Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

TPS82150

SLVSDN4 – JUNE 2017

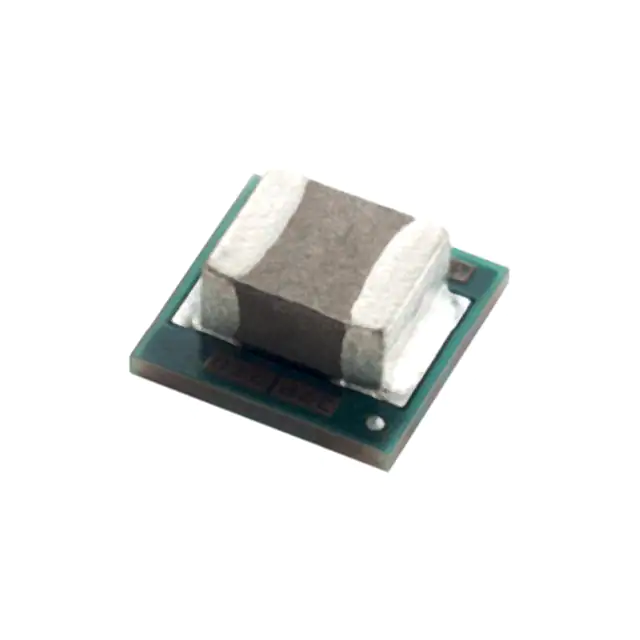

TPS82150 17-V Input 1-A Step-Down Converter MicroSiP™ Module with Integrated

Inductor

1 Features

3 Description

•

•

•

•

•

•

•

•

•

•

•

•

The TPS82150 is a 17-V input 1-A step-down

converter MicroSiP™ power module optimized for

small solution size and high efficiency. The module

integrates a synchronous step-down converter and an

inductor to simplify design, reduce external

components and save PCB area. The low profile and

compact solution is suitable for automated assembly

by standard surface mount equipment.

1

•

•

3.0-mm x 2.8-mm x 1.5-mm MicroSiP™ Package

3.0-V to 17-V Input Range

1-A Continuous Output Current

DCS-Control™ Topology

Power Save Mode for Light Load Efficiency

20-µA Operating Quiescent Current

0.9-V to 6-V Adjustable Output Voltage

100% Duty Cycle for Lowest Dropout

Power Good Output

Programmable Soft Startup with Tracking

Thermal Shutdown Protection

Pin to Pin compatible with TPS82130 and

TPS82140

–40°C to 125°C Operating Temperature Range

Create a Custom Design using the TPS82150 with

the WEBENCH® Power Designer

To maximize efficiency, the converter operates in

PWM mode with a nominal switching frequency of 2.0

MHz and automatically enters Power Save Mode

operation at light load currents. In Power Save Mode,

the device operates with typically 20-µA quiescent

current. Using the DCS-Control™ topology, the

device achieves excellent load transient performance

and accurate output voltage regulation.

space

Device Information(1)

PART NUMBER

PACKAGE

BODY SIZE (NOM)

2 Applications

TPS82150SIL

•

•

•

•

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Industrial Applications

Telecom and Networking Applications

Solid State Drives

Inverting Power Supply

space

space

Typical Application Schematic

spacespace

100

C1

10µF

C3

3.3nF

VOUT

EN

SS/TR

GND

R1

124k

FB

PG

R3

100k

C2

22µF

VOUT

1.8V/1A

R2

100k

POWER GOOD

Copyright © 2017, Texas Instruments Incorporated

90

Efficiency (%)

VIN

3.0 mm x 2.8 mm x 1.5 mm

Efficiency vs Output Current, VIN=12V

space

TPS82150

VIN

12V

µSiL (8)

80

70

VOUT = 1.0 V

VOUT = 1.8 V

VOUT = 2.5 V

VOUT = 3.3 V

60

50

1m

10m

100m

Load (A)

1

D017

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

6

9 Power Supply Recommendations...................... 18

10 Layout................................................................... 18

10.1 Layout Guidelines ................................................. 18

10.2 Layout Example .................................................... 18

10.3 Thermal Consideration.......................................... 19

11 Device and Documentation Support ................. 20

11.1

11.2

11.3

11.4

11.5

11.6

Detailed Description .............................................. 7

7.1

7.2

7.3

7.4

8

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommend Operating Conditions...........................

Thermal Information ..................................................

Electrical Characteristics..........................................

Typical Characteristics ..............................................

8.1 Application Information............................................ 11

8.2 Typical Applications ................................................ 11

8.3 System Examples ................................................... 17

Overview ...................................................................

Functional Block Diagram .........................................

Feature Description...................................................

Device Functional Modes..........................................

