TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

MULTIFUNCTION 3-CHANNEL LED DRIVERS

Check for Samples: TPS68401, TPS68402

FEATURES

1

•

•

•

•

•

•

•

•

•

•

•

•

Multifunction LED Driver With Three

Independent Channels

Integrated High Efficiency 1x / 1.5x Charge

Pump With Automatic or Manual Gain Change

3 x 25.5-mA Total Output Current

3 x 25.5-mA Total Output Current

Three Independent Program Execution

Engines (3 x 16 Instructions)

8-Bit PWM With Exponential Control Option

8-Bit Current DAC Control

200-nA Typical Shutdown Current

Automatic Power-Save Mode

Autonomous Operation Without External

Control

Trigger I/O for Synchronizing Multiple Devices

One or Two General Purpose Output

Controlled Via Serial Interface

•

•

I2C Interface

Operating Temperature Range: -30ºC to 85ºC

APPLICATIONS

•

•

•

•

•

LED Control for Portable Applications

Accent Lighting (Mood, Personalization, etc.)

Function Indication (Charge, Messages, etc.)

Keypad Illumination / Backlight (White or RGB)

Display Backlight

DESCRIPTION

The TPS68401/TPS68402 is an advanced lighting management unit for handheld devices. It has three

independent channels optimized for driving RGB LEDs. The built-in fractional charge pump boosts the input

voltage to power the LEDs at low input voltage. Channel one can optionally be supplied directly from the battery

voltage to reduce power consumption and improve efficiency.

At the heart of the device is a programmable state machine which executes a lighting program consisting of up to

16 instructions per channel. Once the program is loaded through the I2C interface the device is fully independent

from the main processor resulting in significant system-level power savings. The device can issue an interrupt to

the main processor via the INT pin.

The TRIG I/O allows synchronization between multiple devices. A general-purpose output pin is provided which

is addressable through the serial interface. In addition, the INT pin can also be configured as general-purpose

output.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2010–2011, Texas Instruments Incorporated

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

FUNCTIONAL BLOCK DIAGRAM

VOUT

VDD

R_TO_BATT

CPLY 1P

8bit DAC

CPLY1N

CPLY 2P

1x/1.5x

Charge Pump

8-bit PWM

Charge Pump

Control

8bit DAC

R

CPLY2N

EN

G

8-bit PWM

GND

Reference

TRIM

GND

1.25 MHz Qpump

Oscillator

8bit DAC

HF PWM

32768 Hz (PWM)

CLK32K

B

8-bit PWM

Ext. PWM clock

Control

Register

PUC

SCL

SDA

ADDR_SEL0

ADDR_SEL1

Controller / Sequencer

ENABLE

VDD

GPO

2

Program

Register

INT_AS_GPO

I2C

Submit Documentation Feedback

VDD

INT

TRIG

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

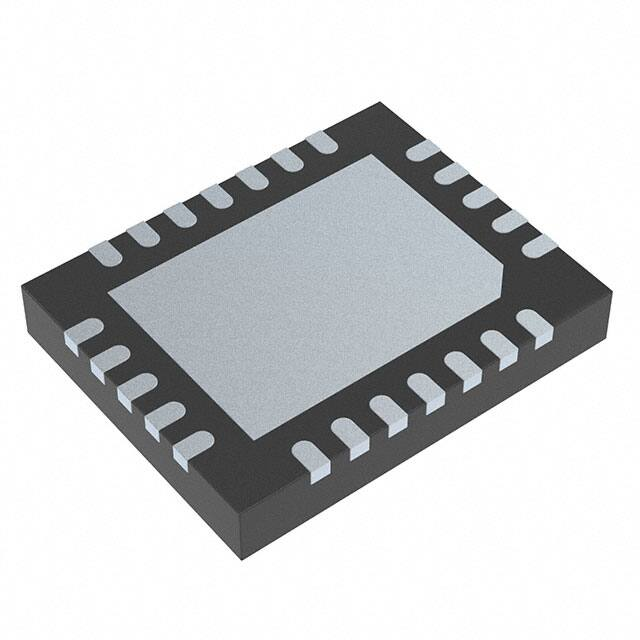

ORDERING INFORMATION

TA

PACKAGE

-30°C to 85°C

ORDERABLE PART NUMBER

TOP-SIDE MARKING

YFF

TPS68401C4YFFR

TPS68401C4YFF

RHF

TPS68402A0RHFR

24RHF

TERMINAL FUNCTIONS

NanoFree YFF PACKAGE

(BOTTOM VIEW )

PACKAGE MARKING

TRIG

GND

VDD

CFLY

1P

CFLY

2P

4

INT

CLK

32K

GND

CFLY

1N

CFLY

2N

3

EN

GPO

ADDR

SEL0

ADDR

SEL1

VOUT

2

SDA

SCL

R

G

B

1

E

D

C

B

A

TERMINAL

NAME

NO.

YMILLL

PA1S

I/O

YM = YEAR / MONTH DATE CODE

LLLL = LOT TRACE CODE

S

= ASSEMBLY SITE CODE

A

= MAJOR DIE REVISION

1

= MINOR DIE REVISION

P

= PREPRODUCTION INDICATOR

0

= Pin A1 (Filled Solid)

DESCRIPTION

CFLY1P

4B

Positive terminal of charge pump fly capacitor

CFLY1N

3B

Negative terminal of charge pump fly capacitor

CFLY2P

4A

Positive terminal of charge pump fly capacitor

CFLY2N

3A

Negative terminal of charge pump fly capacitor

VDD

4C

Power pin

GND

4D

Ground

VOUT

2A

R

1C

O

Charge pump output

Current source output, Channel 1 (Red)

G

1B

O

Current source output, Channel 2 (Green)

B

1A

O

Current source output, Channel 3 (Blue)

SCL

1D

I

I2C Serial interface clock input

SDA

1E

I/O

CLK32K

3D

I

32.768-kHz clock input – If no clock present on power-up or after RESET, uses internal

oscillator

I2C Serial interface data input/output (open drain)

EN

2E

I

Chip enable (active high)

ADDR_SEL0

2C

I

I2C address select input

ADDR_SEL1

2B

I

I2C address select input

INT

3E

O

Interrupt output (open drain, active low); Can be configured as push-pull GPO

TRIG

4E

I/O

Trigger input / output (open drain, active low)

GPO

2D

O

General purpose output

GND

3C

Ground

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

3

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

RHF PACKAGE MARKING - TOP VIEW

RHF PACKAGE - BOTTOM VIEW

TERMINAL

4

I/O

DESCRIPTION

NAME

NO.

CFLY2P

1

Positive terminal of charge pump fly capacitor

CFLY1P

2

Positive terminal of charge pump fly capacitor

VDD

3

Power pin

GND

4

Ground

CLK32K

5

I

32.768-kHz clock input. If no clock present on power-up or after RESET, uses internal

oscillator.

INT

6

O

Interrupt output (open drain, active low); Can be configured as push-pull GPO.

