Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

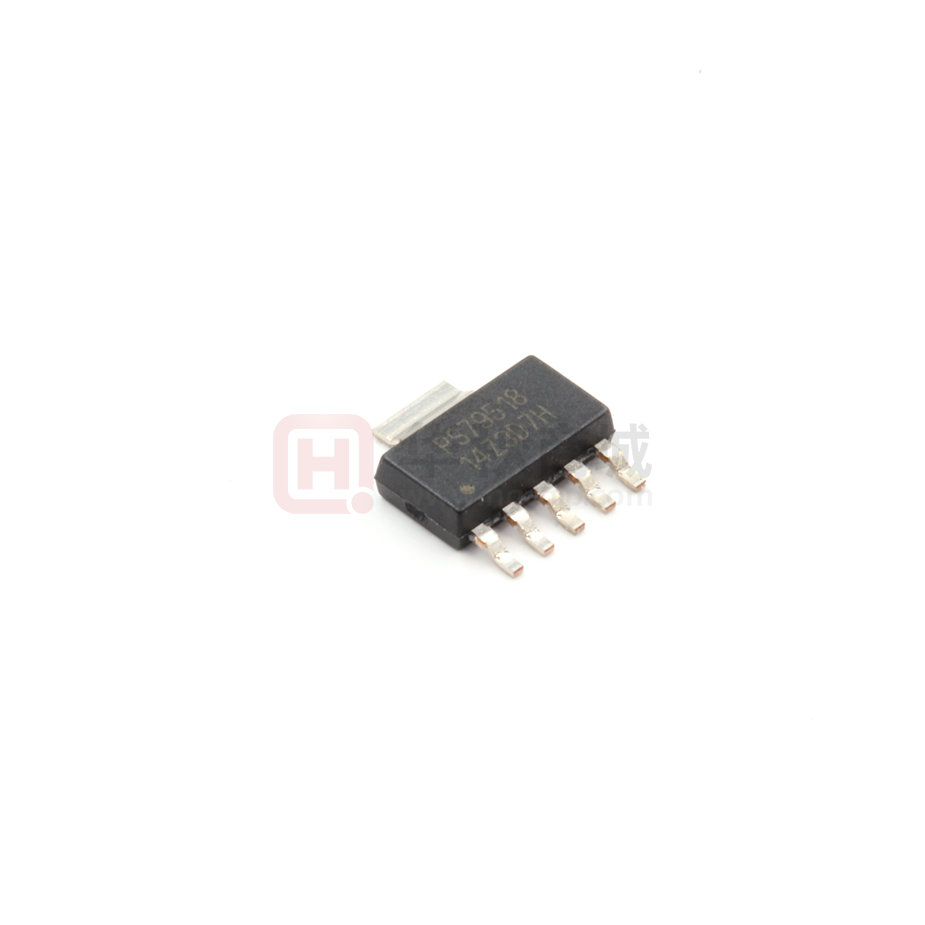

TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

TPS795 Ultralow-Noise, High-PSRR, Fast, RF, 500-mA, Low-Dropout Linear Regulators

1 Features

3 Description

•

•

The TPS795 family of low-dropout (LDO), low-power

linear voltage regulators features high power-supply

rejection ratio (PSRR), ultralow noise, fast start-up,

and excellent line and load transient responses in

small outline, 6-pin SOT-223 and 3-mm × 3-mm

VSON packages. Each device in the family is stable

with a small 1-µF ceramic capacitor on the output.

The family uses an advanced, proprietary BiCMOS

fabrication process to yield extremely low dropout

voltages (for example, 110 mV at 500 mA). Each

device achieves fast start-up times (approximately

50 µs with a 0.001-µF bypass capacitor) while

consuming very low quiescent current (265 µA,

typical). Moreover, when the device is placed in

standby mode, the supply current is reduced to less

than 1 µA. The TPS79530 device exhibits

approximately 33 µVRMS of output voltage noise at 3V output with a 0.1-µF bypass capacitor. Applications

with analog components that are noise-sensitive,

such as portable RF electronics, benefit from the

high-PSRR and low-noise features, as well as from

the fast response time.

1

•

•

•

•

•

•

•

500-mA low-dropout regulator with enable

Available in fixed and adjustable (1.2-V to 5.5-V)

versions

High PSRR (50 dB at 10 kHz)

Ultralow noise (33 µVRMS, TPS79530)

Fast start-up time (50 µs)

Stable with a 1-µF ceramic capacitor

Excellent load and line transient response

Low dropout voltage (110 mV at full load,

TPS79530)

6-pin SOT-223 and 3-mm × 3-mm VSON

packages

2 Applications

•

•

•

•

•

RF: VCOs, receivers, ADCs

Audio

Bluetooth®, wireless LAN

Cellular and cordless telephones

Handheld organizers, PDAs

Device Information(1)

PART NUMBER

TPS795

PACKAGE

BODY SIZE (NOM)

SOT-223 (6)

6.50 mm × 3.50 mm

VSON (8)

3.00 mm × 3.00 mm

(1) For all available packages, see the package option addendum

at the end of the data sheet.

TPS79530 Ripple Rejection vs Frequency

TPS79530 vs Frequency

0.5

VIN = 4 V

COUT = 10mF

CNR = 0.01mF

Ripple Rejection − dB

70

Output Spectral Noise Density − mV/ÖHz

80

IOUT = 1 mA

60

50

40

IOUT = 500 mA

30

20

10

0

1

10

100

1 k 10 k 100 k 1 M

Frequency (Hz)

10 M

VIN = 5.5 V

COUT = 2.2mF

CNR = 0.1mF

0.4

0.3

IOUT = 1 mA

0.2

IOUT = 0.5 A

0.1

0

100

1k

10 k

Frequency (Hz)

100 k

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

3

6.1

6.2

6.3

6.4

6.5

6.6

3

3

4

4

5

6

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 10

7.1

7.2

7.3

7.4

Overview .................................................................