7

7

8

9

Device Support ....................................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

20

20

20

20

20

21

12 Mechanical, Packaging, and Orderable

Information ........................................................... 21

12.1 Package Materials Information ............................. 25

Application and Implementation ........................ 11

4 Revision History

2

DATE

REVISION

NOTES

June 2017

*

Initial release.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

5 Pin Configuration and Functions

space

EN

1

VIN

2

GND

3

VOUT

4

E

TH XPOS

ER

MA ED

LP

AD

8-Pin µSiL Package

(SIL0008C Top View)

8

SS/TR

7

PG

6

FB

5

VOUT

space

Pin Functions

PIN

NAME

NO.

I/O

EN

1

I

VIN

2

PWR

DESCRIPTION

Enable pin. Pull High to enable the device. Pull Low to disable the device. This pin has an

internal pull-down resistor of typically 400kΩ when the device is disabled.

Input pin.

GND

3

VOUT

4,5

PWR

FB

6

I

Feedback reference pin. An external resistor divider connected to this pin programs the output

voltage.

PG

7

O

Power good open drain output pin. A pull-up resistor can be connected to any voltage less than

6V. Leave it open if it is not used.

SS/TR

8

I

Soft startup and voltage tracking pin. An external capacitor connected to this pin sets the internal

reference voltage rising time.

Exposed Thermal Pad

Ground pin.

Output pin.

The exposed thermal pad must be connected to the GND pin. Must be soldered to achieve

appropriate power dissipation and mechanical reliability.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

3

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings (1)

Voltage at pins (2)

Sink current

MIN

MAX

VIN

–0.3

20

EN, SS/TR

–0.3

VIN + 0.3

PG, FB

–0.3

7

VOUT

0

UNIT

V

7

PG

10

mA

Module operating temperature

–40

125

°C

Storage temperature

–55

125

°C

(1)

(2)

Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltage values are with respect to network ground pin.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

±2000

Charged device model (CDM), per JEDEC specification JESD22C101 (2)

±1000

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommend Operating Conditions

VIN

Input voltage

VPG

Power good pull-up resistor voltage

VOUT

Output voltage

IOUT

Output current

TJ

Module operating temperature range for 100,000 hours lifetime (1)

(1)

MIN

MAX

UNIT

3

17

V

6

V

0.9

6

V

0

1

A

–40

110

°C

The module operating temperature range includes module self temperature rise and IC junction temperature rise. In applications where

high power dissipation is present, the maximum operating temperature or maximum output current must be derated. For applications

where the module operates continuously at 125 °C temperature, the maximum lifetime is reduced to 50,000 hours.

6.4 Thermal Information

TPS82150

THERMAL METRIC (1)

8-Pin SIL

UNIT

JEDEC 51-5

EVM

58.2

46.1

°C/W

RθJC(top) Junction-to-case (top) thermal resistance

9.4

9.4

°C/W

RθJB

Junction-to-board thermal resistance

14.4

14.4

°C/W

ψJT

Junction-to-top characterization parameter

0.9

0.9

°C/W

ψJB

Junction-to-board characterization parameter

14.2

14.0

°C/W

RθJC(bot) Junction-to-case (bottom) thermal resistance

21.3

21.3

°C/W

RθJA

(1)

4

Junction-to-ambient thermal resistance

For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

Theta-JA can be improved with a custom PCB design containing thermal vias where possible.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

6.5

SLVSDN4 – JUNE 2017

Electrical Characteristics

TJ = -40°C to 125°C and VIN = 3.0V to 17V. Typical values are at TJ = 25°C and VIN = 12V, unless otherwise noted.

PARAMETER

TEST CONDITIONS

MIN

TYP MAX

UNIT

SUPPLY

IQ

Quiescent current into VIN

No load, device not switching

20

35

µA

ISD

Shutdown current into VIN

EN = Low

1.5

7.4

µA

2.7

2.8

V

2.9

3.0

VUVLO

TJSD

Under voltage lock out threshold

Thermal shutdown threshold

VIN falling

2.6

VIN rising

2.8

V

TJ rising

160

°C

TJ falling

140

°C

LOGIC INTERFACE (EN)

VIH

High-level input voltage

VIL

Low-level input voltage

Ilkg(EN)

Input leakage current into EN pin

0.9

EN = High

0.65

V

0.45

0.3

V

0.01

1

µA

µA

CONTROL (SS/TR, PG)

ISS/TR

SS/TR pin source current

2.1

2.5

2.8

VOUT rising, referenced to VOUT nominal

92%

95%

99%

VOUT falling, referenced to VOUT nominal

87%

90%

94%

VPG

Power good threshold

VPG,OL

Power good low-level voltage

Isink = 2mA

0.1

0.3

V

Ilkg(PG)