TRIG

7

I/O

Trigger input/output (open drain, active low)

N/C

8

Not connected

N/C

9

Not connected

N/C

10

Not connected

N/C

11

Not connected

N/C

12

SDA

13

I/O

Not connected

I2C Serial interface data input/output (open drain)

EN

14

I

Chip enable (active high)

SCL

15

I

I2C Serial interface clock input

GPO

16

O

General purpose output.

R

17

O

Current source output, Channel 1 (Red)

G

18

O

Current source output, Channel 2 (Green)

B

19

O

Current source output, Channel 3 (Blue)

ADDR_SEL0

20

I

I2C address select input

ADDR_SEL1

21

I

I2C address select input

VOUT

22

Charge pump output

CFLY2N

23

Negative terminal of charge pump fly capacitor

CFLY1N

24

Negative terminal of charge pump fly capacitor

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

(1) (2)

VOUT VDD (unregulated input battery voltage)

INT, GPO, R, G, B, CFLY1N,

CFLY1P, CFLY2N, CFLY2P,

Input/Output voltage range (with respect to PGND) ADDR_SEL0, ADDR_SEL1

VALUE

UNIT

-0.3 to 6

V

-0.3 to VDD+0.3

(6.0 max)

V

100

°C/W

SDA, SCL, EN, TRIG, CLK32K

qJA

Junction-to-ambient thermal resistance

PD

Continuous power dissipation

TJ

Operating junction temperature

Tstg

Storage temperature

ESD rating

(1)

(2)

Internally limited

W

-30 to 125

°C

-65 to 150

°C

(HBM) Human body model

±2000

(CDM) Charged device model

±100

V

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

All voltage values are with respect to network ground terminal.

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

VDD

Unregulated input battery voltage

MIN

NOM

MAX

UNIT

2.7

3.6

5.5

V

INT, GPO,

ADDR_SEL0,

ADDR_SEL1

0

5.5

V

SDA, SCL, EN,

TRIG

0

1.8

V

64

kHz

CLK_32K

External clock frequency

16

TA

Operating ambient temperature

Flying capacitor

Input capacitor (VDD)

Output capacitor (VOUT)

32

-30

85

°C

0.47

mF

1

mF

1

mF

SCA, SDA pull-up resistor value

10

kΩ

INT pull-up resistor value

10

kΩ

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

5

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

ELECTRICAL CHARACTERISTICS

VBAT = 3.6 V ±5%, TA = 25ºC (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

mA

SUPPLY CURRENT

Shutdown current

EN = 0

Standby current

IDD

Normal mode supply current

Power save current

0.2

2.0

EN = 1; CHIP_EN = 0

Ext. 32-kHz clock not running

1

2.0

EN = 1; CHIP_EN = 0

Ext. 32-kHz clock running

1

2.0

mA

EN = 1, CHIP_EN = 1

Ext. 32-kHz clock running

C/P, G & B channel disabled

R_TO_BATT = 1 (R channel enabled)

[CLK_DET_EN : INT_CLK_EN] = 00b

(clock detection disabled)

ILED = 5 mA, 50% duty cycle

180

EN = 1, CHIP_EN = 1

C/P and LED drivers disabled

[CLK_DET_EN : INT_CLK_EN] = 10b

(automatic clock source selection)

PWRSAVE_EN = 0

190

EN = 1, CHIP_EN = 1

C/P in 1x mode, no load (1),

LED drivers disabled

Ext. 32-kHz clock running

70

EN = 1, CHIP_EN = 1

C/P in 1.5x mode, no load (1),

LED drivers disabled

1700

EN = 1, CHIP_EN = 1

C/P in 1x mode, no load (1),

LED drivers enabled

Ext. 32-kHz clock running

650

EN = 1, CHIP_EN = 1

C/P in 1x mode, 5-mA load LED drivers

enabled

Ext. 32-kHz clock running

800

EN = 1, CHIP_EN = 1

CLK32K active

10

EN = 1, CHIP_EN = 1

Internal oscillator running

190

STANDBY to NORMAL mode

500

mA

mA

STARTUP

tSTARTUP

Startup time

1000

ms

BOOST VOLTAGE (VOUT)

1x mode, no load (1)

VOUT

Output voltage

VHYS

Automatic gain change hysteresis

VDD

1.5x mode, VDD = 3.6 V, no load (1)

4.55

C/P in automatic mode, no load (1)

200

Continuous output current

IOUT

fS

ZO

tON

(1)

(2)

6

V

mV

150

VOUT < 1V

Max output current

150

VOUT > 1V

150

Switching frequency

1.25

Open loop output impedance

mA

250

1x mode (VDD - VOUT) / IOUT

1.1

1.5x mode (2)

4.1

Turn on time from 1x to 1.5x mode.

VDD = 3.6 V

50

Turn on time from off to 1.5x mode.

VOUT = 0 V

100

MHz

Ω

ms

No-load measurement condition is as follows: DAC setting = default (17.5 mA); PWM = 0; Output connected to ground via 150-Ω

resistor.

Charge pump Impedance is measured at VDD = 3 V, IOUT = 50 mA follows: [VOUT (IOUT = 0) – VOUT (IOUT)] / IOUT

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

ELECTRICAL CHARACTERISTICS (continued)

VBAT = 3.6 V ±5%, TA = 25ºC (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

INTERNAL OSCILLATOR

fOSC

Internal oscillator frequency

TA = 25 ºC

-4

4

-30 ºC ≤ TA ≤ 85 ºC

-7

7

%

OUTPUT CHANNELS (R,G,B)

VLED

VDRP

LED forward voltage

1.5

Driver saturation voltage

IR,G,B = 17.5 mA

LED current

IR,G,B

fPWM

(3)

Per channel

50

0

LED current resolution

IR,G,B = 17.5 mA

LED current matching

IR,G,B = 17.5 mA, Vf = 3.0 V

PWM frequency

Pin leakage current

PWMRES

PWM resolution

mV

mA

8

LED current accuracy

ILEAK

100

25.5

-4

1

PWM_HF = 1

Internal high frequency oscillator

558

PWM_HF = 0

Internal clock or CLK_32K

256

TA = 25 ºC

0.1

Bit

4

%

2

%

Hz

-30 ºC ≤ TA ≤ 85 ºC

1

8

mA

Bit

LOGIC INPUT LEVELS (EN)

VIL

Input low level

VIH

Input high level

IIH, IIL

Input bias current

tdelay

Input delay

0.5

V

1

mA

1.2

VEN = 0 V to 1.65 V

V

-1

EN pin low to high

2

ms

LOGIC INPUT LEVELS (SCL, SDA, TRIG, CLK_32K)

VIL

Input low level

VEN = 1.65 V to 3.6 V

VIH

Input high level

VEN = 1.65V to 3.6 V

IIH, IIL

Input bias current

fSCL

I2C clock frequency

0.2 x VEN

0.8 x VEN

V

V

-1.0

1.0

mA

400

kHz

LOGIC INPUT LEVELS (ADD_SEL0, ADD_SEL1)