Functional Block Diagrams .....................................

Feature Description.................................................

Device Functional Modes........................................

10

10

11

12

8

Application and Implementation ........................ 13

8.1 Application Information............................................ 13

8.2 Typical Application .................................................. 13

8.3 What to Do and What Not to Do ............................. 15

9 Power Supply Recommendations...................... 16

10 Layout................................................................... 16

10.1 Layout Guidelines ................................................. 16

10.2 Layout Examples................................................... 19

11 Device and Documentation Support ................. 21

11.1

11.2

11.3

11.4

11.5

11.6

11.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

21

21

21

21

22

22

22

12 Mechanical, Packaging, and Orderable

Information ........................................................... 22

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision I (May 2015) to Revision J

Page

•

Changed DRB package name throughout data sheet from SON to VSON ........................................................................... 1

•

Changed Pin Configuration package names; switched designators to match correct package names (typo) ..................... 3

•

Added note (1) to Recommended Operating Conditions; moved from Electrical Characteristics.......................................... 4

•

Changed thermal values in Thermal Information table........................................................................................................... 4

•

Deleted Input Voltage from Electrical Characteristics; already shown in Recommended Operating Conditions................... 5

•

Deleted Junction Temperature from Electrical Characteristics; already shown in Recommended Operating Conditions..... 5

Changes from Revision H (August 2010) to Revision I

Page

•

Added ESD Ratings table, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section ................................................................................................. 1

•

Changed front-page graphic .................................................................................................................................................. 1

•

Changed Pin Configuration and Functions section; updated table format and added pinout drawings................................. 3

•

Changed "free-air" to "junction" temperature in condition statement for Absolute Maximum Ratings .................................. 3

•

Added Added Operating junction temperature specification to Electrical Characteristics ..................................................... 5

•

Deleted Start-up time symbol ................................................................................................................................................. 5

•

Corrected min value for IEN(HI) parameter ............................................................................................................................... 5

•

Added Thermal shutdown temperature specification to Electrical Characteristics ................................................................ 5

•

Added condition statement to Typical Characteristics section .............................................................................................. 6

•

Changed title for Thermal Protection section ...................................................................................................................... 16

Changes from Revision G (July, 2006) to Revision H

Page

•

Replaced the Dissipation Ratings table with the Thermal Information table .......................................................................... 4

•

Updated the Thermal Protection section .............................................................................................................................. 16

2

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

5 Pin Configuration and Functions

DRB Package

8-Pin VSON

Top View

DCQ Package

6-Pin SOT-223

Top View

1

8

EN

IN 2

7

N/C

IN

OUT 3

6

GND

OUT 4

5

NR/FB

6

1

3

2

EN

NR/FB

GND

IN

5

4

OUT

Pin Functions

PIN

NAME

VSON

IN

SOT-223

I/O

DESCRIPTION

1, 2

2

I

GND

6

3, 6

—

Unregulated input to the device

EN

8

1

I

NR

5

5

—

FB

5

5

I

Feedback input voltage for the adjustable device.

(Not available on fixed voltage versions.)

OUT

3, 4

4

O

Regulator output

N/C

7

–

—

No internal connection

Regulator ground

Driving the enable pin (EN) high turns on the regulator. Driving this pin low puts the

regulator into shutdown mode. EN can be connected to IN if not used.

Noise-reduction pin for fixed versions only. Connecting an external capacitor to this pin

bypasses noise generated by the internal bandgap, which improves power-supply

rejection and reduces output noise. (Not available on adjustable versions.)

6 Specifications

6.1 Absolute Maximum Ratings

over operating junction temperature range (unless otherwise noted) (1)

MIN

Voltage

MAX

IN

–0.3

6

EN

–0.3

VIN + 0.3

OUT

Peak output

Power dissipation

Continuous total

(1)

V

6

Current

Temperature

UNIT

Internally limited

A

See Thermal Information

Junction, TJ

–40

150

°C

Storage, Tstg

–65

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic

discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins (1)

±2000

Charged device model (CDM), per JEDEC specification JESD22-C101, all pins (2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

3

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

6.3 Recommended Operating Conditions

over operating junction temperature range (unless otherwise noted)

MIN

(1)

VIN

Input voltage

IOUT

Output current

TJ

Operating junction temperature

(1)

NOM

MAX

UNIT

2.7

5.5

V

0

500

mA

–40

125

°C

Minimum VIN is 2.7 V or VOUT + VDO, whichever is greater.

6.4 Thermal Information

over operating free-air temperature range (unless otherwise noted)

TPS795 (3)

THERMAL METRIC

(1) (2)

DRB (VSON)

DCQ (SOT-223)

UNIT

6 PINS

8 PINS

RθJA

Junction-to-ambient thermal resistance

46.8

74.0

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

45.1

44.5

°C/W

RθJB

Junction-to-board thermal resistance

18.4

8.6

°C/W

ψJT

Junction-to-top characterization parameter

0.7

3.2

°C/W

ψJB

Junction-to-board characterization parameter

18.4

8.5

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

5.3

N/A

°C/W

(1)

(2)

(3)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

For thermal estimates of this device based on PCB copper area, see the TI PCB Thermal Calculator.