Input leakage current into PG pin

VPG = 1.8V

1

400

nA

OUTPUT

PWM mode

VFB

Feedback regulation voltage

PSM

Ilkg(FB)

785

800

815

TJ = 0°C to 85°C

788

800

812

COUT = 22µF

785

800

823

COUT = 2x22µF, TJ = 0°C to 85°C

788

800

815

1

100

Feedback input leakage current

VFB = 0.8V

Line regulation

IOUT = 1A, VOUT = 1.8V

Load regulation

IOUT = 0.5A to 1A, VOUT = 1.8V

mV

nA

0.002

%/V

0.12

%/A

POWER SWITCH

High-side FET on-resistance

RDS(on)

Low-side FET on-resistance

ISW = 500mA, VIN ≥ 6V

90

ISW = 500mA, VIN = 3V

120

ISW = 500mA, VIN ≥ 6V

40

ISW = 500mA, VIN = 3V

50

100% mode, VIN ≥ 6V

125

100% mode, VIN = 3V

160

RDP

Dropout resistance

ILIMF

High-side FET switch current limit

VIN = 6V, TJ = 25°C

fSW

PWM switching frequency

IOUT = 1A, VOUT = 1.8V

1.7

2.2

170

70

mΩ

2.7

2.0

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

mΩ

A

MHz

5

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

6.6 Typical Characteristics

50

250

TJ = -40°C

TJ = 25°C

TJ = 85°C

TJ = 125°C

$

4XLHVFHQW &XUUHQW

'URSRXW 5HVLVWDQFH P

40

200

150

100

30

20

10

VIN = 3.0 V

VIN = 6.0 V

50

-40

-20

0

20

40

60

80

Module Temperature (°C)

100

0

120

3

5

7

9

11

Input Voltage (V)

D014

13

15

17

D025

Figure 2. Quiescent Current

Figure 1. Dropout Resistance

6KXWGRZQ &XUUHQW

$

8

TJ = -40°C

TJ = 25°C

TJ = 85°C

TJ = 125°C

6

4

2

0

3

5

7

9

11

Input Voltage (V)

13

15

17

D026

Figure 3. Shutdown Current

6

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

7 Detailed Description

7.1 Overview

The TPS82150 synchronous step-down converter MicroSiP™ power module is based on DCS-Control™ (Direct

Control with Seamless transition into Power Save Mode). This is an advanced regulation topology that combines

the advantages of hysteretic and voltage mode control.

The DCS-Control™ topology operates in PWM (Pulse Width Modulation) mode for medium to heavy load

conditions and in PSM (Power Save Mode) at light load currents. In PWM mode, the converter operates with its

nominal switching frequency of 2.0 MHz having a controlled frequency variation over the input voltage range. As

the load current decreases, the converter enters Power Save Mode, reducing the switching frequency and

minimizing the IC's quiescent current to achieve high efficiency over the entire load current range. DCS-Control™

supports both operation modes using a single building block and therefore has a seamless transition from PWM

to PSM without effects on the output voltage. The TPS82150 offers excellent DC voltage regulation and load

transient regulation, combined with low output voltage ripple, minimizing interference with RF circuits.

7.2 Functional Block Diagram

space

space

PG

VIN

VFB

High Side

Current Sense

VREF

EN

(1)

400kΩ

Bandgap

Undervoltage Lockout

Thermal Shutdown

L

(2)

MOSFET Driver

Control Logic

VIN

Ramp

SS/TR

Voltage

Clamp

VREF

Timer

ton

Direct Control

and

Compensation

FB

Comparator

Error Amplifier

DCS - Control

VOUT

22pF

TM

VREF

GND

Note:

(1) When the device is enabled, the 400 kΩ resistor is disconnected.

(2) The integrated inductor of 1 µH in the module.

Copyright © 2016, Texas Instruments Incorporated

space

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

7

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

7.3 Feature Description

7.3.1 PWM and PSM Operation

The TPS82150 includes an on-time (tON) circuitry. This tON, in steady-state operation in PWM and PSM modes, is

estimated as:

space

t ON = 500ns ´

VOUT

VIN

(1)

space

In PWM mode, the TPS82150 operates with pulse width modulation in continuous conduction mode (CCM) with

a tON shown in Equation 1 at medium and heavy load currents. A PWM switching frequency of typically 2.0MHz

is achieved by this tON circuitry. The device operates in PWM mode as long as the output current is higher than

half the inductor's ripple current estimated by Equation 2.

space

DIL = t ON ´

VIN - VOUT

L

(2)

space

To maintain high efficiency at light loads, the device enters Power Save Mode seamlessly when the load current

decreases. This happens when the load current becomes smaller than half the inductor's ripple current. In PSM,

the converter operates with reduced switching frequency and with a minimum quiescent current to maintain high

efficiency. PSM is also based on the tON circuitry. The switching frequency in PSM is estimated as:

space

fPSM =

2 ´ IOUT

V - VOUT

V

t ON2 ´ IN ´ IN

VOUT

L

(3)

space

In PSM, the output voltage rises slightly above the nominal output voltage in PWM mode. This effect is reduced

by increasing the output capacitance. The output voltage accuracy in PSM operation is reflected in the electrical

specification table and given for a 22-µF output capacitor.