VIL

Input low level

VIH

Input high level

IIH, IIL

Input bias current

0.2 x VDD

V

1.0

mA

0.5

V

1.0

mA

0.5

V

0.8 x VDD

VADD_SEL0, ADD_SEL1 = 3.6 V

V

-1.0

LOGIC OUTPUT LEVELS (SDA, TRIG, INT pin as INT)

VOL

IIL

Output low level

IOUT = 3 mA through pull-up

0.3

INT pin as INT (open drain), INT = high,

VINT = 0 V to 1.65 V

Output leakage current

LOGIC OUTPUT LEVELS (GPO, INT pin as GPO)

VOL

Output low level

IOUT = 3 mA

VOH

Output high level

IOUT = -2 mA

(3)

0.3

VDD - 0.5

VDD - 0.3

V

IOUT at VDRP = 0.9 x IOUT at (VDD - VLED) = 1 V

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

7

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

DESCRIPTION OF CHARGE PUMP OPERATION

The TPS68401/TPS68402 includes a regulated fractional charge pump with bypass mode. It is used to boost the

supply voltage for the output drivers when the battery voltage is close to or below the forward bias voltage of the

LEDs. In 1.5x mode VOUT is boosted to 1.5x VDD or 4.55 V, whichever value is lower. In 1x (bypass) mode the

output is connected directly to the input supply.

The charge pump is controlled with two CP_MODE bits in the CONFIG register. When disabled, VOUT is

connected to ground through a 300-kΩ resistive path. The user can manually select 1x and 1.5x mode or select

automatic mode. When automatic mode is enabled, the charge pump will operate in bypass mode as long as the

input supply voltage is sufficient to drive the LEDs. Dropout voltage of all three channels is monitored and charge

pump gain is set to 1.5x if any one driver does not have enough headroom to drive the LED. When the part

enters Power Save mode the output capacitor is connected to the input supply through a resistive path. See

Power Save mode description for details.

The mode selection logic utilizes digital filtering to prevent glitches of the supply voltage from triggering gain

changes. If R-driver current source is connected to battery (CONFIG register, bit R_TO_BATT set to 1) voltage

monitoring is disabled in R output, but still functional in G and B output.

BYPASS

VDD

CIN

WEAK 1x

CP _MODE [ 1:0]

REG

1x/1.5x

C/P

VOUT

COUT

CP _MODE [ 1:0] = OFF

Figure 1. Functional Model of Charge Pump

8

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

5.5

1 .5

xM

OD

E

1x

M

O

D

E

V OUT [V]

4.5

3.0

5.5

V DD [V]

Figure 2. Charge Pump Output Voltage

LED DRIVER OPERATIONAL DESCRIPTION

The TPS68401/TPS68402 has three independent constant current LED drivers with 8-bit PWM control. Output

current is programmed through the I2C register and ranges from 0 mA to 25.5 mA with 8-bit resolution. PWM

duty cycle is controlled either by program instructions or R/G/B PWM registers. Green and blue channels are

always connected to the charge pump output VOUT. The red channel is connected to either VOUT or VDD

depending on R_TO_BAT bit setting of the CONFIG register. If red channel is connected to VDD, automatic

charge pump gain control is not used for this output. Connecting the red channel to VDD provides better efficiency

when driving LEDs with low VF or the supply voltage is high enough to drive a LED with high VF.

PWM frequency is either 256 Hz or 558 Hz and is selected through PWM_HF bit in the CONFIG register. Linear

and logarithmic PWM duty-cycle-to-input response is selectable through the LOG_EN bit of the ENABLE register.

LOG_EN bit controls PWM response for all three channels. Logarithmic response is approximated by

piece-wise-linear function as shown below.

When the external clock source is selected for driving the PWM, PWM frequency scales with the external clock

frequency. Nominal 256-Hz PWM frequency requires external clock frequency of 32.768 kHz.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

9

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

PWM CONTROL

Table 1. PWM Value and Output in LIN and EXP Mode

PWM OUTPUT

PWM REGISTER VALUE

PWM REGISTER VALUE

PWM OUTPUT

LIN

EXP

LIN

EXP

0

0

0

128

128

64

1

1

0

129

129

65

2

2

1

130

130

66

3

3

1

131

131

67

4

4

2

132

132

68

69

5

5

2

133

133

...

...

...

...

...

...

61

61

30

189

189

125

62

62

31

190

190

126

63

63

31

191

191

127

64

64

32

192

192

129

65

65

32

193

193

131

66

66

33

194

194

133

...

...

...

...

...

...

125

125

62

253

253

251

126

126

63

254

254

253

127

127

63

255

255

255

256

224

EXP

LIN

PWM OUT PUT [T ICKS]

192

160

128

96

64

32

0

0

32

64

96

128

160

192

224

256

PWM LINEAR INPUT

Figure 3. Graph of PWM Output vs. PWM Input

10

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

Table 2. LED Channel Output Current Control

REGISTER

R_CURRENT,

G_CURRENT,

B_CURRENT

BITS

7:0

VALUE

CHANNEL CURRENT

0x00

0.0 mA

0x01

0.1 mA

↕

↕

0xAE

17.4 mA

0xAF

17.5 mA

0xB0

17.6 mA

↕

↕

0xFE

25.4 mA

0xFF

25.5 mA

DATA TRANSMISSION

TPS68401/TPS68402 features an I2C slave interface for communication to a controlling microprocessor. SDA,

SCL, CLK_32K and TRIG pins input levels are defined by EN pin. EN pin is used as voltage reference for logic

inputs and therefore no dedicated VIO pin is required.

VDD

EN

Input

Buffer

SDA

Level

Shifter

SCL

Level

Shifter

CLK32K

Level

Shifter

TRIG

Level

Shifter

Figure 4. Internal Logic Level Shifters

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

11

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

SUBADDRESS DEFINITION

Slave Address + R/nW

Start

G3

G2

G1

G0

A2

A1

A0

Sub Address

R/nW

ACK

S7

S6

S5

S4

S3

S2

Data

S1

S0

ACK

D7

D6

D5

D4

D3

D2

D1

D0

ACK

Stop

Figure 5. Subaddress in I2C Transmission

Start – Start Condition

ACK – Acknowledge

G(3:0) – Group ID: Address fixed at 0110b

S(7:0) – Subaddress: defined per register map

– Device address: Device address is selectable via

A(2:0)

ADDR_SEL input pin.

D(7:0) – Data; Data to be loaded into the device

R/nW – Read / not Write select bit

Stop – Stop condition

Table 3. Subaddress Bits

Defined by ADDR_SEL Inputs

ADDR_SEL

[1:0]

A [2:0]

00

010

01

011

10

100

11

101

The address bits used in the slave address portion of the I2C transaction are defined by the device pins

ADDR_SEL1 and ADDR_SEL0 (combined as ADDR_SEL [1:0] above). The table above gives the values of the

address bits for all combinations of ADDR_SEL1 and ADDR_SEL0.

I2C BUS OPERATION

The I2C bus is a communications link between a controller and a series of slave terminals. The link is established

using a two-wired bus consisting of a serial clock signal (SCL) and a serial data signal (SDA). The serial clock is

sourced from the controller in all cases where the serial data line is bi-directional for data communication

between the controller and the slave terminals. Each device has an open drain output to transmit data on the

serial data line. An external pull-up resistor must be placed on the serial data line to pull the drain output high

during data transmission.

