7

R8

(13)

(14)

Since the reference output driver current should typically not exceed 30 µA, the lower feedback resistor value R8

should be in a range of 40 kΩ to 120 kΩ. The negative charge pump requires two external Schottky diodes. The

peak current rating of the Schottky diode has to be twice the load current of the output. For the external

component selection refer to Table 12.

For a 20-mA output current, the dual Schottky diode BAV99 or BAT54 is recommended.

Table 12. Capacitor Selection

CAPACITOR

COMPONENT SUPPLIER

COMMENT

330 nF/35 V

Taiyo Yuden GMK212BJ334KG

Flying capacitor C15

2.2 µF/10 V

Taiyo Yuden LMK107BJ225KA

Output capacitor on VGL

BAV99/BAT54

Any

Dual Schottky diode

LDO Controller Generating Vaux

The TPS65167 has a LDO controller using an external pass transistor. The input of the LDO controller can be

the 12-V power supply input or the output of the 3.3-V logic rail, as generated by the step-down converter. The

LDO controller is connected to the 3.3-V rail in order to minimize power losses across the external pass

transistor.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

27

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

FBLDO

PGND

5

39

BASE

40

Q2

PZT2907A

Vlogic

3.3V

R14*

100 W

C22

1m F

Vaux

1.5V/500mA

R11

1.6kW

R13

1kW

C23

22mF

R12

6.8kW

*Optional

Figure 30. LDO Controller Block TPS65167

Setting the output voltage, LDO controller

The output voltage of the LDO controller can be set with the resistor divider connected to the output of the LDO

controller. To set the LDO controller output voltage to 1.2V the feedback FBLDO can be connected directly to the

output. Any other output voltages is set using the external resistor divider and is calculated as:

V out + 1.213 V

ǒ1 ) R11

Ǔ

R12

(15)

Input Capacitor and Output Capacitor Selection, LDO Controller

For input voltage filtering, a 1-µF input capacitor is sufficient. The output requires a least one 10-µF output

capacitor for stability for load currents up to 300-mA. For load currents larger 300 mA, one 22-µF output

capacitor is required. See Table 13 for the capacitor selection.

Table 13. Output Capacitor Selection

CAPACITOR

Iout

1 µF/10 V

COMPONENT SUPPLIER

COMMENT

Taiyo Yuden LMK107BJ105KK

Input capacitor

10 µF/10 V

≤300 mA

Taiyo Yuden LMK212BJ106KG

Output capacitor

22 µF/10 V

>300 mA

Taiyo Yuden LMK212BJ226MG

Output capacitor

Base and Emitter Base Resistor Selection

A 1-kΩ resistor (R13) is required across the emitter base of the external transistor. To limit the current into the

base during a short-circuit event, a 100-Ω base resistor (R4) is required when the input is connected to the 3.3-V

rail. If the input is connected to the 12-V rail, then a 1-kΩ (R4) resistor is required. R4 is optional and protects the

TPS65167 in case of a short-circuit event at the output of the LDO controller.

28

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

External Transistor Selection

The external transistor is selected based on the required output current and collector saturation voltage. The

maximum collector saturation voltage is only important as the output voltage is close to the input voltage. This is

the case for a 3.3 V to 2.5 V conversion where the collector saturation voltage of the external transistor is lower

than 800 mV. To use low cost external transistors, the TPS65167 provides a minimum base drive current of 25

mA. The other important parameter is the maximum power dissipation the external transistor must be able to

handle. The power dissipation is the output current times the input to output voltage difference. See Table 14 for