For very small output voltages, an absolute minimum on-time of about 80ns is kept to limit switching losses. The

operating frequency is thereby reduced from its nominal value, which keeps efficiency high. Also the off-time can

reach its minimum value at high duty cycles. The output voltage remains regulated in such cases.

When VIN decreases to typically 15% above VOUT, the TPS82150 can't enter Power Save Mode, regardless of

the load current. The device maintains output regulation in PWM mode.

7.3.2 Low Dropout Operation (100% Duty Cycle)

The TPS82150 offers a low input to output voltage differential by entering 100% duty cycle mode. In this mode,

the high-side MOSFET switch is constantly turned on. This is particularly useful in battery powered applications

to achieve longest operation time by taking full advantage of the whole battery voltage range. The minimum input

voltage to maintain a minimum output voltage is given by:

space

VIN(min) = VOUT(min) + IOUT ´ RDP

(4)

space

Where

RDP = Resistance from VIN to VOUT, including high-side FET on-resistance and DC resistance of the inductor

VOUT(min) = Minimum output voltage the load can accept.

8

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

Feature Description (continued)

7.3.3 Switch Current Limit

The switch current limit prevents the device from high inductor current and from drawing excessive current from

the battery or input voltage rail. Excessive current might occur with a heavy load/shorted output circuit condition.

If the inductor peak current reaches the switch current limit after a propagation delay of typically 30ns, the highside FET is turned off and the low-side FET is turned on to ramp down the inductor current.

7.3.4 Undervoltage Lockout

To avoid mis-operation of the device at low input voltages, an under voltage lockout is implemented, which shuts

down the devices at voltages lower than VUVLO with a hysteresis of 200mV.

7.3.5 Thermal Shutdown

The device goes into thermal shutdown and stops switching once the junction temperature exceeds TJSD. Once

the device temperature falls below the threshold by 20°C, the device returns to normal operation automatically.

7.4 Device Functional Modes

7.4.1 Enable and Disable (EN)

The device is enabled by setting the EN pin to a logic High. Accordingly, the shutdown mode is forced if the EN

pin is pulled Low with a shutdown current of typically 1.5 μA.

An internal pull-down resistor of 400kΩ is connected to the EN pin when the EN pin is Low. The pull-down

resistor is disconnected when the EN pin is High.

7.4.2 Soft Startup (SS/TR)

The internal voltage clamp controls the output voltage slope during startup. This avoids excessive inrush current

and ensures a controlled output voltage rise time. When the EN pin is pulled high, the device starts switching

after a delay of typically 55μs and the output voltage rises with a slope controlled by an external capacitor

connected to the SS/TR pin. Using a very small capacitor or leaving the SS/TR pin floating provides fastest

startup time.

The TPS82150 is able to start into a pre-biased output capacitor. During the pre-biased startup, both the power

MOSFETs are not allowed to turn on until the internal voltage clamp sets an output voltage above the pre-bias

voltage.

When the device is in shutdown, undervoltage lockout or thermal shutdown, the capacitor connected to SS/TR

pin is discharged by an internal resistor. Returning from those states causes a new startup sequence.

7.4.3 Voltage Tracking (SS/TR)

The SS/TR pin is externally driven by another voltage source to achieve output voltage tracking. The application

circuit is shown in Figure 4.

VOUT1

VOUT2

TPS82150

R3

R1

SS/TR

FB

R2

R4

Figure 4. Output Voltage Tracking

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

9

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

Device Functional Modes (continued)

When the SS/TR pin voltage is between 50 mV and 1.2 V, the VOUT2 tracks the VOUT1 as described in

Equation 5.

space

VOUT 2

R2

R3 + R4

» 0.64 ´

´

R1 + R2

R4

VOUT1

(5)

space

When the SS/TR pin voltage is above 1.2 V, the voltage tracking is disabled and the FB pin voltage is regulated

at 0.8 V. For decreasing SS/TR pin voltage, the device doesn't sink current from the output. So the resulting

decreases of the output voltage may be slower than the SS/TR pin voltage if the load is light. When driving the

SS/TR pin with an external voltage, do not exceed the voltage rating of the SS/TR pin which is VIN+0.3V.