Data transmission is initiated with a start bit from the controller as shown in Figure 6. The start condition is

recognized when the SDA line transitions from high to low during the high portion of the SCL signal. Upon

reception of a start bit, the device will receive serial data on the SDA input and check for valid address and

control information. If the appropriate group and address bits are set for the device, then the device will issue an

acknowledge pulse and prepare the receive subaddress data. Subaddress data is decoded and responded to as

per the Register Map section of this document. Data transmission is completed by either the reception of a stop

condition or the reception of the data word sent to the device. A stop condition is recognized as a low to high

transition of the SDA input during the high portion of the SCL signal. All other transitions of the SDA line must

occur during the low portion of the SCL signal. An acknowledge is issued after the reception of valid address,

sub-address and data words. The I2C interface will auto-sequence through register addresses, so that multiple

data words can be sent for a given I2C transmission.

12

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

...

SDA

SCL

1

2

3

4

5

6

7

START CONDITION

8

...

9

ACKNOWLEDGE

STOP CONDITION

2

Figure 6. I C Start / Stop / Acknowledge Protocol

tLOW

tr(

t H(STA )

tF

SCL

t H(STA )

t H(DAT)

tHIGH

t S(DAT)

tS(STO)

tS(STA )

SDA

t(BUF )

P

S

S

P

Figure 7. I2C Data Transmission Timing

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

13

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

DATA TRANSMISSION TIMING

VBAT = 3.6 ±5%, TA = 25 ºC, CL = 100 pF (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

100

f(SCL)

Serial clock frequency

t(BUF)

Bus free time between stop and start

condition

t(SP)

Tolerable spike width on bus

tLOW

SCL low time

tHIGH

SCL high time

tS(DAT)

SDA → SCL setup time

tS(STA)

Start condition setup time

tS(STO)

Stop condition setup time

tH(DAT)

SDA → SCL hold time

tH(STA)

Start condition hold time

tr(SCL)

Rise time of SCL Signal

tf(SCL)

Fall time of SCL Signal

tr(SDA)

Rise time of SDA Signal

tf(SDA)

Fall time of SDA Signal

400

SCL = 100 kHz

4.7

SCL = 400 kHz

1.3

SCL = 100 kHz

SCL = 400 kHz

4.7

SCL = 400 kHz

1.3

4

SCL = 400 kHz

0.6

SCL = 100 kHz

250

SCL = 400 kHz

100

SCL = 100 kHz

4.7

SCL = 400 kHz

0.6

SCL = 100 kHz

4

SCL = 400 kHz

0.6

SCL = 100 kHz

0

3.45

SCL = 400 kHz

0

0.9

4

SCL = 400 kHz

0.6

ns

µs

SCL = 100 kHz

SCL = 100 kHz

KHz

µs

50

SCL = 100 kHz

UNIT

µs

ns

µs

µs

µs

µs

SCL = 100 kHz

1000

SCL = 400 kHz

300

SCL = 100 kHz

300

SCL = 400 kHz

300

SCL = 100 kHz

1000

SCL = 400 kHz

300

SCL = 100 KHz

300

SCL = 400 kHz

300

ns

ns

ns

ns

FUNCTIONAL DESCRIPTION OF DEVICE PINS

ADDR_SEL0 AND ADDR_SEL1 PINS

ADDR_SEL0 and ADDR_SEL1 pins define the chip I2C address. Pins are referenced to VDD signal level. See

Data Transmission section for I2C address definitions.

GENERAL PURPOSE OUTPUT PIN

The TPS68401/TPS68402 has one dedicated general purpose output pin (GPO) with digital CMOS output.

High-level output voltage is defined by VDD and no pull-up resistor is needed. GPO output is controlled by GPO

bit of the GPO register.

INT PIN

The INT pin is used to issue an interrupt to a host processor when END instruction is executed and the INT bit is

set (see Instruction Description section for details). The INT pin can also be configured as a GPO pin by setting

the INT_AS_GPO bit of the GPO register. When configured as INT pin it has an open drain output and requires

an external pull-up resistor. As GPO pin it has a digital CMOS output, high-level output voltage is defined by VDD,

and no pull-up resistor is needed. In GPO mode the output is controlled by the INT bit of the GPO register.

14

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

TRIG PIN

TRIG pin is used to send and receive trigger pulses between multiple TPS68401/TPS68402 devices for pattern

synchronization. TRIG is an open drain output and requires an external pull-up resistor. External trigger input

signal must be at least two 32-kHz clock cycles long to be recognized. Trigger output signal is three 32-kHz clock

cycles long. If TRIG pin is not used on application, it should be connected to GND.

CLK_32K PIN

CLK_32K pin is used for connecting external 32.768-kHz clock to TPS68401/TPS68402. Connecting several

devices to the same clock source ensures synchronous instruction execution. When external clock source is

used the internal oscillator is shut down during automatic power save mode to achieve lowest possible current

consumption. An external clock source is not required for device operation. If external clock is not used,

CLK_32K pin should be connected to GND.

CLK_32K EXTERNAL CLOCK DETECTION

The instruction execution engine and PWM are clocked either by an internal 32.768-kHz or an external clock.

The user can manually select internal or external clock or enable automatic clock source selection. In automatic

mode the TPS68401/TPS68402 monitors the CLK32K pin; If external clock frequency is < 15 kHz, stuck-at-zero,

or stuck-at-one, the clock detector indicates that no external clock is present and switches to internal clock

source. It switches back to external clock source once the external clock is detected again. In any mode (manual

or automatic selection) the clock source can be checked by reading the EXT_CLK_USED bit of the STATUS

register. Clock source selection is controlled by CONFIG register bits INT_CLK_EN and CLK_DET_EN. External

clock detection is disabled in POWER SAVE mode.

When external clock source is selected, instruction timing and PWM frequency scale with the external clock

frequency. Nominal external clock frequency is 32.768 kHz.

MODES OF OPERATION

RESET

In the RESET mode all the internal registers are reset to the default values. Reset is initiated if 0xFFh is written

into the RESET register or internal power-up clear (PUC) is activated. PUC will activate when supply voltage is

connected to VDD pin or when the supply voltage drops below the nPUC_VIL level. Once VDD rises above

nPUC_VIH, PUC is released and the chip will continue to the STANDBY mode. CHIP_EN control bit is low after

PUC by default.

SHUTDOWN

Whenever the EN pin is pulled low the device enters SHUTDOWN mode. All functions are disabled, including the

serial interface. This is the lowest power mode.

STANDBY

STANDBY mode is entered if the CHIP_EN bit of the ENABLE register is set to 0 and reset is not active.

Registers can be written to in this mode with the exception of the EXEC bits of the ENABLE register

(R_EXEC[1:0], G_EXEC[1:0], B_EXEC[1:0]). Control bits are effective after start up.