Thermal data for the DRB and DCQ packages are derived by thermal simulations based on JEDEC-standard methodology as specified

in the JESD51 series. The following assumptions are used in the simulations:

(a) i. DRB: The exposed pad is connected to the PCB ground layer through a 2-mm x 2-mm thermal via array.

. ii. DCQ: The exposed pad is connected to the PCB ground layer through a 3-mm x 2-mm thermal via array.

(b) i. DRB: The top and bottom copper layers are assumed to have a 20% thermal conductivity of copper representing a 20% copper

coverage.

. ii. DCQ: Each of top and bottom copper layers has a dedicated pattern for 20% copper coverage.

(c) These data were generated with only a single device at the center of a JEDEC high-K (2s2p) board with 3in × 3in copper area. To

understand the effects of the copper area on thermal performance, see Thermal Considerations and Estimating Junction Temperature

of this data sheet.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

6.5 Electrical Characteristics

over recommended operating temperature range (TJ = –40°C to 125°C), VEN = VIN, VIN = VOUT(nom) + 1 V (1), IOUT = 1 mA, COUT

= 10 µF, and CNR = 0.01 µF (unless otherwise noted); typical values are at 25°C

PARAMETER

VFB

MIN

TYP

MAX

UNIT

Internal reference (TPS79501)

TEST CONDITIONS

1.200

1.225

1.25

V

Output voltage range

1.225

5.5 – VDO

V

1.02VOUT(nom)

V

TPS79501

TPS79501

(2)

Accuracy

Fixed VOUT < 5 V

(1)

ΔVO(ΔVI)

Line regulation

ΔVO(ΔIO)

Load regulation

0 µA ≤ IOUT ≤ 500 mA,

VOUT(nom) + 1 V ≤ VIN ≤ 5.5 V (1)

0.98VOUT(nom)

0 µA ≤ IOUT ≤ 500 mA,

VOUT(nom) + 1 V ≤ VIN ≤ 5.5 V (1)

–2%

VOUT + 1 V ≤ VIN ≤ 5.5 V

2%

0.05

0 µA ≤ IOUT ≤ 500 mA

(3)

VOUT(nom)

0.12

3

%/V

mV

TPS79530

IOUT = 500 mA

110

170

mV

TPS79533

IOUT = 500 mA

105

160

mV

2.8

4.2

A

VDO

Dropout voltage

(VIN = VOUT(nom) – 0.1 V)

ICL

Output current limit

VOUT = 0 V

IGND

Ground pin current

0 µA ≤ IOUT ≤ 500 mA

265

385

µA

ISHDN

Shutdown current (4)

VEN = 0 V, 2.7 V ≤ VIN ≤ 5.5 V

0.07

1

µA

IFB

Feedback pin current

VFB = 1.225 V

1

µA

PSRR

Vn

Power-supply rejection ratio (TPS79530)

Output noise voltage (TPS79530)

Start-up time (TPS79530)

2.4

f = 100 Hz, IOUT = 10 mA

59

dB

f = 100 Hz, IOUT = 500 mA

58

dB

f = 10 kHz, IOUT = 500 mA

50

dB

f = 100 kHz, IOUT = 500 mA

BW = 100 Hz to

100 kHz,

IOUT = 500 mA

RL = 6 Ω, COUT = 1 µF

39

dB

CNR = 0.001 µF

46

µVRMS

CNR = 0.0047 µF

41

µVRMS

CNR = 0.01 µF

35

µVRMS

CNR = 0.1 µF

33

µVRMS

CNR = 0.001 µF

50

µs

CNR = 0.0047 µF

75

µs

CNR = 0.01 µF

110

VEN(HI)

Enable high (enabled)

2.7 V ≤ VIN ≤ 5.5 V

VEN(LO)

Enable low (shutdown)

2.7 V ≤ VIN ≤ 5.5 V

IEN(HI)

Enable pin current, enabled

VEN = 0 V

–1

UVLO

Undervoltage lockout

VCC rising

2.25

UVLO hysteresis

Tsd

(1)

(2)

(3)

(4)

Thermal shutdown temperature

1.7

µs

VIN

V

0.7

V

1

µA

2.65

V

100

mV

Shutdown, temperature increasing

165

°C

Reset, temperature decreasing

140

°C

Minimum VIN is 2.7 V or VOUT + VDO, whichever is greater.

Tolerance of external resistors not included in this specification.

Dropout is not measured for the TPS79501 and TPS79525 because minimum VIN = 2.7 V.

For adjustable version, this applies only after VIN is applied; then VEN transitions high to low.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

5

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

6.6 Typical Characteristics

at VEN = VIN, VIN = VOUT(nom) + 1 V, IOUT = 1 mA, COUT = 10 µF, CNR = 0.01 µF, CIN = 2.2 µF, and TJ = 25°C (unless otherwise

noted)

3.005

3.02

VIN = 4 V

COUT = 10 mF

3

3.01

IOUT = 1 mA

VOUT (V)

2.995

2.99

VOUT (V)

3

IOUT = 0.5 A

2.985

2.98

2.99

2.975

2.98

0

0.1

0.2

0.3

IOUT (mA)

0.4

2.97

0.5

−40 −25 −10 5

TJ (°C)

Figure 1. TPS79530 Output Voltage vs Output Current

Figure 2. TPS79530 Output Voltage vs Junction

Temperature

0.5

276

VIN = 4 V

COUT = 10 mF

Output Spectral Noise Density − mV/√Hz

274

272

IOUT = 1 mA

IGND (mA)