the transistor selection

Table 14. Transistor Selection

CAPACITOR

Iout

COMPONENT SUPPLIER

COMMENT

PZT2907A

500 mA

Any

3.3 V to ≤2.5 V conversion at 150 mA

3.3 V to ≤1.6 V conversion at 500 mA

BCP52

1A

Any

3.3 V to ≤2.5 V conversion

BCP69

1A

Any

3.3 V to ≤2.5 V conversion

PCB Layout Design Guidelines

Temperature

Output

C29

1nF

31

9

C12

22nF 30

R6

0W

C13

10nF

25

27

CTRL

Signal

24

D3

R7

160kW

R8

39kW

C15

0.33mF

13

D4

11

C20

0.33mF

15

16

S UP

PGND

POUT

C2P

EN

C2N

REGOUT

COMP

VGH

TPS65167

GDLY

DRN

HVS

Vlogic

CTRL

BOOT

DRVN

SWB

FBN

SWB

C1P

FBB

C1N

10

14

37

6

32

PGND

26

C11

4.7uF

FBP

PGND

5

AVIN

PGND

38

GND

C1

22mF

RHVS

GND

C2

1mF

FB

VINB

REF

1

33

C6

10mF

C7

10mF

R1

365kW

19

TEMP

SW

GD

34

SUPN

Vin

6 V to 14V

C16

2.2mF

35

36

12

BASE

C28

470nF

C5

1mF

C4

10mF

C31

10mF

C3

10mF

Vs

15 V/1.5 A

SW

C24

1nF

VGL

-5 V/150mA

D1

SL22

L1

10mH

Q1

SI2343

FBLDO

R2

30kW

29

28

C8

47pF

C25 C26

C27 C32

10mF 10mF 10mF 10mF

R3

82kW

20

R4

300kW

21

C9

0.33mF

17

C10

1mF

18

R5

16kW

C30

100pF

VGH

24 V/50 mA

22

R14

1kW

23

7

2

C14

100nF

L2

10mH

4

3

D2

SL22

8

Vlogic

3.3V/2.5A

C18

22mF

C19

22mF

39

40

Q2

PZT2907A

C21

100nF

R16

100kW

C22

1mF

Vaux

1.5V/500mA

R11

1.6kW

R13

1kW

C23

22mF

R12

6.8kW

Figure 31. PCB Layout

1. Place the power components outlined in bold first on the PCB.

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

Submit Documentation Feedback

29

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

2.

3.

4.

5.

6.

7.

8.

Route the traces outlined in bold with wide PCB traces.

Place a 1-µF bypass capacitor directly from the SUP pin to GND and from AVIN to GND.

Use a short and wide trace to connect the SUP pin to the output of the boost converter Vs.

Place a 470-nF bypass capacitor directly from the SUPN pin to GND.

Place the 100-nF reference capacitor directly from REF to GND close to the IC pins.

The feedback resistor for the negative charge pump between FBN and REF needs to be >40 kΩ.

Use short traces for the charge pump drive pin (DRVN) of VGL because the traces carry switching

waveforms.

9. Place the feedback resistors of the negative charge pump away from the DRVN trace to minimize coupling

10. Place the flying capacitors as close as possible to the C1P, C1N and C2P, C2N pin.

11. Solder the PowerPad™ of the QFN package to GND and use thermal vias to lower the thermal resistance.

12. A solid PCB ground structure is essential for good device performance.

The power pad is the analog ground connected to the internal reference

Pin 32, 33 are the power grounds for the boost converter Vs

Pin 5 is the power ground for the step-down converter Vlogic and internal digital circuit

Pin 6 is the power ground for the negative charge pump VGL

Pin 14 is the power ground for the positive charge pump POUT

Pin 37 is the analog ground for the internal reference

13. For more layout recommendations, see the TPS65167 evaluation module (EVM)

30

Submit Documentation Feedback

Copyright © 2007–2008, Texas Instruments Incorporated

Product Folder Link(s): TPS65167 TPS65167A

�TPS65167

TPS65167A

www.ti.com

SLVS760C – APRIL 2007 – REVISED MARCH 2008

TYPICAL APPLICATION

Temperature

Output

C27

1nF

1

C2

1uF

38

5

26

C11

4.7uF

9

C12

22nF 30

C13

10nF

25

27

CTRL

Signal

24

C15

0.33uF

D4

SUP

TEMP

POUT

EN