STARTUP

When CHIP_EN bit of the ENABLE register is written 1 and EN pin is high, the chip executes the internal startup

sequence to power up analog blocks (VREF, bias, oscillator etc.). If the chip temperature rises too high, the over

temperature shutdown (OTS) disables the chip and automatically re-enters STARTUP mode, until no thermal

shutdown event is present.

NORMAL

During NORMAL mode the user controls the chip using the control registers. If EN pin is set low, the CHIP_EN

bit is reset to 0.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

15

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

POWER SAVE

In POWER SAVE mode analog blocks are disabled to minimize power consumption. See the Power Save Mode

section for further information.

MODE TRANSITIONS

Setting the CHIP_EN bit of the ENABLE register to 0 resets the program counters (PC) but does not change the

LED controller operational mode (see NORMAL MODE settings). Pulling the EN pin low resets the CHIP_EN bit

and PC but does not affect operational mode (see NORMAL MODE settings).

POWER OFF

nPUC=0

RESET = 0xFFh or

nPUC=0

RESET

nPUC=1 and EN pin = Low

nPUC=1 and

EN pin = High

SHUTDOWN

EN pin = Low

EN pin = High

STANDBY

CHIP_EN bit = 0

CHIP_EN bit = 1

STARTUP

TSD=1

TSD=1

TSD=0

TSD RECOVERY

TSD=0

TSD=1

NORMAL

Enable

Power Save

Disable

Power Save

POWER SAVE

Figure 8. Device Startup Flow and Modes of Operation

16

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

POWER SAVE MODE

Automatic power save mode is enabled when PWRSAVE_EN bit in the CONFIG register is set to 1. In power

save mode all analog blocks are powered down with exception of charge pump protection circuits, provided

external clock source is used to run the PWM. If internal clock source has been selected, only charge pump and

LED drivers are disabled and the digital part of the LED controller remains active. In both cases charge pump

enters a special 1x mode to keep the output at battery level. During program execution the device can enter

power save if there is no PWM activity in R, G and B outputs for > 50ms. To prevent the device from entering

power-save mode for short periods of time the device does a command look-ahead. In every instruction cycle R,

G, B commands are analyzed, and if there is sufficient time left with no PWM activity, device will enter power

save mode. In power save mode program execution continues uninterruptedly. When a command that requires

PWM activity is executed, the device starts up automatically. The following table describes commands and

conditions that can activate power save mode. All channels (R, G, and B) need to meet power save condition in

order to enable power save.

POWER SAVE MODE can only be entered when no channel is in the LOAD MODE, all PWM values are zero or

channel is disabled, and C/P mode is either OFF or Automatic.

Table 4. Requirements for Power Save By Command

COMMAND

POWER SAVE REQUIREMENT

WAIT

Enter power save only if PWM is zero and wait is greater then 50 ms.

RAMP

Enter power save only if ramp ends with PWM set to zero and there is 50 ms before the next command.

TRIGGER

Enter power save only if PWM is zero while waiting for trigger.

END

Enter power save only if PWM is zero or reset bit of command is set to 1.

SET

Enter power save only if PWM is set to zero and the next command generates at least a 50-ms wait.

Other

Cannot enter power save mode

LED CONTROLLER OPERATIONAL MODES (NORMAL MODE)

In NORMAL MODE, operation of the red, green, and blue LED controller is defined independently by the

OP_MODE, and respective R/G/B_PC, R/G/B_PWM, and R/G/B_CURRENT registers. The R/G/B CURRENT

registers define the maximum output current for the respective channel. MODE control bits are synchronized to a

32-kHz clock.

In the following, PC denotes either R_PC, G_PC, or B_PC program counter. MODE denotes either R_MODE,

G_MODE, or B_MODE bits of the OP_MODE register.

DISABLED MODE

LED output current is set to 0 and PC counter is reset.

LOAD MODE

The device can store 16 16-bit commands for each channel (R, G, B). Due to the 8-bit format of the I2C protocol

two writes are required to load a single instruction. The device supports auto-increment addressing to reduce

program load time. Register address is incremented after each 8 data bits which allows the whole program

memory to be written in a single I2C write sequence. Program memory is defined in the register table. Read /

write access to program memory is allowed only in LOAD mode and only to the channel in LOAD mode. LOAD

mode resets respective channel’s PC. Program execution on all other channels is halted and PWM value

remains static while at least one channel is in LOAD mode. Program execution continues when all channels are

out of LOAD program mode.

RUN MODE

In RUN mode the LED controller executes instructions stored in program memory. Execution is controlled by the

R, G, and B program counters (R_PC, G_PC, B_PC) and the ENABLE register. For details refer to RUN MODE

OPTIONS section. Program start position can be determined by writing to the PC registers. If program counter

runs to end (15) the next command will be executed from program location 0. If internal PWM clock source is

selected in RUN mode, the LED controller must be disabled (MODE = 00b) before disabling the chip (with

CHIP_EN bit or EN pin) to ensure that the sequence starts from the correct program counter (PC) value when

restarting the sequence. PC registers are synchronized to a 32-kHz clock.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

17

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

DIRECT MODE

In DIRECT mode the LED channels can be controlled independently through the I2C interface. For each channel

there is a PWM control register (R_PWM, G_PWM, B_PWM) which contains the PWM duty cycle. If the charge

pump is set to automatic 1x / 1.5x mode selection, PWM values need to be written 0 before disabling the drivers

(MODE = 00b) to ensure proper automatic gain change operation.

MODE TRANSITIONS

A transition between operational modes aborts the instruction being executed (if any), resets the PC and sets the

PWM duty cycle to 0. The channel current setting is not affected.

10b

RUN

10b

10b

10b

00b

01b

11b

DISABLED

11b

01b

00b

00b

00b

DIRECT

LOAD

11b

01b

01b

11b

NORMAL MODE

Bit settings refer to the R/G/B_MODE[1:0] bits of the OP_MODE register.

Figure 9. Operational Modes of LED Controller in NORMAL Mode of Operation

RUN MODE SETTINGS

Run mode is set independently for each channel in the ENABLE register. In the following PC denotes either

R_PC, G_PC, or B_PC program counter. EXEC denotes either R_EXEC, G_EXEC, or B_EXEC bits of the

ENABLE register.

HOLD

Wait until current command is finished then stop while EXEC[1:0] = 00b (Hold). PC can be read or written only in

this mode.

STEP

Execute instruction defined by PC, increment PC and change EXEC[1:0] to 00b (Hold).

18

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

CONTINUE

Start program execution at PC value, increment PC and continue.

EXECUTE

Execute instruction defined by PC, do not update PC, change EXEC[1:0] to 00b (Hold).

MODE TRANSITIONS

A transition between run modes does not abort the instruction being executed. PC is updated before mode

transition. Note that PC is also incremented when transitioning out of EXECUTE mode.

10b

CONTINUE

10b

10b

10b

00b

11b

01b

HOLD

11b

01b

11b

or

00b

EXECUTE

00b

01b

or

00b

STEP

01b

11b

RUN MODE

Bit settings refer to the R/G/B_EXEC[1:0] bits of the ENABLE register.