270

268

IOUT = 0.5 A

266

264

262

260

−40 −25 −10 5

20 35 50 65 80 95 110 125

VIN = 5.5 V

COUT = 2.2 mF

CNR = 0.1 mF

0.4

IOUT = 1 mA

0.3

0.2

IOUT = 0.5 A

0.1

0

100

TJ (°C)

1k

10 k

Frequency (Hz)

Figure 3. TPS79530 Ground Current vs Junction

Temperature

Figure 4. TPS79530 Output Spectral Noise Density vs

Frequency

0.5

0.4

IOUT = 1 mA

0.3

0.2

IOUT = 0.5 A

0.1

0

100

100 k

2.5

VIN = 5.5 V

COUT = 10 mF

CNR = 0.1 mF

Output Spectral Noise Density − mV/√Hz

Output Spectral Noise Density − mV/√Hz

0.6

1k

10 k

VIN = 5.5 V

IOUT = 500 mA

COUT= 10 mF

2

CNR = 0.001 mF

CNR = 0.0047 mF

1.5

CNR = 0.01 mF

1

CNR = 0.1 mF

0.5

0

100

100 k

Frequency (Hz)

1k

10 k

100 k

Frequency (Hz)

Figure 5. TPS79530 Output Spectral Noise Density vs

Frequency

6

20 35 50 65 80 95 110 125

Figure 6. TPS79530 Output Spectral Noise Density vs

Frequency

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

Typical Characteristics (continued)

50

175

IOUT = 500 mA

COUT= 10 mF

40

125

30

20

75

50

25

BW = 100 Hz to 100 kHz

0

0.001

0.01

0.0047

CNR (mF)

0

−40 −25 −10 5

0.1

20 35 50 65 80 95 110 125

TJ (°C)

Figure 8. TPS79530 Dropout Voltage vs Junction

Temperature

80

80

60

IOUT = 1 mA

50

40

IOUT = 500 mA

30

VIN = 4 V

COUT = 10 mF

CNR = 0.01 mF

70

Ripple Rejection − dB

VIN = 4 V

COUT = 10 mF

CNR = 0.1 mF

70

Ripple Rejection − dB

100

10

Figure 7. TPS79530 Root Mean Squared Output Noise vs

CNR

IOUT = 1 mA

60

50

40

IOUT = 500 mA

30

20

20

10

10

0

0

1

10

100

1 k 10 k 100 k 1 M

Frequency (Hz)

10 M

Figure 9. TPS79530 Ripple Rejection vs Frequency

1

10

100

1 k 10 k 100 k 1 M

Frequency (Hz)

10 M

Figure 10. TPS79530 Ripple Rejection vs Frequency

80

80

VIN = 4 V

COUT = 2.2 mF

CNR = 0.01 mF

IOUT = 1 mA

60

VIN = 4 V

COUT = 2.2 mF

CNR = 0.1 mF

70

Ripple Rejection − dB

70

Ripple Rejection − dB

VIN = 2.9 V

COUT = 10 mF

IOUT = 500 mA

150

VDO (mV)

RMS− Root Mean Squared Output Noise −mVRMS

at VEN = VIN, VIN = VOUT(nom) + 1 V, IOUT = 1 mA, COUT = 10 µF, CNR = 0.01 µF, CIN = 2.2 µF, and TJ = 25°C (unless otherwise

noted)

50

40

30

IOUT = 500 mA

50

40

30

IOUT = 500 mA

20

20

10

10

0

IOUT = 1 mA

60

0

1

10

100

1 k 10 k 100 k 1 M

Frequency (Hz)

10 M

Figure 11. TPS79530 Ripple Rejection vs Frequency

1

10

100

1 k 10 k 100 k 1 M 10 M

Frequency (Hz)

Figure 12. TPS79530 Ripple Rejection vs Frequency

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

7

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

Typical Characteristics (continued)

at VEN = VIN, VIN = VOUT(nom) + 1 V, IOUT = 1 mA, COUT = 10 µF, CNR = 0.01 µF, CIN = 2.2 µF, and TJ = 25°C (unless otherwise

noted)

20

3

2.50

VOUT (mV)

CNR = 0.001 mF

2.75

CNR = 0.0047 mF

2.25

CNR = 0.01 mF

2

Enable

VIN (V)

1.75

10

0

−10

1.50

−20

1.25

COUT = 10 mF, CNR = 0.01 mF,

IOUT = 0.5 A, dv/dt = 1 V/ms

1

4

VIN (V)

0.75

VIN = 4 V

COUT = 10 mF

IOUT = 0.5 A

0.50

0.25

0

3

2

0

100

200

300

400

0

500 600

50

Figure 13. TPS79530 Start-Up Time

150

200

Figure 14. TPS79518 Line Transient Response

60

VOUT (mV)

30

20

VOUT (mV)

100

t (ms)

t (ms)

10

40

20

0

0

−20

−10

−40

−20

IOUT (A)

5

VIN (V)

−60

COUT = 10 mF, CNR = 0.01 mF,

IOUT = 0.5 A, dv/dt = 1 V/ms

4

0

50

100

t (ms)

150

0

200

200

400

600

800

1000

t (ms)

Figure 15. TPS79530 Line Transient Response

Figure 16. TPS79530 Load Transient Response

4.5

180

VOUT = 2.5 V,

RL = 10 W

4

160

3.5

140

VIN

3

TJ = 125°C

120

TJ = 25°C

2.5

VDO (mV)

VOUT (V)