Details about tracking and sequencing circuits are found in SLVA470.

7.4.4 Power Good Output (PG)

The device has a power good (PG) output. The PG pin goes high impedance once the output is above 95% of

the nominal voltage, and is driven low once the output voltage falls below typically 90% of the nominal voltage.

The PG pin is an open drain output and is specified to sink up to 2mA. The power good output requires a pull-up

resistor connecting to any voltage rail less than 6V.

The PG pin goes low when the device is in shutdown or thermal shutdown. When the device is in UVLO, the PG

pin is high impedance. The PG signal can be used for sequencing of multiple rails by connecting it to the EN pin

of other converters. Leave the PG pin floating when it is not used. Table 1 shows the PG pin logic.

Table 1. Power Good Pin Logic

PG Logic Status

Device State

Enable (EN=High)

High Impedance

VFB ≥ VTH_PG

VFB ≤ VTH_PG

√

√

Shutdown (EN=Low)

UVLO

Thermal Shutdown

Power Supply Removal

10

Low

√

0.7 V < VIN < VUVLO

√

TJ > TSD

√

VIN < 0.7 V

Submit Documentation Feedback

√

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The output voltage of the TPS82150 is adjusted by component selection. The following section discusses the

design of the external components to complete the power supply design for several input and output voltage

options by using typical applications as a reference.

8.2 Typical Applications

8.2.1

1.8-V Output Application

space

TPS82150

VIN

12 V

VIN

C1

10µF

EN

SS/TR

C3

3.3nF

VOUT

1.8 V/1 A

VOUT

GND

R1

124kΩ

FB

PG

R3

100kΩ

C2

22µF

R2

100kΩ

POWER GOOD

Copyright © 2016, Texas Instruments Incorporated

Figure 5. 1.8-V Output Application

space

8.2.1.1 Design Requirements

For this design example, use the following as the input parameters.

Table 2. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

Input voltage range

12V

Output voltage

1.8V

Output ripple voltage

< 20mV

Output current rating

1A

The components used for measurements are given in the following table.

Table 3. List of Components

DESCRIPTION (1)

MANUFACTURER

C1

10 µF, 25 V, X7R, ±20%, size 1206, C3216X7R1E106M160AE

TDK

C2

22 µF, 10 V, X7S, ±20%, size 0805, C2012X7S1A226M125AC

TDK

C3

3300 pF, 50 V, ±5%, C0G/NP0, size 0603,

GRM1885C1H332JA01D

R1, R2, R3

Standard

REFERENCE

(1)

Murata

See Third-party Products Disclaimer

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

11

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

8.2.1.2 Detailed Design Procedure

8.2.1.2.1 Custom Design with WEBENCH® Tools

Click here to create a custom design using the TPS82150 device with the WEBENCH® Power Designer.

1. Start by entering your VIN, VOUT, and IOUT requirements.

2. Optimize your design for key parameters like efficiency, footprint and cost using the optimizer dial and

compare this design with other possible solutions from Texas Instruments.

3. The WEBENCH Power Designer provides you with a customized schematic along with a list of materials with

real time pricing and component availability.

4. In most cases, you will also be able to:

– Run electrical simulations to see important waveforms and circuit performance

– Run thermal simulations to understand the thermal performance of your board

– Export your customized schematic and layout into popular CAD formats

– Print PDF reports for the design, and share your design with colleagues

5. Get more information about WEBENCH tools at www.ti.com/WEBENCH.

8.2.1.2.2 Setting the Output Voltage

The output voltage is set by an external resistor divider according to the following equations:

space

R1 ö

R1 ö

æ

æ

VOUT = VFB ´ ç 1 +

= 0.8 V ´ ç 1 +

÷

R2 ø

R2 ÷ø

è

è

(6)

space

R2 should not be higher than 100kΩ to achieve high efficiency at light load while providing acceptable noise

sensitivity. Larger currents through R2 improve noise sensitivity and output voltage accuracy. Figure 5 shows the

external resistor divider value for a 1.8-V output. Choose appropriate resistor values for other outputs.

In case the FB pin gets opened, the device clamps the output voltage at the VOUT pin internally to about 7V.

8.2.1.2.3

Input and Output Capacitor Selection

For best output and input voltage filtering, low ESR ceramic capacitors are required. The input capacitor

minimizes input voltage ripple, suppresses input voltage spikes and provides a stable system rail for the device.

A 10-µF or larger input capacitor is required. The output capacitor value can range from 22μF up to more than

400μF. Higher values are possible as well and can be evaluated through the transient response. Larger soft start

times are recommended for higher output capacitances.