Figure 10. Run Mode State Diagram

INSTRUCTION DESCRIPTION

The three channels are independent, except for the trigger connections between the channels. The following

table describes the binary format used. In this implementation, there are 16 program steps available per channel.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

19

�TPS68401, TPS68402

0

Int. 32kHz clock

1

Running Counter Value

Increment

Counter

PWM Output

Step Time

Counter

Current value of trigger point

Prescale

Div 16 or

512

Inc / Dec

Ext. clock (CLK32K)

Step time set

G1

Clock for step time counter

Prescale Select

www.ti.com

PWM_HF

Clock Source Select

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

Comparator

Free

Running

Counter

x2

G1

0

HF PWM clock

1

Figure 11. Simplified Block Diagram of PWM

RAMP / WAIT

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

0

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

prescale

0 = 16

1 = 512

sign

0= INC

1= DEC

step time

1 to 63

number of steps

0 to 127

The ramp command generates a PWM ramp starting from the current value. At each ramp step the PWM value

is incremented or decremented by one. Time for one step is defined by prescale and step time bits. The number

of increments executed by the instruction is defined by number of steps which has a maximum value of 127 or

half of full scale. If, during a ramp command, PWM reaches minimum / maximum (0 / 255), the ramp command

will continue for the remaining number of steps without changing the PWM value (PWM value saturates). This

enables the ramp command to be used as combined ramp and wait command in single instruction.

Ramp command can be used as a single step time wait instruction when increment is zero.

SET PWM

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

0

1

0

0

0

0

0

0

x

x

x

x

x

x

x

x

PWM value

Set PWM output value from 0 to 255 in a single instruction.

20

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

BRANCH

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

1

0

1

x

x

x

x

x

x

x

x

x

x

x

x

x

loop count

0 to 63 (0 = loop forever)

not used

step number

Loop instruction. Code between (step number) and BRANCH command will be executed (loop count + 1) times.

Set (loop count) = 0 for infinite looping. Nested looping is supported. The number of nested loops is not limited.

GO TO START

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Command resets program counter register and continues executing program from the 00H location.

END

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

1

1

0

INT

RST

x

x

x

x

x

x

x

x

x

x

x

interupt

reset

0 = Keep the current PWM value

1 = Set PWM value to 0

0 = Do not issue interrupt

1 = Issue interrupt and set corresponding status bit high. Interrupt is cleared by reading interrupt status register.

Stops program execution. Set (interrupt) = 1 to issue an interrupt on the INT pin. If INT is used it must be cleared

before pulling the EN pin low or writing CHIP_EN low.

TRIGGER

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

1

1

1

EXT

x

x

B

G

R

EXT

x

x

B

G

R

x

Wait for trigger

R=RED; G=GREEN; B=BLUE; EXT=EXTERNAL

1 = Wait for trigger from specified channel.

Own channel position is ignored.

0 = Continue without wait

Issue trigger

R=RED; G=GREEN; B=BLUE; EXT=EXTERNAL

1 = Issue trigger for specified channel.

Own channel position is ignored.

0 = Continue without issuing trigger

Used to synchronize channels and / or multiple units. The wait for trigger command is executed until all defined

trigger have been received. An external trigger is ignored by the issuing channel / device. External trigger input

signal must be at least two 32-kHz clock cycles long to be recognized. Trigger output signal is three 32-kHz clock

cycles long. External trigger signal is active low, i.e. when trigger is send / received the pin is pulled to GND.

Sent external trigger is masked, i.e. the device which has sent the trigger will not recognize it. If send and wait

external trigger are used on the same command, the send external trigger is executed first, then the wait external

trigger. Channel (R, G, or B) waiting for its own trigger is not allowed.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

21

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

Table 5. ADDRESS REGISTER MAP

22

REGISTER

ADDRESS

(HEX)

NAME

DEFAULT

VALUE

0

0

ENABLE

0000 0000

Chip enable and execution control

1

1

OP_MODE

0000 0000

RGB operating mode control

2

2

R_PWM

0000 0000

Red channel PWM value

3

3

G_PWM

0000 0000

Green channel PWM value

4

4

B_PWM

0000 0000

Blue channel PWM value

5

5

R_CURRENT

1010 1111

Red channel current limit value

6

6

G_CURRENT

1010 1111

Green channel current limit value

7

7

B_CURRENT

1010 1111

Blue channel current limit value

8

8

CONFIG

0000 0000

Charge pump configuration

9

9

R_PC

0000 0000

Red channel program counter value

10

0A

G_PC

0000 0000

Green channel program counter value

DESCRIPTION

11

0B

B_PC

0000 0000

Blue channel program counter value

12

0C

STATUS

0000 0000

Clock and interrupt status

13

0D

RESET

0000 0000

Device reset

14

0E

GPO

1000 0000

GPO configuration and value

15

N/A

N/A

N/A

16

10

PROG_MEM_R1_H

0000 0000

Red channel instruction 1 MSB

17

11

PROG_MEM_R1_L

0000 0000

Red channel instruction 1 LSB

...

...

...

...

46

2E

PROG_MEM_R16_H

0000 0000

Red channel instruction 16 MSB

47

2F

PROG_MEM_R16_L

0000 0000

Red channel instruction 16 LSB

48

30

PROG_MEM_G1_H

0000 0000

Green channel instruction 1 MSB

49

31

PROG_MEM_G1_L

0000 0000

Green channel instruction 1 LSB

...

...

...

...

78

4E

PROG_MEM_G16_H

0000 0000

Green channel instruction 16 MSB

79

4F

PROG_MEM_G16_L

0000 0000

Green channel instruction 16 LSB

80

50

PROG_MEM_B1_H

0000 0000

Blue channel instruction 1 MSB

81

51

PROG_MEM_B1_L

0000 0000

Blue channel instruction 1 LSB

...

...

...

...

110

6E

PROG_MEM_B16_H

0000 0000

Blue channel instruction 16 MSB

111

6F

PROG_MEM_B16_L

0000 0000

Blue channel instruction 16 LSB

Submit Documentation Feedback

Register not implemented

...

...

...

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

ENABLE REGISTER (ENABLE)

Address – 0x00h

DATA BIT

FIELD NAME

D7

D6

D5

LOG_EN CHIP_EN

D4

D3

R_EXEC[1:0]

D2

D1

G_EXEC[1:0]

D0

B_EXEC[1:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

D1

D0

FIELD NAME

BIT DEFINITION

LOG_EN

Enable logarithmic current adjustment mode

CHIP_EN

Chip enable: Forcing EN pin low resets CHIP_EN to zero. See state diagram for details.

Program execution control for red channel

00b – Hold: Finish current instruction, then stop until R_EXEC[1:0] changes.