0

−0.5

3

2

1.5

100

80

60

VOUT

1

TJ = −40°C

0.5

40

0

20

−0.5

0

0

400

800

1200

1600

2000

0

Time (ms)

Figure 17. TPS79525 Power Up and Power Down

8

COUT = 10 mF, CNR = 0.01 mF,

VL = 3.8 V, dv/dt = 0.5 A/ms

0.5

100

200

300

IOUT (mA)

400

500

Figure 18. TPS79530 Dropout Voltage vs Output Current

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

Typical Characteristics (continued)

at VEN = VIN, VIN = VOUT(nom) + 1 V, IOUT = 1 mA, COUT = 10 µF, CNR = 0.01 µF, CIN = 2.2 µF, and TJ = 25°C (unless otherwise

noted)

100

200

COUT = 1 mF

COUT = 10 mF,

CNR = 0.01 mF,

IOUT = 50 mA

Region of

Instability

10

150

100

ESR (Ω)

VDO (mV)

TJ = 125°C

TJ = 25°C

50

1

0.01

0

2.5

3

3.5

4

VIN (V)

4.5

0

5

Figure 19. TPS79501 Dropout Voltage vs Input Voltage

100

200

300

IOUT (mA)

400

500

Figure 20. TPS79530 Typical Regions of Stability Equivalent

Series Resistance (ESR) vs Output Current

100

100

COUT = 2.2 mF

COUT = 10 mF

Region of

Instability

10

ESR (Ω)

10

ESR (Ω)

Region of Stability

0.1

TJ = −40°C

1

Region of Stability

0.1

Region of

Instability

1

Region of Stability

0.1

0.01

0.01

1

10

100

0

1000

100

200

300

400

500

IOUT (A)

IOUT (mA)

Figure 21. TPS79530 Typical Regions of Stability Equivalent

Series Resistance (ESR) vs Output Current

Figure 22. TPS79530 Typical Regions of Stability Equivalent

Series Resistance (ESR) vs Output Current

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

9

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

7 Detailed Description

7.1 Overview

The TPS795 family of LDO regulators combines the high performance required of many RF and precision analog

applications with low current consumption. High PSRR is provided by a high-gain, high-bandwidth error loop with

good supply rejection at very low headroom (VIN – VOUT). A noise-reduction pin is provided to bypass noise

generated by the band-gap reference and to improve PSRR, while a quick-start circuit quickly charges this

capacitor at start-up. All versions have thermal and overcurrent protection, and are fully specified from –40°C to

+125°C.

7.2 Functional Block Diagrams

IN

OUT

300 W

UVLO

Current

Sense

Overshoot

Detect

GND

ILIM

SHUTDOWN

R1

EN

FB

UVLO

Thermal

Shutdown

R2

Quickstart

Bandgap

Reference

1.225 V

VIN

External to

the Device

VREF

250 kW

Figure 23. Functional Block Diagram—Adjustable Version

IN

OUT

300 W

UVLO

Current

Sense

Overshoot

Detect

GND

ILIM

SHUTDOWN

R1

EN

UVLO

Thermal

Shutdown

R2

R2 = 40 kW

Quickstart

VIN

Bandgap

Reference

1.225 V

VREF

NR

250 kW

Figure 24. Functional Block Diagram—Fixed Versions

10

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

7.3 Feature Description

7.3.1 Shutdown

The enable pin (EN) is active high and is compatible with standard and low-voltage TTL-CMOS levels. When

shutdown capability is not required, EN can be connected to IN.

7.3.2 Start-Up

The TPS795 uses a start-up circuit to quickly charge the noise reduction capacitor, CNR, if present (see

Functional Block Diagrams). This circuit allows for the combination of very low output noise and fast start-up

times. The NR pin is high impedance so a low leakage CNR capacitor must be used; most ceramic capacitors are

appropriate for this configuration.

For the fastest start-up, apply VIN first, and then drive the enable pin (EN) high. If EN is tied to IN, start-up is

somewhat slower. To ensure that CNR is fully charged during start-up, use a 0.1-µF or smaller capacitor.

7.3.3 Undervoltage Lockout (UVLO)

The TPS795 uses an undervoltage lockout circuit to keep the output shut off until internal circuitry is operating

properly. The UVLO circuit has approximately 100 mV of hysteresis to help reject input voltage drops when the

regulator first turns on.

7.3.4 Regulator Protection

The TPS795 PMOS-pass transistor has a built-in back diode that conducts reverse current when the input

voltage drops below the output voltage (for example, during power down). Current is conducted from the output

to the input and is not internally limited. If extended reverse voltage operation is anticipated, external limiting

might be appropriate.

The TPS795 features internal current limiting and thermal protection. During normal operation, the TPS795 limits

output current to approximately 2.8 A. When current limiting engages, the output voltage scales back linearly until

the overcurrent condition ends. While current limiting is designed to prevent gross device failure, care should be

taken not to exceed the power dissipation ratings of the package. If the temperature of the device exceeds

approximately 165°C (Tsd), thermal-protection circuitry shuts it down. Once the device has cooled down to less

than approximately 140°C, regulator operation resumes.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

11

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

7.4 Device Functional Modes

Table 1 provides a quick comparison between the normal, dropout, and disabled modes of operation.

Table 1. Device Functional Mode Comparison

PARAMETER

OPERATING MODE

VIN

EN

IOUT

TJ

Normal

VIN > VOUT(nom) + VDO

VEN > VEN(HI)

IOUT < ICL

TJ < Tsd

Dropout

VIN < VOUT(nom) + VDO

VEN > VEN(HI)

IOUT < ICL

TJ < Tsd

Disabled

—

VEN < VEN(LO)

—

TJ > Tsd

7.4.1 Normal Operation

The device regulates to the nominal output voltage under the following conditions:

• The input voltage is greater than the nominal output voltage plus the dropout voltage (VOUT(nom) + VDO).