High capacitance ceramic capacitors have a DC Bias effect, which will have a strong influence on the final

effective capacitance. Therefore the right capacitor value has to be chosen carefully. Package size and voltage

rating in combination with dielectric material are responsible for differences between the rated capacitor value

and the effective capacitance.

8.2.1.2.4 Soft Startup Capacitor Selection

A capacitance connected between the SS/TR pin and the GND allows programming the startup slope of the

output voltage. A constant current of 2.5 μA charges the external capacitor. The capacitance required for a given

soft startup time for the output voltage is given by:

space

CSS / TR = t SS / TR ´

12

ISS / TR

1.25 V

(7)

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

8.2.1.3 Application Performance Curves

100

100

90

90

Efficiency (%)

Efficiency (%)

TA = 25°C, VIN = 12 V, VOUT = 1.8 V, unless otherwise noted.

80

70

60

50

1m

80

70

60

VIN = 3.3 V

VIN = 5.0 V

VIN = 12 V

IOUT = 0.1 A

IOUT = 1.0 A

50

10m

100m

3

1

Load (A)

5

100

100

90

90

80

70

60

15

17

D019

80

70

IOUT = 0.1 A

IOUT = 1.0 A

50

10m

100m

3

1

5

7

D002

Figure 8. Efficiency, VOUT = 1.8 V

100

100

90

90

80

70

60

9

11

Input Voltage (V)

13

15

17

D020

Figure 9. Efficiency, VOUT = 1.8 V

Efficiency (%)

Efficiency (%)

13

60

VIN = 3.3 V

VIN = 5.0 V

VIN = 12 V

Load (A)

50

1m

9

11

Input Voltage (V)

Figure 7. Efficiency, VOUT = 1.0 V

Efficiency (%)

Efficiency (%)

Figure 6. Efficiency, VOUT = 1.0 V

50

1m

7

D001

80

70

60

VIN = 3.3 V

VIN = 5.0 V

VIN = 12 V

IOUT = 0.1 A

IOUT = 1.0 A

50

10m

100m

1

Load (A)

3

D003

Figure 10. Efficiency, VOUT = 2.5 V

5

7

9

11

Input Voltage (V)

13

15

Product Folder Links: TPS82150

D021

Figure 11. Efficiency, VOUT = 2.5 V

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

17

13

�TPS82150

www.ti.com

100

100

90

90

Efficiency (%)

Efficiency (%)

SLVSDN4 – JUNE 2017

80

70

60

80

70

60

VIN = 5.0 V

VIN = 12 V

IOUT = 0.1 A

IOUT = 1.0 A

50

50

1m

10m

100m

5

1

Load (A)

7

100

100

90

90

80

70

60

17

D022

80

70

IOUT = 0.1 A

IOUT = 1.0 A

VIN = 12 V

50

10m

100m

6

1

Load (A)

7

8

9

10 11 12 13

Input Voltage (V)

D023

Figure 14. Efficiency, VOUT = 5.0 V

14

15

16

17

D024

Figure 15. Efficiency, VOUT = 5.0 V

1.5

Output Current (A)

1.5

Output Current (A)

15

60

50

1m

1

0.5

1

0.5

VIN = 3.3 V

VIN = 5.0 V

VIN = 12 V

VIN = 3.3 V

VIN = 5.0 V

VIN = 12 V

55

65

75

85

95

105

Ambient Temperature (°C)

115

125

0

45

55

D002

θJA = 46.1 °C/W

65

75

85

95

105

Ambient Temperature (°C)

115

125

D001

θJA = 46.1 °C/W

Figure 16. Thermal Derating, VOUT = 1 V

14

11

13

Input Voltage (V)

Figure 13. Efficiency, VOUT = 3.3 V

Efficiency (%)

Efficiency (%)

Figure 12. Efficiency, VOUT = 3.3 V

0

45

9

D004

Figure 17. Thermal Derating, VOUT = 1.8 V

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

1.5

Output Current (A)

Output Current (A)

1.5

1

0.5

1

0.5

VIN = 5.0V

VIN = 12 V

0

45

55

65

VIN = 8.4 V

VIN = 12 V

75

85

95

105

Ambient Temperature (°C)

115

0

45

125

θJA = 46.1 °C/W

65

75

85

95

105

Ambient Temperature (°C)

115

125

D003

θJA = 46.1 °C/W

Figure 18. Thermal Derating, VOUT = 3.3 V

Figure 19. Thermal Derating, VOUT = 5 V

1.0

1.0

Output Voltage Accuracy (%)

Output Voltage Accuracy (%)

55

D003

0.5

0.0

-0.5

TA = -40°C

TA = 25°C

TA = 85°C

-1.0

1m

0.5

0.0

-0.5

TA = -40°C

TA = 25°C

TA = 85°C

-1.0

10m

100m

Load (A)