R_EXEC[1:0]

01b – Step: Finish current instruction, increment R_PC and set EXEC to hold

10b – Continue: Execute command indicated by PC, then increment R_PC

11b – Execute: Execute command indicated by R_PC, then set R_EXEC[1:0] to 00b (Hold)

Program execution control for green channel

00b – Hold: Finish current instruction, then stop until G_EXEC[1:0] changes

G_EXEC[1:0]

01b – Step: Finish current instruction, increment R_PC and set EXEC to hold

10b – Continue: Execute command indicated by PC, then increment G_PC

11b – Execute: Execute command indicated by G_PC, then set G_EXEC[1:0] to 00b (Hold)

Program execution control for blue channel

00b – Hold: Finish current instruction, then stop until B_EXEC[1:0] changes

B_EXEC[1:0]

01b – Step: Finish current instruction, increment R_PC and set EXEC to hold

10b – Continue: Execute command indicated by PC, then increment B_PC

11b – Execute: Execute command indicated by B_PC, then set B_EXEC[1:0] to 00b (Hold)

OPERATION MODE REGISTER (OP_MODE)

Address – 0x01h

DATA BIT

D7

D6

FIELD NAME

N/A

N/A

D5

D4

D3

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

R_MODE[1:0]

FIELD NAME

D2

G_MODE[1:0]

B_MODE[1:0]

BIT DEFINITION

Red channel operating mode

00b – Disable

R_MODE[1:0]

01b – Load: Load program to instruction registers and reset R_PC

10b – Run: Execute commands according to R_EXEC[1:0] setting in ENABLE register

11b – Direct: Direct control (through R_PWM register)

Green channel operating mode

00b – Disable

G_MODE[1:0]

01b – Load: Load program to instruction registers and reset G_PC

10b – Run: Execute commands according to G_EXEC[1:0] setting in ENABLE register

11b – Direct: Direct control (through G_PWM register)

Blue channel operating mode

00b – Disable

B_MODE[1:0]

01b – Load: Load program to instruction registers and reset B_PC

10b – Run: Execute commands according to B_EXEC[1:0] setting in ENABLE register

11b – Direct: Direct control (through B_PWM register)

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

23

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

RED CHANNEL PWM CONTROL REGISTER (R_PWM)

Address – 0x02h

DATA BIT

D7

D6

D5

D4

FIELD NAME

D3

D2

D1

D0

R_PWM[7:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

D2

D1

D0

FIELD NAME

R_PWM[7:0]

BIT DEFINITION

Red channel PWM value used when R_MODE is Direct

GREEN CHANNEL PWM CONTROL REGISTER (G_PWM)

Address – 0x03h

DATA BIT

D7

D6

D5

D4

FIELD NAME

D3

G_PWM[7:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

D2

D1

D0

FIELD NAME

G_PWM[7:0]

BIT DEFINITION

Green channel PWM value used when G_MODE is Direct

BLUE CHANNEL PWM CONTROL REGISTER (B_PWM)

Address – 0x04h

DATA BIT

D7

D6

D5

D4

FIELD NAME

D3

B_PWM[7:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

D2

D1

D0

FIELD NAME

B_PWM[7:0]

BIT DEFINITION

Blue channel PWM value used when B_MODE is Direct

RED CHANNEL CURRENT CONTROL REGISTER (R_CURRENT)

Address – 0x05h

DATA BIT

D7

D6

D5

D4

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

1

0

1

0

1

1

1

1

FIELD NAME

D3

R_CURRENT[7:0]

FIELD NAME

BIT DEFINITION

Red channel current setting

0000 0000b - 0.0 mA

0000 0001b - 0.1 mA

0000 0002b - 0.2 mA

R_CURRENT[7:0]

...

1010 1111b - 17.5 mA (default)

...

1111 1101b - 25.3 mA

1111 1110b - 25.4 mA

1111 1111b - 25.5 mA

24

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

GREEN CHANNEL CURRENT CONTROL REGISTER (G_CURRENT)

Address – 0x06h

DATA BIT

D7

D6

D5

D4

D3

FIELD NAME

D2

D1

D0

G_CURRENT[7:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

1

0

1

0

1

1

1

1

D2

D1

D0

FIELD NAME

BIT DEFINITION

Green channel current setting

0000 0000b - 0.0 mA

0000 0001b - 0.1 mA

0000 0002b - 0.2 mA

G_CURRENT[7:0]

...

1010 1111b - 17.5 mA (default)

...

1111 1101b - 25.3 mA

1111 1110b - 25.4 mA

1111 1111b - 25.5 mA

BLUE CHANNEL CURRENT CONTROL REGISTER (B_CURRENT)

Address – 0x07h

DATA BIT

D7

D6

D5

D4

D3

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

1

0

1

0

1

1

1

1

FIELD NAME

B_CURRENT[7:0]

FIELD NAME

BIT DEFINITION

Blue channel current setting

0000 0000b - 0.0 mA

0000 0001b - 0.1 mA

0000 0002b - 0.2 mA

B_CURRENT[7:0]

...

1010 1111b - 17.5 mA (default)

...

1111 1101b - 25.3 mA

1111 1110b - 25.4 mA

1111 1111b - 25.5 mA

CONFIGURATION CONTROL REGISTER (CONFIG)

Address – 0x08h

DATA BIT

D7 (1)

D6

D5

FIELD NAME

N/A

PWM_HF

PWRSAVE_EN

READ/WRITE

N/A

R/W

R/W

R/W

RESET VALUE

0

0

0

0

(1)

D4

D3

D2

D1

D0

R_TO_BATT

CLK_DET_EN

INT_CLK_EN

R/W

R/W

R/W

R/W

0

0

0

0

CP_MODE[1:0]

Bit D7 must be set to 0 at all times. Writing 1 may result in unexpected behavior.

FIELD NAME

BIT DEFINITION

Source clock for PWM blocks

PWM_HF

0b - 256-Hz PWM frequency

1b - 558-Hz PWM frequency

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

25

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

FIELD NAME

PWRSAVE_EN

BIT DEFINITION

0b - Power save mode disabled

1b – Power save mode enabled

Charge pump operating mode

00b – OFF

CP_MODE[1:0]

01b – Forced 1x mode

10b – Forced 1.5x mode

11b – Automatic mode selection

Red channel source supply

R_TO_BAT

0b – Red channel connected to charge pump output (VOUT)

1b – Red channel connected to battery supply (VDD)

PWM clock source

00b - Use external clock source (CLK_32)

[CLK_DET_EN

INT_CLK_EN]

01b - Use internal clock source, clock detection disabled

10b - Automatically select clock source, clock detection enabled

11b - Use internal clock source, clock detection disabled

RED CHANNEL PROGRAM COUNTER REGISTER (R_PC)

Address – 0x09h

DATA BIT

D7

D6

D5

D4

FIELD NAME

N/A

N/A

N/A

N/A

READ/WRITE

N/A

N/A

N/A

N/A

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

(1)

D3

D2

D1

D0

R_PC[3:0] (1)

R_PC register can only be read or written to when R channel is in HOLD mode (R_EXEC[1:0] = 11b). In STANDBY mode R_PC can be

written to but not read. Value is effective after startup. Any change of the R_MODE[1:0] bits reset the R_PC value. For read access

device must be in NORMAL mode.