• The enable voltage has previously exceeded the enable rising threshold voltage and not yet decreased below

the enable falling threshold.

• The output current is less than the current limit (IOUT < ICL).

• The device junction temperature is less than the thermal shutdown temperature (TJ < Tsd).

7.4.2 Dropout Operation

If the input voltage is lower than the nominal output voltage plus the specified dropout voltage, but all other

conditions are met for normal operation, the device operates in dropout mode. In this mode, the output voltage

tracks the input voltage. During this mode, the transient performance of the device becomes significantly

degraded because the pass device is in the linear region and no longer controls the current through the LDO.

Line or load transients in dropout can result in large output-voltage deviations.

7.4.3 Disabled

The device is disabled under the following conditions:

• The enable voltage is less than the enable falling threshold voltage or has not yet exceeded the enable rising

threshold.

• The device junction temperature is greater than the thermal shutdown temperature (TJ > Tsd).

12

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The TPS795 family of LDO regulators has been optimized for use in noise-sensitive equipment. The device

features extremely low dropout voltages, high PSRR, ultralow output noise, low quiescent current (265 µA,

typically), and an enable input to reduce supply currents to less than 1 µA when the regulator is turned off.

8.2 Typical Application

A typical application circuit is shown in Figure 25.

VIN

IN

VOUT

OUT

TPS795xx

1mF

EN

GND

1mF

NR

0.01mF

Figure 25. Typical Application Circuit

8.2.1 Design Requirements

Table 2 lists the design requirements.

Table 2. Design Parameters

PARAMETER

DESIGN REQUIREMENT

Input voltage

3.3 V

Output voltage

2.5 V

Maximum output current

500 mA

8.2.2 Detailed Design Procedure

Select the desired device based on the output voltage.

Provide an input supply with adequate headroom to account for dropout and output current to account for the

GND terminal current, and power the load.

8.2.2.1 Input and Output Capacitor Requirements

Although not required, it is good analog design practice to place a 0.1-µF to 2.2-µF capacitor near the input of

the regulator to counteract reactive input sources. A higher-value input capacitor may be necessary if large, fastrise time load transients are anticipated and the device is located several inches from the power source.

Like most low dropout regulators, the TPS795 requires an output capacitor connected between OUT and GND to

stabilize the internal control loop. The minimum recommended capacitor is 1 µF. Any 1-µF or larger ceramic

capacitor is suitable.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

13

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

8.2.2.2 Output Noise

The internal voltage reference is a key source of noise in an LDO regulator. The TPS795 has an NR pin which is

connected to the voltage reference through a 250-kΩ internal resistor. The 250-kΩ internal resistor, in

conjunction with an external bypass capacitor connected to the NR pin, creates a low-pass filter to reduce the

voltage reference noise and, therefore, the noise at the regulator output. For the regulator to operate properly,

the current flow out of the NR pin must be at a minimum, because any leakage current creates an IR drop across

the internal resistor, thus creating an output error. Therefore, the bypass capacitor must have minimal leakage

current. The bypass capacitor should be no more than 0.1 µF to ensure that it is fully charged during the

quickstart time provided by the internal switch shown in Functional Block Diagrams.

For example, the TPS79530 exhibits 40 µVRMS of output voltage noise using a 0.1-µF ceramic bypass capacitor

and a 10-µF ceramic output capacitor. The output starts up slower as the bypass capacitance increases due to

the RC time constant at the bypass pin that is created by the internal 250-kΩ resistor and external capacitor.

8.2.2.3 Dropout Voltage

The TPS795 uses a PMOS pass transistor to achieve a low dropout voltage. When (VIN – VOUT) is less than the

dropout voltage (VDO), the PMOS pass device is in its linear region of operation and rDS(on) of the PMOS pass

element is the input-to-output resistance. Because the PMOS device behaves like a resistor in dropout, VDO

approximately scales with the output current.

As with any linear regulator, PSRR degrades as (VIN – VOUT) approaches dropout. This effect is illustrated in

Figure 9 through Figure 12.

8.2.2.4 Programming the TPS79501 Adjustable LDO Regulator

The output voltage of the TPS79501 adjustable regulator is programmed using an external resistor divider as

shown in Figure 26.

VIN

IN

1μF

OUT

TPS79501

EN

GND

OUTPUT VOLTAGE

PROGRAMMING GUIDE

VOUT

R1

C1

1μF

FB

R2

OUTPUT

VOLTAGE

R1

R2

C1

1.8 V

14.0 kΩ

30.1 kΩ

33 pF

3.6 V

57.9 kΩ

30.1 kΩ

15 pF

Figure 26. Typical Application, Adjustable Output

The output voltage is calculated using Equation 1.

VOUT

§

R1 ·

VREF u ¨ 1

¸

© R2 ¹

where

•

VREF = 1.2246 V typical (the internal reference voltage)

(1)

Resistors R1 and R2 should be chosen for approximately 40-µA divider current. Lower value resistors can be

used for improved noise performance, but the device wastes more power. Higher values should be avoided, as

leakage current at FB increases the output voltage error.

14

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

The recommended design procedure is to choose R2 = 30.1 kΩ to set the divider current at 40 µA, C1 = 15 pF for

stability, and then calculate R1 using Equation 2.