1

5

3

5

7

D005

9

11

Input Voltage (V)

13

15

17

D006

IOUT = 1A

Figure 20. Load Regulation

Figure 21. Line Regulation

5x106

3x106

6

1x106

Switching Frequency (Hz)

Switching Frequency (Hz)

2x10

5x105

2x105

1x105

5x104

2x104

1x104

5x103

TA = 25°C

TA = -40°C

TA = 85°C

2x103

1x103

1m

10m

100m

Load (A)

1

2x106

1x106

VOUT = 1.0 V

VOUT = 1.8 V

VOUT = 2.5 V

VOUT = 3.3 V

0x100

5

3

D009

VOUT = 1.8V

5

7

9

11

Input Voltage (V)

13

15

17

D018

IOUT = 1A

Figure 22. Switching Frequency

Figure 23. Switching Frequency

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

15

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

No Load

IOUT = 1A

Figure 24. Input and Output Ripple in PWM Mode

Figure 25. Input and Output Ripple in PSM Mode

IOUT = 0.5A to 1A,

1A/µs

IOUT = 0A to 1A,

1A/µs

Figure 27. Load Transient

Figure 26. Load Transient

No Load

ROUT = 1.8Ω

Figure 28. Startup without Load

Figure 29. Startup / Shutdown with Resistance Load

16

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

8.3 System Examples

8.3.1 Inverting Power Supply

The TPS82150 can be used as inverting power supply by rearranging external circuitry as shown in Figure 30.

As the former GND node now represents a voltage level below system ground, the voltage difference between

VIN and VOUT has to be limited for operation to the maximum supply voltage of 17V (see Equation 8).

space

VIN + VOUT £ VIN max

(8)

space

space

VIN

VIN

VOUT

R3

TPS82150

PG

R1

CIN

EN

COUT

FB

R2

SS/TR

GND

CSS

- VOUT

Copyright © 2017, Texas Instruments Incorporated

Figure 30. Inverting Power Supply Schematic

space

The transfer function of the inverting power supply configuration differs from the buck mode transfer function,

incorporating a Right Half Plane Zero additionally. Therefore the loop stability has to be adapted. More detailed

information is given in TIDUCV2.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

17

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

9 Power Supply Recommendations

The devices are designed to operate from an input voltage supply range between 3V and 17V. The average

input current of the TPS82150 is calculated as:

space

IIN =

1 VOUT ´ IOUT

´

h

VIN

(9)

space

Ensure that the power supply has a sufficient current rating for the applications.

10 Layout

10.1 Layout Guidelines

•

•

•

•

TI recommends placing all components as close as possible to the IC. The input capacitor placement

specifically, must be closest to the VIN and GND pins of the device.

Use wide and short traces for the main current paths to reduce the parasitic inductance and resistance.

To enhance heat dissipation of the device, the exposed thermal pad should be connected to bottom or

internal layer ground planes using vias.

Refer to Figure 31 for an example of component placement, routing and thermal design.

10.2 Layout Example

space

space

C3

VIN

C1

R2

EN

SS/TR

VIN

PG

GND

FB

VOUT

VOUT

R1

VOUT

GND

C2

Figure 31. TPS82150 PCB Layout

18

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

10.3 Thermal Consideration

The output current of the TPS82150 needs to be derated when the device operates in a high ambient

temperature or delivers high output power. The amount of current derating is dependent upon the input voltage,

output power, PCB layout design and environmental thermal condition. Care should especially be taken in

applications where the localized PCB temperature exceeds 65°C.

The TPS82150 module temperature must be kept less than the maximum rating of 125°C. Three basic

approaches for enhancing thermal performance are below:

• Improve the power dissipation capability of the PCB design.

• Improve the thermal coupling of the TPS82150 to the PCB.

• Introduce airflow into the system.

To estimate approximate module temperature of TPS82150, apply the typical efficiency stated in this datasheet

to the desired application condition to find the module's power dissipation. Then calculate the module

temperature rise by multiplying the power dissipation by its thermal resistance. For more details on how to use

the thermal parameters in real applications, see the application notes: SZZA017 and SPRA953.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

19

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.1.2 Development Support

11.1.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the TPS82150 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

11.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

11.4 Trademarks

MicroSiP, DCS-Control, E2E are trademarks of Texas Instruments.

WEBENCH is a registered trademark of Texas Instruments.