FIELD NAME

R_PC[3:0]

BIT DEFINITION

Red channel program counter

GREEN CHANNEL PROGRAM COUNTER REGISTER (G_PC)

Address – 0x0Ah

DATA BIT

D7

D6

D5

D4

D3

D2

D1

FIELD NAME

N/A

N/A

N/A

N/A

READ/WRITE

N/A

N/A

N/A

N/A

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

(1)

G_PC[3:0]

D0

(1)

G_PC register can only be read or written to when G channel is in HOLD mode (G_EXEC[1:0] = 11b). In STANDBY mode G_PC can be

written to but not read. Value is effective after startup. Any change of the G_MODE[1:0] bits reset the G_PC value. For read access

device must be in NORMAL mode.

FIELD NAME

G_PC[3:0]

BIT DEFINITION

Green channel program counter

BLUE CHANNEL PROGRAM COUNTER REGISTER (B_PC)

Address – 0x0Bh

DATA BIT

D7

D6

D5

D4

FIELD NAME

N/A

N/A

N/A

N/A

READ/WRITE

N/A

N/A

N/A

N/A

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

(1)

26

D3

D2

D1

D0

B_PC[3:0] (1)

B_PC register can only be read or written to when B channel is in HOLD mode (B_EXEC[1:0] = 11b). In STANDBY mode B_PC can be

written to but not read. Value is effective after startup. Any change of the B_MODE[1:0] bits reset the B_PC value. For read access

device must be in NORMAL mode.

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

FIELD NAME

B_PC[3:0]

BIT DEFINITION

Blue channel program counter

STATUS AND INTERUPT REGISTER (STATUS)

Address – 0x0Ch

DATA BIT

D7

D6

D5

D4

D3

D2

D1

D0

EXT_CLK_US

ED

R_INT

G_INT

B_INT

FIELD NAME

N/A

N/A

CP_STATUS[1:0]

READ/WRITE

N/A

N/A

R

R

R

R

R

R

RESET VALUE

0

0

0

0

0

0

0

0

FIELD NAME

BIT DEFINITION

Charge pump operating mode

00b – OFF

CP_STATUS[1:0]

01b – Forced 1x mode

10b – Forced 1.5x mode

11b – Power save

External clock selected

EXT_CLK _USED

0b - Internal 32-Hz clock selected

1b - External 32-kHz clock selected

R_INT

(1)

(1)

Red channel interrupt, set upon channel interrupt generation (END instruction), cleared on read

G_INT (1)

Green channel interrupt, set upon channel interrupt generation (END instruction), cleared on read

B_INT (1)

Blue channel interrupt, set upon channel interrupt generation (END instruction), cleared on read

Interrupt bits are cleared and INT output pin will go high-impedance (open drain output) after register read access.

RESET CONTROL REGISTER (RESET)

Address – 0x0Dh

DATA BIT

D7

D6

D5

D4

FIELD NAME

D3

D2

D1

D0

RESET[7:0]

READ/WRITE

W

W

W

W

W

W

W

W

RESET VALUE

0

0

0

0

0

0

0

0

FIELD NAME

BIT DEFINITION

RESET[7:0]

Forced reset state (reset all registers to default values). No I2C acknowledge will be generated when 0xFFh is written to

the RESET register. I2C acknowledge will be generated for any other pattern written to the register.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

27

�TPS68401, TPS68402

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

www.ti.com

GPO CONTROL REGISTER (GPO)

Address – 0x0Eh

DATA BIT

D7

D6

D5

D4

D3

D2

D1

D0

FIELD NAME

ID

N/A

N/A

N/A

N/A

INT_AS_GPO

GPO

INT

READ/WRITE

R

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

1

0

0

0

0

0

0

0

FIELD NAME

BIT DEFINITION

INT pin GPO function enable

INT_AS_GPO

0b – INT pin functions as interrupt pin

1b – INT pin functions as GPO

GPO value

GPO

0b – Output low

1b – Output high

INT value (when INT_AS_GPO is set to 1)

INT

0b – Output low

1b – Output high

ID

ID bit

PROGRAM MEMORY REGISTERS (PROGRAM MEMORY R, G, B)

Address – 0x10h to 0x2F in pairs (Red)

– 0x30h to 0x4F in pairs (Green)

– 0x50h to 0x6F in pairs (Blue)

NOTE

Each program command is composed of two consecutive bytes in the register space. The

most significant byte of the command is stored in the lower order address followed by the

least significant byte.

DATA BIT

D7

D6

D5

FIELD NAME

D4

D3

D2

D1

D0

CMD_Rn_H[7:0], CMD_Rn_L[7:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

FIELD NAME

BIT DEFINITION

CMD_Rn_H[7:0]

Red channel program command n, most significant byte; Address is 0x10h + 2n and 0 ≤ n ≤ 15. See program

commands section for details.

CMD_Rn_L[7:0]

Red channel program command n, least significant byte; Address is 0x11h + 2n and 0 ≤ N ≤ 15. See program

commands section for details.

DATA BIT

D7

D6

D5

READ/WRITE

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

FIELD NAME

D4

D3

D2

D1

D0

R/W

R/W

R/W

R/W

0

0

0

0

CMD_Gn_H[7:0], CMD_Gn_L[7:0]

FIELD NAME

BIT DEFINITION

CMD_Gn_H[7:0]

Green channel program command n, most significant byte; Address is 0x30h + 2n and 0 ≤ n ≤ 15. See program

commands section for details.

CMD_Gn_L[7:0]

Green channel program command n, least significant byte; Address is 0x31h + 2n and 0 ≤ n ≤ 15. See program

commands section for details.

28

Submit Documentation Feedback

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

�TPS68401, TPS68402

www.ti.com

DATA BIT

SLVSA68A – MARCH 2010 – REVISED JANUARY 2011

D7

D6

D5

FIELD NAME

D4

D3

D2

D1

D0

CMD_Bn_H[7:0], CMD_Bn_L[7:0]

READ/WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RESET VALUE

0

0

0

0

0

0

0

0

FIELD NAME

BIT DEFINITION

CMD_Bn_H[7:0]

Blue channel program command n, most significant byte; Address is 0x50h + 2n and 0 ≤ n ≤ 15. See program

commands section for details.

CMD_Bn_L[7:0]

Blue channel program command n, least significant byte; Address is 0x51h + 2n and 0 ≤ n ≤ 15. See program

commands section for details.

Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS68401 TPS68402

Submit Documentation Feedback

29

�PACKAGE OPTION ADDENDUM

www.ti.com

17-Jan-2014

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

Lead/Ball Finish

MSL Peak Temp

(2)

(6)

(3)

Op Temp (°C)

Device Marking

(4/5)

TPS68401C4YFFR

ACTIVE

DSBGA

YFF

20

Green (RoHS

& no Sb/Br)

Call TI

Level-1-260C-UNLIM

-30 to 85

TPS68402A0RHFR

ACTIVE

VQFN

RHF

24

Green (RoHS

& no Sb/Br)

CU NIPDAU

Level-2-260C-1 YEAR

-30 to 85

68402

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

Addendum-Page 1

Samples

�PACKAGE OPTION ADDENDUM

www.ti.com

17-Jan-2014

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 2

���IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to