R1

§ VOUT

¨

© VREF

·

1¸ u R2

¹

(2)

To improve the stability of the adjustable version, TI suggests placing a small compensation capacitor between

OUT and FB.

The approximate value of this capacitor can be calculated using Equation 3.

3 u 10

C1

7

u R1 R2

R1 u R2

(3)

The suggested value of this capacitor for several resistor ratios is shown in the table within Figure 26. If this

capacitor is not used (such as in a unity-gain configuration), then the minimum recommended output capacitor is

2.2 µF instead of 1 µF.

8.2.3 Application Curves

80

VIN = 5.5 V

COUT = 10 mF

CNR = 0.1 mF

0.5

0.4

VIN = 4 V

COUT = 10 mF

CNR = 0.1 mF

70

Ripple Rejection − dB

Output Spectral Noise Density − mV/√Hz

0.6

IOUT = 1 mA

0.3

0.2

IOUT = 0.5 A

60

IOUT = 1 mA

50

40

IOUT = 500 mA

30

20

0.1

10

0

100

0

1k

10 k

100 k

1

10

Frequency (Hz)

Figure 27. TPS79530 Output Spectral Noise Density vs

Frequency

100

1 k 10 k 100 k 1 M

Frequency (Hz)

10 M

Figure 28. TPS79530 Ripple Rejection vs Frequency

8.3 What to Do and What Not to Do

Place at least one 1-µF ceramic capacitor as close as possible to the OUT pin of the regulator.

Do not place the output capacitor more than 10 mm away from the regulator.

Connect a 0.1-µF or larger, low equivalent series resistance (ESR) capacitor across the IN pin and GND input of

the regulator.

Do not exceed the absolute maximum ratings.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

15

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

9 Power Supply Recommendations

These devices are designed to operate from an input voltage supply range from 2.7 V to 5.5 V. The input voltage

range provides adequate headroom for the device to have a regulated output. This input supply is well-regulated

and stable. If the input supply is noisy, additional input capacitors with low ESR can help improve the output

noise performance.

10 Layout

10.1 Layout Guidelines

10.1.1 Board Layout Recommendation to Improve PSRR and Noise Performance

To improve ac measurements like PSRR, output noise, and transient response, TI recommends designing the

board with separate ground planes for VIN and VOUT, with each ground plane connected only at the ground pin of

the device. In addition, the ground connection for the bypass capacitor should connect directly to the ground pin

of the device.

10.1.2 Regulator Mounting

The tab of the 6-pin SOT-223 package is electrically connected to ground. For best thermal performance, solder

the tab of the surface-mount version directly to a circuit-board copper area. Increasing the copper area improves

heat dissipation.

Solder pad footprint recommendations for the devices are presented in application report SBFA015, Solder Pad

Recommendations for Surface-Mount Devices, available from the TI website (www.ti.com).

10.1.3 Thermal Considerations

Knowing the device power dissipation and proper sizing of the thermal plane that is connected to the tab or pad

is critical to avoiding thermal shutdown and ensuring reliable operation.

Power dissipation of the device depends on input voltage and load conditions and can be calculated using

Equation 4:

PD

VIN VOUT u IOUT

(4)

Power dissipation can be minimized and greater efficiency can be achieved by using the lowest possible input

voltage necessary to achieve the required output voltage regulation.

On the VSON (DRB) package, the primary conduction path for heat is through the exposed pad to the printedcircuit-board (PCB). The pad can be connected to ground or be left floating; however, it should be attached to an

appropriate amount of copper PCB area to ensure the device does not overheat. On the SOT-223 (DCQ)

package, the primary conduction path for heat is through the tab to the PCB. The tab should be connected to

ground. The maximum junction-to-ambient thermal resistance depends on the maximum ambient temperature,

maximum device junction temperature, and power dissipation of the device and can be calculated using

Equation 5:

125qC TA

RTJA

PD

(5)

16

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

Layout Guidelines (continued)

Knowing the maximum RθJA, the minimum amount of PCB copper area needed for appropriate heatsinking can

be estimated using Figure 29.

160

140

qJA (°C/W)

120

100

80

DCQ

60

DRB

40

20

0

0

Note:

2

4

6

2

Board Copper Area (in )

8

10

θJA value at board size of 9 in.2 (that is, 3 in. × 3 in.) is a JEDEC standard.

Figure 29. ΘJA vs Board Size

Figure 29 shows the variation of θJA as a function of ground plane copper area in the board. It is intended only as

a guideline to demonstrate the effect of heat spreading in the ground plane and should not be used to estimate

the thermal performance in real application environments.

NOTE

When the device is mounted on an application PCB, it is strongly recommended to use

ΨJT and ΨJB, as explained in Estimating Junction Temperature.

10.1.4 Estimating Junction Temperature

Using the thermal metrics ΨJT and ΨJB, as shown in Thermal Information, the junction temperature can be

estimated with corresponding formulas (given in Equation 6). For backwards compatibility, an older θJC,Top

parameter is also listed.

YJT: TJ = TT + YJT · PD

YJB: TJ = TB + YJB · PD

where

•

•

•

PD is the power dissipation shown by Equation 5

TT is the temperature at the center-top of the IC package

TB is the PCB temperature measured 1 mm away from the IC package on the PCB surface (see Figure 31) (6)

NOTE

Both TT and TB can be measured on actual application boards using a thermo-gun (an

infrared thermometer).

For more information about measuring TT and TB, see the application note SBVA025, Using New Thermal

Metrics, available for download at www.ti.com.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

17

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

Layout Guidelines (continued)

As shown in Figure 30, the new thermal metrics (ΨJT and ΨJB) have little dependency on board size. That is,

using ΨJT or ΨJB with Equation 6 is a good way to estimate TJ by simply measuring TT or TB, regardless of the

application board size.