11.5 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

20

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

11.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

21

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

PACKAGE OUTLINE

SIL0008D

MicroSiP TM - 1.53 mm max height

SCALE 4.000

MICRO SYSTEM IN PACKAGE

2.9

2.7

B

A

PIN 1 INDEX

AREA

(2.5)

3.1

2.9

PICK AREA

NOTE 3

(2)

1.53 MAX

C

0.08 C

1.1±0.1

EXPOSED

THERMAL PAD

SYMM

(0.1)

TYP

5

4

SYMM

2X

1.9±0.1

1.95

1

8

6X 0.65

(45 X0.25)

PIN 1 ID

0.52

8X

0.48

8X

0.42

0.38

0.1

0.05

C A

C

B

4221520/A 07/2015

MicroSiP is a trademark of Texas Instruments

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. Pick and place nozzle 1.3 mm or smaller recommended.

4. The package thermal pad must be soldered to the printed circuit board for thermal and mechanical performance.

www.ti.com

22

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

EXAMPLE BOARD LAYOUT

SIL0008D

MicroSiP TM - 1.53 mm max height

MICRO SYSTEM IN PACKAGE

(1.1)

8X (0.5)

8

1

8X (0.4)

SYMM

(1.9)

(0.75)

6X (0.65)

5

4

SYMM

( 0.2) VIA

TYP

(2.1)

LAND PATTERN EXAMPLE

SOLDER MASK DEFINED

SCALE:20X

0.05 MIN

ALL SIDES

SOLDER MASK

OPENING

METAL UNDER

SOLDER MASK

(R0.05) TYP

DETAIL

NOT TO SCALE

4221520/A 07/2015

NOTES: (continued)

5. This package is designed to be soldered to a thermal pad on the board. For more information, see Texas Instruments literature

number SLUA271 (www.ti.com/lit/slua271).

www.ti.com

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

23

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

EXAMPLE STENCIL DESIGN

SIL0008D

MicroSiP TM - 1.53 mm max height

MICRO SYSTEM IN PACKAGE

SOLDER MASK EDGE

8X (0.5)

1

(R0.05) TYP

(1.04)

8

8X (0.4)

METAL

TYP

(0.85)

SYMM

(1.05)

6X (0.65)

5

4

SYMM

(2.1)

SOLDER PASTE EXAMPLE

BASED ON 0.125 mm THICK STENCIL

EXPOSED PAD

85% PRINTED SOLDER COVERAGE BY AREA

SCALE:30X

4221520/A 07/2015

NOTES: (continued)

6. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

www.ti.com

24

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�TPS82150

www.ti.com

SLVSDN4 – JUNE 2017

12.1 Package Materials Information

12.1.1 Tape and Reel Information

REEL DIMENSIONS

TAPE DIMENSIONS

K0

P1

B0 W

Reel

Diameter

Cavity

A0

B0

K0

W

P1

A0

Dimension designed to accommodate the component width

Dimension designed to accommodate the component length

Dimension designed to accommodate the component thickness

Overall width of the carrier tape

Pitch between successive cavity centers

Reel Width (W1)

QUADRANT ASSIGNMENTS FOR PIN 1 ORIENTATION IN TAPE

Sprocket Holes

Q1

Q2

Q1

Q2

Q3

Q4

Q3

Q4

User Direction of Feed

Pocket Quadrants

Device

Package

Type

Package

Drawing

Pins

SPQ

Reel

Diameter

(mm)

Reel

Width W1

(mm)

A0

(mm)

B0

(mm)

K0

(mm)

P1

(mm)

W

(mm)

Pin1

Quadrant

TPS82150SILR

µSiP

SIL

8

3000

330.0

12.4

3.05

3.25

1.68

8.0

12.0

Q1

TPS82150SILT

µSiP

SIL

8

250

178.0

13.2

3.05

3.25

1.68

8.0

12.0

Q1

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

25

�TPS82150

SLVSDN4 – JUNE 2017

www.ti.com

TAPE AND REEL BOX DIMENSIONS

Width (mm)

L

W

26

H

Device

Package Type

Package Drawing

Pins

SPQ

Length (mm)

Width (mm)

Height (mm)

TPS82150SILR

µSiP

SIL

8

3000

383.0

353.0

58.0

TPS82150SILT

µSiP

SIL

8

250

223.0

194.0

35.0

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Product Folder Links: TPS82150

�PACKAGE OPTION ADDENDUM

www.ti.com

29-Apr-2020

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

Lead/Ball Finish

MSL Peak Temp

(2)

(6)

(3)

Op Temp (°C)

Device Marking

(4/5)

TPS82150SILR

ACTIVE

uSiP

SIL

8

3000

RoHS & Green

NIAU

Level-2-260C-1 YEAR

-40 to 125

5S

TXI1300EC

TPS82150SILT

ACTIVE

uSiP

SIL

8

250

RoHS & Green

NIAU

Level-2-260C-1 YEAR

-40 to 125

5S

TXI1300EC

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of