35

DRB YJT

YJT and YJB (°C/W)

30

25

DRB YJB

20

15

DCQ YJT

DCQ YTB

10

5

0

0

1

2

3

4

5

6

7

8

9

10

2

Board Copper Area (in )

Figure 30. ΨJT and ΨJB vs Board Size

For a more detailed discussion of why TI does not recommend using θJC(top) to determine thermal characteristics,

see the application report SBVA025, Using New Thermal Metrics, available at www.ti.com.

For further information, see the application report SPRA953, IC Package Thermal Metrics, also available on the

TI website.

1mm

TT on Top of IC Surface

X

X

TB

TT

TB on PCB

1mm

(a) Example DRB (SON) Package Measurement

(b) Example DCQ (SOT-223) Package Measurement

Figure 31. Measuring Point for TT and TB

18

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

10.2 Layout Examples

GND PLANE

CIN

TPS79501DRB

VIN

VOUT

IN

1

8

EN

IN

2

7

N/C

OUT

3

6

GND

OUT

4

5

NR/FB

R2

COUT

GND PLANE

R1

Figure 32. TPS79501 (Adjustable Voltage Version)—Layout Example

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

19

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

Layout Examples (continued)

GND PLANE

CIN

TPS795xxDRB

VIN

VOUT

IN

1

8

EN

IN

2

7

N/C

OUT

3

6

GND

OUT

4

5

NR/FB

CNR

COUT

GND PLANE

Figure 33. TPS795 (Fixed Voltage Versions)—Layout Example

20

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�TPS795

www.ti.com

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

11 Device and Documentation Support

11.1 Device Support

11.1.1 Development Support

11.1.1.1 Evaluation Modules

An evaluation module (EVM) is available to assist in the initial circuit performance evaluation using the TPS795.

The TPS79501DRBEVM evaluation module related (and user's guide) can be requested at the TI website

through the product folders or purchased directly from the TI eStore.

11.1.1.2 Spice Models

Computer simulation of circuit performance using SPICE is often useful when analyzing the performance of

analog circuits and systems. A SPICE model for the TPS795 is available through the product folders under Tools

& Software.

11.1.2 Device Nomenclature

Table 3. Device Nomenclature (1)

PRODUCT

TPS795xx(x) yyy z

(1)

VOUT

xx(x) is nominal output voltage (for example, 28 = 2.8 V, 285 = 2.85 V, 01 = adjustable).

yyy is package designator.

z is package quantity.

For the most current package and ordering information see the Package Option Addendum at the end of this document, or visit the

device product folder at www.ti.com.

11.2 Documentation Support

11.2.1 Related Documentation

• Texas Instruments, Using New Thermal Metrics application report

• Texas Instruments, IC Package Thermal Metrics application report

• Texas Instruments, TPS78601/TPS79501/TPS79601DRB Evaluation Module user's guide

• Texas Instruments, Using New Thermal Metrics application report

11.3 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.4 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

21

�TPS795

SLVS350J – OCTOBER 2002 – REVISED MAY 2019

www.ti.com

11.5 Trademarks

E2E is a trademark of Texas Instruments.

Bluetooth is a registered trademark of Bluetooth SIG, Inc.

All other trademarks are the property of their respective owners.

11.6 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.7 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

22

Submit Documentation Feedback

Copyright © 2002–2019, Texas Instruments Incorporated

Product Folder Links: TPS795

�PACKAGE OPTION ADDENDUM

www.ti.com

14-Oct-2022

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

Samples

(4/5)

(6)

TPS79501DCQ

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

SN

Level-2-260C-1 YEAR

-40 to 125

PS79501

Samples

TPS79501DCQG4

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79501

Samples

TPS79501DCQR

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

SN

Level-2-260C-1 YEAR

-40 to 125

PS79501

Samples

TPS79501DRBR

ACTIVE

SON

DRB

8

3000

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

BUH

Samples

TPS79501DRBT

ACTIVE

SON

DRB

8

250

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

BUH

Samples

TPS79501DRBTG4

ACTIVE

SON

DRB

8

250

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

BUH

Samples

TPS79516DCQ

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79516

Samples

TPS79516DCQR

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79516

Samples

TPS79518DCQ

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79518

Samples

TPS79518DCQG4

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79518

Samples

TPS79518DCQR

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79518

Samples

TPS79525DCQ

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79525

Samples

TPS79525DCQG4

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79525

Samples

TPS79525DCQR

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79525

Samples

TPS79525DCQRG4

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79525

Samples

TPS79530DCQ

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79530

Samples

TPS79530DCQR

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79530

Samples

TPS79533DCQ

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

SN

Level-2-260C-1 YEAR

-40 to 125

PS79533

Samples

TPS79533DCQG4

ACTIVE

SOT-223

DCQ

6

78

RoHS & Green

NIPDAU

Level-2-260C-1 YEAR

-40 to 125

PS79533

Samples

TPS79533DCQR

ACTIVE

SOT-223

DCQ

6

2500

RoHS & Green

SN

Level-2-260C-1 YEAR

-40 to 125

PS79533

Samples

Addendum-Page 1

�PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device

14-Oct-2022

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

RoHS & Green

NIPDAU

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

Samples

(4/5)

(6)

TPS79533DCQRG4

ACTIVE

SOT-223

DCQ

6

2500

Level-2-260C-1 YEAR

-40 to 125

PS79533

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of